WO2024171007A1 - 半導体装置、および表示装置 - Google Patents

半導体装置、および表示装置 Download PDFInfo

- Publication number

- WO2024171007A1 WO2024171007A1 PCT/IB2024/051188 IB2024051188W WO2024171007A1 WO 2024171007 A1 WO2024171007 A1 WO 2024171007A1 IB 2024051188 W IB2024051188 W IB 2024051188W WO 2024171007 A1 WO2024171007 A1 WO 2024171007A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- transistor

- wiring

- potential

- semiconductor device

- electrically connected

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09G—ARRANGEMENTS OR CIRCUITS FOR CONTROL OF INDICATING DEVICES USING STATIC MEANS TO PRESENT VARIABLE INFORMATION

- G09G3/00—Control arrangements or circuits, of interest only in connection with visual indicators other than cathode-ray tubes

- G09G3/20—Control arrangements or circuits, of interest only in connection with visual indicators other than cathode-ray tubes for presentation of an assembly of a number of characters, e.g. a page, by composing the assembly by combination of individual elements arranged in a matrix no fixed position being assigned to or needed to be assigned to the individual characters or partial characters

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09G—ARRANGEMENTS OR CIRCUITS FOR CONTROL OF INDICATING DEVICES USING STATIC MEANS TO PRESENT VARIABLE INFORMATION

- G09G3/00—Control arrangements or circuits, of interest only in connection with visual indicators other than cathode-ray tubes

- G09G3/20—Control arrangements or circuits, of interest only in connection with visual indicators other than cathode-ray tubes for presentation of an assembly of a number of characters, e.g. a page, by composing the assembly by combination of individual elements arranged in a matrix no fixed position being assigned to or needed to be assigned to the individual characters or partial characters

- G09G3/22—Control arrangements or circuits, of interest only in connection with visual indicators other than cathode-ray tubes for presentation of an assembly of a number of characters, e.g. a page, by composing the assembly by combination of individual elements arranged in a matrix no fixed position being assigned to or needed to be assigned to the individual characters or partial characters using controlled light sources

- G09G3/30—Control arrangements or circuits, of interest only in connection with visual indicators other than cathode-ray tubes for presentation of an assembly of a number of characters, e.g. a page, by composing the assembly by combination of individual elements arranged in a matrix no fixed position being assigned to or needed to be assigned to the individual characters or partial characters using controlled light sources using electroluminescent panels

- G09G3/32—Control arrangements or circuits, of interest only in connection with visual indicators other than cathode-ray tubes for presentation of an assembly of a number of characters, e.g. a page, by composing the assembly by combination of individual elements arranged in a matrix no fixed position being assigned to or needed to be assigned to the individual characters or partial characters using controlled light sources using electroluminescent panels semiconductive, e.g. using light-emitting diodes [LED]

- G09G3/3208—Control arrangements or circuits, of interest only in connection with visual indicators other than cathode-ray tubes for presentation of an assembly of a number of characters, e.g. a page, by composing the assembly by combination of individual elements arranged in a matrix no fixed position being assigned to or needed to be assigned to the individual characters or partial characters using controlled light sources using electroluminescent panels semiconductive, e.g. using light-emitting diodes [LED] organic, e.g. using organic light-emitting diodes [OLED]

- G09G3/3225—Control arrangements or circuits, of interest only in connection with visual indicators other than cathode-ray tubes for presentation of an assembly of a number of characters, e.g. a page, by composing the assembly by combination of individual elements arranged in a matrix no fixed position being assigned to or needed to be assigned to the individual characters or partial characters using controlled light sources using electroluminescent panels semiconductive, e.g. using light-emitting diodes [LED] organic, e.g. using organic light-emitting diodes [OLED] using an active matrix

- G09G3/3233—Control arrangements or circuits, of interest only in connection with visual indicators other than cathode-ray tubes for presentation of an assembly of a number of characters, e.g. a page, by composing the assembly by combination of individual elements arranged in a matrix no fixed position being assigned to or needed to be assigned to the individual characters or partial characters using controlled light sources using electroluminescent panels semiconductive, e.g. using light-emitting diodes [LED] organic, e.g. using organic light-emitting diodes [OLED] using an active matrix with pixel circuitry controlling the current through the light-emitting element

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09G—ARRANGEMENTS OR CIRCUITS FOR CONTROL OF INDICATING DEVICES USING STATIC MEANS TO PRESENT VARIABLE INFORMATION

- G09G3/00—Control arrangements or circuits, of interest only in connection with visual indicators other than cathode-ray tubes

- G09G3/20—Control arrangements or circuits, of interest only in connection with visual indicators other than cathode-ray tubes for presentation of an assembly of a number of characters, e.g. a page, by composing the assembly by combination of individual elements arranged in a matrix no fixed position being assigned to or needed to be assigned to the individual characters or partial characters

- G09G3/34—Control arrangements or circuits, of interest only in connection with visual indicators other than cathode-ray tubes for presentation of an assembly of a number of characters, e.g. a page, by composing the assembly by combination of individual elements arranged in a matrix no fixed position being assigned to or needed to be assigned to the individual characters or partial characters by control of light from an independent source

- G09G3/36—Control arrangements or circuits, of interest only in connection with visual indicators other than cathode-ray tubes for presentation of an assembly of a number of characters, e.g. a page, by composing the assembly by combination of individual elements arranged in a matrix no fixed position being assigned to or needed to be assigned to the individual characters or partial characters by control of light from an independent source using liquid crystals

Definitions

- One aspect of the present invention relates to a semiconductor device and a display device.

- one aspect of the present invention is not limited to the above technical fields.

- the technical field of one aspect of the invention disclosed in this specification relates to an object, a method, a driving method, or a manufacturing method.

- one aspect of the present invention relates to a process, a machine, manufacture, or a composition of matter.

- examples of the technical field of one aspect of the present invention disclosed in this specification include semiconductor devices, display devices, light-emitting devices, power storage devices, optical devices, imaging devices, lighting devices, arithmetic devices, control devices, memory devices, input devices, output devices, input/output devices, signal processing devices, arithmetic processing devices, electronic computers, electronic devices, driving methods thereof, or manufacturing methods thereof.

- Examples of display devices that can be used include liquid crystal display devices and light-emitting devices equipped with light-emitting elements such as organic electroluminescence (EL) elements (also called OLEDs (organic light-emitting diodes)) or light-emitting diodes (LEDs: light-emitting diodes).

- EL organic electroluminescence

- LEDs light-emitting diodes

- a source follower circuit is an analog circuit for outputting an output voltage according to an input voltage.

- a bias current flows in a transistor to which a bias voltage is applied, thereby obtaining an output voltage according to the input voltage (see, for example, Patent Document 1 and Patent Document 2).

- bias current flows through a transistor to which a bias voltage is applied, resulting in high power consumption.

- One embodiment of the present invention has an object to provide a high-definition semiconductor device or display device. Alternatively, one embodiment of the present invention has an object to provide a miniaturized semiconductor device or display device. Alternatively, one embodiment of the present invention has an object to provide a semiconductor device or display device with improved display quality. Alternatively, one embodiment of the present invention has an object to provide a semiconductor device or display device with increased operating speed. Alternatively, one embodiment of the present invention has an object to provide a semiconductor device or display device with reduced power consumption. Alternatively, one embodiment of the present invention has an object to provide a highly reliable semiconductor device or display device. Alternatively, one embodiment of the present invention has an object to provide a novel semiconductor device or display device.

- one embodiment of the present invention has an object to provide a method for driving a semiconductor device or a method for driving a display device that can improve display quality.

- one embodiment of the present invention has an object to provide a method for driving a semiconductor device or a display device that can increase the operating speed.

- one embodiment of the present invention has an object to provide a method for driving a semiconductor device or a display device that can reduce power consumption.

- one object of one embodiment of the present invention is to provide a method for driving a semiconductor device or a display device that can improve reliability.

- one object of one embodiment of the present invention is to provide a novel method for driving a semiconductor device or a display device.

- One aspect of the present invention is a semiconductor device having a first transistor, a first switch, a second switch, and a signal line, where the first transistor has a function of providing an output voltage to the signal line via the first switch according to an input voltage provided to the gate, the second switch has a function of performing an initialization operation to initialize the potential of the signal line, and the first switch has a function of performing a signal output operation to provide an output voltage to the signal line.

- One aspect of the present invention is a semiconductor device having a first transistor, a second transistor, a first switch, a second switch, a first power supply line, a second power supply line, and a signal line

- the first transistor has a function of providing an output voltage to the signal line via the first switch according to an input voltage provided to the gate

- one of the source and drain of the first transistor is electrically connected to the first power supply line

- one of the source and drain of the second transistor is electrically connected to the other of the source and drain of the first transistor

- the gate and the other of the source and drain of the second transistor are electrically connected to the second power supply line

- the second switch has a function of performing an initialization operation to initialize the potential of the signal line

- the first switch has a function of performing a signal output operation to provide an output voltage to the signal line following the initialization operation.

- One aspect of the present invention is a semiconductor device having a first transistor, a second transistor, a first switch, a second switch, a first power supply line, a second power supply line, and a signal line

- the first transistor has a function of providing an output voltage to the signal line via the first switch according to an input voltage provided to the gate

- one of the source and drain of the first transistor is electrically connected to the first power supply line

- one of the source and drain of the second transistor is electrically connected to the other of the source and drain of the first transistor

- the other of the source and drain of the second transistor is electrically connected to the second power supply line

- the gate of the second transistor is electrically connected to a first capacitor that holds the threshold voltage of the second transistor

- the second switch has a function of performing an initialization operation to initialize the potential of the signal line

- the first switch has a function of performing a signal output operation to provide an output voltage to the signal line following the initialization operation.

- a semiconductor device in which the gate of the first transistor is electrically connected to one electrode of a second capacitor that holds the threshold voltage of the first transistor, and the wiring that provides the input voltage is electrically connected to the other electrode of the second capacitor.

- the first transistor and the second transistor each preferably have a semiconductor layer, and the semiconductor layer preferably has an oxide semiconductor.

- a semiconductor device in which at least a portion of the semiconductor layer is provided inside an opening formed in the insulating layer is preferred.

- One aspect of the present invention is a display device having the semiconductor device of the above aspect of the present invention and a pixel, the pixel having a third transistor, and one of the source and drain of the third transistor being electrically connected to a signal line.

- the third transistor preferably has a semiconductor layer, and the semiconductor layer preferably includes an oxide semiconductor.

- a display device in which at least a portion of the semiconductor layer is provided inside an opening formed in the insulating layer is preferred.

- One embodiment of the present invention can provide a high-definition semiconductor device or display device. Alternatively, one embodiment of the present invention can provide a miniaturized semiconductor device or display device. Alternatively, one embodiment of the present invention can provide a semiconductor device or display device with improved display quality. Alternatively, one embodiment of the present invention can provide a semiconductor device or display device with increased operating speed. Alternatively, one embodiment of the present invention can provide a semiconductor device or display device with reduced power consumption. Alternatively, one embodiment of the present invention can provide a highly reliable semiconductor device or display device. Alternatively, one embodiment of the present invention can provide a novel semiconductor device or display device. Alternatively, one embodiment of the present invention can provide a method for driving a semiconductor device or a display device with improved display quality.

- one embodiment of the present invention can provide a method for driving a semiconductor device or a display device with increased operating speed.

- one embodiment of the present invention can provide a method for driving a semiconductor device or a display device with reduced power consumption.

- one embodiment of the present invention can provide a method for driving a semiconductor device or a display device with improved reliability.

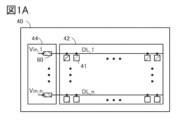

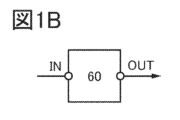

- 1A to 1C are circuit diagrams illustrating a semiconductor device.

- 2A and 2B are circuit diagrams illustrating a semiconductor device.

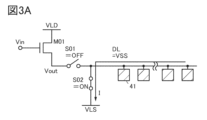

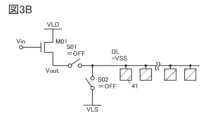

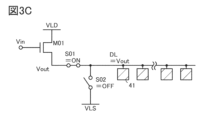

- 3A to 3C are circuit diagrams illustrating a semiconductor device.

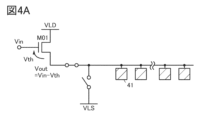

- 4A to 4C are circuit diagrams illustrating a semiconductor device.

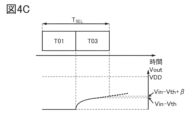

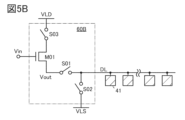

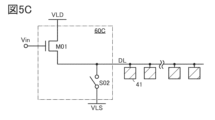

- 5A to 5C are circuit diagrams illustrating a semiconductor device.

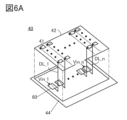

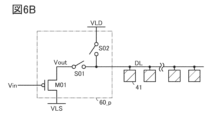

- 6A and 6B are circuit diagrams illustrating a semiconductor device.

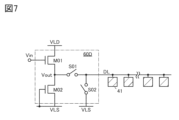

- FIG. 7 is a circuit diagram illustrating a semiconductor device.

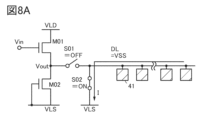

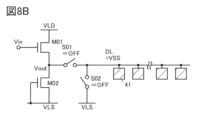

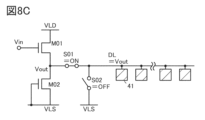

- 8A to 8C are circuit diagrams illustrating a semiconductor device.

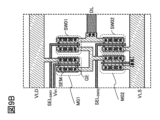

- 9A to 9C are circuit diagrams and layout diagrams illustrating a semiconductor device.

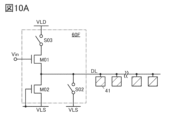

- 10A and 10B are circuit diagrams illustrating a semiconductor device.

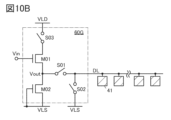

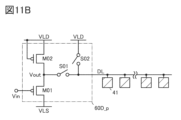

- 11A and 11B are circuit diagrams illustrating a semiconductor device.

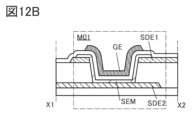

- FIG. 12A and 12B are a layout diagram and a cross-sectional view illustrating a semiconductor device.

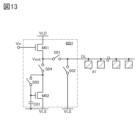

- FIG. 13 is a circuit diagram illustrating a semiconductor device.

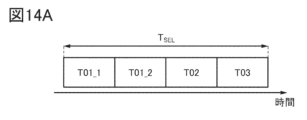

- 14A and 14B are circuit diagrams illustrating a semiconductor device.

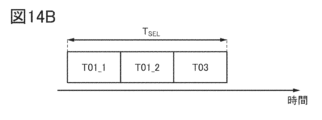

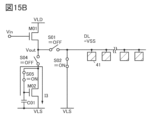

- 15A and 15B are circuit diagrams illustrating a semiconductor device.

- 16A and 16B are circuit diagrams illustrating a semiconductor device.

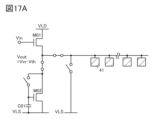

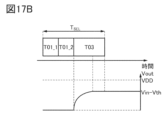

- 17A and 17B are circuit diagrams illustrating a semiconductor device.

- FIG. 18 is a layout diagram illustrating a semiconductor device.

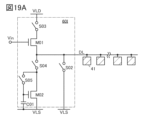

- 19A and 19B are circuit diagrams illustrating a semiconductor device.

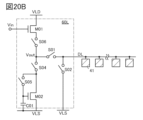

- 20A and 20B are circuit diagrams illustrating a semiconductor device.

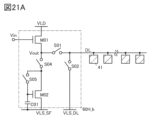

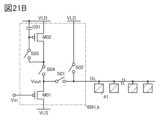

- 21A and 21B are circuit diagrams illustrating a semiconductor device.

- 22A and 22B are a layout diagram and a cross-sectional view illustrating a semiconductor device.

- FIG. 23 is a circuit diagram illustrating a semiconductor device.

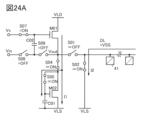

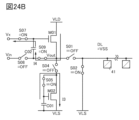

- 24A and 24B are circuit diagrams illustrating a semiconductor device.

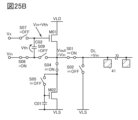

- 25A and 25B are circuit diagrams illustrating a semiconductor device.

- 26A and 26B are circuit diagrams illustrating a semiconductor device.

- 27A and 27B are circuit diagrams illustrating a semiconductor device.

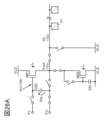

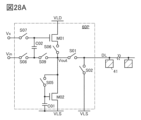

- 28A and 28B are circuit diagrams illustrating a semiconductor device.

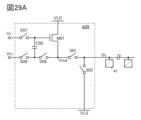

- 29A and 29B are circuit diagrams illustrating a semiconductor device.

- 30A and 30B are circuit diagrams illustrating a semiconductor device.

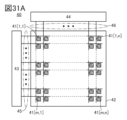

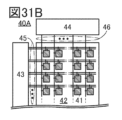

- 31A to 31E are block diagrams showing configuration examples of the display device.

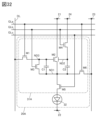

- FIG. 32 is a circuit diagram showing a configuration example of a semiconductor device.

- FIG. 33 is a timing chart showing an example of the operation of the semiconductor device.

- FIG. 32 is a circuit diagram showing a configuration example of a semiconductor device.

- FIG. 33 is a timing chart showing an example of the operation of the semiconductor device.

- FIG. 32 is a circuit diagram

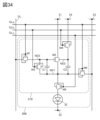

- FIG. 34 is a circuit diagram showing a configuration example of a semiconductor device.

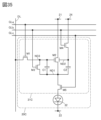

- FIG. 35 is a circuit diagram showing a configuration example of a semiconductor device.

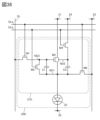

- FIG. 36 is a circuit diagram showing a configuration example of a semiconductor device.

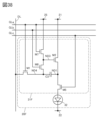

- FIG. 37 is a circuit diagram showing a configuration example of a semiconductor device.

- FIG. 38 is a circuit diagram showing a configuration example of a semiconductor device.

- FIG. 39 is a circuit diagram showing a configuration example of a semiconductor device.

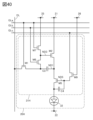

- FIG. 40 is a circuit diagram showing a configuration example of a semiconductor device.

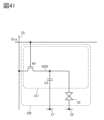

- FIG. 41 is a circuit diagram showing a configuration example of a semiconductor device.

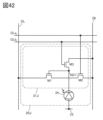

- FIG. 42 is a circuit diagram illustrating a semiconductor device.

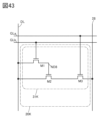

- FIG. 43 is a circuit diagram illustrating a semiconductor device.

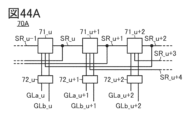

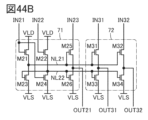

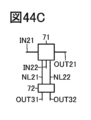

- 44A to 44C and 44E are circuit diagrams showing a configuration example of a semiconductor device, and Fig. 44D is a timing chart showing an operation example of the semiconductor device.

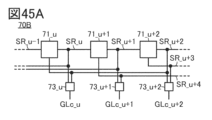

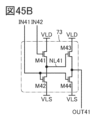

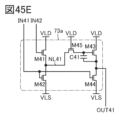

- 45A to 45C and 45E are circuit diagrams showing a configuration example of a semiconductor device, and Fig. 45D is a timing chart showing an operation example of the semiconductor device.

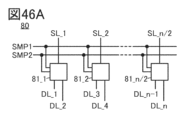

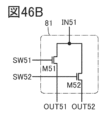

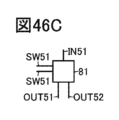

- 46A to 46C are circuit diagrams showing configuration examples of a semiconductor device.

- FIG. 47 is a circuit diagram showing a configuration example of a semiconductor device.

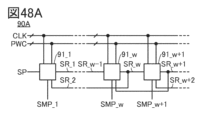

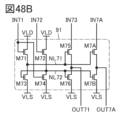

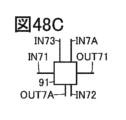

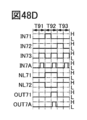

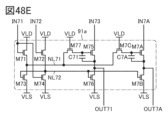

- 48A to 48C and 48E are circuit diagrams showing a configuration example of a semiconductor device, and Fig. 48D is a timing chart showing an operation example of the semiconductor device.

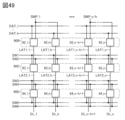

- FIG. 49 is a circuit diagram showing a configuration example of a semiconductor device.

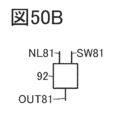

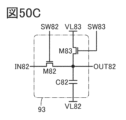

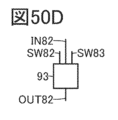

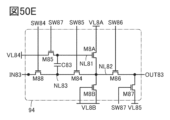

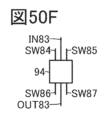

- FIG. 50A to 50F are circuit diagrams showing configuration examples of a semiconductor device.

- FIG. 51 is a timing chart showing an example of the operation of the semiconductor device.

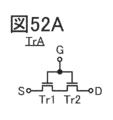

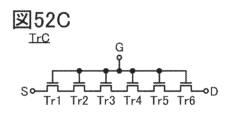

- 52A to 52C are circuit diagrams showing configuration examples of a semiconductor device.

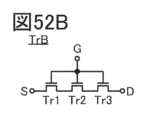

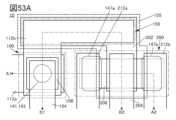

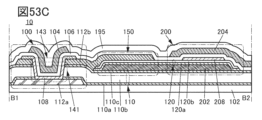

- Fig. 53A is a top view showing a configuration example of a semiconductor device, and Fig. 53B and Fig. 53C are cross-sectional views showing the configuration example of a semiconductor device.

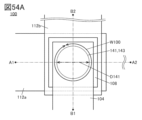

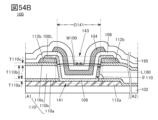

- 54A is a top view showing a configuration example of a semiconductor device, and FIG 54B is a cross-sectional view showing the configuration example of a semiconductor device.

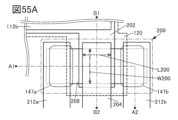

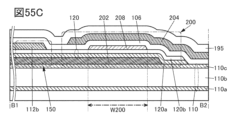

- Fig. 55A is a top view showing a configuration example of a semiconductor device, and Fig. 55B and Fig.

- FIG. 55C are cross-sectional views showing the configuration example of a semiconductor device.

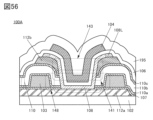

- FIG. 56 is a cross-sectional view showing a configuration example of a semiconductor device.

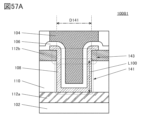

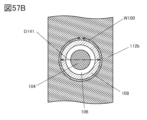

- 57A and 57B are cross-sectional views showing a configuration example of a semiconductor device.

- 58A and 58B are cross-sectional views showing a configuration example of a semiconductor device.

- 59A and 59B are cross-sectional views showing a configuration example of a semiconductor device.

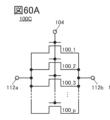

- 60A and 60B are circuit diagrams showing a configuration example of a semiconductor device

- Fig. 60C is a top view showing the configuration example of a semiconductor device.

- FIG. 61 is a cross-sectional view showing a configuration example of a semiconductor device.

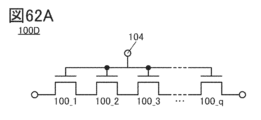

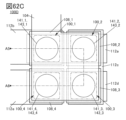

- FIG. 62A and 62B are circuit diagrams showing a configuration example of a semiconductor device, and Fig. 62C is a top view showing a configuration example of a semiconductor device.

- FIG. 63 is a cross-sectional view showing a configuration example of a semiconductor device.

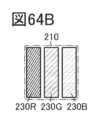

- Fig. 64A is a perspective view showing a configuration example of a display device, and Fig. 64B to Fig. 64F are top views showing an example of a pixel arrangement.

- 65A and 65B are cross-sectional views showing a configuration example of a display device.

- 66A and 66B are cross-sectional views showing a configuration example of a display device.

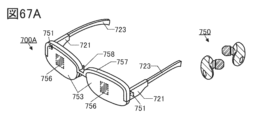

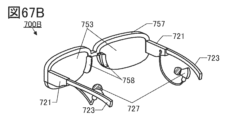

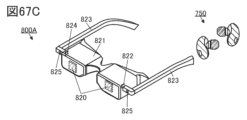

- 67A to 67D are diagrams showing an example of an electronic device.

- 68A to 68F are diagrams showing an example of an electronic device.

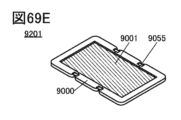

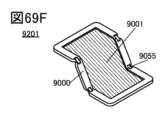

- 69A to 69G are diagrams showing an example of an electronic device.

- a semiconductor device is a device that utilizes semiconductor characteristics, such as a circuit including a semiconductor element (e.g., a transistor or a diode) or a device having such a circuit. It also refers to any device that can function by utilizing semiconductor characteristics.

- a semiconductor element e.g., a transistor or a diode

- an integrated circuit including a semiconductor element, a chip equipped with an integrated circuit, an electronic component in which a chip is housed in a package, or an electronic device equipped with an electronic component are examples of semiconductor devices.

- display devices for example, display devices, light-emitting devices, power storage devices, optical devices, imaging devices, lighting devices, arithmetic devices, control devices, memory devices, input devices, output devices, input/output devices, signal processing devices, electronic computers, or electronic devices may themselves be semiconductor devices and may have semiconductor devices.

- the size, layer thickness, or area may be exaggerated for clarity.

- the drawings are not limited to, for example, their size or aspect ratio.

- the drawings are schematic representations of ideal examples, and are not limited to, for example, the shapes or values shown in the drawings.

- layers or resist masks may be unintentionally thinned by processes such as etching, but this may not be reflected in the drawings to facilitate understanding.

- variations in voltage or current may occur due to noise or timing deviations, but this may not be reflected in the drawings to facilitate understanding.

- the components of the present invention may be classified by function and shown as independent elements.

- the elements shown in this specification and drawings, etc. are not limited to the explanations therein, and may be rephrased appropriately depending on the situation.

- an identifying symbol such as "A”, “b”, “_1”, “[n]”, or “[m, n]” may be added to the reference numeral.

- the identifying symbol may not be added.

- the "conductive state” or “on state” of a transistor refers to, for example, a state in which the source and drain of the transistor can be regarded as being electrically short-circuited, or a state in which a current can flow between the source and drain.

- a state in which the voltage between the gate and source of an n-channel transistor is higher than the threshold voltage, or a state in which the voltage between the gate and source of a p-channel transistor is lower than the threshold voltage may be referred to as the "conductive state” or "on state”.

- non-conductive state refers to a state in which the source and drain of the transistor can be regarded as being electrically cut off.

- a state in which the voltage between the gate and source of an n-channel transistor is lower than the threshold voltage, or a state in which the voltage between the gate and source of a p-channel transistor is higher than the threshold voltage may be referred to as the "non-conductive state", “cut-off state”, or "off state”.

- the voltage between the gate and source may be referred to as the "gate voltage”

- the voltage between the drain and source may be referred to as the “drain voltage”

- the voltage between the backgate and source may be referred to as the “backgate voltage”.

- the current flowing from the drain to the source may be referred to as the "drain current”.

- the "off current" of a transistor refers to the drain current when the transistor is in an off state. Note that in this specification, the off current and the current flowing from the gate to the source and drain (also referred to as gate leakage current) may be referred to as leakage current.

- FIG. 1A is a block diagram illustrating a configuration example of a display device including a semiconductor device.

- a display device 40 shown in FIG. 1A includes a display portion 42 and a driver circuit portion 44.

- the display portion 42 includes a plurality of pixels 41 electrically connected to wirings DL (wirings DL_1 to DL_n (n is an integer of 2 or more)).

- the driver circuit portion 44 includes a semiconductor device 60. Note that the wirings DL may be referred to as signal lines.

- a data potential is applied from the drive circuit unit 44 to the pixels 41 via the wiring DL, whereby light emission according to the data potential is controlled and an image is displayed on the display unit 42.

- the drive circuit unit 44, the display device 40, and the pixels 41 will be described later.

- the semiconductor device 60 is an analog circuit for outputting an output voltage according to an input voltage Vin (Vin_1 to Vin_n) to the wirings DL_1 to DL_n of each row (or each column). As shown in FIG. 1B, the semiconductor device 60 can be represented as a circuit block that outputs an input voltage applied to an input terminal IN from an output terminal OUT.

- FIG. 1C is a circuit diagram illustrating an example configuration of semiconductor device 60.

- Semiconductor device 60 has a transistor M01, a switch S01, and a switch S02.

- the gate of the transistor M01 is electrically connected to a wiring that provides an input voltage Vin to the input terminal IN.

- One of the source and drain of the transistor M01 is electrically connected to a wiring VLD.

- the other of the source and drain of the transistor M01 is electrically connected to a first terminal of the switch S01.

- the second terminal of the switch S01 is electrically connected to a first terminal of the switch S02 and a wiring DL.

- the second terminal of the switch S02 is electrically connected to a wiring VLS.

- the wiring VLD is a wiring that supplies a potential VDD (potential H) to an element such as a transistor.

- the wiring VLD is also called a first power supply line.

- the wiring VLS is a wiring that supplies a potential VSS (potential L) to an element such as a transistor.

- the wiring VLS is also called a second power supply line. The following description assumes that the potential VDD is a potential that is sufficiently higher than the potential VSS and is higher than the threshold voltage of the transistor in the semiconductor device 60.

- Transistor M01 has a function of providing an output voltage Vout corresponding to an input voltage Vin applied to its gate to wiring DL via switch S01.

- Transistor M01 functions as a source follower circuit in which the gate of transistor M01 is the input and the source of transistor M01 is the output. Note that in this specification, a transistor having a function similar to that of transistor M01 may be referred to as a "drive transistor.”

- the semiconductor device 60 having the transistor M01 can reduce the output impedance, thereby shortening the time it takes for the potential of the wiring DL to change in response to changes in the potential of the input voltage Vin, even when the load (parasitic capacitance) of the wiring DL is large. In other words, the semiconductor device 60 has an impedance conversion function.

- Switches S01 and S02 can be transistors, similar to transistor M01. By using transistors as switches S01 and S02, switches S01 and S02 can be manufactured through the same process as transistor M01. Note that switches other than switches S01 and S02 may also be transistors.

- the transistors (e.g., transistor M01) constituting the semiconductor device 60 are enhancement type (normally off type) n-channel transistors unless otherwise specified. Therefore, their threshold voltages are greater than 0 V.

- the semiconductor device 60 can be configured using various transistors.

- some or all of the transistors constituting the semiconductor device 60 may be p-channel transistors.

- transistors constituting the semiconductor device 60 transistors containing various semiconductors can be used.

- a transistor containing a single crystal semiconductor, a polycrystalline semiconductor, a microcrystalline semiconductor, or an amorphous semiconductor in a channel formation region can be used.

- the semiconductor is not limited to a single semiconductor whose main component is composed of a single element (such as silicon or germanium), but can be, for example, a compound semiconductor (such as silicon germanium or gallium arsenide), an oxide semiconductor, or the like.

- transistors that make up the semiconductor device 60 can be used as the transistors that make up the semiconductor device 60.

- MOS type field effect transistors can be used.

- transistors constituting the semiconductor device 60 transistors of various structures can be used.

- transistors of various structures such as planar type, staggered type, FIN type, TRI-GATE type, top gate type, bottom gate type, or dual gate type (structure in which gates are arranged on both sides (e.g., above and below) of a channel formation region) can be used.

- transistors constituting the semiconductor device 60 it is preferable to use vertical transistors (transistors in which at least a part of a semiconductor layer including a channel formation region is provided along the side of an insulating layer in an opening formed in the insulating layer).

- the source electrode and drain electrode are located at different heights, so current flows in the height direction (vertical direction) in the channel formation region of the semiconductor layer.

- the channel length direction has a height direction (vertical direction) component. Therefore, the above-mentioned vertical transistor can also be called a VFET (Vertical Field Effect Transistor), vertical channel transistor, vertical channel transistor, or vertical transistor.

- VFET Vertical Field Effect Transistor

- Vertical transistors have a structure in which the source region, the channel formation region, and the drain region can at least partially overlap when viewed from above, so that the area they occupy (also called the footprint) can be made small.

- the structure allows the channel length to be small and the channel width to be large, the on-resistance can be made small (the on-current can be made large).

- the source electrode and the drain electrode can be located at the same height, and current can flow in the circumferential (horizontal) direction in the channel formation region of the semiconductor layer.

- the channel width direction can have a height (vertical) component.

- a transistor with such a configuration can be called a VLFET (Vertical Lateral Field Effect Transistor). Since the VLFET has a structure that can reduce the occupied area while increasing the channel length, it can reduce short channel effects such as drain induced barrier lowering (DIBL).

- DIBL drain induced barrier lowering

- vertical transistors are preferably used as some or all of the transistors constituting the semiconductor device 60.

- vertical transistors are preferably used as transistors that function as switches (e.g., switches S01 and S02).

- a transistor with high saturation should be used as the drive transistor (e.g., transistor M01).

- the drive transistor e.g., transistor M01

- a transistor with a long channel length should be used.

- the above-mentioned VLFET may be used.

- an OS transistor (a transistor that includes an oxide semiconductor in a channel formation region) may be used as a transistor that constitutes the semiconductor device 60.

- the OS transistor has a characteristic of having an extremely low off-state current because the band gap of the oxide semiconductor in which the channel is formed is 2 eV or more.

- the off-state current value of the OS transistor per 1 ⁇ m of channel width at room temperature can be 1 aA (1 ⁇ 10 ⁇ 18 A) or less, 1 zA (1 ⁇ 10 ⁇ 21 A) or less, or 1 yA (1 ⁇ 10 ⁇ 24 A) or less.

- the off-state current value of a Si transistor (a transistor containing silicon in a channel formation region) per 1 ⁇ m of channel width at room temperature is 1 fA (1 ⁇ 10 ⁇ 15 A) or more and 1 pA (1 ⁇ 10 ⁇ 12 A) or less. Therefore, it can be said that the off-state current of an OS transistor is about 10 orders of magnitude lower than that of a Si transistor.

- the charge accumulated in a capacitor and a wiring having a parasitic capacitor can be held for a long period of time.

- the potential of the wiring DL can be held for a long period of time. Therefore, the power consumption of the semiconductor device can be reduced.

- the off-current of an OS transistor hardly increases even in a high-temperature environment. Specifically, the off-current hardly increases even in an environment of room temperature or higher and 200° C. or lower. Furthermore, the on-current of an OS transistor is unlikely to decrease even in a high-temperature environment.

- the on-current of a Si transistor decreases in a high-temperature environment. That is, the on-current of an OS transistor is higher than that of a Si transistor in a high-temperature environment.

- an OS transistor can perform a good switching operation even in an environment of 125° C. or higher and 150° C. or lower because the ratio of the on-current to the off-current is large. Therefore, a semiconductor device using an OS transistor can operate stably and with high reliability even in a high-temperature environment. That is, by using an OS transistor as a transistor constituting the semiconductor device 60, the reliability of the semiconductor device can be improved.

- OS transistors have a high withstand voltage between the source and drain (also referred to as drain withstand voltage). Therefore, a semiconductor device using an OS transistor can operate stably even when driven at a high voltage, and can achieve high reliability. That is, for example, by using an OS transistor as transistor M01 among the transistors constituting the semiconductor device 60, the operation of the semiconductor device 60 can be stabilized even when the potential difference (voltage) between the potential VDD and the potential VSS is large. Therefore, the reliability of the semiconductor device can be improved.

- one embodiment of the present invention is not limited to a configuration in which an OS transistor is used as the semiconductor device 60, and may be a configuration in which multiple types of transistors containing different semiconductor materials are used.

- the semiconductor device 60 may be configured with a transistor (LTPS transistor) containing low temperature polysilicon (LTPS) in the channel formation region, and an OS transistor.

- the LTPS transistor has high field-effect mobility and good frequency characteristics.

- a configuration in which an LTPS transistor and an OS transistor are combined may be referred to as LTPO.

- OS transistors can be used for the transistors functioning as switches S01 and S02

- an LTPS transistor can be used for the driving transistor (transistor M01).

- the transistors may be provided in different layers for each type of transistor.

- the semiconductor device 60 is configured with Si transistors and OS transistors

- a layer containing the Si transistors and a layer containing the OS transistors may be stacked. With such a configuration, the area occupied by the semiconductor device 60 can be reduced.

- vertical OS transistors may be used as the transistors functioning as switches S01 and S02, and a dual-gate OS transistor may be used as the driver transistor (transistor M01).

- a driver transistor transistor M01

- the semiconductor device 60 performs an initialization operation T01, an initialization ending operation T02, and a signal output operation T03 during a period TSEL during which the semiconductor device 60 outputs an output voltage corresponding to the input voltage Vin.

- the semiconductor device 60 may omit the initialization ending operation T02 as shown in Fig. 2B.

- the time required for the initialization operation T01 and the signal output operation T03 can be set long, and therefore a stable output voltage can be obtained.

- FIG. 3A is a circuit diagram for explaining the initialization operation T01.

- the initialization operation T01 the potential of the wiring DL is initialized.

- the initialization operation T01 is performed with the switch S01 in a non-conducting state (OFF) and the switch S02 in a conducting state (ON).

- the switch S02 has a function of performing the initialization operation to initialize the potential of the wiring DL by being in a conducting state.

- the switch S01 is in a non-conducting state, so the output voltage Vout (the voltage on the first terminal side of the switch S01) corresponding to the input voltage Vin does not change.

- the switch S02 is turned on, so that the potential of the wiring DL can be set to the potential VSS.

- the initialization operation T01 will be described as an operation for discharging the charge of the wiring DL. Note that the initialization operation is sometimes called a discharging operation.

- the potential of the wiring DL changes depending on the current I that flows through the switch S02.

- a transistor can be used for the switch S02, similar to the transistor M01. The same applies to the switch S01.

- switch S02 is a transistor

- a bias voltage may be applied to the gate of the transistor so that a bias current flows.

- the transistor may be operated by switching between allowing or not allowing a bias current to flow, depending on whether or not a bias voltage is applied.

- FIG. 3B is a circuit diagram for explaining the initialization end operation T02.

- both switches S01 and S02 are in a non-conducting state (OFF).

- the potential VSS of the wiring DL set in the initialization operation T01 is maintained.

- FIG. 3C is a circuit diagram for explaining the signal output operation T03.

- a current flows through the transistor M01 by turning the switch S01 on (ON).

- the wiring DL becomes the output voltage Vout.

- the switch S01 When the switch S01 is turned on, it has the function of performing a signal output operation that provides the output voltage Vout to the wiring DL.

- Vout When the output voltage Vout becomes Vin-Vth, a voltage equal to or lower than Vth, which corresponds to the threshold voltage of transistor M01, is applied between the gate and source of transistor M01, causing a subthreshold current to flow between the source and drain.

- the period TSEL during which the output voltage according to the input voltage Vin is output may end before the output voltage Vout increases to Vin-Vth (see FIG. 4B). In this case, the output voltage Vout becomes Vin-Vth- ⁇ ( ⁇ >0), which is smaller than Vin-Vth.

- the output voltage Vout can rise to Vin-Vth. Since a voltage equal to or lower than Vth, which corresponds to the threshold voltage of the transistor M01, is applied between the gate and source of the transistor M01, a subthreshold current flows between the source and drain. Since a subthreshold current flows through the transistor M01, the output voltage Vout may continue to rise until the end of the period TSEL (see FIG. 4C). In this case, the output voltage Vout becomes Vin-Vth+ ⁇ ( ⁇ >0), which is larger than Vin-Vth.

- One aspect of the present invention reduces power consumption by blocking or reducing the bias current flowing through a source follower circuit. Specifically, the number of transistors to which a bias voltage is applied is reduced, and the steady flow of bias current is suppressed, thereby reducing power consumption. If the bias current does not flow steadily, it may take some time (also called the settling time) until the output voltage according to the input voltage stabilizes. In particular, the settling time may be long when changing the voltage of the signal line in a decreasing direction.

- the conductive state of the switch is changed over to perform an initialization operation and then a signal output operation.

- charging to a desired voltage by the signal output operation can be performed in a state where the voltage of the signal line is lowered before the signal output operation is performed. Therefore, when inputting an input voltage, even if the voltage of the signal line is changed in a lowering direction, it can be changed to a desired voltage.

- a vertical transistor in order to reduce the settling time, it is preferable to use a vertical transistor as the driving transistor.

- the footprint of the driving transistor can be reduced, and the channel length and channel width can be increased.

- a vertical driving transistor can reduce the on-resistance (increase the on-current), but consumes more power. Therefore, by combining it with the above-described configuration in which a signal output operation is performed after the initialization operation, it is possible to improve the operating speed of a display device having a semiconductor device while suppressing increases in the area occupied by the semiconductor device and power consumption.

- one aspect of the present invention is not limited to the configuration example of the semiconductor device 60 described above.

- Figs. 5A to 5C modified examples of the semiconductor device 60 described above are described.

- the switch S01 may be located in the path between the wiring VLD and the wiring DL.

- a switch having the function of the switch S01 may be provided between the drain side of the transistor M01 and the wiring VLD.

- the switch S01 in the semiconductor device 60 shown in FIG. 1C may be omitted in cases where the period required for the initialization operation is short.

- the semiconductor device 60A shown in FIG. 5A is a modified example of the semiconductor device 60 shown in FIG. 1C in which the switch S01 in the semiconductor device 60 shown in FIG. 1C is omitted and a new switch S03 is added.

- the semiconductor device 60B shown in FIG. 5B is a modified example of the semiconductor device 60 shown in FIG. 1C in which a switch S03 is added to the semiconductor device 60 shown in FIG. 1C.

- the semiconductor device 60C shown in FIG. 5C is a modified example of the semiconductor device 60 shown in FIG. 1C in which the switch S01 in the semiconductor device 60 shown in FIG. 1C is omitted.

- the arrangement of switch S01 and the number of switches having the function of switch S01 can be changed as appropriate.

- the arrangement of switch S01 it is possible to increase the degree of freedom in design.

- by increasing the number of switches it is possible to further reduce the current flowing through transistor M01 during the initialization operation.

- the display section 42 and the drive circuit section 44 may be arranged so as to overlap each other.

- the display section 42 having the pixels 41 may be provided on a layer above the layer on which the drive circuit section 44 having the semiconductor device 60 is provided.

- the transistors in the display unit 42 and the transistors in the drive circuit unit 44 can be arranged in different layers. Therefore, transistors with different structures can be applied to the transistors in the display unit 42 or the transistors in the drive circuit unit 44.

- connection distance (wiring length) between the pixels 41 of the display section 42 and the semiconductor device 60 of the drive circuit section 44 can be made extremely short.

- the wiring resistance and parasitic capacitance of the wiring DL are reduced, so the time required for charging and discharging is shortened, and high-speed driving can be achieved. Also, power consumption can be reduced. Also, miniaturization and weight reduction can be achieved.

- FIG. 6B shows a configuration example of a semiconductor device 60_p in which a p-channel transistor is used for the transistor M01.

- the potential of each wiring may be set so that the high and low potentials are inverted.

- the wiring DL that is discharged via the switch S02 in FIG. 1C may be configured to be charged by the wiring VLD in FIG. 6B.

- FIG. 7 is a circuit diagram illustrating an example of the configuration of semiconductor device 60D.

- Semiconductor device 60D has transistor M02 in addition to transistor M01, switch S01, and switch S02. Note that the explanations of transistor M01, switch S01, and switch S02 in semiconductor device 60D overlap with the explanation of semiconductor device 60 described above, and therefore may be omitted.

- the gate of the transistor M02 is electrically connected to the wiring VLS.

- One of the source and drain of the transistor M02 is electrically connected to the other of the source and drain of the transistor M01 and the first terminal of the switch S01.

- the other of the source and drain of the transistor M02 is electrically connected to the wiring VLS.

- transistor M02 Because the gate and source voltages of transistor M02 are equipotential, that is, 0 V is applied as the gate-source voltage Vgs, a subthreshold current flows between the source and drain. Transistor M02 functions as a current source that passes subthreshold current. The subthreshold current that flows through transistor M02 is much smaller than the current that flows through transistor M01 when charging line DL.

- a transistor that functions like transistor M02 may be called a "load transistor.” Note that transistor M02 that functions as a load transistor may be replaced with, for example, a resistive element.

- the description of the drive transistor can be referred to as an example of the configuration of the load transistor (transistor M02).

- a transistor with high saturation and a large channel length may be used as the load transistor.

- the semiconductor device 60D performs an initialization operation T01, an initialization ending operation T02, and a signal output operation T03 during a period TSEL during which an output voltage corresponding to an input voltage Vin is output, similar to the semiconductor device 60 described above. Note that the semiconductor device 60D may omit the initialization ending operation T02 as illustrated in FIG. 2B.

- FIG. 8A is a circuit diagram for explaining the initialization operation T01 in a schematic manner.

- the explanation of the initialization operation T01 in FIG. 8A is the same as that in FIG. 3A.

- FIG. 8B is a circuit diagram for illustrating the initialization end operation T02.

- the explanation of the initialization end operation T02 in FIG. 8B is the same as that in FIG. 3B.

- FIG. 8C is a circuit diagram for illustrating signal output operation T03.

- the explanation of signal output operation T03 in FIG. 8C is the same as that in FIG. 3C.

- Vout When the output voltage Vout becomes Vin-Vth, a voltage equal to or lower than Vth, which corresponds to the threshold voltage of transistor M01, is applied between the gate and source of transistor M01, causing a subthreshold current to flow between the source and drain.

- Semiconductor device 60D has a configuration including transistor M02. Therefore, during signal output operation T03, a subthreshold current also flows through transistor M02.

- the subthreshold current flowing through transistor M02 is preferably designed to be the same in magnitude as the subthreshold current flowing through transistor M01. For example, as shown in the layout diagram of FIG. 9B, it is preferable that the areas of the overlapping regions between the semiconductor layer SEM and the wiring GE functioning as the gate electrode in transistors M01 and M02 are approximately the same. With this configuration, the subthreshold current flowing through transistor M02 can be made close to the same in magnitude as the subthreshold current flowing through transistor M01.

- signals SEL SW01 and SEL SW02 are shown as signals for controlling the conductive states of switches S01 and S02.

- the signals SEL SW01 and SEL SW02 are signals provided to the gates of transistors functioning as switches.

- one aspect of the present invention is not limited to the configuration example of the semiconductor device 60D described above.

- Figs. 10A and 12B a modified example of the semiconductor device 60D described above is described.

- the switch S01 may be located in the path between the wiring VLD and the wiring DL.

- a switch having the function of the switch S01 may be provided between the drain side of the transistor M01 and the wiring VLD.

- the switch S01 in the semiconductor device 60D shown in FIG. 7 can be omitted in cases where the period required for the initialization operation is short.

- the semiconductor device 60F shown in FIG. 10A is a modified example of the semiconductor device 60D shown in FIG. 7, in which the switch S01 in the semiconductor device 60D shown in FIG. 7 is omitted and a new switch S03 is provided.

- the semiconductor device 60G shown in FIG. 10B is a modified example of the semiconductor device 60D shown in FIG. 7, in which the switch S03 is added to the semiconductor device 60D shown in FIG. 7.

- the arrangement of switch S01 and the number of switches having the function of switch S01 can be changed as appropriate. Being able to change the arrangement of switch S01 as appropriate increases the degree of freedom in design. Also, by increasing the number of switches, the current flowing through transistor M01 during the initialization operation can be made smaller.

- the wiring VLS electrically connected to the other of the source and drain of the transistor M02 and the wiring VLS electrically connected to the second terminal of the switch S02 may be different wirings.

- FIG. 11A shows a configuration example of a semiconductor device 60D_b in which the wiring electrically connected to the other of the source and drain of the transistor M02 is wiring VLS_SF and the wiring electrically connected to the second terminal of the switch S02 is wiring VLS_DL.

- the potentials of the wirings VLS_SF and VLS_D may be the same potential VSS or different potentials.

- FIG. 11B shows a configuration example of a semiconductor device 60D_p in which p-channel transistors are used for the transistors M01 and M02.

- the potential of each wiring may be set so that the high and low potentials are inverted.

- the wiring DL that is discharged via the switch S02 in FIG. 7 may be configured to be charged by the wiring VLD in FIG. 11B.

- FIG. 12A shows a modified version of the layout diagram shown in FIG. 9B.

- VFETs are used for the transistors M01 and M02 and the transistors that function as switches S01 and S02.

- a VFET can have at least a portion of the source region, the channel formation region, and the drain region overlap.

- FIG. 12B shows a cross-sectional view between the dashed lines X1-X2 in FIG. 12A.

- a VFET has a configuration in which the electrodes SDE1 and SDE2 that contact the source region or drain region, the semiconductor layer SEM having the channel formation region, and the wiring GE that becomes the gate electrode overlap.

- This allows the occupied area (also called the footprint) to be small.

- the on-resistance can be small (the on-current can be large).

- a VLFET can be applied to FIG. 12A as a modified version of the above-mentioned vertical transistor.

- FIG. 13 is a circuit diagram illustrating an example configuration of semiconductor device 60H.

- semiconductor device 60H has switches S04, S05, and a capacitor C01. Note that the explanations of transistors M01, M02, switches S01, and S02 in semiconductor device 60H may be omitted because they overlap with the explanations of semiconductor devices 60 and 60D described above.

- the first terminal of the switch S04 is electrically connected to the other of the source and drain of the transistor M01 and the first terminal of the switch S01.

- the second terminal of the switch S04 is electrically connected to one of the source and drain of the transistor M02 and the first terminal of the switch S05.

- the second terminal of the switch S05 is electrically connected to the gate of the transistor M02 and the first electrode of the capacitor C01.

- the wiring VLS is electrically connected to the other of the source and drain of the transistor M02 and the second electrode of the capacitor C01.

- Switches S04 and S05 have the function of controlling the charging or discharging of capacitor C01 by controlling the conductive state.

- Capacitor C01 has the function of holding the gate-source voltage of transistor M02. The charge stored in capacitor C01 can be discharged through the source and drain of transistor M02 to hold the threshold voltage of transistor M02.

- the threshold voltage of transistor M02 is applied as a bias voltage to transistor M02, and transistor M02 has the function of passing a bias current corresponding to the threshold voltage.

- Transistor M02 has the function of a current source that passes a bias current corresponding to the threshold voltage. The bias current flowing through transistor M02 according to the threshold voltage is much smaller than the current flowing through transistor M01 when charging line DL.

- the threshold voltage of transistor M02 is described as being Vth, the same as the threshold voltage of transistor M01, but it may be a different value.

- the semiconductor device 60H performs a first initialization operation T01_1, a second initialization operation T01_2, an initialization ending operation T02, and a signal output operation T03 during a period TSEL during which the semiconductor device 60H outputs an output voltage corresponding to the input voltage Vin.

- the semiconductor device 60H may omit the initialization ending operation T02 as shown in Fig. 14B.

- the times required for the first initialization operation T01_1, the second initialization operation T01_2, and the signal output operation T03 can be set long, and therefore a stable output voltage can be obtained.

- FIG. 15A is a circuit diagram for illustrating a schematic of the first initialization operation T01_1.

- the potential of the wiring DL is initialized and the capacitor C01 is charged.

- the first initialization operation T01_1 is performed with the switch S01 in a non-conductive state (OFF) and the switches S02, S04, and S05 in a conductive state (ON).

- the switches S04 and S05 have the function of charging the capacitor C01 by being in a conductive state.

- the switches S04 and S05 are in a conductive state, so a current I1 flows according to the input voltage Vin.

- a voltage for passing the current I1 is held in the capacitor C01 as the gate-source voltage of the transistor M02.

- the input voltage Vin is set to a voltage at which the current I1 flows through the transistors M01 and M02 during the first initialization operation T01_1.

- the switch S02 is in a conductive state, so the potential of the line DL changes to the potential VSS due to the current I2 flowing through the switch S02.

- FIG. 15B is a circuit diagram for illustrating the second initialization operation T01_2.

- the capacitor C01 is discharged.

- the second initialization operation T01_2 is performed with the switches S01 and S04 in a non-conductive state (OFF) and the switches S02 and S05 in a conductive state (ON).

- the switches S04 and S05 have the function of discharging the capacitor C01 by putting the switch S04 in a non-conductive state and the switch S05 in a conductive state.

- FIG. 16A is a circuit diagram for explaining the initialization end operation T02.

- the switches S01, S02, S04, and S05 are all in a non-conducting state (OFF).

- the potential VSS of the wiring DL set in the initialization operation T01_2 and the threshold voltage of the transistor M02 are held in the capacitor C01.

- FIG. 16B is a circuit diagram for explaining the signal output operation T03.

- a current flows through the transistor M01 by turning the switch S01 on (ON).

- the wiring DL becomes the output voltage Vout.

- the switch S01 When the switch S01 is turned on, it has the function of performing a signal output operation that provides the output voltage Vout to the wiring DL.

- a current flows through transistor M02 by turning switch S04 conductive (ON).

- the current flowing through transistor M02 is a current at the threshold voltage of transistor M02.

- a subthreshold current flows between the gate and source of transistor M02.

- Switches S04 and S05 have the function of passing a subthreshold current through transistor M02 by turning switch S04 conductive and switch S05 non-conductive.

- the subthreshold current flowing through transistor M02 is a current that corresponds to the threshold voltage held between the gate and source of transistor M02. Therefore, even if the transistor characteristics fluctuate in response to fluctuations in the threshold voltage, a small, constant current can flow.

- Vout When the output voltage Vout becomes Vin-Vth, a voltage equal to or lower than Vth, which corresponds to the threshold voltage of transistor M01, is applied between the gate and source of transistor M01, causing a subthreshold current to flow between the source and drain.

- Semiconductor device 60H has a configuration including transistor M02. Therefore, during signal output operation T03, a subthreshold current also flows through transistor M02.

- the subthreshold current flowing through transistor M02 is preferably designed to be the same in magnitude as the subthreshold current flowing through transistor M01. For example, as shown in the layout diagram of FIG. 18, it is preferable that the areas of the overlapping regions between the semiconductor layer SEM and the wiring GE functioning as the gate electrode in transistors M01 and M02 are approximately the same. With this configuration, the subthreshold current flowing through transistor M02 can be made close to the same in magnitude as the subthreshold current flowing through transistor M01.

- signals SEL SW04 and SEL SW05 are shown as signals for controlling the conductive states of switches S04 and S05.

- the signals SEL SW04 and SEL SW05 are signals given to the gates of transistors functioning as switches.

- One aspect of the present invention reduces power consumption by blocking or reducing the bias current flowing through a source follower circuit.

- a transistor to which a bias voltage is applied is designed to have a gate and source connected so that a subthreshold current flows, and power consumption can be reduced by preventing the bias current from flowing steadily. If the bias current does not flow steadily, it may take some time (also called the settling time) for the output voltage according to the input voltage to stabilize. In particular, the settling time may be long when changing the voltage of the signal line in a downward direction.

- the conductive state of the switch is changed over to perform an initialization operation and then a signal output operation.

- charging to a desired voltage by the signal output operation can be performed in a state where the voltage of the signal line is lowered before the signal output operation is performed. Therefore, when inputting an input voltage, even if the voltage of the signal line is changed in a lowering direction, it can be changed to a desired voltage.

- a vertical transistor in order to reduce the settling time, it is preferable to use a vertical transistor as the driving transistor.

- the footprint of the driving transistor can be reduced, and the channel length and channel width can be increased.

- a vertical driving transistor can reduce the on-resistance (increase the on-current), but consumes more power. Therefore, by combining it with the above-described configuration in which a signal output operation is performed after the initialization operation, it is possible to improve the operating speed of a display device having a semiconductor device while suppressing increases in the area occupied by the semiconductor device and power consumption.

- one embodiment of the present invention is not limited to the configuration example of the semiconductor device 60H described above. Modifications of the semiconductor device 60H described above are described in Figures 19A to 22B.

- the switch S01 may be located in the path between the wiring VLD and the wiring DL.

- a switch having the function of the switch S01 may be provided between the drain side of the transistor M01 and the wiring VLD.

- the switch S01 in the semiconductor device 60H shown in FIG. 13 may be omitted in cases where the period required for the initialization operation is short.

- Semiconductor device 60I shown in FIG. 19A is a modified example of semiconductor device 60H shown in FIG. 13, in which switch S01 in semiconductor device 60H shown in FIG. 13 is omitted and a new switch S03 is provided.

- Semiconductor device 60J shown in FIG. 19B is a modified example of semiconductor device 60H shown in FIG. 13, in which switch S03 is added to semiconductor device 60H shown in FIG. 13.

- the switch S04 may be located in the path between the wiring VLD and the transistor M02.

- a switch having the function of the switch S04 may be provided between the source side of the transistor M01 and the switch S01.

- the semiconductor device 60K shown in FIG. 20A is a modified example of the semiconductor device 60H shown in FIG. 13, in which the switch S04 in the semiconductor device 60H shown in FIG. 13 is omitted and a new switch S06 is provided.

- the semiconductor device 60L shown in FIG. 20B is a modified example of the semiconductor device 60H shown in FIG. 13, in which a switch S06 is added to the semiconductor device 60H shown in FIG. 13.

- the arrangement of switch S01 or switch S04 and the number of switches having the functions of switch S01 or switch S04 can be changed as appropriate.

- the arrangement of switch S01 or switch S04 it is possible to increase the degree of freedom in design. Also, by increasing the number of switches, it is possible to further reduce the current flowing through transistor M01 or switch S04 during the initialization operation.

- the wiring VLS electrically connected to the other of the source and drain of the transistor M02 and the wiring VLS electrically connected to the second terminal of the switch S02 may be different wirings.

- FIG. 21A shows a configuration example of a semiconductor device 60H_b in which the wiring electrically connected to the other of the source and drain of the transistor M02 is wiring VLS_SF and the wiring electrically connected to the second terminal of the switch S02 is wiring VLS_DL.

- the potentials of the wirings VLS_SF and VLS_D may be the same potential VSS or different potentials.

- FIG. 21B shows a configuration example of a semiconductor device 60H_p in which p-channel transistors are used for the transistors M01 and M02.

- the potential of each wiring may be set so that the high and low potentials are inverted.

- the wiring DL that is discharged via the switch S02 in FIG. 13 may be configured to be charged by the wiring VLD in FIG. 21B.

- FIG. 22A shows a modified version of the layout diagram shown in FIG. 18.

- VFETs are used as the transistors M01 and M02 and the transistors that function as the switches S01, S02, S04, and S05.

- a VFET can have at least a portion of the source region, the channel formation region, and the drain region overlap.

- FIG. 22B shows a cross-sectional view between the dashed lines X1-X2 in FIG. 22A.

- a VFET has a configuration in which the electrodes SDE1 and SDE2 in contact with the region that will become the source region or the drain region, the semiconductor layer SEM having the channel formation region, and the wiring GE that will become the gate electrode overlap. This allows the occupied area (also called the footprint) to be reduced.

- a VLFET can also be applied to FIG. 22A as a modified version of the above-mentioned vertical transistor.

- FIG. 23 is a circuit diagram illustrating an example of the configuration of semiconductor device 60M.

- semiconductor device 60M also has switches S07 to S09 and capacitor C02. Note that the explanations of transistor M01, transistor M02, switch S01, switch S02, switch S04, switch S05, and capacitor C01 in semiconductor device 60M may be omitted because they overlap with the explanations of semiconductor devices 60, 60D, and 60H described above.

- the first terminal of the switch S07 is electrically connected to a terminal that provides a potential Vx.

- the second terminal of the switch S07 is electrically connected to a first electrode of the capacitor C02 and the gate of the transistor M01.

- the first terminal of the switch S08 is electrically connected to a terminal that provides an input voltage Vin.

- the second terminal of the switch S08 is electrically connected to a second electrode of the capacitor C02 and a first terminal of the switch S09.

- the second terminal of the switch S09 is electrically connected to a first terminal of the switch S04, the other of the source and drain of the transistor M01, and the first terminal of the switch S01.

- the potential Vx is a voltage for making the transistor M01 conductive during the first initialization operation.

- the potential Vx may be the potential VDD.

- the switch S07 has a function of controlling whether or not the potential Vx is applied to the gate of the transistor M01 by controlling the conductive state.

- the switch S08 has a function of controlling whether or not the input voltage Vin is applied to the second electrode of the capacitor C02 by controlling the conductive state.

- the switch S09 has a function of controlling the conductive state to control the retention of the threshold voltage of the transistor M01 in the capacitor C02 by charging and discharging the capacitor C02.

- Capacitor C02 has the function of holding a voltage for turning on transistor M01 during the first initialization operation.

- Capacitor C02 which has been charged with a voltage for turning on transistor M01 during the first initialization operation, holds the threshold voltage of transistor M02 by the current flowing through the source and drain of transistor M01 during the second initialization operation.

- the threshold voltage of transistor M01 held in capacitor C02 is held during the second initialization operation, the initialization end operation, and the signal output operation.

- Vth threshold voltage

- the semiconductor device 60M performs a first initialization operation T01_1, a second initialization operation T01_2, an initialization ending operation T02, and a signal output operation T03 during a period TSEL during which an output voltage corresponding to an input voltage Vin is output. Note that the semiconductor device 60M may omit the initialization ending operation T02 as illustrated in FIG. 14B.

- FIG. 24A is a circuit diagram for explaining the first initialization operation T01_1.

- the potential of the wiring DL is initialized and the capacitor C01 is charged.

- the first initialization operation T01_1 is performed with the switches S01, S08, and S09 in a non-conductive state (OFF) and the switches S02, S04, S05, and S07 in a conductive state (ON).

- the switch S07 By making the switch S07 conductive, the potential Vx is held in the capacitor C02 and a current I1 flows through the transistor M01.

- the potential Vx is set to a voltage at which the current I1 flows through the transistors M01 and M02 during the first initialization operation T01_1.

- the switches S04 and S05 are in a conductive state, so a current I1 corresponding to the potential Vx flows.

- a voltage for passing the current I1 is held in the capacitor C01 as the gate-source voltage of the transistor M02.

- the switch S02 is in a conductive state, so the potential of the line DL changes to the potential VSS due to the current I2 flowing through the switch S02.

- FIG. 24B is a circuit diagram for illustrating the second initialization operation T01_2.

- the second initialization operation T01_2 is performed with switches S01, S04, and S08 in a non-conductive state (OFF), and switches S02, S05, S07, and S09 in a conductive state (ON).

- Switches S04 and S05 have the function of discharging capacitor C01 by setting switch S04 in a non-conductive state and switch S05 in a conductive state.

- Switches S07, S08, and S09 have the function of discharging capacitor C02 by setting switch S08 in a non-conductive state and switches S07 and S09 in a conductive state.

- capacitor C2 When capacitor C2 is discharged, a current I4 flows, and the current I4 becomes small when the gate-source voltage of transistor M01 becomes the threshold voltage of transistor M01. In other words, when capacitor C02 is discharged, the threshold voltage of transistor M01 is held in capacitor C02.

- FIG. 25A is a circuit diagram for illustrating the initialization end operation T02.

- switches S01, S02, S04, S05, S07, S08, and S09 are all in a non-conducting state (OFF).

- the potential VSS of the wiring DL set in the initialization operation T01_2 is held, and the threshold voltage of the transistor M02 is held in the capacitor C01.

- the threshold voltage of the transistor M01 is held in the capacitor C02.

- FIG. 25B is a circuit diagram for explaining the signal output operation T03.

- a current flows through the transistor M01 by turning the switch S01 on (ON).

- the wiring DL becomes the output voltage Vout.

- the switch S01 When the switch S01 is turned on, it has the function of performing a signal output operation that provides the output voltage Vout to the wiring DL.

- switch S07 is turned off (OFF) to put the first electrode side of capacitor C02, i.e., the gate of transistor M01, into an electrically floating state (floating), and switch S08 is turned on (ON). Therefore, with a voltage corresponding to the threshold voltage (Vth) of transistor M01 held across capacitor C02, the potential of the second electrode side of capacitor C02 becomes the input voltage Vin. Therefore, due to the capacitive coupling of capacitor C02, the potential of the first electrode side of capacitor C02, i.e., the gate of transistor M01, becomes Vin+Vth.

- Vth threshold voltage

- the potential of the gate of transistor M01 is set to Vin+Vth, and the switch S01 is turned on (ON), so that the current flowing through transistor M01 is reduced by the gate-source voltage of transistor M01 being equal to or lower than Vth.

- the output voltage Vout can be a voltage with the threshold voltage Vth corrected.

- a current flows through transistor M02 by turning switch S04 conductive (ON).

- the current flowing through transistor M02 is a current at the threshold voltage of transistor M02.

- a subthreshold current flows between the gate and source of transistor M02.

- Switches S04 and S05 have the function of passing a subthreshold current through transistor M02 by turning switch S04 conductive and switch S05 non-conductive.

- the subthreshold current flowing through transistor M02 is a current that corresponds to the threshold voltage held between the gate and source of transistor M02. Therefore, even if the transistor characteristics fluctuate in response to fluctuations in the threshold voltage, a small, constant current can flow.

- Vout When the output voltage Vout becomes Vin, a voltage equal to or lower than Vth, which corresponds to the threshold voltage of transistor M01, is applied between the gate and source of transistor M01, causing a subthreshold current to flow between the source and drain.

- Semiconductor device 60M has a configuration including transistor M02. Therefore, during signal output operation T03, a subthreshold current also flows through transistor M02.

- the subthreshold current flowing through the transistor M02 is the same as the subthreshold current flowing through the transistor M01.

- the area of the region where the semiconductor layer SEM and the wiring GE functioning as the gate electrode overlap in the transistor M01 and the transistor M02 is preferable to make the area of the region where the semiconductor layer SEM and the wiring GE functioning as the gate electrode overlap in the transistor M01 and the transistor M02 approximately the same.

- the subthreshold current (I st ) flowing through the transistor M02 shown in FIG. 26A can be made to approach the same magnitude as the subthreshold current (I st ) flowing through the transistor M01.

- one aspect of the present invention is not limited to the configuration example of the semiconductor device 60M described above. Modifications of the semiconductor device 60M described above are described in Figures 27A to 30B.

- the switch S01 may be located in the path between the wiring VLD and the wiring DL.

- a switch having the function of the switch S01 may be provided between the drain side of the transistor M01 and the wiring VLD.

- the switch S01 in the semiconductor device 60M shown in FIG. 23 may be omitted in cases where the period required for the initialization operation is short.

- the potential Vx may be the potential VDD.

- the semiconductor device 60N shown in FIG. 27A is a modified example of the semiconductor device 60M shown in FIG. 23, in which the switch S01 in the semiconductor device 60M shown in FIG. 23 is omitted and a new switch S03 is provided.

- the semiconductor device 60O shown in FIG. 27B is a modified example of the semiconductor device 60M shown in FIG. 23, in which the terminal for applying the potential Vx in the semiconductor device 60M shown in FIG. 23 is connected to the wiring VLD.

- the switch S04 may be located in the path between the wiring VLD and the transistor M02.

- a switch having the function of the switch S04 may be provided between the drain side of the transistor M01 and the switch S01.

- the semiconductor device 60P shown in FIG. 28A is a modified example of the semiconductor device 60M shown in FIG. 23, in which the switch S04 in the semiconductor device 60M shown in FIG. 23 is omitted and a new switch S06 is provided.

- the semiconductor device 60Q shown in FIG. 28B is a modified example of the semiconductor device 60M shown in FIG. 23, in which the switches S03 and S06 are added to the semiconductor device 60M shown in FIG. 23.

- the switches S04, S05, and the transistor M02 can be omitted, as in FIG. 1C described above. Also, in the configuration example of the semiconductor device 60M shown in FIG. 23, the switches S04, S05, and the transistor M02 can be replaced with the configuration of the transistor M02 described in FIG. 7 described above.