WO2024252769A1 - 無方向性電磁鋼板およびその製造方法 - Google Patents

無方向性電磁鋼板およびその製造方法 Download PDFInfo

- Publication number

- WO2024252769A1 WO2024252769A1 PCT/JP2024/013541 JP2024013541W WO2024252769A1 WO 2024252769 A1 WO2024252769 A1 WO 2024252769A1 JP 2024013541 W JP2024013541 W JP 2024013541W WO 2024252769 A1 WO2024252769 A1 WO 2024252769A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- less

- steel sheet

- hot

- group

- rolled

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P10/00—Technologies related to metal processing

- Y02P10/20—Recycling

Definitions

- the present invention relates to a non-oriented electrical steel sheet with excellent punching workability and magnetic properties, and a method for manufacturing the same.

- Non-oriented electrical steel sheets used in the drive motors of electric and hybrid vehicles are required to have low iron loss in order to reduce energy loss. It has been proposed that adding elements such as Si and Al is an effective way to reduce iron loss, but this method has the problem of significantly degrading the punching workability when the electrical steel sheets are made into motor cores. Poor punching workability also means that the punching dies wear out quickly.

- Patent Document 1 discloses a method for manufacturing a non-oriented electrical steel sheet characterized by controlling the mass ratio of Si and Al. Specifically, the objective is to provide a non-oriented electrical steel sheet that has excellent magnetic properties as an electrical equipment core material and also has excellent punching workability that facilitates forming into electrical equipment cores.

- the non-oriented electrical steel sheet has excellent magnetic properties and punching workability, characterized by containing, by mass%, C: 0.003% or less, Si: 1.0% to 3.0% or less, Al: 0.1% to 3.0% or less, and Mn: 0.1% to 1.0% or less, the Al and Si contents satisfying the relationship 0.2 ⁇ Al/(Si+Al) ⁇ 0.6, the balance being Fe and inevitable impurity elements, and having a steel composition, and having a yield ratio expressed as (yield strength/tensile strength) of 0.6 or more and a Vickers hardness of 200 or less.

- Patent Document 2 discloses a method of adding Cr to the composition.

- the object is to provide an electrical steel sheet having low iron loss after finish annealing and excellent punching workability.

- the non-oriented electrical steel sheet has excellent punching workability and is characterized by containing, by mass%, C: 0.005% or less, P: 0.05% or less, Si: 1 to 3.5%, Mn: 0.05 to 1.5%, Al: 0.1 to 3%, S: 0.02% or less, N: 0.005% or less, Cr: 0.2 to 3%, and the balance being substantially Fe, the Vickers hardness of the steel sheet surface is 190 or less, and the number of oxide-based inclusions having a diameter of 1 ⁇ m or more in the cross section of the steel sheet is 30 pieces/ mm2 or less.

- Patent Document 1 it is necessary to add Al in an amount of 2.29% or more as shown in the examples, which causes a problem in the manufacturability of the steel sheet. Furthermore, the technique described in Patent Document 2 has a problem in that expensive Cr is added, resulting in high manufacturing costs.

- the present invention was developed in consideration of the above-mentioned problems with conventional technology, and aims to provide an excellent non-oriented electrical steel sheet that combines punching workability and low iron loss at a low cost.

- the non-oriented electrical steel sheet according to the present invention which advantageously solves the above problems, is configured as follows. [1] In mass%, C: 0.005% or less, Si: 2.5% or more and 5.0% or less, Mn: 0.1% or more and 3.0% or less, P: 0.100% or less, S: 0.005% or less, Al: 2.0% or less, N: 0.005% or less, Pb: 0.00010% or more and 0.00200% or less, and Ca: 0.0010% or more and 0.020% or less, and optionally further containing at least one group of components selected from the following groups A to E; Group A: one or more selected from Mo: 0.001-0.050%, Zn: 0.001-0.010%, Ti: 0.001-0.010%, Sn: 0.001-0.200%, and Sb: 0.001-0.200%.

- Group B one or more selected from As: 0.020% or less, Nb: 0.005% or less, W: 0.050% or less, V: 0.050% or less, Ta: 0.0020% or less, and Cu: 0.01-1.0%.

- Group C one or more selected from Ni: 0.01-1.0%, B: 0.0020% or less.

- Group D one or more selected from Cr: 0.01 to 3.0%, Mg: 0.0001 to 0.005%, REM: 0.001 to 0.05%;

- Group E one or more selected from Co: 0.10% or less, Ge: 0.030% or less, Ga: 0.030% or less, with the balance being Fe and unavoidable impurities.

- This non-oriented electrical steel sheet is characterized in that it has a component composition in which the number density of Pb precipitates having a grain size of 10 to 100 nm is 100 precipitates/mm2 or less , and the number density of Pb-Ca composite precipitates having a grain size of 0.5 to 5.0 ⁇ m is 0.1 precipitates/mm2 or more and 1000 precipitates/mm2 or less .

- the method for producing a non-oriented electrical steel sheet according to the present invention is configured as follows. [2] In mass%, C: 0.005% or less, Si: 2.5% or more and 5.0% or less, Mn: 0.1% or more and 3.0% or less, P: 0.100% or less, S: 0.005% or less, Al: 2.0% or less, N: 0.005% or less, Pb: 0.00010% or more and 0.00200% or less, Ca: 0.0010% or more and 0.020% or less, and optionally, further containing at least one group of components selected from the following groups A to E; Group A: one or more selected from Mo: 0.001-0.050%, Zn: 0.001-0.010%, Ti: 0.001-0.010%, Sn: 0.001-0.200%, and Sb: 0.001-0.200%.

- Group B one or more selected from As: 0.020% or less, Nb: 0.005% or less, W: 0.050% or less, V: 0.050% or less, Ta: 0.0020% or less, and Cu: 0.01-1.0%.

- Group C one or more selected from Ni: 0.01-1.0%, B: 0.0020% or less.

- Group D one or more selected from Cr: 0.01 to 3.0%, Mg: 0.0001 to 0.005%, REM: 0.001 to 0.05%

- Group E one or more selected from Co: 0.10% or less, Ge: 0.030% or less, Ga: 0.030% or less, with the balance being Fe and unavoidable impurities

- a hot rolling process in which a steel slab having a composition is heated and hot rolled to obtain a hot rolled steel sheet

- a hot rolled sheet annealing process in which the hot rolled steel sheet is annealed to obtain a hot rolled annealed sheet

- a cold rolling process in which the hot rolled annealed sheet is subjected to one cold rolling or two or more cold rollings with intermediate annealing therebetween to obtain a cold rolled steel sheet

- a finish annealing process in which the cold rolled steel sheet is subjected to finish annealing.

- the heating of the steel slab includes a two-stage step of heating the steel slab at a first stage at 460°C or more and 540°C or less for 5 min or more and at a second stage at 1060°C or more and 1140°C or less for 20 min or more, in which the finishing rolling of the hot rolling has an inlet steel sheet temperature of 940°C or more and 1100°C or less in the first pass and a rolling reduction rate of the first pass of 40% or more, and in which the hot-rolled sheet annealing process has an annealing temperature of 900°C or more and 1100°C or less.

- the method for producing a non-oriented electrical steel sheet is a thin slab continuously cast to a plate thickness of 70 mm or more and 200 mm or less.

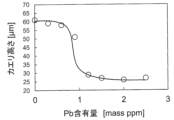

- FIG. 1 is a graph showing the relationship between the Pb content in a steel sheet and the burr height of a punched test piece.

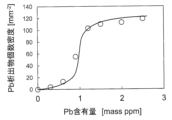

- FIG. 2 is a graph showing the relationship between the Pb content in a steel sheet and the number density of Pb precipitates having a grain size of 10 to 100 nm.

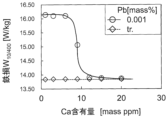

- FIG. 3 is a graph showing the effect of the addition of Pb on the relationship between the Ca content in the steel sheet and the iron loss W 10/400 .

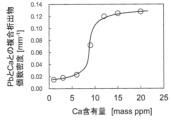

- FIG. 4 is a graph showing the relationship between the Ca content in a steel sheet and the number density of Pb-Ca composite precipitates having a grain size of 0.5 to 5.0 ⁇ m.

- test materials were heated at 1100°C for 20 minutes and then hot-rolled to obtain hot-rolled steel sheets with a thickness of 2.0 mm.

- the temperature at the entry side of the first pass of hot rolling was 1050° C.

- the reduction ratio of the steel sheet was 50%

- the temperature at the exit side of the final pass was 950° C.

- hot-rolled sheet annealing was performed at 980° C. for 30 s.

- the sheet was cold-rolled to a cold-rolled steel sheet with a sheet thickness of 0.25 mm

- an Epstein test sample of width: 30 mm ⁇ length: 280 mm was cut out, and the iron loss W 10/400 was measured with an Epstein tester.

- the punching workability was evaluated by the burr height of the end face of the test piece when a 17 mm square was punched 2 ⁇ 105 times with a die made of SKD11 from the obtained steel sheet.

- This test material was subjected to hot rolling and finish annealing in the same manner as in Experiment 1, and an Epstein test sample with a width of 30 mm and a length of 280 mm was cut out from the rolling direction and the sheet width direction of the obtained steel sheet, and the iron loss W 10/400 was measured with an Epstein device.

- the Pb-Ca composite precipitate is a precipitate in which the ratio of Pb is 10% or more and the ratio of Ca is 20% or more in the atomic ratio obtained by EDS (energy dispersive X-ray spectrometry). Therefore, the inventors have investigated the control of Pb--Ca composite precipitates and the suppression of the increase in iron loss due to Pb.

- test materials were heated in two stages, at 500 ° C for 5 min and then at 1100 ° C for 20 min, and then hot rolled to obtain a hot rolled sheet having a thickness of 2.0 mm.

- the temperature at the first pass of hot rolling was 1050 ° C

- the rolling reduction ratio of the steel sheet was 50%

- the temperature at the final pass was 950 ° C.

- an Epstein test sample of width: 30 mm ⁇ length: 280 mm was cut out, and the iron loss W 10/400 was measured with an Epstein tester.

- the punching workability was evaluated by the burr height of the end face of the test piece when a 17 mm square was punched 2 ⁇ 105 times with a die made of SKD11 from the obtained steel sheet.

- Figure 3 shows the relationship between the amount of Ca in the steel sheet and the iron loss W 10/400 in Pb-added and Pb-less materials. It is clear from Figure 3 that the addition of Ca to Pb-added materials reduces iron loss. In comparison with Pb-less materials, the reduction in iron loss due to the addition of Ca is thought to be due to Ca suppressing the increase in iron loss caused by Pb.

- FIG. 4 shows the relationship between the number density of Pb-Ca composite precipitates and the amount of Ca.

- Figure 4 shows that as the amount of Ca increased with the addition of Ca, the number density of Pb-Ca composite precipitates increased. This shows that the amount of Pb precipitates, which is a cause of the refinement of the structure, decreased.

- the non-oriented electrical steel sheet according to this embodiment will be described.

- the chemical components of the non-oriented electrical steel sheet are, in mass%, C: 0.005% or less, Si: 2.5% to 5.0%, Mn: 0.1% to 3.0%, P: 0.100% or less, S: 0.005% or less, Al: 2.0% or less, N: 0.005% or less, Pb: 0.00010% to 0.00200%, and Ca: 0.0010% to 0.020%.

- Each component is described below.

- "%" representing the content of a component means “mass%” unless otherwise specified.

- C 0.005% or less

- C is a harmful element that causes magnetic aging in the product sheet, forming carbides and deteriorating iron loss. Therefore, in order to suppress magnetic aging, the C content is set to 0.005% or less. There is no particular lower limit for the C content, but from the viewpoint of suppressing decarburization costs, it is preferable to set it to about 0.0001%.

- Si 2.5% or more and 5.0% or less Si has the effect of increasing the electrical resistance of the steel sheet and reducing iron loss. In order to sufficiently reduce iron loss, it is necessary to add 2.5% or more. Therefore, the Si content is set to 2.5% or more. On the other hand, if the Si content exceeds 5.0%, not only does it become difficult to roll, but punching workability is also reduced. Therefore, the Si content is set to 5.0% or less. From the viewpoint of manufacturability, the Si content is preferably 4.0% or less.

- Mn 0.1% or more and 3.0% or less Mn, like Si and Al, has the effect of increasing the electrical resistance of the steel sheet and reducing iron loss. Therefore, the Mn content is set to 0.1% or more. On the other hand, if the Mn content exceeds 3.0%, Mn carbides precipitate, which actually worsens the iron loss. Therefore, the Mn content is set to 3.0% or less. Preferably, the Mn content is in the range of 0.2% or more and 1.0% or less.

- P 0.100% or less P has the effect of increasing the strength of steel and can be used for strength adjustment. On the other hand, if the P content exceeds 0.100%, the steel becomes brittle and the manufacturability decreases. Therefore, the P content is set to 0.100% or less. There is no particular lower limit for the P content, but from the viewpoint of suppressing the dephosphorization cost, it is preferable to set it to about 0.001 mass%.

- S 0.005% or less

- S is a harmful element that forms fine sulfides, inhibits grain growth, and increases iron loss, so it is desirable to reduce it as much as possible.

- the S content is set to 0.005% or less. More preferably, the S content is 0.003% or less.

- Al 2.0% or less Al, like Si, has the effect of increasing the electrical resistance of the steel sheet and reducing iron loss. However, if the Al content exceeds 2.0%, not only does it become difficult to roll the steel sheet, but also the punching workability decreases. Therefore, the Al content is set to 2.0% or less. However, when the Al content is in the range of 0.01% or more and less than 0.1%, fine AlN precipitates and the iron loss increases, so the Al content is preferably in the range of 0.1% or more and 2.0% or less.

- N 0.005% or less

- N is a harmful element that forms fine nitrides, inhibits grain growth, and increases iron loss, so it is desirable to reduce it as much as possible.

- the N content exceeds 0.005%, the above-mentioned adverse effects become significant, so the N content is set to 0.005% or less. More preferably, the N content is 0.003% or less.

- Pb 0.00010% to 0.00200% Adding Pb can improve punching workability. Therefore, the Pb content is set to 0.00010% or more. On the other hand, if the Pb content exceeds 0.00200%, Pb alone forms many fine precipitates, inhibiting grain growth and increasing iron loss. Therefore, the Pb content is set to 0.00010% to 0.00200%.

- Ca 0.0010% or more and 0.020% or less Ca reacts with S to form coarse precipitates as CaS, which has the effect of suppressing the precipitation of fine sulfides such as MnS and reducing iron loss. CaS and CaO also form complex precipitates with Pb, which has the effect of suppressing the precipitation of fine Pb precipitates. Therefore, the Ca content is set to 0.0010% or more. On the other hand, if it exceeds 0.020%, the amount of CaS and CaO increases, which inhibits grain growth and increases iron loss. Therefore, the Ca content is set to 0.020% or less.

- Group A one or more selected from Mo: 0.001-0.050%, Zn: 0.001-0.010%, Ti: 0.001-0.010%, Sn: 0.001-0.200%, and Sb: 0.001-0.200%.

- Group B one or more selected from As: 0.020% or less, Nb: 0.005% or less, W: 0.050% or less, V: 0.050% or less, Ta: 0.0020% or less, and Cu: 0.01-1.0%.

- Group C one or more selected from Ni: 0.01-1.0%, B: 0.0020% or less.

- Group D Cr: 0.01-3.0%, Mg: 0.0001-0.005%, REM: 0.001-0.05%;

- Group E Co: 0.10% or less, Ge: 0.030% or less, Ga: 0.030% or less,

- Mo 0.001-0.050% Mo reacts with C to form carbides at grain boundaries, improving strength. Therefore, the Mo content is set to 0.001% or more. However, if it exceeds 0.050%, iron loss tends to increase. Therefore, the Mo content is set to 0.050% or less.

- Zn 0.001-0.010% Zn reacts with S to form coarse sulfides, suppressing the precipitation of fine sulfides such as MnS, and has the effect of reducing iron loss. Therefore, the Zn content is set to 0.001% or more. On the other hand, if the Zn content exceeds 0.010%, the amount of the above sulfides increases, which inhibits grain growth and increases iron loss. Therefore, the Zn content is set to 0.010% or less.

- Ti 0.001 ⁇ 0.010% Like Mo, Ti reacts with C to form carbides, which suppresses grain growth and improves toughness. Therefore, the Ti content is set to 0.001% or more. However, if the Ti content is less than 0.001%, If the Ti content exceeds 0.010%, iron loss tends to increase, so the Ti content is set to 0.010% or less.

- Sn 0.001-0.200%

- the addition of Sn can greatly improve the texture, increase the magnetic flux density, and reduce the iron loss. Therefore, the Sn content is set to 0.001% or more. However, if the Sn content exceeds 0.200%, the effect becomes saturated and manufacturability is deteriorated. Therefore, the Sn content is set to 0.200% or less.

- Sb 0.001-0.200%

- the addition of Sb greatly improves the texture, increases the magnetic flux density, and reduces the iron loss. Therefore, the Sb content is set to 0.001% or more.

- the Sb content is set to 0.200% or less.

- Nb 0.005% or less Nb has the effect of refining crystal grains and improving strength. On the other hand, if the content exceeds 0.005%, fine precipitates are generated and iron loss increases. Therefore, the Nb content is set to 0.005% or less.

- W 0.050% or less W has the effect of refining crystal grains and improving strength. On the other hand, if the content exceeds 0.050%, fine precipitates are generated and iron loss increases. Therefore, the W content is set to 0.050% or less.

- V 0.050% or less V has the effect of refining crystal grains and improving strength. On the other hand, if the content exceeds 0.050%, fine precipitates are generated and iron loss increases. Therefore, the V content is set to 0.050% or less.

- Ta 0.0020% or less Ta has the effect of refining crystal grains and improving strength. On the other hand, if it is contained in an amount exceeding 0.0020%, fine precipitates are generated and iron loss is increased. Therefore, the Ta content is set to 0.0020% or less.

- Cu 0.01 ⁇ 1.0% Cu has the effect of improving the strength of steel sheets by aging treatment. Therefore, the Cu content is set to 0.01% or more. On the other hand, if the Cu content exceeds 1.0%, the precipitates Therefore, the Cu content is set to 0.01 to 1.0%.

- Ni 0.01 ⁇ 1.0% Ni has the effect of improving the toughness of steel plates and increasing productivity. Therefore, the Ni content is set to 0.01% or more. On the other hand, if the Ni content exceeds 1.0%, the effect saturates. This not only increases the cost but also the amount of Ni added. Therefore, the Ni content is set to 0.01 to 1.0%.

- B 0.0020% or less B has the effect of improving the toughness of the steel plate and increasing productivity. On the other hand, if the B content exceeds 0.0020%, the iron loss increases. Therefore, the B content is set to 0.0020% or less.

- Cr:0.01 ⁇ 3.0% Cr has the effect of increasing the electrical resistance of the steel sheet and reducing iron loss. Therefore, the Cr content is set to 0.01% or more. On the other hand, if the Cr content exceeds 3.0%, the magnetic flux density decreases. Therefore, the Cr content is set to 3.0% or less.

- Mg 0.0001-0.005%

- Mg has the effect of forming coarse sulfides with S in the steel and reducing iron loss. Therefore, the Mg content is set to 0.0001% or more. On the other hand, if the Mg content exceeds 0.005%, Adding Mg would instead increase iron loss, so the Mg content is set to 0.0001% to 0.005%.

- REM 0.001 ⁇ 0.05% REM has the effect of coarsening sulfides in steel and reducing iron loss. Therefore, the REM content is set to 0.001% or more. On the other hand, if the content exceeds 0.05%, the iron loss is increased. Therefore, the REM content is set to 0.001 to 0.05%.

- Co 0.10% or less Co has the effect of improving the texture of the steel sheet and increasing the magnetic flux density. On the other hand, if the Co content exceeds 0.10%, the effect is saturated and the cost increases. Therefore, the Co content is set to 0.10% or less.

- Ge 0.030% or less Ge has the effect of improving the texture of the steel sheet and increasing the magnetic flux density. On the other hand, if the Ge content exceeds 0.030%, the effect is saturated and the cost increases. Therefore, the Ge content is set to 0.030% or less.

- Ga 0.030% or less Ga has the effect of improving the texture of the steel sheet and increasing the magnetic flux density. On the other hand, if the Ga content exceeds 0.030%, the effect is saturated and the cost increases. Therefore, the Ga content is set to 0.030% or less.

- the chemical composition of the non-oriented electrical steel sheet according to this embodiment contains the above elements, with the remainder being Fe and unavoidable impurities.

- the number density of Pb precipitates having a grain size of 10 to 100 nm is controlled to be within the range of 100 precipitates/mm2 or less .

- the number density of composite precipitates of Pb and Ca having a grain size of 0.5 to 5.0 ⁇ m is controlled to be within the range of 0.1 precipitates/mm2 or more and 1000 precipitates/mm2 or less .

- the grain size of the precipitates is evaluated as a circle-equivalent diameter from a projected area measured under a microscope.

- the non-oriented electrical steel sheet is manufactured by a process including a hot rolling step of a steel slab adjusted to the above-mentioned composition, a hot-rolled sheet annealing step, a cold rolling step, and a finish annealing step.

- Slabs can be produced by melting steel having a composition suitable for the present invention in a refining process consisting of a converter and vacuum degassing, and then using a conventional continuous casting method, ingot casting-blooming rolling method, etc. From the viewpoint of reducing the environmental load (reducing CO2 emissions), it is preferable to use an electric furnace method using scrap instead of blast furnace pig iron as the steel raw material (iron source).

- scrap is melted in an electric furnace to produce slabs, the Pb content is high due to the Pb contained in the scrap, so there is also the advantage that the cost of adding Pb can be reduced.

- the scrap also contains elements such as Mo, Ti, and Zn that can be added arbitrarily in the present invention, so it is possible to improve the properties of the steel plate while reducing the environmental load.

- Hot Rolling Process The slab is reheated before hot rolling. At that time, at least two heating devices with different output values are installed in series to perform heating in two steps.

- the first stage of heating is intended to dissolve the Pb present as a single substance, increase fluidity, and facilitate composite precipitation with Ca, and the heating temperature is set to 460°C or higher and 540°C or lower, and the heating time is set to 5 min or more. If the slab heating temperature is lower than 460°C, Pb cannot be dissolved, and composite precipitation of Ca and Pb becomes difficult. On the other hand, if the temperature exceeds 540°C, Pb will preferentially exist as a single substance rather than as a composite precipitation with Ca, making it difficult to precipitate a composite precipitate of Pb and Ca. There is no particular upper limit on the heating time, but from the viewpoint of reducing operating costs, it is preferable to set it to about 10 min.

- the second heating stage is intended to raise the slab temperature to facilitate rolling, with the heating temperature set to 1060°C to 1140°C and the heating time set to 20 min or more. If the slab heating temperature exceeds 1140°C, precipitates such as AlN and MnS will dissolve in the steel and re-precipitate in subsequent processes, inhibiting grain growth and increasing iron loss. On the other hand, if the temperature falls below 1060°C, the hot rolling load will increase and the finishing rolling entry temperature (hereinafter, the rolling entry temperature will also be referred to as FET) will not be able to be secured. There is no particular upper limit on the heating time, but from the viewpoint of reducing operating costs, it is preferable to set it to around 30 min.

- Hot rolling consists of rough rolling, in which the slab is turned into a sheet bar of a specified thickness using multiple single-stand rolling mills, and then finishing rolling, which follows the rough rolling and continues to roll to the target thickness using a finishing mill consisting of multiple stands. Conventional methods can be used for rough rolling.

- the steel sheet temperature at the entry side of the first pass i.e., the finish rolling entry side temperature FET (°C)

- the finish rolling entry side temperature FET is set to 940°C or higher to promote recrystallization and grain growth.

- the reduction rate in the first pass is set to 40% or more. There is no upper limit for the reduction rate, but a range of 40 to 50% is preferable when considering manufacturability.

- the temperature at the exit is preferably 930°C or higher from the viewpoint of promoting recrystallization and grain growth in the hot-rolled steel sheet and improving the magnetic properties.

- Hot-rolled sheet annealing process the above hot-rolled steel sheet is subjected to hot-rolled sheet annealing, which is held at a predetermined temperature for 1 s or more.

- the hot-rolled sheet annealing temperature is set to 900 ° C or higher.

- the hot-rolled sheet annealing temperature exceeds 1100 ° C, some of the precipitates containing MnS and Pb will dissolve and precipitate in the subsequent process, increasing iron loss, so the hot-rolled sheet annealing temperature is set to 1100 ° C or lower.

- pickling, cold rolling, and finish annealing after hot-rolled sheet annealing may be performed by conventional methods.

- Cold rolling is a process in which the hot-rolled annealed sheet that has been pickled is cold-rolled to the thickness (final thickness) of the product sheet.

- This cold rolling is preferably 50% or more, more preferably 70% or more.

- the cold rolling is not limited to one time, and two or more cold rollings with intermediate annealing in between may be performed as necessary.

- the intermediate annealing conditions in this case may also be ordinary conditions, and are not particularly limited.

- Finish annealing process is a process of annealing a cold-rolled sheet having a final thickness by cold rolling to impart desired magnetic properties and strength properties.

- the finish annealing temperature of the cold-rolled sheet is preferably 850 ° C or higher.

- the finish annealing temperature of the cold-rolled sheet is more preferably 880 ° C or higher.

- the finish annealing temperature of the cold-rolled sheet is preferably 1050 ° C or lower. More preferably, the finish annealing temperature of the cold-rolled sheet is 1030 ° C or lower.

- steels No. 1 to 104 having the composition shown in Tables 1-1 to 1-4 were melted and formed into slabs by continuous casting, and the slabs were heated in two steps at 500°C for 5 min and then at 1100°C for 20 min, and hot rolled to obtain hot rolled steel sheets with a thickness of 2.0 mm.

- the temperature at the entry side of the first pass of hot rolling was 1050°C with a reduction rate of 50% and the temperature at the exit side of the final pass was 950°C.

- An Epstein test sample having a width of 30 mm and a length of 280 mm was cut out from the rolling direction and the width direction of the steel plate thus obtained, and an Epstein test in accordance with JIS C 2550-3 (2019) was performed to measure the iron loss W 10/400 . If the plate thickness is 0.25 mm, it is good if the iron loss W 10/400 is 14 W/kg or less.

- a test piece of 17 mm square was cut out from the obtained steel plate, and punched 2 ⁇ 10 5 times with a die made of SKD11, and the burr height of the end face of the test piece was measured. If the burr height is 30 ⁇ m or less, the punching workability is good.

- Tables 2-1 to 2-4 show that by controlling the composition of the steel material within the range of this invention, a non-oriented electrical steel sheet with excellent core loss and punching workability can be obtained.

- steel having, by mass%, C: 0.0025%, Si: 2.85%, Mn: 0.30%, P: 0.006%, S: 0.0018%, N: 0.0025%, Al: 1.20%, Pb: 0.0006%, and Ca: 0.04% was produced.

- the steel was then formed into a slab by a continuous casting method.

- An Epstein test sample having a width of 30 mm and a length of 280 mm was cut out from the rolling direction and the width direction of the steel plate thus obtained, and an Epstein test in accordance with JIS C 2550-3 (2019) was performed to measure the iron loss W 10/400 . If the plate thickness is 0.25 mm, it is good if the iron loss W 10/400 is 14 W/kg or less.

- a test piece of 17 mm square was cut out from the obtained steel plate, and punched 2 ⁇ 10 5 times with a die made of SKD11, and the burr height of the end face of the test piece was measured. If the burr height is 30 ⁇ m or less, the punching workability is good.

- Table 4 shows that by controlling the manufacturing conditions of the steel sheet within the range of the present invention, a non-oriented electrical steel sheet that combines low core loss and punching workability can be obtained.

Landscapes

- Soft Magnetic Materials (AREA)

- Manufacturing Of Steel Electrode Plates (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2024541651A JPWO2024252769A1 (enExample) | 2023-06-06 | 2024-04-02 | |

| CN202480037157.3A CN121241157A (zh) | 2023-06-06 | 2024-05-27 | 无取向性电磁钢板及其制造方法 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2023-093004 | 2023-06-06 | ||

| JP2023093004 | 2023-06-06 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2024252769A1 true WO2024252769A1 (ja) | 2024-12-12 |

Family

ID=93795793

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2024/013541 Pending WO2024252769A1 (ja) | 2023-06-06 | 2024-05-27 | 無方向性電磁鋼板およびその製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JPWO2024252769A1 (enExample) |

| CN (1) | CN121241157A (enExample) |

| TW (1) | TWI901072B (enExample) |

| WO (1) | WO2024252769A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN120624775A (zh) * | 2025-08-13 | 2025-09-12 | 江苏省沙钢钢铁研究院有限公司 | 无取向硅钢的生产方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014142149A1 (ja) * | 2013-03-15 | 2014-09-18 | Jfeスチール株式会社 | 高周波鉄損特性に優れる無方向性電磁鋼板 |

| WO2017115657A1 (ja) * | 2015-12-28 | 2017-07-06 | Jfeスチール株式会社 | 無方向性電磁鋼板および無方向性電磁鋼板の製造方法 |

| WO2024057940A1 (ja) * | 2022-09-13 | 2024-03-21 | Jfeスチール株式会社 | 高強度無方向性電磁鋼板とその製造方法 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3333794B2 (ja) * | 1994-09-29 | 2002-10-15 | 川崎製鉄株式会社 | 無方向性電磁鋼板の製造方法 |

| JP4352691B2 (ja) * | 2002-12-05 | 2009-10-28 | Jfeスチール株式会社 | 打ち抜き性及び鉄損の優れた時効硬化性無方向性電磁鋼板、その製造方法及びそれを用いたローターの製造方法 |

| KR20130116332A (ko) * | 2011-08-18 | 2013-10-23 | 신닛테츠스미킨 카부시키카이샤 | 무방향성 전자 강판, 그 제조 방법, 모터 철심용 적층체 및 그 제조 방법 |

| CN108699619B (zh) * | 2016-02-22 | 2020-07-14 | 杰富意钢铁株式会社 | 方向性电磁钢板的制造方法 |

| JP6628016B1 (ja) * | 2018-03-23 | 2020-01-08 | 日本製鉄株式会社 | 無方向性電磁鋼板 |

-

2024

- 2024-04-02 JP JP2024541651A patent/JPWO2024252769A1/ja active Pending

- 2024-05-27 CN CN202480037157.3A patent/CN121241157A/zh active Pending

- 2024-05-27 WO PCT/JP2024/013541 patent/WO2024252769A1/ja active Pending

- 2024-05-31 TW TW113113598A patent/TWI901072B/zh active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014142149A1 (ja) * | 2013-03-15 | 2014-09-18 | Jfeスチール株式会社 | 高周波鉄損特性に優れる無方向性電磁鋼板 |

| WO2017115657A1 (ja) * | 2015-12-28 | 2017-07-06 | Jfeスチール株式会社 | 無方向性電磁鋼板および無方向性電磁鋼板の製造方法 |

| WO2024057940A1 (ja) * | 2022-09-13 | 2024-03-21 | Jfeスチール株式会社 | 高強度無方向性電磁鋼板とその製造方法 |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN120624775A (zh) * | 2025-08-13 | 2025-09-12 | 江苏省沙钢钢铁研究院有限公司 | 无取向硅钢的生产方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| TWI901072B (zh) | 2025-10-11 |

| TW202449179A (zh) | 2024-12-16 |

| CN121241157A (zh) | 2025-12-30 |

| JPWO2024252769A1 (enExample) | 2024-12-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US11718891B2 (en) | Non-oriented electrical steel sheet and method for producing same, and motor core and method for producing same | |

| US12448662B2 (en) | Non-oriented electrical steel sheet and method for producing same | |

| JP7609266B2 (ja) | 無方向性電磁鋼板用熱延鋼板の製造方法および無方向性電磁鋼板の製造方法 | |

| WO2022163723A1 (ja) | 方向性電磁鋼板の製造方法および電磁鋼板製造用圧延設備 | |

| KR20210003908A (ko) | 무방향성 전자 강판 및 그의 제조 방법 | |

| US20160020007A1 (en) | Non-oriented electrical steel sheet having excellent high-frequency iron loss property | |

| US9637812B2 (en) | Non-oriented electrical steel sheet | |

| TWI901072B (zh) | 無方向性電磁鋼板及其製造方法 | |

| JP4331969B2 (ja) | 無方向性電磁鋼板の製造方法 | |

| JP2008156737A (ja) | 無方向性電磁鋼板およびその製造方法 | |

| TWI850132B (zh) | 無方向性電磁鋼板的製造方法 | |

| CN118996087A (zh) | 无取向硅钢板及其加工方法 | |

| JP2018111847A (ja) | 無方向性電磁鋼板 | |

| WO2020090156A1 (ja) | 無方向性電磁鋼板の製造方法 | |

| TW202307230A (zh) | 無方向性電磁鋼板及其製造方法、以及馬達鐵芯 | |

| CN117062931A (zh) | 热轧钢板及其制造方法 | |

| JPH0533056A (ja) | 磁気特性の優れた方向性けい素鋼板の製造方法 | |

| JP7736157B2 (ja) | 無方向性電磁鋼板とその製造方法 | |

| JP7473862B1 (ja) | 無方向性電磁鋼板の製造方法 | |

| US20260015686A1 (en) | Non-oriented electrical steel sheet and method for producing same | |

| JP2007177282A (ja) | 高磁束密度を有する無方向性電磁鋼板の製造方法 | |

| TW202532661A (zh) | 無方向性電磁鋼板用熱軋鋼板的製造方法及無方向性電磁鋼板的製造方法 | |

| JP6852965B2 (ja) | 電磁鋼板とその製造方法 | |

| JPH1060609A (ja) | 鉄損特性または低磁場特性の優れた無方向性電磁鋼板 | |

| JP2002194513A (ja) | 加工変形特性に優れるシリコンクロム鋼板及びその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 2024541651 Country of ref document: JP |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 24819008 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2501008270 Country of ref document: TH |