CN101384422A - 未硫化带状橡胶构件的带分隔物的卷取衬垫的制造方法及其装置、以及该卷取衬垫的分隔物构件的制造方法及其装置 - Google Patents

未硫化带状橡胶构件的带分隔物的卷取衬垫的制造方法及其装置、以及该卷取衬垫的分隔物构件的制造方法及其装置 Download PDFInfo

- Publication number

- CN101384422A CN101384422A CNA2007800055623A CN200780005562A CN101384422A CN 101384422 A CN101384422 A CN 101384422A CN A2007800055623 A CNA2007800055623 A CN A2007800055623A CN 200780005562 A CN200780005562 A CN 200780005562A CN 101384422 A CN101384422 A CN 101384422A

- Authority

- CN

- China

- Prior art keywords

- liner

- separator

- separator member

- band

- rubber component

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000000034 method Methods 0.000 title claims abstract description 31

- 238000004804 winding Methods 0.000 title claims abstract description 6

- 125000006850 spacer group Chemical group 0.000 title abstract description 7

- 239000000463 material Substances 0.000 claims abstract description 52

- 239000000853 adhesive Substances 0.000 claims abstract description 48

- 230000001070 adhesive effect Effects 0.000 claims abstract description 48

- 238000004519 manufacturing process Methods 0.000 claims description 33

- 230000000750 progressive effect Effects 0.000 claims description 15

- 238000009434 installation Methods 0.000 claims description 12

- 230000009193 crawling Effects 0.000 claims description 2

- 229910000838 Al alloy Inorganic materials 0.000 description 4

- 238000001816 cooling Methods 0.000 description 4

- 239000007787 solid Substances 0.000 description 4

- 238000010276 construction Methods 0.000 description 3

- 238000002788 crimping Methods 0.000 description 3

- 238000010586 diagram Methods 0.000 description 3

- 238000001125 extrusion Methods 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 239000007767 bonding agent Substances 0.000 description 2

- 230000008602 contraction Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000013536 elastomeric material Substances 0.000 description 2

- 238000007493 shaping process Methods 0.000 description 2

- 238000005987 sulfurization reaction Methods 0.000 description 2

- 229920000742 Cotton Polymers 0.000 description 1

- 240000002853 Nelumbo nucifera Species 0.000 description 1

- 235000006508 Nelumbo nucifera Nutrition 0.000 description 1

- 235000006510 Nelumbo pentapetala Nutrition 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- 239000004411 aluminium Substances 0.000 description 1

- 230000003321 amplification Effects 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000003199 nucleic acid amplification method Methods 0.000 description 1

- 238000002161 passivation Methods 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 238000007665 sagging Methods 0.000 description 1

- 238000010008 shearing Methods 0.000 description 1

- 230000037303 wrinkles Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H39/00—Associating, collating, or gathering articles or webs

- B65H39/16—Associating two or more webs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/48—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding

- B29C65/50—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding using adhesive tape, e.g. thermoplastic tape; using threads or the like

- B29C65/5057—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding using adhesive tape, e.g. thermoplastic tape; using threads or the like positioned between the surfaces to be joined

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/48—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding

- B29C65/50—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding using adhesive tape, e.g. thermoplastic tape; using threads or the like

- B29C65/5092—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding using adhesive tape, e.g. thermoplastic tape; using threads or the like characterised by the tape handling mechanisms, e.g. using vacuum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/10—Particular design of joint configurations particular design of the joint cross-sections

- B29C66/11—Joint cross-sections comprising a single joint-segment, i.e. one of the parts to be joined comprising a single joint-segment in the joint cross-section

- B29C66/112—Single lapped joints

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/10—Particular design of joint configurations particular design of the joint cross-sections

- B29C66/13—Single flanged joints; Fin-type joints; Single hem joints; Edge joints; Interpenetrating fingered joints; Other specific particular designs of joint cross-sections not provided for in groups B29C66/11 - B29C66/12

- B29C66/131—Single flanged joints, i.e. one of the parts to be joined being rigid and flanged in the joint area

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/40—General aspects of joining substantially flat articles, e.g. plates, sheets or web-like materials; Making flat seams in tubular or hollow articles; Joining single elements to substantially flat surfaces

- B29C66/47—Joining single elements to sheets, plates or other substantially flat surfaces

- B29C66/474—Joining single elements to sheets, plates or other substantially flat surfaces said single elements being substantially non-flat

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/71—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the composition of the plastics material of the parts to be joined

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/73—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset

- B29C66/737—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the state of the material of the parts to be joined

- B29C66/7375—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the state of the material of the parts to be joined uncured, partially cured or fully cured

- B29C66/73751—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the state of the material of the parts to be joined uncured, partially cured or fully cured the to-be-joined area of at least one of the parts to be joined being uncured, i.e. non cross-linked, non vulcanized

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/80—General aspects of machine operations or constructions and parts thereof

- B29C66/83—General aspects of machine operations or constructions and parts thereof characterised by the movement of the joining or pressing tools

- B29C66/834—General aspects of machine operations or constructions and parts thereof characterised by the movement of the joining or pressing tools moving with the parts to be joined

- B29C66/8341—Roller, cylinder or drum types; Band or belt types; Ball types

- B29C66/83411—Roller, cylinder or drum types

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/80—General aspects of machine operations or constructions and parts thereof

- B29C66/83—General aspects of machine operations or constructions and parts thereof characterised by the movement of the joining or pressing tools

- B29C66/834—General aspects of machine operations or constructions and parts thereof characterised by the movement of the joining or pressing tools moving with the parts to be joined

- B29C66/8341—Roller, cylinder or drum types; Band or belt types; Ball types

- B29C66/83411—Roller, cylinder or drum types

- B29C66/83413—Roller, cylinder or drum types cooperating rollers, cylinders or drums

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/0016—Handling tyres or parts thereof, e.g. supplying, storing, conveying

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H18/00—Winding webs

- B65H18/08—Web-winding mechanisms

- B65H18/10—Mechanisms in which power is applied to web-roll spindle

- B65H18/103—Reel-to-reel type web winding and unwinding mechanisms

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2791/00—Shaping characteristics in general

- B29C2791/001—Shaping in several steps

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C51/00—Shaping by thermoforming, i.e. shaping sheets or sheet like preforms after heating, e.g. shaping sheets in matched moulds or by deep-drawing; Apparatus therefor

- B29C51/08—Deep drawing or matched-mould forming, i.e. using mechanical means only

- B29C51/082—Deep drawing or matched-mould forming, i.e. using mechanical means only by shaping between complementary mould parts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C51/00—Shaping by thermoforming, i.e. shaping sheets or sheet like preforms after heating, e.g. shaping sheets in matched moulds or by deep-drawing; Apparatus therefor

- B29C51/18—Thermoforming apparatus

- B29C51/20—Thermoforming apparatus having movable moulds or mould parts

- B29C51/22—Thermoforming apparatus having movable moulds or mould parts rotatable about an axis

- B29C51/225—Thermoforming apparatus having movable moulds or mould parts rotatable about an axis mounted on a vacuum drum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/40—General aspects of joining substantially flat articles, e.g. plates, sheets or web-like materials; Making flat seams in tubular or hollow articles; Joining single elements to substantially flat surfaces

- B29C66/41—Joining substantially flat articles ; Making flat seams in tubular or hollow articles

- B29C66/43—Joining a relatively small portion of the surface of said articles

- B29C66/438—Joining sheets for making hollow-walled, channelled structures or multi-tubular articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/40—General aspects of joining substantially flat articles, e.g. plates, sheets or web-like materials; Making flat seams in tubular or hollow articles; Joining single elements to substantially flat surfaces

- B29C66/47—Joining single elements to sheets, plates or other substantially flat surfaces

- B29C66/472—Joining single elements to sheets, plates or other substantially flat surfaces said single elements being substantially flat

- B29C66/4722—Fixing strips to surfaces other than edge faces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/0016—Handling tyres or parts thereof, e.g. supplying, storing, conveying

- B29D2030/0038—Handling tyre parts or semi-finished parts, excluding beads, e.g., storing, transporting, transferring

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2021/00—Use of unspecified rubbers as moulding material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/24—Condition, form or state of moulded material or of the material to be shaped crosslinked or vulcanised

- B29K2105/246—Uncured, e.g. green

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2016/00—Articles with corrugations or pleats

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/40—Type of handling process

- B65H2301/41—Winding, unwinding

- B65H2301/412—Roll

- B65H2301/4127—Roll with interleaf layer, e.g. liner

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2801/00—Application field

- B65H2801/93—Tyres

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Tyre Moulding (AREA)

- Winding Of Webs (AREA)

- Folding Of Thin Sheet-Like Materials, Special Discharging Devices, And Others (AREA)

- Lining Or Joining Of Plastics Or The Like (AREA)

- Heating, Cooling, Or Curing Plastics Or The Like In General (AREA)

Abstract

提供一种能够以较高的生产率高效地制造未硫化带状橡胶构件的带分隔物的卷取衬垫的制造方法及其装置、以及该卷取衬垫的分隔物构件的制造方法及其装置。使从材料的开卷辊(16)开卷的板状的带状材料(Rw)通过赋形装置(19)的赋形齿轮(19a、19b)之间而连续成形为凹凸状,在该成形为凹凸状的带状的分隔物构件(12a、12b)的单面上贴附粘接构件(14),沿着从开卷装置(45)开卷的板状的基础构件(11)的长度方向的侧缘部连续地贴附该分隔物构件(12a、12b)的粘接面。

Description

技术领域

本发明涉及未硫化带状橡胶构件的带分隔物(spacer)的卷取衬垫(liner)的制造方法及其装置、以及该卷取衬垫的分隔物构件的制造方法及其装置,更详细地说,涉及例如能够将到成形时为止需要保持一定的挤压形状的轮胎胎面或胎侧橡胶构件等未硫化带状橡胶构件不变形地卷取成卷状进行保持、保管的、未硫化带状橡胶构件的带分隔物的卷取衬垫的制造方法及其装置、以及该卷取衬垫的分隔物构件的制造方法及其装置。

背景技术

以往,在轮胎成形工序等中,如图12所示,进行下述的方法:通过切断装置2,将通过挤压机1挤压成形并赋形(型付,赋予形状等、成形、轧花)的包括轮胎胎面、胎侧橡胶构件等轮胎结构构件的未硫化带状橡胶构件W定长切断成规定的长度,然后出于直到轮胎成形时为止保持形状等的目的,将该定长切断的未硫化带状橡胶构件Wa多层状地载置在货车(ケリ—トラック)等台车3上进行保管。

但是,被定长切断的未硫化状态的轮胎胎面、胎侧橡胶构件等未硫化带状橡胶构件Wa在放置到之后的轮胎成形时使用为止的期间内,由于冷却等而产生形状尺寸的收缩,轮胎成形时材料的尺寸精度变得不稳定,成为使轮胎成形后的轮胎均匀性恶化的原因。

因此,近年来如图13所示,将由挤压机1挤压成形并赋形的未硫化带状橡胶构件W并不预先定长切断,而夹着卷取衬垫R地以长条状态卷取成卷状(筒状),在即将成形使用之前开卷(卷出)并定长切断,由此抑制材料的形状尺寸的收缩,保证尺寸精度(例如,参照专利文献1)。

但是,以往的卷取衬垫,包括:具有未硫化带状橡胶构件的至少宽度以上的横向宽度的树脂制的不伸缩性的带状的载置件,和在该载置件表面的宽度方向两侧缘部由橡胶材料形成为具有未硫化带状橡胶构件的至少厚度以上的高度的凹凸状的、实心的分隔物部;将未硫化带状橡胶构件夹在该实心的分隔物部之间地卷取成卷状而保管。然而,存在由于卷取衬垫的自重和未硫化带状橡胶构件的自重而下垂的问题,并且存在未硫化带状橡胶构件的赋形的形态损坏、崩塌的问题。

而且,由于将由橡胶材料构成的实心的分隔物部固定在载置件表面的宽度方向两侧缘部,所以相对于长度方向的伸缩性较小并且重量增大,而且在弯曲成卷状使用的情况下,分隔物部的弯曲阻力较大,存在棒条(栈,棂条,梃)的形状变形或损伤而不能再使用等问题。另外,由于使用实心的分隔物部,所以即使赋形的未硫化带状橡胶构件的形状得到保持,也存在分隔物部之间的空气的流通较差、保管时的加温·冷却效率极差的问题。

因此,本申请的发明者等申请了能够使卷取衬垫的重量轻型化、并且能够不引起分隔物构件的损伤地反复使用、能够保持未硫化带状橡胶构件的形状、提高保管时的加温·冷却效率的未硫化带状橡胶构件的卷取衬垫以及该卷取衬垫的制造方法(例如,参照专利文献2)。

但是,在上述的申请中,并没有提出连续高效地进行未硫化带状橡胶构件卷取衬垫的的分隔物构件的制造以及带分隔物的卷取衬垫的制造的方法和装置。

专利文献1:日本特开平5-301300号公报(第2~第3页、图1)

专利文献2:国际公开号WO 2005/053941号A1的小册子(文本)

发明内容

本发明着眼于该以往的问题点,其目的在于提供一种能够高效且连续地制造带分隔物的卷取衬垫以及该卷取衬垫的分隔物构件的、未硫化带状橡胶构件的带分隔物的卷取衬垫的制造方法及其装置,以及该卷取衬垫的分隔物构件的制造方法及其装置。

为了达成上述目的,本发明的未硫化带状橡胶构件的带分隔物的卷取衬垫的制造方法,其主旨在于:使从材料的开卷辊开卷的板状的带状材料通过赋形装置而连续成形为凹凸状,在该成形为凹凸状的带状的分隔物构件的单面上贴附粘接构件,沿着板状的基础构件的长度方向的侧缘部贴附这样构成的分隔物构件的粘接面。

另外,本发明的其它的未硫化带状橡胶构件的带分隔物的卷取衬垫的制造方法,其主旨在于:使从材料的开卷辊开卷的板状的带状材料通过赋形装置而连续成形为凹凸状,在该成形为凹凸状的带状的分隔物构件的单面上贴附粘接构件,沿着从开卷装置开卷的板状的基础构件的长度方向的侧缘部连续地贴附该分隔物构件的粘接面。

在这里,也可以:在将所述分隔物构件贴附在板状的基础构件上的工序中,通过紧固连接构件将规定长度的分隔物构件的末端部固定。

另外,本发明的未硫化带状橡胶构件的带分隔物的卷取衬垫的制造装置,其主旨在于,包括:赋形装置,其将从材料的开卷辊开卷的板状的带状材料以规定的间距连续成形为凹凸状;粘接构件贴附装置,其在由该赋形装置赋形后的带状的分隔物构件的单面上贴附粘接构件;基础构件的开卷装置,其沿着板状的基础构件的长度方向的侧缘部贴附该贴附有粘接构件的分隔物构件的粘接面;和在基础构件上贴附有分隔物构件的卷取衬垫的卷取装置。

另外,本发明的其它的未硫化带状橡胶构件的带分隔物的卷取衬垫的制造装置,其主旨在于,包括:赋形装置,其将从材料的开卷辊开卷的板状的带状材料以规定的间距连续成形为凹凸状;粘接构件贴附装置,其在由该赋形装置赋形后的带状的分隔物构件的单面上贴附粘接构件;基础构件的开卷装置,其沿着从开卷辊开卷的板状的基础构件的长度方向的侧缘部连续地贴附该贴附有粘接构件的分隔物构件的粘接面;和在基础构件上贴附有分隔物构件的卷取衬垫的卷取装置。

在这里,也可以:在所述基础构件的开卷装置与卷取衬垫的卷取装置之间配设有将带状的分隔物构件的末端部相对于基础构件固定的紧固连接装置,另外,在所述材料开卷辊以及卷取衬垫的卷取装置上,设置有用于防止材料的蛇行(折皱、扭曲)以及溃散(荷崩れ,溃塌)的导辊,进而,在所述卷取装置的卷取轴上设有制动装置。

另外,本发明的未硫化带状橡胶构件卷取衬垫的分隔物构件的制造方法,其主旨在于:使从材料开卷辊开卷的板状的带状材料通过赋形装置而连续成形为凹凸状,在该成形为凹凸状的带状的分隔物构件的单面上贴附粘接构件。

另外,本发明的未硫化带状橡胶构件卷取衬垫的分隔物构件的制造装置,其主旨在于,包括:赋形装置,其将从材料开卷辊开卷的板状的带状材料以规定的间距连续成形为凹凸状;和粘接构件贴附装置,其在由该赋形装置赋形后的带状的分隔物构件的单面上贴附粘接构件。

在这里,可以将所述赋形装置设为具有规定间距的凹凸刃的能够旋转驱动的一对赋形齿轮,也可以将所述粘接构件设为双面粘接带。

通过这样制造带分隔物的卷取衬垫以及该卷取衬垫的分隔物构件,能够连续且高效、廉价地制造,另外通过单独地制造卷取衬垫的分隔物构件,能够应对各种轮胎结构构件。

本发明由于如上所述那样构成,所以起到如下所述的优异的效果。

(a)通过单独地制造卷取衬垫的分隔物构件、根据用途而贴附在基础构件上使用,能够与大小、厚度等不同的各种轮胎结构构件相对应地使用。

(b)能够连续且高效地制造卷取衬垫的分隔物构件。

(c)能够通过简单的装置制造分隔物构件。

(d)能够连续地制造卷取衬垫的分隔物构件,并经由粘接构件将该卷取衬垫的分隔物构件贴附在基础构件上制造,所以能够高效地制造带分隔物的卷取衬垫。

(e)能够连续地制造卷取衬垫的分隔物构件,在该卷取衬垫的分隔物构件上贴附粘接构件并且贴附在从开卷装置开卷的基础构件上而连续地制造,所以能够高效地制造带分隔物的卷取衬垫。

(f)能够高效地制造带分隔物的卷取衬垫,将该带分隔物的卷取衬垫以没有蛇行地码放在卷取装置上的状态进行卷取、开卷。

(g)能够简单且廉价地制造带分隔物的卷取衬垫的制造装置整体。

(h)通过使用由板状的材料构成的具备凹凸部的分隔物构件,能够实现轻型化,而且能够使分隔物构件间的空气的流通较好,未硫化带状橡胶构件的形状得到保持,提高保管时的加温·冷却效率,能够保持品质保证。

附图说明

图1是表示通过本发明的带分隔物的卷取衬垫将未硫化带状橡胶构件卷取的状态的立体图。

图2是图1的X-X向视放大剖视图。

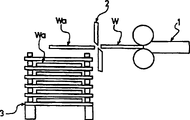

图3是具备凹凸部的分隔物构件的制造工序的概略说明图。

图4是图3的A部的放大主视图。

图5是图4的侧视图。

图6是图3的B部的放大主视图。

图7是图3的C部的放大主视图。

图8是图7的侧视图。

图9是连续地制造分隔物构件、并且将该分隔物构件贴附在基础构件上而连续地制造卷取衬垫的工序的说明图。

图10是图9的D部的放大主视图。

图11是图10的侧视图。

图12是以往的将未硫化带状橡胶构件保管在台车上的方法的说明图。

图13是以往的将未硫化带状橡胶构件夹着衬垫卷取成卷状进行保管的方法的说明图。

符号说明

11:基础构件

12a、12b:分隔物构件

13:凹凸部

14:粘接构件

16:材料开卷辊

17a、17b:导向滚筒

18:导向构件

19:赋形装置

19a、19b:赋形齿轮

20:粘接构件贴附装置

23:带式制动器

24:手动式操作柄

26:导辊

29:转印辊

30:贴附装置

31:双面胶带开卷辊

32:双面胶带

33:压接辊

34:剥落纸

35:纸卷取辊

36:衬垫卷取装置

41:带式制动器

42:手动式操作柄

44a、44b:导向齿轮

45:开卷装置

46:紧固连接构件

47:卷取辊

W、Wa:未硫化带状橡胶构件

R:卷取衬垫

α:倾斜角度

Rw:带状材料

具体实施方式

下面,基于附图,对本发明的实施方式进行说明。另外,在下面的说明中对于与以往例相同的结构要素标注相同符号而省略说明。

图1是表示实施本发明时的通过卷取衬垫R将未硫化带状橡胶构件W卷取在芯材10上的状态的立体图,本发明的卷取衬垫R,包括:由铝合金(JIS A3000系、A5000系、A6000系的合金等)制的板材形成的带状的基础构件11,和安装在该基础构件11的表面的宽度方向两侧缘部的形成为凹凸状的带状的分隔物构件12a、12b。

具体地说,所述带状的基础构件11是对厚度0.6mm~1.0mm的铝合金(JIS A5052P)制的板材的表面进行铝表面钝化处理加工而成的,该基础构件11具有卷取保管的未硫化带状橡胶构件W的至少宽度h以上的横向宽度H。

另外,所述形成为凹凸状的带状的分隔物构件12a、12b如图2所示,由厚度0.5mm~0.8mm的铝合金(A5052P)制的窄幅板材形成,为了相对于长度方向具有伸缩性,沿着长度方向以规定间距P形成剖面大致梯形形状的凹凸部13,沿着长度方向通过粘接构件14(在该实施方式中使用双面胶带,但不限定于双面胶带,也能够使用通常的粘接剂)平行地安装在所述基础构件11表面的宽度方向两侧缘部。

即,剖面大致梯形形状的凹凸部13具有至少未硫化带状橡胶构件W的厚度t以上的高度T,凹凸部13的宽度、高度T以及间距P根据保管的未硫化带状橡胶构件W的剖面形状等的大小任意地设定。

作为上述那样的卷取衬垫R的制造方法有:分别制造带状的基础构件11和形成为凹凸状的带状的分隔物构件12a、12b、然后通过粘接构件14组装而制造的方法,和连续地制造带状的分隔物构件12a、12b、同时一边通过粘接构件14将该分隔物构件12a、12b贴附在带状的基础构件11上一边连续地制造的方法。

作为单独地制造所述带状的分隔物构件12a或12b的方法,如图3~图5所示,从能够旋转驱动地架设在支撑台15上的材料开卷辊16将板状的带状材料Rw开卷,使该开卷的带状材料Rw通过导向滚筒17a、17b和导向构件18,然后通过图6所示的赋形装置19的一对赋形齿轮19a、19b之间而连续成形为凹凸状,在该成形为凹凸状的带状的分隔物构件12a或12b的单面上通过粘接构件贴附装置20贴附粘接构件14,这样进行制造。

另外,在上述的说明中,说明了从材料开卷辊16使卷取的一张板状的带状材料Rw通过赋形装置19的一对赋形齿轮19a、19b之间而连续成形为凹凸状的方法,但也能够并列设置多台赋形装置19、将多张板状的带状材料Rw同时赋形成凹凸状。

能够旋转驱动地架设在所述支撑台15上的材料开卷辊16,如图4以及图5所示,经由设置在支撑台15上的轴承构件21a、21b旋转自如地支持有辊轴22,在该辊轴22的一端侧,设有带式制动器23和手动式操作柄24,另外在另一端侧设有经由轴承构件21b使辊轴22在轴的长度方向上移动的移动用操作柄25。

另外,在材料开卷辊16的侧面上,朝向径方向地配设有用于防止板状的带状材料Rw在开卷时蛇行的蛇行防止用的导辊26。

接下来,图6所示的赋形装置19由具有规定间距的凹凸刃的能够旋转驱动的一对赋形齿轮19a、19b构成,该赋形齿轮19a构成为由驱动马达27经由链条或带等驱动传递装置28以规定的速度旋转驱动。

所述粘接构件贴附装置20,如图7以及图8所示,包括将粘接构件14转印到分隔物构件12a或12b的单面上的转印辊29,和将粘接构件14贴附到该转印辊29的表面的贴附装置30。该贴附装置30构成为:经由压接辊33将从双面胶带开卷辊31开卷的双面胶带32的粘接剂涂覆面压接,并且将粘接构件14转印到转印辊29的外周面上,双面胶带32的剥落纸34由纸卷取辊35卷取。

涂覆有所述粘接构件14的分隔物构件12a或12b在导向齿轮44a、44b之间通过而向衬垫卷取装置36等的下一工序搬运。另外所述转印辊29的辊轴38如图8所示,经由轴承构件40a、40b能够旋转驱动地架设在支撑台39上,在材料开卷辊30的一端侧,设有带式制动器41和手动式操作柄42,另外在另一端侧设有经由轴承构件40b使辊轴38在轴的长度方向上移动的移动用操作柄43。

这样,在预先以规定的长度制造出规定的大小的分隔物构件12a、12b后制造卷取衬垫R时,经由粘接构件14将分隔物构件12a、12b贴附在基础构件11的表面的宽度方向两侧缘部而制造。另外,规定长度的分隔物构件12a、12b,以经由铆钉等紧固连接构件连接末端部的状态贴附在基础构件11的表面上。

接下来,一边经由粘接构件14将分隔物构件12a、12b贴附在带状的基础构件11上一边连续地制造的方法如图9~图11所示,从能够旋转驱动地架设在支撑台15上的材料开卷辊16将板状的带状材料Rw开卷,使该开卷的带状材料Rw经由导向滚筒17a、17b和导向构件18通过赋形装置19而连续成形为凹凸状,在该成形为凹凸状的带状的分隔物构件12a或12b的单面上经由粘接构件贴附装置20贴附粘接构件14,这样进行制造。

此时,将贴附有粘接构件14的带状的分隔物构件12a或12b的单面(粘接面),沿着从开卷装置45开卷的板状的基础构件11的长度方向的侧缘部连续地贴附。然后,贴附有分隔物构件12a、12b的基础构件11在导向齿轮44a、44b之间通过而向衬垫卷取装置36搬运,并且一边在该过程中将规定的长度的分隔物构件12a、12b的末端部经由铆钉等紧固连接构件46连接固定在基础构件11上一边通过衬垫卷取装置36卷取。

衬垫卷取装置36,如图10以及图11所示,经由设置于支撑台49上的轴承部件50a、50b能够旋转驱动地架设卷取辊47的辊轴48,在辊轴48的一端侧设置有棘轮51、链轮(sprocket)52a,经由链条52b连接于图未示的驱动马达,在另一端侧设置有经由轴承部件50b使辊轴48在轴的长度方向上移动的移动用操作柄53。

在该实施方式中,连续地制造规定的大小的分隔物构件12a、12b,并且在制造后经由粘接构件14将分隔物构件12a、12b贴附在基础构件11的表面的宽度方向两侧缘部上,由此能够不经由人手地连续地制造卷取衬垫R,另外制造出的规定长度的卷取衬垫R卷状地卷取在衬垫卷取装置36的卷取辊47上来进行保管。

另外,其它的结构以及作用与上述实施方式同样所以标注相同符号而省略说明。如上所述,通过铝合金制的板材形成带状的基础构件11和具备凹凸部13的分隔物构件12a、12b后、将其组合来制作,所以制作容易且廉价,另外能够使卷取衬垫R整体的重量轻型化。另外,对于分隔物构件12a、12b,将板材加工成凹凸状后经由双面胶带等粘接构件14以及铆钉等紧固连接构件46相对于长度方向连接固定,能够安装成可进行伸缩,所以在将卷取衬垫R卷起来时阻力较小,能够容易地弯曲。

Claims (12)

1.一种未硫化带状橡胶构件的带分隔物的卷取衬垫的制造方法,其特征在于:使从材料的开卷辊开卷的板状的带状材料通过赋形装置而连续成形为凹凸状,在该成形为凹凸状的带状的分隔物构件的单面上贴附粘接构件,将这样构成的分隔物构件的粘接面沿着板状的基础构件的长度方向的侧缘部进行贴附。

2.一种未硫化带状橡胶构件的带分隔物的卷取衬垫的制造方法,其特征在于:使从材料的开卷辊开卷的板状的带状材料通过赋形装置而连续成形为凹凸状,在该成形为凹凸状的带状的分隔物构件的单面上贴附粘接构件,将该分隔物构件的粘接面沿着从开卷装置开卷的板状的基础构件的长度方向的侧缘部连续地贴附。

3.如权利要求1或2所述的未硫化带状橡胶构件的带分隔物的卷取衬垫的制造方法,其特征在于:在将所述分隔物构件贴附在板状的基础构件上的工序中,通过紧固连接构件将规定长度的分隔物构件的末端部固定。

4.一种未硫化带状橡胶构件的带分隔物的卷取衬垫的制造装置,其特征在于,包括:赋形装置,其将从材料的开卷辊开卷的板状的带状材料以规定的间距连续成形为凹凸状;粘接构件贴附装置,其在由该赋形装置赋形后的带状的分隔物构件的单面上贴附粘接构件;基础构件的开卷装置,其将该贴附有粘接构件的分隔物构件的粘接面沿着板状的基础构件的长度方向的侧缘部贴附;和在基础构件上贴附有分隔物构件的卷取衬垫的卷取装置。

5.一种未硫化带状橡胶构件的带分隔物的卷取衬垫的制造装置,其特征在于,包括:赋形装置,其将从材料的开卷辊开卷的板状的带状材料以规定的间距连续成形为凹凸状;粘接构件贴附装置,其在由该赋形装置赋形后的带状的分隔物构件的单面上贴附粘接构件;基础构件的开卷装置,其将该贴附有粘接构件的分隔物构件的粘接面沿着从开卷辊开卷的板状的基础构件的长度方向的侧缘部连续地贴附;和在基础构件上贴附有分隔物构件的卷取衬垫的卷取装置。

6.如权利要求4或5所述的未硫化带状橡胶构件的带分隔物的卷取衬垫的制造装置,其特征在于:在所述基础构件的开卷装置与卷取衬垫的卷取装置之间配设有将带状的分隔物构件的末端部相对于基础构件固定的紧固连接装置。

7.如权利要求4、5或6所述的未硫化带状橡胶构件的带分隔物的卷取衬垫的制造装置,其特征在于:在所述材料开卷辊以及卷取衬垫的卷取装置上,设置有用于防止材料的蛇行以及溃散的导辊。

8.如权利要求4、5、6或7所述的未硫化带状橡胶构件的带分隔物的卷取衬垫的制造装置,其特征在于:在所述卷取装置的卷取轴上设有制动装置。

9.一种未硫化带状橡胶构件卷取衬垫的分隔物构件的制造方法,其特征在于:使从材料开卷辊开卷的板状的带状材料通过赋形装置而连续成形为凹凸状,在该成形为凹凸状的带状的分隔物构件的单面上贴附粘接构件。

10.一种未硫化带状橡胶构件卷取衬垫的分隔物构件的制造装置,其特征在于,包括:赋形装置,其将从材料开卷辊开卷的板状的带状材料以规定的间距连续成形为凹凸状;和粘接构件贴附装置,其在由该赋形装置赋形后的分隔物构件的单面上贴附粘接构件。

11.如权利要求10所述的未硫化带状橡胶构件卷取衬垫的分隔物构件的制造装置,其特征在于:所述赋形装置为具有规定间距的凹凸刃的能够旋转驱动的一对赋形齿轮。

12.如权利要求10或11所述的未硫化带状橡胶构件卷取衬垫的分隔物构件的制造装置,其特征在于:所述粘接构件为双面粘接带。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006037763A JP4011088B2 (ja) | 2006-02-15 | 2006-02-15 | 未加硫帯状ゴム部材のスペーサ付き巻取りライナーの製造方法及びその製造装置 |

| JP037763/2006 | 2006-02-15 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN101384422A true CN101384422A (zh) | 2009-03-11 |

Family

ID=38371485

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNA2007800055623A Pending CN101384422A (zh) | 2006-02-15 | 2007-02-13 | 未硫化带状橡胶构件的带分隔物的卷取衬垫的制造方法及其装置、以及该卷取衬垫的分隔物构件的制造方法及其装置 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20080308218A1 (zh) |

| JP (1) | JP4011088B2 (zh) |

| CN (1) | CN101384422A (zh) |

| WO (1) | WO2007094305A1 (zh) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7176930B2 (ja) * | 2018-11-05 | 2022-11-22 | Toyo Tire株式会社 | ゴム材料を供給する装置及び方法 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2429482A (en) * | 1939-04-06 | 1947-10-21 | Munters Carl Georg | Method and means for the production of foil material |

| JP3139575B2 (ja) * | 1991-11-01 | 2001-03-05 | 栄二 加藤 | 発泡プラスチック波型中芯段ボールの製造方法 |

| JP4490370B2 (ja) * | 2003-12-03 | 2010-06-23 | 横浜ゴム株式会社 | 未加硫ゴム部材の巻取りライナー |

-

2006

- 2006-02-15 JP JP2006037763A patent/JP4011088B2/ja not_active Expired - Fee Related

-

2007

- 2007-02-13 US US12/161,499 patent/US20080308218A1/en not_active Abandoned

- 2007-02-13 CN CNA2007800055623A patent/CN101384422A/zh active Pending

- 2007-02-13 WO PCT/JP2007/052495 patent/WO2007094305A1/ja active Application Filing

Also Published As

| Publication number | Publication date |

|---|---|

| WO2007094305A8 (ja) | 2007-11-29 |

| WO2007094305A1 (ja) | 2007-08-23 |

| US20080308218A1 (en) | 2008-12-18 |

| JP2007216454A (ja) | 2007-08-30 |

| JP4011088B2 (ja) | 2007-11-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103429541B (zh) | 玻璃辊的制造方法及制造装置 | |

| CN106257712B (zh) | 用于卷取电极板的系统 | |

| CN107253428B (zh) | 充气轮胎 | |

| WO2011111625A1 (ja) | ガラスロール及びその製造方法 | |

| CN1254359A (zh) | 双面胶带、双面胶带的制造方法与制造装置 | |

| CN101384422A (zh) | 未硫化带状橡胶构件的带分隔物的卷取衬垫的制造方法及其装置、以及该卷取衬垫的分隔物构件的制造方法及其装置 | |

| JP2014124929A (ja) | ゴムストリップの貼付装置 | |

| CN104395214A (zh) | 连续的卷盘到卷盘的装置 | |

| EP1232981A2 (en) | Winder with variable tension zones | |

| CN209957014U (zh) | 印刷电路薄膜的贴片剥离装置 | |

| CN1569453A (zh) | 粘贴辊 | |

| US20160176669A1 (en) | Winding device and method for designing winding device | |

| EP1568476A1 (en) | Method of forming cord-embedded tire component | |

| CN211496460U (zh) | 用于自动撕膜的收放卷机构 | |

| JP4929750B2 (ja) | 未加硫帯状ゴム部材巻取りライナーのスペーサ部材の製造方法 | |

| CN100509369C (zh) | 未硫化橡胶构件的卷绕衬板 | |

| JP2009285939A (ja) | タイヤ用ビードコアの製造方法およびタイヤ用ビードコアの製造装置 | |

| JP2008200998A (ja) | タイヤ成型装置 | |

| WO2021117405A1 (ja) | ガラスロール | |

| JPWO2012169368A1 (ja) | 巻取装置及び巻取方法 | |

| CN217920730U (zh) | 一种贴胶机构 | |

| JP7095650B2 (ja) | 蛇行補正装置のグリス供給方法 | |

| KR101165779B1 (ko) | 라이너 재권취 장치 | |

| JP4909162B2 (ja) | タイヤ部材の製造装置、及びタイヤ部材の製造方法 | |

| CN209889954U (zh) | 一种不干胶剥离供料装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication |

Application publication date: 20090311 |