WO2018062274A1 - Magnetic core piece and magnetic core - Google Patents

Magnetic core piece and magnetic core Download PDFInfo

- Publication number

- WO2018062274A1 WO2018062274A1 PCT/JP2017/034960 JP2017034960W WO2018062274A1 WO 2018062274 A1 WO2018062274 A1 WO 2018062274A1 JP 2017034960 W JP2017034960 W JP 2017034960W WO 2018062274 A1 WO2018062274 A1 WO 2018062274A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- magnetic core

- laminated

- electromagnetic steel

- laminated structure

- amorphous

- Prior art date

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F27/00—Details of transformers or inductances, in general

- H01F27/24—Magnetic cores

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F27/00—Details of transformers or inductances, in general

- H01F27/24—Magnetic cores

- H01F27/245—Magnetic cores made from sheets, e.g. grain-oriented

Definitions

- This disclosure relates to a magnetic core piece and a magnetic core.

- Cores used in transformers, reactors, choke coils, motors, noise countermeasure components, laser power supplies, pulse power magnetic components for accelerators, generators, etc. silicon steel, soft ferrite, permalloy, Fe-based amorphous alloys, Fe-based Soft magnetic materials such as nanocrystalline alloys are used.

- a core manufactured by winding a plate or a ribbon-like soft magnetic material is known.

- Such a core is called a wound magnetic core or a wound core because it is manufactured by winding a long plate or ribbon.

- the wound magnetic core is usually manufactured by winding a thin ribbon so as to have a desired inner diameter and outer diameter, and performing a heat treatment for removing strain introduced by winding.

- the ribbon in the form in which the ribbon is wound, not only the size of the wound magnetic core may be limited in production, but also the excellent characteristics of the amorphous ribbon having different characteristics from silicon steel and the like are sufficiently obtained. It is not demonstrated. This is presumably because the temperature of the heat treatment performed to maintain the amorphous structure for the amorphous ribbon is lower than that of silicon steel, so that the strain introduced by winding cannot be sufficiently removed. That is, the form of the wound magnetic core has a problem that the degree of freedom in design is poor and the excellent characteristics of the amorphous ribbon are easily impaired.

- a laminated magnetic core loaded with thin strip pieces is known.

- an iron core see, for example, Japanese Patent Laid-Open No. 5-275255

- a method of manufacturing an iron core including laminating a plurality of strip-like amorphous magnetic materials and impregnating or applying an adhesive to the laminated end portions of the laminated amorphous magnetic materials (for example, JP-A-62-108513). No. gazette) is disclosed.

- a plurality of amorphous alloy ribbons are stacked to form a unit laminate plate having a thickness substantially the same as that of a silicon steel plate, and the laminate plates are stacked to form a laminate of transformer cores (for example, JP, 61-74314, A) is disclosed.

- transformer cores for example, JP, 61-74314, A

- an amorphous thin material that is narrower than the non-amorphous plate is placed between the wide non-amorphous plates, and the non-amorphous material is placed in the area where the non-amorphous plate exists from the end of the amorphous thin material, and in this area the laminated structure Is disclosed as a laminated amorphous core (see, for example, US Pat. No. 4,506,248).

- Japanese Patent Application Laid-Open No. 5-275255 the grain-oriented electrical steel sheets and the foil of amorphous or the like are alternately arranged, so that the volume fraction of amorphous or the like is low and it is difficult to keep energy loss low.

- Japanese Patent Laid-Open No. 62-108513 discloses a technique in which a plurality of (about 3 to 5) strip-like amorphous magnetic materials are laminated and the ends of the laminated body are bonded together, and then incorporated into a transformer. The ease of assembly of the magnetic core and coil at the time is not taken into consideration.

- 61-74314 relates to a technique for manufacturing a laminated body by stacking a plurality of amorphous alloy ribbons, and aims to maintain the same workability as a silicon steel sheet. is there.

- the workability is considered to be closer to the workability when using a silicon steel plate than when handling the ribbon as it is, but the manufacturing process of the magnetic core produced by stacking thousands of extremely thin amorphous ribbons In fact, it is impossible to realize until the simplification of the process.

- US Pat. No. 4,506,248 discloses a structure in which amorphous thin materials are laminated.

- the amorphous thin material is narrower than the non-amorphous plate, the amorphous volume fraction is low. Therefore, it is difficult to keep the energy loss low. It is a mechanically fixed and integrated structure, and handles amorphous thin material like a sheet. Therefore, the assembly work of the magnetic core becomes complicated.

- the present disclosure has been made in view of the above situation.

- the problem to be solved in the present disclosure is that the handling property of the amorphous ribbon and the assembly work of the laminated core using the amorphous ribbon are dramatically improved when the laminated magnetic core using the amorphous ribbon is manufactured. It is to provide a magnetic core piece and a magnetic core.

- the magnetic core is divided into several structural parts (block structures), and the divided block structure is used. It is meaningful to provide a strip unit that is provided with a work process for assembling and can be adapted to any shape and size of the divided block structure. Specific means for solving the above-described problems include the following aspects.

- the magnetic core according to the first aspect of the present invention is: ⁇ 1> comprising a plurality of magnetic core blocks forming a closed magnetic path, wherein the magnetic core block is a laminated body of a plurality of magnetic core pieces, and the magnetic core piece has a laminated structure in which a plurality of amorphous ribbon pieces are laminated; An electromagnetic steel plate disposed on at least a part of each of both end surfaces in the stacking direction of the stacked structure, and the stacked structure and the electromagnetic steel plate are fixed on the stacked surface.

- the magnetic core block is configured by using a plurality of magnetic core pieces. Therefore, not only the handling of an extremely thin amorphous ribbon is facilitated, but also the assembly workability in a laminated magnetic core having an arbitrary shape and size is dramatically improved. That is, in the first aspect, a plurality of amorphous ribbon pieces are stacked, the electromagnetic steel plates are disposed on at least a part of both end surfaces in the stacking direction of the laminated portions of the amorphous ribbon pieces, and the laminated portions and the electromagnetic steel plates are The magnetic core piece fixed on the laminated surface is used as one unit of the amorphous ribbon piece.

- the “laminated surface” is not a surface whose normal is the lamination direction of the amorphous ribbons, but a surface formed by collecting side surfaces corresponding to the thicknesses of a plurality of laminated amorphous ribbons and electrical steel sheets. Point to.

- the closed magnetic path is formed by joining the four magnetic core blocks into a quadrangular annular shape, and a plurality of laminated structures of the respective magnetic core pieces are disposed between two adjacent magnetic core blocks in the longitudinal direction of the magnetic core block.

- step difference formed in step shape shifted in the direction is preferable.

- the inclined surface in the step formed by shifting the laminated structure in the longitudinal direction of the magnetic core block has an inclination angle of 30 ° to 60 ° with respect to the longitudinal direction of the magnetic core block (ie, More preferably, the tilt angle is -15 ° to + 15 ° with respect to 45 °.

- a magnetic core (core) having a quadrangular ring structure can be manufactured by joining four magnetic core blocks into a quadrangular ring shape.

- the longitudinal direction (magnetization) in one magnetic core block at the joint (joint) between the magnetic core blocks in the joint that is joined at right angles to the easy magnetization direction Magnetic flux flows in a direction perpendicular to the easy direction), and iron loss and apparent power tend to increase.

- the inclined surfaces of the magnetic core pieces of the two magnetic core blocks which are inclined at an inclination angle ⁇ with respect to the longitudinal direction of the magnetic core block, are joined to each other, and the inclined surfaces provided in a staircase shape are provided between the magnetic core pieces.

- the magnetic flux of one magnetic core block can be prevented from crossing the magnetic flux of the other magnetic core block, and energy loss can be suppressed low.

- each of the magnetic core pieces has a joint portion joined to each other at the end face in the stacking direction, and in the joint portion, the magnetic steel sheet of the magnetic core piece in one magnetic core block; A mode in which the magnetic steel sheet of the magnetic core piece in the other magnetic core block is disposed so as to face each other is preferable.

- the two magnetic core blocks overlap each other. Therefore, when the electromagnetic steel plate of one magnetic core block and the electromagnetic steel plate of the other magnetic core block face each other, it is easy to maintain slipperiness, and the magnetic core pieces can be easily inserted and removed between the magnetic core blocks. Thereby, assembly or disassembly of a magnetic core can be performed easily.

- the magnetic core piece includes the two laminated structures, the two first electromagnetic steel plates disposed on the respective end surfaces of the two laminated structures opposite to the sides facing each other, and the two laminated layers.

- a predetermined number of amorphous ribbon pieces are bundled and sandwiched between electromagnetic steel plates, and one longitudinal end of one laminated structure and one longitudinal end of the other laminated structure are In the longitudinal direction, a predetermined distance is shifted in the longitudinal direction from a position where they overlap each other, and the two laminated structures are arranged so as to partially overlap. Therefore, it is easy to handle an extremely thin amorphous ribbon piece, and the magnetic core pieces can be easily joined to each other. In addition, since the magnetic core blocks are manufactured with the units stacked in advance, the stacking accuracy is excellent and the productivity is also excellent.

- the second electrical steel sheet disposed between the two laminated structures is composed of one electrical steel sheet having a size that can be disposed on the entire surface of the laminated structure corresponding to the entire length in the longitudinal direction of the magnetic core piece.

- it may be configured by using two electromagnetic steel sheets having a size that can be disposed on the entire end face of each of the two laminated structures.

- a plurality of amorphous ribbon strips and magnetic steel sheets forming a laminated structure in a magnetic core piece are difficult to maintain a predetermined shape due to misalignment or the like only by being stacked.

- a desired shape can be stably maintained over a long period of time.

- the length of the transverse direction (width length) perpendicular to the longitudinal direction of the laminated amorphous ribbons is equal to or greater than the length of the electrical steel sheet in the transverse direction (width length) perpendicular to the longitudinal direction. Therefore, the assemblability is improved. Further, the volume fraction of amorphous in the magnetic core is increased, and the energy loss is suppressed to a lower level.

- the magnetic core piece according to the second aspect of the present invention is: ⁇ 8> A laminated structure in which a plurality of amorphous ribbon strips are laminated, and an electromagnetic steel sheet disposed on at least a part of both end faces in the lamination direction of the laminated structure, wherein the laminated structure and the electromagnetic steel sheet are It is fixed on the laminated surface.

- a plurality of amorphous ribbon pieces having a laminated structure and electromagnetic steel sheets arranged on both end faces in the lamination direction of the laminated structure are fixed.

- an extremely thin amorphous ribbon can be easily handled, and a magnetic core having an arbitrary shape and size can be efficiently manufactured (assembled).

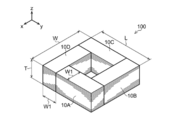

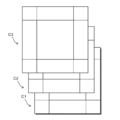

- FIG. 1 is a perspective view conceptually showing a laminated core according to an embodiment.

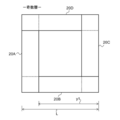

- FIG. 2A is a plan view showing a quadrangular ring structure of odd layers forming a laminated core.

- FIG. 2B is a plan view showing a quadrangular ring structure of even layers forming the laminated core.

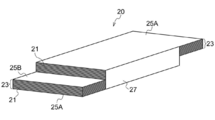

- FIG. 3 is a perspective view showing an example of a laminated packet which is a laminated unit body of a plurality of amorphous ribbon strips.

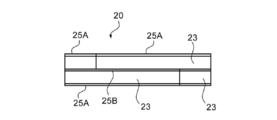

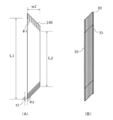

- 4A is a schematic plan view of FIG. 3

- FIG. 4B is a schematic side view of FIG.

- FIG. 5 is a schematic side view showing a form in which a plurality of the stacked packets of FIG. 3 are connected.

- FIG. 1 is a perspective view conceptually showing a laminated core according to an embodiment.

- FIG. 2A is a plan view showing a quadrangular ring structure of odd layers forming a laminated core.

- FIG. 2B is a plan view showing a quad

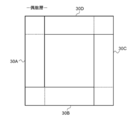

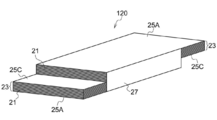

- FIG. 6 is a perspective view showing another example of a laminated packet which is a laminated unit body of a plurality of amorphous ribbon strips.

- 7A is a schematic plan view of FIG. 6, and FIG. 7B is a schematic side view of FIG. 6.

- FIG. 8 is a schematic side view showing a form in which a plurality of stacked packets of FIG. 6 are connected.

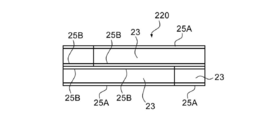

- 9A is a schematic plan view of a stacked packet

- FIG. 9B is a schematic side view of the stacked packet.

- FIG. 10 is a schematic side view showing a form in which a plurality of stacked packets in FIG. 9 are connected.

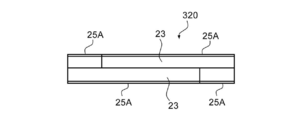

- 11A is a schematic plan view of a stacked packet

- FIG. 11B is a schematic side view of the stacked packet.

- FIG. 12 is a schematic side view showing a form in which a plurality of stacked packets in FIG. 11 are connected.

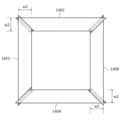

- FIG. 13 is a schematic explanatory diagram for explaining that two types of square rings formed by joining four stacked packets are alternately stacked to form a magnetic core.

- (A) is a plane when placing a lamination

- (B) is a side view at the time of observing (A) from the side part.

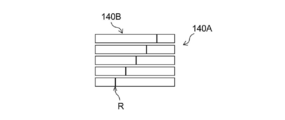

- FIG. 15 is a plan view showing a laminated core obtained by joining the joint portions of four laminated packets in a step wrap structure.

- FIG. 16 is a schematic cross-sectional view for explaining the step lap structure of the joint.

- FIG. 17 is a perspective view showing another example of a laminated packet that is a laminated unit body of a plurality of amorphous ribbon pieces.

- a magnetic core according to an embodiment of the present invention has a plurality of magnetic core blocks constituting a closed magnetic path, and the magnetic core block is a laminated body of a plurality of magnetic core pieces.

- the magnetic core piece includes a laminated structure in which a plurality of amorphous ribbon pieces are laminated, and an electromagnetic steel sheet disposed on at least a part of each of both end faces in the lamination direction of the laminated structure, and the laminated structure and electromagnetic A steel plate is fixed on the laminated surface.

- the magnetic core according to the embodiment of the present invention includes magnetic core pieces for forming a plurality of magnetic core blocks constituting a closed magnetic circuit. Since the amorphous thin strip is used as a unit of magnetic core, it is easy to handle an extremely thin amorphous thin strip, and the assembly workability for a magnetic core of any shape and size is dramatically improved.

- amorphous ribbon means a long alloy ribbon having an amorphous phase.

- amorphous ribbon strip means a metal strip (fragment) cut out in a strip shape from a long amorphous alloy ribbon.

- a magnetic core refers to a laminated magnetic core formed by stacking a plurality of amorphous ribbon pieces, for example, in a quadrangular ring shape, and a wound core around which a long amorphous ribbon is wound. Are distinguished from each other.

- the shape of the magnetic core is, for example, a quadrilateral (square or rectangular)

- a plurality of magnetic core pieces are at least a part of the outer edge (for example, in the longitudinal direction of the magnetic core piece).

- a magnetic core piece (Laminated packet) is a laminate in which a plurality of amorphous ribbon pieces and a plurality of electromagnetic steel sheets are laminated, and is a unit piece used for manufacturing a magnetic core.

- a numerical range expressed using “to” means a range including numerical values described before and after “to” as a lower limit value and an upper limit value.

- the first embodiment and the second embodiment will be described as specific embodiments of the magnetic core of the present invention, and the embodiments of the magnetic core piece of the present invention will be described in detail.

- the embodiments of the magnetic core and the magnetic core piece of the present invention are not limited to the first embodiment and the second embodiment described below.

- the first embodiment there are two laminated structures in which a plurality of amorphous ribbon strips are laminated, and two first electromagnetic steel sheets disposed on each end face of the two laminated structures on the opposite side to the side facing each other. And a second magnetic steel sheet disposed between the two laminated structures, and a laminated piece of a quadrangular ring structure formed by stacking the laminated packets using a magnetic piece (hereinafter also referred to as a laminated packet) as a unit piece.

- the core magnetic core

- the laminated core 100 of the first embodiment includes four magnetic core blocks 10A, 10B, 10C, and 10D, and the four magnetic core blocks are arranged in a quadrangular ring at an angle of 90 ° with each other.

- the four magnetic core blocks are joined at the end faces in the longitudinal direction.

- the four magnetic core blocks are joined so that the laminated packets of the magnetic core blocks form an angle of 90 ° between two adjacent magnetic core blocks, thereby forming a square ring structure.

- a closed magnetic circuit is formed by joining four magnetic core blocks in a square ring shape.

- Each of the four magnetic core blocks is a laminated body in which laminated packets, which are magnetic core pieces in which amorphous strips are laminated, are stacked.

- the laminated packet according to the first embodiment includes two laminated structures (reference numeral 23 in FIG. 3) in which a plurality of amorphous ribbons are laminated, and end faces of the two laminated structures opposite to the sides facing each other.

- Two first electromagnetic steel sheets (reference numeral 25A in FIG. 3) arranged in the two, and a single second electromagnetic steel sheet (reference numeral 25B in FIG. 3) arranged between the two laminated structures. It is formed by stacking.

- FIG. 3 shows the laminated packet (magnetic core) of the first embodiment.

- FIG. 1 is a perspective view conceptually showing the laminated core 100 of the first embodiment.

- the arrangement surface of the four magnetic core blocks 10A, 10B, 10C, and 10D arranged in a square ring is an xy plane (a plane including the x axis and the y axis), and the normal direction of the xy plane is the z axis direction.

- the four magnetic core blocks 10A, 10B, 10C, and 10D all have the same shape (rectangular shape) in length L-w1, width w1, and height T in appearance. It is a square square ring of length L.

- the laminated core 100 of the first embodiment is manufactured by using a plurality of identical laminated packets, arranging the plural laminated packets in a square ring shape, and joining the longitudinal ends of each laminated packet to each other. Yes. That is, the laminated core 100 is obtained by joining four laminated packets to obtain a square annular body, and stacking one annular body as one layer in the z direction.

- the laminated core 100 of 1st Embodiment is an example formed in the square, it is not restricted to a square, It can be set as other quadrilaterals, such as a rectangle.

- the annular body forming the laminated core 100 may be formed by alternately stacking odd layers and even layers as shown in FIG.

- the odd-numbered layer has one end of the laminated packet 20D over one end of the laminated packet 20A, one end of the laminated packet 20C over the other end of the laminated packet 20D, and the other end of the laminated packet 20C.

- the stacked packet 20B has a square ring structure in which one end of the stacked packet 20B is overlapped and the other end of the stacked packet 20A is stacked on the other end of the stacked packet 20B.

- the even layers are stacked in a direction opposite to the overlapping direction in the odd layers to form a square ring structure.

- one end of the laminated packet 30B is overlaid on one end of the laminated packet 30A

- one end of the laminated packet 30C is overlaid on the other end of the laminated packet 30B

- one end of the laminated packet 30D is overlaid on the other end of the laminated packet 30C. It has a quadrangular ring structure in which the other end of the stacked packet 30A is stacked on the other end of the stacked packet 30D.

- the laminated core 100 is formed by laminating the above-described odd layers and even layers alternately so as to have a desired number of layers (number of laminated packets) (for example, the first layer (odd layer) as shown in FIG. ) C1, second layer (even layer) C2, third layer (odd layer) C3.

- the laminated core 100 of the first embodiment has a structure in which 11 laminated packets are laminated on each of the four sides of the square ring.

- the magnetic core blocks 10A, 10B, 10C, and 10D forming the laminated core 100 of the first embodiment are formed by overlapping the laminated packets 20 having the structure shown in FIG.

- a laminated packet is a laminated unit body in which a plurality of amorphous ribbon strips forming four magnetic core blocks forming a laminated core are laminated.

- a laminated unit of a plurality of amorphous ribbons is used, it is easy to handle extremely thin amorphous ribbons, and it is possible to manufacture a magnetic core block with excellent stacking accuracy. it can.

- the laminated packet 20 includes two thin bundles 23 having a laminated structure in which a plurality of amorphous thin strips 21 are laminated, and two thin piece bundles 23 on the side opposite to the side facing each other.

- the thin sheet bundle 23 in which a plurality of amorphous strips are laminated, and the electromagnetic steel plates 25A and 25B arranged so as to overlap in the lamination direction of the thin piece bundle 23 are fixed by the resin layer 27 formed on the laminated surface.

- the thin piece bundle 23 is formed by laminating a plurality of amorphous thin pieces, and the number of laminated amorphous thin pieces in the two thin piece bundles is the same.

- 30 amorphous ribbon strips are stacked in one thin-sheet bundle. Therefore, the number of laminated amorphous ribbons in the laminated packet 20 of the first embodiment is 60.

- the size of the amorphous ribbon is length 426 mm ⁇ width 142 mm.

- the electromagnetic steel sheet 25A has the same dimension in the width direction (short direction) as that of the thin ribbon bundle 23. That is, the thin ribbon bundle 23 of the amorphous ribbon is disposed on the entire surface in the short direction of the electromagnetic steel sheet.

- the electromagnetic steel plate 25B is disposed between the two thin piece bundles 23 and is in contact with the entire surface of one of the two thin piece bundles 23 and in part with the other surface. Therefore, although the electromagnetic steel sheet 25B is disposed between the two thin piece bundles 23, it is in an exposed state on the thin piece bundle other than the portion where the two thin piece bundles overlap each other.

- the surface roughness of the main plane of the electrical steel sheet is preferably in the range of 0.10 ⁇ m to 0.20 ⁇ m in arithmetic average roughness measured in accordance with JIS B0601-2001, preferably 0.1 ⁇ m to 0.15 ⁇ m. More preferably, it is the range.

- the slipperiness is improved when the electrical steel sheets are in contact with each other, which is advantageous in terms of increasing manufacturing efficiency.

- FIG. 4A is a plan view when the laminated packet 20 shown in FIG. 3 is placed on a horizontal desk surface and the electromagnetic steel plate 25A is viewed from above.

- FIG. 4B is a side view of the laminated packet 20 shown in FIG. 3 as viewed from the side. In FIG. 4, the resin layer 27 in FIG. 3 is not shown.

- the laminated packet 20 of the first embodiment is positioned on the end face of one end in the longitudinal direction (the end in the direction of length y1 or y2 (Lw1)) with respect to the other.

- the two thin piece bundles 23 arranged so as not to be aligned form one side of a square ring having a length L shown in FIG.

- the laminated portion is fixed by the resin layer 27.

- a part of electromagnetic steel plate 25B is two thin piece bundles. 23.

- one of the two thin piece bundles 23 has the electromagnetic steel plate 25B disposed on the side opposite to the side on which the electromagnetic steel plate 25A is disposed.

- the two thin piece bundles 23 are arranged so as to be shifted from each other in the surface direction of the electromagnetic steel plate 25B.

- a thin piece bundle 23 is disposed between the two thin piece bundles (laminated structure) 23 on the entire surfaces of the two thin piece layers facing each other. What laminated

- stacked on both sides of the long single electromagnetic steel plate 25C may be used.

- a laminated packet 120 having a laminated portion of electromagnetic steel plate 25A / thin piece bundle 23 / electromagnetic steel plate 25C / thin piece bundle 23 / magnetic steel plate 25A may be used.

- the laminated portion of the laminated packet 120 is fixed by the resin layer 27. In this case, as shown in FIG.

- the electromagnetic steel sheet 25 ⁇ / b> C has a total length defined by two thin-piece bundles arranged so that one end is not aligned with the other end face in the longitudinal direction. (Distance L in FIG. 7), that is, the same length and width as the total length of the laminated packet 120 in the longitudinal direction.

- the electromagnetic steel plate 25C is shared by the two thin piece bundles 23 in the laminated portion of the electromagnetic steel plate 25A / the thin piece bundle 23 / the electromagnetic steel plate 25C / the thin piece bundle 23 / the electromagnetic steel plate 25A.

- the electromagnetic steel plates 25C are arranged so as to cover a part of the surface of one thin piece bundle and the other thin piece bundle, and the electromagnetic steel plates 25C are exposed.

- a form in which a plurality of laminated packets are connected can be obtained by preparing the laminated packet 121 having a different laminated structure.

- FIGS. 9 to 10 a structure in which two electromagnetic steel plates are arranged between two thin piece bundles (laminated structure) 23 may be used.

- the laminated packet 220 may be formed by stacking the two first electromagnetic steel plates 25A arranged and the second electromagnetic steel plates 25B arranged in the respective thin piece bundles on the other surface on the side where the two thin piece bundles face each other. .

- the thin piece bundle 23 sandwiched between two electromagnetic steel plates is arranged so as to be shifted from each other in the surface direction of the electromagnetic steel plate 25B, so that the surface of the electromagnetic steel plate 25B where the thin strips of the laminated packet do not overlap each other. Is partially exposed.

- the position of the end surface of one of the two ribbon strips 23 sandwiched between the electromagnetic steel plates with respect to the other is the end in the longitudinal direction (the end in the direction of the length y1 or y2). They are made so as not to be aligned.

- the laminated packet 220 has a laminated structure of an electromagnetic steel plate 25A / a thin piece bundle 23 / an electromagnetic steel plate 25B / an electromagnetic steel plate 25B / a thin piece bundle 23 / an electromagnetic steel plate 25A.

- the two electromagnetic steel plates 25B in the laminated structure are shared in a state where two sheets are stacked.

- the laminated packet As another modified example of the laminated packet, as shown in FIGS. 11 to 12, no electromagnetic steel plate is provided between the two thin piece bundles 23, and an electromagnetic steel plate 25A is provided on each end face opposite to the side facing each other. May be arranged.

- the step wrap shape described in the second embodiment to be described later is adopted, which is preferable in terms of suppressing iron loss.

- two thin piece bundles (laminated structure) 23 in which a plurality of amorphous thin pieces are laminated and one of the two thin piece bundles on the side opposite to the side facing each other.

- the laminated packet 320 may be a stack of the two first electromagnetic steel plates 25A arranged.

- the position of the end surface of the longitudinal end portion (the end portion in the direction of the length y1 or y2) is not aligned with respect to the other.

- the laminated packet 320 has a laminated structure of electromagnetic steel plates 25A / thin piece bundles 23 / thin piece bundles 23 / electromagnetic steel plates 25A as shown in FIG.

- the amorphous alloy (composition) forming the amorphous ribbon will be described.

- the alloy composition described in International Publication No. 2013/137117, International Publication No. 2013/137118, International Publication No. 2016/084741 and the like can be referred to as appropriate.

- an Fe-based amorphous alloy is preferable.

- the Fe-based amorphous alloy refers to an amorphous alloy mainly composed of Fe.

- the “main component” refers to a component having the highest content ratio.

- the Fe-based amorphous alloy contains Fe, Si and B, and when the total content of Fe, Si and B is 100 atomic%, the Fe content is 50 atomic% or more (preferably 60 atomic% or more, More preferably, an Fe-based amorphous alloy is more preferably 70 atomic% or more.

- an amorphous ribbon that has been heat-treated so as to have a direction of easy magnetization in the longitudinal direction of the ribbon is effective.

- a method for obtaining such an amorphous ribbon when heat treatment is performed, for example, a method of heat treatment in a stretched state (tension annealing), a method of heat treatment in a state where a magnetic field is applied in the longitudinal direction of the ribbon, a tension A method of heat treatment in a state where a magnetic field is applied in the longitudinal direction of the ribbon while laying is suitable.

- the heat treatment may be performed by temporarily holding a laminate in which a plurality of amorphous ribbon strips are sandwiched between metal plates and placing the laminate in a furnace, and then performing the heat treatment as it is.

- the surface roughness of the surface of the amorphous ribbon is preferably in the range of 0.20 ⁇ m to 0.50 ⁇ m in terms of arithmetic average roughness measured according to JIS B0601-2001, preferably 0.20 ⁇ m to 0. A range of 40 ⁇ m is more preferable.

- the surface roughness is 0.20 ⁇ m or more, it is advantageous from the viewpoint of securing interlayer insulation when the amorphous ribbons are laminated.

- the surface roughness is 0.40 ⁇ m or less, it is advantageous in increasing the space factor of the laminated magnetic core.

- an electrical steel sheet manufactured by cold rolling and then forming a surface film has higher surface accuracy than an amorphous ribbon produced by a liquid quenching method, that is, its surface roughness is small.

- the absolute value of the difference between the surface roughness of the electrical steel sheet and the surface roughness of the amorphous ribbon is preferably 0.4 ⁇ m or less, and more preferably 0.2 ⁇ m or less. If the absolute value of the difference in surface roughness between the two is 0.2 ⁇ m or less, it is advantageous in that the space factor of the laminated core can be increased.

- the resin layer 27 is formed by, for example, laminating surfaces (laminated strips and side surfaces corresponding to the thicknesses of the electromagnetic steel plates) in a laminated portion such as the electromagnetic steel plate 25A / thin piece bundle / electromagnetic steel plate 25B / thin piece bundle / electromagnetic steel plate 25A.

- the magnetic steel sheet and the thin piece side are fixed in the laminated portion.

- the resin layer 27 is formed using an epoxy resin.

- Amorphous ribbon pieces are laminated, and a resin layer is formed by applying and curing a curable resin (for example, epoxy resin) on at least a part of the laminated surface in the laminated structure of the amorphous ribbon. Is preferred.

- a curable resin for example, epoxy resin

- the resin layer is formed by applying a curable resin to the laminated surface without applying a curable resin to the main surface with the lamination direction of the amorphous ribbons as the normal. Strain that is likely to occur due to shrinkage or the like accompanying curing is suppressed to a low level, and characteristic deterioration due to stress is suppressed.

- a laminated packet can be manufactured as follows, for example. After continuous heat treatment while applying tension to the long amorphous alloy ribbon, cutting (cutting, punching) and laminating to a desired size, and applying epoxy resin etc. to the laminated surface of the obtained laminate It is fixed by attaching a resin layer.

- an amorphous alloy ribbon having a desired composition is produced and cut into a desired size, and a plurality of cut amorphous ribbons are stacked to form a laminate between metal plates. Insert and temporarily fix it. Then, after putting in a furnace, heat-treating and cooling, an epoxy resin or the like may be applied to the laminated surface of the laminate, and a resin layer may be attached and fixed.

- a curable resin can be used for the formation of the resin layer.

- an epoxy resin is preferably used.

- a two-component mixed epoxy resin composition composed of an A solution containing an epoxy resin and a B solution containing a curing agent may be used.

- the method for forming the resin layer is not particularly limited, and a known coating method can be used.

- a brush or a part of a lamination surface when a plurality of amorphous ribbon pieces and electromagnetic steel sheets are laminated may be used.

- a method of applying using an application member such as a spatula is suitable.

- the thickness of the resin layer 27 is not particularly limited, and may be appropriately selected in consideration of strength required for a fixed laminated portion, long-term durability, and the like.

- two thin piece bundles formed by laminating a plurality of amorphous thin piece pieces one end of one thin piece bundle extends from one end of the other thin piece bundle in the longitudinal direction of the thin piece bundle.

- the present invention is not limited to such a configuration, and one unit is selected by selecting an arbitrary stack unit.

- (Laminated unit body) may be used.

- a magnetic core piece in which a laminated structure 23 in which a plurality of amorphous ribbon pieces 21 are laminated and two electromagnetic steel plates 25 ⁇ / b> A sandwiching the laminated structure 23 are fixed by a resin layer 27. (Laminated packet 420) may be used.

- FIGS. 1-10 A second embodiment of the magnetic core of the present invention will be described with reference to FIGS.

- a joining portion where the laminated packets in the magnetic core block forming the laminated core (magnetic core) of the first embodiment are joined in a step shape, and the laminated packets are 45 ° with respect to the longitudinal direction.

- the step lap structure is formed by being joined to each other at an inclined inclined surface.

- the laminated packet (magnetic core piece) 140 includes five thin piece bundles 30 and a pair of electromagnetic steel plates 35 arranged so as to sandwich the five thin piece bundles 30.

- the five thin-piece bundles 30 and the two electromagnetic steel plates 35 are made of a resin (not shown) formed by applying an epoxy resin to a laminated surface formed by laminating the thin-piece layers and the electromagnetic steel plates and curing them. It is fixed by the layer.

- 14A is a plan view when the stacked packet is placed on a horizontal desk surface and the stacked packet is observed from above in the stacking direction

- FIG. 14B is a plan view of the stacked packet from the side. It is a side view at the time of observing.

- the amorphous alloy ribbon and the resin layer that form each bundle of laminated packets are not shown.

- the laminated packet 140 is formed by laminating the five thin piece bundles 30 by shifting each of them by a predetermined distance t ⁇ b> 1.

- Each of the electromagnetic steel plates 35 has a laminated structure in which the electromagnetic steel plates 35 are laminated while being shifted by a distance t1 in the longitudinal direction in the same manner as the thin piece bundle.

- Each of the laminated thin piece bundles 30 is obtained by laminating a plurality of amorphous ribbon pieces.

- the tilt angle ⁇ 1 can be selected from an acute angle range greater than 0 ° and less than 90 °, and the tilt angle ⁇ 2 can be an angle selected from a range of obtuse angles greater than 90 ° and less than 180 °, among others

- the inclination angle ⁇ 1 is preferably in the range of an acute angle of 30 ° to 60 ° (a deflection angle of ⁇ 15 ° to + 15 ° with respect to 45 °).

- the joint part in 2nd Embodiment has a joining form by a step wrap structure.

- the square ring forming the magnetic core block is formed by joining the four stacked packets to each other in the longitudinal direction.

- Each of the stacked packets is formed obliquely at both ends in the longitudinal direction at inclination angles of ⁇ 1 and ⁇ 2, as shown in FIG. 14A, by disposing the trapezoidal thin piece bundle 30 by shifting the distance t1.

- a stepped step is formed by a bundle of thin pieces.

- the viewing surface of one of the two regions (regions of w2 ⁇ w2) serving as a junction of the stacked packet 140A The non-viewing surface (rear surface) of the other region of the two regions (regions in the two sides of w2 ⁇ w2) of the stacked packet 140B is overlaid on the upper surface of the stacked packet 140B.

- the non-viewing surface (back surface) of the other region of the two regions (w2 ⁇ w2 square regions) of the stacked packet 140C is superimposed on the viewing surface of one region of the stacked packet 140B.

- the non-viewing surface (back surface) of the other region of the two regions (w2 ⁇ w2 square regions) of the stacked packet 140D is superimposed on the viewing surface of one region of the stacked packet 140C. Then, the non-viewing surface of the other area of the laminated packet 140A is overlaid on one area of the laminated packet 140D. Thereby, it can be set as a square ring structure.

- a magnetic core (laminated core) having a desired shape can be produced by stacking a plurality of square ring structures formed by joining four laminated packets A to D.

- the structure portion forming the four sides of the laminated core produced by stacking the quadrangular ring structure is a magnetic core block.

- the quadrangular ring structure is stacked, for example, to form a laminated layer.

- a laminated portion formed by stacking the packets 140A is a magnetic core block.

- the viewing surface (back surface) of the other area of the two regions of the stacked packet 140B is overlapped on the viewing surface of one of the two regions of the stacked packet 140A

- the viewing surface The stepped step portion formed in the step and the stepped step portion formed on the non-viewing surface face each other to form a plurality of joint surfaces. That is, as shown in FIG. 16, for example, a structure (step wrap structure) in which the joining points R of the amorphous thin strip pieces between the laminated packet 140A and the laminated packet 140B are shifted in a stepped manner.

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Manufacturing Cores, Coils, And Magnets (AREA)

- Soft Magnetic Materials (AREA)

Abstract

According to one embodiment of the present invention, a magnetic core and a magnetic core piece are provided, the magnetic core having a plurality of magnetic core blocks constituting a closed magnetic path, and the magnetic block being a laminate of a plurality of magnetic core pieces. The magnetic core piece includes: a laminated structure in which a plurality of amorphous thin strip pieces are laminated; and an electromagnetic steel plate disposed on at least one end surface of the laminated structure in the lamination direction. The laminated structure and the electromagnetic steel plate are fixed at a lamination surface.

Description

本開示は、磁心片及び磁心に関する。

This disclosure relates to a magnetic core piece and a magnetic core.

トランス、リアクトル、チョークコイル、モーター、ノイズ対策部品、レーザ電源、加速器用パルスパワー磁性部品、発電機等に用いられる磁心(コア)として、珪素鋼、ソフトフェライト、パーマロイ、Fe基アモルファス合金、Fe基ナノ結晶合金等の軟磁性材料が用いられている。その中では、板もしくは薄帯状の軟磁性材料を巻回して製造されたコアが知られている。

このようなコアは、長尺状の板もしくは薄帯が巻き回されて製造されることから、巻磁心又は巻コア等と呼ばれている。 Cores used in transformers, reactors, choke coils, motors, noise countermeasure components, laser power supplies, pulse power magnetic components for accelerators, generators, etc., silicon steel, soft ferrite, permalloy, Fe-based amorphous alloys, Fe-based Soft magnetic materials such as nanocrystalline alloys are used. Among them, a core manufactured by winding a plate or a ribbon-like soft magnetic material is known.

Such a core is called a wound magnetic core or a wound core because it is manufactured by winding a long plate or ribbon.

このようなコアは、長尺状の板もしくは薄帯が巻き回されて製造されることから、巻磁心又は巻コア等と呼ばれている。 Cores used in transformers, reactors, choke coils, motors, noise countermeasure components, laser power supplies, pulse power magnetic components for accelerators, generators, etc., silicon steel, soft ferrite, permalloy, Fe-based amorphous alloys, Fe-based Soft magnetic materials such as nanocrystalline alloys are used. Among them, a core manufactured by winding a plate or a ribbon-like soft magnetic material is known.

Such a core is called a wound magnetic core or a wound core because it is manufactured by winding a long plate or ribbon.

巻磁心は、薄帯を所望とする内径及び外径となるように巻回し、巻き回すことより導入される歪を除去するための熱処理を行うことによって製造されることが通例である。ところが、薄帯が巻き回された形態では、製造上、巻磁心の大きさが制限される場合があるだけでなく、珪素鋼等とは特性の異なるアモルファス薄帯が有する優れた特性が十分に発揮されない。これは、アモルファス薄帯に対してアモルファス構造を維持するために行う熱処理の温度が珪素鋼より低いため、巻き回すことよって導入される歪を十分に取り除けないためと考えられる。すなわち、巻磁心の形態は、設計の自由度が乏しく、アモルファス薄帯の持つ優れた特性が損なわれやすいという問題がある。

The wound magnetic core is usually manufactured by winding a thin ribbon so as to have a desired inner diameter and outer diameter, and performing a heat treatment for removing strain introduced by winding. However, in the form in which the ribbon is wound, not only the size of the wound magnetic core may be limited in production, but also the excellent characteristics of the amorphous ribbon having different characteristics from silicon steel and the like are sufficiently obtained. It is not demonstrated. This is presumably because the temperature of the heat treatment performed to maintain the amorphous structure for the amorphous ribbon is lower than that of silicon steel, so that the strain introduced by winding cannot be sufficiently removed. That is, the form of the wound magnetic core has a problem that the degree of freedom in design is poor and the excellent characteristics of the amorphous ribbon are easily impaired.

磁心の形態としては、巻磁心以外に、薄帯の断片を積載した積層磁心が知られている。積層磁心に関する技術として、方向性電磁鋼板とアモルファス等の箔とを交互に積層した鉄心(例えば、特開平5-275255号公報参照)が開示されている。また、帯状の非晶質磁性材料を複数枚積層し、積層した非晶質磁性材料の積層端部に接着剤を含浸又は塗布することを含む鉄心の製造方法(例えば、特開昭62-108513号公報参照)が開示されている。更に、非晶質合金薄帯を複数枚積み重ね、珪素鋼板とほぼ同程度の厚さを有する単位積層板をつくり、この積層板同士を積み重ねて変圧器鉄心の積層体を形成する方法(例えば、特開昭61-74314号公報参照)が開示されている。

また、広幅の非アモルファス板間に非アモルファス板より狭幅のアモルファス薄材を配置し、アモルファス薄材の端部から非アモルファス板が存在する領域に非アモルファス材料を配置し、この領域で積層構造の全体がボルト固定された積層アモルファスコアが開示されている(例えば、米国特許第4506248号明細書参照)。 As a form of the magnetic core, in addition to the wound magnetic core, a laminated magnetic core loaded with thin strip pieces is known. As a technique related to a laminated magnetic core, an iron core (see, for example, Japanese Patent Laid-Open No. 5-275255) in which grain-oriented electrical steel sheets and amorphous foils are alternately laminated is disclosed. Also, a method of manufacturing an iron core including laminating a plurality of strip-like amorphous magnetic materials and impregnating or applying an adhesive to the laminated end portions of the laminated amorphous magnetic materials (for example, JP-A-62-108513). No. gazette) is disclosed. Further, a plurality of amorphous alloy ribbons are stacked to form a unit laminate plate having a thickness substantially the same as that of a silicon steel plate, and the laminate plates are stacked to form a laminate of transformer cores (for example, JP, 61-74314, A) is disclosed.

Also, an amorphous thin material that is narrower than the non-amorphous plate is placed between the wide non-amorphous plates, and the non-amorphous material is placed in the area where the non-amorphous plate exists from the end of the amorphous thin material, and in this area the laminated structure Is disclosed as a laminated amorphous core (see, for example, US Pat. No. 4,506,248).

また、広幅の非アモルファス板間に非アモルファス板より狭幅のアモルファス薄材を配置し、アモルファス薄材の端部から非アモルファス板が存在する領域に非アモルファス材料を配置し、この領域で積層構造の全体がボルト固定された積層アモルファスコアが開示されている(例えば、米国特許第4506248号明細書参照)。 As a form of the magnetic core, in addition to the wound magnetic core, a laminated magnetic core loaded with thin strip pieces is known. As a technique related to a laminated magnetic core, an iron core (see, for example, Japanese Patent Laid-Open No. 5-275255) in which grain-oriented electrical steel sheets and amorphous foils are alternately laminated is disclosed. Also, a method of manufacturing an iron core including laminating a plurality of strip-like amorphous magnetic materials and impregnating or applying an adhesive to the laminated end portions of the laminated amorphous magnetic materials (for example, JP-A-62-108513). No. gazette) is disclosed. Further, a plurality of amorphous alloy ribbons are stacked to form a unit laminate plate having a thickness substantially the same as that of a silicon steel plate, and the laminate plates are stacked to form a laminate of transformer cores (for example, JP, 61-74314, A) is disclosed.

Also, an amorphous thin material that is narrower than the non-amorphous plate is placed between the wide non-amorphous plates, and the non-amorphous material is placed in the area where the non-amorphous plate exists from the end of the amorphous thin material, and in this area the laminated structure Is disclosed as a laminated amorphous core (see, for example, US Pat. No. 4,506,248).

しかしながら、特開平5-275255号公報では、方向性電磁鋼板とアモルファス等の箔とを交互に配置しているため、アモルファス等の体積分率が低く、エネルギー損失を低く抑えることは困難である。

また、特開昭62-108513号公報では、帯状の非晶質磁性材料を複数枚(3~5枚程度)積層し、積層体の端部を接着する技術であり、その後、変圧器へ組み込む際の磁心とコイルの組み立て容易性については考慮されていない。

特開昭61-74314号公報では、非晶質合金薄帯を複数積み重ねて積層体を製造する技術に関するものであるが、珪素鋼板と同程度の作業性を保持することを目的とするものである。これにより、作業性は、薄帯をそのまま取り扱う場合に比べ、珪素鋼板を用いる際の作業性に近づくと考えられるが、極めて薄いアモルファス薄帯が数千枚以上積み重ねて作製される磁心の製造プロセスの工程の簡易化までは実現し得ないのが実情である。加えて、その後の変圧器へ組み込む際の磁心とコイルの組み立て容易性については考慮されていない。

更に、米国特許第4506248号明細書では、アモルファス薄材が積層された構造が開示されている。しかし、アモルファス薄材が非アモルファス板に比べて狭幅であるためにアモルファス体積分率が低くなり、したがってエネルギー損失を低く抑えることは困難なことに加え、積層構造とした後の構造全体がボルトで機械的に固定されて一体化した構造となっており、アモルファス薄材を枚様に扱うものである。そのため、磁心の組み立て作業は煩雑になる。 However, in Japanese Patent Application Laid-Open No. 5-275255, the grain-oriented electrical steel sheets and the foil of amorphous or the like are alternately arranged, so that the volume fraction of amorphous or the like is low and it is difficult to keep energy loss low.

Japanese Patent Laid-Open No. 62-108513 discloses a technique in which a plurality of (about 3 to 5) strip-like amorphous magnetic materials are laminated and the ends of the laminated body are bonded together, and then incorporated into a transformer. The ease of assembly of the magnetic core and coil at the time is not taken into consideration.

Japanese Patent Application Laid-Open No. 61-74314 relates to a technique for manufacturing a laminated body by stacking a plurality of amorphous alloy ribbons, and aims to maintain the same workability as a silicon steel sheet. is there. As a result, the workability is considered to be closer to the workability when using a silicon steel plate than when handling the ribbon as it is, but the manufacturing process of the magnetic core produced by stacking thousands of extremely thin amorphous ribbons In fact, it is impossible to realize until the simplification of the process. In addition, the ease of assembly of the magnetic core and the coil when assembled in a subsequent transformer is not considered.

Further, US Pat. No. 4,506,248 discloses a structure in which amorphous thin materials are laminated. However, since the amorphous thin material is narrower than the non-amorphous plate, the amorphous volume fraction is low. Therefore, it is difficult to keep the energy loss low. It is a mechanically fixed and integrated structure, and handles amorphous thin material like a sheet. Therefore, the assembly work of the magnetic core becomes complicated.

また、特開昭62-108513号公報では、帯状の非晶質磁性材料を複数枚(3~5枚程度)積層し、積層体の端部を接着する技術であり、その後、変圧器へ組み込む際の磁心とコイルの組み立て容易性については考慮されていない。

特開昭61-74314号公報では、非晶質合金薄帯を複数積み重ねて積層体を製造する技術に関するものであるが、珪素鋼板と同程度の作業性を保持することを目的とするものである。これにより、作業性は、薄帯をそのまま取り扱う場合に比べ、珪素鋼板を用いる際の作業性に近づくと考えられるが、極めて薄いアモルファス薄帯が数千枚以上積み重ねて作製される磁心の製造プロセスの工程の簡易化までは実現し得ないのが実情である。加えて、その後の変圧器へ組み込む際の磁心とコイルの組み立て容易性については考慮されていない。

更に、米国特許第4506248号明細書では、アモルファス薄材が積層された構造が開示されている。しかし、アモルファス薄材が非アモルファス板に比べて狭幅であるためにアモルファス体積分率が低くなり、したがってエネルギー損失を低く抑えることは困難なことに加え、積層構造とした後の構造全体がボルトで機械的に固定されて一体化した構造となっており、アモルファス薄材を枚様に扱うものである。そのため、磁心の組み立て作業は煩雑になる。 However, in Japanese Patent Application Laid-Open No. 5-275255, the grain-oriented electrical steel sheets and the foil of amorphous or the like are alternately arranged, so that the volume fraction of amorphous or the like is low and it is difficult to keep energy loss low.

Japanese Patent Laid-Open No. 62-108513 discloses a technique in which a plurality of (about 3 to 5) strip-like amorphous magnetic materials are laminated and the ends of the laminated body are bonded together, and then incorporated into a transformer. The ease of assembly of the magnetic core and coil at the time is not taken into consideration.

Japanese Patent Application Laid-Open No. 61-74314 relates to a technique for manufacturing a laminated body by stacking a plurality of amorphous alloy ribbons, and aims to maintain the same workability as a silicon steel sheet. is there. As a result, the workability is considered to be closer to the workability when using a silicon steel plate than when handling the ribbon as it is, but the manufacturing process of the magnetic core produced by stacking thousands of extremely thin amorphous ribbons In fact, it is impossible to realize until the simplification of the process. In addition, the ease of assembly of the magnetic core and the coil when assembled in a subsequent transformer is not considered.

Further, US Pat. No. 4,506,248 discloses a structure in which amorphous thin materials are laminated. However, since the amorphous thin material is narrower than the non-amorphous plate, the amorphous volume fraction is low. Therefore, it is difficult to keep the energy loss low. It is a mechanically fixed and integrated structure, and handles amorphous thin material like a sheet. Therefore, the assembly work of the magnetic core becomes complicated.

本開示は、上記のような状況に鑑みてなされたものである。

本開示において解決しようとする課題は、アモルファス薄帯片を用いた積層磁心を作製する際のアモルファス薄帯片の取り扱い性及びアモルファス薄帯片を用いた積層磁心の組み立て作業が飛躍的に改善される磁心片及び磁心を提供することにある。 The present disclosure has been made in view of the above situation.

The problem to be solved in the present disclosure is that the handling property of the amorphous ribbon and the assembly work of the laminated core using the amorphous ribbon are dramatically improved when the laminated magnetic core using the amorphous ribbon is manufactured. It is to provide a magnetic core piece and a magnetic core.

本開示において解決しようとする課題は、アモルファス薄帯片を用いた積層磁心を作製する際のアモルファス薄帯片の取り扱い性及びアモルファス薄帯片を用いた積層磁心の組み立て作業が飛躍的に改善される磁心片及び磁心を提供することにある。 The present disclosure has been made in view of the above situation.

The problem to be solved in the present disclosure is that the handling property of the amorphous ribbon and the assembly work of the laminated core using the amorphous ribbon are dramatically improved when the laminated magnetic core using the amorphous ribbon is manufactured. It is to provide a magnetic core piece and a magnetic core.

薄厚のアモルファス薄帯の断片を積み重ねて積層磁心を組み立てる際の作業性を飛躍的に改善するには、磁心を幾つかの構造部分(ブロック構造)に分割し、分割されたブロック構造を用いて組み立てる作業工程を設け、かつ、分割されたブロック構造の任意の形状及び大きさに適合し得る薄帯片単位を用意することが有意義である。

上記した課題を解決するための具体的手段には、以下の態様が含まれる。 In order to dramatically improve workability when assembling a laminated magnetic core by stacking thin amorphous ribbon pieces, the magnetic core is divided into several structural parts (block structures), and the divided block structure is used. It is meaningful to provide a strip unit that is provided with a work process for assembling and can be adapted to any shape and size of the divided block structure.

Specific means for solving the above-described problems include the following aspects.

上記した課題を解決するための具体的手段には、以下の態様が含まれる。 In order to dramatically improve workability when assembling a laminated magnetic core by stacking thin amorphous ribbon pieces, the magnetic core is divided into several structural parts (block structures), and the divided block structure is used. It is meaningful to provide a strip unit that is provided with a work process for assembling and can be adapted to any shape and size of the divided block structure.

Specific means for solving the above-described problems include the following aspects.

本発明の第1の態様である磁心は、

<1> 閉磁路を形成する複数の磁心ブロックを備え、前記磁心ブロックは、複数の磁心片の積層体であり、前記磁心片は、複数のアモルファス薄帯片が積層された積層構造と、前記積層構造の積層方向における両方の端面のそれぞれの少なくとも一部に配置された電磁鋼板と、を含み、前記積層構造及び前記電磁鋼板が積層面で固定化されている。 The magnetic core according to the first aspect of the present invention is:

<1> comprising a plurality of magnetic core blocks forming a closed magnetic path, wherein the magnetic core block is a laminated body of a plurality of magnetic core pieces, and the magnetic core piece has a laminated structure in which a plurality of amorphous ribbon pieces are laminated; An electromagnetic steel plate disposed on at least a part of each of both end surfaces in the stacking direction of the stacked structure, and the stacked structure and the electromagnetic steel plate are fixed on the stacked surface.

<1> 閉磁路を形成する複数の磁心ブロックを備え、前記磁心ブロックは、複数の磁心片の積層体であり、前記磁心片は、複数のアモルファス薄帯片が積層された積層構造と、前記積層構造の積層方向における両方の端面のそれぞれの少なくとも一部に配置された電磁鋼板と、を含み、前記積層構造及び前記電磁鋼板が積層面で固定化されている。 The magnetic core according to the first aspect of the present invention is:

<1> comprising a plurality of magnetic core blocks forming a closed magnetic path, wherein the magnetic core block is a laminated body of a plurality of magnetic core pieces, and the magnetic core piece has a laminated structure in which a plurality of amorphous ribbon pieces are laminated; An electromagnetic steel plate disposed on at least a part of each of both end surfaces in the stacking direction of the stacked structure, and the stacked structure and the electromagnetic steel plate are fixed on the stacked surface.

第1の態様の磁心は、磁心ブロックが複数の磁心片を用いて構成されている。そのため、極めて薄いアモルファス薄帯片の取り扱いが容易になるだけでなく、任意の形状及び大きさの積層磁心における組み立て作業性が飛躍的に改善される。つまり、第1の態様では、複数のアモルファス薄帯片を積み重ね、アモルファス薄帯片の積層部分の積層方向における両方の端面の少なくとも一部に電磁鋼板を配置し、かつ、積層部分及び電磁鋼板が積層面にて固定化された磁心片が、アモルファス薄帯片の一単位として用いられる。これにより、磁心に求められる任意の形状及び大きさに適用し得、製造時の積み精度、及びアモルファス薄帯片に必要な強度を安定的に確保することが可能である。

アモルファス薄帯の積層方向を法線とする面ではなく、積層されたアモルファス薄帯及び電磁鋼板からなる積層面で固定化するので、樹脂又は接着剤等に起因する応力による特性劣化が小さい。 In the magnetic core of the first aspect, the magnetic core block is configured by using a plurality of magnetic core pieces. Therefore, not only the handling of an extremely thin amorphous ribbon is facilitated, but also the assembly workability in a laminated magnetic core having an arbitrary shape and size is dramatically improved. That is, in the first aspect, a plurality of amorphous ribbon pieces are stacked, the electromagnetic steel plates are disposed on at least a part of both end surfaces in the stacking direction of the laminated portions of the amorphous ribbon pieces, and the laminated portions and the electromagnetic steel plates are The magnetic core piece fixed on the laminated surface is used as one unit of the amorphous ribbon piece. Thereby, it can apply to the arbitrary shapes and magnitude | sizes calculated | required by a magnetic core, and it is possible to ensure stably the stacking precision at the time of manufacture, and the intensity | strength required for an amorphous thin strip.

Since the fixing is not performed on the surface where the lamination direction of the amorphous ribbon is the normal line but on the laminated surface composed of the laminated amorphous ribbon and the electromagnetic steel sheet, the characteristic deterioration due to stress caused by the resin or the adhesive is small.

アモルファス薄帯の積層方向を法線とする面ではなく、積層されたアモルファス薄帯及び電磁鋼板からなる積層面で固定化するので、樹脂又は接着剤等に起因する応力による特性劣化が小さい。 In the magnetic core of the first aspect, the magnetic core block is configured by using a plurality of magnetic core pieces. Therefore, not only the handling of an extremely thin amorphous ribbon is facilitated, but also the assembly workability in a laminated magnetic core having an arbitrary shape and size is dramatically improved. That is, in the first aspect, a plurality of amorphous ribbon pieces are stacked, the electromagnetic steel plates are disposed on at least a part of both end surfaces in the stacking direction of the laminated portions of the amorphous ribbon pieces, and the laminated portions and the electromagnetic steel plates are The magnetic core piece fixed on the laminated surface is used as one unit of the amorphous ribbon piece. Thereby, it can apply to the arbitrary shapes and magnitude | sizes calculated | required by a magnetic core, and it is possible to ensure stably the stacking precision at the time of manufacture, and the intensity | strength required for an amorphous thin strip.

Since the fixing is not performed on the surface where the lamination direction of the amorphous ribbon is the normal line but on the laminated surface composed of the laminated amorphous ribbon and the electromagnetic steel sheet, the characteristic deterioration due to stress caused by the resin or the adhesive is small.

なお、「積層面」とは、アモルファス薄帯の積層方向を法線とする面ではなく、積層された複数のアモルファス薄帯及び電磁鋼板の各厚みに相当する側面が集まって形成される面を指す。

The “laminated surface” is not a surface whose normal is the lamination direction of the amorphous ribbons, but a surface formed by collecting side surfaces corresponding to the thicknesses of a plurality of laminated amorphous ribbons and electrical steel sheets. Point to.

前記<1>に記載の第1の態様の磁心では、

<2> 前記閉磁路は、四つの前記磁心ブロックが四角環状に接合されて形成されており、互いに隣り合う二つの磁心ブロック間に、それぞれの磁心片の、複数の積層構造を磁心ブロックの長手方向にずらして階段状に形成された段差における、前記長手方向に対して傾斜角θで傾斜した傾斜面が互いに接合する接合部を有する態様が好ましい。 In the magnetic core according to the first aspect described in <1>,

<2> The closed magnetic path is formed by joining the four magnetic core blocks into a quadrangular annular shape, and a plurality of laminated structures of the respective magnetic core pieces are disposed between two adjacent magnetic core blocks in the longitudinal direction of the magnetic core block. The aspect which has the junction part which the inclined surface inclined by inclination-angle (theta) with respect to the said longitudinal direction mutually joins in the level | step difference formed in step shape shifted in the direction is preferable.

<2> 前記閉磁路は、四つの前記磁心ブロックが四角環状に接合されて形成されており、互いに隣り合う二つの磁心ブロック間に、それぞれの磁心片の、複数の積層構造を磁心ブロックの長手方向にずらして階段状に形成された段差における、前記長手方向に対して傾斜角θで傾斜した傾斜面が互いに接合する接合部を有する態様が好ましい。 In the magnetic core according to the first aspect described in <1>,

<2> The closed magnetic path is formed by joining the four magnetic core blocks into a quadrangular annular shape, and a plurality of laminated structures of the respective magnetic core pieces are disposed between two adjacent magnetic core blocks in the longitudinal direction of the magnetic core block. The aspect which has the junction part which the inclined surface inclined by inclination-angle (theta) with respect to the said longitudinal direction mutually joins in the level | step difference formed in step shape shifted in the direction is preferable.

前記<2>に記載の第1の態様の磁心では、

<3> 前記接合部において、磁心ブロックの長手方向に積層構造をずらすことで階段状に形成された段差における傾斜面は、磁心ブロックの長手方向に対して30°~60°の傾斜角(すなわち、45°に対して-15°~+15°の振れ角)で傾斜させて形成されている態様がより好ましい。 In the magnetic core according to the first aspect described in <2>,

<3> In the joint portion, the inclined surface in the step formed by shifting the laminated structure in the longitudinal direction of the magnetic core block has an inclination angle of 30 ° to 60 ° with respect to the longitudinal direction of the magnetic core block (ie, More preferably, the tilt angle is -15 ° to + 15 ° with respect to 45 °.

<3> 前記接合部において、磁心ブロックの長手方向に積層構造をずらすことで階段状に形成された段差における傾斜面は、磁心ブロックの長手方向に対して30°~60°の傾斜角(すなわち、45°に対して-15°~+15°の振れ角)で傾斜させて形成されている態様がより好ましい。 In the magnetic core according to the first aspect described in <2>,

<3> In the joint portion, the inclined surface in the step formed by shifting the laminated structure in the longitudinal direction of the magnetic core block has an inclination angle of 30 ° to 60 ° with respect to the longitudinal direction of the magnetic core block (ie, More preferably, the tilt angle is -15 ° to + 15 ° with respect to 45 °.

例えば四つの磁心ブロックを四角環状に接合することで、四角環構造を有する磁心(コア)を作製することができる。この場合、各磁心ブロックにおける磁化容易方向が長手方向にある場合、磁化容易方向と直角に接合する接合部における磁心ブロック同士の接合箇所(繋ぎ目)では、一方の磁心ブロック中で長手方向(磁化容易方向)と直角方向に磁束が流れることとなり、鉄損と皮相電力が増加しやすい。この点に関し、二つの磁心ブロックのそれぞれの磁心片の、磁心ブロックの長手方向に対して傾斜角θで傾斜した傾斜面が互いに接合し、磁心片間において、階段状に設けられた傾斜面同士が互いに接合されていることにより、一方の磁心ブロックの磁束が他方の磁心ブロックの磁束と交差するのを防ぎ、エネルギー損失を低く抑えることができる。

For example, a magnetic core (core) having a quadrangular ring structure can be manufactured by joining four magnetic core blocks into a quadrangular ring shape. In this case, when the direction of easy magnetization in each magnetic core block is in the longitudinal direction, the longitudinal direction (magnetization) in one magnetic core block at the joint (joint) between the magnetic core blocks in the joint that is joined at right angles to the easy magnetization direction. Magnetic flux flows in a direction perpendicular to the easy direction), and iron loss and apparent power tend to increase. In this regard, the inclined surfaces of the magnetic core pieces of the two magnetic core blocks, which are inclined at an inclination angle θ with respect to the longitudinal direction of the magnetic core block, are joined to each other, and the inclined surfaces provided in a staircase shape are provided between the magnetic core pieces. Are mutually joined, the magnetic flux of one magnetic core block can be prevented from crossing the magnetic flux of the other magnetic core block, and energy loss can be suppressed low.

前記<1>に記載の第1の態様の磁心では、

<4> 互いに隣り合う二つの磁心ブロック間に、それぞれの磁心片が前記積層方向における端面で互いに接合する接合部を有し、前記接合部において、一方の磁心ブロックにおける磁心片の電磁鋼板と、他方の磁心ブロックにおける磁心片の電磁鋼板と、が対向配置されて接している態様が好ましい。 In the magnetic core according to the first aspect described in <1>,

<4> Between two magnetic core blocks adjacent to each other, each of the magnetic core pieces has a joint portion joined to each other at the end face in the stacking direction, and in the joint portion, the magnetic steel sheet of the magnetic core piece in one magnetic core block; A mode in which the magnetic steel sheet of the magnetic core piece in the other magnetic core block is disposed so as to face each other is preferable.

<4> 互いに隣り合う二つの磁心ブロック間に、それぞれの磁心片が前記積層方向における端面で互いに接合する接合部を有し、前記接合部において、一方の磁心ブロックにおける磁心片の電磁鋼板と、他方の磁心ブロックにおける磁心片の電磁鋼板と、が対向配置されて接している態様が好ましい。 In the magnetic core according to the first aspect described in <1>,

<4> Between two magnetic core blocks adjacent to each other, each of the magnetic core pieces has a joint portion joined to each other at the end face in the stacking direction, and in the joint portion, the magnetic steel sheet of the magnetic core piece in one magnetic core block; A mode in which the magnetic steel sheet of the magnetic core piece in the other magnetic core block is disposed so as to face each other is preferable.

接合部では、二つの磁心ブロックが互いに重なった状態にある。そのため、一方の磁心ブロックの電磁鋼板と、他方の磁心ブロックの電磁鋼板と、が互いに向き合う状態であると、滑り性を保持しやすく、磁心ブロック間における磁心片の抜き差しが容易になる。これにより、磁心の組み立て又は解体が容易に行える。

At the joint, the two magnetic core blocks overlap each other. Therefore, when the electromagnetic steel plate of one magnetic core block and the electromagnetic steel plate of the other magnetic core block face each other, it is easy to maintain slipperiness, and the magnetic core pieces can be easily inserted and removed between the magnetic core blocks. Thereby, assembly or disassembly of a magnetic core can be performed easily.

前記<1>に記載の第1の態様の磁心において、

<5> 前記磁心片は、二つの前記積層構造と、前記二つの積層構造の、互いに対向する側とは反対側の各端面に配置された二つの第1の電磁鋼板と、前記二つの積層構造の間に配置された第2の電磁鋼板と、を有し、

前記二つの積層構造は、一方の積層構造の長手方向の一端と他方の積層構造の長手方向の一端とが、前記長手方向において互いに重なる位置から前記長手方向にずらされ、前記二つの積層構造が一部で重なる状態で配置され、前記二つの積層構造の積層部分における積層端面を含む平面において前記積層構造と前記第1の電磁鋼板と前記第2の電磁鋼板とが固定化されている態様が好ましい。 In the magnetic core according to the first aspect described in <1>,

<5> The magnetic core piece includes the two laminated structures, the two first electromagnetic steel plates disposed on the respective end surfaces of the two laminated structures opposite to the sides facing each other, and the two laminated layers. A second electrical steel sheet disposed between the structures,

In the two laminated structures, one end in the longitudinal direction of one laminated structure and one end in the longitudinal direction of the other laminated structure are shifted in the longitudinal direction from a position where they overlap each other in the longitudinal direction, and the two laminated structures are The aspect which is arrange | positioned in the state which overlaps in part, and the said laminated structure, the said 1st electromagnetic steel plate, and the said 2nd electromagnetic steel plate are being fixed in the plane containing the lamination | stacking end surface in the lamination | stacking part of the said two laminated structures. preferable.

<5> 前記磁心片は、二つの前記積層構造と、前記二つの積層構造の、互いに対向する側とは反対側の各端面に配置された二つの第1の電磁鋼板と、前記二つの積層構造の間に配置された第2の電磁鋼板と、を有し、

前記二つの積層構造は、一方の積層構造の長手方向の一端と他方の積層構造の長手方向の一端とが、前記長手方向において互いに重なる位置から前記長手方向にずらされ、前記二つの積層構造が一部で重なる状態で配置され、前記二つの積層構造の積層部分における積層端面を含む平面において前記積層構造と前記第1の電磁鋼板と前記第2の電磁鋼板とが固定化されている態様が好ましい。 In the magnetic core according to the first aspect described in <1>,

<5> The magnetic core piece includes the two laminated structures, the two first electromagnetic steel plates disposed on the respective end surfaces of the two laminated structures opposite to the sides facing each other, and the two laminated layers. A second electrical steel sheet disposed between the structures,

In the two laminated structures, one end in the longitudinal direction of one laminated structure and one end in the longitudinal direction of the other laminated structure are shifted in the longitudinal direction from a position where they overlap each other in the longitudinal direction, and the two laminated structures are The aspect which is arrange | positioned in the state which overlaps in part, and the said laminated structure, the said 1st electromagnetic steel plate, and the said 2nd electromagnetic steel plate are being fixed in the plane containing the lamination | stacking end surface in the lamination | stacking part of the said two laminated structures. preferable.

このような態様では、所定数のアモルファス薄帯片を束ねて電磁鋼板で挟んだ構造を有し、かつ、一方の積層構造の長手方向の一端と他方の積層構造の長手方向の一端とが、前記長手方向において、互いに重なる位置から前記長手方向に所定の距離ずらされ、前記二つの積層構造が一部で重なる状態で配置される。そのため、極めて薄厚のアモルファス薄帯片の取り扱いが容易であり、かつ、磁心片同士の接合が容易に行える。また、あらかじめ積み重ねられた単位をもって磁心ブロックが製造されるので、積み精度に優れ、生産性にも優れたものとなる。

また、二つの積層構造の間に配置される第2の電磁鋼板は、磁心片の長手方向の全長に相当する積層構造の表面全体に配置し得る大きさの1枚の電磁鋼板で構成されてもよいし、二つの積層構造の各々の端面の全面に配置し得る大きさの2枚の電磁鋼板を用いて構成されてもよい。 In such an aspect, a predetermined number of amorphous ribbon pieces are bundled and sandwiched between electromagnetic steel plates, and one longitudinal end of one laminated structure and one longitudinal end of the other laminated structure are In the longitudinal direction, a predetermined distance is shifted in the longitudinal direction from a position where they overlap each other, and the two laminated structures are arranged so as to partially overlap. Therefore, it is easy to handle an extremely thin amorphous ribbon piece, and the magnetic core pieces can be easily joined to each other. In addition, since the magnetic core blocks are manufactured with the units stacked in advance, the stacking accuracy is excellent and the productivity is also excellent.

Further, the second electrical steel sheet disposed between the two laminated structures is composed of one electrical steel sheet having a size that can be disposed on the entire surface of the laminated structure corresponding to the entire length in the longitudinal direction of the magnetic core piece. Alternatively, it may be configured by using two electromagnetic steel sheets having a size that can be disposed on the entire end face of each of the two laminated structures.

また、二つの積層構造の間に配置される第2の電磁鋼板は、磁心片の長手方向の全長に相当する積層構造の表面全体に配置し得る大きさの1枚の電磁鋼板で構成されてもよいし、二つの積層構造の各々の端面の全面に配置し得る大きさの2枚の電磁鋼板を用いて構成されてもよい。 In such an aspect, a predetermined number of amorphous ribbon pieces are bundled and sandwiched between electromagnetic steel plates, and one longitudinal end of one laminated structure and one longitudinal end of the other laminated structure are In the longitudinal direction, a predetermined distance is shifted in the longitudinal direction from a position where they overlap each other, and the two laminated structures are arranged so as to partially overlap. Therefore, it is easy to handle an extremely thin amorphous ribbon piece, and the magnetic core pieces can be easily joined to each other. In addition, since the magnetic core blocks are manufactured with the units stacked in advance, the stacking accuracy is excellent and the productivity is also excellent.

Further, the second electrical steel sheet disposed between the two laminated structures is composed of one electrical steel sheet having a size that can be disposed on the entire surface of the laminated structure corresponding to the entire length in the longitudinal direction of the magnetic core piece. Alternatively, it may be configured by using two electromagnetic steel sheets having a size that can be disposed on the entire end face of each of the two laminated structures.

前記<1>~<5>のいずれか1つに記載の第1の態様の磁心において、

<6> 前記磁心片における前記積層構造と前記電磁鋼板とは、エポキシ系樹脂を用いて固定化されている態様が好ましい。 In the magnetic core of the first aspect according to any one of <1> to <5>,

<6> The aspect in which the laminated structure and the electromagnetic steel sheet in the magnetic core piece are fixed using an epoxy resin is preferable.

<6> 前記磁心片における前記積層構造と前記電磁鋼板とは、エポキシ系樹脂を用いて固定化されている態様が好ましい。 In the magnetic core of the first aspect according to any one of <1> to <5>,

<6> The aspect in which the laminated structure and the electromagnetic steel sheet in the magnetic core piece are fixed using an epoxy resin is preferable.

磁心片における、積層構造を形成する複数のアモルファス薄帯片と電磁鋼板とは、積み重ねただけでは位置ずれを起こす等により所定の形状を保ち難い。しかし、エポキシ系樹脂を用いて少なくとも一部が固定化されることで、長期間にわたって安定的に所望とする形状を維持することができる。

A plurality of amorphous ribbon strips and magnetic steel sheets forming a laminated structure in a magnetic core piece are difficult to maintain a predetermined shape due to misalignment or the like only by being stacked. However, by fixing at least a part using an epoxy resin, a desired shape can be stably maintained over a long period of time.

前記<1>~<6>のいずれか1つに記載の第1の態様の磁心において、

<7> 前記積層構造は、前記電磁鋼板の短手方向の表面全体に配置されている態様が好ましい。 In the magnetic core of the first aspect according to any one of <1> to <6>,

<7> The aspect with which the said laminated structure is arrange | positioned at the whole surface of the transversal direction of the said electromagnetic steel plate is preferable.

<7> 前記積層構造は、前記電磁鋼板の短手方向の表面全体に配置されている態様が好ましい。 In the magnetic core of the first aspect according to any one of <1> to <6>,

<7> The aspect with which the said laminated structure is arrange | positioned at the whole surface of the transversal direction of the said electromagnetic steel plate is preferable.

積層されている複数のアモルファス薄帯片の、長手方向と直交する短手方向(幅長)の長さが、電磁鋼板の、長手方向と直交する短手方向(幅長)の長さと同等以上であるので、組立性が向上する。更に、磁心におけるアモルファスの体積分率が高くなり、エネルギー損失がより低く抑えられる。

The length of the transverse direction (width length) perpendicular to the longitudinal direction of the laminated amorphous ribbons is equal to or greater than the length of the electrical steel sheet in the transverse direction (width length) perpendicular to the longitudinal direction. Therefore, the assemblability is improved. Further, the volume fraction of amorphous in the magnetic core is increased, and the energy loss is suppressed to a lower level.

本発明の第2の態様である磁心片は、

<8> 複数のアモルファス薄帯片が積層された積層構造と、前記積層構造の積層方向における両方の端面の少なくとも一部に配置された電磁鋼板と、を含み、前記積層構造及び前記電磁鋼板が積層面で固定化されている。 The magnetic core piece according to the second aspect of the present invention is:

<8> A laminated structure in which a plurality of amorphous ribbon strips are laminated, and an electromagnetic steel sheet disposed on at least a part of both end faces in the lamination direction of the laminated structure, wherein the laminated structure and the electromagnetic steel sheet are It is fixed on the laminated surface.

<8> 複数のアモルファス薄帯片が積層された積層構造と、前記積層構造の積層方向における両方の端面の少なくとも一部に配置された電磁鋼板と、を含み、前記積層構造及び前記電磁鋼板が積層面で固定化されている。 The magnetic core piece according to the second aspect of the present invention is:

<8> A laminated structure in which a plurality of amorphous ribbon strips are laminated, and an electromagnetic steel sheet disposed on at least a part of both end faces in the lamination direction of the laminated structure, wherein the laminated structure and the electromagnetic steel sheet are It is fixed on the laminated surface.

第2の態様の磁心片は、積層構造をなす複数のアモルファス薄帯片と、積層構造の積層方向における両方の端面に配置された電磁鋼板と、が固定化されている。これにより、極めて薄いアモルファス薄帯が取り扱いやすくなり、任意の形状及び大きさの磁心の製造(組み立て作業)を効率良く行うことができる。

In the magnetic core piece of the second aspect, a plurality of amorphous ribbon pieces having a laminated structure and electromagnetic steel sheets arranged on both end faces in the lamination direction of the laminated structure are fixed. Thereby, an extremely thin amorphous ribbon can be easily handled, and a magnetic core having an arbitrary shape and size can be efficiently manufactured (assembled).

本開示によれば、アモルファス薄帯片を用いた積層磁心を作製する際のアモルファス薄帯片の取り扱い性及びアモルファス薄帯片を用いた積層磁心の組み立て作業が飛躍的に改善される磁心片及び磁心が提供される。

According to the present disclosure, it is possible to dramatically improve the handling property of the amorphous ribbon when producing the laminated magnetic core using the amorphous ribbon and the assembly operation of the laminated core using the amorphous ribbon, and A magnetic core is provided.

以下、本発明の一実施形態について説明する。

本発明の一実施形態の磁心は、閉磁路を構成する複数の磁心ブロックを有し、前記磁心ブロックは、複数の磁心片の積層体である。前記磁心片は、複数のアモルファス薄帯片が積層された積層構造と、前記積層構造の積層方向における両方の端面のそれぞれの少なくとも一部に配置された電磁鋼板と、を含み、積層構造及び電磁鋼板が積層面で固定化されたものである。 Hereinafter, an embodiment of the present invention will be described.

A magnetic core according to an embodiment of the present invention has a plurality of magnetic core blocks constituting a closed magnetic path, and the magnetic core block is a laminated body of a plurality of magnetic core pieces. The magnetic core piece includes a laminated structure in which a plurality of amorphous ribbon pieces are laminated, and an electromagnetic steel sheet disposed on at least a part of each of both end faces in the lamination direction of the laminated structure, and the laminated structure and electromagnetic A steel plate is fixed on the laminated surface.

本発明の一実施形態の磁心は、閉磁路を構成する複数の磁心ブロックを有し、前記磁心ブロックは、複数の磁心片の積層体である。前記磁心片は、複数のアモルファス薄帯片が積層された積層構造と、前記積層構造の積層方向における両方の端面のそれぞれの少なくとも一部に配置された電磁鋼板と、を含み、積層構造及び電磁鋼板が積層面で固定化されたものである。 Hereinafter, an embodiment of the present invention will be described.