WO2012118127A1 - Nonaqueous secondary battery - Google Patents

Nonaqueous secondary battery Download PDFInfo

- Publication number

- WO2012118127A1 WO2012118127A1 PCT/JP2012/055115 JP2012055115W WO2012118127A1 WO 2012118127 A1 WO2012118127 A1 WO 2012118127A1 JP 2012055115 W JP2012055115 W JP 2012055115W WO 2012118127 A1 WO2012118127 A1 WO 2012118127A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- electrode

- secondary battery

- positive electrode

- current collector

- conductive material

- Prior art date

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/64—Carriers or collectors

- H01M4/66—Selection of materials

- H01M4/665—Composites

- H01M4/667—Composites in the form of layers, e.g. coatings

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/50—Current conducting connections for cells or batteries

- H01M50/531—Electrode connections inside a battery casing

- H01M50/534—Electrode connections inside a battery casing characterised by the material of the leads or tabs

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/50—Current conducting connections for cells or batteries

- H01M50/531—Electrode connections inside a battery casing

- H01M50/536—Electrode connections inside a battery casing characterised by the method of fixing the leads to the electrodes, e.g. by welding

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/50—Current conducting connections for cells or batteries

- H01M50/531—Electrode connections inside a battery casing

- H01M50/54—Connection of several leads or tabs of plate-like electrode stacks, e.g. electrode pole straps or bridges

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/04—Construction or manufacture in general

- H01M10/0413—Large-sized flat cells or batteries for motive or stationary systems with plate-like electrodes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/50—Current conducting connections for cells or batteries

- H01M50/528—Fixed electrical connections, i.e. not intended for disconnection

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Definitions

- the present invention relates to a non-aqueous secondary battery, and more particularly to a non-aqueous secondary battery having an electrode in which an active material layer is formed on a current collector.

- Non-aqueous secondary batteries represented by lithium ion secondary batteries have high capacity and high energy density, and are excellent in storage performance and charge / discharge repetition characteristics. It's being used. In recent years, lithium ion secondary batteries have come to be used for electric power storage applications and in-vehicle applications such as electric vehicles due to increasing awareness of environmental issues and energy savings.

- the non-aqueous secondary battery has a high risk of abnormal overheating or ignition when exposed to an overcharged state or a high temperature environment because of its high energy density. Therefore, various countermeasures for safety are taken in the non-aqueous secondary battery.

- Patent Document 1 proposes a lithium ion secondary battery using a current collector in which a metal layer is formed on both surfaces of a resin film having a low melting point of 130 ° C. to 170 ° C.

- a current collector in which a metal layer is formed on both surfaces of a resin film having a low melting point of 130 ° C. to 170 ° C.

- the low melting point resin film melts. And the electrode is damaged by melting of the resin film. Thereby, since an electric current is cut, the temperature rise inside a battery is suppressed and ignition is prevented.

- the current collector proposed in Patent Document 1 is very effective as a safety measure for non-aqueous secondary batteries, and can ensure safety under normal use conditions. .

- the present invention has been made to solve the above-described problems, and an object of the present invention is to provide a nonaqueous secondary battery capable of further improving safety.

- the present invention provides an electrode including a current collector having a multilayer structure in which an insulating layer is sandwiched between conductive layers, an active material layer formed on the current collector, and a connection to the electrode.

- a tab electrode for drawing out the wiring, and the tab electrode is electrically connected to the electrode through a conductive material formed of a low melting point metal.

- the current collector insulating layer melts and the electrode is damaged. Can be cut. Thereby, since the temperature rise inside a battery can be suppressed, it can prevent that abnormal states, such as ignition, arise.

- the tab electrode by electrically connecting the tab electrode to the electrode through a conductive material made of a low melting point metal, if the temperature inside the battery rises due to some cause such as an overcharged state, the tab electrode becomes conductive at the temperature inside the battery. The material can be melted. Thereby, the electrical connection between the tab electrode and the electrode can be interrupted.

- the current can be interrupted not only by the current collector having the multilayer structure but also by the conductive material connecting the tab electrode and the electrode, so that the safety can be further improved.

- the current can be interrupted by a current collector having a multilayer structure.

- the temperature rise inside a battery can be suppressed.

- the conductive material is made of a metal material that melts due to heat generated in the battery. If comprised in this way, since the abnormal heat generation of a battery can be suppressed easily, the non-aqueous secondary battery in which safety

- a plurality of electric electrodes are stacked, and the tab electrode is electrically connected to at least a part of the electrodes via the conductive material. If comprised in this way, a tab electrode and an electrode can be electrically connected easily via a electrically conductive material.

- the conductive material is configured as a penetrating member that penetrates the electrode in the thickness direction. If comprised in this way, a tab electrode and an electrode can be electrically connected easily via a electrically conductive material.

- the current collector has a configuration in which an insulating layer is sandwiched between conductive layers, for example, in the case of a stacked non-aqueous secondary battery in which a plurality of electrodes are stacked, a tab electrode for wiring extraction When the electrode is connected to the current collector, conduction between the electrodes cannot be obtained. For this reason, when the collector which has a multilayer structure is used in order to improve safety, the problem that battery performance falls will arise. Note that the battery performance can be degraded even when the electrode using the current collector having a multilayer structure is a single layer.

- the penetrating member can electrically connect the conductive layer on one side of the insulating layer and the conductive layer on the other side of the current collector. Therefore, even when a current collector having a multilayer structure is used, a decrease in battery performance can be suppressed.

- the non-aqueous secondary battery having the above-described configuration, it is more preferable that a plurality of the electrodes are stacked and the penetrating member continuously penetrates the plurality of electrodes in the thickness direction. If comprised in this way, since a tab electrode can be electrically connected with a some electrode (for example, all the electrodes), the fall of battery performance can be suppressed effectively. As a result, the performance of the non-aqueous secondary battery can be maximized.

- the conductive material is formed in a foil shape, and the conductive material is connected to the electrode so that a part of the conductive material extends outside the electrode. More preferably, the extended portion is connected to the tab electrode. If comprised in this way, a tab electrode and an electrode can be electrically connected easily via a electrically conductive material. In addition, even when a current collector having a multilayer structure is used, a decrease in battery performance can be suppressed.

- a plurality of the electrodes are stacked, the conductive material is disposed between the electrodes, and the extended portions of the conductive material are welded to the tab electrodes, respectively. More preferably. If comprised in this way, since a tab electrode can be electrically connected with a some electrode (for example, all the electrodes), the fall of battery performance can be suppressed effectively. As a result, the performance of the non-aqueous secondary battery can be maximized.

- the non-aqueous secondary battery having the above-described configuration includes a foil-like member formed of a conductive material, and is connected to the electrode so that a part of the foil-like member extends outside the electrode. More preferably, the extended portion of the foil-like member is welded to the tab electrode by the conductive material. If comprised in this way, a tab electrode and an electrode can be electrically connected easily via a electrically conductive material. In addition, even when a current collector having a multilayer structure is used, a decrease in battery performance can be suppressed.

- the non-aqueous secondary battery having the above-described configuration, it is more preferable that a plurality of the electrodes are stacked and the foil-like member is disposed between each of the electrodes. If comprised in this way, since a tab electrode can be electrically connected with a some electrode (for example, all the electrodes), the fall of battery performance can be suppressed effectively. As a result, the performance of the non-aqueous secondary battery can be maximized.

- the conductive material has a melting point equal to or higher than the melting point of the insulating layer of the current collector. If comprised in this way, the abnormal heat generation inside a battery which was difficult to prevent with the collector which has a multilayer structure can be prevented by fusing of a conductive material. Thereby, safety can be improved more easily.

- the conductive material may be configured to have a melting point lower than the melting point of the insulating layer of the current collector. With this configuration, the conductive material can be blown before the insulating layer of the current collector is melted. For this reason, even when comprised in this way, the safety

- the conductive material is made of an alloy mainly composed of any one of indium, zinc, gallium, tin, and bismuth. If comprised in this way, a conductive material can be easily blown out by the abnormal heat generation inside a battery.

- the electrode includes a positive electrode and a negative electrode, and at least one of the positive electrode and the negative electrode is formed using the current collector having a multilayer structure. If comprised in this way, the safety

- the insulating layer is formed of a film-like or fibrous resin.

- the insulating layer is formed of a thermoplastic resin, and the thermal shrinkage rate at 120 ° C. of the insulating layer is 1.5% or more in any one of the planar directions. More preferred. If comprised in this way, when abnormal heat_generation

- the insulating layer is made of a resin containing any of polyolefin resins, a resin containing any of polystyrene, polyvinyl chloride, or polyamide, or a composite material thereof. If comprised in this way, the safety

- the electrode includes a positive electrode and a negative electrode, and includes a separator disposed between the positive electrode and the negative electrode. It is more preferable that it is smaller. If comprised in this way, when abnormal heat_generation

- the heat shrinkage rate of the separator at 180 ° C. is 1.0% or less. If comprised in this way, when abnormal heat_generation

- the separator includes any one of an aramid resin, a polyester resin, and a cellulose resin.

- the present invention also provides an electrode including a current collector having a multilayer structure in which an insulating layer is sandwiched between conductive layers, an active material layer formed on the current collector, and a wiring lead connected to the electrode. And a tab electrode, wherein the tab electrode is electrically connected to the electrode via a conductive material whose resistance increases in response to a temperature change.

- the temperature inside the battery rises for some reason by electrically connecting the tab electrode to the electrode through a conductive material whose resistance increases in response to a temperature change, the temperature inside the battery is increased.

- the resistance of the conductive material can be increased.

- conduction between the tab electrode and the electrode can be interrupted.

- the resistance of the conductive material may increase due to the current. Even in such a case, conduction between the tab electrode and the electrode can be interrupted.

- the safety of the non-aqueous secondary battery can be further improved.

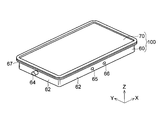

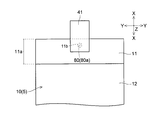

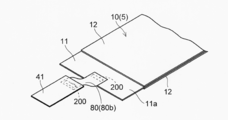

- FIG. 1 is an exploded perspective view of a lithium ion secondary battery according to a first embodiment of the present invention.

- 1 is an exploded perspective view of an electrode group of a lithium ion secondary battery according to a first embodiment of the present invention.

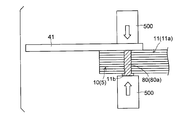

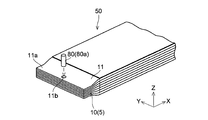

- 1 is an overall perspective view of a lithium ion secondary battery according to a first embodiment of the present invention. It is sectional drawing which expanded and showed a part of FIG. It is sectional drawing which showed typically the connection method of the tab electrode in the lithium ion secondary battery by 1st Embodiment of this invention.

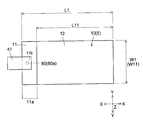

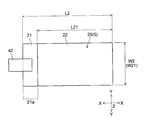

- FIG. 12 is a cross-sectional view of the positive electrode of the lithium ion secondary battery according to the first embodiment of the present invention (a view corresponding to a cross section taken along line AA in FIG. 10). It is a top view of the positive electrode of the lithium ion secondary battery by 1st Embodiment of this invention.

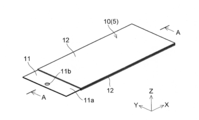

- 1 is a perspective view of a positive electrode of a lithium ion secondary battery according to a first embodiment of the present invention. It is the top view which showed typically a part of positive electrode used for the lithium ion secondary battery by 1st Embodiment of this invention.

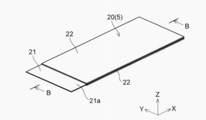

- FIG. 17 is a cross-sectional view of the negative electrode of the lithium ion secondary battery according to the first embodiment of the present invention (a diagram corresponding to a cross section taken along line BB in FIG. 16). It is a top view of the negative electrode of the lithium ion secondary battery by 1st Embodiment of this invention.

- 1 is a perspective view of a negative electrode of a lithium ion secondary battery according to a first embodiment of the present invention.

- 1 is a perspective view of a separator of a lithium ion secondary battery according to a first embodiment of the present invention.

- FIG. 1 is a cross-sectional view schematically showing an electrode group of a lithium ion secondary battery according to a first embodiment of the present invention.

- FIG. 2 is an exploded perspective view of the lithium ion secondary battery according to the first embodiment of the present invention.

- FIG. 3 is an exploded perspective view of an electrode group of the lithium ion secondary battery according to the first embodiment of the present invention.

- 4 to 16 are views for explaining the lithium ion secondary battery according to the first embodiment of the present invention.

- the lithium ion secondary battery according to the first embodiment is a large-sized secondary battery having a square flat shape as shown in FIGS.

- the lithium ion secondary battery includes an electrode group 50 (see FIGS. 1 and 2) including a plurality of electrodes 5 and a metal outer container 100 that encloses the electrode group 50 together with a non-aqueous electrolyte.

- the electrode 5 includes a positive electrode 10 and a negative electrode 20. Between the positive electrode 10 and the negative electrode 20, a separator 30 for suppressing a short circuit between the positive electrode 10 and the negative electrode 20 is disposed. Specifically, the positive electrode 10 and the negative electrode 20 are arranged so as to face each other with the separator 30 interposed therebetween, and the positive electrode 10, the separator 30, and the negative electrode 20 are sequentially laminated to form a laminated structure (laminated body). Has been. Note that the positive electrodes 10 and the negative electrodes 20 are alternately stacked one by one. The electrode group 50 is configured such that one positive electrode 10 is positioned between two adjacent negative electrodes 20.

- the electrode group 50 includes, for example, 13 positive electrodes 10, 14 negative electrodes 20, and 28 separators 30, and the positive electrodes 10 and the negative electrodes 20 are alternately stacked with the separators 30 interposed therebetween. Further, a separator 30 is disposed on the outermost side of the electrode group 50 (outside of the outermost negative electrode 20), and insulation from the outer container 100 is achieved.

- the positive electrode 10 and the negative electrode 20 are connected to tab electrodes 41 and 42 for drawing out wiring, respectively.

- the tab electrode 41 connected to the positive electrode 10 is electrically connected to the positive electrode 10 via a conductive member (conductive material) 80 made of a low melting point metal.

- the low melting point metal constituting the conductive member 80 is made of a metal material that melts due to the heat generated inside the battery.

- the electrically-conductive member 80 is comprised by the penetration member 80a which penetrates the said positive electrode 10 (electrode) in the thickness direction.

- the positive electrode 10 constituting the electrode group 50 has a structure in which the positive electrode active material layer 12 is supported on both surfaces of the positive electrode current collector 11 as shown in FIG.

- the positive electrode current collector 11 has a function of collecting current from the positive electrode active material layer 12.

- the positive electrode current collector 11 has a multilayer structure (three-layer structure) in which the conductive layers 14 are formed on both surfaces of the insulating resin layer 13.

- the resin layer 13 is an example of the “insulating layer” in the present invention.

- the conductive layer 14 constituting the positive electrode current collector 11 is made of, for example, aluminum or an aluminum alloy, and has a thickness of about 4 ⁇ m to about 10 ⁇ m. Since aluminum is easily passivated, it can be suitably used as the conductive layer 14 of the positive electrode current collector 11.

- the said conductive layer 14 may be other than aluminum or aluminum alloy, for example, may be comprised from metal materials, such as titanium, stainless steel, nickel, or these alloys.

- the method for forming the conductive layer 14 is not particularly limited, and examples thereof include a method by vapor deposition, sputtering, electrolytic plating, electroless plating, bonding of metal foil, and the like, and a method composed of a combination of these methods.

- the resin layer 13 of the positive electrode current collector 11 is made of a plastic material made of a thermoplastic resin.

- This resin layer 13 consists of a sheet-like resin member (resin film), for example.

- the thermoplastic resin constituting the plastic material for example, polyolefin resins such as polyethylene (PE) and polypropylene (PP) having a heat distortion temperature of 150 ° C. or less, polystyrene (PS), polyvinyl chloride, polyamide, etc. are suitable. Used for.

- polyolefin resins such as polyethylene (PE) and polypropylene (PP), which have a heat shrinkage rate at 120 ° C. of 1.5% or more in any direction in the plane direction, and polyvinyl chloride are preferable.

- these composite films and the resin film which gave these surface treatment processes can also be used suitably.

- a resin film made of the same material as that of the separator 30 can be used.

- any resin having different heat deformation temperature, heat shrinkage rate, etc. can be used for both the resin layer 13 and the separator 30 due to differences in manufacturing process and processing.

- the thickness of the resin layer 13 is not particularly limited, but is preferably 5 ⁇ m or more and 70 ⁇ m or less, and more preferably 10 ⁇ m or more and 50 ⁇ m or less in order to balance the energy density improvement and strength maintenance as a secondary battery.

- the resin layer 13 (resin film) may be a resin film manufactured by any method such as uniaxial stretching, biaxial stretching, or non-stretching.

- the resin layer 13 of the positive electrode current collector 11 may be, for example, in the form of a fiber other than a film.

- the positive electrode current collector 11 has a film shape, a sheet shape, a net shape, a punched or expanded shape, a lath body, a porous body, a foamed body, a formed body of fiber groups, and the like. Also good.

- the above heat deformation temperature and heat shrinkage mean values obtained by the following method.

- the heat deformation temperature means a temperature at which the resin layer (resin film) starts to shrink (the same applies to the separator described later).

- the heat distortion temperature is kept at a constant temperature for a certain time in a thermostatic chamber, the heat shrinkage rate is measured, the temperature is increased if not contracted, the temperature is decreased if contracted, and this is repeated.

- the resin film is held at, for example, 100 ° C. for 15 minutes, and the thermal shrinkage rate of the resin film is measured.

- the heat shrinkage rate at this time is 20% or less

- the temperature is raised to 105 ° C. using a new sample, and the heat shrinkage rate is measured after holding at this temperature for 15 minutes. This process is repeated until the temperature reaches 150 ° C., and the temperature at which the heat shrinkage rate becomes 10% or more is defined as the heat distortion temperature.

- the heat shrinkage rate is measured, for example, by attaching two points on the resin film with an interval of 50 mm or more and measuring the distance between the two points using a caliper. Then, after heat-processing for 15 minutes at 120 degreeC (180 degreeC also about the separator mentioned later), the same distance between points is measured again, and a thermal contraction rate is calculated

- the distance between three or more points is measured for each of the plane directions (for example, the vertical direction and the horizontal direction) of the resin layer (resin film). And the average value of the thermal contraction rate computed from each measurement result is employ

- the longitudinal direction and the lateral direction of the resin film at least two points within 10% from the end of the resin film and one point around 50% from the end of the resin film are measured points of the distance between points.

- Select as Any large value in the plane direction (for example, the vertical direction and the horizontal direction) is defined as the heat shrinkage rate.

- the positive electrode active material layer 12 includes a positive electrode active material that can occlude and release lithium ions.

- the positive electrode active material include an oxide containing lithium. Specific examples include LiCoO 2 , LiFeO 2 , LiMnO 2 , LiMn 2 O 4 , and compounds in which transition metals in these oxides are partially substituted with other metal elements.

- a positive electrode active material that can utilize 80% or more of the lithium amount possessed by the positive electrode for the battery reaction. Thereby, it becomes possible to improve the safety of the secondary battery against accidents such as overcharging.

- a positive electrode active material for example, a compound having a spinel structure such as LiMn 2 O 4 and Li X MPO 4 (M is at least one selected from Co, Ni, Mn, and Fe). And a compound having an olivine structure represented by (element).

- a positive electrode active material containing at least one of Mn and Fe is preferable from the viewpoint of cost.

- LiFePO 4 from the viewpoint of safety and charging voltage. In LiFePO 4 , since all oxygen (O) is bonded to phosphorus (P) by a strong covalent bond, release of oxygen due to a temperature rise hardly occurs. Therefore, it is excellent in safety.

- the thickness of the positive electrode active material layer 12 is preferably about 20 ⁇ m to 2 mm, and more preferably about 50 ⁇ m to 1 mm.

- the configuration of the positive electrode active material layer 12 is not particularly limited as long as it includes at least the positive electrode active material.

- the positive electrode active material layer 12 may include other materials such as a conductive material, a thickener, and a binder in addition to the positive electrode active material.

- the conductive material is not particularly limited as long as it is an electron conductive material that does not adversely affect the battery performance of the positive electrode 10.

- carbon black, acetylene black, ketjen black, graphite (natural graphite, artificial graphite), carbonaceous material such as carbon fiber, or conductive metal oxide can be used as the conductive material.

- carbon black and acetylene black are preferable from the viewpoints of electron conductivity and coatability.

- the thickener for example, polyethylene glycols, celluloses, polyacrylamides, poly N-vinyl amides, poly N-vinyl pyrrolidones and the like can be used.

- celluloses such as polyethylene glycols and carboxymethyl cellulose (CMC) are preferable, and CMC is particularly preferable.

- the binder plays a role of holding the active material particles and the conductive material particles together.

- the binder for example, fluorine-based polymers such as polyvinylidene fluoride (PVDF), polyvinyl pyridine, and polytetrafluoroethylene, polyolefin-based polymers such as polyethylene and polypropylene, styrene-butadiene rubber, and the like can be used.

- Examples of the solvent for dispersing the positive electrode active material, the conductive material, the binder, etc. include N-methyl-2-pyrrolidone, dimethylformamide, dimethylacetamide, methyl ethyl ketone, cyclohexanone, methyl acetate, methyl acrylate, diethyltriamine, N, Organic solvents such as N-dimethylaminopropylamine, ethylene oxide, and tetrahydrofuran can be used.

- the positive electrode 10 described above is prepared by mixing a positive electrode active material, a conductive material, a thickener and a binder, and adding an appropriate solvent to form a paste-like positive electrode mixture.

- the positive electrode mixture is applied and dried on the surface of the positive electrode current collector 11, and is compressed to increase the electrode density as necessary.

- the positive electrode 10 has a substantially rectangular shape in plan view.

- the width W1 in the Y direction of the positive electrode 10 is about 100 mm, for example, and the length L1 in the X direction is about 150 mm, for example.

- the width W11 in the Y direction is the same as the width W1 of the positive electrode 10 (for example, about 100 mm), and the length L11 in the X direction is about 135 mm, for example. It is said that.

- the positive electrode 10 has a current collector in which the surface (conductive layer 14) of the positive electrode current collector 11 is exposed without forming the positive electrode active material layer 12 on one end side in the X direction. It has an exposed portion (exposed region) 11a.

- a tab electrode 41 for taking out a current to the outside is electrically connected to the current collector exposed portion 11a.

- the tab electrode 41 is formed in a shape having a width of about 30 mm and a length of about 70 mm, for example.

- the current collector exposed portion 11a of the positive electrode 10 is formed with a through hole 11b penetrating in the thickness direction.

- the through holes 11b are formed so that the through holes 11b of the respective positive electrodes 10 are aligned (overlap) when a plurality of the positive electrodes 10 are laminated.

- the conductive member 80 (through member 80a) (see FIG. 1) formed in a substantially rod shape is inserted into the through hole 11b of the positive electrode 10.

- the negative electrode 20 constituting the electrode group 50 has a configuration in which a negative electrode active material layer 22 is supported on both surfaces of a negative electrode current collector 21, as shown in FIG.

- the negative electrode current collector 21 has a function of collecting current from the negative electrode active material layer 22.

- the negative electrode current collector 21 does not include a resin layer. That is, only the positive electrode current collector 11 (see FIG. 8) has a multilayer structure including a resin layer.

- the negative electrode current collector 21 is made of, for example, a metal foil such as copper, nickel, stainless steel, iron, or a nickel plating layer, or an alloy foil made of these alloys.

- the thickness of the negative electrode current collector 21 is formed to be about 1 ⁇ m to about 100 ⁇ m (for example, about 16 ⁇ m).

- the negative electrode current collector 21 is preferably a metal foil made of copper or a copper alloy from the viewpoint that it is difficult to alloy with lithium, and the thickness thereof is preferably 4 ⁇ m or more and 20 ⁇ m or less.

- the negative electrode current collector 21 has a film shape, a sheet shape, a net shape, a punched or expanded shape, a lath body, a porous body, a foamed body, a formed body of fiber groups, and the like. Also good.

- the negative electrode active material layer 22 includes a negative electrode active material that can occlude and release lithium ions.

- a negative electrode active material for example, a material containing lithium or a material capable of occluding and releasing lithium is used.

- the potential for insertion / extraction of lithium is close to the deposition / dissolution potential of metallic lithium.

- Typical examples thereof include particulate natural graphite or artificial graphite (scale-like, lump-like, fibrous, whisker-like, spherical, pulverized particle-like, etc.).

- the negative electrode active material artificial graphite obtained by graphitizing mesocarbon microbeads, mesophase pitch powder, isotropic pitch powder, or the like may be used. Further, graphite particles having amorphous carbon attached to the surface can also be used. Furthermore, lithium transition metal oxides, lithium transition metal nitrides, transition metal oxides, silicon oxides, and the like can also be used. As the lithium transition metal oxide, for example, when lithium titanate represented by Li 4 Ti 5 O 12 is used, the deterioration of the negative electrode 20 is reduced, so that the battery life can be extended.

- the thickness of the negative electrode active material layer 22 is preferably about 20 ⁇ m to 2 mm, and more preferably about 50 ⁇ m to 1 mm.

- the configuration of the negative electrode active material layer 22 is not particularly limited as long as it includes at least the negative electrode active material.

- the negative electrode active material layer 22 may include other materials such as a conductive material, a thickener, and a binder in addition to the negative electrode active material.

- a conductive material, a thickening material, and a binder can be the same as the positive electrode active material layer 12 (that can be used for the positive electrode active material layer 12).

- the negative electrode 20 described above is mixed with a negative electrode active material, a conductive material, a thickener and a binder, and an appropriate solvent is added to obtain a paste-like negative electrode mixture.

- This negative electrode mixture is applied and dried on the surface of the negative electrode current collector 21, and is compressed to increase the electrode density as necessary.

- the negative electrode 20 has a substantially rectangular shape in plan view, and is formed to be slightly larger than the positive electrode 10 (see FIGS. 9 and 10).

- the negative electrode 20 has a width W2 in the Y direction of about 110 mm, for example, and a length L2 in the X direction is the same as the length L1 of the positive electrode 10 (see FIG. 9) ( For example, about 150 mm).

- the width W21 in the Y direction is the same as the width W2 of the negative electrode 20 (for example, about 110 mm), and the length L21 in the X direction is, for example, about 140 mm. It is said that.

- the negative electrode 20 is a current collector in which the surface of the negative electrode current collector 21 is exposed without forming the negative electrode active material layer 22 at one end in the X direction, like the positive electrode 10. It has an exposed portion 21a.

- a tab electrode 42 for taking out current to the outside is electrically connected to the current collector exposed portion 21a.

- the tab electrode 42 is formed in a shape of, for example, a width of about 30 mm and a length of about 70 mm, similar to the tab electrode 41.

- the separator 30 constituting the electrode group 50 is appropriately selected from, for example, electrically insulating synthetic resin fibers, non-woven fabrics such as glass fibers and natural fibers, woven fabrics, or microporous membranes. Is possible. Among these, non-woven fabrics such as polyethylene, polypropylene, polyester, aramid resins, and cellulose resins, and microporous membranes are preferable from the viewpoint of quality stability, and in particular, non-woven fabrics composed of aramid resins, polyester resins, or cellulose resins. A microporous membrane is preferred.

- the separator 30 preferably has a higher melting point than the resin layer 13 of the positive electrode current collector 11.

- the separator 30 is preferably configured so that the thermal contraction rate at 120 ° C. is smaller than that of the resin layer 13 of the positive electrode current collector 11.

- the separator 30 preferably has a thermal shrinkage rate of 1.0% or less at a temperature not higher than the heat deformation temperature (or melting point) of the resin layer 13 of the positive electrode current collector 11.

- the separator 30 is preferably composed of a porous film containing an aramid resin, a polyester resin, a cellulose resin, etc., and its thermal shrinkage rate is preferably 1.0% or less at 180 ° C.

- the thickness of the separator 30 is not particularly limited, but is a thickness that can hold a necessary amount of electrolyte and can prevent a short circuit between the positive electrode 10 and the negative electrode 20. Is preferred. Specifically, the separator 30 can have a thickness of 0.02 mm (20 ⁇ m) to 0.1 mm (100 ⁇ m), for example. The thickness of the separator 30 is preferably about 0.01 mm to 1 mm, more preferably about 0.02 mm to 0.07 mm. The material constituting the separator 30 is such that the air permeability per unit area (1 cm 2 ) is about 0.1 sec / cm 3 to 500 sec / cm 3 while maintaining a low battery internal resistance. This is preferable because strength sufficient to prevent an internal short circuit can be secured.

- the heat-deformation temperature and heat-shrink rate mean the value obtained by the method similar to the resin layer (resin film) mentioned above.

- heat treatment is performed at 120 ° C.

- heat treatment is performed at 180 ° C.

- the separator 30 is larger than the application region (formation region) of the positive electrode active material layer 12 and is equal to the application region (formation region) of the negative electrode active material layer 22 or the application region (formation region) of the negative electrode active material layer 22.

- the separator 30 is formed in a rectangular shape, and the width W3 in the Y direction is, for example, about 110 mm, and the length L3 in the X direction is, for example, about 150 mm.

- the positive electrode 10 and the negative electrode 20 are arranged such that the current collector exposed portion 11a of the positive electrode 10 and the current collector exposed portion 21a of the negative electrode 20 are positioned on opposite sides. They are stacked with a separator 30 interposed between the negative electrodes.

- the current collector exposed portion 11 a of the stacked positive electrode 10 is electrically conductive through the positive electrode current collector 11 having a multilayer structure in the thickness direction.

- a member 80 (penetrating member 80a) is provided. The conductive member 80 is inserted through the through hole 11 b of the positive electrode current collector 11, thereby continuously passing through all of the stacked positive electrodes 10 (electrodes 5 having the same polarity).

- the conductive member 80 is made of a metal material that melts due to heat generated in the battery.

- a metal material for example, an alloy mainly containing any one of indium, zinc, gallium, tin, and bismuth can be used. Specific examples include a tin-bismuth alloy (melting point: about 130 ° C. to 150 ° C.) and indium (melting point: 156.4 ° C.).

- the conductive member 80 may have a melting point equal to or higher than the melting point of the resin layer 13 of the positive electrode current collector 11, or may have a melting point lower than the melting point of the resin layer 13.

- the through hole 11b of the positive electrode current collector 11 is formed to have the same diameter as that of the conductive member 80 as shown in FIGS.

- the conductive member 80 is inserted into the through hole 11b, so that the surface (outer surface) of the conductive member 80 is in close contact (electrical contact) with the inner side surface of the through hole 11b.

- the conductive layer 14 on one side and the conductive layer 14 on the other side of the resin layer 13 in the positive electrode current collector 11 are electrically connected to each other via the conductive member 80.

- the conductive member 80 continuously penetrates all the positive electrodes 10, all the stacked positive electrodes 10 are electrically connected to each other.

- the conductive member 80 inserted through the through hole 11 b is pressed in the thickness direction (see white arrow) by the welding machine 500, for example, so that the protruding portion of the conductive member 80 is It is crushed and squeezed.

- the tab electrode 41 for wiring connection is electrically connected to each of the positive electrodes 10 via the conductive member 80.

- the conductive member 80 that electrically connects the tab electrode 41 and the positive electrode 10 is provided at one location of the current collector exposed portion 11a of the positive electrode current collector 11, as shown in FIGS. Also good. Further, the conductive member 80 may be provided at a plurality of locations on the current collector exposed portion 11a. Thus, by providing (penetrating) the conductive member 80 at a plurality of locations on the current collector exposed portion 11a, the contact resistance between the positive electrodes is reduced, so that the conduction between the electrodes (between the positive electrodes) is improved.

- the above-described tab electrode 41 is welded and fixed to the outermost positive electrode 10 (the conductive layer 14 of the positive electrode current collector 11) via a conductive member 80 made of a low melting point metal.

- the tab electrode 41 may be welded to the positive electrode 10 of the intermediate layer instead of the outermost layer.

- the tab electrode 41 is welded and fixed so as to overlap the conductive member 80 at a substantially central portion in the width direction (Y direction) of the positive electrode current collector 11 (positive electrode 10). Yes. Thereby, all the laminated positive electrodes 10 (all the conductive layers 14) are electrically connected to the tab electrode 41 through the conductive member 80.

- the tab electrode 41 is connected to the electrode (positive electrode 10) via the conductive member 80, the conductive member 80 is blown when abnormal heat is generated inside the battery. The current is cut off.

- the plurality of negative electrodes 20 are laminated so that the current collector exposed portions 21a are aligned, as with the positive electrode 10.

- the tab electrode 42 is fixed by welding to the outermost negative electrode 20 (negative electrode current collector 21).

- the tab electrode 42 may be welded to the negative electrode 20 of the intermediate layer instead of the outermost layer. Thereby, all the laminated negative electrodes 20 are welded and fixed to the tab electrode 42 and are electrically connected to the tab electrode 42.

- the tab electrode 42 is welded and fixed to a substantially central portion in the width direction (Y direction) of the negative electrode current collector 21 (negative electrode 20).

- the welding of the tab electrodes 41 and 42 is preferably ultrasonic welding, but may be other than ultrasonic welding, for example, laser welding, resistance welding, spot welding, or the like may be used.

- the resin layer 13 may be dissolved by a method of joining by applying heat such as laser welding, resistance welding, or spot welding. There is. Therefore, it is preferable to use ultrasonic welding without applying heat for the welding of the tab electrode 41.

- the tab electrode 41 connected to the positive electrode 10 is preferably made of aluminum, and the tab electrode 42 connected to the negative electrode 20 is preferably made of copper.

- the tab electrodes 41 and 42 are preferably made of the same material as the current collector, but may be made of different materials. Further, the tab electrode 41 connected to the positive electrode 10 and the tab electrode 42 connected to the negative electrode 20 may be made of the same material or different materials.

- the tab electrodes 41 and 42 are preferably welded to substantially the center portion in the width direction of the positive electrode current collector 11 and the negative electrode current collector 21 as described above, but are fixed to the regions other than the center portion by welding. May be.

- the nonaqueous electrolytic solution enclosed with the electrode group 50 in the outer container 100 is not particularly limited, but examples of the solvent include ethylene carbonate (EC), propylene carbonate, butylene carbonate, and diethyl.

- Esters such as carbonate (DEC), dimethyl carbonate, methyl ethyl carbonate, ⁇ -butyrolactone, ethers such as tetrahydrofuran, 2-methyltetrahydrofuran, dioxane, dioxolane, diethyl ether, dimethoxyethane, diethoxyethane, methoxyethoxyethane, Polar solvents such as dimethyl sulfoxide, sulfolane, methyl sulfolane, acetonitrile, methyl formate, and methyl acetate can be used. These solvents may be used alone, or two or more kinds may be mixed and used as a mixed solvent.

- the nonaqueous electrolytic solution may contain an electrolyte supporting salt.

- the electrolyte supporting salt include LiClO 4 , LiBF 4 (lithium borofluoride), LiPF 6 (lithium hexafluorophosphate), LiCF 3 SO 3 (lithium trifluoromethanesulfonate), LiF (lithium fluoride), LiCl

- lithium salts such as (lithium chloride), LiBr (lithium bromide), LiI (lithium iodide), LiAlCl 4 (lithium tetrachloride aluminate). These may be used singly or in combination of two or more.

- the concentration of the electrolyte supporting salt is not particularly limited, but is preferably 0.5 mol / L to 2.5 mol / L, more preferably 1.0 mol / L to 2.2 mol / L.

- concentration of the electrolyte support salt is less than 0.5 mol / L, the carrier concentration for carrying charges in the non-aqueous electrolyte is lowered, and the resistance of the non-aqueous electrolyte may be increased.

- the concentration of the electrolyte supporting salt is higher than 2.5 mol / L, the dissociation degree of the salt itself is lowered, and there is a possibility that the carrier concentration in the non-aqueous electrolyte does not increase.

- the exterior container 100 that encloses the electrode group 50 is a large flat rectangular container, and an exterior can 60 that houses the electrode group 50 and the like, and a sealing plate 70 that seals the exterior can 60. It is comprised including. Further, a sealing plate 70 is attached to the outer can 60 containing the electrode group 50 by, for example, laser welding.

- the outer can 60 is formed by, for example, deep drawing processing or the like on a metal plate, and is formed in a substantially box shape having a bottom surface portion 61 and a side wall portion 62. As shown in FIG. 2, an opening 63 for inserting the electrode group 50 is provided at one end of the outer can 60 (opposite the bottom surface portion 61).

- the outer can 60 is formed in a size that can be accommodated such that the electrode surface of the electrode group 50 faces the bottom surface portion 61.

- the outer can 60 has an electrode terminal 64 (for example, a positive electrode terminal) formed on a side wall 62 on one side (short side) in the X direction, and the other in the X direction.

- An electrode terminal 64 (for example, a negative electrode terminal) is formed on the side wall portion 62 on the side (short side).

- a liquid injection hole 65 for injecting a nonaqueous electrolytic solution is formed in the side wall 62 of the outer can 60.

- the liquid injection hole 65 is formed in a size of ⁇ 2 mm, for example.

- a safety valve 66 for releasing the battery internal pressure is formed in the vicinity of the liquid injection hole 65.

- a folded portion 67 is provided at the periphery of the opening 63 of the outer can 60, and the sealing plate 70 is fixed to the folded portion 67 by welding.

- the outer can 60 and the sealing plate 70 can be formed using, for example, a metal plate such as iron, stainless steel, or aluminum, or a steel plate obtained by applying nickel plating to iron. Since iron is an inexpensive material, it is preferable in terms of price, but in order to ensure long-term reliability, it is better to use a metal plate made of stainless steel, aluminum, etc. or a steel plate with iron plated with nickel. preferable.

- the thickness of the metal plate can be, for example, about 0.4 mm to about 1.2 mm (eg, about 1.0 mm).

- the electrode group 50 described above is housed in the outer can 60 such that the positive electrode 10 and the negative electrode 20 face the bottom surface portion 61 of the outer can 60.

- the current collector exposed portion 11a of the positive electrode 10 and the current collector exposed portion 21a of the negative electrode 20 are electrically connected to the electrode terminal 64 of the outer can 60 through the tab electrodes 41 and 42, respectively. ing.

- the nonaqueous electrolytic solution is injected under reduced pressure from the injection hole 65 after the opening 63 of the outer can 60 is sealed by the sealing plate 70, for example. Then, after a metal sphere having a diameter substantially the same as the liquid injection hole 65 or a metal plate (not shown) slightly larger than the liquid injection hole 65 is installed in the liquid injection hole 65, the liquid injection hole 65 is formed by resistance welding or laser welding. It is sealed.

- a current collector having a multilayer structure is used for the positive electrode current collector 11 as described above. For this reason, for example, when a local short circuit occurs between the electrodes, the resin layer 13 of the positive electrode current collector 11 is melted and the electrode (positive electrode 10) is damaged, so that the current can be cut. Thereby, since the temperature rise inside a battery can be suppressed, it can prevent that abnormal states, such as ignition, arise.

- the tab electrode 41 is electrically connected to the current collector exposed portion 11a of the positive electrode 10 through the conductive member 80 (penetrating member 80a) made of a low melting point metal. For this reason, when the temperature inside the battery rises due to some cause such as an overcharged state, the conductive member 80 (penetrating member 80a) can be melted at the temperature inside the battery. Thereby, the electrical connection between the tab electrode 41 and the electrode (positive electrode 10) can be cut off.

- the current can be interrupted not only by the current collector 11 having a multilayer structure, but also by the conductive member 80 that connects the tab electrode 41 and the electrode (positive electrode 10). Safety can be further improved.

- the current can be interrupted by the positive electrode current collector 11 having a multilayer structure as described above. Can be suppressed.

- the positive electrode current collector 11 having a multilayer structure may be difficult for the positive electrode current collector 11 having a multilayer structure to suppress the temperature rise inside the battery.

- the internal current can be cut off by fusing the conductive member 80 by heat generation inside the battery, a temperature rise inside the battery can be suppressed.

- the tab electrode 41 (conductive member 80) connected to the stacked positive electrode 10 is a portion through which a total current flows, and thus the flowing current is large. Therefore, when an abnormal current flows, the amount of heat generated by the resistance also increases, so that the conductive member 80 can be melted by the heat. For this reason, even when an abnormal current flows, the current can be interrupted.

- the conductive member 80 is provided inside the battery (near the electrode), the current interruption function by the conductive member 80 can be effectively activated against abnormal heat generation inside the battery.

- a current interruption mechanism such as a PTC (Positive Temperature Coefficient) element is provided outside the battery, it becomes difficult to detect abnormal heat generation inside the battery.

- the electrically-conductive member 80 is provided in the inside of a battery, the abnormal heat_generation

- the conductive member 80 is made of a low melting point metal (metal material) that melts due to heat generated in the battery, abnormal heat generation of the battery can be easily suppressed, so that safety is further improved. An improved lithium ion secondary battery can be easily obtained.

- the positive electrode current collector 11 has a configuration (multilayer structure) in which the resin layer 13 is sandwiched between the conductive layers 14, when a plurality of electrodes are stacked as described above, the tab electrode 41 for wiring extraction is provided.

- the electrodes cannot conduct each other. For this reason, when the collector which has a multilayer structure is used in order to improve safety, the problem that battery performance falls will arise.

- the conductive member 80 as the penetrating member 80a, the conductive layer 14 on one side of the resin layer 13 in the positive electrode current collector 11 via the conductive member 80 (penetrating member 80a)

- the other conductive layer 14 can be electrically connected.

- the current collector (positive electrode current collector 11) having a multilayer structure was used by continuously penetrating all of the plurality of positive electrodes 10 (positive electrode current collector 11) on which the penetrating member 80a was laminated. Even in this case, conduction between the stacked electrodes can be achieved. Thereby, the tab electrode 41 can be electrically connected to all of the plurality of stacked electrodes (positive electrode 10). Therefore, since the deterioration of battery performance can be suppressed, the performance of the lithium ion secondary battery can be fully utilized.

- the conductive member 80 by providing the conductive member 80, for example, when the tab electrode 41 is connected to the electrode (positive electrode 10) by ultrasonic welding, the contact between the tab electrode 41 and the electrode (positive electrode 10). Resistance and contact resistance between electrodes can be reduced. Thereby, the tab electrode 41 can be firmly connected to the electrode (positive electrode 10). In addition, by firmly connecting the tab electrode 41 to the electrode (positive electrode 10), it is possible to suppress a decrease in battery capacity due to an increase in contact resistance.

- the conductive member 80 is easily formed in the thickness direction of the current collector by previously forming the through hole 11b through which the conductive member 80 (through member 80a) is inserted in the positive electrode current collector 11. Can be penetrated. Thereby, the conductive layer 14 on one side of the resin layer 13 in the positive electrode current collector 11 and the conductive layer 14 on the other side can be easily electrically connected.

- the conductive member 80 made of a low melting point metal is configured to have a melting point equal to or higher than the melting point of the resin layer 13 of the positive electrode current collector 11, it is difficult to prevent the current collector 11 having a multilayer structure. Abnormal heat generation inside can be prevented by fusing the conductive member 80. Thereby, safety can be improved more easily.

- the conductive member 80 made of a low melting point metal is configured to have a melting point lower than the melting point of the resin layer 13 of the positive electrode current collector 11, the conductive member 80 may be removed before the resin layer 13 of the positive electrode current collector 11 melts. Can be blown. For this reason, even when comprised in this way, the safety

- the resin layer 13 of the positive electrode electrical power collector 11 is comprised from a thermoplastic resin, and the thermal contraction rate in 120 degreeC is in any direction of a plane direction (for example, the vertical direction and a horizontal direction). It is configured to be 1.5% or more.

- the resin layer 13 of the positive electrode current collector 11 is formed of a polyolefin resin such as polyethylene or polypropylene, the safety of the lithium ion secondary battery can be easily improved.

- the resin layer 13 may be formed of a resin containing any of polystyrene, polyvinyl chloride, and polyamide. Moreover, you may form the resin layer 13 with the composite material of said each resin.

- the separator 30 is configured such that the thermal shrinkage rate at 120 ° C. is smaller than that of the resin layer 13 of the positive electrode current collector 11. Thereby, before the shutdown function of the separator 30 act

- the thermal contraction rate of the separator 30 at 180 ° C. is 1.0% or less, an internal short circuit (electrical current) caused by the thermal contraction of the separator 30 when abnormal heat generation occurs in an overcharged state or a high temperature state. It is possible to suppress the occurrence of internal short circuit of the battery that occurs at the extreme part. For this reason, it is possible to suppress an abrupt increase in temperature. As a result, the safety of the lithium ion secondary battery can be further improved.

- the melting / fluidization of the separator 30 can be suppressed even at a temperature of 180 ° C., resulting in a disadvantage that the pores of the separator 30 are enlarged due to the melting / fluidization. Can be suppressed. For this reason, when the inside of the battery reaches 180 ° C., even if the electrode (positive electrode 10) is not damaged for some reason, the short-circuited portion of the positive and negative electrodes is caused by the large hole in the separator 30. It is also possible to suppress the inconvenience of spreading.

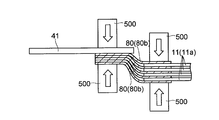

- FIG. 17 is a cross-sectional view schematically showing an electrode group of the lithium ion secondary battery according to the second embodiment of the present invention.

- FIG. 18 is a perspective view schematically showing a part of the electrode group of the lithium ion secondary battery according to the second embodiment of the present invention.

- 19 and 20 are cross-sectional views illustrating a lithium ion secondary battery according to a second embodiment of the present invention.

- a lithium ion secondary battery according to a second embodiment of the invention will be described.

- symbol is attached

- a conductive member 80 made of a low melting point metal is composed of a metal foil 80b.

- the conductive member 80 is disposed between each of the stacked positive electrode current collectors 11.

- the plurality of conductive members 80 formed in a foil shape are arranged so as to extend (extend) to the outside of the positive electrode current collector 11 (on the side opposite to the active material layer 12).

- the conductive member 80 is formed in a substantially strip shape (band shape), and the conductive member 80 is arranged so as to be shifted in the X direction. Thereby, the conductive member 80 extends (extends) to the outside of the positive electrode current collector 11.

- the plurality of conductive members 80 collect current from the positive electrode 10 (the positive electrode current collector 11) in a portion (welding region M ⁇ b> 1) disposed between the positive electrode current collectors 11. It is fixed to the body exposed portion 11a by welding. Each extending portion of the plurality of conductive members 80 is fixed to the tab electrode 41 by welding. That is, one end of the conductive member 80 is welded and fixed to the positive electrode 10 in the welding region M1, and the other end of the conductive member 80 is welded and fixed to the tab electrode 41 in the welding region M2.

- the conductive member 80 when one end portion of the conductive member 80 is pressed together with the positive electrode current collector 11 in the thickness direction (see the white arrow) by, for example, a welding machine 500, the conductive member 80 and the positive electrode The current collector 11 (current collector exposed portion 11a) is fixed by welding. Further, the other end of the conductive member 80 is pressed together with the tab electrode 41 in the thickness direction (see the white arrow) by the welding machine 500, for example, so that the conductive member 80 and the tab electrode 41 are fixed by welding. Thereby, the tab electrode 41 for drawing out the wiring is in a state of being electrically connected to the current collector exposed portion 11a of the positive electrode 10 through the conductive member 80 made of a low melting point metal. Moreover, as shown in FIG. 18, the welding location 200 is in the state where it was dented with the pressure at the time of welding.

- the foil-like conductive member 80 is not only between the positive electrode current collectors 11 but also the outermost (uppermost layer, lowermost layer) positive electrode 10 (conductivity of the positive electrode current collector 11). It is also preferably arranged in layer 14).

- the thickness of the conductive member 80 (metal foil 80b) is not particularly limited, but is preferably about 0.05 mm to about 0.5 mm, for example.

- the through hole 11b through which the penetrating member is inserted into the positive electrode current collector 11 see FIG. 3). Is not provided.

- the tab electrode 41 is electrically connected to the electrode (positive electrode 10) through the foil-like conductive member 80 made of a low melting point metal as described above.

- the electrically-conductive member 80 can be blown by the temperature inside the battery. For this reason, the electrical connection between the tab electrode 41 and the electrode (positive electrode 10) can be cut off.

- a foil-like conductive member 80 made of a low-melting-point metal is disposed between the positive electrode current collectors 11 (current collector exposed portions 11a) in the stacked positive electrodes 10.

- the conductive layer 14 of each positive electrode current collector 11 can be electrically connected to the tab electrode 41 via the conductive member 80.

- all of the positive electrodes 10 can be electrically connected to the tab electrode 41, thereby suppressing a decrease in battery performance. Can do. As a result, the performance of the lithium ion secondary battery can be maximized.

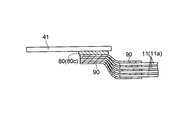

- FIG. 21 is a cross-sectional view schematically showing an electrode group of the lithium ion secondary battery according to the third embodiment of the present invention.

- 22 and 23 are diagrams for explaining a lithium ion secondary battery according to a third embodiment of the present invention.

- a lithium ion secondary battery according to a third embodiment of the invention will be described with reference to FIGS.

- symbol is attached

- the metal foil 90 disposed between the positive electrode current collectors 11 is made of a metal material other than the low melting point metal. ing.

- the metal foil 90 is welded to the tab electrode 41 by a conductive member 80 made of a low melting point metal.

- all metal foils 90 are joined to the tab electrode 41 using a block-shaped conductive member 80 (80c).

- the tab electrode 41 for drawing out the wiring is electrically connected to the current collector exposed portion 11a of the positive electrode 10 through the conductive member 80 made of a low melting point metal.

- the metal foil 90 is an example of the “foil-like member” in the present invention.

- ultrasonic welding or resistance welding can be used for welding the tab electrode 41.

- the metal foil 90 is made of, for example, aluminum or an aluminum alloy.

- the metal foil 90 may be other than aluminum or an aluminum alloy, and may be made of, for example, a metal material such as titanium, stainless steel, or nickel, or an alloy thereof.

- the thickness of the metal foil 90 is not particularly limited, but is preferably about 0.05 mm to about 0.5 mm, for example.

- the metal foil 90 is connected to the positive electrode 10 so that a part of the metal foil 90 extends outside the electrode (positive electrode 10), and the extended part of the metal foil 90 is a low melting point metal. It welds to the tab electrode 41 with the electrically-conductive member 80 which consists of. Thereby, the tab electrode 41 can be electrically connected to the electrode (positive electrode 10) via the conductive member 80. For this reason, when the temperature inside the battery rises due to some cause such as an overcharged state, the conductive member 80 can be melted at the temperature inside the battery. Thereby, the electrical connection between the tab electrode 41 and the electrode (positive electrode 10) can be cut off.

- the metal foil 90 is disposed between the positive electrode current collectors 11 (current collector exposed portions 11 a) in the stacked positive electrodes 10, and a part of the metal foil 90 is used as the tab electrode 41. Weld. Thereby, the conductive layer 14 of each positive electrode current collector 11 can be electrically connected to the tab electrode 41 via the conductive member 80. For this reason, even when a current collector having a multilayer structure (positive electrode current collector 11) is used, all of the positive electrodes 10 can be electrically connected to the tab electrode 41, thereby suppressing a decrease in battery performance. Can do. As a result, the performance of the lithium ion secondary battery can be maximized.

- Modification of the third embodiment 24 and 25 are cross-sectional views schematically showing an electrode group of a lithium ion secondary battery according to a modification of the third embodiment.

- a conductive member (conductive material) 80 (80d) made of a low melting point metal is melted to obtain a metal foil.

- 90 is joined to the tab electrode 41.

- the metal foil 90 is joined to the tab electrode 41 in the manner of soldering.

- the present invention is not limited thereto.

- the present invention may be applied to non-aqueous secondary batteries other than lithium ion secondary batteries.

- the present invention can also be applied to non-aqueous secondary batteries that will be developed in the future.

- the present invention is not limited to this, and for example, windings other than the stacked type

- the present invention may be applied to a rechargeable secondary battery.

- a film-like resin layer is used as the resin layer (insulating layer) of the current collector, but the present invention is not limited to this.

- a fibrous resin layer may be used. Examples of the fibrous resin layer include a layer made of woven fabric or non-woven fabric.

- the current collector on the positive electrode side is configured in a multilayer structure including the resin layer and the conductive layer.

- the present invention is not limited to this, and the negative electrode

- the current collector on the side may be configured in a multilayer structure including a resin layer and a conductive layer.

- both the positive electrode and the negative electrode may be formed using a current collector having a multilayer structure (three-layer structure), or one of the positive electrode and the negative electrode is used as a current collector having a multilayer structure (three-layer structure). May be formed.

- the positive electrode side is preferably formed using a current collector having a multilayer structure (three-layer structure). .

- the conductive layer is preferably made of copper or a copper alloy. Specifically, it is preferable to use a copper foil or a copper alloy foil having a thickness of about 4 ⁇ m to about 10 ⁇ m as the conductive layer.

- the conductive layer of the negative electrode current collector may be other than copper or a copper alloy, and may be composed of, for example, nickel, stainless steel, iron, or an alloy thereof.

- the resin layer of the negative electrode current collector may be the same as the resin layer of the positive electrode current collector (that can be used for the resin layer of the positive electrode current collector 11).

- the current collector on the negative electrode side has a multi-layer structure

- a plurality of stacked electrodes are provided in the same manner as the positive electrode (positive current collector) shown in the first to third embodiments (including modifications). It is preferable that the (negative electrode) and the tab electrode are configured to be electrically connected via a conductive member.

- a material that can be melted at a desired temperature can be appropriately used as the low melting point metal constituting the conductive member.

- the conductive member (conductive material) is made of a low melting point metal.

- the resistance of the conductive member increases according to temperature change. You may comprise from the material to do.

- the conductive member may be made of a PTC material.

- the conductive member may be, for example, a temperature sensitive element such as a bimetal, a fuse, or the like.

- the tab electrode and all the stacked electrodes (positive electrodes) are electrically connected via the conductive member.

- the present invention is not limited to this.

- the tab electrode and at least some of the electrodes (conductive layer) may be electrically connected via a conductive member.

- a portion of the tab electrode 41 is connected to the uppermost positive electrode 10 (the current collector exposed portion 11a of the positive electrode current collector 11) as shown in FIG. It can also be configured.

- the tab electrode 41 is connected to the uppermost positive electrode 10.

- the positive electrode current collector 11 has a multilayer structure having the resin layer 13, the electrical connection with the lower layer positive electrode 10 is interrupted. For this reason, even when comprised in this way, safety

- the connection strength of the tab electrode 41 can be improved, durability and vibration resistance can also be improved.

- part of the tab electrode 41 is connected to the uppermost positive electrode 10 (the current collector exposed portion 11a of the positive electrode current collector 11). Can be configured. The same applies to the configuration of the first embodiment.

- the present invention is not limited to this, and the shape of the outer container is used. May be other than a flat square.

- the outer container may be a thin flat tube type, a cylindrical type, a rectangular tube type, or the like.

- the outer container may be an outer container using a laminated sheet, for example, in addition to a metal can.

- the negative electrode (negative electrode active material layer) is larger than the positive electrode (positive electrode active material layer) is shown.

- the (negative electrode active material layer) and the positive electrode (positive electrode active material layer) may be configured to have the same size. However, the negative electrode (negative electrode active material layer) is preferably configured to be larger than the positive electrode (positive electrode active material layer). If comprised in this way, the formation area (positive electrode active material area

- the shape of the outer container not only the shape of the outer container but also the size and structure can be variously changed. Further, the shape, size, number of sheets used, etc. of the electrodes (positive electrode, negative electrode) can be changed as appropriate. Furthermore, the shape and dimensions of the separator can be changed as appropriate. Examples of the shape of the separator include various shapes such as a rectangle such as a square or a rectangle, a polygon, and a circle.

- the active material layer is formed on both surfaces of the current collector.

- the present invention is not limited to this, and the current collector is formed on one surface of the current collector. Only the active material layer may be formed. Moreover, you may comprise so that the electrode (positive electrode, negative electrode) which formed the active material layer only in the single side

- surface of a collector may be included in a part of electrode group.

- a non-aqueous electrolyte is used as an electrolyte of a lithium ion secondary battery.

- the present invention is not limited to this, and non-aqueous electrolysis is used.

- a gel electrolyte, a polymer solid electrolyte, an inorganic solid electrolyte, a molten salt, or the like other than the liquid may be used as the electrolyte.

- the laminated electrode (current collector) ) May be configured to penetrate through a penetrating member.

- a plurality of stacked electrodes (current collectors) are divided into a plurality of groups (groups), and the electrodes (current collectors) are penetrated by conductive members (penetrating members) for each group (each group).

- the conductive member (penetrating member) only needs to be configured to continuously penetrate two or more electrodes (current collectors).

- the present invention can be used for a non-aqueous secondary battery having an electrode in which an active material layer is formed on a current collector.

- Electrode 10 Positive electrode 11 Positive electrode collector 11a Current collector exposed part 11b Through-hole 12 Positive electrode active material layer 13 Resin layer (insulating layer) DESCRIPTION OF SYMBOLS 14 Conductive layer 20 Negative electrode 21 Negative electrode collector 21a Current collector exposed part 22 Negative electrode active material layer 30 Separator 41, 42 Tab electrode 50 Electrode group 60 Exterior can 61 Bottom surface part 62 Side wall part 63 Opening part 64 Electrode terminal 65 Injection hole 66 Safety valve 67 Folded part 70 Sealing plate 80 Conductive member (conductive material) 80a Penetration member (conductive material) 80b Metal foil (conductive material) 90 Metal foil (foil-like member) 100 exterior container 200 welding location 500 welding machine

Abstract

This nonaqueous secondary battery is provided with: a positive electrode (10) which comprises a positive electrode collector (11) that has a multilayer structure wherein a resin layer (13) is sandwiched between conductive layers (14) and a positive electrode active material layer (12) that is formed on the positive electrode collector (11); and a tab electrode (41) which is electrically connected to the positive electrode (10). The tab electrode (41) is electrically connected to the positive electrode collector (11) of the positive electrode (10) via a conductive member (80) that is formed of a metal having a low melting point.

Description

本発明は、非水系二次電池に関し、特に、集電体上に活物質層が形成された電極を有する非水系二次電池に関する。

The present invention relates to a non-aqueous secondary battery, and more particularly to a non-aqueous secondary battery having an electrode in which an active material layer is formed on a current collector.

リチウムイオン二次電池に代表される非水系二次電池は、高容量・高エネルギ密度を有し、かつ、貯蔵性能や充放電の繰り返し特性等にも優れるため、携帯機器などの民生機器に広く利用されている。また、近年では、環境問題や省エネルギに関する意識の高まりから、電力貯蔵用途や、電気自動車などの車載用途にリチウムイオン二次電池が利用されるようになってきている。

Non-aqueous secondary batteries represented by lithium ion secondary batteries have high capacity and high energy density, and are excellent in storage performance and charge / discharge repetition characteristics. It's being used. In recent years, lithium ion secondary batteries have come to be used for electric power storage applications and in-vehicle applications such as electric vehicles due to increasing awareness of environmental issues and energy savings.

一方、非水系二次電池は、そのエネルギ密度の高さ故に、過充電状態や高温環境下にさらされた状態においては、異常過熱や発火などの危険性が高い。そのため、非水系二次電池では、安全性に対する種々の対応策が講じられている。

On the other hand, the non-aqueous secondary battery has a high risk of abnormal overheating or ignition when exposed to an overcharged state or a high temperature environment because of its high energy density. Therefore, various countermeasures for safety are taken in the non-aqueous secondary battery.

また、従来、異常発熱による発火を防止するために、多層構造を有する集電体を用いたリチウムイオン二次電池が提案されている(たとえば、特許文献1参照)。

Also, conventionally, in order to prevent ignition due to abnormal heat generation, a lithium ion secondary battery using a current collector having a multilayer structure has been proposed (for example, see Patent Document 1).

上記特許文献1には、130℃~170℃の低融点を持つ樹脂フィルムの両面に金属層が形成された集電体を用いたリチウムイオン二次電池が提案されている。このリチウムイオン二次電池では、過充電状態や高温状態等で異常発熱が発生すると、低融点の樹脂フィルムが溶融する。そして、樹脂フィルムの溶融により、電極が破損される。これにより、電流がカットされるので、電池内部の温度上昇が抑制されて、発火が防止される。