US8990982B2 - Latching motion transfer mechanism - Google Patents

Latching motion transfer mechanism Download PDFInfo

- Publication number

- US8990982B2 US8990982B2 US14/085,827 US201314085827A US8990982B2 US 8990982 B2 US8990982 B2 US 8990982B2 US 201314085827 A US201314085827 A US 201314085827A US 8990982 B2 US8990982 B2 US 8990982B2

- Authority

- US

- United States

- Prior art keywords

- channel

- latch

- catch

- plunger

- motion transfer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- CIVHHTUYLNCOGH-UHFFFAOYSA-N CCC=[b]12c3c1C2CC1=CC31 Chemical compound CCC=[b]12c3c1C2CC1=CC31 CIVHHTUYLNCOGH-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61G—TRANSPORT, PERSONAL CONVEYANCES, OR ACCOMMODATION SPECIALLY ADAPTED FOR PATIENTS OR DISABLED PERSONS; OPERATING TABLES OR CHAIRS; CHAIRS FOR DENTISTRY; FUNERAL DEVICES

- A61G7/00—Beds specially adapted for nursing; Devices for lifting patients or disabled persons

- A61G7/05—Parts, details or accessories of beds

- A61G7/0528—Steering or braking devices for castor wheels

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61G—TRANSPORT, PERSONAL CONVEYANCES, OR ACCOMMODATION SPECIALLY ADAPTED FOR PATIENTS OR DISABLED PERSONS; OPERATING TABLES OR CHAIRS; CHAIRS FOR DENTISTRY; FUNERAL DEVICES

- A61G7/00—Beds specially adapted for nursing; Devices for lifting patients or disabled persons

- A61G7/08—Apparatus for transporting beds

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C20/00—Head -, foot -, or like rests for beds, sofas or the like

- A47C20/04—Head -, foot -, or like rests for beds, sofas or the like with adjustable inclination

- A47C20/043—Head -, foot -, or like rests for beds, sofas or the like with adjustable inclination by means of peg-and-notch or pawl-and-ratchet mechanism

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C21/00—Attachments for beds, e.g. sheet holders, bed-cover holders; Ventilating, cooling or heating means in connection with bedsteads or mattresses

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61G—TRANSPORT, PERSONAL CONVEYANCES, OR ACCOMMODATION SPECIALLY ADAPTED FOR PATIENTS OR DISABLED PERSONS; OPERATING TABLES OR CHAIRS; CHAIRS FOR DENTISTRY; FUNERAL DEVICES

- A61G7/00—Beds specially adapted for nursing; Devices for lifting patients or disabled persons

- A61G7/002—Beds specially adapted for nursing; Devices for lifting patients or disabled persons having adjustable mattress frame

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61G—TRANSPORT, PERSONAL CONVEYANCES, OR ACCOMMODATION SPECIALLY ADAPTED FOR PATIENTS OR DISABLED PERSONS; OPERATING TABLES OR CHAIRS; CHAIRS FOR DENTISTRY; FUNERAL DEVICES

- A61G7/00—Beds specially adapted for nursing; Devices for lifting patients or disabled persons

- A61G7/05—Parts, details or accessories of beds

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16H—GEARING

- F16H35/00—Gearings or mechanisms with other special functional features

- F16H35/14—Mechanisms with only two stable positions, e.g. acting at definite angular positions

-

- A61G2007/0528—

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S292/00—Closure fasteners

- Y10S292/04—Automatic release latches

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T292/00—Closure fasteners

- Y10T292/03—Miscellaneous

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T292/00—Closure fasteners

- Y10T292/08—Bolts

- Y10T292/0862—Swinging and hooked end, multiple head

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T292/00—Closure fasteners

- Y10T292/08—Bolts

- Y10T292/0886—Sliding and swinging

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T292/00—Closure fasteners

- Y10T292/08—Bolts

- Y10T292/096—Sliding

- Y10T292/0969—Spring projected

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T292/00—Closure fasteners

- Y10T292/54—Trippers

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T403/00—Joints and connections

- Y10T403/32—Articulated members

- Y10T403/32254—Lockable at fixed position

- Y10T403/32426—Plural distinct positions

- Y10T403/32442—At least one discrete position

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T74/00—Machine element or mechanism

- Y10T74/20—Control lever and linkage systems

- Y10T74/20576—Elements

- Y10T74/20636—Detents

Definitions

- Motion transfer arrangements are used in a wide variety of different applications. Motion transfer mechanisms have been used as “brakes” for articulating beds that are supported by casters. Moving a lift pedal of a brake assembly causes the brake assembly to engage the ground or other support surface to raise the caster (s) up and out of engagement with the ground or other support surface. Moving a second, disengagement pedal, causes the brake assembly to lower the casters back onto the support surface to allow the articulating bed to be moved on the support surface.

- the present application discloses exemplary embodiments of latching motion transfer arrangements.

- the mechanism is caused to lift and latch by applying force in a first direction, a first time, and is caused to release and lower by applying force in the first direction, a second time.

- FIG. 1A illustrates a latching motion transfer mechanism of an exemplary embodiment with a detent member latched at a retracted position

- FIG. 1B illustrates the latching motion transfer mechanism where force has been applied to a drive member to move the detent member from the retracted position to an intermediate, disengaged position

- FIG. 1C illustrates the latching motion transfer mechanism with the detent member latched at an extended position, while force is maintained on the drive member

- FIG. 1D illustrates the latching motion transfer mechanism with the detent member latched at an extended position, when force is removed from the drive member

- FIG. 1E illustrates the latching motion transfer mechanism where force has been applied to a drive member to move the detent member from the extended position to an extendedly disengaged position

- FIG. 1F illustrates the latching motion transfer mechanism with the detent member latched at the retracted position, while force is maintained on the drive member

- FIG. 1G illustrates the latching motion transfer mechanism with the detent member latched at the retracted position, when force is removed from the drive member to return the detent to the initial position;

- FIG. 2 illustrates an embodiment, where two latching motion transfer mechanisms are coupled together to maintain synchronization between the two latching motion transfer mechanisms

- FIG. 3 shows the embodiment of FIG. 2 where the detent member of one of the motion transfer members has disengaged from the extended position, while the detent member of the other motion transfer member remains engaged at the extended position;

- FIGS. 4A and 4B schematically illustrate how the coupling of the of the two latching motion transfer mechanisms together maintains synchronization of the detent members when the situation illustrated by FIG. 3 occurs;

- FIG. 5 shows the embodiment of FIG. 3 where the detent member of one of the motion transfer members has failed to engage at the extended position, while the detent member of the other motion transfer member has engaged at the extended position;

- FIGS. 6A-6C schematically illustrate how the coupling of the of the two latching motion transfer mechanisms together maintains synchronization of the detent members when the situation illustrated by FIG. 5 occurs;

- FIG. 7 illustrates another embodiment, where two latching motion transfer mechanisms are coupled together to maintain synchronization between the two latching motion transfer members

- FIG. 8A is a perspective view of another embodiment of a latching motion transfer mechanism that includes a pin and follower arrangement that moves the drive member in a retracted position;

- FIG. 8B is a side view of the latching motion transfer mechanism of FIG. 8A ;

- FIG. 8C is a sectional view of the latching motion transfer mechanism of FIG. 8A ;

- FIG. 9A is a perspective view of the latching motion transfer mechanism of FIG. 8A with the detent member moved beyond a second catch to allow the detent member to latch at the extended position;

- FIG. 9B is a side view of the latching motion transfer mechanism of FIG. 9A ;

- FIG. 9C is a sectional view of the latching motion transfer mechanism of FIG. 9A ;

- FIG. 10A is a perspective view of the latching motion transfer mechanism of FIG. 8A with the detent member latched at the extended position;

- FIG. 10B is a side view of the latching motion transfer mechanism of FIG. 10A ;

- FIG. 10C is a sectional view of the latching motion transfer mechanism of FIG. 10A ;

- FIG. 11A is a perspective view of the latching motion transfer mechanism of FIG. 8A with the detent member disengaged from the second catch;

- FIG. 11B is a side view of the latching motion transfer mechanism of FIG. 11A ;

- FIG. 11C is a sectional view of the latching motion transfer mechanism of FIG. 11A ;

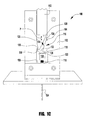

- FIG. 12 is a perspective view of an embodiment of a lever assembly for actuating a pair of latching motion transfer mechanisms

- FIG. 13A is a perspective view of an embodiment of a latching motion transfer mechanism that includes a synchronization arrangement

- FIG. 13B is a view similar to the view of FIG. 13A where components of the latching motion transfer mechanism are transparent to illustrate internal components;

- FIG. 13C is a sectional view of the latching motion transfer mechanism of FIG. 13A ;

- FIG. 13D is a perspective view of the latching motion transfer mechanism of FIG. 13A with components removed to more clearly illustrate the synchronization arrangement

- FIG. 13E is a side view of the latching motion transfer mechanism of FIG. 13A with components removed to more clearly illustrate the synchronization arrangement

- FIG. 13F is a front view of the latching motion transfer mechanism of FIG. 13A with components removed to more clearly illustrate the synchronization arrangement

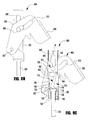

- FIG. 14 is a side view of an articulating bed with a caster assembly and a latching motion transfer mechanism used as a caster lock;

- FIG. 15 is an enlarged portion of FIG. 14 as indicated by the reference FIG. 15 in FIG. 14 ;

- FIG. 16 is a perspective view that is similar to the view of FIG. 15 ;

- FIG. 17 is a perspective sectional view taken along lines 17 - 17 in FIG. 16 ;

- FIG. 18 is an exploded perspective that illustrates an embodiment of a caster assembly mounting arrangement

- FIG. 19 is a sectional view of the caster assembly mounting arrangement.

- the present application discloses embodiments of latching motion transfer arrangements.

- the latching motion transfer arrangements may take a wide variety of different forms and may be used in a wide variety of different applications.

- a variety of different features are included in the different latching motion transfer mechanism embodiments that are disclosed in this application.

- the scope of this application is intended to encompass all combinations and sub-combinations of the features of the latching motion transfer mechanisms disclosed in this application, as well as the wide variety of uses in different applications.

- a latching motion transfer arrangement is used as a lift mechanism.

- the latching motion transfer mechanism may be used to lift a wheel or caster off of a support surface.

- the mechanism may take a wide variety of different forms.

- the mechanism is caused to lift and latch by applying force in a first direction, a first time, and is caused to release and lower by applying force in the first direction, a second time.

- a wide variety of vehicles may include wheels and/or casters that may be lifted from the support surface by the mechanism, including but not limited to, beds supported by casters, wheelchairs, scooters, automobiles, etc.

- FIGS. 1A-1G illustrate an embodiment of a latching motion transfer mechanism 100 .

- the illustrated latching motion transfer mechanism 100 includes a frame 102 , a first catch 104 , a second catch 106 , a plunger 108 , a biasing member 110 , a drive member 112 , and a detent member 114 .

- the frame 102 includes a channel 116 with first and second spaced apart walls 118 , 120 .

- the channel may take a wide variety of different forms. In the illustrated embodiment, the channel 116 is straight. However, the channel may be curved, or the channel may have one or more straight and or curved portions or other configuration.

- the walls 118 , 120 of the channel are illustrated as being parallel to one another. However, the walls 118 , 120 may be non-parallel such that a spacing between the walls changes along the channel.

- the first catch 104 extends from the first side wall 118 into the channel 116 at a first position along a length of the channel.

- the second catch 106 extends from the second side wall 120 into the channel 116 at a second position along the length of the channel.

- the catches 104 , 106 may take a wide variety of different forms.

- either catch may be a portion of the channel wall that is bent into the channel, may be a projection that extends into the channel from the wall, may be a member that is attached to the channel wall, and/or may be a recess in the wall, instead of a projection that extends from the wall.

- Each catch may be any physical arrangement that is configured to latch with a second member.

- the plunger 108 is disposed in the channel 116 .

- the illustrated plunger 108 is a generally rectangular member having a detent member slide surface 122 .

- the illustrated slide surface 122 may be generally transverse to a path of travel P formed by the channel 116 .

- the plunger 108 may take a wide variety of different forms. Any configuration that is able to move along the path of travel P may be used.

- the slide surface 122 may be configured in any manner that allows the detent member 114 to slide and pivot within the channel 116 .

- the illustrated biasing member 110 is coupled to plunger 108 such that the plunger is urged along the path of travel P toward the first catch member 104 .

- the biasing member 110 may take a wide variety of different forms and may be coupled to the plunger 108 in a wide variety of different ways.

- the biasing member 110 is a spring disposed around a driven member 124 that is connected to the plunger 108 .

- the biasing member 110 is disposed between the plunger 108 and an end wall of the frame 102 .

- the biasing member may be any structure in any configuration that imparts a reaction force on the plunger toward the first catch member 104 when the plunger is moved in the channel toward an end wall 126 of the channel 116 .

- the drive member 112 is at least partially disposed in the channel 116 in the exemplary embodiment.

- the portion of the drive member 112 that is disposed in the channel is moveable long the path of travel P.

- the illustrated drive member 112 is a generally rectangular member having a detent member slide surface 128 .

- the illustrated slide surface 128 is transverse to a path of travel P formed by the channel.

- the drive member may take a wide variety of different forms. Any configuration that is able to move along the path of travel P may be used.

- the slide surface 128 may be configured in any manner that allows a surface of the detent member 114 to slide between the side walls 116 , 118 of the channel may be used.

- the detent member 114 is disposed in the channel 116 between the drive member 112 and the plunger 108 .

- the detent member 114 may take a wide variety of different forms.

- the detent member 114 may take any form that transfers motion of the drive member 112 to the plunger 108 and selectively latches and disengages from the first and second catches.

- the illustrated detent member 114 includes a leg portion 130 operably coupled with the drive member 112 and a latch portion 132 operably coupled with the plunger 108 .

- the illustrated latch portion 132 has first and second latch projections 136 , 138 extending generally from opposite sides of the leg portion.

- An optional pivot protrusion 140 extends from the latch portion 132 away from the leg portion 130 .

- the latch portion 132 is configured to slide across the channel between the side walls 118 , 120 such that the first latch projection 136 may latch with the first catch 104 and the second latch projection 138 may latch with the second catch 106 .

- the optional pivot protrusion 140 may be rounded to ease sliding of the latch portion 132 across the surface 122 .

- An end of the leg portion 130 is moveable across the plunger surface 128 between the first and second walls 118 , 120 of the channel to allow the latch portion 132 to disengage from said first and second catches 104 , 106 when the drive member moves a second time in the direction toward the surface 126 .

- the upper end of the leg 130 is rounded to ease sliding of the leg 130 across the plunger slide surface 128 between the side walls 118 , 120 .

- FIGS. 1A-1G illustrate operation of the latching motion transfer mechanism 100 .

- FIG. 1A illustrates the mechanism 100 latched at a retracted or first position. At this position, the first latch projection 136 is in engagement with the first catch 104 .

- the biasing member 110 urges the first latch projection 136 against the first catch 104 to inhibit the first latch projection from disengaging from the first catch 104 .

- the engagement of the first latch projection 136 with the first catch inhibits further movement of the plunger 108 and the driven member 124 in the direction indicated by arrow 144 .

- FIG. 1B illustrates how the mechanism 100 in the position shown in FIG. 1A responds when a force indicated by arrow 146 is applied to drive member 112 .

- Initial downward movement of the drive member 112 separates the detent member 114 from the first catch 104 along the path of travel.

- the end of the leg portion 130 may be disposed against the first wall 118 and the drive member 112 .

- the latch portion 132 engages the plunger 108 at a point that is laterally offset across the channel from the first wall 118 where the drive member 112 engages the leg portion 130 .

- FIG. 1C illustrates how the mechanism 100 in the position shown in FIG. 1B responds when force indicated by arrow 146 continues to be applied to the drive member 112 .

- the force applied by the drive member 112 continues to move the detent member 114 and the plunger 108 along the path of travel P.

- the second latch projection 138 slides over and past the second catch 106 and into engagement with the second wall 120 .

- FIG. 1D illustrates how the mechanism 100 in the position shown in FIG. 1C latches in an extended position when the drive member 112 is released.

- the biasing member 110 urges the second latch projection 138 against the second catch 106 .

- the force applied by the biasing member 110 to the latch portion 132 causes the detent member 114 to pivot about the second catch such that the end of the leg portion 130 slides across the surface 128 of the drive member 112 and into engagement with second wall 120 .

- the biasing member 110 urges the second latch projection 138 against the second catch 106 to inhibit the second latch projection 138 from disengaging from the second catch 106 .

- the engagement of the second latch projection 138 with the second catch inhibits movement of the plunger 108 and the driven member 124 in the direction indicated by arrow 158 .

- FIG. 1E illustrates how the mechanism 100 latched in the extended position shown in FIG. 1D disengages when a force indicated by arrow 160 is again applied to drive member 112 .

- Initial downward movement of the drive member 112 separates the detent member 114 from the second catch along the path of travel P.

- the end of the leg portion 130 is disposed against the second wall 120 and the drive member 112 .

- the latch portion 132 engages the plunger 108 at a point that is laterally offset across the channel from the second wall 120 where the drive member engages the leg portion.

- FIG. 1F illustrates how the mechanism 100 in the position shown in FIG. 1E responds when the force applied to the drive member 112 is gradually removed. As the force applied to the drive member 112 is reduced, biasing member 112 and the plunger 108 move upward along the path of travel until the first latch projection 136 engages the first catch 104 again.

- FIG. 1G illustrates how the mechanism 100 in the position shown in FIG. 1F latches in the retracted position when the drive member 112 is released.

- the biasing member 110 urges the first latch projection 136 against the first catch 104 .

- the force applied by the biasing member 110 to the latch portion 132 causes the detent member 114 to pivot about the first catch such that the end of the leg portion 130 slides across the surface 128 of the drive member 112 and into engagement with first wall 118 , to thereby return the mechanism to the position shown in FIG. 1A .

- the mechanism may be alternately moved between the latched extended position and the latched retracted position by repeatedly applying and releasing force to the drive member in the same direction.

- FIG. 2 illustrates an embodiment where a latching motion transfer mechanism 100 may be operably coupled to a second motion transfer mechanism 200 .

- the latching motion transfer mechanisms may be linked together for use in a wide variety of different applications. For example, the latching motion transfer mechanisms may be linked together to lift multiple objects at the same time.

- One use for latching motion transfer mechanisms that are linked together is lifting one or more pairs of caster assemblies from a support surface at the same time.

- the drive members 112 of the two mechanisms 100 , 200 are driven by a commonly actuated member or assembly 201 .

- the single member 201 allows both mechanisms to be actuated by a single movement.

- the latching motion transfer mechanism 100 is coupled to the second latching motion transfer mechanism 200 by a linkage 203 that maintains mechanical synchronization between the first mechanism 100 and the second mechanism 200 and resynchronizes detent members that become unsynchronized.

- two latching motion transfer mechanisms are mechanically synchronized if they are both in a substantially extended position or they are both in a substantially retracted position, even if one of the detent members is latched and the other detent member is disengaged.

- the linkage causes the detent members 114 of the mechanisms 100 , 200 to resynchronize upon pressing of the single member 201 as will be described in more detail below.

- the detent members 114 are mechanically synchronized when both detent members latch with the same catch at substantially the same time.

- the linkage may take a wide variety of different fauns. Any linkage that keeps detent members of two latching motion transfer mechanisms mechanically synchronized and resynchronizes the detent members upon movement of the drive members 112 may be used.

- the linkage 203 may be a member that is coupled to the driven member 124 of the latching motion transfer mechanism 100 and to a driven member 124 of the latching motion transfer member 200 .

- the driven members 124 are coupled to the linkage 203 such that the driven members 124 can move only a small amount without engaging the linkage 203 .

- the relative position of the plunger 108 of the first mechanism 100 with respect to a plunger 108 of the second mechanism 200 is limited to a small amount of travel, which is less than the distance between the latched position and the unlatched position.

- the linkage 203 maintains a disengaged mechanism in the extended position whenever a coupled mechanism is latched in the extended position. That is, latching of one mechanism in the extended position holds both mechanisms in the extended position.

- the linkage 203 illustrated by FIG. 2 comprises a member 205 and stops 207 A, 207 B, 207 C, 207 D.

- the driven members 124 extends through openings 209 in the member 205 .

- Stops 207 A, 207 B, 207 C, 207 D are positioned on the driven member 124 to limit relative movement of the driven members 124 with respect to the member 205 .

- FIG. 3 illustrates a situation where both detent members 114 were initially latched and the detent member of the mechanism 100 then disengaged while the detent member of the second mechanism 200 remained latched.

- This situation may occur in a variety of different ways. For example, if the member 201 is bumped near the first mechanism 100 , the detent member 114 of the first mechanism 100 might disengage while the detent member of the second mechanism 200 remains engaged. If this situation were to occur, the coupling 203 maintains both driven members in the extended position.

- the driven member 124 moves upward as indicated by arrow 250 until the lower stop 207 B of the mechanism 100 engages the member 205 and member 205 engages the upper stop 207 C of the second mechanism. This engagement prevents additional retraction of the driven member 124 of the mechanism 100 .

- FIG. 4A schematically illustrates the situation shown in FIG. 3 .

- FIG. 4B illustrates that when the single drive member 201 is depressed again the detent member of the second mechanism 200 disengages (the detent member of the first mechanism is already disengaged) and, both detent members 114 move to the retracted position and engage the first catches 104 , 204 .

- both detent members 114 will latch with the second catches 106 , to latch the mechanisms 100 , 200 in the extended position.

- FIG. 5 illustrates a situation where the detent member 114 of the second mechanism 200 initially latched and the detent member 114 of the first mechanism 200 failed to latch.

- This situation may occur in a variety of different ways. For example, if the member 201 is depressed near the mechanism 200 the detent member 114 of the second mechanism 200 could latch while the detent member 114 of the first mechanism 100 remains disengaged. If this situation were to occur, the coupling 203 maintains both driven members in the extended position. When the detent member 114 of the mechanism 100 is not latched, the lower stop 207 B of the mechanism 100 engages the member 205 and member 205 engages the upper stop 207 C of the second mechanism. This engagement maintains the mechanism 100 in the extended position.

- FIG. 6A schematically illustrates the situation shown in FIG. 5 .

- FIG. 6B illustrates that when the single drive member 201 (shown in FIG. 5 ) is depressed again, the detent member 114 of the first mechanism 100 latches and the detent member 114 of the second mechanism 200 disengages. As a result, both mechanisms remain in the extended position.

- both detent members 114 move to the retracted position and engage the first catches 104 .

- both detent members 114 will latch with the second catches 106 , to latch the driven members 124 , in the extended position.

- FIG. 7 illustrates another embodiment of a latching motion transfer mechanism 100 that is coupled to a second latching motion transfer mechanism 200 by a linkage 703 that maintains synchronization between the driven members 124 of the mechanisms 100 , 200 and resynchronizes the detent members of the mechanisms if one becomes disengaged while the other is latched.

- the linkage 703 comprises a member 710 that is attached to the driven member 124 of the mechanism 100 and a member 712 that is attached to the driven member 124 of the mechanism 200 .

- the members 710 , 712 are coupled to the member 201 such that each member 710 , 712 may move only a small amount without engaging the member 201 .

- the linkage 201 maintains a disengaged mechanism in the extended position whenever a coupled mechanism is latched in the extended position.

- the coupling of the members 710 , 712 to the member 201 may be achieved in a wide variety of different ways.

- a pin 720 is attached to the member 710 that is disposed in a slot 730 of the member 201 and a pin 722 is attached to the member 712 that is disposed in a slot 732 of the member 201 . Ends of the slots 730 , 732 act as stops that limit movement of the members 710 , 712 .

- the embodiment linkage 703 maintains synchronization in generally the same manner as the linkage 203 and as described with respect to FIGS. 3-6 .

- the drive member 112 may be moved or driven in a wide variety of different ways.

- the drive member may be moved or driven directly, or indirectly by a powered or manual mechanism. Any mechanism may be used to move the drive member 112 .

- FIGS. 8-11 illustrate an embodiment of a latching motion transfer mechanism 800 where the drive member 112 is moved by a pin and follower mechanism 802 .

- the pin and follower mechanism 802 includes a pin 804 that is connected to the drive member 112 and pivot arm 806 that is pivotally connected to the frame 102 at a pivot connection 807 . Referring to FIGS. 8B and 8C , the pin 804 extends through a slot 808 in the frame and a slot 810 in the pivot arm 806 .

- the slot 808 through the frame 102 allows the pin 804 to move with the drive member along the path of travel P. Edges of the slot 810 engage the pin 804 when the pivot arm 806 is pivoted about the pivotal connection 807 to move the pin 804 and drive member 112 along the path of travel.

- the shape of the slot 810 in the pivot arm 806 defines the movement of the pin 804 as the pivot arm 806 is pivoted.

- the slot 810 may be shaped to accommodate a wide variety of different applications.

- the slot 810 illustrated by FIGS. 8-11 provides a variable actuation speed and force (for a constant speed/force input).

- the slot 810 governs the position of the follower pin 804 relative to the pivot connection, which in turn determines, at any given point, the instantaneous ratio of pivot arm 806 speed to pin 804 speed and also the amount of mechanical advantage (potential lifting force).

- the slot 810 shape illustrated by FIGS. 8-11 is configured to cause the pin 804 to move downward quickly at the top of the stroke ( FIG. 8 ) of the pivot arm 806 with lower potential lifting force and then the speed of the pin decreases near the bottom of the stroke ( FIGS. 9 and 10 ) of the with higher potential lifting force.

- the potential lifting force increases as the driven member 124 engages the floor or support surface.

- the shape of the slot 810 may be optimized to reduce the amount of travel of the pivot arm 806 .

- the travel of the pivot arm may be configured to accommodate a wide variety of different applications.

- the pivot arm 806 may initially be positioned at a horizontal position at the top of the stroke and then rotate downward.

- the pivot arm could also be initially positioned above horizontal at the top of the stroke and then pivot downward.

- FIGS. 8A-C illustrate the mechanism 800 latched at a retracted position where the pivot arm 806 is at the top of the stroke. Referring to FIG. 8C , at this position the first latch projection 136 is in latched with the first catch 104 .

- FIGS. 9A-9C illustrate the mechanism where the pivot arm 806 has been rotated to the bottom of the stroke of the pivot arm.

- the latch portion 132 of the detent member 114 is moved over and past the second catch 106 .

- FIGS. 10A-10C illustrate the mechanism 800 when the pivot arm 806 is released after being moved to the bottom of the stroke to latch the mechanism in the extended position.

- the second latch projection 138 latches with the second catch 106 .

- FIGS. 11A-11C illustrate the mechanism 800 when the pivot arm 806 is moved to the bottom of the stroke again and then gradually released.

- the second latch projection 138 disengages from the second catch 106 and moves toward the retracted position.

- the mechanism returns to the condition illustrated by FIGS. 8A-8C and is ready to operate again.

- FIG. 12 illustrates an example of a single member 1200 that may be used to operate two latching motion transfer mechanisms 800 (See FIG. 8 ).

- the member 1200 may be configured to accommodate a wide variety of different applications.

- the member 1200 is configured to be engaged by an operators foot.

- the member may be configured to be moved by an operator stepping on the member to cause two mechanisms to lift two caster assemblies off of a support surface.

- the member 1200 is an elongated bar that is attached to two pivot arms 806 a pin and follower mechanism to drive two mechanisms at the same time (such as the pivot arms of mechanism 800 described above). Referring to FIGS.

- the member 1200 by connecting the member 1200 to two pivot arms 806 of two mechanisms 800 , the movement of the pins 806 and the drive members 112 are substantially coupled together.

- the follower pins 804 are disposed at substantially the same position along their respective path of travel and the member 1200 maintains the pins in substantial alignment.

- FIGS. 13A-13F illustrate another embodiment of a linkage 1303 with synchronization members 1310 that maintains synchronization between of two latching motion transfer mechanisms 800 and that resynchronizes detent members that become unsynchronized.

- the linkage 1303 operates to have substantially the same effect as the linkage 203 illustrated by FIG. 2 and the linkage 703 illustrated by FIG. 7 .

- the linkage 1303 comprises synchronization members 1310 connected to the driven member 124 and coupled to the pin 804 of two latching motion transfer mechanisms 800 .

- FIGS. 13A and 13B only one of the latching motion transfer mechanisms 800 with a synchronization member 1310 is shown connected to one end of the member 1200 illustrated by FIG. 12 .

- FIG. 13B Another substantially identical or mirror image mechanism 800 with a substantially identical or mirror image synchronization member 1310 is connected to the other end of the member 1200 and is not shown.

- the synchronization member 1310 is coupled to the pin 804 . Since the pins 804 are coupled together by the pivot arms 806 and the member 1200 , the coupling of the both driven members 124 to both pins 804 prevents one driven member from moving substantially with respect to the other driven member.

- the synchronization member 1310 may be coupled to the pin in a wide variety of different ways. In the example illustrated by FIG. 13B , the synchronization member 1310 includes a slot 1320 ( FIG. 13B ) that the pin 804 is disposed in.

- the synchronization member is coupled to the member 1200 through the pin such that the member 1310 may move only a small amount without engaging the pin 1310 .

- the synchronization members 1310 maintain a disengaged mechanism in the extended position whenever a coupled mechanism is latched in the extended position. Ends of the slot 1320 act as stops that limit movement of the members 1310 with respect to the pin.

- the embodiment of the linkage 1303 maintains synchronization in generally the same manner as the linkage 203 and 703 and as described with respect to FIGS. 3-6 .

- an optional second biasing member 1350 is positioned to act between the frame 102 and the lever 806 of the mechanism 800 .

- the second biasing member 1350 assists the lever 806 in returning to the initial position at the top of its stroke (i.e. the position shown in FIG. 8A ).

- the biasing member 1350 may take a wide variety of different forms and may be positioned in any manner that urges the pivot arm toward the top of the stroke of the pivot arm.

- FIGS. 14-16 illustrates one of the wide variety of applications the motion transfer mechanisms may be used in.

- FIG. 14 illustrates a bed 1400 , which may be an articulating bed.

- the bed 1400 is supported by caster assemblies 1402 that allow the articulating bed to be rolled over a support surface 1404 .

- the latching motion transfer mechanisms 100 , 800 may be connected one or more of the casters or to the bed 1400 near one or more of the caster assemblies 1402 for selectively lifting the one or more caster assemblies from the support surface 1404 to stabilize the bed 1400 at a stationary position.

- the latching motion transfer mechanisms When the bed is to be moved or otherwise supported by the casters, the latching motion transfer mechanisms are returned to the retracted position to return the caster assemblies to engagement with the support surface 1404 . Pairs of the latching motion transfer mechanisms may be coupled together, or all four latching motion transfer mechanisms may be coupled together and be actuated simultaneously. In another embodiment, each latching motion transfer mechanism is actuated individually.

- the caster assemblies 1402 may be coupled to the bed 1400 in a wide variety of different ways. Any coupling arrangement may be used that moveably or fixedly attaches a caster assembly to the bed.

- FIGS. 18 and 19 illustrate one exemplary embodiment of a caster coupling arrangement 1800 .

- the caster coupling arrangement 1800 is used with a bed 1400 that includes a tubular frame element 1802 .

- the caster coupling arrangement 1800 includes a caster bracket 1804 , a first wedge member 1806 , a second wedge member 1808 , and a clamping arrangement 1810 .

- One or more casters 1812 are rotatably mounted to the caster bracket 1804 .

- the first wedge member 1806 may take a wide variety of different forms. In the example illustrated by FIG.

- the first wedge member 1806 is generally cylindrical with an inclined end surface 1820 .

- the second wedge member 1808 may take a wide variety of different forms. In the illustrated example, the second wedge member 1808 is generally cylindrical with an inclined end surface 1822 .

- the clamping arrangement 1810 may take a wide variety of different forms. Any arrangement that forces the first and second wedge members 1806 , 1810 together may be used.

- the clamping arrangement 1810 comprises a bolt 1830 and a nut 1832 .

- the bolt 1830 extends through a hole 1834 in the caster bracket 1804 , a hole 1836 through the first wedge member 1806 , and a hole 1838 through the second wedge member 1808 . Referring to FIG.

- the nut 1832 is threaded onto the bolt.

- the first and second wedge members 1806 , 1808 are slid into the tubular frame element 1802 .

- the bolt an and nut are tightened to pull the inclined surfaces of the wedge members 1806 , 1808 against one another.

- the inclined surfaces force the wedge members outward into engagement with the tubular frame element 1802 to secure the caster to the tubular frame element.

Landscapes

- Health & Medical Sciences (AREA)

- Nursing (AREA)

- General Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Invalid Beds And Related Equipment (AREA)

- Handcart (AREA)

Abstract

Description

Claims (7)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US14/085,827 US8990982B2 (en) | 2007-10-17 | 2013-11-21 | Latching motion transfer mechanism |

| US14/644,411 US9381126B2 (en) | 2007-10-17 | 2015-03-11 | Latching motion transfer mechanism |

| US15/176,369 US20170035635A1 (en) | 2007-10-17 | 2016-06-08 | Latching motion transfer mechanism |

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US98047607P | 2007-10-17 | 2007-10-17 | |

| US12/246,634 US8191940B2 (en) | 2007-10-17 | 2008-10-07 | Latching motion transfer mechanism |

| US13/487,356 US8590073B2 (en) | 2007-10-17 | 2012-06-04 | Latching motion transfer mechanism |

| US14/085,827 US8990982B2 (en) | 2007-10-17 | 2013-11-21 | Latching motion transfer mechanism |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US13/487,356 Division US8590073B2 (en) | 2007-10-17 | 2012-06-04 | Latching motion transfer mechanism |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US14/644,411 Division US9381126B2 (en) | 2007-10-17 | 2015-03-11 | Latching motion transfer mechanism |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| US20140245535A1 US20140245535A1 (en) | 2014-09-04 |

| US8990982B2 true US8990982B2 (en) | 2015-03-31 |

Family

ID=40560115

Family Applications (5)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US12/246,634 Expired - Fee Related US8191940B2 (en) | 2007-10-17 | 2008-10-07 | Latching motion transfer mechanism |

| US13/487,356 Active US8590073B2 (en) | 2007-10-17 | 2012-06-04 | Latching motion transfer mechanism |

| US14/085,827 Active US8990982B2 (en) | 2007-10-17 | 2013-11-21 | Latching motion transfer mechanism |

| US14/644,411 Active US9381126B2 (en) | 2007-10-17 | 2015-03-11 | Latching motion transfer mechanism |

| US15/176,369 Abandoned US20170035635A1 (en) | 2007-10-17 | 2016-06-08 | Latching motion transfer mechanism |

Family Applications Before (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US12/246,634 Expired - Fee Related US8191940B2 (en) | 2007-10-17 | 2008-10-07 | Latching motion transfer mechanism |

| US13/487,356 Active US8590073B2 (en) | 2007-10-17 | 2012-06-04 | Latching motion transfer mechanism |

Family Applications After (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US14/644,411 Active US9381126B2 (en) | 2007-10-17 | 2015-03-11 | Latching motion transfer mechanism |

| US15/176,369 Abandoned US20170035635A1 (en) | 2007-10-17 | 2016-06-08 | Latching motion transfer mechanism |

Country Status (2)

| Country | Link |

|---|---|

| US (5) | US8191940B2 (en) |

| CA (1) | CA2619102C (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20150182401A1 (en) * | 2007-10-17 | 2015-07-02 | Invacare Corporation | Latching motion transfer mechanism |

| US11439549B2 (en) * | 2016-03-28 | 2022-09-13 | NOA Medical Industries, Inc. | Castor base with load sensor |

Families Citing this family (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CZ17216U1 (en) * | 2006-11-09 | 2007-02-05 | Linet, Spol. S R. O. | Guide wheel assembly, especially for hospital bed |

| CA2747256C (en) * | 2008-12-18 | 2014-11-18 | Invacare Corporation | Wheelchair with adjustable seat |

| US8418283B2 (en) | 2010-05-10 | 2013-04-16 | Drive Medical Design & Mfg. | Universal bed system |

| US8424135B2 (en) | 2010-05-10 | 2013-04-23 | Drive Medical Design & Mfg | Universal bed system |

| FR2976792B1 (en) * | 2011-06-21 | 2013-07-26 | Edena Sas | BRAKING SYSTEM OF A MEDICAL BED |

| US8800080B2 (en) * | 2011-09-01 | 2014-08-12 | Drive Medical Design & Mfg. | Long term care bed |

| CN102389354B (en) * | 2011-09-09 | 2013-01-23 | 宁波康麦隆医疗器械有限公司 | Lifting sickbed |

| US20130318720A1 (en) * | 2012-06-01 | 2013-12-05 | Chg Hospital Beds Inc. | Patient support with improved patient safety |

| CN102895081A (en) * | 2012-09-27 | 2013-01-30 | 宁波康麦隆医疗器械有限公司 | Lifting sickbed |

| EP2873400B1 (en) | 2013-11-18 | 2018-01-31 | Völker GmbH | Person support apparatus |

| US9603764B2 (en) | 2014-02-11 | 2017-03-28 | Medline Industries, Inc. | Method and apparatus for a locking caster |

| US9918888B2 (en) * | 2014-03-21 | 2018-03-20 | Medline Industries, Inc. | Locking mechanism with pivotable foot actuation lever |

| US10111790B2 (en) | 2014-06-13 | 2018-10-30 | Medical Depot, Inc. | Long term care bed |

| US9994072B2 (en) | 2014-09-17 | 2018-06-12 | Medical Depot, Inc. | Patient care bed |

| US10667976B2 (en) * | 2015-05-28 | 2020-06-02 | Medical Positioning, Inc. | Low clearance medical imaging chair |

| CA2955296C (en) * | 2016-01-21 | 2024-01-02 | Midmark Corporation | Medical examination table with retractable moving wheels |

| US10660813B2 (en) * | 2016-01-21 | 2020-05-26 | Midmark Corporation | Medical examination table with retractable moving wheels |

| US11266554B2 (en) * | 2017-09-08 | 2022-03-08 | Kreg Medical, Inc. | Bed base frame |

| CZ2020330A3 (en) * | 2020-06-10 | 2021-04-07 | BORCAD Medical a.s. | Adjustable manipulating wheel mechanism and positioning it |

| CN111904767A (en) * | 2020-08-26 | 2020-11-10 | 翁欣欣 | Clinical examination device for emergency internal medicine |

| CN113006621A (en) * | 2021-03-29 | 2021-06-22 | 珠海格力电器股份有限公司 | Lock mechanism and dish washing machine |

| CN113606269B (en) * | 2021-07-09 | 2022-04-29 | 武汉大学 | Emergency braking device and braking method for medical bed trolley |

Citations (35)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US756453A (en) * | 1903-12-23 | 1904-04-05 | P & F Corbin | Sash-bolt. |

| US780417A (en) * | 1904-04-13 | 1905-01-17 | Hurwood Mfg Company | Window-blind fastener. |

| US950545A (en) * | 1909-07-07 | 1910-03-01 | Kny Scheerer Company | Caster for operating-tables. |

| US1133798A (en) * | 1913-12-26 | 1915-03-30 | Frank A Hall | Caster for beds, operating-tables, and the like. |

| US1174582A (en) * | 1915-11-13 | 1916-03-07 | George P Clark Company | Caster. |

| US1253179A (en) * | 1917-01-08 | 1918-01-08 | George P Clark Company | Lifting and lowering apparatus. |

| US1636325A (en) * | 1921-12-16 | 1927-07-19 | Colson Company | Caster mechanism |

| US1999106A (en) * | 1934-04-17 | 1935-04-23 | Muller Hans | Travel support device for bedsteads and the like |

| US2262288A (en) * | 1940-04-15 | 1941-11-11 | Raleigh I Klipstein | Fluid lift and stabilizer for washers and the like |

| US2671242A (en) * | 1951-04-06 | 1954-03-09 | Gilbert L Lewis | Hydraulic caster lift |

| US2675285A (en) * | 1952-10-14 | 1954-04-13 | Terry Eselle | Vertically adjustable therapy treatment table having hinged end sections |

| US2783055A (en) * | 1954-03-08 | 1957-02-26 | Frank H Michaud | Vertically adjustable wheeled supporting frame for cabinets and the like |

| US2830304A (en) * | 1953-12-21 | 1958-04-15 | Sangfabriken Ab | Raising and lowering mechanisms in wheeled hospital beds |

| US3422828A (en) | 1966-12-30 | 1969-01-21 | Henry Dommer | Cleaner for paint rollers |

| US3422929A (en) * | 1967-07-31 | 1969-01-21 | Carl W Oja | Floor contacting brake mechanism |

| US3918752A (en) * | 1974-04-11 | 1975-11-11 | Adolph A Leone | Safety locking device |

| US4482175A (en) * | 1983-02-04 | 1984-11-13 | Kabushiki Kaisha Isshin Kenkyusho | Locking devices |

| US4747180A (en) * | 1985-06-17 | 1988-05-31 | Colson Castors (U.K.) | Castor incorporating a braking mechanism |

| US4917416A (en) * | 1988-09-21 | 1990-04-17 | Certainteed Corporation | Window latching device |

| US5347682A (en) * | 1993-02-02 | 1994-09-20 | Joerns Healthcare Inc. | Two position floor lock and caster assembly |

| US5984381A (en) * | 1997-02-03 | 1999-11-16 | Tokyo Magnet Ohyo Seihin Kabushiki Kaisha | Locking devices |

| US6055704A (en) * | 1998-06-29 | 2000-05-02 | Xerox Corporation | Caster with built-in adjustment |

| US6588809B1 (en) * | 2002-04-29 | 2003-07-08 | Jay S. Derman | Push-to-release cabinet door latch |

| US6591449B1 (en) * | 1999-04-10 | 2003-07-15 | Apw Ltd. | Caster assemblies |

| US20030172459A1 (en) * | 2000-09-29 | 2003-09-18 | Roussy Richard Brian | Height adjustable bed and automatic leg stabilizer system therefor |

| US20040105733A1 (en) * | 2002-11-26 | 2004-06-03 | Timothy Hewitt | Floor stop for a mobile base |

| US20050017138A1 (en) * | 2003-07-23 | 2005-01-27 | Hardin Larry C. | Stable tripod for telescope |

| US6981538B2 (en) * | 2001-08-31 | 2006-01-03 | William English | Positional control device for sectional doors |

| US20070080030A1 (en) * | 2005-10-06 | 2007-04-12 | Sunrise Medical Hhg Inc. | Brake assembly for beds |

| US20070226907A1 (en) * | 2006-02-11 | 2007-10-04 | Volker Ag | Bed, in particular sickbed or nursing bed |

| US20070234477A1 (en) * | 2006-02-11 | 2007-10-11 | Volker Ag | Bed, in particular sickbed or nursing bed |

| US7503722B2 (en) * | 2006-06-22 | 2009-03-17 | Zippy Technology Corp. | Positioning device for clipping apparatus |

| US20090100598A1 (en) * | 2007-10-17 | 2009-04-23 | Invacare Corporation | Latching motion transfer mechanism |

| US7766407B2 (en) * | 2005-06-24 | 2010-08-03 | Nifco Inc. | Door opening and closing device |

| US7793995B2 (en) * | 2006-07-27 | 2010-09-14 | Illinois Tool Works Inc. | Push/push latch |

-

2008

- 2008-01-29 CA CA2619102A patent/CA2619102C/en active Active

- 2008-10-07 US US12/246,634 patent/US8191940B2/en not_active Expired - Fee Related

-

2012

- 2012-06-04 US US13/487,356 patent/US8590073B2/en active Active

-

2013

- 2013-11-21 US US14/085,827 patent/US8990982B2/en active Active

-

2015

- 2015-03-11 US US14/644,411 patent/US9381126B2/en active Active

-

2016

- 2016-06-08 US US15/176,369 patent/US20170035635A1/en not_active Abandoned

Patent Citations (46)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US756453A (en) * | 1903-12-23 | 1904-04-05 | P & F Corbin | Sash-bolt. |

| US780417A (en) * | 1904-04-13 | 1905-01-17 | Hurwood Mfg Company | Window-blind fastener. |

| US950545A (en) * | 1909-07-07 | 1910-03-01 | Kny Scheerer Company | Caster for operating-tables. |

| US1133798A (en) * | 1913-12-26 | 1915-03-30 | Frank A Hall | Caster for beds, operating-tables, and the like. |

| US1174582A (en) * | 1915-11-13 | 1916-03-07 | George P Clark Company | Caster. |

| US1253179A (en) * | 1917-01-08 | 1918-01-08 | George P Clark Company | Lifting and lowering apparatus. |

| US1636325A (en) * | 1921-12-16 | 1927-07-19 | Colson Company | Caster mechanism |

| US1999106A (en) * | 1934-04-17 | 1935-04-23 | Muller Hans | Travel support device for bedsteads and the like |

| US2262288A (en) * | 1940-04-15 | 1941-11-11 | Raleigh I Klipstein | Fluid lift and stabilizer for washers and the like |

| US2671242A (en) * | 1951-04-06 | 1954-03-09 | Gilbert L Lewis | Hydraulic caster lift |

| US2675285A (en) * | 1952-10-14 | 1954-04-13 | Terry Eselle | Vertically adjustable therapy treatment table having hinged end sections |

| US2830304A (en) * | 1953-12-21 | 1958-04-15 | Sangfabriken Ab | Raising and lowering mechanisms in wheeled hospital beds |

| US2783055A (en) * | 1954-03-08 | 1957-02-26 | Frank H Michaud | Vertically adjustable wheeled supporting frame for cabinets and the like |

| US3422828A (en) | 1966-12-30 | 1969-01-21 | Henry Dommer | Cleaner for paint rollers |

| US3422929A (en) * | 1967-07-31 | 1969-01-21 | Carl W Oja | Floor contacting brake mechanism |

| US3918752A (en) * | 1974-04-11 | 1975-11-11 | Adolph A Leone | Safety locking device |

| US4482175A (en) * | 1983-02-04 | 1984-11-13 | Kabushiki Kaisha Isshin Kenkyusho | Locking devices |

| US4747180A (en) * | 1985-06-17 | 1988-05-31 | Colson Castors (U.K.) | Castor incorporating a braking mechanism |

| US4917416A (en) * | 1988-09-21 | 1990-04-17 | Certainteed Corporation | Window latching device |

| US5347682A (en) * | 1993-02-02 | 1994-09-20 | Joerns Healthcare Inc. | Two position floor lock and caster assembly |

| US5984381A (en) * | 1997-02-03 | 1999-11-16 | Tokyo Magnet Ohyo Seihin Kabushiki Kaisha | Locking devices |

| US6055704A (en) * | 1998-06-29 | 2000-05-02 | Xerox Corporation | Caster with built-in adjustment |

| US6591449B1 (en) * | 1999-04-10 | 2003-07-15 | Apw Ltd. | Caster assemblies |

| US6920656B2 (en) * | 2000-09-29 | 2005-07-26 | Carroll Healthcare, Inc. | Height adjustable bed and automatic leg stabilizer system therefor |

| US20030172459A1 (en) * | 2000-09-29 | 2003-09-18 | Roussy Richard Brian | Height adjustable bed and automatic leg stabilizer system therefor |

| US7185377B2 (en) * | 2000-09-29 | 2007-03-06 | Invacare Corporation | Height adjustable bed and automatic leg stabilizer system therefor |

| US20050283912A1 (en) * | 2000-09-29 | 2005-12-29 | Roussy Richard B | Height adjustable bed and automatic leg stabilizer system therefor |

| US6981538B2 (en) * | 2001-08-31 | 2006-01-03 | William English | Positional control device for sectional doors |

| US6588809B1 (en) * | 2002-04-29 | 2003-07-08 | Jay S. Derman | Push-to-release cabinet door latch |

| US6843625B2 (en) * | 2002-11-26 | 2005-01-18 | Htc Products, Inc. | Floor stop for a mobile base |

| US20040105733A1 (en) * | 2002-11-26 | 2004-06-03 | Timothy Hewitt | Floor stop for a mobile base |

| US20050017138A1 (en) * | 2003-07-23 | 2005-01-27 | Hardin Larry C. | Stable tripod for telescope |

| US7077369B2 (en) * | 2003-07-23 | 2006-07-18 | Hardin Optical Co. | Stable tripod for telescope |

| US7766407B2 (en) * | 2005-06-24 | 2010-08-03 | Nifco Inc. | Door opening and closing device |

| US20070080030A1 (en) * | 2005-10-06 | 2007-04-12 | Sunrise Medical Hhg Inc. | Brake assembly for beds |

| US7509697B2 (en) * | 2006-02-11 | 2009-03-31 | Völker AG | Height-adjustable bed |

| US20070234477A1 (en) * | 2006-02-11 | 2007-10-11 | Volker Ag | Bed, in particular sickbed or nursing bed |

| US7703157B2 (en) * | 2006-02-11 | 2010-04-27 | Völker AG | Bed, in particular sickbed or nursing bed |

| US20070226907A1 (en) * | 2006-02-11 | 2007-10-04 | Volker Ag | Bed, in particular sickbed or nursing bed |

| US7503722B2 (en) * | 2006-06-22 | 2009-03-17 | Zippy Technology Corp. | Positioning device for clipping apparatus |

| US7793995B2 (en) * | 2006-07-27 | 2010-09-14 | Illinois Tool Works Inc. | Push/push latch |

| US20090100598A1 (en) * | 2007-10-17 | 2009-04-23 | Invacare Corporation | Latching motion transfer mechanism |

| US8191940B2 (en) * | 2007-10-17 | 2012-06-05 | Invacare Corp. | Latching motion transfer mechanism |

| US20120233779A1 (en) * | 2007-10-17 | 2012-09-20 | Invacare Corp. | Latching motion transfer mechanism |

| US8590073B2 (en) * | 2007-10-17 | 2013-11-26 | Invacare Corporation | Latching motion transfer mechanism |

| US20140245535A1 (en) * | 2007-10-17 | 2014-09-04 | Invacare Corporation | Latching motion transfer mechanism |

Non-Patent Citations (9)

| Title |

|---|

| Interview Summary from U.S. Appl. No. 12/246,634 dated Jan. 27, 2012. |

| Notice of Allowance from U.S. Appl. No. 12/246,634 dated Mar. 28, 2012. |

| Notice of Allowance from U.S. Appl. No. 13/487,356 dated Jul. 29, 2013. |

| Office Action from U.S. Appl. No. 12/246,634 dated Feb. 23, 2012. |

| Office Action from U.S. Appl. No. 12/246,634, dated Aug. 17, 2011. |

| Office Action from U.S. Appl. No. 13/487,356 dated Nov. 16, 2012. |

| Response to Office Action from U.S. Appl. No. 12/246,634 dated Jan. 17, 2012. |

| Response to Office Action from U.S. Appl. No. 12/246,634 dated Mar. 15, 2012. |

| Response to Office Action from U.S. Appl. No. 13/487,356 date May 15, 2013. |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20150182401A1 (en) * | 2007-10-17 | 2015-07-02 | Invacare Corporation | Latching motion transfer mechanism |

| US9381126B2 (en) * | 2007-10-17 | 2016-07-05 | Invacare Corporation | Latching motion transfer mechanism |

| US11439549B2 (en) * | 2016-03-28 | 2022-09-13 | NOA Medical Industries, Inc. | Castor base with load sensor |

| US11877967B2 (en) | 2016-03-28 | 2024-01-23 | NOA Medical Industries, Inc. | Castor base with load sensor |

Also Published As

| Publication number | Publication date |

|---|---|

| US20150182401A1 (en) | 2015-07-02 |

| CA2619102C (en) | 2015-11-03 |

| US8191940B2 (en) | 2012-06-05 |

| US20140245535A1 (en) | 2014-09-04 |

| CA2619102A1 (en) | 2009-04-17 |

| US9381126B2 (en) | 2016-07-05 |

| US20090100598A1 (en) | 2009-04-23 |

| US8590073B2 (en) | 2013-11-26 |

| US20170035635A1 (en) | 2017-02-09 |

| US20120233779A1 (en) | 2012-09-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9381126B2 (en) | Latching motion transfer mechanism | |

| CA2201253C (en) | Chair control | |

| KR101048162B1 (en) | Sheet conveying track device | |

| US8235407B2 (en) | Wheelchair with adjustable seat | |

| US7229091B2 (en) | Automatically unfoldable stroller | |

| US9579241B2 (en) | Support arrangement with activation mechanism | |

| JPWO2002051347A1 (en) | stretcher | |

| US7100316B2 (en) | Collapsible ironing board | |

| US9950726B2 (en) | Combination dolly-pallets | |

| CA2454466A1 (en) | Bag and method of moving | |

| JP2015531329A (en) | Vehicle seats, especially automobile seats | |

| CN103392073A (en) | Device for mutually locking two slidably mounted tubes | |

| TW512110B (en) | Swivel arm of lifting device for vehicle maintenance | |

| CN108715182B (en) | Base lock mechanism of stopping | |

| WO2018113320A1 (en) | Chair capable of being used as bed | |

| US9918888B2 (en) | Locking mechanism with pivotable foot actuation lever | |

| DE202018102424U1 (en) | Wheelchair with adjustable drive wheel | |

| JP3560236B2 (en) | Stop and hold mechanism for furniture with casters | |

| JP3347049B2 (en) | Battery drawer | |

| CN218552588U (en) | Medical bed truckle brake equipment and medical bed | |

| JP3799548B2 (en) | Caster with swivel control mechanism | |

| JPH0732162Y2 (en) | Castor structure with two-dimensional stopper | |

| DE112022003429T5 (en) | Conversion mechanism for a dual purpose seat-bed support for a storage device, seat and storage device | |

| JPH033233Y2 (en) | ||

| CN118383620A (en) | Leg support device and seat |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AS | Assignment |

Owner name: PNC BANK, NATIONAL ASSOCIATION, PENNSYLVANIA Free format text: SECURITY AGREEMENT;ASSIGNORS:INVACARE CORPORATION;ADAPTIVE SWITCH LABORATORIES, INC.;THE AFTERMARKET GROUP, INC.;AND OTHERS;REEL/FRAME:032162/0921 Effective date: 20131231 |

|

| AS | Assignment |

Owner name: INVACARE CORP., OHIO Free format text: ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNORS:BLY, ROBERT R;WYSOCKI, KEVIN S;GREGORY, MICHAEL A;SIGNING DATES FROM 20080124 TO 20080208;REEL/FRAME:033186/0583 |

|

| AS | Assignment |

Owner name: INVACARE CORPORATION, OHIO Free format text: ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNORS:BLY, ROBERT R.;WYSOCKI, KEVIN S.;GREGORY, MICHAEL A.;SIGNING DATES FROM 20080124 TO 20080208;REEL/FRAME:034142/0728 |

|

| STCF | Information on status: patent grant |

Free format text: PATENTED CASE |

|

| MAFP | Maintenance fee payment |

Free format text: PAYMENT OF MAINTENANCE FEE, 4TH YEAR, LARGE ENTITY (ORIGINAL EVENT CODE: M1551); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY Year of fee payment: 4 |

|

| AS | Assignment |

Owner name: GLAS TRUST CORPORATION LIMITED, AS COLLATERAL AGENT, UNITED KINGDOM Free format text: PATENT SECURITY AGREEMENT (TRANCHE II NOTES);ASSIGNORS:INVACARE CORPORATION;FREEDOM DESIGNS, INC.;REEL/FRAME:061131/0852 Effective date: 20220726 Owner name: GLAS TRUST CORPORATION LIMITED, AS COLLATERAL AGENT, UNITED KINGDOM Free format text: PATENT SECURITY AGREEMENT (TRANCHE I NOTES);ASSIGNORS:INVACARE CORPORATION;FREEDOM DESIGNS, INC.;REEL/FRAME:061131/0833 Effective date: 20220726 Owner name: GLAS TRUST CORPORATION LIMITED, AS COLLATERAL AGENT, UNITED KINGDOM Free format text: PATENT SECURITY AGREEMENT (TERM LOAN);ASSIGNORS:INVACARE CORPORATION;FREEDOM DESIGNS, INC.;REEL/FRAME:061131/0814 Effective date: 20220726 |

|

| MAFP | Maintenance fee payment |

Free format text: PAYMENT OF MAINTENANCE FEE, 8TH YEAR, LARGE ENTITY (ORIGINAL EVENT CODE: M1552); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY Year of fee payment: 8 |

|

| AS | Assignment |

Owner name: GLAS TRUST CORPORATION LIMITED, AS COLLATERAL AGENT, UNITED KINGDOM Free format text: PATENT SECURITY AGREEMENT;ASSIGNORS:INVACARE CORPORATION;MOTION CONCEPTS L.P.;FREEDOM DESIGNS, INC.;REEL/FRAME:063090/0603 Effective date: 20230202 Owner name: PNC BANK, NATIONAL ASSOCIATION, PENNSYLVANIA Free format text: SECURITY INTEREST;ASSIGNORS:INVACARE CORPORATION;ADAPTIVE SWITCH LABORATORIES, INC.;FREEDOM DESIGNS, INC.;AND OTHERS;REEL/FRAME:062739/0687 Effective date: 20230202 |

|

| AS | Assignment |

Owner name: WHITE OAK COMMERCIAL FINANCE, LLC, AS COLLATERAL AGENT, CALIFORNIA Free format text: SECURITY INTEREST;ASSIGNORS:INVACARE CORPORATION;FREEDOM DESIGNS, INC.;MOTION CONCEPTS L.P.;REEL/FRAME:063553/0217 Effective date: 20230505 |

|

| AS | Assignment |

Owner name: FREEDOM DESIGNS, INC., CALIFORNIA Free format text: INTELLECTUAL PROPERTY RELEASE (TRANCHE II NOTES);ASSIGNOR:GLAS TRUST CORPORATION LIMITED, AS COLLATERAL AGENT;REEL/FRAME:063601/0183 Effective date: 20230505 Owner name: INVACARE CORPORATION, OHIO Free format text: INTELLECTUAL PROPERTY RELEASE (TRANCHE II NOTES);ASSIGNOR:GLAS TRUST CORPORATION LIMITED, AS COLLATERAL AGENT;REEL/FRAME:063601/0183 Effective date: 20230505 Owner name: MOTION CONCEPTS L.P., CANADA Free format text: INTELLECTUAL PROPERTY RELEASE (DIP PAYOFF);ASSIGNOR:GLAS TRUST CORPORATION LIMITED, AS COLLATERAL AGENT;REEL/FRAME:063594/0272 Effective date: 20230505 Owner name: FREEDOM DESIGNS, INC., CALIFORNIA Free format text: INTELLECTUAL PROPERTY RELEASE (DIP PAYOFF);ASSIGNOR:GLAS TRUST CORPORATION LIMITED, AS COLLATERAL AGENT;REEL/FRAME:063594/0272 Effective date: 20230505 Owner name: INVACARE CORPORATION, OHIO Free format text: INTELLECTUAL PROPERTY RELEASE (DIP PAYOFF);ASSIGNOR:GLAS TRUST CORPORATION LIMITED, AS COLLATERAL AGENT;REEL/FRAME:063594/0272 Effective date: 20230505 Owner name: FREEDOM DESIGNS, INC., CALIFORNIA Free format text: INTELLECTUAL PROPERTY RELEASE (TRANCHE I NOTES);ASSIGNOR:GLAS TRUST CORPORATION LIMITED, AS COLLATERAL AGENT;REEL/FRAME:063594/0906 Effective date: 20230505 Owner name: INVACARE CORPORATION, OHIO Free format text: INTELLECTUAL PROPERTY RELEASE (TRANCHE I NOTES);ASSIGNOR:GLAS TRUST CORPORATION LIMITED, AS COLLATERAL AGENT;REEL/FRAME:063594/0906 Effective date: 20230505 |

|

| AS | Assignment |

Owner name: GLAS TRUST COMPANY LLC, AS SUCCESSOR COLLATERAL AGENT, NEW JERSEY Free format text: ASSIGNMENT OF SECURITY INTEREST IN INTELLECTUAL PROPERTY RIGHTS;ASSIGNOR:GLAS TRUST CORPORATION LIMITED, AS EXISTING COLLATERAL AGENT;REEL/FRAME:063625/0607 Effective date: 20230505 |

|

| AS | Assignment |

Owner name: GLAS TRUST COMPANY LLC, AS COLLATERAL AGENT, NEW JERSEY Free format text: PATENT SECURITY AGREEMENT (TRANCHE I NOTES);ASSIGNORS:INVACARE CORPORATION;MOTION CONCEPTS L.P;FREEDOM DESIGNS, INC.;REEL/FRAME:064005/0231 Effective date: 20230505 |

|

| AS | Assignment |

Owner name: GLAS TRUST COMPANY LLC, AS COLLATERAL AGENT, NEW JERSEY Free format text: PATENT SECURITY AGREEMENT (TRANCHE II NOTES);ASSIGNORS:INVACARE CORPORATION;MOTION CONCEPTS L.P;FREEDOM DESIGNS, INC.;REEL/FRAME:063637/0705 Effective date: 20230505 |

|

| AS | Assignment |

Owner name: INVACARE OUTCOMES MANAGEMENT LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: INVAMEX HOLDINGS LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: INVACARE INTERNATIONAL CORPORATION, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: INVACARE HOLDINGS, LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: INVACARE FLORIDA HOLDINGS, LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: INVACARE FLORIDA CORPORATION, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: INVACARE CREDIT CORPORATION, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: INVACARE CANDIAN HOLDINGS, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: INVACARE CANADIAN FINANCE, LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: THE HELIXX GROUP, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: CENTRALIZED MEDICAL EQUIPMENT LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: ADAPTIVE SWITCH LABORATORIES, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: MEDBLOC, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: INVACARE CONTINUING CARE, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: DYNAMIC MEDICAL SYSTEMS, LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: THE AFTERMARKET GROUP, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: GARDEN CITY MEDICAL INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: FREEDOM DESIGNS, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: INVACARE CORPORATION, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063668/0639 Effective date: 20230505 Owner name: INVACARE HCS, LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: INVACARE FLORIDA HOLDINGS, LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: GARDEN CITY MEDICAL INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: FREEDOM DESIGNS, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: ROADRUNNER MOBILITY, INCORPORATED, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: KUSCHALL, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: INVAMEX HOLDINGS LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: INVACARE SUPPLY GROUP, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: INVACARE INTERNATIONAL CORPORATION, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: INVACARE HOLDINGS, LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: INVACARE FLORIDA CORPORATION, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: INVACARE CREDIT CORPORATION, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: INVACARE CONTINUING CARE, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: INVACARE CANADIAN HOLDINGS, LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: INVACARE CANADIAN HOLDINGS, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: THE HELIXX GROUP, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: FAMILY MEDICAL SUPPLY LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: CHAMPION MANUFACTURING INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: CENTRALIZED MEDICAL EQUIPMENT LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: ALTIMATE MEDICAL, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: THE AFTERMARKET GROUP, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: ADAPTIVE SWITCH LABORATORIES, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 Owner name: INVACARE CORPORATION, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063662/0430 Effective date: 20230505 |

|

| AS | Assignment |

Owner name: INVAMEX HOLDINGS LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063695/0106 Effective date: 20230505 Owner name: INVACARE HOLDINGS, LLC, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063695/0106 Effective date: 20230505 Owner name: INVACARE CREDIT CORPORATION, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063695/0106 Effective date: 20230505 Owner name: MEDBLOC, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063695/0106 Effective date: 20230505 Owner name: FREEDOM DESIGNS, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063695/0106 Effective date: 20230505 Owner name: ADAPTIVE SWITCH LABORATORIES, INC., OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063695/0106 Effective date: 20230505 Owner name: INVACARE CORPORATION, OHIO Free format text: RELEASE BY SECURED PARTY;ASSIGNOR:PNC BANK, NATIONAL ASSOCIATION;REEL/FRAME:063695/0106 Effective date: 20230505 |