CN217190007U - Domestic garbage treatment device - Google Patents

Domestic garbage treatment device Download PDFInfo

- Publication number

- CN217190007U CN217190007U CN202220108143.4U CN202220108143U CN217190007U CN 217190007 U CN217190007 U CN 217190007U CN 202220108143 U CN202220108143 U CN 202220108143U CN 217190007 U CN217190007 U CN 217190007U

- Authority

- CN

- China

- Prior art keywords

- transportation

- housing

- subassembly

- liquid

- frame

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A40/00—Adaptation technologies in agriculture, forestry, livestock or agroalimentary production

- Y02A40/10—Adaptation technologies in agriculture, forestry, livestock or agroalimentary production in agriculture

- Y02A40/20—Fertilizers of biological origin, e.g. guano or fertilizers made from animal corpses

Landscapes

- Crushing And Pulverization Processes (AREA)

Abstract

The utility model provides a domestic waste processing apparatus, including the frame, frame upper portion is equipped with crushing unit, and the frame lower part is equipped with the transportation subassembly that the slope was arranged, and crushing unit's bottom export corresponds with the import of transportation subassembly, and transportation subassembly upper portion is equipped with the solid export, and transportation subassembly lower part is equipped with the liquid collection subassembly, and the feed liquor end and the transportation subassembly intercommunication of liquid collection subassembly, the play liquid end of liquid collection subassembly are equipped with the drain pipe. The utility model discloses the beneficial effect who produces is: the mode that uses helical blade to rotate transports the rubbish after smashing to higher position from lower position, and helical blade has certain squeezing action in the transportation, can extrude the liquid in the rubbish, and liquid flows down and discharges from the drain pipe under the effect of self gravity, and solid rubbish removes the upper end that upwards moves to the transportation casing and discharges from the solid export, realizes the abundant separation of solid-liquid.

Description

Technical Field

The utility model relates to an environmental protection equipment technical field especially indicates a domestic waste processing apparatus.

Background

Environmental protection (environmental protection for short) is a general term for various actions taken by humans to solve real or potential environmental problems, coordinate the relationship between humans and the environment and guarantee the sustainable development of the economic society, at the level of individuals, organizations or governments, to protect the natural environment for the welfare of the nature and the humans. A lot of domestic waste can often produce in present daily life, and the variety of rubbish is various, has solid and liquid, handles very inconvenience like this, and current device is used for domestic waste to carry out solid-liquid separation, but the sufficiency of separation operation, and the water content in the solid rubbish that obtains is higher, is unfavorable for subsequent further processing.

SUMMERY OF THE UTILITY MODEL

The utility model provides a domestic waste processing apparatus has solved the insufficient problem of domestic waste solid-liquid separation degree among the prior art.

The technical scheme of the utility model is realized like this:

the utility model provides a domestic waste processing apparatus, which comprises a frame, frame upper portion is equipped with crushing unit, the frame lower part is equipped with the transportation subassembly that the slope was arranged, crushing unit's bottom export corresponds with the import of transportation subassembly, transportation subassembly upper portion is equipped with the solid export, the transportation subassembly lower part is equipped with the liquid collection subassembly, the feed liquor end and the transportation subassembly intercommunication of liquid collection subassembly, the play liquid end of liquid collection subassembly is equipped with the drain pipe, domestic waste gets into crushing unit and smashes, rubbish after the smashing gets into the transportation subassembly, the transportation subassembly drives fixed rubbish rebound and discharges from the solid export, move up in-process liquid downward at rubbish, liquid gets into the liquid collection subassembly and discharges from the drain pipe behind liquid and the solid separation, realize solid-liquid separation.

The transportation subassembly is equipped with the pivot including the transportation casing that the slope was arranged in the transportation casing, and the both ends of pivot rotate with the both ends of transporting the casing respectively and be connected, be equipped with helical blade in the pivot, the pivot upper end is stretched out the transportation casing and is connected with the transportation motor that sets up in the frame, the transportation motor drives helical blade and rotates, and then promote solid waste along transporting the casing rebound, and remove in-process liquid and flow down along transporting the casing, helical blade has certain squeezing action to solid waste when rotating, realize the abundant separation of solid-liquid, more be favorable to subsequent refuse treatment.

The upper end and the lower end of the transportation shell are respectively fixed on the frame, and the frame fixes the transportation motor and the transportation shell, so that the stability of the transportation shell and the transportation motor in the garbage disposal process is ensured.

The lower extreme of transportation casing can be dismantled and be equipped with the end cover, and the solid export setting is in the upper end of transportation casing, and solid rubbish removes the upper end of transportation casing and discharges from the solid export under helical blade's effect, opens the end cover and conveniently carries out pivot and helical blade's installation and maintenance.

The liquid collecting assembly comprises a filter plate and a water collecting tank, the filter plate is fixedly arranged on the lower side of the transportation shell, the water collecting tank is fixedly arranged on the transportation shell and corresponds to the filter plate in position, the drain pipe is arranged at the bottom of the water collecting tank, the filter plate is used as the side wall of the lower side of the transportation shell, and liquid in the transportation shell flows into the water collecting tank from the filter plate and is discharged from the drain pipe.

Crushing unit includes the shell, and the shell is fixed to be set up in the frame, is equipped with parallel arrangement's driving shaft and driven shaft in the shell, is equipped with staggered arrangement's blade on driving shaft and the driven shaft, and driving shaft and driven shaft stretch out the shell and are connected with drive assembly, and drive assembly drives driving shaft and driven shaft and rotates, and then makes the blade smash rubbish, conveniently carries out subsequent refuse treatment.

The driving assembly comprises a crushing motor fixedly arranged on the rack, the crushing motor is connected with the driving shaft, the driving shaft is provided with a driving gear, the driven shaft is provided with a driven gear, and the driving gear is meshed with the driven gear.

The shell open-top department is equipped with the feeder hopper, and the feeder hopper makes things convenient for rubbish to get into crushing unit.

The bottom opening of shell is equipped with the guide fill, and the guide fill passes through the access connection of guide passageway and transportation casing, and rubbish after smashing gets into the transportation casing through guide fill and guide passageway.

The utility model discloses the beneficial effect who produces is: the mode that uses helical blade to rotate transports the rubbish after smashing to higher position from lower position, and helical blade has certain squeezing action in the transportation, can extrude the liquid in the rubbish, and liquid flows down and discharges from the drain pipe under the effect of self gravity, and solid rubbish removes the upper end that upwards moves to the transportation casing and discharges from the solid export, realizes the abundant separation of solid-liquid.

Drawings

In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the drawings used in the description of the embodiments or the prior art will be briefly described below, it is obvious that the drawings in the following description are only some embodiments of the present invention, and for those skilled in the art, other drawings can be obtained according to these drawings without creative efforts.

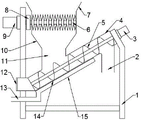

Fig. 1 is a schematic structural view of a domestic garbage disposal apparatus of the present invention.

Figure 2 is a schematic view of the size reduction assembly.

In the figure: 1-frame, 2-solid outlet, 3-transport motor, 4-transport shell, 5-helical blade, 6-crushing component, 61-shell, 62-driven shaft, 63-driving shaft, 64-blade, 7-feeding hopper, 8-driving gear, 9-crushing motor, 10-guide hopper, 11-guide channel, 12-end cover, 13-liquid outlet pipe, 14-filter plate, 15-water collecting tank, 16-driven gear.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by a person skilled in the art without any creative effort belong to the protection scope of the present invention.

Embodiment 1, as shown in fig. 1, a domestic waste processing apparatus, including frame 1, frame 1 upper portion is equipped with crushing unit 6, frame 1 lower part is equipped with the transportation subassembly that the slope was arranged, the bottom export of crushing unit 6 corresponds with the import of transportation subassembly, transportation subassembly upper portion is equipped with solid export 2, the transportation subassembly lower part is equipped with the liquid collection subassembly, the inlet end and the transportation subassembly intercommunication of liquid collection subassembly, the play liquid end of liquid collection subassembly is equipped with drain pipe 13, crushing unit 6 lets in the transportation subassembly after smashing rubbish, the transportation subassembly transports rubbish to the eminence from the low, in the transportation, liquid flows down under the effect of self gravity and gets into the liquid collection subassembly, and discharge from drain pipe 13, the solid rebound is discharged from solid export 2.

Further, the transportation subassembly is including the transportation casing 4 that the slope was arranged, the upper and lower both ends of transportation casing 4 are fixed respectively in frame 1, frame 1 provides the support for transportation casing 4, be equipped with the pivot in the transportation casing 4, and the both ends of pivot rotate with the both ends of transportation casing 4 respectively and be connected, be equipped with helical blade 5 in the pivot, the pivot upper end is stretched out transportation casing 4 and is connected with transportation motor 3, transportation motor 3 is fixed to be set up in frame 1, transportation motor 3 drives the pivot and rotates, and then it is rotatory to drive helical blade 5, make solid rubbish rebound, and at rubbish rebound in-process, helical blade 5 has certain squeezing action to rubbish, can extrude the liquid in the rubbish and flow downwards, guarantee rubbish can the intensive separation.

Furthermore, an end cover 12 is detachably arranged at the lower end of the transportation shell 4, the solid outlet 2 is arranged at the upper end of the transportation shell 4, and the solid garbage is discharged from the solid outlet 2 after moving to the upper end of the transportation shell 4; the end cover 12 is fixed at the lower end of the transportation shell 4 through screws, the end cover 12 is installed after the rotating shaft and the helical blades 5 are installed, the sealing performance of the lower end of the transportation shell 4 is guaranteed, the end cover 12 can be detached after the transportation shell is used for a period of time, and the lower end of the transportation shell 4 is cleaned.

Further, as shown in fig. 2, the crushing assembly 6 includes a housing 61, the housing 61 is fixedly disposed on the frame 1, a driving shaft 63 and a driven shaft 62 which are arranged in parallel are disposed in the housing 61, blades 64 which are arranged in a staggered manner are disposed on the driving shaft 63 and the driven shaft 62, the driving shaft 63 and the driven shaft 62 extend out of the housing 61 to be connected with the driving assembly, and the driving assembly drives the driving shaft 63 and the driven shaft 62 to rotate, so that the blades 64 on the driving shaft 63 and the driven shaft 62 crush the garbage. The drive assembly comprises a crushing motor 9 fixedly arranged on the rack 1, the crushing motor 9 is connected with a driving shaft 63, a driving gear 8 is arranged on the driving shaft 63, a driven gear 16 is arranged on the driven shaft 62, the driving gear 8 is meshed with the driven gear 16, the crushing motor 9 drives the driving shaft 63 to rotate, the driving shaft 63 drives the driven shaft 62 to rotate through transmission of the driving gear 8 and the driven gear 16, and rotation of the blade 64 is achieved.

Further, shell 61 top opening part is equipped with feeder hopper 7, and feeder hopper 7 conveniently drops into rubbish in crushing unit 6. The bottom opening of the shell 61 is provided with a material guide hopper 10, the material guide hopper 10 is connected with the bottom inlet of the transportation shell 4 through a material guide channel 11, and the crushed garbage enters the transportation shell 4 through the material guide hopper 10 and the material guide channel 11 to be subjected to solid-liquid separation.

The other structure is the same as that of embodiment 1.

The above description is only a preferred embodiment of the present invention, and should not be taken as limiting the invention, and any modifications, equivalent replacements, improvements, etc. made within the spirit and principle of the present invention should be included in the protection scope of the present invention.

Claims (9)

1. The utility model provides a domestic waste treatment device, includes frame (1), its characterized in that, frame (1) upper portion is equipped with crushing unit (6), frame (1) lower part is equipped with the transportation subassembly that the slope was arranged, the bottom export of crushing unit (6) corresponds with the import of transportation subassembly, transportation subassembly upper portion is equipped with solid export (2), the transportation subassembly lower part is equipped with the liquid collection subassembly, the feed liquor end and the transportation subassembly intercommunication of liquid collection subassembly, the play liquid end of liquid collection subassembly is equipped with drain pipe (13).

2. The household garbage disposal device according to claim 1, wherein the transportation assembly comprises a transportation housing (4) arranged obliquely, a rotating shaft is arranged in the transportation housing (4), two ends of the rotating shaft are respectively and rotatably connected with two ends of the transportation housing (4), a helical blade (5) is arranged on the rotating shaft, and the upper end of the rotating shaft extends out of the transportation housing (4) and is connected with a transportation motor (3) arranged on the rack (1).

3. The household garbage disposal apparatus according to claim 2, wherein the upper and lower ends of the transportation housing (4) are fixed to the frame (1), respectively.

4. A domestic waste treatment apparatus according to claim 3, wherein the lower end of the transport housing (4) is removably provided with an end cap (12) and the solids outlet (2) is provided at the upper end of the transport housing (4).

5. The household garbage disposal device according to any one of claims 2 to 4, wherein the liquid collection assembly comprises a filter plate (14) and a water collection tank (15), the filter plate (14) is fixedly arranged at the lower side of the transportation housing (4), the water collection tank (15) is fixedly arranged on the transportation housing (4), the water collection tank (15) corresponds to the filter plate (14), and the liquid outlet pipe (13) is arranged at the bottom of the water collection tank (15).

6. The household garbage treatment device according to claim 5, wherein the crushing assembly (6) comprises a housing (61), the housing (61) is fixedly arranged on the frame (1), a driving shaft (63) and a driven shaft (62) which are arranged in parallel are arranged in the housing (61), blades (64) which are arranged in a staggered manner are arranged on the driving shaft (63) and the driven shaft (62), and the driving shaft (63) and the driven shaft (62) extend out of the housing (61) and are connected with the driving assembly.

7. The household garbage disposal device according to claim 6, wherein the driving assembly comprises a crushing motor (9) fixedly arranged on the frame (1), the crushing motor (9) is connected with a driving shaft (63), a driving gear (8) is arranged on the driving shaft (63), a driven gear (16) is arranged on the driven shaft (62), and the driving gear (8) is meshed with the driven gear (16).

8. The household garbage disposal apparatus according to claim 7, wherein the top opening of the housing (61) is provided with a feed hopper (7).

9. The household garbage disposal device according to claim 8, wherein the bottom opening of the housing (61) is provided with a material guiding hopper (10), and the material guiding hopper (10) is connected with the inlet of the transportation housing (4) through a material guiding channel (11).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202220108143.4U CN217190007U (en) | 2022-01-17 | 2022-01-17 | Domestic garbage treatment device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202220108143.4U CN217190007U (en) | 2022-01-17 | 2022-01-17 | Domestic garbage treatment device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN217190007U true CN217190007U (en) | 2022-08-16 |

Family

ID=82792592

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202220108143.4U Active CN217190007U (en) | 2022-01-17 | 2022-01-17 | Domestic garbage treatment device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN217190007U (en) |

-

2022

- 2022-01-17 CN CN202220108143.4U patent/CN217190007U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN210906358U (en) | Domestic waste environmental protection treatment facility | |

| CN112108491A (en) | Environment-friendly refuse handling installation | |

| CN211026491U (en) | Garbage processor | |

| CN212559740U (en) | Urban sewage treatment device | |

| CN216629866U (en) | Sewage collection device for environmental engineering | |

| CN111229370A (en) | Domestic waste handles with broken recovery unit | |

| CN215654144U (en) | Anti-blocking type filtering device for wastewater treatment | |

| CN213914032U (en) | Road garbage crushing treatment equipment | |

| CN112604753B (en) | Biomass waste treatment equipment | |

| CN213201013U (en) | Intelligence house is retrieved and is used dustbin | |

| CN214289945U (en) | Environment-friendly refuse handling installation | |

| CN217190007U (en) | Domestic garbage treatment device | |

| CN210753061U (en) | Kitchen waste pretreatment equipment | |

| CN114308292B (en) | Fruit and vegetable garbage disposer | |

| CN208775180U (en) | A kind of household garbage bag-breaking machine that can effectively mitigate refuse bag winding | |

| CN216936202U (en) | Garbage crushing treatment device for environmental protection | |

| CN214183409U (en) | Garbage classification and recovery system | |

| CN214556180U (en) | Kitchen waste treatment equipment | |

| CN213474282U (en) | Rural area refuse treatment environmental protection equipment | |

| CN211678077U (en) | A processing apparatus for kitchen garbage | |

| CN115672459A (en) | Water surface garbage removing device and offshore wind power station | |

| CN111921612A (en) | Garbage disposal equipment with circulating cleaning function | |

| CN221492664U (en) | Urban domestic garbage is with collecting processing apparatus | |

| CN217888217U (en) | Garbage recycling and treating equipment | |

| CN221675283U (en) | Kitchen waste treatment integrated device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |