WO2019049771A1 - 繊維強化複合材料及びその製造方法 - Google Patents

繊維強化複合材料及びその製造方法 Download PDFInfo

- Publication number

- WO2019049771A1 WO2019049771A1 PCT/JP2018/032195 JP2018032195W WO2019049771A1 WO 2019049771 A1 WO2019049771 A1 WO 2019049771A1 JP 2018032195 W JP2018032195 W JP 2018032195W WO 2019049771 A1 WO2019049771 A1 WO 2019049771A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- fiber

- silk

- composite material

- reinforced composite

- reinforcing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/026—Knitted fabric

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/04—Reinforcing macromolecular compounds with loose or coherent fibrous material

- C08J5/047—Reinforcing macromolecular compounds with loose or coherent fibrous material with mixed fibrous material

- C08J5/048—Macromolecular compound to be reinforced also in fibrous form

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/04—Reinforcing macromolecular compounds with loose or coherent fibrous material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/08—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer the fibres or filaments of a layer being of different substances, e.g. conjugate fibres, mixture of different fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/10—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer characterised by a fibrous or filamentary layer reinforced with filaments

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/22—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed

- B32B5/24—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer

- B32B5/26—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer another layer next to it also being fibrous or filamentary

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/04—Reinforcing macromolecular compounds with loose or coherent fibrous material

- C08J5/0405—Reinforcing macromolecular compounds with loose or coherent fibrous material with inorganic fibres

- C08J5/042—Reinforcing macromolecular compounds with loose or coherent fibrous material with inorganic fibres with carbon fibres

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/04—Reinforcing macromolecular compounds with loose or coherent fibrous material

- C08J5/045—Reinforcing macromolecular compounds with loose or coherent fibrous material with vegetable or animal fibrous material

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/24—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs

- C08J5/247—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs using fibres of at least two types

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L23/00—Compositions of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Compositions of derivatives of such polymers

- C08L23/02—Compositions of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Compositions of derivatives of such polymers not modified by chemical after-treatment

- C08L23/04—Homopolymers or copolymers of ethene

- C08L23/08—Copolymers of ethene

- C08L23/0846—Copolymers of ethene with unsaturated hydrocarbons containing atoms other than carbon or hydrogen

- C08L23/0853—Ethene vinyl acetate copolymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L25/00—Compositions of, homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an aromatic carbocyclic ring; Compositions of derivatives of such polymers

- C08L25/02—Homopolymers or copolymers of hydrocarbons

- C08L25/04—Homopolymers or copolymers of styrene

- C08L25/06—Polystyrene

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L29/00—Compositions of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an alcohol, ether, aldehydo, ketonic, acetal or ketal radical; Compositions of hydrolysed polymers of esters of unsaturated alcohols with saturated carboxylic acids; Compositions of derivatives of such polymers

- C08L29/02—Homopolymers or copolymers of unsaturated alcohols

- C08L29/04—Polyvinyl alcohol; Partially hydrolysed homopolymers or copolymers of esters of unsaturated alcohols with saturated carboxylic acids

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L89/00—Compositions of proteins; Compositions of derivatives thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2260/00—Layered product comprising an impregnated, embedded, or bonded layer wherein the layer comprises an impregnation, embedding, or binder material

- B32B2260/02—Composition of the impregnated, bonded or embedded layer

- B32B2260/021—Fibrous or filamentary layer

- B32B2260/023—Two or more layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2260/00—Layered product comprising an impregnated, embedded, or bonded layer wherein the layer comprises an impregnation, embedding, or binder material

- B32B2260/04—Impregnation, embedding, or binder material

- B32B2260/046—Synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2260/00—Layered product comprising an impregnated, embedded, or bonded layer wherein the layer comprises an impregnation, embedding, or binder material

- B32B2260/04—Impregnation, embedding, or binder material

- B32B2260/048—Natural or synthetic rubber

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0246—Acrylic resin fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0253—Polyolefin fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0261—Polyamide fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0261—Polyamide fibres

- B32B2262/0269—Aromatic polyamide fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0276—Polyester fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/04—Cellulosic plastic fibres, e.g. rayon

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/06—Vegetal fibres

- B32B2262/062—Cellulose fibres, e.g. cotton

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/08—Animal fibres, e.g. hair, wool, silk

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/10—Inorganic fibres

- B32B2262/101—Glass fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/10—Inorganic fibres

- B32B2262/103—Metal fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/10—Inorganic fibres

- B32B2262/105—Ceramic fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/10—Inorganic fibres

- B32B2262/106—Carbon fibres, e.g. graphite fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/10—Inorganic fibres

- B32B2262/108—Rockwool fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/51—Elastic

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/54—Yield strength; Tensile strength

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2419/00—Buildings or parts thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2457/00—Electrical equipment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2457/00—Electrical equipment

- B32B2457/08—PCBs, i.e. printed circuit boards

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2603/00—Vanes, blades, propellers, rotors with blades

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2605/00—Vehicles

- B32B2605/08—Cars

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2605/00—Vehicles

- B32B2605/12—Ships

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2605/00—Vehicles

- B32B2605/18—Aircraft

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2300/00—Characterised by the use of unspecified polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2303/00—Characterised by the use of starch, amylose or amylopectin or of their derivatives or degradation products

- C08J2303/02—Starch; Degradation products thereof, e.g. dextrin

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2305/00—Characterised by the use of polysaccharides or of their derivatives not provided for in groups C08J2301/00 or C08J2303/00

- C08J2305/12—Agar-agar; Derivatives thereof

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2323/00—Characterised by the use of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Derivatives of such polymers

- C08J2323/02—Characterised by the use of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Derivatives of such polymers not modified by chemical after treatment

- C08J2323/04—Homopolymers or copolymers of ethene

- C08J2323/08—Copolymers of ethene

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2489/00—Characterised by the use of proteins; Derivatives thereof

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L2205/00—Polymer mixtures characterised by other features

- C08L2205/14—Polymer mixtures characterised by other features containing polymeric additives characterised by shape

- C08L2205/16—Fibres; Fibrils

Definitions

- the present invention relates to a fiber-reinforced composite material containing minnow silk as a reinforcing fiber, and a method for producing the same.

- Fiber-reinforced composite materials in which reinforcing fibers and a matrix are combined are lightweight as represented by carbon fiber-reinforced plastics (CFRP: Carbon Fiber-Reinforced Plastics) and glass fiber-reinforced plastics (GFRP: Glass Fiber-Reinforced Plastics) And a material having high strength and elastic modulus.

- CFRP Carbon Fiber-Reinforced Plastics

- GFRP Glass Fiber-Reinforced Plastics

- Such high strength and elastic modulus are largely based on mechanical properties of reinforcing fibers such as carbon fibers, glass fibers and aramid fibers.

- carbon fiber is known to have about 10 times the mechanical properties of iron at a specific strength obtained by dividing the strength by the mass of the material (Non-patent Document 1). Because of such mechanical properties, fiber reinforced composite materials are used as a substitute for metals in various fields ranging from sports and leisure goods, automobiles, houses, buildings, and aircraft.

- spider silk is actually used as a reinforcing fiber, there are many points to be solved in practice. For example, spiders are difficult to mass-produce or collect a large amount of threads from spiders, so spider threads can not be mass-produced and there is a problem that the production cost is high. At present, this problem has been attempted by producing spider silk in E. coli or silkworm using genetic recombination technology (Patent Document 1 and Non-Patent Document 3). However, since E. coli and silkworms used for spider silk production are genetically modified, they can be cultured and reared only in facilities equipped with predetermined facilities, and a large-scale production facility is required for mass production. In addition, there is a new problem that the maintenance and management burden increases.

- spider silk proteins expressed in E. coli are in a liquid state, a step of converting them into fibers is required, but at this point, no fiber conversion step has been found to reproduce the mechanical properties of natural fibers.

- An object of the present invention is to develop and provide a fiber reinforced composite material having high strength, high elastic modulus, and further having the property of "stretching" in a conventional fiber reinforced composite material. It aims at solving the problem of brittleness and exfoliation in a conventional fiber reinforced composite material by this.

- a silk thread which is often referred to as "minom silk thread” in the present specification

- a worm worm Basket worm, alias "bag worm”

- the term 'Minomushi' is a generic name for the winged larvae belonging to the order Lepidopteridae (Psychidae), and usually hides and feeds in a spindle-shaped or cylindrical nest (Bag nest) in which leaves and branches are entwined with a thread It is known to live in the whole larval stage with the nest, such as moving every nest during the

- This minomushi silk has a well-balanced combination of strength and elongation, and has mechanical superior properties to silkworm silk and spider silk.

- a minnow beetle silk of chaminoga Esumeta minuscula

- its modulus of elasticity is 3.5 times that of silkworm silk thread and 2.5 times that of spider silk of Nephila clavata (Osaki Shigeyoshi, 2002, Journal of the Fiber Society Industry), 58: 74-78; Gosline J. M. et al., 1999, J. Exp. Biol. 202, 3295-3303).

- the inventors of the present invention have revealed that the minnow silk of Ominaga (Eumeta japonica) also has similar mechanical properties as compared with silkworm silk and spider silk derived from the spider spider (Japanese Patent Application No. 2017-110003).

- the elastic modulus is about 5 times that of silkworm silk thread and more than 3 times that of spider silk.

- the breaking strength was at least 3 times that of silkworm silk, and about 2 times that of spider silk, and the breaking elongation was at least 1.3 times that of silkworm silk, and substantially comparable to spider silk.

- the toughness is more than 4 times that of silkworm silk and 1.7 times that of spider silk, and it has become clear that the highest level of toughness among natural fibers is exhibited.

- minnows have advantages over silkworms.

- silkworms are basically reared only because they feed only fresh leaves of species belonging to the genus Morus, for example, M. bombycis, M. alba, and M. Ihou.

- the area and breeding season depend on the area where mulberry leaves are supplied and the open season of mulberry.

- the minnow beetle is an edible herbivore with low specificity to the baiting leaf, and many species can feed on leaves of various tree species. Therefore, it is easy to obtain prey leaves and do not choose any breeding area.

- minnows are superior to silkworms.

- silkworms take a large amount of thread only when ingested, and engulfment is performed simultaneously with all larvae.

- the yarn production time is overlapped and the working period is concentrated.

- the minnow beetles repeatedly perform vomiting during nesting and movement throughout the larval stage. Therefore, there is an advantage that the working period can be dispersed by artificially adjusting the yarn production time.

- minomushi silk can be directly collected from a wild-type minomushi, and has the advantage that it does not require preparation and maintenance of a recombinant as in the production of spider silk.

- the fiber-reinforced composite material using the Minomushi silk yarn as a reinforcing fiber has an elastic modulus that is improved by 10 times or more than that of the polymer matrix alone.

- the low elongation at break which was the problem to be solved for carbon fiber reinforced plastics (CFRP) and glass fiber reinforced plastics (GFRP) Problems could be significantly improved.

- the present invention is based on the above-mentioned research results and provides the following inventions.

- a fiber-reinforced composite material comprising a polymer matrix and a reinforcing fiber containing a minmushi silk thread.

- the fiber reinforced composite material according to (2) which comprises a minmomi silk yarn consisting of short fibers of 1 mm or more and less than 1 m.

- the fiber-reinforced composite material according to (3) which comprises silk spinning of a minamushi silk thread.

- the fiber-reinforced composite material according to any one of (2) to (5) which further contains an organic fiber other than minomushi silk as a reinforcing fiber, an inorganic fiber, or a combination thereof.

- the fiber-reinforced composite material according to any one of (2) to (6) which comprises a minmomi silk thread arranged in one or more directions.

- the fiber-reinforced composite material according to (7) which comprises a woven fabric or a woven fabric composed entirely or partially of a minmomi silk yarn.

- the present specification includes the disclosure content of Japanese Patent Application No. 2017-170648 on which the priority of the present application is based.

- the fiber-reinforced composite material of the present invention it is possible to provide a fiber-reinforced composite material having high strength and high elastic modulus, and having "elongation" properties not found in conventional CFRP and GFRP.

- a first aspect of the present invention is a reinforcing fiber.

- the reinforcing fiber of the present invention is a reinforcing fiber for a fiber reinforced composite material, and is characterized by containing a minmomi silk thread. According to the reinforcing fiber of the present invention, the properties of high strength, high elastic modulus and elongation can be imparted to the fiber reinforced composite material.

- Fiber-reinforced composite material refers to a material in which two or more different materials, that is, reinforcing fibers and a base material are integrally combined in a separated state without fusion.

- reinforcing fiber refers to a fiber base in a fiber-reinforced composite material.

- a reinforcing fiber is a reinforcing material that imparts strength to a fiber-reinforced composite material, but in the present specification, a reinforcing material that imparts at least one or more of strength, elastic modulus, and elongation to a fiber-reinforced composite material .

- the "base material” is also referred to as a "matrix” and refers to a support base in a fiber reinforced composite material.

- the base material is usually the side to which strength is imparted in the fiber-reinforced composite material.

- the reinforcing fibers in the present specification can not only be the reinforcing fibers themselves as a reinforcing agent, but also the base material can also be a reinforcing material that gives strength to the reinforcing fibers as a filler for filling between the reinforcing fibers. That is, in the fiber-reinforced composite material of the present invention, the respective constituent materials enhance their respective advantages and / or mutually complement the disadvantages. Thereby, it is possible to obtain a fiber-reinforced composite material having new properties not found in the original material.

- polymer matrix refers to a base material composed of an organic polymer and / or an inorganic polymer.

- silk thread refers to a protein-made thread on which worms and adults of insects run for the purpose of nesting, migration, fixation, feeding, and the like.

- the silk yarn in the present specification includes monofilaments, yarn spinning fibers, silk spun fibers, and aggregated fibers.

- “monofilament” is a filament (monofilament) yarn of the smallest unit constituting a silk yarn, and is a fiber such as fibroin protein obtained by removing a coating component such as sericin protein from the yarn spinning fiber described later We say ingredient. Monofilaments in principle do not exist in the natural state and are obtained by subjecting the spun fibers to a scouring treatment.

- the term "threading fiber” refers to silk thread in the state where an insect has spun.

- the spinneret's twine fibers are composed of difilaments in which two single fibers are bound by a coating component.

- “silk spinning” refers to a spun yarn obtained by spinning a silk yarn of a short fiber described later.

- aggregated fiber is a fiber composed of a plurality of silk fiber bundles, also referred to as multifilament.

- the aggregate fiber of the present invention is composed of monofilaments, yarn spinning fibers, silk spinning, or a combination thereof.

- the aggregate fiber of the present specification is also a composite fiber composed of only silk threads derived from the same biological species such as minomushi silk threads alone, or a mixed fiber composed of different types of silk threads derived from minomushi silk threads and silkworm silk threads Include.

- the biological species from which the minnow silk thread etc. are derived are not limited.

- Aggregate fibers also include untwisted fibers as well as twisted fibers.

- the term "minomushi” refers to a generic name of a caterpillar of the order belonging to the order Lepidoptera (Psychidae).

- the Minogaea spp. Is distributed all over the world, but every larva (Minimus) is a silk thread that sheds herself through the entire larval stage, spells natural materials such as leaf pieces and branches, and lives in the nest where they are crawled doing.

- the nest is in the form of a bag that can be wrapped around the whole body, and has a spindle-like shape, a cylindrical shape, a conical shape or the like.

- the minnow bug usually hides in this nest, always acts along with the nest when feeding and moving, and hatching also takes place in the nest in principle.

- the term “minom silk” refers to a silk that is mined by the minimus.

- the reinforcing fibers of the present invention include minmomi silk yarn.

- minmomi silk yarn There is no limitation on the kind of minoga from which the minimus silk yarn used as the reinforcing fiber of the present invention is derived.

- Minogidae Acanthopsyche, Anatolopsyche, Bacotina, Canephora, Chalioides, Dahlica, Diplodoma, Eumeta, Eumasia, Kozhantshikovia, Mahasena, Nipponopsyche, Parautarychia, Psychia, Pteroma, Siederia, Mitritracitiveilium

- Minogidae Acanthopsyche, Anatolopsyche, Bacotina, Canephora, Chalioides, Dahlica, Diplodoma, Eumeta, Eumasia, Kozhantshikovia, Mahasena, Nipponopsyche, Parautarychia, Psychia, Pte

- Minoga As a specific example of the kind of Minoga, there can be mentioned Ominoga (Eumeta japonica), Chaminoga (Eumeta minuscula), and Shibaminoga (Nipponopsyche fuscescens).

- Ominoga Esumeta japonica

- Chaminoga Eumeta minuscula

- Shibaminoga Neipponopsyche fuscescens

- the age of the larvae is from the first age to the last age.

- males and females do not matter.

- larger species are more preferable in Minogidae. Therefore, from the viewpoint of obtaining a thicker and longer minomushi silk thread, Ominoga and chaminoga are suitable species as minnows used in the present invention.

- the last-instar larva is more preferable, and the larger female is more preferable.

- Scaffold silk threads and nest silk threads are present in the minomushi silk thread, but the minomushi silk thread used as a reinforcing fiber may be either or both of them.

- the “scaffold silk thread” is a silk thread which minnows are spouted prior to movement, and has a function as a scaffold for preventing falling from a branch, a leaf or the like during movement.

- a “nest silk thread” is a silk thread that constitutes a nest, and is used to splint leaves and branches and to make the inner wall of the nest, which is a residential area, a comfortable environment.

- scaffold silk is thicker than nest silk and is mechanically strong, and therefore it is more preferable as a reinforcing fiber.

- the length of minomushi silk thread used as a reinforcing fiber does not matter.

- short fiber short fiber silk yarn

- long fiber long fiber silk yarn

- a combination thereof can be mentioned.

- short fibers means that the length of the major axis is 1.0 mm or more and less than 1 m, 1.5 mm or more and less than 80 cm, 2 mm or more and less than 60 cm, 2.5 mm or more and less than 50 cm, 3 mm or more and less than 40 cm, 3.5 mm or more and less than 30 cm 4 mm or more and less than 20 cm, 4.5 mm or more and less than 10 cm, and 5.0 mm or more and less than 5 cm.

- scaffold silk threads and fragments of nest silk threads are relevant.

- the short fiber silk yarn may be used as spun silk yarn or it may be used by arranging individual short fiber silk yarns in a fiber reinforced composite material And may be used in combination.

- the term "long fiber” refers to a fiber length of 1 m or more, 2 m or more, preferably 3 m or more, more preferably 4 m or more, 5 m or more, 6 m or more, 7 m or more, 8 m or more, 9 m or more, or 10 m or more I say silk thread.

- the long fiber silk yarn may be any of filament yarns such as monofilaments and yarns, pile yarns such as silk spinning, or a combination thereof as long as the fiber length is equal to or longer than the above length.

- the upper limit of the fiber length of the long fiber silk yarn is not particularly limited. In the case of pile yarns, their length can be extended indefinitely by spinning.

- the fiber length corresponds to the length of the long axis of silk yarn which can be continuously spun by minnow beetles.

- the distance is 1.5 km or less, 1 km or less, 900 m or less, 800 m or less, 700 m or less, 600 m or less, 500 m or less, 400 m or less, 300 m or less, 200 m or less, or 100 m or less.

- silk threads are fragmented in the nest and become discontinuous.

- the nest of the minnow beetle itself is constituted by intertwining relatively short silk yarns, it is not possible to obtain long fiber silk yarn of filament yarn from the nest by the usual method.

- the silkworm scaffolding thread is relatively continuous, it is spit like a zigzag because it is a foothold for movement, and the movement is also entrusted with insects, so the silk thread can be entangled and recovered in complex It was also difficult to reel.

- the orientation of the minmomi silk yarn is not limited.

- the minomushi silk yarn can be formed into a string shape, a sheet shape, or a three-dimensional structure.

- the fiber bundles of the minmomi silk yarn in one direction, in the case of arranging them in a straight line and arranging in a plane (UD material) or forming a continuous loop (course) in the fiber bundles of the minomushi silk yarn, adjacent

- a knit knit or the like which is locked to a loop of a fiber bundle to connect longitudinal loops (wales) to form a flat surface (sheet).

- the knit fabric is stretchable in the fabric itself due to its structure.

- carbon fibers and glass fibers which are conventional main reinforcing fibers, are broken when they are bent in a loop shape, making it difficult to make a knit.

- minomushi silk yarn is easy to produce a fabric because of the flexibility of the fiber.

- the knit fabric of Minomushi silk yarn as a reinforcing fiber, in addition to the mechanical properties of "stretching" of the silk yarn itself, the elasticity of the knit fabric is added to obtain superior properties not found in conventional reinforced fiber composite materials. it can.

- a woven fabric is one in which warps and wefts are crossed to form a flat surface (sheet). In the case of a woven fabric, it may be either a plain weave in which the warp and the weft cross each other or a twill weave in which the warp and the weft cross each other at an angle.

- the braid is a combination of a plurality of fibers in a cord shape or a band shape, and includes braids, woven cords, knitted cords and the like.

- a braid is a tubular structure in which a plurality of fibers are assembled in a cylindrical shape along a mandrel (a mandrel) to form a braided structure (braid).

- nonwoven fabric which arrange

- the reinforcing fiber of the present invention may be composed only of a minmomi silk thread, but may further include one or more other reinforcing fibers within the range not impairing the effects of the present invention.

- Other reinforcing fibers include organic fibers other than minomushi silk or inorganic fibers.

- Organic fibers include plant natural fibers such as cotton and hemp mainly composed of cellulose, silk threads and spider threads obtained from insects such as silkworm silkworms and other silkworms such as silkworms such as silkworms which are larvae of silkworms (Saturnidae)

- Animal natural fibers and synthetic fibers such as aramid, polyamide (including nylon), polyester, polyethylene, acrylic, rayon and the like can be mentioned.

- Inorganic fibers include carbon fibers, glass fibers, metal fibers (stainless steel, titanium, copper, aluminum, nickel, iron, tungsten, molybdenum and the like), and amorphous fibers (ceramic fiber, rock wool and the like).

- a synergistic effect of reinforcing fibers can be obtained.

- carbon fiber which is a reinforcing fiber of CFRP and glass fiber which is a reinforcing fiber of GFRP have extremely high strength and elastic modulus, but they are low in toughness and brittle because they have no elongation property.

- minomushi silk yarn also has high strength and elastic modulus, but is less than that of carbon fiber and glass fiber.

- the minmomi silk yarn has an elongation property which is not found in carbon fibers and glass fibers. Therefore, by combining the minomushi silk yarn and the carbon fiber and / or the glass fiber, it is possible to utilize the advantages of both as reinforcing fiber and to complement each other's defects.

- the reinforcing fiber in which the minmomi silk yarn and the carbon fiber and / or the glass fiber are combined a fiber reinforced composite material having extremely high strength and elastic modulus and having an elongation property can be manufactured.

- the content of the minnow silk in the reinforcing fiber when used in the fiber-reinforced composite material is not limited. 1% or more, 3% or more, 5% or more, 8% or more, 10% or more, 15% or more, 20% or more, 25% or more, 30% or more, 35% or more, 40% or more, 45% or more, 50% 55% or more, 60% or more, 65% or more, 70% or more, 75% or more, 80% or more, 85% or more, 90% or more, 92% or more, 95% or more, 97% or more, 98% or more Alternatively, the content may be 99% or more.

- the reinforcing fiber also includes other reinforcing fibers in addition to the minomushi silk

- the other reinforcing fiber also uses a long fiber silk

- the orientation of the above minimus silk as a rule for the orientation of the other reinforcing fibers, etc. It is good with the same. Therefore, the specific description is omitted.

- a second aspect of the present invention is a fiber reinforced composite material.

- the fiber-reinforced composite material of the present invention is characterized by using the reinforcing fiber for a fiber-reinforced composite material according to the first aspect, that is, a reinforcing fiber containing a minmushi silk thread as a fiber base.

- a fiber-reinforced composite material having high strength and high elastic modulus, and further having elongation characteristics not found in conventional CFRP and GFRP.

- the fiber reinforced composite material of the present invention comprises, as essential components, a reinforcement matrix containing a polymer matrix and a minmushi silk.

- the polymer matrix refers to a base material composed of an organic polymer and / or an inorganic polymer, and the polymer matrix used for the fiber-reinforced composite material of the present invention is either an organic polymer or an inorganic polymer, or It includes both.

- the organic polymers referred to here include natural polymers and synthetic polymers.

- Natural polymers are polymers that occur in nature, and include, for example, proteins, polysaccharides and natural resins.

- proteins include glue (including collagen and gelatin).

- polysaccharides include starch, cellulose, mannan, agar and the like.

- natural resin include lacquer, rosin, latex (natural rubber), shellac and the like.

- Synthetic polymers are polymers obtained by linking monomers by a condensation reaction or addition polymerization reaction, and examples thereof include synthetic resins and synthetic rubbers.

- Synthetic resins are also called plastics.

- the synthetic resin used as the polymer matrix in the fiber-reinforced composite material of the present invention may be a thermosetting resin, a thermoplastic resin, or a combination thereof.

- thermosetting resins include epoxy resins, unsaturated polyester resins, vinyl ester resins, and phenol resins.

- examples of the thermoplastic resin include polyethylene, polypropylene, polyester, polystyrene, polyvinyl chloride, methacrylic resin, fluorine resin, polycarbonate, polyurethane, aromatic polyether ketone resin, polyphenylene sulfide resin and the like.

- Synthetic rubbers include butadiene rubber, chloroprene rubber, styrene butadiene rubber, isoprene rubber, ethylene propylene rubber, nitrile rubber, silicone rubber, acrylic rubber, fluororubber, urethane rubber and the like.

- the reinforcing fibers used in the fiber-reinforced composite material of the present invention are the reinforcing fibers described in the first aspect, that is, reinforcing fibers including a minmomi silk thread.

- the specific configuration of the reinforcing fiber is described in detail in the first embodiment, and thus the description thereof is omitted.

- the blending ratio of the reinforcing fiber to the polymer matrix in the fiber-reinforced composite material of the present invention is not limited. In general, it may be blended at a ratio that can be imparted to the polymer matrix which is the base material, according to the high strength, high elastic modulus, elongation and the like which are the characteristics of the reinforcing fiber to be targeted.

- a compounding ratio capable of imparting elongation, which is a characteristic of minmushi silk, to a polymer matrix is preferable.

- the mass fraction of minomushi silk yarn is 0.5% by mass to 50% by mass, 0.8% by mass to 40% by mass, 1% by mass to 35% by mass, and 1.5% by mass to 30% of the total dry mass of the fiber reinforced composite material. % By mass, 2% by mass to 28% by mass, or 3% by mass to 25% by mass.

- the structure of the fiber-reinforced composite material of the present invention is not particularly limited.

- a state in which a reinforcing fiber of short fibers is dispersed in a polymer matrix and / or on a surface a state in which a polymer matrix layer and a reinforcing fiber layer are laminated and integrated, a sheet-like reinforcing fiber is impregnated with a liquid polymer matrix.

- a state in which a plurality of prepregs or the like are laminated so as to differ in the orientation of reinforcing fibers and the integrated prepreg as a structure is mentioned.

- a prepreg is an intermediate material of a fiber reinforced composite material, it is included in a fiber reinforced composite material in this specification.

- the fiber-reinforced composite material of the present invention can provide a fiber-reinforced composite material exhibiting elongation characteristics not found in conventional fiber-reinforced composite materials, CFRP and GFRP, by including the minomushi silk yarn as a reinforcing fiber.

- the fiber-reinforced composite materials of the present invention can be used in various fields including conventional fiber-reinforced composite materials.

- sports and leisure golf shaft, racket, fishing rod, bicycle parts, etc.

- residence bath, septic tank, etc.

- civil engineering and construction aseismic reinforcements, lightweight building materials, walls, floor reinforcements, truss structural materials, etc.

- transport equipment Cars, ships, planes, helicopters, high-pressure hydrogen tanks, etc.

- industrial equipment housings, home electronics parts, printed circuit boards, wind turbines, etc.

- space-related rockets, artificial satellites, etc.

- the fiber-reinforced composite material of the present invention has an elongation property not found in conventional fiber-reinforced composite materials, its use in a material field requiring elongation in addition to strength and elastic modulus is suitable. is there.

- the reinforcing fiber to be used is a minomushi silk thread alone, or the minomushi silk thread and other silk threads, and the polymer matrix is a natural organic polymer such as collagen and gelatin, a fiber-reinforced composite material with high biocompatibility is obtained. Therefore, it can be used in the medical field as a tissue regeneration substrate, a blood vessel regeneration substrate, etc.

- a third aspect of the present invention is a method of making a fiber reinforced composite material.

- the method of the present invention is a method for producing and / or molding a fiber-reinforced composite material according to the second aspect. According to the manufacturing method of the present invention, a fiber-reinforced composite material including a minamushi silk can be easily manufactured and shaped.

- the method for producing a fiber-reinforced composite material according to the present invention is based on the conventional method for producing a fiber-reinforced composite except that minomushi silk yarn is used as the reinforcing fiber.

- a manufacturing method usually used for CFRP or GFRP can be used as it is.

- an appropriate method may be selected according to the purpose such as the use and the shape.

- a method of producing a prepreg may be to impregnate a woven, knitted or non-woven fabric of a reinforcing fiber containing a minmomi silk yarn with a suitable polymer matrix.

- the polymer matrix is a thermosetting resin, it becomes a semi-cured prepreg whose polymerization is incomplete.

- the polymer matrix is a natural polymer such as a thermoplastic resin or collagen, it becomes a cured prepreg in which the polymerization is completed.

- a filament winding forming method a sheet winding forming method, a press forming method, an autoclave forming method, a RTM (Resin Transfer Molding) forming method, VaRTM (Vacuum Resin Transfer Molding)

- the molding method the SMC (Sheet Molding Compound) molding method, the vacuum bag (Vacuum bag) molding method, the hand lay-up molding method, the fiber placement molding method and the like can be mentioned.

- filament winding molding method 1 to several tens of bundles of tow (a bundle of 1000 to several tens of thousands of filament yarns) are aligned and wound around a rotating mold (mandrel) while impregnated with a polymer matrix and hardened It is a molding method which is subsequently de-cored, which is a method suitable for forming a tubular product.

- sheet winding molding method is the same as the filament winding molding method, and is a molding method in which a prepreg is wound around a mandrel in place of tow and cored after curing.

- the “press molding method” is a method in which a compound or a prepreg is put in a mold, and is pressed and heated to be molded.

- the “autoclave molding method” is a method of laminating a prepreg on a mold, covering it with a bag, vacuum-removing air and volatile substances present in the autoclave, and molding under pressure and heat.

- RTM molding method is also called resin injection molding method, in which a thermosetting resin melted in a closed system in which a reinforcing fiber preform is placed in a mold is introduced under low pressure, heat cured, and then removed. It is.

- the “VaRTM molding method” is a type of RTM method, which is a method of evacuating a closed system in which reinforcing fibers are laminated, introducing a thermosetting resin, heat curing, and removing the mold.

- the “SMC molding method” is a method of laminating and molding sheet-like materials composed of reinforcing fibers and a polymer matrix.

- the “vacuum back molding method” is a method of compression molding at atmospheric pressure by applying a vacuum to a laminate sealed with a sealed film.

- the “hand lay-up molding method” is a method in which a prepreg is manually laminated on a mold and cured and molded.

- the "fiber placement molding method” is a method of laminating a tow impregnated with a prepreg processed with a tape shape or a polymer matrix into various three-dimensional shape molds and curing molding.

- the specific methods of these molding methods are all known methods in the field of fiber reinforced composite materials, and may be referred to.

- the basic operation may be performed in the same manner as the conventional method for producing a fiber reinforced composite material.

- a method of dispersing a short fiber minomushi silk yarn in a molten polymer matrix bringing the two into contact with each other, introducing the mixture into a desired mold, and curing and shaping.

- reinforcing fibers of short fibers are dispersed on the polymer matrix surface, they may be integrated by thermocompression bonding to form a structure composed of a polymer matrix layer and a reinforcing fiber layer.

- the manufacturing process of the method for manufacturing a fiber-reinforced composite material of the present invention includes a contacting process as an essential process, and optionally includes a forming process, a curing process, and a demolding process. Each step is specifically described below.

- the “contacting step” is a step of bringing the reinforcing fiber into contact with the polymer matrix.

- the contact method is not particularly limited as long as the two components can be in direct contact with each other.

- Reinforcing fibers may be dispersed, dipped or impregnated in the dissolved liquid polymer matrix, or fiber bundles or sheets of reinforcing fibers may be sandwiched between sheets of the polymer matrix as in the SMC molding method.

- the aforementioned prepreg is obtained by impregnating a sheet composed of reinforcing fibers with a polymer matrix, and the process is constituted only by the contact process.

- the “forming step” refers to a step of forming the reinforcing fiber and / or polymer matrix, which is a component of the fiber-reinforced composite material, into a desired shape. This process is a selection process and is performed according to various manufacturing methods.

- a mold such as a mold is used, and molding is performed according to the mold. If necessary, reinforcing fibers and prepregs can be laminated and molded.

- the order of the forming step and the above-mentioned contacting step differs depending on the manufacturing method and is not limited. For example, in the filament winding molding method, the sheet winding molding method, the press molding method, the autoclave molding method, the hand lay-up molding method, the fiber placement molding method and the like described above, the molding step is performed after the contact step.

- a contact process is performed after the molding process in order to introduce a polymer matrix into the mold. It may be performed according to each manufacturing method.

- the "curing step” refers to a step of promoting and / or completing the polymerization reaction of the polymer matrix after the above step. In this step, the polymer matrix is cured to complete the fiber reinforced composite material.

- the curing step may include a heating step and / or a cooling step.

- the "heating step” is a step of promoting and / or completing the polymerization reaction by heating the polymer matrix. It is carried out when using a thermosetting resin for the polymer matrix. On the other hand, when the polymer matrix is a thermoplastic resin or a natural polymer, the polymerization is released by heating and the resin is softened or dissolved, so that this step may correspond to the contacting step or the forming step.

- the heating temperature is not particularly limited. Depending on the type of polymer matrix to be used, generally, the temperature may be in the range of 20 ° C. to 250 ° C., 23 ° C. to 200 ° C., 25 ° C. to 180 ° C., 27 ° C. to 150 ° C., or 30 ° C. to 120 ° C. . Also, the heating time is related to the heating temperature, and generally, the lower the temperature, the longer the time, and the higher the temperature, the shorter the heating time. Usually, the reaction may be performed in the range of 0.5 to 48 hours, 1 to 42 hours, 1.5 to 36 hours, 2 to 30 hours, 2.5 to 24 hours, or 3 to 18 hours.

- the “cooling step” is a step of cooling the heated polymer matrix or curing by cooling.

- a thermosetting resin is used for the polymer matrix

- it is carried out when cooling the fiber-reinforced composite material in which the thermosetting reaction is completed in the heating step.

- a thermoplastic resin or a natural polymer is used for the polymer matrix

- the polymerization reaction is accelerated and / or completed by cooling, and the fiber-reinforced composite material is completed by curing the polymer matrix.

- the cooling temperature is also not limited. Depending on the type of polymer matrix to be used, generally, 260 ° C. or less, 200 ° C. or less, 180 ° C. or less, 150 ° C. or less, 120 ° C. or less, 100 ° C. or less, 90 ° C. or less, 80 ° C. or less, 70 ° C. or less, 60 ° C or less, 50 ° C or less, 40 ° C or less, 35 ° C or less, 30 ° C or less, 27 ° C or less, 25 ° C or less, 23 ° C or less, 20 ° C or less, 18 ° C or less, 15 ° C or less, or 10 ° C or less It is good.

- the lower limit temperature is not particularly limited, but may generally be about 4 ° C., 0 ° C., -10 ° C., -15 ° C., or -20 ° C.

- the cooling time may be 0.1 to 1 hour, 0.2 to 0.9 hours, 0.3 to 0.8 hours, 0.4 to 0.7 hours, or 0.5 to 0.6 hours.

- the “demolding step” is a step of demolding the fiber-reinforced composite material after the curing step. Specifically, in this step, the finished fiber-reinforced composite material is extracted from the mold and mandrel used in the molding step.

- the demolding method may be according to methods known in the art.

- Example 1 Production of a fiber-reinforced composite material using a minomushi silk yarn as a reinforcing fiber (1)> (the purpose) A fiber-reinforced composite material containing Minomushi silk as a reinforcing fiber is produced and its physical properties are verified.

- a long fiber bundle of Minomushi silk yarn was used as a reinforcing fiber, and an ethylene-vinyl acetate copolymer (EVA) resin was used as a polymer matrix.

- EVA ethylene-vinyl acetate copolymer

- the long fiber bundle of the minomushi silk yarn was prepared according to the method described in the specification of Japanese Patent Application No. 2017-110003.

- the minomushi used last-instar larvae of Ominoga collected from orchards in Tsukuba city, Ibaraki prefecture.

- the substantially square metal can described in Example 1 of the specification of Japanese Patent Application No. 2017-110003 was used as a long fiber production apparatus for a minamushi silk yarn.

- a minomushi was placed on the linear path, and after confirming that the minomushi orbited while running on the linear path, it was left at room temperature as it was.

- the minnow beetle is recovered from the apparatus, the minnow silk thread laminated on the linear path is peeled off with a peeler, and the minomushi silk yarn covering a total length of about 150 m is bundled in a ring shape with a circumference of 1.1 m, 150

- the long fiber bundle consisting of the above single fibers was recovered. Subsequently, the long fiber bundle was scoured with a 0.05 mol / L boiling sodium carbonate aqueous solution for 2 minutes. After washing with pure water, air dried one was used as a reinforcing fiber.

- the adhesive resin for hot guns (TAICO CORPORATION) was used for EVA resin.

- a 35 mm long and 10 mm wide form made of a 0.5 mm thick silicone rubber sheet is prepared as a substitute for the mold, and after an EVA resin is placed in the form, it is pressed at 1 to 2 MPa and pressed. Two resin sheets were produced. Next, two sheets of long-fiber bundles (bag worm silk fiber: BSF) prepared between EVA resin sheets, or carbon fiber (CF) as a control, as a reinforcing fiber and heated to 100 ° C.

- BSF bag worm silk fiber

- BSF / EVA composite material consisting of long fiber bundles (BSF) and EVA resin of Minomushi silk yarn and carbon fiber (CF)

- a fiber reinforced composite material (CF / EVA composite material) composed of EVA resin was obtained.

- an EVA resin alone was also prepared, in which only two sheets were pressed without a reinforcing fiber.

- elastic modulus means an initial elastic modulus. This corresponds to a proportional relationship between force and deformation when the sample is pulled, that is, a proportional constant in a deformation region satisfying the Hooke's law, and is given as the slope of the initial gradient of the stress-strain curve.

- maximum strength refers to the maximum stress immediately before breaking. In general, the larger the value is, the more stress it can withstand.

- strain means the elongation at break, which refers to the elongation until the sample breaks. Generally, it means that the larger the value, the better.

- the “differential elastic modulus” and the “differential strength” indicate the difference in elastic modulus and the maximum strength between the resin alone and the fiber composite.

- minomushi silk yarn effectively improves mechanical properties such as strength, elastic modulus, and elongation at break of a polymer matrix with a slight fiber content of about 2 wt%, and changes its fiber content It became clear that the contribution to the mechanical property can be controlled.

- Example 2 Production of a fiber-reinforced composite material using a minomushi silk yarn as a reinforcing fiber (2)> (the purpose) A fiber-reinforced composite material using a polymer matrix different from that of Example 1 is produced by using Minomushi silk as a reinforcing fiber, and the physical properties thereof are verified.

- the EVA resin used in Example 1 was a soft resin that can be stretched several times. Therefore, in this example, fiber reinforcement using a polystyrene resin (PS resin) (Eiken Chemical Co., Ltd.), which is a hard resin having a small elongation compared to EVA resin and a breaking elongation of only about 5%, as a polymer matrix A composite material (BSF / PS composite material) was prepared and its mechanical properties were verified in the same manner as in Example 1.

- PS resin polystyrene resin

- BSF / PS composite material polymer matrix A composite material

- Example 2 The basic conditions followed the method of Example 1. However, the pressing conditions were 10 MPa to 12 MPa at 150 ° C.

- Example 3 Production of a fiber-reinforced composite material in which the short fibers of minomushi silk yarn are used as a reinforcing fiber> (the purpose) The physical properties of the fiber reinforced composite material when the short fiber of the Minomushi silk yarn is used as a reinforcing fiber are verified.

- a reinforcing fiber As a reinforcing fiber, a short fiber of minomushi silk yarn was used, and as a polymer matrix, polyvinyl alcohol (PVA) (Uehara Chemical) was used.

- PVA polyvinyl alcohol

- the monofilaments of the minmushi silk were cut into short fibers so that the major axis was about 5 mm in length. Thereafter, the short fibers were dispersed in a PVA aqueous solution and formed on a slide glass to obtain a film as a BSF / PVA composite material.

- the fiber content was defined as the mass fraction of the short fiber of the minmushi silk with respect to the total dry mass of the film.

- a strip-like test piece was cut out of the film and subjected to the subsequent mechanical test.

- the elastic modulus of the BSF / PVA composite material having a fiber content of 3.74 wt% was 184.1 MPa, and an improvement of 10 times or more was observed as compared with the PVA resin alone (elastic modulus 14.1 MPa). This result suggests that even if the minomushi silk is a short fiber, the fiber reinforced composite material can be given a very high elastic modulus.

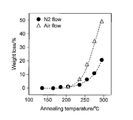

- Example 4 Thermal decomposition evaluation test of minomushi silk yarn> (the purpose)

- heat treatment may be included to de- or accelerate the polymerization of the polymer matrix.

- the polymer matrix is a thermoplastic resin

- the resin is softened or dissolved by heating to be released by heating, and conversely, when the thermosetting resin is heated, the resin is hardened by promoting polymerization. .

- the reinforcing fibers are exposed to high temperatures as well as the polymer matrix under the production of fiber reinforced composite materials.

- the minomushi silk is a protein, when heated above the resistance temperature, the fiber itself may be denatured or degraded, and the effect of the invention may not be achieved. Therefore, the heat resistant temperature in the minmomi silk yarn is examined.

- the minmushi silk was treated at each temperature of 130 ° C. to 300 ° C. for 1 hour, and then the mass loss rate (%) due to thermal decomposition was evaluated by thermogravimetric analysis (TGA) measurement.

- TGA thermogravimetric analysis

- the experiment was performed under a nitrogen-substituted atmosphere (N 2 flow) and an air atmosphere (Air flow).

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Inorganic Chemistry (AREA)

- Textile Engineering (AREA)

- Reinforced Plastic Materials (AREA)

- Yarns And Mechanical Finishing Of Yarns Or Ropes (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310844583.5A CN116904041B (zh) | 2017-09-05 | 2018-08-30 | 纤维增强复合材料及其制造方法 |

| US16/644,055 US11732096B2 (en) | 2017-09-05 | 2018-08-30 | Fiber-reinforced composite material and method for manufacturing same |

| EP18853035.6A EP3680279A4 (en) | 2017-09-05 | 2018-08-30 | FIBER REINFORCED COMPOSITE MATERIAL AND METHOD FOR MANUFACTURING THEREOF |

| CN201880056859.0A CN111032748B (zh) | 2017-09-05 | 2018-08-30 | 纤维增强复合材料及其制造方法 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017-170648 | 2017-09-05 | ||

| JP2017170648A JP6963765B2 (ja) | 2017-09-05 | 2017-09-05 | 繊維強化複合材料及びその製造方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019049771A1 true WO2019049771A1 (ja) | 2019-03-14 |

Family

ID=65634080

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/032195 Ceased WO2019049771A1 (ja) | 2017-09-05 | 2018-08-30 | 繊維強化複合材料及びその製造方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US11732096B2 (enExample) |

| EP (1) | EP3680279A4 (enExample) |

| JP (2) | JP6963765B2 (enExample) |

| CN (2) | CN111032748B (enExample) |

| WO (1) | WO2019049771A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2020067519A1 (ja) * | 2018-09-28 | 2020-04-02 | 小島プレス工業株式会社 | 樹脂成形品及びその製造方法 |

| EP3940131A4 (en) * | 2019-03-13 | 2022-12-14 | National Agriculture And Food Research Organization | FIBER REINFORCED COMPOSITE AND METHOD OF MAKING THEREOF |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20210372691A1 (en) * | 2020-05-29 | 2021-12-02 | Whirlpool Corporation | Appliance liner system |

| WO2022014525A1 (ja) * | 2020-07-15 | 2022-01-20 | Spiber株式会社 | 開繊剤 |

| EP4261271B1 (en) * | 2020-12-10 | 2025-12-10 | National Agriculture And Food Research Organization | Bagworm moth egg collection tool |

| US12053908B2 (en) | 2021-02-01 | 2024-08-06 | Regen Fiber, Llc | Method and system for recycling wind turbine blades |

| AU2023418640A1 (en) | 2022-12-27 | 2025-06-12 | Kowa Company, Ltd. | Gel containing bagworm silk and method for producing same |

| CN120967674A (zh) * | 2025-10-21 | 2025-11-18 | 河北华密新材科技股份有限公司 | 一种纤维毛毡复合材料及其制备方法和应用 |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08208861A (ja) * | 1995-02-08 | 1996-08-13 | Koken Kk | 有機高分子材料からなる産業用材料及び製品 |

| JP2001207585A (ja) * | 2000-01-25 | 2001-08-03 | Koken Kk | 建築用材料 |

| JP2002363862A (ja) * | 2001-06-04 | 2002-12-18 | Toyobo Co Ltd | 成形材料用繊維、繊維補強成形材料および成形体 |

| JP2011126987A (ja) * | 2009-12-17 | 2011-06-30 | Gunma Prefecture | 絹繊維強化生分解性複合材料 |

| WO2012165477A1 (ja) | 2011-06-01 | 2012-12-06 | スパイバー株式会社 | タンパク質繊維及びその製造方法 |

| JP2017110003A (ja) | 2015-12-16 | 2017-06-22 | 日本曹達株式会社 | ジアリールトリアゾール化合物および有害生物防除剤 |

| JP2017170648A (ja) | 2016-03-18 | 2017-09-28 | 富士ゼロックス株式会社 | 三次元造形装置及び三次元造形プログラム |

| WO2018116979A1 (ja) * | 2016-12-20 | 2018-06-28 | Spiber株式会社 | 繊維強化樹脂材および積層体 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001207325A (ja) * | 2000-01-25 | 2001-08-03 | Koken Kk | 動物繊維 |

| GB0605929D0 (en) * | 2006-03-24 | 2006-05-03 | Leuven K U Res & Dev | Silk fibre composites |

| EP2256163B1 (en) * | 2008-03-25 | 2018-11-14 | Toray Industries, Inc. | Epoxy resin composition, fiber-reinforced composite material and method for producing the same |

| EP3766686A1 (en) * | 2015-09-17 | 2021-01-20 | Roberto Velozzi Jerez | Load-bearing composite panels, materials, products, and processes to make and use same |

| DE102016109843A1 (de) * | 2016-05-27 | 2017-11-30 | Sml Verwaltungs Gmbh | Härtbare Auskleidungsschläuche zur Sanierung fluidführender Systeme |

-

2017

- 2017-09-05 JP JP2017170648A patent/JP6963765B2/ja active Active

-

2018

- 2018-08-30 CN CN201880056859.0A patent/CN111032748B/zh active Active

- 2018-08-30 EP EP18853035.6A patent/EP3680279A4/en active Pending

- 2018-08-30 WO PCT/JP2018/032195 patent/WO2019049771A1/ja not_active Ceased

- 2018-08-30 CN CN202310844583.5A patent/CN116904041B/zh active Active

- 2018-08-30 US US16/644,055 patent/US11732096B2/en active Active

-

2021

- 2021-07-27 JP JP2021122090A patent/JP7088501B2/ja active Active

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08208861A (ja) * | 1995-02-08 | 1996-08-13 | Koken Kk | 有機高分子材料からなる産業用材料及び製品 |

| JP2001207585A (ja) * | 2000-01-25 | 2001-08-03 | Koken Kk | 建築用材料 |

| JP2002363862A (ja) * | 2001-06-04 | 2002-12-18 | Toyobo Co Ltd | 成形材料用繊維、繊維補強成形材料および成形体 |

| JP2011126987A (ja) * | 2009-12-17 | 2011-06-30 | Gunma Prefecture | 絹繊維強化生分解性複合材料 |

| WO2012165477A1 (ja) | 2011-06-01 | 2012-12-06 | スパイバー株式会社 | タンパク質繊維及びその製造方法 |

| JP2017110003A (ja) | 2015-12-16 | 2017-06-22 | 日本曹達株式会社 | ジアリールトリアゾール化合物および有害生物防除剤 |

| JP2017170648A (ja) | 2016-03-18 | 2017-09-28 | 富士ゼロックス株式会社 | 三次元造形装置及び三次元造形プログラム |

| WO2018116979A1 (ja) * | 2016-12-20 | 2018-06-28 | Spiber株式会社 | 繊維強化樹脂材および積層体 |

Non-Patent Citations (6)

| Title |

|---|

| GOSLINE J. M. ET AL., J. EXP. BIOL., vol. 202, 1999, pages 3295 - 3303 |

| KUWANA Y ET AL., PLOS ONE, 2014 |

| MATHIJSEN D., REINFORCED PLASTICS, vol. 60, 2016, pages 38 - 44 |

| OHSAKI, SHIGEYOSHI: "Why is strong silk from Psychidae?", POLYMER PREPRINTS JAPAN, vol. 50, no. 14, 28 August 2001 (2001-08-28), Japan, pages 3493 - 3494, XP009519987 * |

| SHIGEYOSI OHSAKI, SEN'I GAKKAISHI (SEN'I TO KOGYO, vol. 58, 2002, pages 74 - 78 |

| TORN HIRAMATSU: "Well Understandable Introduction for Carbon Fiber Composite", 2015, NIKKAN KOGYO SHIMBUN, LTD |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2020067519A1 (ja) * | 2018-09-28 | 2020-04-02 | 小島プレス工業株式会社 | 樹脂成形品及びその製造方法 |

| EP3940131A4 (en) * | 2019-03-13 | 2022-12-14 | National Agriculture And Food Research Organization | FIBER REINFORCED COMPOSITE AND METHOD OF MAKING THEREOF |

| US12467170B2 (en) | 2019-03-13 | 2025-11-11 | National Agriculture And Food Research Organization | Fiber-reinforced composite material and method for producing the same |

Also Published As

| Publication number | Publication date |

|---|---|

| US20200407518A1 (en) | 2020-12-31 |

| JP6963765B2 (ja) | 2021-11-10 |

| CN111032748B (zh) | 2023-07-21 |

| US11732096B2 (en) | 2023-08-22 |

| CN111032748A (zh) | 2020-04-17 |

| EP3680279A1 (en) | 2020-07-15 |

| JP2019044117A (ja) | 2019-03-22 |

| EP3680279A4 (en) | 2021-06-09 |

| JP2021167114A (ja) | 2021-10-21 |

| CN116904041B (zh) | 2025-10-21 |

| CN116904041A (zh) | 2023-10-20 |

| JP7088501B2 (ja) | 2022-06-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP7088501B2 (ja) | 繊維強化複合材料及びその製造方法 | |

| Samivel | Mechanical behavior of stacking sequence in kenaf and bananafiber reinforced-Polyester laminate | |

| US12467170B2 (en) | Fiber-reinforced composite material and method for producing the same | |

| US9481948B2 (en) | Robust pre-impregnated yarn for manufacturing textile composites | |

| TW201231257A (en) | Article of carbon fiber strengthened plastic | |

| Jabbar et al. | Textile raw materials | |

| JP2022028690A (ja) | 長尺ミノムシ絹糸の生産方法及びその生産装置 | |

| Ranakoti et al. | Silk and silk-based composites: opportunities and challenges | |

| JP6998069B2 (ja) | 長尺ミノムシ絹糸の生産方法及びその生産装置 | |

| JP4748717B2 (ja) | 繊維強化熱可塑性樹脂成形体 | |

| Sealy | Silk shows new strengths in composites | |

| Yusif | INVESTIGATION OF THE SILK FIBER EXTRACTION PROCESS FROM THE SATURNIA PYRI (DENIS & SCHIFFERMÜLLER, 1775) COCOON | |

| Islam | Composites derived from biodegradable Textile wastes: A pathway to the future | |

| CN106426975B (zh) | 一种复合钓鱼竿的制备工艺 | |

| Ranakoti et al. | Synthesis and surface treatments of bio-based fibers | |

| JP6364798B2 (ja) | 補強繊維織物及びその製造方法 | |

| Pandey et al. | A review on bast fiber reinforced thermosetting matrix composite | |

| Yadav et al. | Fabrication of composite material using jute fiber/glass fiber | |

| Ranakoti et al. | 1Department of Mechanical Engineering, National Institute of Technology, Srinagar, India, 2Department of Mechanical Engineering, SOET, HNBGU, Chauras Campus, Srinagar, India | |

| Elsi et al. | Manufacturing and characterization of glass fiber-fishnet-woven roving and polyester composites | |

| Abilash et al. | INFLUENCE OF HYBRIDISATION IN SISAL/JUTE FIBER REINFORCED POLYMERIC COMPOSITES | |

| CN111194728A (zh) | 蛛蚕丝生产方法及由其生产的蛛蚕丝 | |

| Ya’acob et al. | Investigation on improvement of mechanical properties of kenaf/E-glass fiber composites by mercerization process | |

| Węcławski | The potential of bast natural fibres as reinforcement for polymeric composite materials in building applications | |

| Singh et al. | Fabrication of light weight farms yoke with the use of composite material |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |