EP0020271B1 - Dispositif de boulonnage à positionnement linéaire - Google Patents

Dispositif de boulonnage à positionnement linéaire Download PDFInfo

- Publication number

- EP0020271B1 EP0020271B1 EP80400762A EP80400762A EP0020271B1 EP 0020271 B1 EP0020271 B1 EP 0020271B1 EP 80400762 A EP80400762 A EP 80400762A EP 80400762 A EP80400762 A EP 80400762A EP 0020271 B1 EP0020271 B1 EP 0020271B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- axis

- hole

- drilling

- movable support

- systems

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000005553 drilling Methods 0.000 claims abstract description 17

- 238000007789 sealing Methods 0.000 claims abstract description 17

- 238000006073 displacement reaction Methods 0.000 claims abstract 2

- 239000011888 foil Substances 0.000 description 13

- 238000002347 injection Methods 0.000 description 5

- 239000007924 injection Substances 0.000 description 5

- 239000000470 constituent Substances 0.000 description 4

- 239000000945 filler Substances 0.000 description 3

- 239000004567 concrete Substances 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 239000004568 cement Substances 0.000 description 1

- 230000009977 dual effect Effects 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000002250 progressing effect Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21D—SHAFTS; TUNNELS; GALLERIES; LARGE UNDERGROUND CHAMBERS

- E21D20/00—Setting anchoring-bolts

- E21D20/003—Machines for drilling anchor holes and setting anchor bolts

Definitions

- the invention relates to a bolting device which allows easy, rapid and precise installation of retaining bolts for roofs and walls, in particular in mines and tunnels.

- the so-called bolting method used for many years for the support of walls and roofs consists in drilling in the wall to support holes having most often 20 to 60 mm in which one introduces either rods or steel cables of 1 to 6 mm (more generally 1 to 2 mm) which are sealed with cement or resins in the case of long-term support, or expansion anchor bolts in the case of provisional support.

- the number of bolts to be installed is high. Indeed in general they are installed at the rate of one per m 2 of roof or wall.

- the means currently used are unsuitable because they require manual operations: the hole is first drilled with a hole punch carried by hand or by a slide, the sealing charges are introduced by hand, then the bolt is substituted for the rod of the hole punch and is introduced into the previously drilled hole so as to mix the different constituents of the sealing filler and cause it to set.

- This type of bolting process is long and therefore expensive. On the other hand it is dangerous.

- the operator must be in the immediate vicinity of the hole, therefore in an unconsolidated area and there are many accidents.

- the present invention relates to a bolting device which offers good visibility conditions.

- the invention relates to a bolting device comprising a mobile support carrying a drilling system, an injection system, sealing loads and a system for inserting and tightening bolts, these systems being able to be successively placed in the working position in the axis of the drill hole.

- a bolting device comprising a mobile support carrying a drilling system, an injection system, sealing loads and a system for inserting and tightening bolts, these systems being able to be successively placed in the working position in the axis of the drill hole.

- a device is known from DE-A-2 808 977.

- the invention is characterized in that the mobile support moves linearly along an axis to successively bring the different systems into position and that the axis of each of the above systems is perpendicular to the axis of movement of the mobile support. The positioning of the various systems required for bolting is therefore done in a linear fashion.

- the support is brought into a position such that it moves linearly in a plane parallel to the wall to be supported and that the axes of the 3 systems are perpendicular to this wall.

- the axis of the mobile support is horizontal, the drilling, load injection, introduction and clamping systems have a vertical axis.

- This arrangement allows the roofs of the galleries to be treated.

- the mobile support is carried in a known manner by an arm mounted on a vehicle, generally automatic, mounted on tires or tracks.

- the mobile arm is generally fixed to the vehicle so that it can rotate 180 ° C around an axis.

- the assembly thus produced has a very high mobility which makes it possible to pass quickly and easily from one bolt to another, or from a gallery or tunnel to another.

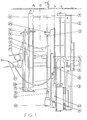

- Figure 1 shows an elevational view of the device according to the invention and Figure 2 is a top view of the device.

- FIG. 3 is a variant of the device shown in FIG. 1.

- the references A, B and C represent the three main axes which move in a, b and c when the machine performs its linear movement during its various operations.

- the device comprises a drilling system of the rotary or rotary hammer type, symbolized by the foil 2, a system 8 for injecting sealing charges and a system 11 for the introduction and tightening of the anchor bolts 9, generally provided with plates. 24.

- An advancer 19, progressing by means of a jack 3, makes it possible to apply the foil 2 to the roof.

- a second feeder 6 makes it possible to set up, via the jack 23, the sealing charge injector tube or the anchor bolt.

- advancer 19 should be understood any system allowing a device to be pushed or pushed back along a vertical axis, for example a jack or any other similar system.

- the two advancers 6 and 19 are contained in a support box 5 whose movement forwards or backwards is effected by means of a jack 15 on a guide 16.

- the injector tube 8 is connected to a jack 10.

- a motor 12 makes it possible to drive the device 11 for tightening the bolts 9.

- a wrench 13 makes it possible to give the device 11 a rotational movement for facilitate the mixing of the constituents of the sealing filler.

- All of these mobile elements are connected to an arm 20 which can rotate about its axis 21 by means of the lever 22.

- this machine is as follows: at the beginning of the cycle, the drill is immobilized by applying a support point 1 to the roof of the gallery to be bolted. The drill with its foil 2 pushed by the advance 19 is then along the axis C ready to drill the hole for the bolt. The charge booster 6 and the bolt 9 are placed respectively along the axes B and A.

- the advancers allow to move on the one hand the perforator and on the other hand the injection and tightening in two orthogonal directions of this plane.

- the two advancers also have independent movements in the direction of the drilled hole and linked movements in the orthogonal direction (for example horizontal when the hole is drilled along a vertical C axis).

- Foil 2 is applied to the roof by advancing the advance 19 by means of the jack 3.

- the hole punch and its foil 2 as well as the advance 19 are moved back and one moves to the right by means of the jack 15 the whole of the support box 5 so that the charge injector tube 8 is in turn along the axis C.

- the injector tube 8 is advanced by means of the jack 10 and the feeder 6 is itself approached from the roof by means of the jack 23.

- the sealing filler, resin or concrete is then introduced into the hole along the axis C.

- the load once introduced, the tube injection 8 and the feeder 6 are moved back and the support box 5 is again moved so that the anchor bolt 9 is in turn along the axis C.

- the bolt is then pushed into the hole using the tightener 11 ju until the bolt nut comes into contact with the roof.

- the nut drives in its progression the plate 24 which is applied between the nut and the roof.

- the clamp tightens the jaw guides 14 which are erased by rotation about the axis 25 inside the advance 6.

- the tightening device 11 is generally completed by a wrench 13 which allows the bolt to be pushed into the hole while turning. This system is particularly recommended when the sealing load comprises at least two constituents and the homogeneous mixing of these constituents must take place or end inside the hole.

- the bolt being thus placed, the tightener 11 is brought back to its starting point by reversing the thrust motor 12.

- the feeder 6 is moved back to the low position.

- the complete bolting device is then returned to its starting position by sliding the support box 5 to the left by means of the jack 15 on the guide 16.

- the jaw guides 14 come to grip the bolt 18 placed in standby in rack 17.

- the machine is loaded again, ready for a new cycle.

- the small feed cylinders 26 will push a new bolt 18 in a position such that it can be gripped at the end of the cycle by the jaw 14.

- All the supply hoses of the various feeders are guided either in the gutter 27 for the drill, or in the gutter 28 for the feeder of loads and bolts.

- the entire device can be oriented by rotation of 180 ° around the axis of the arm 20 by means of the lever 22 which is itself driven by jacks.

- the supporting frame of the bolting device being placed in the axis of the gallery, this rotation keeps the entire device perpendicular to the wall to be bolted.

- FIG. 3 represents a variant of the bolting device according to the invention, more particularly intended for galleries of low height.

- the bolt hole is drilled in two successive operations by the installation of a drilling extension.

- the two-part foil is then deposited and the sealing charges and a flexible bolt are introduced, which can be a cable or a combination of small twisted diameter concrete rods.

- the feeder 19 is provided at its upper part with a locking bezel 30.

- the feeder 6 has two hydraulic clamps 31 which hold an extension rod for drilling. It is also equipped with a device 33 which performs a dual function: introducing the loads and introducing the flexible bolt via the flexible slide 32.

- the drill 34 is equipped with a foil 2 and the extension bar 35 can move through a jack 36.

- the advance device 6 which supports the devices for injecting loads and for introducing the bolts has movements completely independent of the advance device 19 which supports the drilling device, both in the direction of the hole through the jack 29 only in the orthogonal direction through the jack 36. This independence of movement makes it possible to present the extension bar in the axis of the drilling device.

- this device is as follows.

- the drill and its foil 2 supported by the advance 19 are placed along the axis to drill the bolt hole.

- the locking bezel 30 blocks the foil at the entrance of the hole.

- the drill 34 is then moved back, the foil 2 remaining in the hole.

- the extension bar 35 carried by the hydraulic clamps 31 and the feeder 6 is moved on the support 5 by means of the jack 36 so that the extension 35 is in turn located in the axis of the hole and the drill back in rear position.

- the drill is then pushed back towards the hole to be drilled, turning so as to take the extension 35, which is thus screwed on the one hand into the nose of the drill and on the other hand into the foil introduced into the hole C and held by the clamp 30.

- the clamps 31 are open, the advance 6 retracted; pushed by the jack 36, the drill can continue its progression and complete the hole C.

- the extension and the foil are removed in the reverse order to that just described.

- the feeder 6 which carries the device -33 is moved using the movable box and the cylinder 15 so that the injection device is in turn on the axis C along which the axis of the hole comes to be drilled.

- the sealing charges and the flexible rod are then placed in the flexible slide 32 so as to be introduced into the hole by turning, the bolt being driven in rotation by a cable clamp which progresses along the flexible slide 32.

Landscapes

- Engineering & Computer Science (AREA)

- Mining & Mineral Resources (AREA)

- Structural Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Geology (AREA)

- Drilling And Boring (AREA)

- Earth Drilling (AREA)

- Processing Of Stones Or Stones Resemblance Materials (AREA)

- Vehicle Body Suspensions (AREA)

- Body Structure For Vehicles (AREA)

- Radiation-Therapy Devices (AREA)

- Rock Bolts (AREA)

- Automatic Assembly (AREA)

- Excavating Of Shafts Or Tunnels (AREA)

- Butt Welding And Welding Of Specific Article (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT80400762T ATE2861T1 (de) | 1979-06-01 | 1980-05-29 | Verbolzungsvorrichtung mit linearer einstellung. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR7914083A FR2457962A1 (fr) | 1979-06-01 | 1979-06-01 | Dispositif de boulonnage a positionnement lineaire |

| FR7914083 | 1979-06-01 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0020271A1 EP0020271A1 (fr) | 1980-12-10 |

| EP0020271B1 true EP0020271B1 (fr) | 1983-03-23 |

Family

ID=9226144

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP80400762A Expired EP0020271B1 (fr) | 1979-06-01 | 1980-05-29 | Dispositif de boulonnage à positionnement linéaire |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP0020271B1 (ja) |

| JP (1) | JPS5625600A (ja) |

| AT (1) | ATE2861T1 (ja) |

| DE (1) | DE3062421D1 (ja) |

| FR (1) | FR2457962A1 (ja) |

| ZA (1) | ZA803194B (ja) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4398850A (en) * | 1981-02-09 | 1983-08-16 | Copper Range Company | Roof bolter and process |

| FI831481L (fi) * | 1983-04-29 | 1984-10-30 | Tampella Oy Ab | Bergbultningsaggregat. |

| AT384860B (de) * | 1983-06-30 | 1988-01-25 | Ver Edelstahlwerke Ag | Ankerbohr- und -setzeinrichtung |

| FR2556771B1 (fr) * | 1983-12-16 | 1986-05-02 | Eimco Secoma | Tete avant de tourelle ou glissiere d'appareil de foration, permettant l'injection de cartouches de resine |

| SE537968C2 (sv) * | 2012-07-09 | 2015-12-22 | Atlas Copco Rock Drills Ab | Förfarande och anordning vid bultinstallation i berg |

| SE539411C2 (en) | 2014-07-03 | 2017-09-19 | Skanska Sverige Ab | Method and arrangement for mounting bolts in a tunnel wall |

| DE102014110155A1 (de) * | 2014-07-18 | 2016-01-21 | Deilmann-Haniel Mining Systems Gmbh | Bohr- und Ankersetzgerät mit Querverschiebung |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2815191A (en) * | 1950-05-10 | 1957-12-03 | Jeffrey Mfg Co | Apparatus for carrying a drilling mechanism along a desired path |

| FR1359282A (fr) * | 1963-03-14 | 1964-04-24 | Glissière de boulonnage pour chantiers de hauteur limitée dite glissière de boulonnage pour couches basses | |

| SE417995B (sv) * | 1977-03-03 | 1981-04-27 | Atlas Copco Ab | Bergbultaggregat med gemensam styrning for borrmaskinen och rotationsanordningen for bergbultar |

| SE426511B (sv) * | 1978-06-13 | 1983-01-24 | Linden Alimak Ab | Anordning for automatiserad bultisettning vid bergforsterkning |

| DE2842788A1 (de) * | 1978-09-30 | 1980-04-10 | Secoma | Ankermagazin fuer ein gebirgsankersetzgeraet |

-

1979

- 1979-06-01 FR FR7914083A patent/FR2457962A1/fr active Granted

-

1980

- 1980-05-28 ZA ZA00803194A patent/ZA803194B/xx unknown

- 1980-05-29 DE DE8080400762T patent/DE3062421D1/de not_active Expired

- 1980-05-29 AT AT80400762T patent/ATE2861T1/de not_active IP Right Cessation

- 1980-05-29 EP EP80400762A patent/EP0020271B1/fr not_active Expired

- 1980-06-02 JP JP7411780A patent/JPS5625600A/ja active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| DE3062421D1 (en) | 1983-04-28 |

| FR2457962B1 (ja) | 1983-02-04 |

| FR2457962A1 (fr) | 1980-12-26 |

| ZA803194B (en) | 1981-05-27 |

| ATE2861T1 (de) | 1983-04-15 |

| EP0020271A1 (fr) | 1980-12-10 |

| JPS5625600A (en) | 1981-03-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5263545A (en) | Method and apparatus for drilling holes in soil or rock | |

| AU706612B2 (en) | Blasthole drill with improved automatic breakout wrench | |

| US3218893A (en) | Roof-bolting machine | |

| EP0020271B1 (fr) | Dispositif de boulonnage à positionnement linéaire | |

| CS273315B2 (en) | Device for guy holes boring and anchors location | |

| CH652799A5 (fr) | Dispositif pour la reception des boulons et leur maintien en cours de pose. | |

| CN108843249B (zh) | 一种用于井下液压钻机且具有储杆功能的自动上杆装置 | |

| CN110185483B (zh) | 一种用于锚杆台车的多功能锚杆送杆机构及操作方法 | |

| WO2008033831A3 (en) | Tong positioning and alignment device | |

| FR2494414A1 (fr) | Tete de guidage et de support d'une tige de percage du trou de coulee d'un four a cuve et perceuse pourvue d'une telle tete | |

| CA2518290C (en) | Apparatus and method for manufacturing a rock bolt | |

| US3604754A (en) | Apparatus for and method of driving a tunnel shaft | |

| EP3545223B1 (en) | Machine and method for repairing a pipeline in a body of water | |

| US5246313A (en) | Apparatus for forming long and short holes and setting rock bolts | |

| FR2545150A1 (fr) | Dispositif de boulonnage pour la fixation dans des forages de boulons au moyen d'un agent de cimentation | |

| US4436455A (en) | Universally positionable low profile mine drilling machine and method | |

| JPH03158592A (ja) | 補強ロッド積み込み装置 | |

| NO169608B (no) | Innretning for aa tilveiebringe et monteringsroer eller stikkledning for et nedgravet hovedroer | |

| CH634381A5 (fr) | Dispositif d'alesage d'un trou fore et de captage des poussieres produites par la meche d'un appareil de foration. | |

| US9534457B2 (en) | Drilling apparatus with drill guide | |

| CN114991836B (zh) | 一种锚钻注一体台车的推进梁 | |

| JPS5985091A (ja) | 鉱山用掘削機械 | |

| EP1345710B1 (fr) | Dispositif et procede de realisation de raccordements traversant sur des dispositifs d'echappements | |

| JPH0996196A (ja) | トンネル用ロックボルト施工装置 | |

| FR2780441A3 (fr) | Equipement de forage pour percer des trous dans le sol |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed | ||

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB IT LU NL SE |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 2861 Country of ref document: AT Date of ref document: 19830415 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3062421 Country of ref document: DE Date of ref document: 19830428 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19830531 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19830609 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19840327 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19840510 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19840526 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19840531 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19840630 Year of fee payment: 5 Ref country code: BE Payment date: 19840630 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19850529 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19850530 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19850531 Ref country code: CH Effective date: 19850531 Ref country code: BE Effective date: 19850531 |

|

| BERE | Be: lapsed |

Owner name: CONSTRUCTION DE MATERIELS DE MINES Effective date: 19850529 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19851201 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19860201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19881118 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 80400762.3 Effective date: 19860702 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |