WO2018168914A1 - Electric mobility and disassembly method therefor - Google Patents

Electric mobility and disassembly method therefor Download PDFInfo

- Publication number

- WO2018168914A1 WO2018168914A1 PCT/JP2018/009922 JP2018009922W WO2018168914A1 WO 2018168914 A1 WO2018168914 A1 WO 2018168914A1 JP 2018009922 W JP2018009922 W JP 2018009922W WO 2018168914 A1 WO2018168914 A1 WO 2018168914A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- vehicle body

- wheel side

- side vehicle

- rear wheel

- front wheel

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61G—TRANSPORT, PERSONAL CONVEYANCES, OR ACCOMMODATION SPECIALLY ADAPTED FOR PATIENTS OR DISABLED PERSONS; OPERATING TABLES OR CHAIRS; CHAIRS FOR DENTISTRY; FUNERAL DEVICES

- A61G5/00—Chairs or personal conveyances specially adapted for patients or disabled persons, e.g. wheelchairs

- A61G5/08—Chairs or personal conveyances specially adapted for patients or disabled persons, e.g. wheelchairs foldable

- A61G5/0875—Chairs or personal conveyances specially adapted for patients or disabled persons, e.g. wheelchairs foldable dismountable, e.g. where the wheelchair can be disassembled for transportation or storage

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61G—TRANSPORT, PERSONAL CONVEYANCES, OR ACCOMMODATION SPECIALLY ADAPTED FOR PATIENTS OR DISABLED PERSONS; OPERATING TABLES OR CHAIRS; CHAIRS FOR DENTISTRY; FUNERAL DEVICES

- A61G5/00—Chairs or personal conveyances specially adapted for patients or disabled persons, e.g. wheelchairs

- A61G5/04—Chairs or personal conveyances specially adapted for patients or disabled persons, e.g. wheelchairs motor-driven

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61G—TRANSPORT, PERSONAL CONVEYANCES, OR ACCOMMODATION SPECIALLY ADAPTED FOR PATIENTS OR DISABLED PERSONS; OPERATING TABLES OR CHAIRS; CHAIRS FOR DENTISTRY; FUNERAL DEVICES

- A61G5/00—Chairs or personal conveyances specially adapted for patients or disabled persons, e.g. wheelchairs

- A61G5/10—Parts, details or accessories

- A61G5/1089—Anti-tip devices

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61G—TRANSPORT, PERSONAL CONVEYANCES, OR ACCOMMODATION SPECIALLY ADAPTED FOR PATIENTS OR DISABLED PERSONS; OPERATING TABLES OR CHAIRS; CHAIRS FOR DENTISTRY; FUNERAL DEVICES

- A61G5/00—Chairs or personal conveyances specially adapted for patients or disabled persons, e.g. wheelchairs

- A61G5/04—Chairs or personal conveyances specially adapted for patients or disabled persons, e.g. wheelchairs motor-driven

- A61G5/041—Chairs or personal conveyances specially adapted for patients or disabled persons, e.g. wheelchairs motor-driven having a specific drive-type

- A61G5/046—Chairs or personal conveyances specially adapted for patients or disabled persons, e.g. wheelchairs motor-driven having a specific drive-type at least three driven wheels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K7/00—Disposition of motor in, or adjacent to, traction wheel

- B60K2007/0038—Disposition of motor in, or adjacent to, traction wheel the motor moving together with the wheel axle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K7/00—Disposition of motor in, or adjacent to, traction wheel

- B60K2007/0092—Disposition of motor in, or adjacent to, traction wheel the motor axle being coaxial to the wheel axle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K7/00—Disposition of motor in, or adjacent to, traction wheel

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K7/00—Disposition of motor in, or adjacent to, traction wheel

- B60K7/0007—Disposition of motor in, or adjacent to, traction wheel the motor being electric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B62—LAND VEHICLES FOR TRAVELLING OTHERWISE THAN ON RAILS

- B62K—CYCLES; CYCLE FRAMES; CYCLE STEERING DEVICES; RIDER-OPERATED TERMINAL CONTROLS SPECIALLY ADAPTED FOR CYCLES; CYCLE AXLE SUSPENSIONS; CYCLE SIDE-CARS, FORECARS, OR THE LIKE

- B62K5/00—Cycles with handlebars, equipped with three or more main road wheels

- B62K5/003—Cycles with four or more wheels, specially adapted for disabled riders, e.g. personal mobility type vehicles with four wheels

- B62K5/007—Cycles with four or more wheels, specially adapted for disabled riders, e.g. personal mobility type vehicles with four wheels power-driven

Definitions

- the present invention relates to an electric mobility and a disassembling method thereof.

- the rear wheel side vehicle body When the front wheel side vehicle body is removed, the rear wheel side vehicle body is tilted by its own weight toward the rear until the protruding member contacts the ground, as explained in the document, but the rear wheel side vehicle body is For fear of hitting, it may be possible to control the rearward tilt of the rear wheel side vehicle body by holding a part of the rear wheel side vehicle body. In this case, since it is necessary to support the rear wheel side vehicle body while lifting the rear end side of the front wheel side vehicle body, it may not be possible to easily disassemble the front wheel side vehicle body and the rear wheel side vehicle body by one person.

- the present invention has been made in view of such circumstances, and it is possible to easily perform the disassembly work and the assembly work of the front wheel side vehicle body and the rear wheel side vehicle body by one person and the disassembly thereof.

- the purpose is to provide a method.

- the electric mobility according to the first aspect of the present invention includes a front wheel side vehicle body and a rear wheel side vehicle body that is detachably connected to the front wheel side vehicle body, and the rear wheel side vehicle body is detached from the front wheel side vehicle body.

- the rear wheel side vehicle body is provided with a first engagement portion used for connection with the front wheel side vehicle body, and the rear wheel side vehicle body is in the self-standing state.

- a second engagement portion provided on the rear end side of the front wheel side vehicle body and used for the connection can be supported by the first engagement portion.

- the rear wheel side vehicle body when the rear wheel side vehicle body is detached from the front wheel side vehicle body to be in a self-supporting state, the second engagement provided on the rear end side of the front wheel side vehicle body by the first engagement portion of the rear wheel side vehicle body.

- the front wheel side vehicle body is supported by the front wheel and the first engagement portion of the rear wheel side vehicle body.

- the person who performs the disassembling work in this state does not need to support the front wheel side vehicle body.

- the front wheel side vehicle body can be supported by the first engagement portion of the rear wheel side vehicle body and the front wheel in a self-supporting state.

- the second engagement body is provided on the rear wheel side vehicle body, is provided on the vehicle front side with respect to the first engagement portion, and is provided on the front wheel side vehicle body.

- a fourth engaging portion that engages with the third engaging portion at the time of the connection, and has the self-standing state of the rear wheel side vehicle body.

- the first engagement portion is disposed on the front side of the vehicle with respect to the lower contact portion, a lower contact portion that contacts the second engagement portion of the front wheel side vehicle body from below, and the lower side It is preferable to have a front abutting portion disposed at a position higher than the abutting portion.

- the operation member provided on the rear wheel side vehicle body and operated to release the connection and the rear wheel side vehicle body disposed on the vehicle front side with respect to the rotation axis of the rear wheel. It is preferable to further provide a handle portion provided.

- the operation member in a state where the front wheel side vehicle body and the rear wheel side vehicle body are connected, for example, while holding the handle portion with one hand, the operation member is operated with the other hand to release the connection,

- the handle is lifted in this state, the rear wheel side vehicle body tilts rearward and becomes self-supporting.

- the front wheel side vehicle body is supported by the front wheel and the first engagement portion of the rear wheel side vehicle body. For this reason, the disassembling work can be easily performed.

- the rear wheel side vehicle body is inclined rearward of the vehicle to be in the self-supporting state. It is preferable that the second engagement portion is continuously supported from below.

- the person who performs the disassembly work supports only the rear wheel side vehicle body and makes the rear wheel side vehicle body self-supporting. Since the rear end side of the front wheel side vehicle body is supported by the rear wheel side vehicle body, it is advantageous in facilitating disassembly work.

- a second aspect of the present invention is an electric mobility disassembling method capable of removing a rear wheel side vehicle body from a front wheel side vehicle body, wherein the rear end side of the front wheel side vehicle body is supported by the rear wheel side vehicle body, Tilting the rear wheel side vehicle body rearward around the rear wheel until the rear wheel side vehicle body is in a self-supporting state, and the rear end side of the front wheel side vehicle body after the rear wheel side vehicle body is in a self-supporting state. Removing from the rear wheel side vehicle body.

- the person who performs the disassembly work supports only the rear wheel side vehicle body and makes the rear wheel side vehicle body self-supporting. Since the rear end side of the front wheel side vehicle body is supported by the rear wheel side vehicle body, it is advantageous in facilitating disassembly work.

- the rear wheel side vehicle body includes an operation member that is operated to release the connection of the travelable aspect between the front wheel side vehicle body and the rear wheel side vehicle body.

- the connection is released by operating the operation member while applying a force toward the rear of the vehicle.

- the rear end side of the front wheel side vehicle body is supported by the rear wheel side vehicle body that is self-supported by simply releasing the connection by operating the operation member while applying a force that tilts the rear wheel side vehicle body in its own direction. Therefore, the division work can be performed more easily.

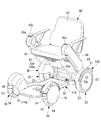

- the electric mobility has a mobility main body 30 as shown in FIGS. 1 to 3, and the mobility main body 30 is supported by a pair of front wheels 10, a pair of rear wheels 20, and a front wheel 10 and a rear wheel 20.

- the electric mobility includes a seat unit 40 that is detachably attached to the mobility main body 30, and a motor 50 that is attached to the mobility main body 30 and drives at least one of the pair of front wheels 10 and the pair of rear wheels 20.

- the vehicle front-rear direction may be referred to as the front-rear direction

- the vehicle width direction may be referred to as the width direction.

- a motor 50 is connected to each of the pair of rear wheels 20, and the two rear wheels 20 can be driven by each motor 50.

- You may comprise so that the driving force of the motor 50 may be transmitted to a pair of front wheels 10 via power transmission means, such as a belt and a gear.

- Each front wheel 10 is supported by the body 31 via an axle, a suspension, etc. (not shown).

- Each front wheel 10 has a ground contact surface formed by a plurality of rollers 13 and 14 arranged in the circumferential direction.

- the outer shape of the roller 13 is smaller than the outer shape of the roller 14, and the roller 13 and the roller 14 are alternately arranged in the circumferential direction.

- each front wheel 10 includes a hub 15 attached to the axle, and a plurality of roller support shafts arranged in the circumferential direction of the hub 15 and supported by the hub 15, respectively. Each is rotatably supported on a roller spindle.

- the hub 15 may be directly attached to the axle via a bearing or the like, or may be attached to the axle via a buffer member or other intermediate member.

- each front wheel 10 can move in all directions with respect to the ground plane. It is a moving wheel.

- each rear wheel 20 is provided on an axle (may be common with the main shaft of the motor 50), a hub 22 attached to the axle, and an outer peripheral side of the hub 22, and the outer peripheral surface has rubber-like elasticity.

- the outer peripheral member 23 is made of a material, an omnidirectional moving wheel may be used similarly to the front wheel 10.

- each front wheel 10 may be the same wheel as the rear wheel 10.

- each front wheel 10 may be the same wheel as the rear wheel 20, and means for changing the steering angle of the front wheel 10 and / or the rear wheel 20 may be provided.

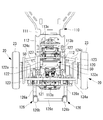

- the mobility main body 30 includes a front wheel side vehicle body 110 and a rear wheel side vehicle body 120 that is detachably connected to the front wheel side vehicle body 110.

- the front wheel side vehicle body 110 is formed so as to extend along the ground, and is provided so as to cover at least a part of the front wheel side frame 111 and the front wheel side frame 111 to which the axle of the front wheel 10 is attached.

- a front wheel side cover 110a used for protection, a part on which a foot of a passenger sitting on the seat unit 40 is placed, a luggage placing part, mudguard and the like.

- the front wheel side frame 111 is made of a material suitable for obtaining strength, such as metal.

- the first to third cross members 113a to 113c extend in the vehicle width direction and connect the pair of side members 112 to each other.

- the first cross member (second engaging portion) 113a is provided at the rear end portion of the pair of side members 112, and the second cross member (fourth engaging portion). ) 113b is disposed on the vehicle front side relative to the first cross member 113a.

- the rear wheel side body 120 supports the motor 50 and the rear wheel 20 on both sides in the vehicle width direction, and the rear wheel side frame 121 that supports the seat unit 40 on the upper end side, and at least a part of the rear wheel side frame 121.

- the rear wheel side cover 120a is provided so as to cover and used for protection of the rear wheel side frame 121, mudguard and the like.

- the rear wheel side frame 121 is made of a material suitable for obtaining strength such as metal, and as shown in FIGS. 3 and 5, for example, a lower member 122 having a pair of side members 122a extending in the front-rear direction.

- a pair of motor fixing portions 123 in the vehicle width direction to which the motor 50 to which the rear wheel 20 is attached is fixed, and a pair of motor fixing portions 123 extending in the vehicle width direction and connecting the pair of motor fixing portions 123 to each other.

- each fall prevention member 126 includes a metal tilting member 126a supported at one end side by the rear wheel side frame 121 and tiltable in the vertical direction, and an auxiliary wheel 126b rotatably supported at the other end of the tilting member 126a.

- Each fall prevention member 126 is supported by the rear wheel side frame 121 at one end side and can tilt in the vertical direction, and the auxiliary wheel 126 b as the other end portion protrudes rearward of the pair of rear wheels 20.

- the pair of fall prevention members 126 are connected to each other by the connecting member 126c, whereby the pair of fall prevention members 126 are tilted together in the vertical direction.

- a seat support portion 33 for supporting the seat unit 40 is formed on the body 31 by the support portion frame 125 and a portion of the rear wheel side cover 120a that covers the support portion frame 125.

- the support portion frame 125 is inclined forward of the vehicle from the lower end side toward the upper end side. Therefore, the seat support portion 33 is also inclined forward of the vehicle from the lower end side toward the upper end side. Since the support part frame 125 has such a shape, the center of gravity of the rear wheel side vehicle body 120 is disposed in front of the vehicle with respect to the rotational axis 20a of the rear wheel 20 to such an extent that the center of gravity can be clearly seen.

- the seat support portion 33 has a front surface 33a, a back surface 33b, and a pair of side surfaces 33c disposed between the front surface 33a and the back surface 33b.

- a handle portion 125 c (see FIG. 4) is integrally provided on the upper end side of the support portion frame 125, and the handle portion 125 c protrudes from the upper end side of the back surface 33 b of the seat support portion 33. It is preferable that the position of the handle portion 125c to be gripped by the hand is arranged in front of the rotation axis 20a of the rear wheel 20 of the rear wheel side vehicle body 120 connected to the front wheel side vehicle body 110.

- a rechargeable battery BA is detachably attached to the seat support 33.

- the front surface 33a and the rear surface 33b of the seat support portion 33 are inclined forward from the lower end side toward the upper end side, and an opening portion of an accommodation space 33d for accommodating the battery BA is provided on the rear surface 33b.

- a control unit 60 described later is disposed in the seat support portion 33.

- the seat mounting member 32 is a member having a longitudinal length, and is provided with a plurality of positioning holes 32a spaced in the vertical direction. Each positioning hole 32a penetrates the seat mounting member 32 in a direction orthogonal to the longitudinal direction thereof.

- a cylindrical portion 125a through which the seat mounting member 32 is inserted in the vertical direction is provided on the upper end side of the support portion frame 125, and a support portion side hole 125b penetrating in the front-rear direction is provided in the cylindrical portion 125a.

- the inner shape of the cylindrical portion 125 a is slightly larger than the outer shape of the seat mounting member 32.

- the seat mounting member 32 is inserted into the cylindrical portion 125a, and any positioning hole 32a and the support portion side hole 125b are aligned, and the positioning member 32b is inserted into the support portion side hole 125b and the positioning hole 32a.

- the seat attachment member 32 is attached by attaching to the cylindrical part 125a. Further, by changing the positioning hole 32a through which the positioning member 32b is inserted, the height position of the seat mounting member 32 relative to the mobility main body 30, that is, the height position of the seat unit 40 can be adjusted.

- the seat unit 40 is fixed under the seat surface portion 41, the backrest portion 42, the pair of control arms 43 in the vehicle width direction, and the seat surface portion 41, and is attached to and detached from the seat mounting member 32 of the seat support portion 33. And a seating frame 44 that can.

- An operation portion 43a having an operation lever 43b is provided at the upper end of the right control arm 43.

- the operation lever 43b is moved by a biasing member (not shown) disposed in the operation portion 43a. It is arranged at the neutral position, and the rider can displace the operation lever 43b in the right direction, the left direction, the front direction, and the rear direction with respect to the neutral position with the right hand.

- a signal corresponding to the displacement direction and displacement amount of the operation lever 43b is transmitted from the operation unit 43a to the control unit 60 described later, and each motor 50 is driven according to the signal.

- the operation lever 43b is displaced in the forward direction with respect to the neutral position

- a signal for rotating each motor 50 toward the front of the vehicle is transmitted, and the electric mobility advances at a speed corresponding to the displacement amount of the operation lever 43b.

- the operation lever 43b is displaced diagonally left forward with respect to the neutral position, a signal for rotating the left motor 50 toward the front of the vehicle at a slower speed than the right motor 50 is transmitted, and the electric mobility is operated by the operation lever.

- the vehicle advances while turning left at a speed corresponding to the amount of displacement 43b.

- the upper end of the left control arm 43 is provided with a setting unit 43c capable of performing various settings related to electric mobility such as maximum speed setting, operation mode setting, electric mobility lock setting, and the like. Operating buttons, a display device and the like are provided.

- the driving mode an energy saving driving mode that suppresses power consumption, a sports driving mode that emphasizes driving performance without reducing power consumption, a normal driving mode between the energy saving driving mode and the sports driving mode, etc.

- Examples of the setting of electric mobility lock include setting of a personal identification number for locking, setting of unlock timing, and the like.

- the setting signal of the setting unit 43c is transmitted to the control unit 60 described later, and the setting of the electric mobility is registered or changed in the control unit 60.

- the control unit 60 includes a motor driver 70 that drives each motor 50 and a control device 80.

- the motor driver 70 is connected to the battery BA through a power line and is connected to each motor 50 through a power line, and drives each motor 50 by supplying power.

- the control device 80 includes, for example, a control unit 81 having a CPU, a RAM, a storage device 82 having a nonvolatile memory, a ROM, and the like, and a transmission / reception unit 83.

- the storage device 82 stores a program for controlling the electric mobility.

- the control unit 81 operates based on the program, and drives each motor 50 based on signals from the operation unit 43a and the setting unit 43c. A drive signal is transmitted to the motor driver 70.

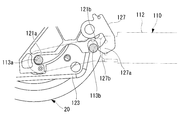

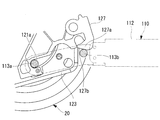

- each side member 122a of the rear wheel side frame 121 is formed with a substantially U-shaped first recess (first engaging portion) 121a that opens toward the front of the vehicle.

- a substantially U-shaped second recess (third engagement portion) 121b is formed which is disposed in front of the vehicle relative to the first recess 121a and opens downward.

- the first recess 121a is engaged with the first cross member 113a of the front wheel side frame 111

- the second recess 121b is engaged with the second cross member 113b of the front wheel side frame 111 (See FIG. 9).

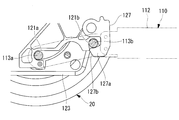

- the front wheel side frame 111 is in a state where the rear wheel side vehicle body 120 is tilted rearward around the rotation axis 20 a of the rear wheel 20 rather than being connected to the front wheel side vehicle body 110.

- the first cross member 113a is placed in the pair of first recesses 121a. In this state, each of the first recesses 121a is opened obliquely upward, so that the first cross member 113a of the front wheel side vehicle body 110 is difficult to drop off from the first recess 121a.

- the first recess 121a has a pair of side surfaces 121c and a bottom surface 121d. Therefore, as shown in FIG. 7, the side surface 121c and the bottom surface 121d arranged on the lower side or the side surface 121c are disposed on the first cross member 113a that has entered the first recess 121a opened obliquely upward. However, it abuts from below. That is, the first recess 121a has the lower contact portion LC that contacts the first cross member 113a from below as described above.

- the first recess 121a also includes a front contact portion FC that is disposed on the vehicle front side with respect to the lower contact portion LC and disposed at a position higher than the lower contact portion LC. Due to the presence of the front contact portion FC, the first cross member 113a of the front wheel side vehicle body 110 is unlikely to drop off from the first recess 121a.

- the second cross of the front-wheel side frame 111 is obtained.

- the member 113b enters the pair of second recesses 121b from below. Accordingly, the vertical movement of the first cross member 113a with respect to the rear wheel side frame 121 is restricted by the pair of side surfaces 121c of the first recess 121a shown in FIG. 11, and the rear wheel side of the second cross member 113b.

- the upward movement with respect to the frame 121 is restricted by the bottom surface 121f of the second recess 121b shown in FIG.

- the movement in the front-rear direction with respect to the rear wheel side frame 121 of the second cross member 113b is performed by the pair of side surfaces 121e (see FIG. 11) of the second recess 121b, or by the pair of side surfaces 121e of the second recess 121b and later.

- the connection lock member 127 is regulated. In this way, the front wheel side vehicle body 110 and the rear wheel side vehicle body 120 are connected. Further, the backward movement of the first cross member 113a with respect to the rear wheel frame 121 is also restricted by the bottom surface 121d of the first recess 121a.

- the rear wheel side frame 121 is provided with a connecting lock member 127 that tilts around a tilt axis 127c extending in the vehicle width direction.

- One end side of the connection lock member 127 is supported by one of the pair of side members 122a, the plurality of cross members 124a to 124c, the support portion frame 125, etc., and the connection lock member 127 tilts around the tilt axis 127c.

- the connection lock member 127 is disposed on the inner side in the vehicle width direction than the pair of second recesses 121b provided in the pair of side members 122a in the vehicle width direction.

- the connecting lock member 127 is urged by an urging member 127d such as a torsion spring so that the other end tilts backward. Further, when the connecting lock member 127 is tilted rearward by the biasing member 127d, a part of the connecting lock member 127 or a member fixed to the connecting lock member 127 comes into contact with a part of the rear wheel side frame 121, and The connection lock member 127 is configured not to tilt to the rear side of the vehicle with respect to the contact position.

- an urging member 127d such as a torsion spring

- the connecting lock member 127 is formed with a protruding portion 127a that protrudes rearward, and when the connecting lock member 127 is tilted rearward by the biasing member 127d and disposed at the lock position A indicated by the solid line in FIG.

- the protrusion 127a is configured to come into contact with the second cross member 113b entering the second recess 121b from below. For this reason, the engagement between the second cross member 113b and the second recess 121b is maintained by the connection lock member 127. That is, the connection between the front wheel side vehicle body 110 and the rear wheel side vehicle body 120 is maintained by the connection lock member 127.

- a part of the protrusion 127a (a part at the rear of the vehicle) is located at the rear of the pair of side surfaces 121e of the second recess 121b. It arrange

- connection means a state where the front wheel side vehicle body 110 and the rear wheel side vehicle body 120 are connected in a state where the second cross member 113b is engaged with the second recess 121b and the vehicle can run.

- connection lock member 127 On the other hand, when the connecting lock member 127 is tilted forward of the vehicle and disposed at the retracted position B shown in FIG. 6, the projecting portion 127a does not come into contact with the second cross member 113b.

- the connection with the side vehicle body 120 can be released or released.

- connection lock member 127 has an inclined surface 127b that is inclined rearward from the bottom upward when the front wheel body 110 and the rear wheel body 120 are connected. Is provided. Then, when the rear wheel side vehicle body 120 is tilted forward of the vehicle around the rotation axis 20a of the rear wheel 20 with the first cross member 113a of the front wheel side frame 111 being in the pair of first recesses 121a, The second cross member 113b is configured to contact the inclined surface 127b from below (see FIG. 10).

- the connecting lock member 127 tilts forward of the vehicle against the urging force of the urging member 127d, whereby the second cross member 113b becomes the second cross member 113b.

- the connecting lock member 127 is tilted rearward by the biasing member 127d, and the front wheel side vehicle body 110 and the rear wheel side vehicle body 120 are moved by the connection lock member 127. The connection with is maintained.

- Each tilting member 126a is provided with a member engaging portion 126e that engages the cross member 124a from above, behind the vehicle, or from below. Further, on each tilting member 126a, the other end side of the member engaging portion 126e is engaged with an engaging pin 128a provided at one end portion of the tilting lock member (first restricting means) 128 from above or from the rear of the vehicle.

- a lock member engaging portion 126f is provided.

- each tilt lock member 128 is supported by the rear wheel side frame 121 and can be tilted around a tilt axis 128b extending in the vehicle width direction, and an engagement pin 128a is provided at one end (lower end).

- an engagement pin 128a is provided at one end (lower end).

- the lock member engaging portion 126f of the fall-preventing member 126 is engaged with the cross member (second restricting means) 124a from above or from the rear of the vehicle. Tilt to is regulated.

- tilting of the fall prevention member 126 below the third tilt position may be restricted.

- the second tilt position is above the first tilt position

- the third tilt position is equivalent to or slightly below the first tilt position.

- One end of a plate-like link member 129 is connected to the other end of the tilt lock member 128, and the other end of the link member 129 is connected to a position away from the tilt axis 127c of the connection lock member 127. .

- the engagement pin 128 a is engaged with the lock member engagement portion 126 f in a state where the connection lock member 127 is disposed at the lock position A, or is disposed at an engageable position.

- the engagement pin 128a and the lock member engagement portion 126f are not engaged.

- the other end of the tilt lock member 128 is connected to one end of an operation lever 130 as an operation means, and the operation lever 130 tilts around the tilt axis 128 b of the tilt lock member 128.

- the other end of the operation lever 130 protrudes from the rear wheel side cover 120a of the rear wheel body 120, so that the operation lever 130 is tilted rearward or downward to engage the engagement lever 130.

- the engagement between the coupling pin 128a and the lock member engagement portion 126f can be released, and the connection lock member 127 can be disposed at the retracted position B.

- the position of the center of gravity of the rear wheel side vehicle body 120 is disposed between or near the ground contact position of the rear wheel 20 and the ground contact position of the auxiliary wheel 126b of the fall prevention member 126 in the vehicle longitudinal direction. It is preferable. As a result, the rear wheel side vehicle body 120 is stably supported by the rear wheel 20 and the overturn prevention member 126.

- each first recess 121a is opened obliquely upward, so that the first cross member 113a of the front wheel side vehicle body 110 is in the first state.

- the presence of the front abutting portion FC makes it difficult for the first cross member 113a of the front wheel side vehicle body 110 to drop off from the first recess 121a.

- the front wheel side vehicle body 110 is removed from the first recess 121a by releasing the handle 125c, lifting the rear end side of the front wheel side vehicle body 110, and pulling out the first cross member 113a from the first recess 121a. Can be removed from. Also at this time, the rear wheel side vehicle body 120 is stably supported by the rear wheel 20 and the fall prevention member 126. After being disassembled in this way, the front wheel side vehicle body 110 and the rear wheel side vehicle body 120 are loaded on an automobile or the like.

- the auxiliary wheel 126b and the rear wheel 20 of the fall prevention member 126 are grounded in a state where the fall prevention member 126 is disposed at the second tilt position.

- the first cross member 113a of the front wheel side vehicle body 110 is inserted into the first recess 121a. Accordingly, the front wheel side vehicle body 110 is supported by the first recess 121a and the front wheel 10.

- the rear wheel body 120 is tilted forward around the axle of the rear wheel 20.

- the second cross member 113 b comes into contact with the inclined surface 127 b of the connection lock member 127 from below.

- the connecting lock member 127 tilts forward of the vehicle, whereby the second cross member 113b is moved into the second recess 121b. enter.

- the connecting lock member 127 is tilted rearward by the biasing member 127d, and the front wheel side vehicle body 110 and the rear wheel side vehicle body 120 are moved by the connection lock member 127. The connection with is maintained.

- the first recess 121a (first engagement portion) of the rear wheel side vehicle body 120 is used.

- a first cross member 113a (second engagement portion) provided on the rear end side of the front wheel side vehicle body 110 is supported, and the front wheel side vehicle body 110 is connected to the front wheel 10 and the first recess 121a of the rear wheel side vehicle body 120. It will be in the state supported by. For this reason, the person who performs the disassembly work in this state does not need to support the front wheel side vehicle body 110.

- the front wheel side vehicle body 110 is supported by the first recess 121a of the rear wheel side vehicle body 120 and the front wheel 10 in a self-supporting state. can do.

- the first recess 121a of the rear wheel side vehicle body 120 in the self-standing state is formed by a lower contact portion LC that contacts the first cross member 113a of the front wheel side vehicle body 110 from below and a lower contact portion LC.

- the front contact portion FC disposed on the vehicle front side and disposed at a position higher than the lower contact portion LC. Therefore, when the first cross member 113a of the front wheel side vehicle body 110 is engaged with the first recess 121a of the rear wheel side vehicle body 120 in a self-supporting state, the first cross member 113a is moved forward of the vehicle. It is regulated or suppressed by the front contact portion FC of the first engagement portion 121a.

- the operation lever 130 is operated with the other hand to release the connection,

- the handle portion 125c is lifted in the state, the rear wheel side vehicle body 120 tilts rearward and becomes a self-supporting state.

- the front wheel side vehicle body 110 is supported by the front wheel 10 and the first recess 121a of the rear wheel side vehicle body 120. For this reason, the disassembling work can be easily performed.

- the first recess 121a has a first cross section until the rear wheel body 120 is tilted rearward and becomes independent after the connection between the front wheel body 110 and the rear wheel body 120 is released. Continue to support the member 113a from below. For this reason, after releasing the connection between the front wheel side vehicle body 110 and the rear wheel side vehicle body 120, the person who performs the disassembly work supports only the rear wheel side vehicle body 120 and makes the rear wheel side vehicle body 120 in an independent state.

- the rear wheel side vehicle body 120 that is self-supporting is in a state where the rear end side of the front wheel side vehicle body 110 is supported. This structure is advantageous in facilitating the disassembly work.

- the fall prevention member 126 tilts to the second tilt position above the first tilt position, and the position Therefore, the upward tilting is restricted by the cross member 124a.

- the auxiliary wheel 126b of the fall prevention member 126 is grounded, the position of the center of gravity of the rear wheel-side vehicle body 120 moves to the rear of the vehicle.

- the position of the center of gravity is the grounding part of the rear wheel 20 and the grounding part of the auxiliary wheel 126b.

- the rear wheel side vehicle body 120 can be stably supported by the rear wheel 20 and the toppling prevention member 126.

- connection lock member 127 when the connection lock member 127 is moved to the retracted position B by the operation lever 130 and the connection lock between the front wheel side vehicle body 110 and the rear wheel side vehicle body 120 is released, the tilting by the tilt lock member 128 is performed.

- the overturn prevention member 126 is tilted to the second tilt position above the first tilt position, and the tilting upward is regulated by the cross member 124a at that position. For this reason, when the connection release operation is performed, the rear wheel body 120 can be stably supported by the rear wheel 20 and the fall-preventing member 126, which is advantageous in facilitating the connection release operation. It is.

- the link lock member 129 also tilts the link lock member 127. Therefore, the tilt restriction by the tilt lock member 128 is released in conjunction with the release operation of the connection, and the rear wheel side vehicle body 120 can be stably and stably supported by the rear wheel 20 and the fall prevention member 126. Can be in a state.

- the operation lever 130 may be fixed to the connection lock member 127, and when the connection lock member 127 is tilted, the tilt lock member 128 may also be tilted by the link member 129.

- a fall prevention member 126 that is disposed at the first tilt position and prevents the electric mobility from falling backward is provided between the front wheel side vehicle body 110 and the front wheel side vehicle body 110. Since it is used to support the rear wheel side vehicle body 120 that has been released from the connection, there is no need to provide a dedicated member for supporting the rear wheel side vehicle body 120.

- the tilting restriction state by the tilting lock member 128 and the locking state by the connecting lock member 127 are physically confirmed. can do. For this reason, unreasonable operations such as tilting the rear wheel side vehicle body 120 rearward in a state where the tilting restriction by the tilting lock member 128 and the lock by the connecting lock member 127 are not released are prevented.

- the front wheel side vehicle body 110 and the rear wheel side vehicle body 120 are connected, the state of tilt restriction by the tilt lock member 128 and the state of lock by the connection lock member 127 can be physically confirmed.

- the downward tilt of the fall prevention member 126 is restricted by the cross member 124a of the rear wheel side frame 121. Further, even when the restriction of the tilting by the tilt lock member 128 is released and the tipping prevention member 126 is tilted to the second tilting position, the upward tilting of the tipping prevention member 126 is restricted by the same cross member 124a. For this reason, the configuration for controlling the tilting of the fall prevention member 126 can be simplified, which is advantageous in electric mobility where there is a strong demand for weight reduction and design space is limited.

- the tilting lock member 128 and the connecting lock member 127 are tilted by the operation lever 130.

- the output shaft of the speed reducer is connected to at least one of the tilting lock member 128 and the connecting lock member 127.

- the drive shaft of the speed reducer can be configured to be driven by a motor.

- the control device 80 may be configured to control the motor 50 based on the lock release signal or the lock signal received by the control device 80.

- the seat unit 40 is disassembled into the front wheel side vehicle body 110 and the rear wheel side vehicle body 120 after being removed from the mobility main body 30.

- the seat unit 40 is attached to the front wheel side vehicle body 110 instead of the rear wheel side vehicle body 120, or when the seat unit 40 is small, it may not be necessary to remove the seat unit 40.

- the fall prevention member 126 protrudes rearward of the rear wheel 20 and tilts the fall prevention member 126 upward so that the auxiliary wheel 126b and the rear wheel 20 at the other end of the fall prevention member 126

- the support for the rear wheel side vehicle body 120 is shown.

- the fall prevention member 126 may be configured without the auxiliary wheel 126b. Even in this case, the fall prevention member 126 can prevent the electric mobility from falling backward, and the rear wheel side vehicle body 120 can be supported by the other end portion of the fall prevention member 126 and the rear wheel 20.

- the fall prevention member 126 when the center of gravity of the rear wheel side vehicle body 120 is located behind the rotation axis 20a of the rear wheel 20, the fall prevention member 126 is located above the first tilt position.

- one end of the projecting member is supported by the rear wheel side vehicle body 120 and can be tilted in the vertical direction. Further, in a connected state of the front wheel side vehicle body 110 and the rear wheel side vehicle body 120, the projecting member is disposed at the first tilt position so as to extend in the vehicle longitudinal direction, for example. When the connection between the front wheel side vehicle body 110 and the rear wheel side vehicle body 120 is released, or after that, the projecting member can be tilted to a second tilt position that is higher than the first tilt position. As a result, when the rear wheel side vehicle body 120 is supported by the other end portion of the protruding member and the rear wheel 20, the position of the center of gravity of the rear wheel side vehicle body 120 moves forward of the vehicle as compared with the connection.

- the rear wheel side frame 121 is provided with a cross member, an engagement pin, etc. extending in the vehicle width direction instead of the first recess 121a, and each side member 112 of the front wheel side frame 111 is replaced with the first cross member 113a.

- a substantially U-shaped recess opening obliquely downward toward the front of the vehicle may be provided, and the recess may be configured such that a cross member, an engagement pin, or the like of the rear wheel side frame 121 is engaged with each recess.

- each side member 112 of the front wheel side frame 111 is replaced with the second cross member 113b.

- a substantially U-shaped recess that opens upward may be provided, and a cross member, an engagement pin, and the like of the rear wheel side frame 121 may be engaged with each recess.

- the front wheel side vehicle body 110 and the rear wheel side vehicle body 120 may be configured to be detachably connected by other methods.

- the first recess 121a contacts the first cross member 113a from below, above, and from the rear of the vehicle when the front wheel side vehicle body 110 and the rear wheel side vehicle body 120 are connected, and opens to the front of the vehicle. If it exists, even if it is another shape, there exists an effect similar to the above-mentioned.

- the second recess 121b is also configured so as to contact the second cross member 113b from the upper side, the rear side of the vehicle, and the front side of the vehicle when the front wheel side vehicle body 110 and the rear wheel side vehicle body 120 are connected, and open downward. Even in other shapes, the same effects as described above can be obtained.

- the front wheel side frame 111 when the front wheel side frame 111 is provided with a recess opening obliquely downward toward the front of the vehicle instead of the first cross member 113a, the front wheel side vehicle body 110 and the rear wheel side vehicle body 120 are connected. As long as it is in contact with the cross member, engagement pin, etc. of the rear wheel side vehicle body 120 from above, below, and from the rear of the vehicle and opens obliquely downward toward the front of the vehicle, it is the same as described above even in other shapes Has the effect of.

- the rear wheel side vehicle body 110 is connected when the front wheel side vehicle body 110 and the rear wheel side vehicle body 120 are connected. Any other shape can be obtained as long as it is in contact with 120 cross members, engagement pins, etc. from below, the rear of the vehicle, and the front of the vehicle and opens upward.

- the locking member engaging portion 126f of the tilting member 126a is engaged with the cross member 124a so that the tilting of the tipping prevention member 126 is restricted from being tilted upward from the second tilting position. Indicated.

- a part between the other end portion of the tilting member 126a and the tilting center 126d is engaged with the rear wheel side cover 120a and the rear wheel side frame 121, thereby the second tilting position of the fall prevention member 126. Further upward tilting may be restricted.

- the tilting of the fall-preventing member 126 upward from the second tilt position may be restricted by another structure.

- the seat unit 40 When the seat unit 40 is attached, the connection between the rear wheel side vehicle body 120 and the front wheel side vehicle body 110 is released, and the rear wheel side vehicle body 110 is tilted rearward so that the fall prevention member 126 is grounded. Further, the center of gravity of the entire rear wheel-side vehicle body 120 may be arranged between the grounding position of the rear wheel 20 and the grounding position of the auxiliary wheel 126b of the fall prevention member 126. In this case, it is possible to easily disassemble the rear wheel body 120 and the front wheel body 110 with the seat unit 40 attached. On the other hand, when the seat unit 40 is first attached to the rear wheel side vehicle body 120 and then the rear wheel side vehicle body 120 is attached to the front wheel side vehicle body 110, the operation can be facilitated.

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Automatic Cycles, And Cycles In General (AREA)

- Motorcycle And Bicycle Frame (AREA)

Abstract

This electric mobility is provided with: a front wheel-side vehicle body (110); and a rear wheel-side vehicle body (120) which is detachably connected to the front wheel-side vehicle body (110). The rear wheel-side vehicle body (120) enters a self-supporting state when detached from the front wheel-side vehicle body (110) and tilted towards the rear of the vehicle. The rear wheel-side vehicle body (120) has, provided thereto, a first recess (121a) which is used for connecting the front wheel-side vehicle body (110). When the rear wheel-side vehicle body (120) is in the self-supporting state, a first cross member (113a), which is provided to the rear end side of the front wheel-side vehicle body (110), and which is used for connecting the front wheel-side vehicle body and the rear wheel-side vehicle body, can be supported by the first recess (121a).

Description

本発明は電動モビリティおよびその分解方法に関する。

The present invention relates to an electric mobility and a disassembling method thereof.

このような電動モビリティとして、取外し可能なシートと、前輪側車体と、後輪側車体とに分解可能であり、前輪側車体を後輪側車体から取外した後に前輪側車体の後端から下方に向けて延びるスタンドを有し、スタンドにより後輪側車体から取外した前輪側車体の後端が地面に直接接触しないようにするものが知られている(例えば、特許文献1参照。)。

As such electric mobility, it can be disassembled into a removable seat, a front wheel side vehicle body, and a rear wheel side vehicle body. It is known to have a stand that extends toward the rear side so that the rear end of the front wheel side vehicle body removed from the rear wheel side vehicle body by the stand does not directly contact the ground (see, for example, Patent Document 1).

また、取外し可能なシートと、取外し可能なバッテリと、前輪側車体と、後輪側車体とに分解可能であり、後輪側車体は後輪よりも後方に突出している突出部材(転倒防止棒)を有し、後輪側車体は後輪の回転軸線よりも後方に重心があるので、前輪側車体から取外された時に後輪側車体が後傾して突出部材が接地し、突出部材と後輪とにより後輪側車体が支持される電動モビリティが知られている(例えば、特許文献2参照。)。

In addition, it can be disassembled into a removable seat, a removable battery, a front wheel side vehicle body, and a rear wheel side vehicle body, and the rear wheel side vehicle body protrudes rearward from the rear wheel (a fall prevention rod). ), And the rear wheel side vehicle body has a center of gravity behind the rotation axis of the rear wheel. Therefore, when the rear wheel side vehicle body is removed from the front wheel side vehicle body, the rear wheel side vehicle body is tilted rearward and the protruding member is grounded. There is known an electric mobility in which a rear wheel-side vehicle body is supported by a rear wheel (see, for example, Patent Document 2).

前者の電動モビリティでは、前輪側車体を後輪側車体から取外した後に、前輪側車体に設けられているスタンドを横倒姿勢から直立姿勢にする必要があり、スタンドの姿勢を変更する分だけ分解作業に手間がかかる。

後者の電動モビリティでは、後輪側車体から取外された前輪側車体の後端側を支持するスタンドが無いので、後輪側車体から前輪側車体を取外した時に分解作業を行っている者が前輪側車体の少なくとも後端側を支持する必要がある。 In the former electric mobility, after removing the front wheel side vehicle body from the rear wheel side vehicle body, it is necessary to change the stand provided on the front wheel side vehicle body from the sideways posture to the upright posture. It takes a lot of work.

In the latter electric mobility, there is no stand for supporting the rear end side of the front wheel side vehicle body removed from the rear wheel side vehicle body, so that a person who is disassembling when removing the front wheel side vehicle body from the rear wheel side vehicle body It is necessary to support at least the rear end side of the front wheel side vehicle body.

後者の電動モビリティでは、後輪側車体から取外された前輪側車体の後端側を支持するスタンドが無いので、後輪側車体から前輪側車体を取外した時に分解作業を行っている者が前輪側車体の少なくとも後端側を支持する必要がある。 In the former electric mobility, after removing the front wheel side vehicle body from the rear wheel side vehicle body, it is necessary to change the stand provided on the front wheel side vehicle body from the sideways posture to the upright posture. It takes a lot of work.

In the latter electric mobility, there is no stand for supporting the rear end side of the front wheel side vehicle body removed from the rear wheel side vehicle body, so that a person who is disassembling when removing the front wheel side vehicle body from the rear wheel side vehicle body It is necessary to support at least the rear end side of the front wheel side vehicle body.

前輪側車体を取外すと、当該文献の説明のように後輪側車体は突出部材が接地するまで後輪側車体が後方に向かって自重により傾くが、後輪側車体が周りの人や物に当ることを恐れ、後輪側車体の一部を持って後輪側車体の後方への傾きを制御することが考えられる。この場合、前輪側車体の後端側を持ち上げながら後輪側車体も支える必要があるので、前輪側車体と後輪側車体との分解作業を一人で容易に行えない場合もある。

When the front wheel side vehicle body is removed, the rear wheel side vehicle body is tilted by its own weight toward the rear until the protruding member contacts the ground, as explained in the document, but the rear wheel side vehicle body is For fear of hitting, it may be possible to control the rearward tilt of the rear wheel side vehicle body by holding a part of the rear wheel side vehicle body. In this case, since it is necessary to support the rear wheel side vehicle body while lifting the rear end side of the front wheel side vehicle body, it may not be possible to easily disassemble the front wheel side vehicle body and the rear wheel side vehicle body by one person.

本発明は、このような事情に鑑みてなされたものであって、前輪側車体と後輪側車体との分解作業や組付作業を一人で容易に行うことを可能とする電動モビリティおよびその分解方法の提供を目的とする。

The present invention has been made in view of such circumstances, and it is possible to easily perform the disassembly work and the assembly work of the front wheel side vehicle body and the rear wheel side vehicle body by one person and the disassembly thereof. The purpose is to provide a method.

上記課題を解決するために、本発明は以下の手段を採用する。

本発明の第1の態様の電動モビリティは、前輪側車体と、該前輪側車体に取外し可能に連結された後輪側車体とを備え、前記後輪側車体が、前記前輪側車体から取外して車両後方に傾けると自立状態となるものであり、前記後輪側車体には前記前輪側車体との連結に用いられる第1の係合部が設けられ、前記後輪側車体が、前記自立状態の時に、前記前輪側車体の後端側に設けられ前記連結に用いられる第2の係合部を前記第1の係合部により支持可能である。 In order to solve the above problems, the present invention employs the following means.

The electric mobility according to the first aspect of the present invention includes a front wheel side vehicle body and a rear wheel side vehicle body that is detachably connected to the front wheel side vehicle body, and the rear wheel side vehicle body is detached from the front wheel side vehicle body. The rear wheel side vehicle body is provided with a first engagement portion used for connection with the front wheel side vehicle body, and the rear wheel side vehicle body is in the self-standing state. At this time, a second engagement portion provided on the rear end side of the front wheel side vehicle body and used for the connection can be supported by the first engagement portion.

本発明の第1の態様の電動モビリティは、前輪側車体と、該前輪側車体に取外し可能に連結された後輪側車体とを備え、前記後輪側車体が、前記前輪側車体から取外して車両後方に傾けると自立状態となるものであり、前記後輪側車体には前記前輪側車体との連結に用いられる第1の係合部が設けられ、前記後輪側車体が、前記自立状態の時に、前記前輪側車体の後端側に設けられ前記連結に用いられる第2の係合部を前記第1の係合部により支持可能である。 In order to solve the above problems, the present invention employs the following means.

The electric mobility according to the first aspect of the present invention includes a front wheel side vehicle body and a rear wheel side vehicle body that is detachably connected to the front wheel side vehicle body, and the rear wheel side vehicle body is detached from the front wheel side vehicle body. The rear wheel side vehicle body is provided with a first engagement portion used for connection with the front wheel side vehicle body, and the rear wheel side vehicle body is in the self-standing state. At this time, a second engagement portion provided on the rear end side of the front wheel side vehicle body and used for the connection can be supported by the first engagement portion.

当該態様では、例えば後輪側車体を前輪側車体から取外して自立状態とした時に、後輪側車体の第1の係合部により前輪側車体の後端側に設けられた第2の係合部が支持され、前輪側車体が前輪と後輪側車体の第1の係合部とにより支持された状態となる。このため、当該状態で分解作業を行う者は前輪側車体を支える必要がない。後輪側車体を前輪側車体に組付ける組付作業を行う際も、自立状態の後輪側車体の第1の係合部と前輪とにより前輪側車体が支持された状態とすることができる。

In this aspect, for example, when the rear wheel side vehicle body is detached from the front wheel side vehicle body to be in a self-supporting state, the second engagement provided on the rear end side of the front wheel side vehicle body by the first engagement portion of the rear wheel side vehicle body. The front wheel side vehicle body is supported by the front wheel and the first engagement portion of the rear wheel side vehicle body. For this reason, the person who performs the disassembling work in this state does not need to support the front wheel side vehicle body. Even when the assembly work for assembling the rear wheel side vehicle body to the front wheel side vehicle body is performed, the front wheel side vehicle body can be supported by the first engagement portion of the rear wheel side vehicle body and the front wheel in a self-supporting state. .

上記態様において、前記後輪側車体に設けられると共に、前記第1の係合部に対して車両前側に配置された第3の係合部と、前記前輪側車体に設けられると共に、前記第2の係合部に対して車両前側に配置され、前記連結時に前記第3の係合部と係合する第4の係合部とを有し、前記自立状態にある前記後輪側車体の前記第1の係合部は、前記前輪側車体の前記第2の係合部に下方から当接する下側当接部と、該下側当接部に対して車両前側に配置され且つ該下側当接部よりも高い位置に配置される前側当接部とを有することが好ましい。

In the above aspect, the second engagement body is provided on the rear wheel side vehicle body, is provided on the vehicle front side with respect to the first engagement portion, and is provided on the front wheel side vehicle body. And a fourth engaging portion that engages with the third engaging portion at the time of the connection, and has the self-standing state of the rear wheel side vehicle body. The first engagement portion is disposed on the front side of the vehicle with respect to the lower contact portion, a lower contact portion that contacts the second engagement portion of the front wheel side vehicle body from below, and the lower side It is preferable to have a front abutting portion disposed at a position higher than the abutting portion.

このように構成すると、自立状態の後輪側車体の第1の係合部に前輪側車体の第2の係合部が係合している時に、第2の係合部の車両前方への移動が第1の係合部の前側当接部により規制又は抑制されるので、前輪側車体の後端側が後輪側車体の第1の係合部により安定して支持される。

If comprised in this way, when the 2nd engagement part of a front-wheel side vehicle body is engaging with the 1st engagement part of the rear-wheel side vehicle body of a self-supporting state, a 2nd engagement part is ahead of a vehicle. Since the movement is restricted or suppressed by the front contact portion of the first engagement portion, the rear end side of the front wheel side vehicle body is stably supported by the first engagement portion of the rear wheel side vehicle body.

上記態様において、前記後輪側車体に設けられ、前記連結を解除するために操作される操作部材と、前記後輪の回転軸線に対して車両前側に配置されるように前記後輪側車体に設けられた持ち手部とをさらも備えることが好ましい。

このように構成すると、前輪側車体と後輪側車体とが連結されている状態で、例えば持ち手部を一方の手で持ちながら、他方の手で操作部材を操作して連結を解除し、その状態で持ち手部を持ち上げると、後輪側車体が後傾して自立状態となる。また、自立状態では前輪側車体が前輪と後輪側車体の第1の係合部とにより支持された状態となる。このため、分解作業を容易に行うことができる。 In the above aspect, the operation member provided on the rear wheel side vehicle body and operated to release the connection, and the rear wheel side vehicle body disposed on the vehicle front side with respect to the rotation axis of the rear wheel. It is preferable to further provide a handle portion provided.

With this configuration, in a state where the front wheel side vehicle body and the rear wheel side vehicle body are connected, for example, while holding the handle portion with one hand, the operation member is operated with the other hand to release the connection, When the handle is lifted in this state, the rear wheel side vehicle body tilts rearward and becomes self-supporting. In the self-supporting state, the front wheel side vehicle body is supported by the front wheel and the first engagement portion of the rear wheel side vehicle body. For this reason, the disassembling work can be easily performed.

このように構成すると、前輪側車体と後輪側車体とが連結されている状態で、例えば持ち手部を一方の手で持ちながら、他方の手で操作部材を操作して連結を解除し、その状態で持ち手部を持ち上げると、後輪側車体が後傾して自立状態となる。また、自立状態では前輪側車体が前輪と後輪側車体の第1の係合部とにより支持された状態となる。このため、分解作業を容易に行うことができる。 In the above aspect, the operation member provided on the rear wheel side vehicle body and operated to release the connection, and the rear wheel side vehicle body disposed on the vehicle front side with respect to the rotation axis of the rear wheel. It is preferable to further provide a handle portion provided.

With this configuration, in a state where the front wheel side vehicle body and the rear wheel side vehicle body are connected, for example, while holding the handle portion with one hand, the operation member is operated with the other hand to release the connection, When the handle is lifted in this state, the rear wheel side vehicle body tilts rearward and becomes self-supporting. In the self-supporting state, the front wheel side vehicle body is supported by the front wheel and the first engagement portion of the rear wheel side vehicle body. For this reason, the disassembling work can be easily performed.

上記態様において、前記第1の係合部が、前記前輪側車体と前記後輪側車体との連結が解除された後、前記後輪側車体が前記車両後方に傾けられて前記自立状態になるまで、前記第2の係合部を下方から支持し続けるように構成されていることが好ましい。

このように構成すると、前輪側車体と後輪側車体との連結を解除した後に、分解作業を行う者は後輪側車体だけを支持して後輪側車体を自立状態とすることにより、自立した後輪側車体により前輪側車体の後端側が支持された状態になるので、分解作業の容易化を図る上で有利である。 In the above aspect, after the first engagement portion releases the connection between the front wheel side vehicle body and the rear wheel side vehicle body, the rear wheel side vehicle body is inclined rearward of the vehicle to be in the self-supporting state. It is preferable that the second engagement portion is continuously supported from below.

In this configuration, after the connection between the front wheel side vehicle body and the rear wheel side vehicle body is released, the person who performs the disassembly work supports only the rear wheel side vehicle body and makes the rear wheel side vehicle body self-supporting. Since the rear end side of the front wheel side vehicle body is supported by the rear wheel side vehicle body, it is advantageous in facilitating disassembly work.

このように構成すると、前輪側車体と後輪側車体との連結を解除した後に、分解作業を行う者は後輪側車体だけを支持して後輪側車体を自立状態とすることにより、自立した後輪側車体により前輪側車体の後端側が支持された状態になるので、分解作業の容易化を図る上で有利である。 In the above aspect, after the first engagement portion releases the connection between the front wheel side vehicle body and the rear wheel side vehicle body, the rear wheel side vehicle body is inclined rearward of the vehicle to be in the self-supporting state. It is preferable that the second engagement portion is continuously supported from below.

In this configuration, after the connection between the front wheel side vehicle body and the rear wheel side vehicle body is released, the person who performs the disassembly work supports only the rear wheel side vehicle body and makes the rear wheel side vehicle body self-supporting. Since the rear end side of the front wheel side vehicle body is supported by the rear wheel side vehicle body, it is advantageous in facilitating disassembly work.

本発明の第2の態様は、前輪側車体から後輪側車体を取外し可能な電動モビリティの分解方法であって、前記前輪側車体の後端側が前記後輪側車体により支持された状態で、前記後輪側車体が自立状態にまるまで前記後輪側車体を前記後輪周りに車両後方に傾けるステップと、前記後輪側車体が自立状態になった後に前記前輪側車体の前記後端側を前記後輪側車体から取外すステップとを有する。

A second aspect of the present invention is an electric mobility disassembling method capable of removing a rear wheel side vehicle body from a front wheel side vehicle body, wherein the rear end side of the front wheel side vehicle body is supported by the rear wheel side vehicle body, Tilting the rear wheel side vehicle body rearward around the rear wheel until the rear wheel side vehicle body is in a self-supporting state, and the rear end side of the front wheel side vehicle body after the rear wheel side vehicle body is in a self-supporting state. Removing from the rear wheel side vehicle body.

このようにすると、例えば前輪側車体と後輪側車体との連結を解除した後に、分解作業を行う者は後輪側車体だけを支持して後輪側車体を自立状態とすることにより、自立した後輪側車体により前輪側車体の後端側が支持された状態になるので、分解作業の容易化を図る上で有利である。

In this case, for example, after the connection between the front wheel side vehicle body and the rear wheel side vehicle body is released, the person who performs the disassembly work supports only the rear wheel side vehicle body and makes the rear wheel side vehicle body self-supporting. Since the rear end side of the front wheel side vehicle body is supported by the rear wheel side vehicle body, it is advantageous in facilitating disassembly work.

上記態様において、前記後輪側車体が、前記前輪側車体と前記後輪側車体との走行可能な態様の連結を解除するために操作される操作部材を備えるものであり、前記後輪側車体に前記車両後方に向かう力を加えながら前記操作部材を操作して前記連結を解除することが好ましい。

このようにすると、後輪側車体にその自立方向に傾ける力を加えながら、操作部材の操作により連結を解除するだけで、自立した後輪側車体により前輪側車体の後端側が支持された状態にすることができるので、分割作業をより容易に行うことが可能となる。 In the above aspect, the rear wheel side vehicle body includes an operation member that is operated to release the connection of the travelable aspect between the front wheel side vehicle body and the rear wheel side vehicle body. Preferably, the connection is released by operating the operation member while applying a force toward the rear of the vehicle.

In this way, the rear end side of the front wheel side vehicle body is supported by the rear wheel side vehicle body that is self-supported by simply releasing the connection by operating the operation member while applying a force that tilts the rear wheel side vehicle body in its own direction. Therefore, the division work can be performed more easily.

このようにすると、後輪側車体にその自立方向に傾ける力を加えながら、操作部材の操作により連結を解除するだけで、自立した後輪側車体により前輪側車体の後端側が支持された状態にすることができるので、分割作業をより容易に行うことが可能となる。 In the above aspect, the rear wheel side vehicle body includes an operation member that is operated to release the connection of the travelable aspect between the front wheel side vehicle body and the rear wheel side vehicle body. Preferably, the connection is released by operating the operation member while applying a force toward the rear of the vehicle.

In this way, the rear end side of the front wheel side vehicle body is supported by the rear wheel side vehicle body that is self-supported by simply releasing the connection by operating the operation member while applying a force that tilts the rear wheel side vehicle body in its own direction. Therefore, the division work can be performed more easily.

本発明によれば、前輪側車体と後輪側車体との分解作業や組付作業を一人で容易に行うことが可能となる。

According to the present invention, it becomes possible for one person to easily disassemble and assemble the front wheel side vehicle body and the rear wheel side vehicle body.

本発明の一実施形態に係る電動モビリティを図面を参照して以下に説明する。

この電動モビリティは、図1~図3に示すように、モビリティ本体30を有し、モビリティ本体30は、一対の前輪10と、一対の後輪20と、前輪10および後輪20により支持されたボディ31とを有する。また、この電動モビリティは、モビリティ本体30に着脱自在に取付けられた座席ユニット40と、モビリティ本体30に取付けられ、一対の前輪10および一対の後輪20の少なくとも一方を駆動するためのモータ50とを有する。以下の説明では、車両前後方向を前後方向と称し、車両幅方向を幅方向と称する場合がある。 An electric mobility according to an embodiment of the present invention will be described below with reference to the drawings.

The electric mobility has a mobilitymain body 30 as shown in FIGS. 1 to 3, and the mobility main body 30 is supported by a pair of front wheels 10, a pair of rear wheels 20, and a front wheel 10 and a rear wheel 20. Body 31. The electric mobility includes a seat unit 40 that is detachably attached to the mobility main body 30, and a motor 50 that is attached to the mobility main body 30 and drives at least one of the pair of front wheels 10 and the pair of rear wheels 20. Have In the following description, the vehicle front-rear direction may be referred to as the front-rear direction, and the vehicle width direction may be referred to as the width direction.

この電動モビリティは、図1~図3に示すように、モビリティ本体30を有し、モビリティ本体30は、一対の前輪10と、一対の後輪20と、前輪10および後輪20により支持されたボディ31とを有する。また、この電動モビリティは、モビリティ本体30に着脱自在に取付けられた座席ユニット40と、モビリティ本体30に取付けられ、一対の前輪10および一対の後輪20の少なくとも一方を駆動するためのモータ50とを有する。以下の説明では、車両前後方向を前後方向と称し、車両幅方向を幅方向と称する場合がある。 An electric mobility according to an embodiment of the present invention will be described below with reference to the drawings.

The electric mobility has a mobility

本実施形態では、一対の後輪20にそれぞれモータ50が接続され、各モータ50によって2つの後輪20をそれぞれ駆動可能である。モータ50の駆動力がベルト、ギヤ等の動力伝達手段を介して一対の前輪10に伝達されるように構成してもよい。

各前輪10は、図示しない車軸、サスペンション等を介してボディ31に支持されている。また、各前輪10はその周方向に並ぶ複数のローラ13,14によって接地面が形成されている。ローラ13の外形はローラ14の外形よりも小さく、ローラ13とローラ14が周方向に交互に並んでいる。 In the present embodiment, amotor 50 is connected to each of the pair of rear wheels 20, and the two rear wheels 20 can be driven by each motor 50. You may comprise so that the driving force of the motor 50 may be transmitted to a pair of front wheels 10 via power transmission means, such as a belt and a gear.

Eachfront wheel 10 is supported by the body 31 via an axle, a suspension, etc. (not shown). Each front wheel 10 has a ground contact surface formed by a plurality of rollers 13 and 14 arranged in the circumferential direction. The outer shape of the roller 13 is smaller than the outer shape of the roller 14, and the roller 13 and the roller 14 are alternately arranged in the circumferential direction.

各前輪10は、図示しない車軸、サスペンション等を介してボディ31に支持されている。また、各前輪10はその周方向に並ぶ複数のローラ13,14によって接地面が形成されている。ローラ13の外形はローラ14の外形よりも小さく、ローラ13とローラ14が周方向に交互に並んでいる。 In the present embodiment, a

Each

より具体的に、各前輪10は、車軸に取付けられたハブ15と、ハブ15の周方向に並ぶと共にそれぞれハブ15に支持された複数のローラ支軸とを備え、複数のローラ13,14はそれぞれローラ支軸に回転可能に支持されている。なお、ハブ15は車軸にベアリング等を介して直接取付けられていてもよく、車軸に緩衝部材やその他の中間部材を介して取付けられていてもよい。

More specifically, each front wheel 10 includes a hub 15 attached to the axle, and a plurality of roller support shafts arranged in the circumferential direction of the hub 15 and supported by the hub 15, respectively. Each is rotatably supported on a roller spindle. The hub 15 may be directly attached to the axle via a bearing or the like, or may be attached to the axle via a buffer member or other intermediate member.

このように構成されているので、各ローラ13,14は車軸の径方向に交差する方向に延びる軸線周りに回転することができ、各前輪10は接地面に対して全方向に移動する全方向移動車輪となっている。

本実施形態では、各後輪20は、車軸(モータ50の主軸と共通でもよい)と、車軸に取付けられたハブ22と、ハブ22の外周側に設けられ、外周面がゴム状弾性を有する材料により形成された外周部材23とを有するが、前輪10と同様に全方向移動車輪を用いてもよい。この場合、各前輪10が後輪10と同様の車輪であってもよい。さらに、各前輪10を後輪20と同様の車輪にすると共に、前輪10および/又は後輪20の操舵角を変更するための手段を設けてもよい。 With this configuration, the rollers 13 and 14 can rotate around an axis extending in a direction intersecting the radial direction of the axle, and each front wheel 10 can move in all directions with respect to the ground plane. It is a moving wheel.

In the present embodiment, eachrear wheel 20 is provided on an axle (may be common with the main shaft of the motor 50), a hub 22 attached to the axle, and an outer peripheral side of the hub 22, and the outer peripheral surface has rubber-like elasticity. Although the outer peripheral member 23 is made of a material, an omnidirectional moving wheel may be used similarly to the front wheel 10. In this case, each front wheel 10 may be the same wheel as the rear wheel 10. Further, each front wheel 10 may be the same wheel as the rear wheel 20, and means for changing the steering angle of the front wheel 10 and / or the rear wheel 20 may be provided.

本実施形態では、各後輪20は、車軸(モータ50の主軸と共通でもよい)と、車軸に取付けられたハブ22と、ハブ22の外周側に設けられ、外周面がゴム状弾性を有する材料により形成された外周部材23とを有するが、前輪10と同様に全方向移動車輪を用いてもよい。この場合、各前輪10が後輪10と同様の車輪であってもよい。さらに、各前輪10を後輪20と同様の車輪にすると共に、前輪10および/又は後輪20の操舵角を変更するための手段を設けてもよい。 With this configuration, the

In the present embodiment, each

モビリティ本体30は、前輪側車体110と、前輪側車体110に取外し可能に連結される後輪側車体120とを有する。前輪側車体110は、地面に沿って延びるように形成され、前輪10の車軸が取付けられた前輪側フレーム111と、前輪側フレーム111の少なくとも一部を覆うように設けられ、前輪側フレーム111の保護、座席ユニット40に座る乗車者の足を載せる部分、荷物載置部、泥除け等に活用される前輪側カバー110aとを有する。

The mobility main body 30 includes a front wheel side vehicle body 110 and a rear wheel side vehicle body 120 that is detachably connected to the front wheel side vehicle body 110. The front wheel side vehicle body 110 is formed so as to extend along the ground, and is provided so as to cover at least a part of the front wheel side frame 111 and the front wheel side frame 111 to which the axle of the front wheel 10 is attached. A front wheel side cover 110a used for protection, a part on which a foot of a passenger sitting on the seat unit 40 is placed, a luggage placing part, mudguard and the like.

前輪側フレーム111は金属等の強度を得るのに適した材料から成り、例えば図3に示すように、それぞれ前後方向に延びる幅方向一対のサイドメンバ112と、互いに前後方向に間隔をおいて配置されると共にそれぞれ車両幅方向に延び、一対のサイドメンバ112を互いに接続する第1~第3のクロスメンバ113a~113cとを有する。複数のクロスメンバ113a~113cのうち、第1のクロスメンバ(第2の係合部)113aは一対のサイドメンバ112における後端部に設けられ、第2のクロスメンバ(第4の係合部)113bは第1のクロスメンバ113aよりも車両前側に配置されている。

The front wheel side frame 111 is made of a material suitable for obtaining strength, such as metal. For example, as shown in FIG. The first to third cross members 113a to 113c extend in the vehicle width direction and connect the pair of side members 112 to each other. Of the plurality of cross members 113a to 113c, the first cross member (second engaging portion) 113a is provided at the rear end portion of the pair of side members 112, and the second cross member (fourth engaging portion). ) 113b is disposed on the vehicle front side relative to the first cross member 113a.

後輪側車体120は、車両幅方向の両側にそれぞれモータ50および後輪20を支持し、上端側に座席ユニット40を支持する後輪側フレーム121と、後輪側フレーム121の少なくとも一部を覆うように設けられ、後輪側フレーム121の保護、泥除け等に活用される後輪側カバー120aとを有する。

The rear wheel side body 120 supports the motor 50 and the rear wheel 20 on both sides in the vehicle width direction, and the rear wheel side frame 121 that supports the seat unit 40 on the upper end side, and at least a part of the rear wheel side frame 121. The rear wheel side cover 120a is provided so as to cover and used for protection of the rear wheel side frame 121, mudguard and the like.

後輪側フレーム121は金属等の強度を得るのに適した材料から成り、例えば図3および図5に示すように、それぞれ前後方向に延びる幅方向一対のサイドメンバ122aを有する下側部材122と、それぞれ後輪20が取付けられたモータ50が固定される車両幅方向一対のモータ固定部123と、それぞれ車両幅方向に延び、一対のモータ固定部123を互いに連結すると共に、一対のモータ固定部123を下側部材122に固定する複数のクロスメンバ124a~124cと、下端側がサイドメンバ122a、クロスメンバ124a~124c等に固定され、上端側に座席ユニット40を装着するための座席取付部材32が取付けられる支持部フレーム125とを有する(図4参照)。

The rear wheel side frame 121 is made of a material suitable for obtaining strength such as metal, and as shown in FIGS. 3 and 5, for example, a lower member 122 having a pair of side members 122a extending in the front-rear direction. A pair of motor fixing portions 123 in the vehicle width direction to which the motor 50 to which the rear wheel 20 is attached is fixed, and a pair of motor fixing portions 123 extending in the vehicle width direction and connecting the pair of motor fixing portions 123 to each other. A plurality of cross members 124a to 124c for fixing 123 to the lower member 122, a lower end side is fixed to the side members 122a, cross members 124a to 124c, etc., and a seat mounting member 32 for mounting the seat unit 40 to the upper end side is provided. And a support frame 125 to be attached (see FIG. 4).

また、後輪側フレーム121には、電動モビリティの車両後方への転倒を防止するために幅方向一対の転倒防止部材(突出部材)126が設けられている。各転倒防止部材126は、一端側が後輪側フレーム121に支持され上下方向に傾動可能である金属製の傾動部材126aと、傾動部材126aの他端に回転可能に支持された補助輪126bとを有する。各転倒防止部材126は一端側が後輪側フレーム121に支持され上下方向に傾動可能であり、他端部である補助輪126bが一対の後輪20よりも車両後方に突出している。また、一対の転倒防止部材126は連結部材126cにより互いに連結され、これにより一対の転倒防止部材126は一緒に上下方向に傾動する。

Further, the rear wheel side frame 121 is provided with a pair of width direction fall prevention members (protruding members) 126 to prevent the electric mobility from falling backward in the vehicle. Each fall prevention member 126 includes a metal tilting member 126a supported at one end side by the rear wheel side frame 121 and tiltable in the vertical direction, and an auxiliary wheel 126b rotatably supported at the other end of the tilting member 126a. Have. Each fall prevention member 126 is supported by the rear wheel side frame 121 at one end side and can tilt in the vertical direction, and the auxiliary wheel 126 b as the other end portion protrudes rearward of the pair of rear wheels 20. Further, the pair of fall prevention members 126 are connected to each other by the connecting member 126c, whereby the pair of fall prevention members 126 are tilted together in the vertical direction.

なお、支持部フレーム125と、後輪側カバー120aのうち支持部フレーム125を覆う部分とにより、座席ユニット40を支持するための座席支持部33がボディ31に形成されている。支持部フレーム125は下端側から上端側に向かって車両前方に傾斜しており、このため座席支持部33も下端側から上端側に向かって車両前方に傾斜している。支持部フレーム125がこのような形状を有するので、後輪側車体120の重心は明確にわかる程度に後輪20の回転軸線20aに対して車両前方に配置されている。

A seat support portion 33 for supporting the seat unit 40 is formed on the body 31 by the support portion frame 125 and a portion of the rear wheel side cover 120a that covers the support portion frame 125. The support portion frame 125 is inclined forward of the vehicle from the lower end side toward the upper end side. Therefore, the seat support portion 33 is also inclined forward of the vehicle from the lower end side toward the upper end side. Since the support part frame 125 has such a shape, the center of gravity of the rear wheel side vehicle body 120 is disposed in front of the vehicle with respect to the rotational axis 20a of the rear wheel 20 to such an extent that the center of gravity can be clearly seen.

図1および図2に示すように、座席支持部33は前面33aと、背面33bと、前面33aと背面33bとの間に配置される一対の側面33cとを有する。支持部フレーム125の上端側には持ち手部125c(図4参照)が一体に設けられ、持ち手部125cは座席支持部33の背面33bの上端側から突出している。持ち手部125cにおいて手で握る位置は、前輪側車体110と連結された状態の後輪側車体120の後輪20の回転軸線20aよりも前方に配置されていることが好ましい。

1 and 2, the seat support portion 33 has a front surface 33a, a back surface 33b, and a pair of side surfaces 33c disposed between the front surface 33a and the back surface 33b. A handle portion 125 c (see FIG. 4) is integrally provided on the upper end side of the support portion frame 125, and the handle portion 125 c protrudes from the upper end side of the back surface 33 b of the seat support portion 33. It is preferable that the position of the handle portion 125c to be gripped by the hand is arranged in front of the rotation axis 20a of the rear wheel 20 of the rear wheel side vehicle body 120 connected to the front wheel side vehicle body 110.

また、図1および図4に示すように、座席支持部33には充電可能なバッテリBAが着脱自在に取付けられている。座席支持部33の前面33aおよび背面33bは下端側から上端側に向かって車両前方に傾斜しており、背面33bにはバッテリBAを収容するための収容スペース33dの開口部が設けられている。また、座席支持部33内には後述する制御ユニット60が配置されている。