WO2019119825A1 - 一种使用石材碎料生产的烧结透水砖及其制备方法 - Google Patents

一种使用石材碎料生产的烧结透水砖及其制备方法 Download PDFInfo

- Publication number

- WO2019119825A1 WO2019119825A1 PCT/CN2018/100126 CN2018100126W WO2019119825A1 WO 2019119825 A1 WO2019119825 A1 WO 2019119825A1 CN 2018100126 W CN2018100126 W CN 2018100126W WO 2019119825 A1 WO2019119825 A1 WO 2019119825A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- stone

- parts

- permeable brick

- fabric

- scrap

- Prior art date

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B33/00—Clay-wares

- C04B33/02—Preparing or treating the raw materials individually or as batches

- C04B33/13—Compounding ingredients

- C04B33/132—Waste materials; Refuse; Residues

- C04B33/1324—Recycled material, e.g. tile dust, stone waste, spent refractory material

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B33/00—Clay-wares

- C04B33/02—Preparing or treating the raw materials individually or as batches

- C04B33/13—Compounding ingredients

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B33/00—Clay-wares

- C04B33/02—Preparing or treating the raw materials individually or as batches

- C04B33/13—Compounding ingredients

- C04B33/1305—Organic additives

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B33/00—Clay-wares

- C04B33/02—Preparing or treating the raw materials individually or as batches

- C04B33/13—Compounding ingredients

- C04B33/131—Inorganic additives

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B33/00—Clay-wares

- C04B33/02—Preparing or treating the raw materials individually or as batches

- C04B33/13—Compounding ingredients

- C04B33/14—Colouring matters

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/622—Forming processes; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/626—Preparing or treating the powders individually or as batches ; preparing or treating macroscopic reinforcing agents for ceramic products, e.g. fibres; mechanical aspects section B

- C04B35/63—Preparing or treating the powders individually or as batches ; preparing or treating macroscopic reinforcing agents for ceramic products, e.g. fibres; mechanical aspects section B using additives specially adapted for forming the products, e.g.. binder binders

- C04B35/6303—Inorganic additives

- C04B35/6316—Binders based on silicon compounds

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/622—Forming processes; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/626—Preparing or treating the powders individually or as batches ; preparing or treating macroscopic reinforcing agents for ceramic products, e.g. fibres; mechanical aspects section B

- C04B35/63—Preparing or treating the powders individually or as batches ; preparing or treating macroscopic reinforcing agents for ceramic products, e.g. fibres; mechanical aspects section B using additives specially adapted for forming the products, e.g.. binder binders

- C04B35/632—Organic additives

- C04B35/634—Polymers

- C04B35/63404—Polymers obtained by reactions only involving carbon-to-carbon unsaturated bonds

- C04B35/63444—Nitrogen-containing polymers, e.g. polyacrylamides, polyacrylonitriles, polyvinylpyrrolidone [PVP], polyethylenimine [PEI]

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/622—Forming processes; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/626—Preparing or treating the powders individually or as batches ; preparing or treating macroscopic reinforcing agents for ceramic products, e.g. fibres; mechanical aspects section B

- C04B35/63—Preparing or treating the powders individually or as batches ; preparing or treating macroscopic reinforcing agents for ceramic products, e.g. fibres; mechanical aspects section B using additives specially adapted for forming the products, e.g.. binder binders

- C04B35/632—Organic additives

- C04B35/636—Polysaccharides or derivatives thereof

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B38/00—Porous mortars, concrete, artificial stone or ceramic ware; Preparation thereof

- C04B38/0038—Porous mortars, concrete, artificial stone or ceramic ware; Preparation thereof by superficial sintering or bonding of particulate matter

- C04B38/0041—Porous mortars, concrete, artificial stone or ceramic ware; Preparation thereof by superficial sintering or bonding of particulate matter the particulate matter having preselected particle sizes

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/70—Aspects relating to sintered or melt-casted ceramic products

- C04B2235/96—Properties of ceramic products, e.g. mechanical properties such as strength, toughness, wear resistance

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P40/00—Technologies relating to the processing of minerals

- Y02P40/60—Production of ceramic materials or ceramic elements, e.g. substitution of clay or shale by alternative raw materials, e.g. ashes

Definitions

- the invention relates to the technical field of water-permeable bricks, in particular to a sintered water-permeable brick produced by using stone scrap material and a preparation method thereof.

- the permeable brick is a new century-old environmental protection building material that was born to alleviate the urban shackles while maintaining moisture and maintaining the ecological balance of the city. It uses solid waste materials such as waste ceramic tiles (waste polished tiles, waste polished glazed tiles, waste tiles, etc.), stone scraps, slag, etc. as the main raw materials, with molding aids, adding appropriate amount of binder, and forming twice by fabric. , high temperature firing, is a green product.

- Permeable bricks can consume a large amount of waste ceramic tiles (solid waste such as stone scrap or slag), which not only solves the problem of solid waste disposal at present, but also greatly reduces environmental pollution.

- the ceramic permeable bricks produced can be directly used in urban construction and turned into waste. Therefore, it has obvious social significance.

- the permeable bricks are divided into sintered permeable bricks and concrete permeable bricks, wherein the sintered permeable bricks need to be fired at a high temperature, and the concrete permeable bricks do not need to be fired at a high temperature.

- Prior Art 1 is an invention patent disclosed in CN 101955349 B, which discloses a water permeable brick which uses ceramic waste powder, waste glass powder, waste porcelain powder, municipal base waste powder, and oxidation.

- Calcium, calcium sulphate, bentonite, talc powder, waste ash powder, waste plant powder and water are used as raw materials, stirred in a wet state, and then mechanically vibrated and extruded into a permeable brick lower layer brick, and then used a secondary cloth machine in the permeable water

- the upper part of the brick under the brick is evenly covered with a layer of fine fabric (the main component is waste ceramic chip powder, bentonite, water), and then it is made into a ceramic waste slag sintered water-permeable green brick under the pressure of 25-30 MPa for natural drying.

- the ceramic slag permeable and environmentally-friendly bricks which have been naturally dried are sent to a tunnel kiln for roasting, and the temperature is controlled to be fired in the range of 1150 to 1200 °C.

- the municipal base waste sludge fine powder and bentonite are binders.

- the waste ceramic chip powder is added in an amount of 20-30 parts

- the bentonite is added in an amount of 5-8 parts

- the municipal base waste mud powder is added in an amount of 20-30 parts, that is, waste.

- the ceramic chip powder is added in an amount of about 20 to 30 parts

- the binder is added in an amount of about 25 to 38 parts.

- the waste ceramic chip powder is added in a small amount, the binder is used in a large amount, and the ultimate load of the binder is low, resulting in low strength of the green body after molding.

- the raw material of the permeable brick disclosed in the prior art 2 is mainly waste polished brick, and the raw material is formulated as: 10-40 parts of waste tile, 66-130 parts of binder, wherein the binder comprises 60-90 parts of bentonite, frit (glass powder, etc.) 5-20 parts, sodium carboxymethyl cellulose 1-20 parts.

- the amount of waste tile added is extremely small, and the amount of the binder is extremely large.

- the ultimate load of the binder is relatively low, generally around 64.8 N, resulting in low strength of the green body after molding.

- the existing permeable bricks have a complicated process, many production processes, long time and high cost, and the process flow chart is shown in FIG. 1 .

- the existing permeable brick adhesive requires a separate ball mill.

- the ball milling process has a long operation time, and the ball mill has a large volume and a large floor area, which greatly increases the production cost of the permeable brick.

- the technical problem to be solved by the present invention is to provide a sintered water-permeable brick produced by using stone scrap material, which has high strength, strong frost resistance and excellent water permeability.

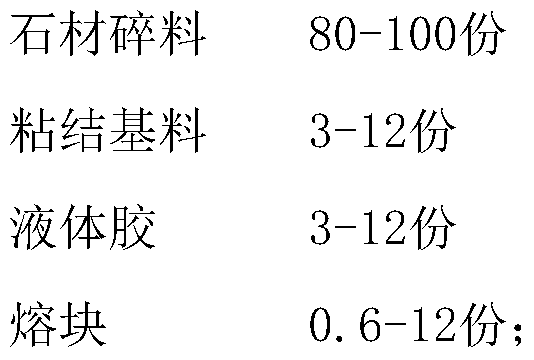

- the present invention provides a sintered water permeable brick produced using stone scrap, comprising a fabric and a bottom material, wherein the main raw materials of the base material in parts by mass are as follows:

- Liquid glue 3-12 parts

- the bonding base is one or more of bentonite and clay

- the liquid glue is one or more of a silica sol solution, a polyacrylamide solution, and a guar gum solution;

- the main raw materials of the fabric in parts by mass are as follows:

- the bonding base is one or more of bentonite and clay

- the liquid glue is one or more of a silica sol solution, a polyacrylamide solution, and a guar gum solution.

- the fabric and the base material are included, wherein the main raw materials of the base material in parts by mass are as follows:

- the bonding base is one or more of bentonite and clay

- the liquid glue is one or more of a silica sol solution, a polyacrylamide solution, and a guar gum solution;

- the main raw materials of the fabric in parts by mass are as follows:

- the bonding base is one or more of bentonite and clay

- the liquid glue is one or more of a silica sol solution, a polyacrylamide solution, and a guar gum solution.

- the polyacrylamide solution is one or more of sodium polyacrylate, polyvinylpyridine salt, and polyethyleneimine.

- the clay is one or more of kaolin, black mud, and municipal municipal sludge.

- the stone scrap material comprises one or more of granite, Luoyuan red, quartz stone, porcelain stone, potassium feldspar or albite waste.

- the weight ratio of the primer to the fabric is 70-100:0-30.

- the stone scrap of the fabric comprises:

- the stone scrap of the primer comprises:

- the present invention also provides a method for preparing a sintered water permeable brick produced by using stone scrap, comprising:

- steps (1) and (2) the stone material is subjected to preliminary crushing and sieving treatment to obtain a stone scrap of the target particle size

- the granulated stone granules after sieving shall be compounded according to the base material formula, added with the binder base and liquid glue, and stirred evenly to obtain the bottom material; the sifted stone granules after sieving, according to the fabric formula The ingredients are added, the binder base, the liquid glue and the colorant are added, and the mixture is uniformly stirred to obtain a fabric;

- the body is fired in a kiln to obtain a finished product.

- the pressure of the press is 1500-2000T;

- the firing temperature is 1100-1220 °C.

- the invention uses the stone scrap as the main raw material, and the amount of the stone scrap is much higher than that of the ordinary permeable brick, and the amount of the stone scrap is >85%, which can consume a large amount of granite, Luoyuan red, quartz stone, porcelain stone, potassium feldspar or Stone scraps such as albite and stone, to achieve the purpose of highly recycling solid waste, turning waste into treasure, environmental protection and energy saving.

- the binder comprises a binder base and a liquid glue

- the binder base may be one or more of bentonite, kaolin, black mud or municipal municipal sludge

- the binder of the invention is innovatively added to the liquid glue.

- the ultimate load of the binder is greatly increased.

- the ultimate load of the binder of the invention is up to 150.8 N, which improves the strength of the green body of the permeable brick.

- the binder of the invention makes the blank easy to form and simplifies the forming process. The difficulty of molding is reduced; finally, the binder of the invention is simple to operate, and only simple mixing is required, and the step of ball milling is not required to be mixed, the process is simplified, and the cost is reduced.

- the preparation method of the permeable brick of the invention comprises the steps of raw material crushing, sieving, compounding, mixing, pressing, pressing and the like, and the invention does not need ball milling, simplifies the process, reduces the cost, shortens the production time, and is obtained by the above preparation method.

- the permeable brick has high strength, excellent water permeability and strong frost resistance.

- 1 is a process flow diagram of a conventional sintered water permeable brick produced using stone scrap material

- FIG. 2 is a process flow diagram of a sintered water permeable brick produced by using the stone scrap material of the present invention.

- the invention provides a sintered water permeable brick produced by using stone scrap material, comprising a fabric and a bottom material, wherein the weight ratio of the base material to the fabric is 70-100:0-30.

- the weight ratio of the primer to the fabric is 80-90:10-20.

- the permeable brick only includes the bottom layer, which is made into a whole body brick.

- the permeable brick requires color, the permeable brick includes a top layer and a bottom layer, and the weight ratio of the bottom material mixture to the fabric mixture is 70-99.9: 0.1-30.

- the main raw materials of the bottom material in parts by mass are as follows:

- Liquid glue 3-12 parts

- the bonding base is one or more of bentonite and clay

- the liquid glue is one or more of a silica sol solution, a polyacrylamide solution, and a guar gum solution.

- the main raw materials of the fabric in parts by mass are as follows:

- the bonding base is one or more of bentonite and clay

- the liquid glue is one or more of a silica sol solution, a polyacrylamide solution, and a guar gum solution.

- the amount of stone scrap is much higher than that of ordinary permeable bricks.

- the amount of stone scrap is >85%, which can consume a large amount of stone scrap such as granite, Luoyuan red, quartz stone, porcelain stone, potassium feldspar or albite waste.

- the purpose of highly recycling solid waste is to turn waste into treasure, environmental protection and energy saving.

- the invention selects a specific binder, which is composed of a binder base and a liquid glue, wherein the binder base has plasticity, can help shape and strengthen the strength of the body, and the liquid glue can make the stone scrap and the binder base.

- the combination is closer. The combination of the two ensures that the permeable brick has good strength and good firing performance in the production process.

- the strength of the permeable brick of the present invention mainly refers to two stages: one stage is the forming strength after the forming of the press (mainly to ensure that the formed body is not easily broken before firing), and the other is the strength of the finished product after firing. (Mainly the final performance of the product, how much pressure the product can withstand, such as whether the car can be directly pressed, etc.).

- the liquid glue of the invention is mainly used for ensuring the forming property and the forming strength of the formulation; the bonding base is mainly capable of bonding between the particles and the particles after being sintered at a high temperature, and is used for ensuring the strength of the final product.

- the main raw materials of the primer in parts by mass are as follows:

- the bonding base is one or more of bentonite and clay

- the liquid glue is one or more of a silica sol solution, a polyacrylamide solution, and a guar gum solution.

- the main raw materials of the fabric in parts by mass are as follows:

- the bonding base is one or more of bentonite and clay

- the liquid glue is one or more of a silica sol solution, a polyacrylamide solution, and a guar gum solution.

- the binder is further added to the frit, ie,

- the main raw materials of the bottom material in parts by mass are as follows:

- the bonding base is one or more of bentonite and clay

- the liquid glue is one or more of a silica sol solution, a polyacrylamide solution, and a guar gum solution;

- the main raw materials of the fabric in parts by mass are as follows:

- the bonding base is one or more of bentonite and clay

- the liquid glue is one or more of a silica sol solution, a polyacrylamide solution, and a guar gum solution.

- the strength of the product can be improved and the firing temperature of the permeable brick can be lowered.

- the polyacrylamide solution is preferably one or more of sodium polyacrylate, polyvinylpyridine salt, and polyethyleneimine.

- the invention selects a polymer organic binder such as sodium polyacrylate, polyvinylpyridinium salt or polyethyleneimine, so that the liquid glue can fully wrap the surface of the permeable brick stone scrap particles and improve the strength of the permeable brick.

- the clay is one or more of kaolin, black mud, and municipal municipal sludge.

- the present invention can not only use bentonite, but also use clay such as kaolin, black mud, and municipal municipal sludge, which greatly improves the convenience of application and is rich in raw materials.

- the performance of the binder of the present invention and the existing binder is as follows when the binder is added in the same amount:

- the adhesive of the invention is innovatively added to the liquid glue, firstly increasing the ultimate load of the binder, and the ultimate load of the binder of the invention is up to 150.8 N, which improves the strength of the green body of the permeable brick; secondly, the bonding of the invention

- the agent makes the blank easy to form, simplifies the molding process, and reduces the difficulty of molding; finally, the binder of the invention is simple to operate, and only needs simple mixing, no need to pre-mix the ball milling step, simplify the process, and reduce the cost.

- the present invention uses stone scrap as a main raw material, and the stone scrap includes one or more of granite, Luoyuan red, quartz stone, porcelain stone, potassium feldspar or albite waste.

- the stone scrap material comprises any one of granite, Luoyuan red, quartz stone, porcelain stone, potassium feldspar or albite waste.

- the stone scrap is selected with a specific particle size, as follows:

- the stone scrap in the fabric mix includes:

- the stone scrap in the fabric mixture is selected from 4-20 mesh stone scraps, and the particle grading helps the finished product to form holes, achieves a water permeable effect, and obtains good appearance performance and comfort.

- the fabric particles are too large, on the one hand, the surface of the finished product is too rough, which is not suitable for the use of square tiles.

- the flatness of the surface of the brick will be poor, especially the edge position is not Leveling, paving out the aesthetics and tightness.

- the fabric particles are too small, the water-permeable holes formed between the particles and the particles will be very small, which is easy to cause the permeable brick holes to be easily blocked by sewage or sand, etc., and affect the water permeability of the product after a period of use.

- the stone scrap in the primer mix includes:

- the stone scraps in the bottom material mixture are selected from 4-20 mesh, 12-40 mesh and ⁇ 40 mesh stone scraps, and the stone scraps of 4-20 mesh, 12-40 mesh and ⁇ 40 mesh are matched according to a certain ratio. Mixing, this particle grading helps the finished product to form holes and achieve a water permeable effect. Moreover, in the case of satisfying the final strength of the product, the broken materials can be used up as much as possible, leaving no surplus material, saving costs and avoiding waste.

- the present invention also provides a method for preparing a sintered water-permeable brick produced by using stone scrap, comprising:

- steps (1) and (2) the stone scrap is subjected to preliminary crushing and sieving treatment to obtain a stone scrap of the target particle size.

- the granulated stone granules after sieving shall be compounded according to the base material formula, added with the binder base and liquid glue, and stirred evenly to obtain the bottom material; the sifted stone granules after sieving, according to the fabric formula The ingredients are added, the binder base, the liquid glue and the color material are added, and the mixture is uniformly stirred to obtain a fabric;

- the pressure of the press is 1500-2000T.

- the pressure of the press is 1600-1800T.

- the body is fired in a kiln to obtain a finished product.

- the firing temperature is 1100-1220 °C.

- the firing temperature is from 1120 to 1200 °C.

- the compressive strength of the present invention is measured by a YQ027SHT4305 microcomputer controlled electro-hydraulic servo tester under the conditions of a temperature of 27 ° C and a humidity of 53%.

- the sample size of the permeable brick sample is as follows: length 68 mm, width 64mm.

- the detection standard for frost resistance is carried out in accordance with the standard JG/T 376-2012.

- the compressive strength of the present invention is significantly improved, the water permeability coefficient is also significantly improved, and the frost resistance is also good, wherein after 25 freeze-thaw cycles, the mass loss Less, less strength loss.

- the bonding base is bentonite, and the liquid glue is a silica sol solution;

- the main raw materials of the fabric in parts by mass are as follows:

- the bonding base is bentonite, and the liquid glue is a silica sol solution;

- the green body is fired in a kiln, and the firing temperature is 1100 ° C to obtain a finished product.

- the binder base is kaolin, and the liquid glue is sodium polyacrylate;

- the main raw materials of the fabric in parts by mass are as follows:

- the binder base is black mud

- the liquid glue is a polyvinylpyridine salt

- the green body is fired in a kiln, and the firing temperature is 1180 ° C to obtain a finished product.

- the bonding base is a municipal municipal sludge, and the liquid glue is a guar gum solution;

- the main raw materials of the fabric in parts by mass are as follows:

- the bonding base is a municipal municipal sludge, and the liquid glue is a guar gum solution;

- the green body is fired in a kiln, and the firing temperature is 1200 ° C to obtain a finished product.

- the bonding base is bentonite, and the liquid glue is a silica sol solution;

- the main raw materials of the fabric in parts by mass are as follows:

- the bonding base is bentonite, and the liquid glue is polyethyleneimine.

- the green body is fired in a kiln, and the firing temperature is 1210 ° C to obtain a finished product.

- the bonding base is bentonite, and the liquid glue is sodium polyacrylate;

- the agitated bottom material is subjected to fabric and press-molding, and the pressure of the press is 2000T to obtain a green body;

- the green body is fired in a kiln, and the firing temperature is 1220 ° C to obtain a finished product.

- the sintered permeable brick of the invention has a compressive strength ⁇ 55 MPa, a water permeability coefficient ⁇ 4.2 * 10 -2 , and the mass loss and compressive strength loss rate after 25 freeze-thaw cycles are very small, which proves that the frost resistance is good.

- the invention uses the stone scrap as the main raw material, and the amount of the stone scrap is much higher than that of the ordinary permeable brick, and the amount of the stone scrap is >85%, which can consume a large amount of granite, Luoyuan red, quartz stone, porcelain stone, potassium feldspar or Stone scraps such as albite and stone, to achieve the purpose of highly recycling solid waste, turning waste into treasure, environmental protection and energy saving.

- the binder comprises a binder base and a liquid glue

- the binder base may be one or more of bentonite, kaolin, black mud or municipal municipal sludge

- the binder of the invention is innovatively added to the liquid glue.

- the ultimate load of the binder is greatly increased.

- the ultimate load of the binder of the invention is up to 150.8 N, which improves the strength of the green body of the permeable brick.

- the binder of the invention makes the blank easy to form and simplifies the forming process. The difficulty of molding is reduced; finally, the binder of the invention is simple to operate, and only simple mixing is required, and the step of ball milling is not required to be mixed, the process is simplified, and the cost is reduced.

- the preparation method of the permeable brick of the invention comprises the steps of raw material crushing, sieving, compounding, mixing, pressing, pressing and the like, and the invention does not need ball milling, simplifies the process, reduces the cost, shortens the production time, and is obtained by the above preparation method.

- the permeable brick has high strength, excellent water permeability and strong frost resistance.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Ceramic Engineering (AREA)

- Materials Engineering (AREA)

- Structural Engineering (AREA)

- Organic Chemistry (AREA)

- Manufacturing & Machinery (AREA)

- Inorganic Chemistry (AREA)

- Dispersion Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Environmental & Geological Engineering (AREA)

- Compositions Of Oxide Ceramics (AREA)

Abstract

一种使用石材碎料生产的烧结透水砖及制备方法,包括面料和底料。以质量份计,底料的主要原料包括:石材碎料80-100份、粘结基料3-12份、液体胶3-12份;面料的主要原料包括:石材碎料0-30份、粘结基料0-4份、液体胶0-4份、色料0-4份。粘结基料为膨润土、粘土中的一种或多种;液体胶为硅溶胶溶液、聚丙烯酰胺溶液、瓜尔豆胶溶液的一种或多种。将石材碎料破碎、过筛、按照配方称取底料和面料,搅拌均匀后经两次布料,压制成型得坯体,烧制得成品。所得透水砖的强度高、抗冻性强、透水性优异。

Description

本发明涉及透水砖技术领域,尤其涉及一种使用石材碎料生产的烧结透水砖及其制备方法。

透水砖是为缓解城市内涝,同时保持水分,维护城市生态平衡构建海绵城市而隆重诞生的世纪环保建材新产品。它采用废瓷砖(废抛光砖、废抛釉砖、废瓷片等)、石材碎料、矿渣等固体废料为主要原料,配以成型助剂,添加适量的粘结剂,经两次布料成型,高温烧成,是绿色环保产品。

透水砖可以消耗大量废瓷砖(石材碎料或矿渣等固体废料),这不仅解决了现阶段固体废料的处理难题,还大大减小了对环境的污染。生产出来的陶瓷透水砖能直接用于城市建设,变废为宝。因此,具有明显的社会意义。

透水砖分为烧结类透水砖和混凝土类透水砖,其中烧结类透水砖是需要经过高温烧成,而混凝土类透水砖无需经过高温烧成。

现有技术1是公开号为CN 101955349 B的发明专利,其公开了一种透水砖,透水砖采用陶瓷废渣粉料、废玻璃粉料、废瓷碎片粉料、市政基础废泥粉料、氧化钙、硫酸钙、膨润土、滑石粉、垃圾灰渣粉料、废植物粉料和水为原料,搅拌呈潮湿状后用机械振动挤压成型为透水砖下层砖,再用二次布料机在透水砖下层砖的上部均匀布上一层细面料(主要成分为废陶瓷碎片粉料、膨润土、水),然后在25~30MPa的压力下制造成陶瓷废渣烧结透水环保砖坯,进行自然干燥。再将成型经自然干燥后的陶瓷废渣透水环保砖坯送进隧道窑进行焙烧,温度控制在1150~1200℃范围内烧制成。上述方案中,市政基础废泥渣细粉和膨润土为粘结剂。现有技术1中,废陶瓷碎片粉料的加入量为20-30份,膨润土的加入量为5-8份,市政基础废泥粉料的加入量为20-30份,也就是说,废陶瓷碎片粉料的加入量大概为20-30份,粘结剂的加入量大概为25-38份。废陶瓷碎片粉料的加入量较少,粘结剂用量较多,且所述粘结剂的极限荷载较低,导致成型后的坯体强度低。

现有技术2公开的透水砖的原材料主要为废抛光砖,原材料的配方为:废瓷砖10-40份、 粘结剂66-130份,其中,粘结剂包括膨润土60-90份、熔块(玻璃粉等)5-20份、羧甲基纤维素钠1-20份。现有技术中,废瓷砖的加入量极少,粘结剂用量极多。且所述粘结剂的极限荷载较低,一般在64.8N左右,导致成型后的坯体强度低。

另外,现有透水砖的工艺流程较为复杂,生产工序多,耗时长,成本高,其工艺流程图如图1所示。参见图1,现有的透水砖的粘结剂需要单独的球磨,但是,球磨工序操作时间长,球磨设备体积庞大,占地面积大,这样将大大增加了透水砖的生产成本。

发明内容

本发明所要解决的技术问题在于,提供一种使用石材碎料生产的烧结透水砖,所述透水砖的强度高、抗冻性强、透水性优异。

为了解决上述技术问题,本发明提供了一种使用石材碎料生产的烧结透水砖,包括面料和底料,其中,所述底料以质量份计的主要原料如下:

石材碎料 80-100份

粘结基料 3-12份

液体胶 3-12份;

所述粘结基料为膨润土、粘土中的一种或多种;

所述液体胶为硅溶胶溶液、聚丙烯酰胺溶液、瓜尔豆胶溶液的一种或多种;

所述面料以质量份计的主要原料如下:

所述粘结基料为膨润土、粘土中的一种或多种;

所述液体胶为硅溶胶溶液、聚丙烯酰胺溶液、瓜尔豆胶溶液的一种或多种。

作为上述方案的改进,包括面料和底料,其中,所述底料以质量份计的主要原料如下:

所述粘结基料为膨润土、粘土中的一种或多种;

所述液体胶为硅溶胶溶液、聚丙烯酰胺溶液、瓜尔豆胶溶液的一种或多种;

所述面料以质量份计的主要原料如下:

所述粘结基料为膨润土、粘土中的一种或多种;

所述液体胶为硅溶胶溶液、聚丙烯酰胺溶液、瓜尔豆胶溶液的一种或多种。作为上述方案的改进,所述聚丙烯酰胺溶液为聚丙烯酸钠、聚乙烯吡啶盐、聚乙烯亚胺中的一种或多种。

作为上述方案的改进,所述粘土为高岭土、黑泥、城市市政污泥中的一种或多种。

作为上述方案的改进,所述石材碎料包括花岗岩、罗源红、石英石、瓷石、钾长石或钠长石废料中的一种或几种。

作为上述方案的改进,所述底料与面料的用量重量比为70-100:0-30。

作为上述方案的改进,所述面料的石材碎料包括:

4-20目石材碎料 100wt%。

作为上述方案的改进,所述底料的石材碎料包括:

4-20目石材碎料 20-50wt%

12-40目石材碎料 20-50wt%

<40目石材碎料 0-60wt%。

相应的,本发明还提供一种使用石材碎料生产的烧结透水砖的制备方法,包括:

(一)将石材碎料破碎;

(二)将破碎后的石材碎料过筛,筛分出不同颗粒度范围的颗粒;

步骤(一)和(二),将石材碎料进行初步的破碎和过筛处理,得到目标颗粒粒径的石材碎料;

(三)将过筛后的石材碎料颗粒,按底料配方进行配料,加入粘结基料、液体胶,并搅拌均匀,得到底料;将过筛后的石材碎料颗粒,按面料配方进行配料,加入粘结基料、 液体胶和色料,并搅拌均匀,得到面料;

(四)将搅拌后的面料和底料经两次布料并压制成型,得到坯体;

(五)将坯体在窑炉内经过烧制,得到成品。

作为上述方案的改进,所述压制成型步骤中,压机的压力为1500-2000T;

所述烧制步骤中,烧制的温度为1100-1220℃。

实施本发明,具有如下有益效果:

本发明使用石材碎料为主要原料,石材碎料的用量比普通的透水砖要高很多,石材碎料的用量>85%,可以大量消耗花岗岩、罗源红、石英石、瓷石、钾长石或钠长石等石材碎料,达到高度回收利用固体废料的目的,变废为宝,环保节能。

所述粘结剂包括粘结基料和液体胶,粘结基料可以是膨润土、高岭土、黑泥或城市市政污泥中的一种或多种,本发明粘结剂创新性地加入液体胶,首先大大增加了粘结剂的极限荷载,本发明粘结剂的极限荷载高达150.8N,提高了透水砖的坯体强度;其次,本发明粘结剂使得坯体易成型,简化成型的工序,降低成型的难度;最后,本发明粘结剂操作简单,只需简单混料即可,无需预先混合球磨的步骤,简化工序,降低成本。

本发明透水砖的制备方法包括原料破碎、筛分、配料、混料搅拌、压制成型、烧制等步骤,本发明无需球磨,简化工序,降低成本,缩短生产时间,且经过上述制备方法制得的透水砖,其强度高、透水性优异、抗冻性强。

图1是现有使用石材碎料生产的烧结透水砖的工艺流程图;

图2是本发明使用石材碎料生产的烧结透水砖的工艺流程图。

为使本发明的目的、技术方案和优点更加清楚,下面将结合附图对本发明作进一步地详细描述。

本发明提供了一种使用石材碎料生产的烧结透水砖,包括面料和底料,所述底料与面料的用量重量比为70-100:0-30。优选的,所述底料与面料的用量重量比为80-90:10-20。当面料混合料为0时,透水砖只包括底层,其制成通体砖。当透水砖需要颜色时,透水砖包括面层和底层,底料混合料与面料混合料的用量重量比为70-99.9:0.1-30。

其中,所述底料以质量份计的主要原料如下:

石材碎料 80-100份

粘结基料 3-12份

液体胶 3-12份;

所述粘结基料为膨润土、粘土中的一种或多种;

所述液体胶为硅溶胶溶液、聚丙烯酰胺溶液、瓜尔豆胶溶液的一种或多种。

所述面料以质量份计的主要原料如下:

所述粘结基料为膨润土、粘土中的一种或多种;

所述液体胶为硅溶胶溶液、聚丙烯酰胺溶液、瓜尔豆胶溶液的一种或多种。

石材碎料的用量比普通的透水砖要高很多,石材碎料的用量>85%,可以大量消耗花岗岩、罗源红、石英石、瓷石、钾长石或钠长石废料等石材碎料,达到高度回收利用固体废料的目的,变废为宝,环保节能。

由于目前国家环保压力加大,很多石材加工企业处于停产状态,达标的企业产生的石材碎料也只有少部分用于铺路等基础设施,大量的石材碎料处于露天堆放状态,既占用了大量的土地也会在长时间的风化过程中污染环境。所以使用石材碎料相当于是废物利用,是利国利民的好事。

本发明选用特定的粘结剂,其由粘结基料和液体胶组成,其中,粘结基料具有可塑性,可帮助成型及增强坯体强度,液体胶可以使石材碎料和粘结基料的结合更为紧密。二者配合,可以确保透水砖在生产过程中具有好的强度及好的烧成性能。

具体的,本发明透水砖的强度主要是分别指两个阶段:一个阶段是压机成型后的成型强度(主要是保障成型坯体在烧成前不易破损),一个是烧成后的成品强度(主要是产品最终的使用性能,产品使用时能够承受多大的压力,比如车能不能直接压上去等)。本发明液体胶主要是用于保障配方的成型性能及成型强度;粘结基料主要是经过高温烧结后能够在颗粒与颗粒之间起到粘结作用,是用于保障最终产品的强度。

作为本发明优选的实施方式,所述底料以质量份计的主要原料如下:

石材碎料 90-96份

粘结基料 5-8份

液体胶 5-8份;

所述粘结基料为膨润土、粘土中的一种或多种;

所述液体胶为硅溶胶溶液、聚丙烯酰胺溶液、瓜尔豆胶溶液的一种或多种。

所述面料以质量份计的主要原料如下:

所述粘结基料为膨润土、粘土中的一种或多种;

所述液体胶为硅溶胶溶液、聚丙烯酰胺溶液、瓜尔豆胶溶液的一种或多种。

作为本发明更佳的实施方式,所述粘结剂还加入熔块,即,

所述底料以质量份计的主要原料如下:

所述粘结基料为膨润土、粘土中的一种或多种;

所述液体胶为硅溶胶溶液、聚丙烯酰胺溶液、瓜尔豆胶溶液的一种或多种;

所述面料以质量份计的主要原料如下:

所述粘结基料为膨润土、粘土中的一种或多种;

所述液体胶为硅溶胶溶液、聚丙烯酰胺溶液、瓜尔豆胶溶液的一种或多种。

本发明加入熔块后,可以提高产品强度及降低透水砖的烧成温度。

在上述任一配方中,所述聚丙烯酰胺溶液优选为聚丙烯酸钠、聚乙烯吡啶盐、聚乙烯亚胺中的一种或多种。本发明选用聚丙烯酸钠、聚乙烯吡啶盐、聚乙烯亚胺等高分子有机粘结剂,使得液体胶可以充分包裹透水砖石材碎料颗粒的表面,提高透水砖的强度。

所述粘土为高岭土、黑泥、城市市政污泥中的一种或多种。本发明不单可以使用膨润土,还可以使用高岭土、黑泥、城市市政污泥等粘土,大大提高了应用的便利性,原料来源丰富。

粘结剂在加入等量的情况下,本发明粘结剂与现有粘结剂的性能对比如下:

| 粘结剂 | 测试坯体尺寸(mm) | 极限荷载(N) | 成本 |

| 市场现有粘结剂 | 80×40×15 | 62-65 | 7.92元/平方 |

| 本发明粘结剂 | 80×40×15 | 150-160 | 3.2元/平方 |

本发明粘结剂创新性地加入液体胶,首先大大增加了粘结剂的极限荷载,本发明粘结剂的极限荷载高达150.8N,提高了透水砖的坯体强度;其次,本发明粘结剂使得坯体易成型,简化成型的工序,降低成型的难度;最后,本发明粘结剂操作简单,只需简单混料即可,无需预先混合球磨的步骤,简化工序,降低成本。

进一步,本发明使用石材碎料作为主要原料,所述石材碎料包括花岗岩、罗源红、石英石、瓷石、钾长石或钠长石废料中的一种或几种。优选的,所述石材碎料包括花岗岩、罗源红、石英石、瓷石、钾长石或钠长石废料中的任意一种。

为了改善透水砖的强度,提高透水砖坯体的成型性能,所述石材碎料选用特定颗粒度搭配,具体如下:

所述面料混合料中的石材碎料包括:

4-20目石材碎料 100wt%。

所述面料混合料中的石材碎料选用4-20目的石材碎料,这种颗粒级配有助于成品形成孔洞,达到透水效果,而且获得良好的外观性能和舒适度。

如果面料颗粒太大,一方面成品表面太粗糙,不适合于广场砖使用,人走到上面或者单车骑在上面影响舒适度,另一方面,砖坯表面的平整度会比较差,尤其边缘位置不平整,铺贴出来美观度和密合度较差。

如果面料颗粒太小,则颗粒与颗粒之间形成的透水孔会非常小,这样容易造成透水砖孔很易被污水或者砂粒等堵塞,经过一段时间使用后影响产品的透水性能。

所述底料混合料中的石材碎料包括:

4-20目石材碎料 20-50wt%

12-40目石材碎料 20-50wt%

<40目石材碎料 0-60wt%。

所述底料混合料中的石材碎料选用4-20目、12-40目以及<40目的石材碎料,并且4-20目、12-40目以及<40目的石材碎料按一定配比混合,这种颗粒级配有助于成品形成孔洞,达到透水效果。而且,在满足产品最终强度的情况下还可以尽可能让破碎出来的料都基本能用完,不留有余料,节约成本,避免浪费。

相应的,如图2所示,本发明还提供一种使用石材碎料生产的烧结透水砖的制备方法,包括:

(一)将石材碎料破碎。

(二)将破碎后的石材碎料过筛,筛分出不同颗粒度范围的颗粒。

步骤(一)和(二),将石材碎料进行初步的破碎和过筛处理,得到目标颗粒粒径的石材碎料。

(三)将过筛后的石材碎料颗粒,按底料配方进行配料,加入粘结基料、液体胶,并搅拌均匀,得到底料;将过筛后的石材碎料颗粒,按面料配方进行配料,加入粘结基料、液体胶和色料,并搅拌均匀,得到面料;

(四)将搅拌后的面料和底料经两次布料并压制成型,得到坯体;

所述压制成型步骤中,压机的压力为1500-2000T。优选的,压机的压力为1600-1800T。

(五)将坯体在窑炉内经过烧制,得到成品。

所述烧制步骤中,烧制的温度为1100-1220℃。优选的,烧制的温度为1180-1200℃。

本发明制得的透水砖与现有透水砖,其性能对比如下:

需要说明的是,本发明抗压强度在是温度27℃、湿度53%的条件下,通过YQ027SHT4305微机控制电液伺服试验机测得,所述透水砖的试样样品规格如下:长68mm、宽64mm。抗冻性的检测标准参照标准JG/T 376-2012进行。

由上可知,与现有技术相比,本发明的抗压强度有了显著的提升,透水系数也有了显著了改善,且抗冻性也好,其中,经过25次冻融循环后,质量损失少,强度损失少。

下面以具体实施例进一步阐述本发明

实施例1

(一)配方:包括面料和底料,其中,所述底料以质量份计的主要原料如下:

所述粘结基料为膨润土,所述液体胶为硅溶胶溶液;

所述面料以质量份计的主要原料如下:

所述粘结基料为膨润土,所述液体胶为硅溶胶溶液;

(二)制备方法

(1)将石材碎料破碎;

(2)将破碎后的石材碎料过筛,筛分出不同颗粒度范围的颗粒;

(3)将过筛后的石材碎料颗粒,按底料配方进行配料,加入粘结基料、液体胶,并搅拌均匀,得到底料;将过筛后的石材碎料颗粒,按面料配方进行配料,加入粘结基料、液体胶和色料,并搅拌均匀,得到面料;

(4)将搅拌后的面料和底料经两次布料并压制成型,压机的压力为1500T,得到坯体;

(5)将坯体在窑炉内经过烧制,烧制的温度为1100℃,得到成品。

实施例2

(一)配方:包括面料和底料,其中,所述底料以质量份计的主要原料如下:

所述粘结基料为高岭土,所述液体胶为聚丙烯酸钠;

所述面料以质量份计的主要原料如下:

所述粘结基料为黑泥,所述液体胶为聚乙烯吡啶盐;

(二)制备方法

(1)将石材碎料破碎;

(2)将破碎后的石材碎料过筛,筛分出不同颗粒度范围的颗粒;

(3)将过筛后的石材碎料颗粒,按底料配方进行配料,加入粘结基料、液体胶,并搅拌均匀,得到底料;将过筛后的石材碎料颗粒,按面料配方进行配料,加入粘结基料、液体胶和色料,并搅拌均匀,得到面料;

(4)将搅拌后的面料和底料经两次布料并压制成型,压机的压力为1800T,得到坯体;

(5)将坯体在窑炉内经过烧制,烧制的温度为1180℃,得到成品。

实施例3

(一)配方:包括面料和底料,其中,所述底料以质量份计的主要原料如下:

所述粘结基料为城市市政污泥,所述液体胶为瓜尔豆胶溶液;

所述面料以质量份计的主要原料如下:

所述粘结基料为城市市政污泥,所述液体胶为瓜尔豆胶溶液;

(二)制备方法

(1)将石材碎料破碎;

(2)将破碎后的石材碎料过筛,筛分出不同颗粒度范围的颗粒;

(3)将过筛后的石材碎料颗粒,按底料配方进行配料,加入粘结基料、液体胶,并搅拌均匀,得到底料;将过筛后的石材碎料颗粒,按面料配方进行配料,加入粘结基料、液体胶和色料,并搅拌均匀,得到面料;

(4)将搅拌后的面料和底料经两次布料并压制成型,压机的压力为1900T,得到坯体;

(5)将坯体在窑炉内经过烧制,烧制的温度为1200℃,得到成品。

实施例4

(一)配方:包括面料和底料,其中,所述底料以质量份计的主要原料如下:

所述粘结基料为膨润土,所述液体胶为硅溶胶溶液;

所述面料以质量份计的主要原料如下:

所述粘结基料为膨润土,所述液体胶为聚乙烯亚胺。

(二)制备方法

(1)将石材碎料破碎;

(2)将破碎后的石材碎料过筛,筛分出不同颗粒度范围的颗粒;

(3)将过筛后的石材碎料颗粒,按底料配方进行配料,加入粘结基料、液体胶,并搅拌均匀,得到底料;将过筛后的石材碎料颗粒,按面料配方进行配料,加入粘结基料、液体胶和色料,并搅拌均匀,得到面料;

(4)将搅拌后的面料和底料经两次布料并压制成型,压机的压力为1900T,得到坯体;

(5)将坯体在窑炉内经过烧制,烧制的温度为1210℃,得到成品。

实施例5

(一)配方:包括底料,其中,所述底料以质量份计的主要原料如下:

所述粘结基料为膨润土,所述液体胶为聚丙烯酸钠;

(二)制备方法

(1)将石材碎料破碎;

(2)将破碎后的石材碎料过筛,筛分出不同颗粒度范围的颗粒;

(3)将过筛后的石材碎料颗粒,按底料配方进行配料,加入粘结基料、液体胶,并搅拌均匀,得到底料;

(4)将搅拌后的底料经布料并压制成型,压机的压力为2000T,得到坯体;

(5)将坯体在窑炉内经过烧制,烧制的温度为1220℃,得到成品。

将实施例1-5做技术检测,结果如下:

由上可知,本发明烧结透水砖,抗压强度≥55MPa,透水系数≥4.2*10

-2,且25次冻融循环后质量损失和抗压强度损失率都非常小,证明抗冻性好。

综上所述,实施本发明,具有如下有益效果:

本发明使用石材碎料为主要原料,石材碎料的用量比普通的透水砖要高很多,石材碎料的用量>85%,可以大量消耗花岗岩、罗源红、石英石、瓷石、钾长石或钠长石等石材碎料,达到高度回收利用固体废料的目的,变废为宝,环保节能。

所述粘结剂包括粘结基料和液体胶,粘结基料可以是膨润土、高岭土、黑泥或城市市政污泥中的一种或多种,本发明粘结剂创新性地加入液体胶,首先大大增加了粘结剂的极限荷载,本发明粘结剂的极限荷载高达150.8N,提高了透水砖的坯体强度;其次,本发明粘结剂使得坯体易成型,简化成型的工序,降低成型的难度;最后,本发明粘结剂操作简单,只需简单混料即可,无需预先混合球磨的步骤,简化工序,降低成本。

本发明透水砖的制备方法包括原料破碎、筛分、配料、混料搅拌、压制成型、烧制等步骤,本发明无需球磨,简化工序,降低成本,缩短生产时间,且经过上述制备方法制得的透水砖,其强度高、透水性优异、抗冻性强。

最后所应当说明的是,以上实施例仅用以说明本发明的技术方案而非对本发明保护范围的限制,尽管参照较佳实施例对本发明作了详细说明,本领域的普通技术人员应当理解,可以对本发明的技术方案进行修改或者等同替换,而不脱离本发明技术方案的实质和范围。

Claims (10)

- 如权利要求1-2任一项所述的使用石材碎料生产的烧结透水砖,其特征在于,所述聚丙烯酰胺溶液为聚丙烯酸钠、聚乙烯吡啶盐、聚乙烯亚胺中的一种或多种。

- 如权利要求1-2任一项所述的使用石材碎料生产的烧结透水砖,其特征在于,所述粘土为高岭土、黑泥、城市市政污泥中的一种或多种。

- 如权利要求1-2任一项所述的使用石材碎料生产的烧结透水砖,其特征在于,所述石材碎料包括花岗岩、罗源红、石英石、瓷石、钾长石或钠长石废料中的一种或几种。

- 如权利要求1-2任一项所述的使用石材碎料生产的烧结透水砖,其特征在于,所述底料与面料的用量重量比为70-100:0-30。

- 如权利要求1所述的使用石材碎料生产的烧结透水砖,其特征在于,所述面料的石材碎料包括:4-20目石材碎料 100wt%。

- 如权利要求1所述的使用石材碎料生产的烧结透水砖,其特征在于,所述底料的石材碎料包括:4-20目石材碎料 20-50wt%12-40目石材碎料 20-50wt%<40目石材碎料 0-60wt%。

- 一种如权利要求1-8所述的使用石材碎料生产的烧结透水砖的制备方法,其特征在于,包括:(一)将石材碎料破碎;(二)将破碎后的石材碎料过筛,筛分出不同颗粒度范围的颗粒;(三)将过筛后的石材碎料颗粒,按底料配方称取,加入粘结基料、液体胶,并搅拌均匀,得到底料;将过筛后的石材碎料颗粒,按面料配方称取,加入粘结基料、液体胶和色料,并搅拌均匀,得到面料;(四)将搅拌后的面料和底料经两次布料并压制成型,得到坯体;(五)将坯体在窑炉内经过烧制,得到成品。

- 如权利要求9所述的使用石材碎料生产的烧结透水砖的制备方法,其特征在于,所述压制成型步骤中,压机的压力为1500-2000T;所述烧制步骤中,烧制的温度为1100-1220℃。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201711401218.8A CN108558359A (zh) | 2017-12-22 | 2017-12-22 | 一种使用石材碎料生产的烧结透水砖及其制备方法 |

| CN201711401218.8 | 2017-12-22 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019119825A1 true WO2019119825A1 (zh) | 2019-06-27 |

Family

ID=63530354

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/CN2018/100126 WO2019119825A1 (zh) | 2017-12-22 | 2018-08-11 | 一种使用石材碎料生产的烧结透水砖及其制备方法 |

Country Status (2)

| Country | Link |

|---|---|

| CN (1) | CN108558359A (zh) |

| WO (1) | WO2019119825A1 (zh) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111592338A (zh) * | 2020-04-30 | 2020-08-28 | 日昌升建筑新材料设计研究院有限公司 | 一种石粉制砖工艺 |

| CN114455886A (zh) * | 2022-02-23 | 2022-05-10 | 江苏东台超凡创新新材料科技有限公司 | 一种利用铝灰制备的轻质砖体及其制备方法 |

| CN115259796A (zh) * | 2022-08-10 | 2022-11-01 | 浙江方远新材料股份有限公司 | 一种仿石材pc透水砖的制备方法 |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109627041B (zh) * | 2018-12-26 | 2022-08-09 | 亚细亚建筑材料股份有限公司 | 一种利用石材废粉制备多孔陶瓷呼吸材料及其制作方法 |

| CN113336531A (zh) * | 2020-03-02 | 2021-09-03 | 广西净雨环保科技有限公司 | 仿花岗岩透水板及其制备方法 |

| CN116135814A (zh) * | 2021-11-17 | 2023-05-19 | 樊静 | 一种陶瓷砂基透水板及其制备方法 |

| CN114573353A (zh) * | 2022-03-16 | 2022-06-03 | 正蓝旗祥升环保建材有限责任公司 | 一种陶瓷透水烧结砖的制作方法 |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1232738A (zh) * | 1999-05-10 | 1999-10-27 | 佛山市乐华陶瓷有限公司(中外合资) | 透水砖制造方法 |

| CN101672079A (zh) * | 2009-09-25 | 2010-03-17 | 周立忠 | 一种高石粉掺量多孔烧结砖制备方法 |

| CN102070343A (zh) * | 2010-10-12 | 2011-05-25 | 厦门三荣陶瓷开发有限公司 | 一种透水砖及其制造方法 |

| WO2011104006A2 (de) * | 2010-02-24 | 2011-09-01 | Vatramaxx Gmbh | Wärmedämmendes feuerfestes formteil |

| CN105948698A (zh) * | 2016-04-06 | 2016-09-21 | 安徽宏发节能设备有限公司 | 一种用于严寒地区的烧结粘土空心砖及其制备方法 |

| CN106087631A (zh) * | 2016-05-27 | 2016-11-09 | 樊传刚 | 一种烧结透水砖及其制备方法 |

| CN107352865A (zh) * | 2017-06-21 | 2017-11-17 | 中国地质大学(武汉) | 一种地质聚合物透水砖及其制备方法 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1640849A (zh) * | 2004-01-13 | 2005-07-20 | 叶荣崧 | 使微粉陶瓷抛光砖具有逼真石材效果的方法 |

| CN101081732A (zh) * | 2006-06-02 | 2007-12-05 | 林建国 | 一种石粉污泥烧结砖及其制作方法 |

| CN101672080B (zh) * | 2009-09-25 | 2011-04-20 | 周立忠 | 一种高石粉掺量烧结砖制备方法 |

-

2017

- 2017-12-22 CN CN201711401218.8A patent/CN108558359A/zh active Pending

-

2018

- 2018-08-11 WO PCT/CN2018/100126 patent/WO2019119825A1/zh active Application Filing

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1232738A (zh) * | 1999-05-10 | 1999-10-27 | 佛山市乐华陶瓷有限公司(中外合资) | 透水砖制造方法 |

| CN101672079A (zh) * | 2009-09-25 | 2010-03-17 | 周立忠 | 一种高石粉掺量多孔烧结砖制备方法 |

| WO2011104006A2 (de) * | 2010-02-24 | 2011-09-01 | Vatramaxx Gmbh | Wärmedämmendes feuerfestes formteil |

| CN102070343A (zh) * | 2010-10-12 | 2011-05-25 | 厦门三荣陶瓷开发有限公司 | 一种透水砖及其制造方法 |

| CN105948698A (zh) * | 2016-04-06 | 2016-09-21 | 安徽宏发节能设备有限公司 | 一种用于严寒地区的烧结粘土空心砖及其制备方法 |

| CN106087631A (zh) * | 2016-05-27 | 2016-11-09 | 樊传刚 | 一种烧结透水砖及其制备方法 |

| CN107352865A (zh) * | 2017-06-21 | 2017-11-17 | 中国地质大学(武汉) | 一种地质聚合物透水砖及其制备方法 |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111592338A (zh) * | 2020-04-30 | 2020-08-28 | 日昌升建筑新材料设计研究院有限公司 | 一种石粉制砖工艺 |

| CN114455886A (zh) * | 2022-02-23 | 2022-05-10 | 江苏东台超凡创新新材料科技有限公司 | 一种利用铝灰制备的轻质砖体及其制备方法 |

| CN115259796A (zh) * | 2022-08-10 | 2022-11-01 | 浙江方远新材料股份有限公司 | 一种仿石材pc透水砖的制备方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN108558359A (zh) | 2018-09-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2019119823A1 (zh) | 一种透水砖的制备方法 | |

| WO2019119825A1 (zh) | 一种使用石材碎料生产的烧结透水砖及其制备方法 | |

| WO2018107659A1 (zh) | 一种复合透水砖及其制备方法 | |

| CN100453499C (zh) | 一种室外陶瓷透水砖及其制备方法 | |

| CN106278352B (zh) | 一种悬浮焙烧铁尾矿透水砖及其制备方法 | |

| CN101423376A (zh) | 一种陶瓷透水砖及其制造方法 | |

| CN107200544A (zh) | 一种节能环保建筑材料及其制备方法 | |

| CN108083769A (zh) | 一种使用陶瓷碎料生产的烧结透水砖及其制备方法 | |

| CN106242428A (zh) | 一种污泥陶粒透水砖及其制备方法 | |

| CN105384403A (zh) | 一种抗污能力强的复合透水地砖 | |

| CN108191392A (zh) | 一种不易堵塞的烧结透水砖及其制备方法 | |

| CN102850038A (zh) | 一种陶瓷渗水砖 | |

| CN102417343A (zh) | 仿砂岩瓷质外墙砖及其生产方法 | |

| CN108083768A (zh) | 一种使用煤矸石生产的烧结透水砖及其制备方法 | |

| CN111892390A (zh) | 一种无原矿泥坯体制成的快烧陶瓷厚砖及制备工艺 | |

| CN108585788A (zh) | 一种使用冶炼尾矿生产的烧结透水砖及其制备方法 | |

| CN100425559C (zh) | 一种多功能水泥助磨剂 | |

| CN103693908B (zh) | 一种以矿热炉渣为主要原料的无机饰面砂浆及其制备方法 | |

| WO2016155343A1 (zh) | 一种利用冶金中间包覆渣生产陶瓷材料的方法 | |

| CN105777066A (zh) | 一种以稀土尾砂为原料制备的龙泉青瓷及其制造方法 | |

| WO2019119824A1 (zh) | 一种不易堵塞的烧结透水砖及其制备方法 | |

| CN108083772A (zh) | 一种使用炉渣生产的烧结透水砖及其制备方法 | |

| CN107698232A (zh) | 新型透水砖及其制备工艺 | |

| CN105367020A (zh) | 一种新型抗裂免烧结节能型透水地砖 | |

| WO2020073183A1 (zh) | 一种利用黄土制备太古砖的方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18892246 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 18892246 Country of ref document: EP Kind code of ref document: A1 |