WO2016121430A1 - 色変換テーブル作成装置、色変換テーブル作成方法、及び色変換テーブル作成プログラム - Google Patents

色変換テーブル作成装置、色変換テーブル作成方法、及び色変換テーブル作成プログラム Download PDFInfo

- Publication number

- WO2016121430A1 WO2016121430A1 PCT/JP2016/050225 JP2016050225W WO2016121430A1 WO 2016121430 A1 WO2016121430 A1 WO 2016121430A1 JP 2016050225 W JP2016050225 W JP 2016050225W WO 2016121430 A1 WO2016121430 A1 WO 2016121430A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- image data

- resolution

- color

- color conversion

- unit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/525—Arrangement for multi-colour printing, not covered by group B41J2/21, e.g. applicable to two or more kinds of printing or marking process

-

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T1/00—General purpose image data processing

-

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N1/00—Scanning, transmission or reproduction of documents or the like, e.g. facsimile transmission; Details thereof

- H04N1/46—Colour picture communication systems

-

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N1/00—Scanning, transmission or reproduction of documents or the like, e.g. facsimile transmission; Details thereof

- H04N1/46—Colour picture communication systems

- H04N1/56—Processing of colour picture signals

- H04N1/60—Colour correction or control

Definitions

- the present invention relates to a color conversion table creation device, a color conversion table creation method, and a color conversion table creation program, and more particularly to a color conversion technique for image data applied to color reproduction by a printing device.

- a profile creation chart composed of a plurality of color patches is printed, the printed profile creation chart is read, and the profile is read from the read data of the profile creation chart.

- the method of creating is generally known.

- Patent Documents 1 and 2 describe a technique for realizing color reproduction without creating a profile creation chart.

- Patent Document 1 discloses an image reading apparatus capable of reproducing a color close to an original by a printing apparatus without excessively compressing a color gamut used in the original read by a scanner.

- the image reading apparatus of Patent Document 1 creates color gamut information of a document from the read document, and outputs an image file to which the color gamut information is added.

- the color gamut information includes maximum brightness information, minimum brightness information, saturation information for each hue, and the like.

- Patent Document 1 when an image file to which color gamut information is added is re-output by a printer as a printing apparatus, the color gamut information is compared with a printer color gamut that is a color gamut reproducible by the printer, A color conversion coefficient is selected.

- Patent Document 2 discloses an image processing apparatus that can adjust the color tones of two printed materials without using a color chart.

- a reference printed matter output by a first image output device serving as a reference printer and a user printed matter output by a second image output device serving as a user printer are read by a scanner, A color tone conversion parameter is obtained from the correspondence between the color component values, and the color tone equivalent to the color tone of the reference printed matter is reproduced by correcting the output image of the second image output device with the obtained color tone conversion parameter.

- Patent Document 1 re-output by a printer is premised on a read image read by a scanner or an image file of a read image.

- the read image lacks definition due to the influence of blur at the time of reading depending on the reading resolution of the scanner, it is difficult to obtain a printed matter that reproduces a high-definition original image.

- Patent Document 2 it is necessary to print a user print and read it by a scanner separately from the reference print, which is troublesome.

- the technique described in Patent Document 2 obtains a color tone conversion parameter for each RGB color component read by the scanner, and performs color correction by one-dimensional conversion for each RGB color component using the color tone conversion parameter for each color component. Is what you do.

- Such a conventional method is considered to be sufficient for correcting a color difference of about the individual difference of the printer device.

- the first image output device as the reference printer that outputs the reference printed matter and the first printer as the user printer.

- the degree of freedom of color correction is not sufficient, and the color correction accuracy may be lowered.

- RGB is a notation method that collectively represents red, green, and yellow.

- red may be represented by R, green by G, and yellow by Y.

- the present invention has been made in view of such circumstances, and a color conversion table creation device, a color conversion table creation method, and a color conversion method capable of achieving both high-definition image reproduction and reliable color reproduction. It is an object to provide a conversion table creation program.

- the color conversion table creation device reads target printed matter and printed matter printed by the printing device with a first resolution, and is target printed matter read image data representing a read image of the target printed matter, and has a first resolution.

- An image reading unit that acquires target printed material read image data having a first resolution and printed product read image data representing a read image of the printed product, and a device-dependent color space obtained from the image reading unit.

- the document image data representing the document image having the second resolution which is the document image data represented by the signal value, is different from the resolution of the print image data having the same resolution as that of the document image data, or the resolution of the document image data.

- a second color conversion unit that converts to print image data having resolution, and a signal value of the first color space obtained by reading the printed matter printed by the printing apparatus according to the print image data in the image reading unit. Processing for associating the positional relationship between the printed material read image data and the original image data, and the target printed material read image data and the original image data represented by the signal value of the first color space obtained by reading the target printed material in the image reading unit.

- the image association unit or the first color conversion unit that performs processing for associating the positional relationship with Processing for associating the positional relationship between the printed material read chromaticity value image data and the document image data obtained by converting the signal value of the product read image data into the chromaticity value of the second color space, and the first color conversion unit

- An image association unit that performs processing for associating the positional relationship between the target printed material read chromaticity value image data obtained by converting the signal value of the target printed material read image data into the chromaticity value in the second color space and the document image data;

- a third resolution less than the first resolution is obtained from the target printed material read chromaticity value image data in which the positional relationship with the document image data is associated by the resolution image creation unit or the image association unit.

- a first low-resolution image creating unit that creates low-resolution target printed matter read chromaticity value image data, and a second that creates low-resolution original image data having a fourth resolution less than the second resolution from the original image data.

- Low resolution image creation unit and low resolution printed matter read image data having a third resolution lower than the first resolution from the printed matter read image data in which the positional relationship with the original image data is associated by the image association unit From the printed material read chromaticity value image data in which the positional relationship with the document image data is associated by the third low-resolution image creation unit or the image association unit, the low resolution having a third resolution less than the first resolution

- the third low-resolution image creation unit that creates the resolution printed material read chromaticity value image data, the signal value of the document image data, the image association unit, and the first color conversion unit First color information correspondence relationship between the chromaticity value of the target printed matter and the chromaticity value of the printed matter obtained through the processing of the image association unit and the first color conversion unit, and low

- the first aspect it is possible to achieve both highly reliable color reproduction and high-definition image reproduction.

- the color conversion table is created using color information of different resolutions, colors can be matched on average from low resolution color information, and colors can be matched with high accuracy using high resolution color information.

- the color conversion table creation unit includes a first color information correspondence creation unit that creates a first color information correspondence relationship, From the second color information correspondence creation unit for creating the color information correspondence relationship, the first color information correspondence relationship, and the second color information correspondence relationship, the first color information correspondence relationship, And a third color information correspondence relationship representing a correspondence relationship between the signal value of the document image data common to the correspondence relationship between the second color information, the chromaticity value of the target printed matter, and the chromaticity value of the printed matter.

- a color conversion data creation unit including a third color information correspondence creation unit may be provided.

- the first inter-color information correspondence creation unit is subjected to processing of the document image data, the image association unit, and the first color conversion unit.

- Correspondence relationship with the target chromaticity value that is the chromaticity value of the target printed matter to be obtained, and printing that is the chromaticity value of the printed matter obtained through the processing of the document image data and the image associating unit and the first color converting unit From the correspondence relationship with the chromaticity value, the first color information correspondence relationship can be created using the target chromaticity value and the printing chromaticity value that match the signal values of the document image data.

- the second color information correspondence creation unit includes a low resolution document image data and an image association unit, a first low resolution image creation unit, And a correspondence relationship with a low resolution target chromaticity value that is a chromaticity value of a target printed matter obtained through the processing of the first color conversion unit, and document image data and an image association unit, a third low resolution image creation unit And the target chromaticity value that matches the signal value of the document image data and the low resolution target from the correspondence relationship with the low resolution printing chromaticity value that is the chromaticity value of the printed matter obtained through the processing of the first color conversion unit

- the second color information correspondence can be created from the chromaticity value and the printing chromaticity value that matches the signal value of the document image data and the low resolution printing chromaticity value.

- the third color information correspondence creation unit includes a first color information correspondence and a second color information correspondence.

- a configuration in which a third color information correspondence relationship is created by using the target chromaticity value and the print chromaticity value in the first color information correspondence relationship for the signal values of the document image data common to the correspondence relationship. Can do.

- the third color information correspondence creation unit includes a first color information correspondence relationship and a second color information correspondence For the signal value of the document image data common to the correspondence relationship, the average value of the target chromaticity value in the first color information correspondence relationship and the target chromaticity value in the second color information correspondence relationship, and the first color

- the third color information correspondence can be created using the average value of the print chromaticity values in the information correspondence and the print chromaticity values in the second color information correspondence.

- the color conversion table creation device reads target printed matter and printed matter printed by the printing device with a first resolution, and is target printed matter read image data representing a read image of the target printed matter, and the first resolution.

- a fourth low-resolution image creation unit that creates an intermediate-resolution document image data representing a document image having a sixth resolution less than the second resolution from the image data; and a fourth lower-resolution image creation unit that creates less than the first resolution from the target printed matter read image data 5th intermediate resolution target printed matter read image data having a resolution of 5 or a fifth solution less than the first resolution is generated from the printed matter read image data.

- a fifth low-resolution image creation unit that creates intermediate-resolution printed material read image data having a degree, a signal value of the first color space that is a device-dependent color space obtained from the image reading unit, and a device-independent color space

- a first color conversion that converts a signal value in the first color space into a signal value in the second color space using a first color conversion table that represents a correspondence relationship with the chromaticity value of the second color space.

- the document image data represented by the signal value of the third color space that is a device-dependent color space has the same resolution as that of the document image data, using the input unit, the input color conversion table, and the output color conversion table A second color conversion unit that converts print image data or print image data having a resolution different from that of the original image data, and an image of a printed matter printed by the printing apparatus according to the print image data

- Intermediate resolution printed material reading obtained by subjecting the printed material read image data represented by the signal value of the first color space obtained by reading in the capturing unit to the reduction processing by the fifth low resolution image creating unit.

- a low-resolution printed material reading chromaticity value image data having a third low-resolution image creation unit, a signal value of document image data, a fifth low-resolution image creation unit, an image association unit, and a first The chromaticity value of the target printed matter obtained through the processing of the color conversion unit, and the chromaticity value of the printed matter obtained through the processing of the fifth low-resolution image creation unit, the image association unit, and the first color conversion unit, , The correspondence relationship between the color information, the signal value of the low-resolution document image data, the fifth low-resolution image creation unit, the image association unit, the first low-resolution image creation unit, and The chromaticity value of the target printed matter obtained through the processing of the first color conversion unit, the fifth low-resolution image creation unit, the image association unit, the third low-resolution image creation unit, and the first color conversion unit.

- a color conversion table creation comprising: a color conversion table creation unit

- the seventh aspect it is possible to obtain the same effect as the first aspect. Further, as the intermediate resolution, a fifth resolution that is less than the first resolution and exceeds the third resolution, and a sixth resolution that is less than the second resolution and exceeds the fourth resolution are employed. Using the original image data, the read image data of the target print having the fifth resolution, the read image data of the print having the fifth resolution, and the read image data of the target print obtained by the image reading unit. Even when the data size of the read image data of the printed matter is large, it is possible to reduce the calculation load of the image association unit.

- the color conversion table creation unit includes a fourth color information correspondence creation unit that creates a fourth color information correspondence relationship, From the fifth color information correspondence creating unit for creating the color information correspondence relationship, the fourth color information correspondence relationship, and the fifth color information correspondence relationship, the fourth color information correspondence relationship, And a sixth color information correspondence relationship that represents a correspondence relationship between the signal value of the document image data, the chromaticity value of the target printed matter, and the chromaticity value of the printed matter.

- a color conversion data creation unit including a sixth color information correspondence creation unit may be provided.

- the fourth color information correspondence creating unit goes through the processing of the document image data, the image correlating unit, and the first color converting unit. Correspondence relationship with the target chromaticity value that is the chromaticity value of the target printed matter to be obtained, and printing that is the chromaticity value of the printed matter obtained through the processing of the document image data and the image associating unit and the first color converting unit From the correspondence relationship with the chromaticity value, the fourth chromaticity correspondence relationship can be created from the target chromaticity value that matches the signal value of the document image data and the printing chromaticity value.

- the fifth color information correspondence creating unit includes a low-resolution document image data and an image associating unit, a third low-resolution image creating unit, And a correspondence relationship with a low resolution target chromaticity value that is a chromaticity value of a target printed matter obtained through the processing of the first color conversion unit, and document image data and an image association unit, a third low resolution image creation unit And the target chromaticity value that matches the signal value of the document image data and the low resolution target from the correspondence relationship with the low resolution printing chromaticity value that is the chromaticity value of the printed matter obtained through the processing of the first color conversion unit

- the fifth color information correspondence relationship can be created from the chromaticity value and the printing chromaticity value that matches the signal value of the document image data and the low-resolution printing chromaticity value.

- the sixth color information correspondence creating unit includes the fourth color information correspondence relation and the fifth color information correspondence.

- a configuration in which a sixth color information correspondence is created by using the target chromaticity value and the print chromaticity value in the fourth color information correspondence for the signal value of the document image data common to the correspondence creation unit. can do.

- the sixth inter-color information correspondence creation unit includes the fourth inter-color information correspondence and the fifth inter-color information

- the fourth inter-color information correspondence relationship may be created using an average value of the print chromaticity values in the color information correspondence relationship and the print chromaticity values in the fifth color information correspondence relationship.

- the fifth resolution and the sixth resolution may be equivalent in resolution.

- the third resolution and the fourth resolution can be configured to be equivalent resolutions.

- the first resolution and the second resolution can be configured to be equivalent resolutions.

- the image association unit specifies a positional relationship between the document image data and the target printed matter read image data.

- An image alignment unit that performs an alignment process or an alignment process that specifies a positional relationship between the document image data and the printed material read image data, an original image data that has undergone the alignment process, and target printed material read image data;

- a color extracting unit that acquires color information from an image position corresponding to the printed material read image data.

- the color extraction unit acquires color information from the original image data, the target printed material read image data, and the printed material read image data before the resolution reduction processing.

- a first color extraction unit, and a second color extraction unit that obtains color information from the original image data after the resolution reduction processing, the target printed material read image data, and the printed material read image data, and creates a color conversion table

- the second identification unit is identified based on the correspondence relationship between the first color information specified based on the color information acquired by the first color extraction unit and the color information acquired by the second color extraction unit.

- a color conversion table showing a multidimensional correspondence can be created using the correspondence between color information.

- the image association unit specifies a positional relationship between the document image data and the target printed material read image data.

- An image alignment unit that performs an alignment process or an alignment process that specifies a positional relationship between the document image data and the printed material read image data, an original image data that has undergone the alignment process, and target printed material read image data;

- a color extracting unit that acquires color information from an image position corresponding to the printed material read image data.

- the color extraction unit acquires color information from the original image data, the target printed material read image data, and the printed material read image data before the resolution reduction processing.

- a first color extraction unit, and a second color extraction unit that obtains color information from the original image data after the resolution reduction processing, the target printed material read image data, and the printed material read image data, and creates a color conversion table

- a color conversion table showing a multidimensional correspondence can be created using the correspondence between color information.

- the color conversion table creation unit includes a plurality of target prints and document image data corresponding to each target print. Based on each of the plurality of correspondences created, a color conversion table indicating a single multidimensional correspondence can be created.

- the color conversion table creation unit obtains a difference between the chromaticity value of the target printed matter and the chromaticity value of the print It can be set as the structure provided with the difference chromaticity value calculating part to perform.

- the color conversion table creation unit includes the document image data, the chromaticity value of the target printed matter, and the chromaticity value of the printed matter.

- the color conversion table used for the second color conversion unit can be created by modifying the input color conversion table or the output color conversion table based on

- the input color conversion table defines a multidimensional correspondence between the third color space and the second color space, and the output color conversion table is suitable for supply to the second color space and the printing apparatus. It defines a multidimensional correspondence with a color space (fourth color space which is a device-dependent color space).

- the corrected multidimensional color conversion table is obtained. Obtainable.

- the color conversion table creating unit includes the document image data, the chromaticity value of the target printed matter, and the chromaticity value of the printed matter.

- the color correction table for correcting the output value of the input color conversion table can be created based on the correspondence relationship between the input color conversion table and the input color conversion table.

- the tentatively set input color conversion table and output color conversion table are used as they are without change, and the output value of the input color conversion table is corrected by the color correction table and output. It can be configured to pass to the input of the color conversion table. Further, in the actual color conversion processing in the second color conversion unit, a series of conversion processes of conversion using the input color conversion table, conversion using the color correction table, and conversion using the output color conversion table are combined into one multidimensional color conversion table. Can be integrated.

- an input color conversion table database storing a plurality of input color conversion tables having different color reproduction characteristics, and an input One input color to be applied to the second color conversion unit based on the correspondence between the original image data and the chromaticity value of the target printed material from among a plurality of input color conversion tables stored in the color conversion table database

- an input color conversion table selection unit that performs a process of selecting a conversion table.

- the input color conversion table selection unit calculates the color difference between the read chromaticity value for the color conversion table document image signal and the chromaticity value defined by each input color conversion table stored in the input color conversion table database.

- An input color conversion table that is calculated and that has the smallest color difference average value (referred to as “average color difference”) or maximum color difference value (referred to as “maximum color difference”) may be selected.

- a relatively good input color conversion table used in the first printing can be used. Thereby, the target color reproduction can be reached in a relatively short time.

- the color conversion table according to any one of the first aspect to the 23rd aspect, at least one of a target printed matter, a printed matter, and a color sample different from the target printed matter and the printed matter is provided.

- a color measurement unit that acquires the color measurement value of the color measurement target and a document image signal corresponding to the position on the document image data from which the color measurement value is acquired by the color measurement unit are acquired.

- the color measurement target document image signal acquisition unit to be read and the read image signal corresponding to the position on the target printed material read image data for which the color measurement value is acquired in the color measurement unit, or the reading corresponding to the position on the printed material read image data A color measurement target image signal acquisition unit including at least one of the color measurement target read image signal acquisition units for acquiring an image signal.

- the twenty-fifth aspect it is possible to reduce the error of the chromaticity value grasped from the image read by the image reading unit and further improve the accuracy of color matching.

- the color conversion result by the first color conversion unit corresponds to the position of the original image data from which the colorimetric value is acquired by the colorimetry unit.

- a chromaticity value replacement unit that replaces the chromaticity value to be replaced with the colorimetric value acquired in the colorimetry unit may be provided.

- a first color conversion table database storing a plurality of color conversion tables applicable as the first color conversion table

- a first color conversion table selection unit that selects one color conversion table from among a plurality of color conversion tables stored in one color conversion table database.

- Including a color conversion table that represents the correspondence between the read signal of the image reading unit and the chromaticity value for each combination of the color material type and the base material type used for creating the printed matter, and the first color conversion table selection unit A read image signal corresponding to a position on the target printed material read image data for which a colorimetric value is obtained in the color portion, or a read image signal corresponding to a position on the printed material read image data It can be based on the correspondence between the colorimetric values obtained in the color measurement unit, and configured to perform a process of selecting one of the color conversion table from among a plurality of color conversion tables.

- the first color conversion table selection unit selects the chromaticity value of the read image signal obtained by referring to the color conversion table stored in the first color conversion table database and the measurement value obtained from the color measurement unit. A color difference with a color value is calculated, and a color conversion table that minimizes the average color difference or the maximum color difference can be selected from the first color conversion table database.

- the accuracy of the chromaticity value obtained from the image read by the image reading unit can be further increased.

- the reading corresponding to the position on the target printed material read image data from which the colorimetric value is acquired by the colorimetric unit the reading corresponding to the position on the target printed material read image data from which the colorimetric value is acquired by the colorimetric unit.

- the chromaticity value acquired via the image reading unit can be brought close to the colorimetric value obtained from the colorimetric unit, and the accuracy of the chromaticity value can be increased.

- the color conversion table creating apparatus in the color conversion table creating apparatus according to any one of the first to twenty-eighth aspects, document image data and an image represented by signal values in a third color space that is a device-dependent color space Based on the correspondence with the chromaticity value of the read image of the target printed matter obtained through the processing by the associating unit and the first color converting unit, the number of the third color space and the second color space of the document image data is increased.

- a third color conversion table creating unit for creating a second color conversion table representing a correspondence relationship between dimensions, and the second color conversion table created by the third color conversion table creating unit is converted into the second color conversion table.

- the input color conversion table can be used as a configuration.

- the accuracy of color reproduction in the first printing is improved.

- the convergence of color matching is accelerated.

- the image associating unit includes original image data from the target printed material read image data or the printed material read image data. And an image extraction unit that performs a process of extracting a corresponding partial image.

- the target color matching can be performed even when the original image data and the target printed matter or the image content of the printed surface of the printed matter do not correspond one-to-one.

- the image association unit is configured to store the original image data and the target printed matter read image data on which the positional relationship has been associated. Color extraction processing for extracting corresponding color information is performed from each of the document image data and the printed material read image data that have been subjected to the processing for associating the positional relationship.

- the read image data that has been subjected to the processing for associating the positional relationship is printed material read image data or target printed material read image data, and may be both of them.

- the color extraction processing includes processing for setting a region of interest in document image data and whether or not the region of interest satisfies the first extraction condition.

- Target printed matter read image data or printed matter read in which a signal value of original image data as color information is extracted from a region of interest that satisfies the first extraction condition and the positional relationship is associated

- a corresponding color information extraction process for extracting a signal value of target printed matter read image data or a signal value of printed matter read image data as color information from a region at a position corresponding to a target region that satisfies the first extraction condition in image data It can be set as the structure containing these.

- the first extraction condition is that a color difference within the region of interest is equal to or less than a first extraction threshold value defined as an allowable range. It can be set as the structure containing the condition of this.

- the color extraction processing includes processing for determining whether or not the region of interest satisfies the second extraction condition, As the information extraction process, the signal value of the target printed matter read image data or the signal value of the printed matter read image data as color information is extracted from the region of interest that satisfies the first extraction condition and satisfies the second extraction condition.

- the processing may include a process of extracting the signal value of the target printed matter read image data or the signal value of the printed matter read image data.

- the second extraction condition is that the target printed matter read image data or the printed matter is within the region corresponding to the target region that satisfies the first extraction condition.

- the read image data exists, and the image defect does not exist in the target print image data area or the print image data area at the position corresponding to the target area that satisfies the first extraction condition. It can be set as the structure containing these conditions.

- the color extraction processing includes processing for determining whether or not the region of interest satisfies the third extraction condition.

- the signal value of the document image data as color information is extracted from the region of interest that satisfies the first extraction condition and satisfies the third extraction condition, and the positional relationship

- a process of extracting the signal value of the read image data is performed, and the third extraction condition is a non-surface processed region without surface processing or a surface processing region with surface processing. It is, may be configured to one of conditions either can be determined.

- the image association unit performs processing for associating the positional relationship with the original image data and the second color

- a color extraction process for extracting corresponding color information from each of the read chromaticity value image data represented by the chromaticity values of the space can be performed.

- the color extraction processing determines whether or not the attention area satisfies the first extraction condition and processing for setting the attention area in the document image data In the read chromaticity value image data in which the signal value of the document image data as color information is extracted from the region of interest that satisfies the first extraction condition and the positional relationship is associated. And corresponding color information extraction processing for extracting the chromaticity value of the read chromaticity value image data as color information from the region corresponding to the target region that satisfies the extraction condition.

- the first extraction condition is that the color difference within the region of interest is equal to or less than a first extraction threshold value defined as an allowable range. It can be set as the structure containing the condition of this.

- the color extraction process includes a process of determining whether the region of interest satisfies the second extraction condition.

- the information extraction process a process of extracting a signal value of document image data as color information from a region of interest satisfying the first extraction condition and satisfying the second extraction condition and associating the positional relationship is performed.

- the second extraction condition is that the target printed material read image data or the printed material is within a region corresponding to the region of interest that satisfies the first extraction condition.

- the read image data exists, and the image defect does not exist in the target print image data area or the print image data area at the position corresponding to the target area that satisfies the first extraction condition. It can be set as the structure containing these conditions.

- the color extraction processing includes processing for determining whether or not the region of interest satisfies the third extraction condition.

- the signal value of the document image data as color information is extracted from the region of interest that satisfies the first extraction condition and satisfies the third extraction condition, and the positional relationship

- the process for extracting the surface is performed, and as the third extraction condition, either a non-surface processed region without surface processing or a surface processed region with surface processing is defined. It can be.

- the image is printed by the first image reading unit that reads the target printed matter and the printing device as the image reading unit. It can be set as the structure provided with the 2nd image reading part which reads printed matter.

- first image reading unit used for reading a target printed material and a second image reading unit used for reading a printed material printed by a printing device are provided separately.

- the combined configuration of the first image reading unit and the second image reading unit functions as an image reading unit as a whole. That is, the first image reading unit and the second image reading unit share functions and play the role of an image reading unit.

- the first image reading unit and the second image reading unit which are two different image reading units

- the first image reading unit and the second image reading unit are also used for the first color conversion table.

- Two different first color conversion tables suitable for each of the above are prepared.

- the first color conversion table corresponding to the first image reading unit is used, and when converting the signal value obtained from the second image reading unit.

- the first color conversion table corresponding to the second image reading unit is used.

- original image data is included in print image data or original image data having the same resolution as that of the original image data using the input color conversion table and the output color conversion table.

- Target print product read image data having image data and first resolution is acquired.

- a read image color conversion step of converting the signal value of the first color space into the chromaticity value of the second color space using the color conversion table, and the first color obtained by reading the printed matter in the image reading unit Printed image read image data represented by space signal values, and document image data representing document images having second resolution, which are document image data represented by signal values of a third color space that is a device-dependent color space

- Printed matter read chromaticity value image data and original image data obtained by converting the signal value of the printed matter read image data into the chromaticity value of the second color space by the image association step or the read image color conversion step

- An image associating step for performing a process of associating a positional relationship with the data, and a third resolution less than the first resolution from the target printed material read image data in which the positional relationship with the document image data is associated by the image associating step.

- the positional relationship with the original image data is correlated in the first low-resolution image creating process or image associating process for creating the low-resolution target printed matter read image data.

- a first low-resolution image creation step of creating low-resolution target printed matter read chromaticity value image data having a third resolution lower than the first resolution from the obtained target printed matter read chromaticity value image data, and original image data A printed matter read image in which the positional relationship between the second low-resolution image creating step for creating low-resolution original image data having a fourth resolution lower than the second resolution and the original image data in the image association step is associated.

- the positional relationship with the document image data is associated by the third low-resolution image creation step of creating low-resolution printed material read image data having a third resolution less than the first resolution from the data, or the image association step.

- Third low-resolution image creation for creating low-resolution printed matter read chromaticity value image data having a third resolution lower than the first resolution from the printed matter read chromaticity value image data.

- a first color information correspondence relationship that is a correspondence relationship with the chromaticity value of the printed matter obtained through the process, a signal value of the low resolution document image data, an image association step, a first low resolution image creation step, and The chromaticity value of the target printed matter obtained through the processing of the read image color conversion step, and the chromaticity value of the printed matter obtained through the processing of the image association step, the third low-resolution image creation step, and the read image color conversion step

- the same matters as the specific matters of the color conversion table creation device specified by the aspect quoting the first aspect can be appropriately combined.

- the processing unit and the functional unit serving as the units responsible for the processing and function specified in the color conversion table creation device can be grasped as the corresponding process or operation process or step element.

- original image data is contained in print image data or original image data having the same resolution as the original image data using the input color conversion table and the output color conversion table.

- Target print product read image data having image data and first resolution is acquired.

- a fourth low-resolution image creating step for creating intermediate-resolution document image data representing a document image having a sixth resolution less than the second resolution from document image data representing a document image having the second resolution.

- Generating intermediate resolution target printed material read image data having a fifth resolution less than the first resolution from the target printed material read image data, or intermediate resolution having a fifth resolution less than the first resolution from the printed material read image data A fifth low-resolution image creation step of creating printed material read image data, a signal value of the first color space obtained from the image reading unit, and a chromaticity value of the second color space which is a device-independent color space

- a read image color conversion step of converting the signal value of the first color space into the chromaticity value of the second color space using the first color conversion table representing the correspondence relationship of Intermediate resolution printed material read image data obtained by subjecting the printed material read image data represented by the signal value of the first color space obtained by performing the low resolution processing in the fifth low resolution image creation step;

- the signal value of the intermediate resolution target printed matter read image data is converted into the chromaticity value of the second color space by the process of associating the positional relationship between the resolution printed matter read chromaticity value image data and the document image data and the read image color conversion step.

- the image association step for performing the process of associating the positional relationship between the intermediate resolution target printed matter read chromaticity value image data and the document image data obtained in this manner, and the positional relationship between the intermediate resolution document image data by the image association step

- the low resolution target printed matter read image data having the third resolution lower than the fifth resolution is generated from the obtained intermediate resolution target printed matter read image data.

- the third resolution less than the fifth resolution is obtained from the intermediate resolution target printed matter read chromaticity value image data in which the positional relationship with the intermediate resolution original image data is correlated in the first low resolution image creation step or the image association step.

- a second resolution less than the fifth resolution is obtained from the intermediate resolution printed material read image data in which the positional relationship between the second low resolution image creation step to be created and the intermediate resolution original image data is associated by the image association step.

- the third low-resolution image creating step for creating the low-resolution printed material read image data, or the intermediate resolution original image data by the image matching step.

- a correspondence relationship between the chromaticity values of the printed matter, the fourth color information correspondence relationship, the signal value of the low-resolution document image data, the image association step, the first low-resolution image creation step, and the read image The chromaticity value of the target printed matter obtained through the color conversion process, the chromaticity value of the printed matter obtained through the image association step, the third low-resolution image creation step, and the read image color conversion step,

- the same matters as the specific matters of the color conversion table creation device specified by the aspect quoting the seventh aspect can be appropriately combined.

- the processing unit and the functional unit serving as the units responsible for the processing and function specified in the color conversion table creation device can be grasped as the corresponding process or operation process or step element.

- the color conversion table created in the color conversion table creation step is used for color conversion in the document image color conversion step, A color conversion process, a printing process, a process for obtaining printed material read image data, a read image color conversion process, an image association process, and a color conversion table creation process can be repeated.

- the conversion process, the image association process, and the color conversion table creation process can be repeated. Thereby, the accuracy of color reproduction can be further improved.

- a color conversion table creation program includes a function of acquiring read image data representing each read image of a target print and a print from an image reading unit that reads the target print and a print printed by the printing apparatus; Using the first color conversion table representing the correspondence between the signal value of the first color space obtained from the reading unit and the chromaticity value of the second color space, which is a device-independent color space, the first color Using the first color conversion function that converts the signal value of the space into the chromaticity value of the second color space, the input color conversion table, and the output color conversion table, the third color space that is a device-dependent color space Document image data representing document image data having a second resolution, which is document image data represented by signal values, is printed image data or document image data having the same resolution as that of the document image data.

- a second color conversion function for performing color conversion into print image data having a resolution different from the resolution to be performed, and a signal in the first color space obtained by reading a printed matter printed by the printing apparatus according to the print image data in the image reading unit Processing for associating the positional relationship between the printed material read image data represented by the value and the document image data, and the target printed material reading represented by the signal value of the first color space obtained by reading the target printed material in the image reading unit

- the signal value of the printed material read image data is converted into the chromaticity value of the second color space by the image association function for performing the process of associating the positional relationship between the image data and the document image data, or the first color conversion function.

- Low-resolution target print reading having a third resolution less than the first resolution from target print-reading chromaticity value image data in which the positional relationship with the original image data is related by the low-resolution image creation function or the image association function

- the third low-resolution image creation function for creating the resolution printed matter read image data, or the printed matter read chromaticity value image data whose positional relationship with the document image data is associated with the image by the image association function. 3 through a process of a third low-resolution image creation function for creating low-resolution printed material reading chromaticity value image data having a resolution of 3, a signal value of document image data, an image association function, and a first color conversion function.

- First color information that is a correspondence relationship between the chromaticity value of the obtained target printed matter and the chromaticity value of the printed matter obtained through the processing by the image association function and the first color conversion function Correspondence relationship, signal value of low-resolution document image data, chromaticity value of target printed matter obtained through processing of image association function, first low-resolution image creation function, and first color conversion function, and image From the correspondence relationship between the second color information, which is the correspondence relationship between the chromaticity values of the printed matter obtained through the processing of the correspondence function, the third low-resolution image creation function, and the first color conversion function, the target printed matter

- a color conversion table creation program for causing a computer to realize a color conversion table creation function for creating a color conversion table used for the second color conversion function based on the difference between the chromaticity value of the print and the chromaticity value of the printed matter.

- the same matters as the specific matters of the color conversion table creation device specified by the aspect quoting the first aspect can be appropriately combined.

- the processing unit and the functional unit serving as the units responsible for the processing and functions specified in the color conversion table creating apparatus can be grasped as the function elements of the program that performs the corresponding processing and operations.

- the color conversion table creation program is target printed matter read image data representing a read image of a target printed matter from an image reading unit that reads the target printed matter and a printed matter printed by the printing apparatus with a first resolution.

- a target printed material read image data having a resolution of 1 a printed material read image data representing a scanned image of the printed material, a function of obtaining printed material read image data having a first resolution, and a document representing a document image having the second resolution

- a fourth low-resolution image creation function for creating an intermediate-resolution document image data representing a document image having a sixth resolution less than the second resolution from the image data, and a first less than the first resolution from the target printed material read image data

- the intermediate resolution target printed material read image data having a resolution of 5 is generated, or the first resolution is generated from the printed material read image data.

- a fifth low-resolution image creation function for creating intermediate resolution printed material read image data having a full fifth resolution; a signal value of the first color space obtained from the image reading unit; and a device-independent color space.

- a first color conversion function for converting a signal value in the first color space into a signal value in the second color space using a first color conversion table representing a correspondence relationship with chromaticity values in the second color space

- the original image data represented by the signal value of the third color space which is a device-dependent color space, is printed with the same resolution as that of the original image data.

- a second color conversion function for converting image data or print image data having a resolution different from that of the original image data, and reading a printed matter printed by the printing device according to the print image data

- the intermediate resolution printed material read image data obtained by subjecting the printed material read image data represented by the signal value of the first color space obtained by reading in step 5 to the resolution reduction processing by the fifth low resolution image creation function

- the document image data represented by the signal value of the third color space and representing the document image having the second resolution is subjected to a resolution reduction process by the fourth low-resolution image creation function.

- a low resolution printed material reading chromaticity value image data having a third resolution lower than the fifth resolution is generated from the intermediate resolution target printed material reading chromaticity value image data associated with the positional relationship with the intermediate resolution original image data.

- 1 low-resolution image creation function a second low-resolution image creation function for creating low-resolution document image data having a fourth resolution less than the sixth resolution from the intermediate-resolution document image data, and an image association function

- a third low-resolution image for generating low-resolution target printed matter read image data having a third resolution lower than the fifth resolution from the intermediate-resolution target printed matter read image data associated with the positional relationship with the intermediate-resolution document image data.

- a third low-resolution image creation function for creating low-resolution target printed matter read chromaticity value image data having a third resolution lower than the fifth resolution from the image data, a signal value of the original image data, and a fifth low

- the correspondence relationship between the fourth color information which is the correspondence relationship with the chromaticity value of the printed matter obtained through the processing of the conversion function, the signal value of the low resolution original image data, the fifth low resolution image creation function, and the image

- the same matters as the specific matters of the color conversion table creation device specified by the aspect quoting the first aspect can be appropriately combined.

- the processing unit and the functional unit serving as the units responsible for the processing and functions specified in the color conversion table creating apparatus can be grasped as the function elements of the program that performs the corresponding processing and operations.

- FIG. 1 is a block diagram showing a system configuration of a printing system including a color conversion table creating apparatus according to an embodiment of the present invention.

- FIG. 2 is a block diagram showing an overall outline of a printing system to which the color conversion table creating apparatus according to the first embodiment is applied.

- FIG. 3 is a block diagram showing a first main configuration of the printing system.

- FIG. 4 is a block diagram showing a modification of the first main configuration.

- FIG. 5 is a block diagram showing a second main configuration.

- FIG. 6 is a flowchart showing a processing procedure according to the second main configuration.

- FIG. 7 is a block diagram illustrating a specific example of image alignment processing in the image association unit.

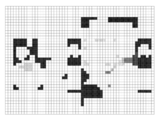

- FIG. 8A shows an example of document image data.

- FIG. 8A shows an example of document image data.

- FIG. 8B is a diagram illustrating an example of the target printed matter.

- FIG. 9 is a block diagram of a configuration for performing image association processing including preprocessing.

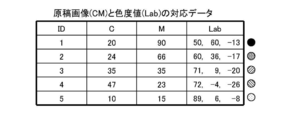

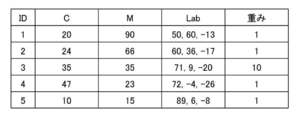

- FIG. 10 is a chart showing an example of correspondence data between document image signals and chromaticity values.

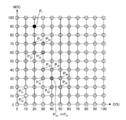

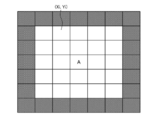

- FIG. 11 is an explanatory diagram showing lattice points in the color space of the document image data corresponding to the input side of the color conversion table.

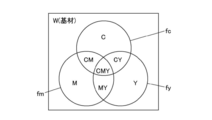

- FIG. 12 is an explanatory diagram of a chromaticity value calculation method using the Neugebauer model.

- FIG. 13 is a principal block diagram relating to the second color conversion unit.

- FIG. 14 is a chart showing an example of correspondence data of a document image signal, a target chromaticity value, a printing chromaticity value, and a differential chromaticity value.

- FIG. 10 is a chart showing an example of correspondence data between document image signals and chromaticity values.

- FIG. 11 is an explanatory diagram showing lattice points in the color space of the document

- FIG. 15 is a conceptual diagram when a color correction table is used.

- FIG. 16 is a diagram showing an example of a graphical user interface when selecting a colorimetric position in a configuration in which a spectrocolorimeter is used together.

- FIG. 17 is a block diagram showing a configuration according to a first example of the colorimetric value utilization method.

- FIG. 18 is a block diagram showing a configuration in which a function for replacing chromaticity values with colorimetric values is added to the second main configuration shown in FIG.

- FIG. 19 is a block diagram showing a configuration example provided with means for selecting and correcting a scanner profile based on a colorimetric value in the first main configuration.

- FIG. 16 is a diagram showing an example of a graphical user interface when selecting a colorimetric position in a configuration in which a spectrocolorimeter is used together.

- FIG. 17 is a block diagram showing a configuration according to a first example of the colorimetric value utilization method.

- FIG. 20 is a block diagram showing a configuration example provided with means for selecting and correcting a scanner profile based on a colorimetric value in the second main configuration.

- FIG. 21 is a block diagram showing a modified example of the configuration shown in FIG.

- FIG. 22 is a block diagram showing a modified example of the configuration shown in FIG.

- FIG. 23 is a flowchart showing an example of a color extraction method.

- FIG. 24 is a conceptual diagram illustrating an example of processing for setting a region of interest in document image data.

- FIG. 25 is a diagram illustrating an example of read image data obtained from the image reading unit.

- FIG. 26 is a diagram showing an example of a region extracted from the document image data shown in FIG. 24 as satisfying the first extraction condition.

- FIG. 21 is a block diagram showing a modified example of the configuration shown in FIG.

- FIG. 22 is a block diagram showing a modified example of the configuration shown in FIG.

- FIG. 23 is a flowchart showing an example of a color extraction

- FIG. 27 is a diagram showing an example of a region extracted from the read image data shown in FIG. 25 as satisfying the second extraction condition.

- FIG. 28 is an explanatory diagram used for explaining a region around the region of interest.

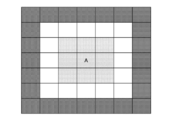

- FIG. 29 is a plan view of the entire scan surface used for explaining a low-reliability region in the scanner used in the image reading unit.

- FIG. 30 is a chart in which an example of “weight” indicating the importance of color is added to the correspondence data shown in FIG.

- FIG. 31 is a chart in which an example of “weight” indicating the importance of color is added to the correspondence data shown in FIG.

- FIG. 32 is an explanatory diagram used to explain how to obtain the center of gravity of the white region.

- FIG. 33 is a schematic diagram showing an example of document image data for package printing.

- FIG. 33 is a schematic diagram showing an example of document image data for package printing.

- FIG. 34 is a flowchart of color extraction processing in which the presence or absence of surface processing is added to the color extraction conditions.

- FIG. 35 is a block diagram showing a system configuration of a printing system according to another embodiment of the present invention.

- FIG. 36 is a block diagram showing a second main configuration in the printing system of FIG.

- FIG. 37 is a block diagram showing a configuration example of the color conversion data creation unit shown in FIG.

- FIG. 38 is a block diagram showing a system configuration of a printing system according to another embodiment of the present invention.

- FIG. 1 is a block diagram showing the overall configuration of a printing system including a color conversion table creation device according to an embodiment of the present invention.

- the printing system 10 includes an image editing device 12, a print control device 14, and a printing unit 16.

- the image editing device 12 serves as a color conversion table creation device according to the embodiment, and performs a color conversion table creation process necessary for color reproduction by the printing unit 16.

- the image editing device 12 is a device that performs image processing such as color conversion processing, image data processing, or editing using a color conversion table.

- the print image data created by the image editing device 12 is sent to the print control device 14.

- the print control device 14 controls the printing operation by the printing unit 16 based on the print image data created by the image editing device 12.

- the print control device 14 may include a halftone processing unit that converts continuous tone image data into binary or multilevel halftone image data.

- the image editing device 12 and the print control device 14 are illustrated as separate configurations, but a configuration in which the functions of the print control device 14 are installed in the image editing device 12 is also possible. For example, a configuration in which one computer functions as the image editing device 12 and the print control device 14 is possible.

- the printing unit 16 is an image forming unit that performs printing in accordance with the control of the print control device 14.

- the printing method in the printing unit 16 and the type of color material to be used are not particularly limited.

- various printers such as an inkjet printing apparatus, an electrophotographic printer, a laser printer, an offset printing apparatus, or a flexographic printing apparatus can be adopted.

- printer is understood to be synonymous with terms such as a printing device, a printing device, an image recording device, an image forming device, or an image output device.

- a printing device a printing device, an image recording device, an image forming device, or an image output device.

- the color material, ink, toner, or the like can be used according to the type of the printing unit 16.

- a plateless digital printing apparatus is assumed, and a configuration in which the printing control device 14 and the printing unit 16 are combined is described as the printing device 18.

- a mode in which the printing control device 14 and the printing unit 16 are integrally combined to form the printing device 18 is also possible.

- the printing control device 14 and the printing unit 16 are configured as separate devices, and wired or wireless.

- a mode in which signals are exchanged by communication connection is also possible.

- the system configuration includes a plate making apparatus such as a plate recorder that creates a printing plate from image data in addition to the printing control apparatus 14.

- a configuration in which the plate making device, the print control device 14, and the printing unit 16 are combined corresponds to the printing device 18. Illustration of the plate making apparatus is omitted.

- the printing system 10 of the present embodiment uses an inkjet printing apparatus capable of forming a color image using four colors of ink of cyan, magenta, yellow, and black as an example of the printing apparatus 18.

- cyan, magenta, yellow, and black colors may be expressed using C, M, Y, and K.

- cyan, magenta, yellow, and black may be collectively referred to as CMYK.

- ink colors and their combinations are not limited to this example.

- a mode in which light color ink such as light cyan or light magenta is added, and a mode in which special color ink such as orange or green is used are also possible.

- light cyan may be expressed using LC, light magenta using LM, and orange using O.

- the image editing apparatus 12 includes an image data input unit 20, an image data storage unit 22, an image processing unit 24, and a control unit 26.

- the image editing device 12 includes an image reading unit 30, a colorimeter, a display unit 34, and an input device 36.

- the image editing device 12 can be realized by a combination of computer hardware and software.

- the image editing device 12 can be realized as a function of the RIP device.

- RIP is an abbreviation for Raster Image Processor.

- software terms can be treated as synonymous with program terms.

- the image data input unit 20 is a data acquisition unit for taking in the original image data 40.

- the image data input unit 20 can be configured by a data input terminal that takes in the document image data 40 from an external or other signal processing unit in the apparatus.

- a wired or wireless communication interface unit may be employed, a media interface unit for reading and writing an external storage medium such as a memory card may be employed, or an appropriate one of these modes may be employed. It may be a combination.

- External storage media such as memory cards include what are called removable disks.

- the target printed material 42 is a color sample printed material of the target color to be reproduced, and is given as an actual color sample.

- the document image data 40 is digital image data representing the image content to be printed.

- the document image data 40 is image data indicating the pattern of the document image of the target printed matter 42.

- the printer or printing apparatus that outputs the target printed matter 42 as an image, the printing conditions, and the like may be unknown. Any printer can be used as the output means for the target printed matter 42.

- the document image data 40 and the target printed material 42 are provided from the requester of printing.

- the document image data 40 may be entire image data indicating the entire image content on the printing surface of the target printed matter 42, data of image components as a part of an image recorded on the printing surface, or document components. It may be the data.

- the data format of the document image data 40 is not particularly limited.

- 8-bit image data expressing each color of CMYK with 256 gradations is used as the document image data 40.

- the original image data 40 is not limited to the CMYK signal, and may be in the form of an RGB signal, or a combination of a CMYK signal and a special color signal. It may be a format. Also, the number of gradations of the signal or the number of bits of the signal is not limited to this example.

- the CMYK signal is a color image signal expressed using cyan, magenta, yellow, and blue colors.

- the RGB signal is a color image signal expressed using red, green, and blue colors.

- the image data storage unit 22 is means for storing document image data 40 acquired via the image data input unit 20. Document image data 40 captured from the image data input unit 20 is stored in the image data storage unit 22.

- the image reading unit 30 reads a printed matter such as the target printed matter 42 or the printed matter 50 printed by the printing apparatus 18, converts the optical image into electronic image data, and creates read image data as a color image representing the read image.

- a color image scanner capable of outputting the read image as RGB image data can be used for the image reading unit 30.

- the read image data is shown in FIG.

- a scanner capable of acquiring read image data represented by image signals of RGB color components is used.

- a read image acquired from the image reading unit 30 may be referred to as a scan image.

- a camera can be used instead of the scanner.

- the image reading unit 30 functions as a means for acquiring read image data of the target printed matter 42. Further, the image reading unit 30 functions as a unit that reads the printed matter 50 printed by the printing device 18 and acquires the read image data of the printed matter 50. The read image data acquired via the image reading unit 30 is sent to the image processing unit 24.

- the image processing unit 24 creates a color conversion table based on the read image data acquired from the image reading unit 30 and the document image data 40.

- the image processing unit 24 has a function of performing color conversion processing using the color conversion table on the document image data 40 and generating image data to be transferred to the printing apparatus 18.

- the image processing unit 24 has a function of performing processing such as resolution conversion and gradation conversion on the document image data 40 and the read image data as necessary. Details of processing contents in the image processing unit 24 will be described later.

- the printing system 10 shown in the present embodiment may include a colorimeter in order to increase the accuracy of color information of the read image by the image reading unit 30.

- the color measuring device corresponds to a color measuring unit.

- a spectrocolorimeter is used as the colorimeter. The spectrocolorimeter measures the reflectance of the visible light wavelength region at a predetermined wavelength increment, calculates the XYZ value using the XYZ color matching function representing the human visual spectral sensitivity, and obtains the colorimetric value To do.

- a spectrocolorimeter used as a colorimeter measures, for example, a reflectance of a wavelength region of 380 nm or more and 730 nm or less, which is a wavelength region of visible light, with a wavelength increment of 10 nm, and a colorimetric value Get.

- the wavelength step size is sometimes called a wavelength step.

- the XYZ values obtained from the colorimeter can be converted into color coordinate values in a device-independent color space such as the L * a * b * color system by a known conversion formula.

- the L * a * b * color system is used as the color system of the device-independent color space representing the target value of the color.

- the color system is not limited to this. Absent.

- an XYZ color system using a stimulus value Y including brightness or brightness, a stimulus value X of color, and a stimulus value Z of color, brightness Y, chromaticity coordinates x, and chromaticity defined by the International Commission on Illumination In addition to the Yxy color system using the coordinate y, the L * u * v * color system, the HSV color system using the hue H, the saturation S, and the lightness V, the hue H, the saturation S, and the luminance L HLS color system using, it is possible to use the luminance Y, chrominance C b, and a YC b C r color system with a color difference C r.

- the color system may be described as a color coordinate system.

- the hue may be expressed by using the initial letter H of hue in English.

- Saturation may be expressed using the initial letter S of saturation in English.

- the lightness may be expressed using the initial letter V of value in English or the initial letter B of brightness.

- Luminance may be expressed using the initial letter L in English.

- the color space of the L * a * b * color system is denoted as the Lab color space

- the chromaticity value represented by the coordinate value of the Lab color space is denoted as the Lab value.

- image data in which the image signal value of each pixel is described by a Lab value may be referred to as a Lab image.

- a color value represented by the color system coordinates of a device-independent color space that is a device-independent color space, such as the Lab color space, is expressed as a chromaticity value.

- Image processing unit 24 creates the color conversion table by taking into consideration the information of the colorimetric values acquired from the colorimeter in addition to the read image data obtained from the image reading unit 30. Can do.

- the control unit 26 controls the operation of each unit of the image editing device 12.

- the display unit 34 and the input device 36 function as a user interface.

- the input device 36 can employ various means such as a keyboard, a mouse, a touch panel, or a trackball, and may be an appropriate combination thereof.

- positioned the touch panel on the screen of the display part 34 is also possible.