WO2019065679A1 - Fan - Google Patents

Fan Download PDFInfo

- Publication number

- WO2019065679A1 WO2019065679A1 PCT/JP2018/035571 JP2018035571W WO2019065679A1 WO 2019065679 A1 WO2019065679 A1 WO 2019065679A1 JP 2018035571 W JP2018035571 W JP 2018035571W WO 2019065679 A1 WO2019065679 A1 WO 2019065679A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- fan

- guard

- axial

- flow

- straightening vane

- Prior art date

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D25/00—Pumping installations or systems

- F04D25/02—Units comprising pumps and their driving means

- F04D25/08—Units comprising pumps and their driving means the working fluid being air, e.g. for ventilation

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/40—Casings; Connections of working fluid

- F04D29/52—Casings; Connections of working fluid for axial pumps

- F04D29/54—Fluid-guiding means, e.g. diffusers

Definitions

- the present disclosure relates to a fan that is installed on a ceiling, a wall, a floor surface, or the like in a living room and used to reduce a sensible temperature due to direct air flow and to circulate indoor air.

- Patent Document 1 Conventionally, for this type of fan, for example, a configuration described in Patent Document 1 is shown as an object for improving the straightness of the wind. The configuration will be described below with reference to FIGS.

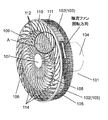

- FIG. 5 is a perspective view showing the configuration of a conventional fan

- FIG. 6 is a perspective view showing the shape of a front guard 12 provided on the downstream side of the axial flow fan 11.

- the front guard 12 is a guard ring for positioning and fixing the rear guard 14 and the front guard 12 on the outer periphery of the ventilation portion 13 through which the wind blown from the axial flow fan 11 passes.

- the ventilation portion 13 is provided with a straightening vane 17 extending from the center side of the front guard 12 toward the guard ring 15 in a spiral shape such that the rotation axis of the axial flow fan 11 is axially symmetrical.

- a part of the straightening vane 17 has a shape in which the center side thereof protrudes upstream in the rotational axis direction of the axial flow fan 11.

- Utility model registration 3196884 gazette Utility model registration No. 3209452 JP, 2011-58382, A JP, 2015-108362, A

- the front guard of such a conventional fan has enhanced the straightness of the wind by collecting the wind blown from the axial fan along the straightening vane at the center.

- the front guard can not sufficiently obtain the straightness of the wind.

- an air flow in the blowing direction is generated in the vicinity of the blades on the outer peripheral side of the axial fan.

- An air flow in the suction direction is generated between the outer peripheral blades of the axial flow fan.

- the straightening vane is not shaped in consideration of the air flow in the suction direction. Rather, the straightening plate resists the air flow in the suction direction on the outer peripheral side of the axial flow fan, and thus causes disturbance of the air flow on the outer peripheral side of the axial flow fan.

- the present disclosure aims to provide a fan that suppresses the resistance to the air flow in the suction direction and improves the straightness of the wind.

- the fan according to an embodiment of the present disclosure includes an axial fan having a plurality of blades for blowing air by rotation, and an axial fan in the axial direction of the axial fan rather than the axial fan.

- a front guard provided on the downstream side.

- the front guard is a disk provided with an inner ring, an outer ring provided on the outer side of the inner ring, an outer ring concentric with the inner ring and an inner ring, and a disk provided in the center of the inner ring and an inner ring.

- Each of the plurality of inner straightening vanes is formed in an arc shape projecting in the rotational direction of the axial fan.

- Each of the plurality of inner baffles includes an inner baffle slope having a first end upstream of the axial fan in the rotational axis direction. The inner straightening vane slope is inclined from the first end toward the rotational direction of the axial fan.

- Each of the plurality of outer baffles includes an outer baffle slope having a second end upstream of the axial fan in the rotational axis direction. The outer straight baffle slope is inclined from the second end in a direction opposite to the rotational direction of the axial fan.

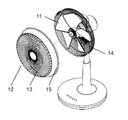

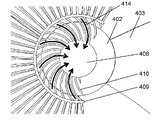

- FIG. 1 is a perspective view of a fan according to a first embodiment of the present disclosure.

- FIG. 2 is a side view of the fan of FIG.

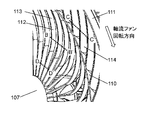

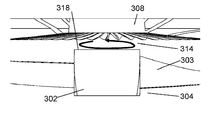

- FIG. 3A is an enlarged view of a portion A in FIG.

- FIG. 3B is a cross-sectional view showing the shape of the cross section B-B 'in FIG. 3A.

- FIG. 4A is a cross-sectional view showing the shape of the cross section C-C 'in FIG. 3A.

- FIG. 4B is a cross-sectional view showing the shape of D-D ′ cross section in FIG. 3A.

- FIG. 5 is a perspective view showing the configuration of a conventional fan.

- FIG. 6 is a perspective view showing the shape of a front guard of a conventional fan.

- FIG. 1 is a perspective view of a fan according to a first embodiment of the present disclosure.

- FIG. 2 is a side view of the fan of FIG.

- FIG. 3A is an enlarged view of a portion A in

- FIG. 7 is a perspective view of a fan according to a second embodiment of the present disclosure.

- FIG. 8 is a side view of the fan according to the second embodiment.

- FIG. 9 is an enlarged view of a portion A in FIG.

- FIG. 10 is a cross-sectional view of the fan according to the second embodiment in the EE 'cross section in FIG.

- FIG. 11 is a perspective view showing the configuration of a conventional fan.

- FIG. 12 is a perspective view showing the shape of a front guard of a conventional fan.

- FIG. 13 is a perspective view of a fan according to a third embodiment of the present disclosure.

- FIG. 14 is a side view of the fan according to the third embodiment.

- FIG. 15 is a perspective view of the guard mark as viewed from the upstream side.

- FIG. 16A is a cross-sectional view in the case where the guard mark has no conical protrusion and no current plate.

- FIG. 16B is a perspective view seen from the downstream side in the case where the guard mark has a conical protrusion and a straightening vane.

- FIG. 16C is a cross-sectional view in the case where the guard mark has a conical protrusion and a straightening vane.

- FIG. 17 is a perspective view showing the shape of a guard mark of a conventional fan.

- FIG. 18 is a perspective view of a conventional fan having a guard mark attached to its central portion.

- FIG. 19 is a perspective view of a fan according to a fourth embodiment of the present disclosure.

- FIG. 20 is a side view of the fan according to the fourth embodiment.

- FIG. 21 is a front view in which a part of the front guard is seen through from the upstream side.

- FIG. 22A is an enlarged view of the vicinity of the guard mark when viewed from the front on the downstream side.

- FIG. 22B is a view of the cross section of the front guard and the positional relationship of the axial fan as viewed from the side.

- FIG. 23 is a perspective view of a conventional straight guarded front guard.

- FIG. 24 is a side view of a conventional straight guarded front guard.

- FIG. 25 is a perspective view of a fan according to a fifth embodiment of the present disclosure.

- FIG. 26 is a side view of the fan according to the fifth embodiment.

- FIG. 27 is a perspective view of the guard mark as viewed from the upstream side.

- FIG. 28 is a cross-sectional view of a guard mark.

- FIG. 29 is a perspective view showing the shape of a guard mark of a conventional fan.

- FIG. 30 is a side view of a conventional fan with a guard mark attached to its central portion.

- FIG. 31 is a cross-sectional view of a conventional guard mark.

- the fan according to the first embodiment of the present disclosure includes an axial fan having a plurality of blades for blowing air by rotation, and a front provided downstream of the axial fan in the axial direction of the axial fan. And a guard.

- the front guard is a disk provided with an inner ring, an outer ring provided on the outer side of the inner ring, an outer ring concentric with the inner ring and an inner ring, and a disk provided in the center of the inner ring and an inner ring.

- Each of the plurality of inner straightening vanes is formed in an arc shape projecting in the rotational direction of the axial fan.

- Each of the plurality of inner baffles includes an inner baffle slope having a first end upstream of the axial fan in the rotational axis direction. The inner straightening vane slope is inclined from the first end toward the rotational direction of the axial fan.

- Each of the plurality of outer baffles includes an outer baffle slope having a second end upstream of the axial fan in the rotational axis direction. The outer straight baffle slope is inclined from the second end in a direction opposite to the rotational direction of the axial fan.

- each inner side straightening vane inclines along blowoff air current. Therefore, the resistance which blowing air flow receives from a front guard can be reduced.

- each inner straightening vane is formed in an arc shape projecting in the rotational direction of the axial fan. Thus, the blowing air flow is collected to the center.

- each outer straightening vane is inclined along the suction air flow along the rotational direction of the axial fan generated on the outer peripheral side of the blade. Therefore, the resistance of the suction air flow from the front guard can be reduced. Thereby, the turbulence of the air flow on the outer peripheral side of the axial fan can be reduced.

- the fan according to the first embodiment of the present disclosure can blow air far by suppressing the diffusion of the blown air collected to the center of the axial fan and improving the straightness of the wind.

- each of the plurality of inner straightening vanes is provided downstream of the inner straightening vane inclined portion on the downstream side in the axial direction of the axial fan and the rotary shaft of the axial fan

- the inner straightening plate straight section further includes a third straight end on the downstream side in the axial direction of the axial flow fan, and the inner straight straightening section at the third end. It may be connected with

- the fan according to the first embodiment of the present disclosure can improve the straightness of the wind and can blow the air far.

- the wind blown by the rotation of the axial fan has a swirl component.

- the inner straightening plate linear portion converts a swirl component of the wind into a rotational axis component. Thereby, the straightness of the wind can be further improved.

- each of the plurality of inner straightening vanes is more inward than the outer circumferential side region including the inner straightening vane inclined portion and the inner straightening vane straight portion and the outer circumferential side region. It may be located on the circumferential side, and may have a region on the inner circumferential side including the inner straightening vane straight portion without including the inner straightening vane inclined portion.

- the fan according to Embodiment 1 of the present disclosure has a ventilation area in the vicinity of the center (region on the inner circumferential side) from the guard mark when the front guard is viewed from the front to a predetermined position of the inner straightening vane. It can be increased. Therefore, the pressure loss near the center (region on the inner circumferential side) near the guard mark can be reduced, and the wind speed near the center can be improved and the air can be blown far.

- the position at which the inner straightening vane inclination angle formed by the inner straightening vane inclined portion and the inner straight straightening vane portion is the smallest is the outer circumference than the middle point of the radius of the inner ring. It may be in the side position.

- the fan according to the first embodiment of the present disclosure can improve the wind speed and can make the wind reach far.

- the swirl component of the wind has a velocity distribution in the radial direction of the front guard.

- the speed of the swirling component of the wind is high.

- the front guard can flow such a high speed wind of a swirling component along the inner baffle. Thereby, the pressure loss can be reduced and the wind speed can be improved.

- FIG. 1 is a perspective view of a fan according to a first embodiment of the present disclosure

- FIG. 2 is a side view of the fan of FIG.

- the fan 101 which concerns on Embodiment 1 is demonstrated using FIG.1 and FIG.2.

- the fan 101 includes an axial fan 103 having a plurality of blades 102, a motor (not shown) for rotating the axial fan 103, and an upstream side of the axial fan 103 in the rotational axis direction. It is comprised with the motor housing 104 which includes a motor.

- the fan 101 further includes a rear guard 105 and a front guard 106.

- the rear guard 105 covers the axial fan 103 from the side face side and the back side which is the upstream side in the axial direction of the axial fan 103 so as to protect foreign matter from contacting the axial fan 103.

- the front guard 106 covers the axial flow fan 103 from the front side, which is the downstream side of the axial flow fan 103 in the rotation axis direction, and protects the axial flow fan 103 from contact with foreign matter.

- the front guard 106 is provided with a disk-like guard mark 107 at the center.

- the front guard 106 includes an inner circumferential ventilation portion 108 positioned on the outer circumferential side than the guard mark 107 and an outer circumferential ventilation portion 109 positioned on the outer circumferential side than the inner circumferential ventilation portion 108.

- the inner side ventilation part 108 mainly allows the wind blown by the axial fan 103 to pass.

- the outer circumferential ventilation portion 109 mainly passes the wind induced along the rotational direction of the axial fan 103 from the outer circumferential side of the blades 102 of the axial fan 103 by the rotation of the axial fan 103.

- the front guard 106 includes an inner ring 110 spaced apart from the guard mark 107 and a plurality of inner straightening vanes 112 provided between the guard mark 107 and the inner ring 110.

- the inner circumferential ventilation portion 108 and the outer circumferential ventilation portion 109 are separated by an inner ring 110 formed in an annular shape.

- the front guard 106 is provided on the outer side of the inner ring 110 so as to be spaced apart from the inner ring 110, and a plurality of outer straightening vanes provided between the inner ring 110 and the outer ring 111.

- the outer ring 111 is formed in an annular shape and provided concentrically with the inner ring 110.

- the front guard 106 is fixed to the rear guard 105 by an outer ring 111.

- each of the plurality of inner flow straightening plates 112 is arranged to connect the side surface of the guard mark 107 and the side surface on the inner peripheral side of the inner ring 110.

- the plurality of inner flow straightening plates 112 are formed to radiate from the side surface of the guard mark 107 toward the inner peripheral side surface of the inner ring 110.

- the inner circumferential ventilation portion 108 is a region defined by the side surfaces of the adjacent inner straightening vanes 112 and the guard marks 107 and the inner peripheral side surface of the inner ring 110.

- the inner straightening vane 112 has an arc shape projecting in the rotational direction of the axial fan 103 (vanes 102). Is formed. Specifically, the inner straightening vane 112 includes a first connecting portion connected to the side surface of the guard mark 107, a second connecting portion connected to the side surface on the inner peripheral side of the inner ring 110, and a first connecting portion. And a central portion located between the second coupling portions. A central portion of the inner straightening vane 112 is formed to project in the rotational direction of the axial flow fan 103 with respect to a straight line connecting the first connecting portion and the second connecting portion.

- the inner straightening vane 112 includes an inner straightening vane slope 113, as shown in FIG. 3B.

- the inner straightening vane inclined portion 113 is inclined toward the rotational direction of the axial flow fan 103 from the first end X 1 on the upstream side in the rotational axial direction of the axial flow fan 103 in the inner straightening plate 112.

- the inner straightening vane inclined portion 113 enables the wind blown by the axial fan 103 to pass through the inner circumferential ventilation portion 108 with low resistance.

- each of the plurality of outer straightening vanes 114 is disposed to connect the side surface on the outer peripheral side of the inner ring 110 and the side surface on the inner peripheral side of the outer ring 111.

- the plurality of outer straightening vanes 114 are formed to radiate from the outer peripheral side surface of the inner ring 110 toward the inner peripheral side surface of the outer ring 111.

- the outer periphery side ventilation part 109 is the area

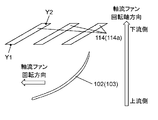

- the outer straightening vane inclined portion 114a is inclined from the second end Y1 on the upstream side of the outer straightening vane 114 in the axial direction of the axial flow fan 103 to the direction opposite to the rotational direction of the axial fan 103. ing.

- suction air flow is generated along the rotation direction of the axial flow fan 103 (blade 102).

- the outer baffle plate inclined portion 114 a allows the suctioned air flow to pass through the outer circumferential ventilation portion 109 with low resistance.

- each inner straightening vane 112 is inclined along the blowout air flow. This reduces the resistance that the blowing air receives from the front guard 106.

- Each of the inner flow straightening plates 112 is further formed in an arc shape projecting in the rotation direction of the axial flow fan 103. As a result, the blown air is collected to the center of the axial fan 103.

- each outer straightening vane 114 is inclined along the suction air flow. Therefore, the resistance of the suction air flow from the front guard 106 can be reduced, and the disturbance of the air flow on the outer peripheral side of the axial flow fan 103 can be reduced. As a result of these, the fan 101 can suppress the diffusion of the blown air collected to the center of the axial fan 103 and improve the straightness of the wind, whereby the fan can be blown far.

- FIG. 3A is an enlarged view of a portion A in FIG. 1, and FIG. 3B is a cross-sectional view showing the shape in the B-B 'cross section in FIG. 3A.

- 4A is a cross-sectional view showing the shape in the C-C 'cross section in FIG. 3A

- FIG. 4B is a cross-sectional view showing the shape in the D-D' cross section in FIG. 3A.

- Each cross-sectional view is a cross-sectional view of the inner straight plate 112 or the outer straight plate 114 cut along a cylindrical surface centered on the rotation axis of the axial flow fan 103 (from the outer circumferential side of the axial flow fan 103 to the inner circumferential side Cross section) in a planar form.

- Each cross-sectional view also includes a cross section obtained by similarly cutting the axial flow fan 103 (blade 102).

- each of the plurality of inner flow straightening plates 112 is disposed to connect the side surface of the guard mark 107 and the side surface on the inner peripheral side of the inner ring 110.

- the plurality of inner flow straightening plates 112 are formed to radiate from the side surface of the guard mark 107 toward the inner peripheral side surface of the inner ring 110.

- the inner straightening vane 112 is formed in an arc shape projecting in the rotation direction of the axial flow fan 103.

- each of the plurality of outer flow straightening plates 114 is arranged to connect the outer peripheral side surface of the inner ring 110 and the inner peripheral side surface of the outer ring 111.

- the plurality of outer straightening vanes 114 are formed to radiate from the outer peripheral side surface of the inner ring 110 toward the inner peripheral side surface of the outer ring 111.

- the inner straightening vane 112 has an inner straightening vane ramp 113.

- the inner straightening vane inclined portion 113 has a first end X1 on the upstream side in the rotational axis direction of the axial flow fan 103 and a third end X2 on the downstream side in the rotational axis direction of the axial flow fan 103.

- the inner straightening vane inclined portion 113 inclines in the rotation direction of the axial fan 103 from the first end X1. That is, the third end X2 is located in the rotation direction of the axial fan 103 as viewed from the first end X1.

- the inner straightening vane 112 further has an inner straightening vane straight portion 115.

- the inner straightening vane linear portion 115 is provided downstream of the inner straightening vane inclined portion 113 in the axial direction of the axial flow fan 103 and extends in the axial direction of the axial flow fan 103.

- the inner straightening vane inclined portion 113 is connected to the inner straightening vane straight portion 115 at the third end X 2 on the downstream side in the rotation axis direction of the axial flow fan 103.

- the outer side baffle plate 114 has the outer side baffle plate inclined part 114a.

- the outer baffle plate inclined portion 114 a has a second end Y 1 on the upstream side in the rotational axis direction of the axial flow fan 103 and a fourth end Y 2 on the downstream side in the rotational axis direction of the axial flow fan 103.

- the outer baffle plate inclined portion 114 a inclines in a direction opposite to the rotational direction of the axial fan 103 from the second end Y 1. That is, the fourth end Y2 is located in the direction opposite to the rotational direction of the axial fan 103 as viewed from the second end Y1.

- the outer straightening vane inclined portion 114 a has the same shape as the outer straightening vane 114. That is, the end on the upstream side in the rotational axis direction of the axial flow fan 103 in the outer straightening vane 114 coincides with the second end Y1. The end on the downstream side in the rotational axis direction of the axial flow fan 103 in the outer straightening vane 114 coincides with the fourth end Y2.

- the inner side straightening plate 112 has the inner side straightening plate linear part 115a along the rotation shaft direction of the axial flow fan 103 in the center vicinity (area

- the inner straightening vane inclined portion 113 is not provided in the vicinity of the center of the axial flow fan 103 (the region on the inner circumferential side).

- the wind generated by the rotation of the axial fan 103 has a wind speed distribution in the radial direction of the axial fan 103. That is, the wind speed differs depending on the radial position of the axial fan 103. For example, when the axial fan 103 has a radius of 250 mm, the maximum of the wind speed in the radial wind velocity distribution immediately downstream of the axial fan 103 is at a radius of 170 mm. Near the position showing the maximum wind speed, the speed of the swirling component of the wind is increased. Then, as shown to FIG. 3B, the inner side baffle plate inclination part 113 is provided in the position where the speed of the rotational component of a wind is large. As a result, the wind having the maximum wind velocity flows along the inner straightening vane inclined portion 113 on the outer circumferential side of the inner straightening vane 112, and wind disturbance can be reduced.

- the wind from the axial fan 103 has a wind speed distribution in the radial direction immediately downstream of the axial fan 103.

- the circumferential speed of the axial fan 103 is slower as it approaches the center of the axial fan 103. Therefore, the closer to the center of the axial fan 103, the lower the speed of the swirling component of the wind. Therefore, the inner straightening vane 112 does not include the inner straightening vane inclined portion 113 near the center of the axial flow fan 103, and includes only the inner straightening vane straight portion 115a as shown in FIG. 4B.

- the inner straightening vane 112 when the radius of the inner ring 110 is, for example, 210 mm, the inner straightening vane 112 is located at a radius of 88 mm from the center of the inner ring 110 (about 0.42 of the radius of the inner ring 110 from the center of the inner ring 110). Up to the double position), only the inner straightening plate straight portion 115a is formed.

- the inner straightening vane 112 includes an inner straightening vane straight portion 115 and an inner straightening vane inclined portion 113 from the 88 mm radius position to the inner ring 110 on the outer peripheral side where the wind speed is high.

- the inner straightening vane 112 has a region on the inner circumferential side constituted by the inner straightening vane straight portion 115 a and a region on the outer circumferential side constituted by the inner straightening vane inclined portion 113 and the inner straightening vane straight portion 115 doing.

- the inner straightening vane 112 is inclined along the blowout air flow, and the resistance of the blowout air flow from the front guard 106 can be reduced.

- the inner straightening vane 112 is formed in an arc shape that protrudes in the rotation direction of the axial flow fan 103. As a result, the blown air can be concentrated to the center of the axial fan 103, and the wind speed can be increased to blow the air far.

- the outer straightening vane 114 is inclined along the suction air flow.

- the resistance when the suctioned air flow passes through the outer peripheral ventilation portion 109 can be reduced, and the disturbance of the air flow on the outer peripheral side of the axial flow fan 103 can be reduced.

- the wind can be made to reach far.

- the wind is generated by the rotation of the axial fan 103 and therefore has a swirl component.

- the swirling component of the wind is diffused as it flows downstream, which causes the straightness of the wind to deteriorate.

- the inner side straightening plate 112 has the inner side straightening plate linear part 115 formed in the surface which becomes parallel to the rotating shaft of the axial flow fan 103 in the downstream rather than the inner side straightening plate inclination part 113.

- the inner straightening plate linear portion 115 can convert a swirling component of the wind into a component in the axial direction of the axial flow fan 103. Therefore, by suppressing the diffusion of the blown air collected to the center of the axial fan 103 and improving the straightness of the wind, the wind can be made to reach far.

- the wind generated by the axial fan 103 has a wind speed distribution in the radial direction immediately downstream of the axial fan 103. That is, there is a position where the wind shows the maximum wind speed.

- the position at which the maximum wind speed is indicated is 170 mm from the center of the axial fan 103.

- the velocity of the turning component becomes large. Therefore, the wind is directed along the inner straightening vane slope 113 by reducing the angle formed by the inner straightening vane slope 113 and the inner straightening vane straight line portion 115, that is, the inner straightening vane slope angle 116 (see FIG. 3B).

- the inner baffle inclination angle 116 may have an angular distribution in the radial direction of the front guard 106.

- the position at which the inner straightening vane inclination angle 116 is minimized may be located on the outer circumferential side of the middle point of the radius of the inner ring 110.

- the inner straightening vane slope portion 113 is formed such that the inner straightening vane inclination angle 116 is a minimum at a position of 140 mm to 189 mm from the center of the inner ring 110. That is, the position where the swirling component of the wind is the maximum corresponds to the position where the inner straightening vane inclination angle 116 is the minimum angle.

- the wind is along the inner straightening vane inclined portion 113, and the resistance due to the wind disturbance of the turning component can be reduced.

- the wind from the portion having a high peripheral speed on the outer peripheral side of the axial fan 103 flows along the inner straightening plate 112, so that the pressure loss can be reduced and the wind speed can be improved. be able to.

- Patent Document 1 Utility Model Registration No. 3196884

- Patent Document 1 Utility Model Registration No. 3196884

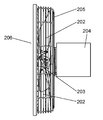

- FIG. 11 is a perspective view showing the configuration of a conventional fan

- FIG. 12 is a perspective view showing the shape of the front guard 22 provided on the downstream side of the axial flow fan 21.

- the front guard 22 is a guard ring for positioning and fixing the rear guard 24 and the front guard 22 on the outer periphery of the ventilation portion 23 through which the wind blown from the axial flow fan 21 passes. It has 25.

- the ventilation portion 23 is provided in a spiral shape in which a straightening plate 27 extending from the center side of the front guard 22 toward the guard ring 25 is axially symmetrical with respect to the rotation axis of the axial flow fan 21.

- a part of the straightening vane 27 has a shape in which the center side thereof protrudes to the upstream side of the axial flow fan 21 in the rotation axis direction.

- the front guard 22 of such a conventional fan improves the straightness of the wind by collecting the wind blown by the axial fan 21 along the straightening plate 27 of uniform thickness at the center. Furthermore, the front guard 22 closely arranges a plurality of flow straightening plates 27 and adjusts the distance between the flow straightening plates 27 to thereby suppress finger insertion between the flow straightening plates 27 of the front guard 22. That is, in order to suppress the insertion of the front guard 22, it is necessary to increase the number of the flow control plates 27 and to arrange the flow control plates 27 densely. However, the dense arrangement of the straightening vanes 27 is a factor of the resistance of the air flow, and there is a problem that the air flow performance is lowered. Therefore, the present embodiment aims to provide a fan that suppresses the insertion of a finger between the flow control plates 27 of the front guard and does not reduce the air blowing performance.

- An electric fan includes an axial fan having a plurality of blades for blowing air by rotation, and a front provided downstream of the axial fan in the axial direction of the axial fan.

- the guard includes a guard and a rear guard provided on the upstream side in the axial direction of the axial fan with respect to the front guard.

- the front guard includes a disk-shaped guard mark provided at the center of the front guard and the outer periphery of the front guard. And a plurality of arc-shaped straightening vanes provided between the guard mark and the outer circumferential ring, the arc-shaped straightening vanes being formed so that an arc is closed in a direction opposite to the rotational direction of the axial fan.

- each of the plurality of straightening vanes is a straightening vane inclined portion which is inclined along the swirling direction of the air flow blown by the axial fan, and a downstream side in the axial direction of the axial fan from the straightening vane inclined portion.

- the straight-line portion parallel to the rotational axis direction of the axial fan, and the straight-line slope has a face facing the blade, and this face protrudes toward the other adjacent straight-line slope With a protruding portion.

- the projecting portion By providing the projecting portion on the surface of the straightening vane inclined portion, the shortest distance between the straightening vane inclined portions of the adjacent straightening vanes becomes short. Therefore, even if it is intended to insert a finger toward the axial fan through the front guard, the projection of the surface of the straightening plate inclined portion of the adjacent straightening vane restricts the finger from passing through the front guard. can do.

- the projecting portion is provided in the straightening vane inclined portion, the resistance to the air flow from the axial flow fan is reduced and the air blowing performance is reduced compared to the case where the projecting portion is provided in the straightening vane straight portion. It can be suppressed.

- the straightening vane inclined portion is positioned on the upstream side end portion located on the upstream side in the axial direction of the axial fan and on the downstream side in the axial direction of the axial fan.

- the projecting portion may be continuous from the upstream end to the downstream end of the straightening vane slope.

- the protrusion can be formed as a smooth surface from the upstream end to the downstream end of the straightening vane inclined portion, and the protrusion can be prevented from becoming a resistance of the air flow by the axial fan. it can. As a result, even when the projecting portion is provided on the straightening vane inclined portion, it is possible to suppress the decrease in the air blowing performance.

- the position where the projecting portion has the maximum thickness is closer to the downstream end than the midpoint between the upstream end and the downstream end of the straightened plate inclined portion. It may be located in

- the second embodiment of the present disclosure will be described below for understanding of the present disclosure.

- the following second embodiment is an example embodying the present disclosure, and does not limit the technical scope of the present disclosure.

- the same number is attached about the same site

- the description of the details of each part not directly related to the present disclosure is omitted.

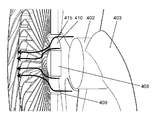

- FIG. 7 is a perspective view of the fan 201 according to the second embodiment of the present disclosure

- FIG. 8 is a side view of the fan 201 according to the second embodiment of the present disclosure

- FIG. FIG. 10 is an enlarged view of the vicinity of the center of the fan 201 according to the second embodiment

- FIG. 10 is a cross-sectional view of the fan 201 according to the second embodiment of the present disclosure.

- the fan 201 includes an axial fan 203 having a plurality of blades 202, a motor (not shown) for rotating the axial fan 203, and a motor provided on the upstream side of the axial fan 203. And a motor housing 204.

- the fan 201 includes a rear guard 205 and a front guard 206.

- the rear guard 205 covers the axial fan 203 from the side surface side and the rear side which is the upstream side of the axial fan 203 so as to protect foreign matter from contacting the axial fan 203.

- the rear guard 205 is formed of a metal or resin wire.

- the front guard 206 covers the axial flow fan 203 from the front side of the axial flow fan 203 downstream of the axial flow fan 203 and protects the axial flow fan 203 from contact with foreign matter.

- the front guard 206 is provided on the downstream side of the axial fan 203 in the rotation axis direction than the axial fan 203.

- the rear guard 205 is provided upstream of the front guard 206 in the axial direction of the axial flow fan 203.

- the front guard 206 includes a cylindrical or disc-like guard mark 207 provided at the center of the front guard 206 and an outer peripheral ring 211 provided at the outer periphery of the front guard 206.

- the front guard 206 further includes a plurality of flow straightening plates 217 provided between the guard marks 207 and the outer peripheral ring 211.

- Each of the plurality of flow straightening plates 217 is disposed to connect the side surface of the guard mark 207 and the side surface on the inner peripheral side of the outer peripheral ring 211.

- the plurality of rectifying plates 217 are formed to radiate from the side surface of the guard mark 207 toward the side surface on the inner peripheral side of the outer peripheral ring 211.

- each flow straightening plate 217 is made of an elongated thin plate having two main surfaces. The two main surfaces are substantially parallel to the rotational axis direction of the axial flow fan 203.

- a ventilating portion 208 through which the wind blown by the axial fan 203 passes is formed on the outer circumferential side of the guard mark 207.

- the ventilation part 208 is an area divided by the guard mark 207 and the outer peripheral ring 211 and the straightening vane 217 adjacent thereto. Further, the front guard 206 is fixed to the rear guard 205 by an outer peripheral ring 211.

- each rectifying plate 217 of the present embodiment has a rectifying plate linear portion 212.

- the straightening vane straight portion 212 has a plane parallel to the rotation axis of the axial fan 203.

- the straight component 212 of the straightening vanes can convert the swirl component of the air flow into a rotational axis component along the rotational axis direction of the axial flow fan 203.

- each flow straightening plate 217 has a shape curved in an arc shape.

- the arc-shaped straightening vane 217 is formed so that the arc is closed in the direction opposite to the rotational direction of the axial fan 203.

- the straightening vane 217 is formed in an arc shape projecting in the rotation direction of the axial flow fan 203.

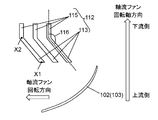

- FIG. 10 shows a cross-sectional view of the straightening vane 217 in FIG. 9 taken along the line EE '.

- each flow straightening plate 217 is provided with a straightening vane slope portion 213 in addition to the straightening vane straight portion 212 so that the wind blown by the axial flow fan 203 passes with low resistance.

- the straightening vane inclined portion 213 is located upstream of the straightening vane linear portion 212 in the rotation axis direction of the axial fan 203, and is connected to the straight straightening vane portion 212.

- the straightening vane inclined portion 213 is inclined along the swirling direction of the air flow blown by the axial fan 203. That is, the straightening vane inclined portion 213 is inclined along the blown air flow. Thereby, the contact resistance between the blowout air flow and the straightening vane inclined portion 213 can be reduced, and the pressure loss is reduced.

- the straightening vane straight portion 212 is formed such that the arc is closed in the direction opposite to the rotational direction of the axial fan 203.

- the blowing air flow is collected to the center of the front guard 206.

- the concentration of the blown air promotes an increase in the air flow of the air flow and an increase in the wind speed of the air flow. By the increase of the air volume and the wind speed, the straightness of the wind can be improved and the air can be blown far.

- the wind from the axial fan 203 has a distribution of wind speed in the radial direction of the axial fan 203.

- the straightening vane 217 has a position (maximum wind speed position) at which the wind from the axial fan 203 reaches the maximum wind speed.

- the swirl component of the wind is also large.

- the curvature of the arc of the straightening vane 217 is large. Thereby, an air flow having a large swirling component can be collected at the center of the axial flow fan 203.

- each straightening vane 217 may have an arc curvature distribution in the radial direction of the front guard 206.

- the portion where the curvature of the arc is maximum may be located closer to the outer peripheral ring 211 than the above-mentioned midpoint.

- the curvature of the arc of the rectifying plate 217 may be small.

- an angle formed between the straightening vane inclined portion 213 and the straight straightening vane portion 212, that is, the straightening vane inclination angle 216 may be small.

- the air flow having a high speed of the swirling component can be converted into an air flow parallel to the rotation axis direction of the axial flow fan 203. Therefore, the straightness of the wind can be improved even in the air flow in which the speed of the turning component is large.

- the straightening vane inclination angle 216 at the position where the turning component is maximum, the wind can be along the straightening vane inclined portion 213, and the resistance due to the disturbance of the turning component wind can be reduced.

- the flow of the wind at the portion where the peripheral velocity on the outer peripheral side of the axial flow fan 203 is large is along the straightening plate linear portion 212.

- the pressure loss can be reduced, the wind speed can be improved, and the wind can be made to reach far.

- the straightening vane inclined portion 213 has a surface facing the rotating blade 202.

- This face of the baffle ramp 213 has a projection 209 projecting towards the other adjacent baffle ramp 213.

- the inter-rectifying plate distance 210 in the rectifying plate inclined portion 213 can be shortened, so that the foreign matter such as a finger can be prevented from passing through the front guard 206.

- the projecting portion 209 is provided on the rectifying plate inclined portion 213.

- the pressure loss is smaller in the case where the projecting portion 209 is provided in the straightening vane inclined portion 213 than in the case where the projecting portion 209 is provided in the straightening vane linear portion 212, and the reduction in air blowing performance can be suppressed.

- the projecting portion 209 may be formed to be continuous from the upstream end 214 to the downstream end 215 of the straightening vane inclined portion 213.

- the contact resistance between the air flow entering between the adjacent flow straightener inclined portions 213 and the projecting portion 209 can be reduced, and the turbulent flow of the air flow can be reduced to suppress the air flow performance deterioration due to the pressure loss. it can.

- the position where the protrusion 209 has the largest thickness may be located closer to the downstream end 215 than the middle point between the upstream end 214 and the downstream end 215 of the straightening vane slope 213. .

- the turbulence of the air flow immediately after flowing into the space between the adjacent straight plate inclined portions 213 can be reduced, compared with the case where the position of the maximum thickness is closer to the upstream end 214 than the middle point. It is possible to suppress the decrease in air blowing performance due to the loss.

- the projecting portion 209 may be provided at the downstream end portion 215 of the straightening vane inclined portion 213.

- the protrusion part 209 can ease the trajectory change of the air flow passing through the straightening vane inclination angle 216, and the separation of the flow at the downstream end 215 of the straightening vane inclined part 213 can be suppressed. Can be suppressed.

- the conventional fan has a configuration described in Patent Document 2 (Utility Model Registration No. 3209452), for example, as a shape for improving the air flow performance of a guard mark at the center of the front guard.

- FIG. 17 is a perspective view showing the configuration of the guard mark 31 used in the conventional fan

- FIG. 18 is a perspective view of the fan having the guard mark 31 attached to the center of the front guard 32.

- the guard mark 31 includes a conical cylindrical portion 33 and a rib 34.

- the conical cylindrical portion 33 has a conical cylindrical top that protrudes on the axial flow fan side.

- the top has a flat and closed conical shape.

- the tip end opposite to the top of the conical cylindrical portion 33 is open.

- the rib 34 is provided on the outer periphery of the conical cylindrical portion 33 so as to protrude in the axial flow fan direction from the tip end side.

- the conical cylindrical portion 33 has a circular tip end 35 and a circular top end 36 having a diameter smaller than that of the tip 35.

- the guard mark 31 is at the center of the front guard 32, as shown in FIG. Air from the fan passes from the top end 36 of the conical cylindrical portion 33 toward the tip end 35, and the air passing therethrough is formed to have diffusibility.

- the wind blown from the axial flow fan is directed from the top end 36 of the conical cylinder 33 of the guard mark 31 toward the tip end 35 larger in diameter than the top to the conical cylinder 33. Flow along.

- an air flow in the radial direction is formed from the vicinity of the guard marks 31 and the wind is diffused in the radial direction to improve the air blowing performance.

- the air flow in the rotational axis direction blown from the blades near the hub is hindered by being diffused by the air flowing radially along the conical cylinder portion 33.

- an object of the third embodiment of the present disclosure is to provide a fan that improves the straightness of the wind by increasing the flow in the rotation axis direction near the center of the axial flow fan.

- the fan according to the third embodiment of the present disclosure includes a hub and a plurality of blades provided on the hub, and an axial fan for blowing air by rotation by a motor, and a rotational shaft of the axial fan rather than the axial fan.

- Rear guard provided on the upstream side of the direction and a front guard provided on the downstream side in the axial direction of the axial fan from the rear guard, the front guard facing the axial fan at the center of the front guard It has a disk-like guard mark having a back surface, and the guard mark is provided on the back surface and has a conical protrusion having a top projecting toward the axial fan, and the back surface of the guard mark is provided with a ridge from the outer edge of the back surface.

- each of the plurality of straightening vanes being formed in an arc shape formed such that an arc is closed in a direction opposite to the rotational direction of the axial fan Having.

- the air flow led to the top of the projection is delivered towards the hub, ie in the direction opposite to the blowing direction of the axial fan.

- the air stream collides with the hub and is sent out from the center of the hub to the outer periphery.

- a circulation flow is formed by the flow of this air flow. This circulating flow attracts the air flow flowing from the upstream to the downstream in the vicinity of the guard marks and the hub, and accelerates the flow velocity of the wind blown from the fan. Therefore, the wind speed performance by a fan can be improved.

- the outer diameter of the guard mark may be larger than the diameter of the downstream portion of the axial flow fan in the rotational direction of the axial flow fan hub.

- the air flow pressurized by a portion of the blade located in the vicinity of the hub collides with the guard mark and is delivered from the outer edge of the back surface of the guard mark toward the top of the protrusion.

- an air flow is generated along the blowing direction of the axial fan. Since this air flow is in the same direction as the circulation flow, the wind speed of the circulation flow can be improved. Therefore, the circulation flow having the improved wind speed can attract the air flow flowing from the upstream to the downstream in the vicinity of the guard mark and the hub, and the flow velocity can be increased, so that the wind speed performance by the fan can be improved.

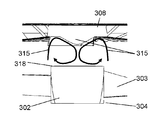

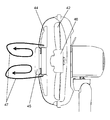

- FIG. 13 is a perspective view of the fan 301 according to the present disclosure

- FIG. 14 is a side view of the fan 301 according to the present disclosure

- FIG. 15 is a guard mark 308 of the front guard 307 of the fan 301 according to the present disclosure. It is the perspective view seen from the upstream side.

- the fan 301 includes an axial fan 304 having a plurality of blades 303 attached to a central hub 302, a motor (not shown) for rotating the axial fan 304, and an upstream side of the axial fan 304. And a motor housing 305 containing a motor provided therein.

- the fan 301 also includes a rear guard 306 and a front guard 307.

- the rear guard 306 covers the axial fan 304 on the side surface side and the rear side which is the upstream side of the axial fan 304 and protects foreign matter from contacting the axial fan 304.

- the rear guard 306 is formed of a metal or resin wire.

- the front guard 307 covers from the front side, which is the downstream side of the axial fan 304, and protects the axial fan 304 from contact with foreign matter.

- the front guard 307 is formed of a metal or resin wire.

- the front guard 307 includes a disk-like guard mark 308 provided at the center of the front guard 307 and an outer peripheral ring 309 provided at the outermost periphery of the front guard 307.

- the guard mark 308 is provided with a conical protrusion 310 protruding toward the axial fan 304 at a central portion of the back surface 316 thereof.

- the conical protrusion 310 has a base 311 and a top 312 smaller in diameter than the base 311.

- Guard mark 308 further includes a plurality of current plates 313 projecting toward axial fan 304 on its back surface 316. Each of the plurality of baffles 313 extends from the outer edge 317 of the back surface 316 of the guard mark 308 to the top 312 of the protrusion 310.

- Each of the plurality of straightening vanes 313 has an arc shape formed so that an arc is closed in a direction opposite to the rotational direction of the axial fan 304. Also, the plurality of current plates 313 are formed to radiate from the top portion 312 of the protrusion 310 to the outer edge 317 of the back surface 316. The back surface 316 of the guard mark 308 faces the axial fan 304.

- FIG. 16A shows a cross-sectional view of a guard mark 308 that has neither a conical protrusion 310 nor a baffle plate 313.

- FIG. 16B is a perspective view of a guard mark 308 having a conical protrusion 310 and a straightening vane 313 as seen from the downstream side of the rotational shaft of the axial flow fan.

- FIG. 16C shows a cross-sectional view of a guard mark 308 having a conical protrusion 310 and a current plate 313. The flow of wind in the vicinity of the guard mark 308 will be described with reference to FIGS. 16A to 16C.

- the hub 302 has a circular plane (downstream surface 318) on the downstream side of the axial flow fan 304 in the rotation axis direction.

- the downstream surface 318 does not have the vanes 303. Therefore, in the vicinity of the downstream surface 318 of the hub 302, there is no air flow flowing in the rotational axis direction of the axial flow fan 304. Instead, an air flow is generated that pivots in the same direction as the axial fan 304 rotates.

- the rotation of the axial fan 304 causes the hub 302 of the axial fan 304 to rotate, and the downstream surface 318 of the hub 302 also to rotate.

- the downstream surface 318 of the hub 302 causes the nearby air to rotate in the same direction by viscosity and to pivot in the same direction as the axial flow fan 304 rotates.

- a swirling flow 314 is generated in the section between the hub 302 and the guard mark 308. The swirling flow 314 does not affect the wind blown from the fan 301.

- the swirling flow 314 has a component along the air flow direction of the axial flow fan 304 near the outer periphery of the section sandwiched by the guard marks 308 and the hub 302. This is because the swirling flow 314 is induced by the air flow from the blades 303 of the axial flow fan 304. Further, the swirling flow 314 collides with the back surface 316 of the guard mark 308 and is delivered from the outer edge 317 of the back surface 316 toward the top 312 of the protrusion 310 along the back surface 316 of the guard mark 308. At this time, the swirling flow 314 is guided along the straightening vane 313 of the guard mark 308 to hold the swirling component along the rotation direction of the axial flow fan 304.

- the swirling flow 314 is collected at the top 312 of the protrusion 310 of the guard mark 308 and is delivered in the direction opposite to the blowing direction of the axial flow fan 304 by the inclination of the protrusion 310.

- the air stream collides with the central portion of the downstream surface 318 of the hub 302 and is delivered along the downstream surface 318 from the central portion to the outer peripheral portion of the downstream surface 318.

- a straightening vane 313 is formed so that the arc is closed in the direction opposite to the rotational direction of the axial fan 304. Therefore, the swirling flow 314 flows toward the center of the guard mark 308, and then flows from the base 311 to the top 312 along the slope of the conical protrusion 310. That is, the swirling flow 314 is directed to the hub 302 of the axial flow fan 304 from the guard marks 308 opposite to the air flow direction of the axial flow fan 304.

- the swirling flow 314 between the guard mark 308 and the hub 302 becomes a circulating flow 315 which is a flow circulating in the rotational axis direction.

- the airflow flowing from the upstream to the downstream of the axially-flowing fan 304 pressurized from the portion near the hub 302 of the vanes 303 is attracted to the circulating flow 315 to increase the speed.

- the axial flow fan 304 has, for example, a radius of 250 mm, a radius of 50 mm of the guard mark 308, a radius of 50 mm of the hub 302, a distance of 50 mm between the guard mark 308 and the downstream surface 318 of the hub 302, a current plate 313, and a conical protrusion 310. And a circulating flow 315 in the direction of the rotation axis with a height of 20 mm.

- the radius of the downstream surface 318 of the hub 302 may be smaller than the radius of the guard mark 308.

- the radius of the downstream surface 318 of the hub 302 may be 40 mm with respect to the radius of 50 mm of the guard mark 308.

- Patent Document 3 Japanese Patent Application Laid-Open No. 2011-58382 discloses a conventional fan as a shape for giving a rectifying effect to a front guard to improve air blowing performance. The configuration will be described below with reference to FIGS. 23 and 24.

- FIG. 23 is a perspective view showing the configuration of a conventional fan 41

- FIG. 24 is a side view of the fan 41.

- the front guard 43 includes a disk-shaped guard mark 45 formed at the center thereof, and a plurality of flow straightening vanes 44 disposed radially from the guard mark 45.

- the front guard 43 covers the front of the axial fan 42. In such a fan 41, the wind blown from the axial fan 42 flows along the straightening vanes 44 so that the wind straightens toward the downstream side. The straightening effect of the straightening vanes 44 allows the wind passing through the front guard 43 to go straight.

- the wind blown from the axial fan 42 is straightened by the straightening vane 44 when passing through the front guard 43, thereby improving the straightness of the wind. I was trying.

- the straightness of the wind is not sufficient.

- the guard marks 45 are provided to face the hub 46 of the axial flow fan 42 and a portion near the central axis of the blades of the axial flow fan 42. Therefore, the air flow from the portion near the central axis of the blades of the axial fan 42 is interrupted by the guard marks 45.

- the wind blown from a portion near the central axis of the blades of the axial flow fan 42 does not flow to the downstream side of the guard mark 45 which is an area facing the guard mark 45.

- the area downstream of the guard mark 45 has a negative pressure. Therefore, the main flow of the air flow of the axial flow fan 42 generated from the outer peripheral side portion of the blade of the axial flow fan 42 flows toward the region on the downstream side of the guard mark 45. Due to this inflow, in the region downstream of the guard mark 45, a vortex 47 is generated which flows backward in the flow direction of the main flow of the axial fan 42.

- the damping action of the main flow velocity of the air flow of the axial fan 42 is reduced by suppressing the vortices 47 generated in the area downstream of the guard mark 45, and the straightness of the air flow Aims to provide a fan that improves the

- An electric fan includes a hub and a plurality of blades provided on the hub, and an axial fan that blows air by rotation by a motor, and a rotational shaft of the axial fan rather than the axial fan.

- Rear guard provided on the upstream side of the direction and a front guard provided on the downstream side in the axial direction of the axial fan from the rear guard, and the front guard is a disk-like guard provided at the center of the front guard

- a plurality of inner circumferences comprising a mark, an intermediate ring provided between the outer circumference of the guard mark and the outer circumference of the front guard, and a plurality of inner circumference ribs provided between the guard mark and the middle ring

- Each of the ribs has a first end connected to the outer periphery of the guard mark and a second end connected to the inner periphery of the intermediate ring, and each of the plurality of inner peripheral ribs is an axial fan

- Anti-rotational direction A formed arc-shape so an inner circumferential side of the arc direction is located, the outer diameter of the guard marks smaller than the outer diameter of the hub, the outer diameter of the intermediate ring is larger than the outer diameter of the hub.

- the outer diameter of the intermediate ring is larger than the outer diameter of the hub, the wind blown from the portion near the hub of the blade passes between the inner circumferential ribs. Since the inner circumferential side of the arc of each inner circumferential rib is located in the direction opposite to the rotational direction of the axial fan, the wind passing between the inner circumferential ribs flows along the shape of the inner circumferential rib, It is guided to the central axis side of the flow fan. Furthermore, since the outer diameter of the guard mark is smaller than the hub outer diameter, the wind guided to the central axis side by the inner circumferential rib is blown to the downstream region of the guard mark.

- the wind blown from the axial fan is guided to the downstream area of the guard mark, whereby the wind flows into the downstream area of the guard mark and the area where the negative pressure is applied is reduced. Therefore, the amount of air flowing into the area downstream of the guard mark in the main flow of the blowing air is reduced, thereby suppressing the generation of a vortex in the area downstream of the guard mark. By suppressing the generation of the vortices, the reduction of the wind speed near the central axis after passing through the front guard is suppressed.

- the fan according to the fourth embodiment of the present disclosure further includes a plurality of outer peripheral ribs connected between the outer peripheral edge of the intermediate ring and the outer peripheral edge of the front guard, and each of the plurality of outer peripheral ribs is an axis. It may be formed to be opposed to the largest wide portion where the chord length of the flow fan is the largest.

- the amount of air flow boosted at the widest part of the axial fan is the largest in the distribution of the amount of air flow boosted by the axial fan. Further, the velocity of the air flow boosted at the maximum wide portion of the axial fan becomes the maximum value in the velocity distribution of the air blown by the axial fan.

- the wind having a large rotational component blown from the portion near the hub of the blade passes between the inner circumferential ribs, and the air flow pressurized at the widest wide portion passes between the outer circumferential ribs. Therefore, the wind having a large rotational component blown from the portion near the hub of the blade of the axial flow fan is guided to the central axis side of the axial flow fan by the inner circumferential rib.

- the inner circumferential rib and the outer circumferential rib can be provided appropriately to control the wind direction.

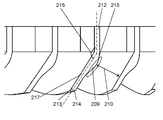

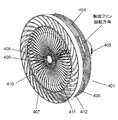

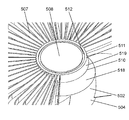

- FIG. 19 is a perspective view of a fan 401 according to Embodiment 4 of the present disclosure

- FIG. 20 is a side view of the fan 401 according to Embodiment 4 of the present disclosure

- FIG. It is the front view which made the front guard 407 and the axial flow fan 404 attached to the upstream of the fan 401 which concerns on form 4 permeate

- the fan 401 includes an axial fan 404 having a plurality of blades 403 attached to a central hub 402, a motor (not shown) for rotating the axial fan 404, and an upstream side of the axial fan 404. And a motor housing 405 containing a motor provided therein.

- the fan 401 further includes a rear guard 406 and a front guard 407.

- the rear guard 406 covers the axial fan 404 on the side and the back side which is the upstream side of the axial fan 404, and protects foreign matter from contacting the axial fan 404.

- the rear guard 406 is formed of a metal or resin wire.

- the front guard 407 covers from the front side which is the downstream side of the axial fan 404 and protects the axial fan 404 from contact with foreign matter.

- the front guard 407 is formed of a metal or resin wire.

- the front guard 407 includes a disk-shaped guard mark 408, an intermediate ring 409, a plurality of outer peripheral ribs 411 (outer outer side flow plates), and a plurality of inner outer ribs 410 (inner peripheral side flow plates).

- Guard mark 408 is located at the center of front guard 407.

- the middle ring 409 is located between the guard mark 408 and the outer peripheral edge 412 of the front guard 407.

- the plurality of outer peripheral ribs 411 are located between the intermediate ring 409 and the outer peripheral edge 412.

- the plurality of inner circumferential ribs 410 are located between the guard marks 408 and the middle ring 409.

- Each inner circumferential rib 410 is formed in an arc shape.

- the inner side of the arc is located in the opposite direction to the rotational direction of the axial fan 404.

- the inner circumferential rib 410 is formed in an arc shape projecting in the rotation direction of the axial flow fan 404.

- FIG. 21 shows a front view of the front guard 407 and the axial flow fan 404 mounted on the upstream side, viewed from the downstream side, with a portion of the front guard 407 transmitted therethrough.

- the outer diameter of the guard mark 408 is smaller than the outer diameter of the hub 402 attached to the central portion of the axial fan 404.

- the outer diameter of the intermediate ring 409 is larger than the outer diameter of the hub 402 of the axial flow fan 404.

- FIGS. 22A and 22B the air flow blown from the portion near the hub 402 of the blade 403 of the axial flow fan 404 is induced to the central axis side of the axial flow fan 404 by the inner circumferential rib 410, and the vortex is suppressed.

- FIG. 22A is an enlarged view of the vicinity of the guard mark 408 of the front guard 407.

- the outer diameter of the intermediate ring 409 is larger than the outer diameter of the hub 402 of the axial flow fan 404. Therefore, the wind blown from the portion near the hub 402 of the blade 403 of the axial flow fan 404 passes between the inner circumferential ribs 410.

- FIG. 22B is a cross-sectional view of the front guard 407 and the axial fan 404 as viewed from the side.

- the wind having passed between the inner circumferential ribs 410 is guided to the central axis side and flows into the area downstream of the guard mark 408.

- an air flow 415 flowing into the area downstream of the guard mark 408 is formed.

- the area under negative pressure is reduced. Therefore, the volume of the air flowing into the area downstream of the guard mark 408 in the mainstream of the wind blown from the outer peripheral side of the blade 403 of the axial fan 404 decreases, and the vortex in the area downstream of the guard mark 408 Occurrence is suppressed.

- the reduction of the speed of the wind near the central axis after passing through the front guard 407 is suppressed, and the air can be efficiently blown.

- an outer peripheral rib 411 is formed between the intermediate ring 409 and the outer peripheral edge 412 of the front guard 407.

- the inner circumferential rib 410 and the outer circumferential rib 411 are each formed in an arc shape having a curvature.

- the curvature of the inner circumferential rib 410 is larger than the curvature of the outer circumferential rib 411.

- the airflow from the portion near the hub 402 of the blade 403 has a large rotational component, and is blown out radially outward in response to centrifugal force.

- the blade 403 provided in the axial fan 404 has a maximum wide portion 413 where the chord length is maximum.

- the outer circumferential rib 411 is provided to face the largest wide portion 413.

- the wind blown from the axial fan 404 is boosted by passing between the blades 403 of the axial fan 404.

- the amount of airflow boosted at the widest part 413 of the axial fan 404 is the largest in the distribution of the amount of airflow boosted by the axial fan 404.

- the velocity of the air flow boosted at the widest wide portion 413 of the axial fan 404 has a maximum value in the velocity distribution of the air blown by the axial fan 404.

- the high-velocity, high-speed air flow that has been boosted at the widest part 413 passes between the outer peripheral ribs 411.

- the outer circumferential rib 411 has a curvature smaller than that of the inner circumferential rib 410. Therefore, the high-speed air flow boosted at the widest part 413 has a direction closer to parallel to the central axis of the axial fan 404 than the air flow blown from a portion near the hub 402 of the blades 403 of the axial fan 404. Be blown out. That is, the air flow boosted at the largest wide portion 413 and the air flow with the largest wind speed are blown in a direction close to parallel to the central axis of the axial flow fan 404. This can improve the blowing efficiency.

- the conventional fan has a configuration described in, for example, Patent Document 4 (Japanese Patent Laid-Open No. 2015-108362) as a shape for improving the air flow performance of a guard mark located at the center of the front guard.

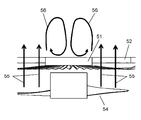

- FIG. 29 is a front view showing the configuration of the guard mark 51 used in the conventional fan

- FIG. 30 is a side view of the fan having the guard mark 51 attached to the center of the front guard 52.

- the guard mark 51 has an opening 53 communicating on the outer periphery side of the guard mark from the upstream side on the axial fan side to the downstream side to be the front side of the fan.

- the air flow blown from the vicinity of the hub of the axial flow fan is allowed to pass through the opening 53 to reduce the air flow resistance of the air flow from the axial flow fan and to increase the amount of air passing through the front guard 52.

- the guard mark 51 of such a conventional fan In the guard mark 51 of such a conventional fan, the air flow blown from the vicinity of the hub of the axial flow fan is blocked by the guard mark 51 on the downstream side of the guard mark 51. Therefore, a pressure difference occurs between the area through which the front guard 52 passes and the air flow generated by the axial fan is blown and the downstream area facing the guard mark 51, and as a result, the downstream area facing the guard mark 51 There is a negative pressure compared to the area where the air flow generated by the axial fan is blown.

- the main flow of the air flow of the axial fan generated on the outer peripheral side of the axial fan blade flows toward the area downstream of the guard mark 51 which is a negative pressure, and the axis downstream of the guard mark 51 It flows backward in the flow direction of the mainstream of the flow fan to generate a circulating flow. Due to the influence of the circulation flow, the main flow of the air flow of the axial flow fan generated on the outer peripheral side of the blades of the axial flow fan is attenuated.

- FIG. 31 shows a cross-sectional view of the guard mark 51 in the conventional example, and conceptually shows the air flow 55 passing through the guard mark 51 and the circulating flow 56 generated in the region on the downstream side of the guard mark 51.

- the air flow 55 from the axial flow fan 54 is blown to the downstream side of the front guard 52.

- the air flow 55 from the axial flow fan 54 is blocked by the guard mark 51 and is not blown. Therefore, the downstream region of the guard mark 51 has a relatively negative pressure as compared to the downstream region facing the front guard 52 through which the air flow 55 passes and the downstream region of the guard mark 51.

- the air flow 55 from the axial flow fan 54 which has passed through the front guard 52 is attracted by the negative pressure in the downstream region of the guard mark 51 and is drawn in the direction of the central axis of the axial flow fan 54.

- a circulating flow 56 flowing toward the guard mark 51 is formed.

- the circulation flow 56 the main flow of the air flow by the axial flow fan 54 is attenuated, and the air blowing efficiency is deteriorated.

- the damping action of the main flow velocity of the air flow of the axial flow fan 54 is reduced by suppressing the circulation flow generated in the region downstream of the guard mark 51, and the air flow straight It aims to provide a fan that improves the quality.

- the fan according to the fifth embodiment of the present disclosure includes an axial fan having a plurality of blades and configured to blow air by rotation by a motor, and is provided upstream of the axial fan in the axial direction of the axial fan.

- Rear guard and a front guard provided on the downstream side in the axial direction of the axial fan than the rear guard, the front guard being parallel to the downstream surface and the downstream surface at the center of the front guard and larger than the downstream surface

- the guard mark has a frusto-conical guard mark having a diameter upstream face, the upstream face of the guard mark faces the axial fan, and the guard mark is an outer edge of the downstream face of the guard mark on the downstream face of the guard mark And an annular groove arranged along the

- the axial fan further includes a hub provided with a plurality of blades, and the diameter of the upstream surface of the guard mark is greater than the diameter of the axial fan hub. It may also be made smaller. With this configuration, the air flow pressurized by the portion of the blade near the hub is prevented from being blocked by the upstream surface of the guard mark. Therefore, the air flow resistance generated when the air flow pressurized by the portion located in the vicinity of the hub of the blade is blown to the downstream side of the guard mark is reduced, and the air flow from the axial flow fan can be efficiently blown.

- the annular groove may be formed concentrically with the downstream surface of the guard mark.

- the distance from the outer edge of the guard mark to the annular groove has a constant value over the entire circumference of the annular groove. Therefore, the vortices generated in the annular groove have the same size all around the groove. Therefore, the air flow blown from the axial fan is evenly attracted to the vortex formed by the annular groove all around the annular groove. Thereby, the turbulence of the air flow in the area

- FIG. 25 is a perspective view of the fan 501 according to the fifth embodiment of the present disclosure

- FIG. 26 is a side view of the fan 501

- FIG. 27 is a downstream side of the guard mark 508 of the front guard 507 of the fan 501. It is the perspective view seen from.

- the fan 501 includes an axial fan 504 having a plurality of blades 503 attached to a central hub 502, a motor (not shown) for rotating the axial fan 504, and an upstream side of the axial fan 504. And a motor housing 505 containing a motor provided therein.

- the fan 501 includes a rear guard 506 and a front guard 507.

- the rear guard 506 covers the axial fan 504 from the side and the back side that is the upstream side of the axial fan 504, and protects foreign matter from contacting the axial fan 504.

- the rear guard 506 is formed of a metal or resin wire.

- the front guard 507 covers from the front side, which is the downstream side of the axial fan 504, and protects the axial fan 504 from contact with foreign matter.

- the front guard 507 is formed of a metal or resin wire.

- the front guard 507 also includes a guard mark 508 provided at the center of the front guard 507.

- the front guard 507 is fixed to the rear guard 506 by an outer peripheral ring 509 located at the outermost periphery of the front guard 507.

- the size of the downstream surface of the hub 502 of the axial flow fan 504 is a size of a radius of 50 mm

- the size of the blades 503 is a size of a maximum radius of 250 mm.

- the guard mark 508 has a truncated cone shape having a circular upstream surface 510, a circular downstream surface 511, and a tapered side surface 519.

- the upstream surface 510 is parallel to the downstream surface 511.

- the upstream surface 510 faces the downstream surface 518 of the axial fan 504.

- the side surface 519 extends between the upstream surface 510 and the downstream surface 511.

- the diameter of the upstream surface 510 is larger than the diameter of the downstream surface 511.

- the guard mark 508 is provided with an annular groove 512 disposed on the downstream surface 511 along the outer edge of the circular downstream surface 511. A clearance of about 1 mm is provided between the outer edge of the downstream surface 511 and the annular groove 512.

- the upstream surface 510 has a radius of 50 mm

- the downstream surface 511 has a radius of 44.7 mm.

- the distance between the upstream surface 510 and the downstream surface 511 corresponding to the height of the truncated cone shape is 30 mm.

- the side surface 519 is inclined with respect to the central axis of the axial fan 504.

- the size of the groove 512 is 5 mm in depth and 5 mm in width.

- FIG. 28 shows a cross-sectional view of the guard mark 508 and further conceptually shows the air flow 513, the side air flow 514, the induced air flow 516, and the circulation flow 517.

- the blowing air flow 513 is an air flow that is pressurized by a portion of the blade 503 near the hub 502 and is blown in a direction parallel to the central axis of the axial flow fan 504. The blowing air 513 passes near the side surface 519 of the guard mark 508.

- a part of the air flow 513 is a side air flow 514 along the side surface 519 of the guard mark 508.

- the side air flow 514 peels off the side surface 519 at the edge portion of the guard mark 508 and is blown toward the center side of the guard mark 508.

- a part of the air flow blown toward the center side of the guard mark 508 is attracted into the annular groove 512 to form the vortex 515.

- the vortex 515 stays in the annular groove 512 and is constantly attracted to a part of the side air flow 514 to generate the induced air flow 516.

- the diameter of the downstream surface 518 of the hub 502 is larger than the diameter of the upstream surface 510 of the guard mark 508.

- the radius of the upstream surface 510 of the guard mark 508 is 50 mm.

- the radius of the downstream surface 518 of the hub 502 is 55 mm. Therefore, the blowing air flow 513 passes through the front guard 507 and flows downstream without colliding with the upstream surface 510 of the guard mark 508. Therefore, the air flow resistance due to the air flow 513 colliding with the upstream surface 510 of the guard mark 508 can be reduced, and the air flow 513 can efficiently flow through the front guard 507 and flow downstream.