US20050221339A1 - Compartmentalised screening by microfluidic control - Google Patents

Compartmentalised screening by microfluidic control Download PDFInfo

- Publication number

- US20050221339A1 US20050221339A1 US10/963,044 US96304404A US2005221339A1 US 20050221339 A1 US20050221339 A1 US 20050221339A1 US 96304404 A US96304404 A US 96304404A US 2005221339 A1 US2005221339 A1 US 2005221339A1

- Authority

- US

- United States

- Prior art keywords

- compound

- microcapsule

- microcapsules

- target

- microbead

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

- 238000012216 screening Methods 0.000 title claims abstract description 34

- 239000003094 microcapsule Substances 0.000 claims abstract description 435

- 150000001875 compounds Chemical class 0.000 claims abstract description 412

- 238000000034 method Methods 0.000 claims abstract description 230

- 230000000694 effects Effects 0.000 claims abstract description 111

- 239000011325 microbead Substances 0.000 claims description 264

- 239000007788 liquid Substances 0.000 claims description 164

- 239000012530 fluid Substances 0.000 claims description 162

- 230000003287 optical effect Effects 0.000 claims description 138

- 230000005684 electric field Effects 0.000 claims description 109

- 238000006243 chemical reaction Methods 0.000 claims description 100

- 239000000758 substrate Substances 0.000 claims description 94

- 230000008859 change Effects 0.000 claims description 82

- 239000000047 product Substances 0.000 claims description 79

- 239000011324 bead Substances 0.000 claims description 63

- 230000027455 binding Effects 0.000 claims description 58

- 102000004190 Enzymes Human genes 0.000 claims description 42

- 108090000790 Enzymes Proteins 0.000 claims description 42

- 239000000839 emulsion Substances 0.000 claims description 42

- 230000015572 biosynthetic process Effects 0.000 claims description 41

- 239000003153 chemical reaction reagent Substances 0.000 claims description 35

- 238000004458 analytical method Methods 0.000 claims description 21

- 230000004048 modification Effects 0.000 claims description 15

- 238000012986 modification Methods 0.000 claims description 15

- 238000001514 detection method Methods 0.000 claims description 14

- 238000002156 mixing Methods 0.000 claims description 13

- 238000002866 fluorescence resonance energy transfer Methods 0.000 claims description 12

- 230000004927 fusion Effects 0.000 claims description 12

- 238000000684 flow cytometry Methods 0.000 claims description 11

- 239000002096 quantum dot Substances 0.000 claims description 11

- 238000003786 synthesis reaction Methods 0.000 claims description 11

- 230000009471 action Effects 0.000 claims description 10

- 230000001105 regulatory effect Effects 0.000 claims description 10

- 238000001261 affinity purification Methods 0.000 claims description 9

- 150000003384 small molecules Chemical class 0.000 claims description 9

- 230000003321 amplification Effects 0.000 claims description 7

- 238000002955 isolation Methods 0.000 claims description 7

- 238000003199 nucleic acid amplification method Methods 0.000 claims description 7

- 230000033228 biological regulation Effects 0.000 claims description 6

- NBVXSUQYWXRMNV-UHFFFAOYSA-N fluoromethane Chemical compound FC NBVXSUQYWXRMNV-UHFFFAOYSA-N 0.000 claims description 6

- 238000004949 mass spectrometry Methods 0.000 claims description 6

- 239000007762 w/o emulsion Substances 0.000 claims description 6

- 238000010348 incorporation Methods 0.000 claims description 5

- 229960001217 perflubron Drugs 0.000 claims description 5

- 230000003197 catalytic effect Effects 0.000 claims description 3

- 230000001976 improved effect Effects 0.000 claims description 3

- 230000006872 improvement Effects 0.000 claims description 3

- 230000005291 magnetic effect Effects 0.000 claims description 3

- 230000005298 paramagnetic effect Effects 0.000 claims description 3

- WTWWXOGTJWMJHI-UHFFFAOYSA-N perflubron Chemical compound FC(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)Br WTWWXOGTJWMJHI-UHFFFAOYSA-N 0.000 claims description 3

- 230000006698 induction Effects 0.000 claims description 2

- 238000012544 monitoring process Methods 0.000 claims description 2

- 239000007795 chemical reaction product Substances 0.000 claims 1

- 238000000295 emission spectrum Methods 0.000 claims 1

- BPHQIXJDBIHMLT-UHFFFAOYSA-N perfluorodecane Chemical compound FC(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)F BPHQIXJDBIHMLT-UHFFFAOYSA-N 0.000 claims 1

- 238000009509 drug development Methods 0.000 abstract 1

- 210000004027 cell Anatomy 0.000 description 71

- 229940088598 enzyme Drugs 0.000 description 41

- 239000003921 oil Substances 0.000 description 37

- 241000894007 species Species 0.000 description 36

- 239000000463 material Substances 0.000 description 28

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 27

- 108010015847 Non-Receptor Type 1 Protein Tyrosine Phosphatase Proteins 0.000 description 23

- 102100033001 Tyrosine-protein phosphatase non-receptor type 1 Human genes 0.000 description 23

- 238000005259 measurement Methods 0.000 description 21

- 239000003446 ligand Substances 0.000 description 20

- 229920000642 polymer Polymers 0.000 description 19

- 239000012071 phase Substances 0.000 description 18

- 238000004519 manufacturing process Methods 0.000 description 16

- 108090000765 processed proteins & peptides Proteins 0.000 description 16

- 108090000623 proteins and genes Proteins 0.000 description 16

- 239000004094 surface-active agent Substances 0.000 description 16

- 230000000670 limiting effect Effects 0.000 description 15

- 239000002245 particle Substances 0.000 description 15

- 229920000435 poly(dimethylsiloxane) Polymers 0.000 description 15

- 239000000126 substance Substances 0.000 description 15

- XMIIGOLPHOKFCH-UHFFFAOYSA-N 3-phenylpropionic acid Chemical compound OC(=O)CCC1=CC=CC=C1 XMIIGOLPHOKFCH-UHFFFAOYSA-N 0.000 description 14

- 238000013537 high throughput screening Methods 0.000 description 14

- 230000005764 inhibitory process Effects 0.000 description 14

- 239000000203 mixture Substances 0.000 description 14

- 238000003556 assay Methods 0.000 description 13

- 239000003112 inhibitor Substances 0.000 description 13

- 239000003801 protein tyrosine phosphatase 1B inhibitor Substances 0.000 description 12

- ZNAMMSOYKPMPGC-UHFFFAOYSA-N 2-(hydroxymethyl)-6-(2-phenylethylsulfanyl)oxane-3,4,5-triol Chemical compound OC1C(O)C(O)C(CO)OC1SCCC1=CC=CC=C1 ZNAMMSOYKPMPGC-UHFFFAOYSA-N 0.000 description 11

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 11

- 230000002209 hydrophobic effect Effects 0.000 description 11

- -1 polydimethylsiloxane Polymers 0.000 description 11

- 229920005573 silicon-containing polymer Polymers 0.000 description 11

- 239000007789 gas Substances 0.000 description 10

- 230000033001 locomotion Effects 0.000 description 10

- 239000004793 Polystyrene Substances 0.000 description 9

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 9

- 238000005859 coupling reaction Methods 0.000 description 9

- 239000003550 marker Substances 0.000 description 9

- 239000012528 membrane Substances 0.000 description 9

- 239000000243 solution Substances 0.000 description 9

- DZANYXOTJVLAEE-UHFFFAOYSA-N 6,8-difluoro-4-methylumbelliferyl phosphate Chemical compound FC1=C(OP(O)(O)=O)C(F)=CC2=C1OC(=O)C=C2C DZANYXOTJVLAEE-UHFFFAOYSA-N 0.000 description 8

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 8

- 230000008901 benefit Effects 0.000 description 8

- 229940125782 compound 2 Drugs 0.000 description 8

- 230000003993 interaction Effects 0.000 description 8

- 229920002223 polystyrene Polymers 0.000 description 8

- 238000000926 separation method Methods 0.000 description 8

- 229910052710 silicon Inorganic materials 0.000 description 8

- 239000010703 silicon Substances 0.000 description 8

- 108010090804 Streptavidin Proteins 0.000 description 7

- 238000010521 absorption reaction Methods 0.000 description 7

- 239000012131 assay buffer Substances 0.000 description 7

- 150000007942 carboxylates Chemical group 0.000 description 7

- 150000001732 carboxylic acid derivatives Chemical class 0.000 description 7

- 238000004581 coalescence Methods 0.000 description 7

- 230000008602 contraction Effects 0.000 description 7

- 230000001747 exhibiting effect Effects 0.000 description 7

- 230000006870 function Effects 0.000 description 7

- 238000001802 infusion Methods 0.000 description 7

- 238000004020 luminiscence type Methods 0.000 description 7

- 230000008569 process Effects 0.000 description 7

- 235000018102 proteins Nutrition 0.000 description 7

- 102000004169 proteins and genes Human genes 0.000 description 7

- YBJHBAHKTGYVGT-ZKWXMUAHSA-N (+)-Biotin Chemical compound N1C(=O)N[C@@H]2[C@H](CCCCC(=O)O)SC[C@@H]21 YBJHBAHKTGYVGT-ZKWXMUAHSA-N 0.000 description 6

- LMDZBCPBFSXMTL-UHFFFAOYSA-N 1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide Substances CCN=C=NCCCN(C)C LMDZBCPBFSXMTL-UHFFFAOYSA-N 0.000 description 6

- 239000004593 Epoxy Substances 0.000 description 6

- PEDCQBHIVMGVHV-UHFFFAOYSA-N Glycerine Chemical compound OCC(O)CO PEDCQBHIVMGVHV-UHFFFAOYSA-N 0.000 description 6

- 239000008346 aqueous phase Substances 0.000 description 6

- 239000007864 aqueous solution Substances 0.000 description 6

- 238000000149 argon plasma sintering Methods 0.000 description 6

- 239000000872 buffer Substances 0.000 description 6

- 150000001735 carboxylic acids Chemical class 0.000 description 6

- 238000004891 communication Methods 0.000 description 6

- 230000008878 coupling Effects 0.000 description 6

- 238000010168 coupling process Methods 0.000 description 6

- 238000010586 diagram Methods 0.000 description 6

- 238000005516 engineering process Methods 0.000 description 6

- 238000006911 enzymatic reaction Methods 0.000 description 6

- 230000005284 excitation Effects 0.000 description 6

- 238000002474 experimental method Methods 0.000 description 6

- 230000001965 increasing effect Effects 0.000 description 6

- 230000007935 neutral effect Effects 0.000 description 6

- 102000039446 nucleic acids Human genes 0.000 description 6

- 108020004707 nucleic acids Proteins 0.000 description 6

- 150000007523 nucleic acids Chemical class 0.000 description 6

- 238000011176 pooling Methods 0.000 description 6

- 102000004196 processed proteins & peptides Human genes 0.000 description 6

- 238000011160 research Methods 0.000 description 6

- 230000002441 reversible effect Effects 0.000 description 6

- 239000004020 conductor Substances 0.000 description 5

- 238000011161 development Methods 0.000 description 5

- 230000018109 developmental process Effects 0.000 description 5

- 239000012212 insulator Substances 0.000 description 5

- 230000004044 response Effects 0.000 description 5

- 239000011780 sodium chloride Substances 0.000 description 5

- TXEYQDLBPFQVAA-UHFFFAOYSA-N tetrafluoromethane Chemical compound FC(F)(F)F TXEYQDLBPFQVAA-UHFFFAOYSA-N 0.000 description 5

- JKMHFZQWWAIEOD-UHFFFAOYSA-N 2-[4-(2-hydroxyethyl)piperazin-1-yl]ethanesulfonic acid Chemical compound OCC[NH+]1CCN(CCS([O-])(=O)=O)CC1 JKMHFZQWWAIEOD-UHFFFAOYSA-N 0.000 description 4

- KCXVZYZYPLLWCC-UHFFFAOYSA-N EDTA Chemical compound OC(=O)CN(CC(O)=O)CCN(CC(O)=O)CC(O)=O KCXVZYZYPLLWCC-UHFFFAOYSA-N 0.000 description 4

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 4

- 238000005033 Fourier transform infrared spectroscopy Methods 0.000 description 4

- 239000007995 HEPES buffer Substances 0.000 description 4

- 108091005804 Peptidases Proteins 0.000 description 4

- 102000035195 Peptidases Human genes 0.000 description 4

- 229920006362 Teflon® Polymers 0.000 description 4

- 230000009286 beneficial effect Effects 0.000 description 4

- DEGAKNSWVGKMLS-UHFFFAOYSA-N calcein Chemical compound O1C(=O)C2=CC=CC=C2C21C1=CC(CN(CC(O)=O)CC(O)=O)=C(O)C=C1OC1=C2C=C(CN(CC(O)=O)CC(=O)O)C(O)=C1 DEGAKNSWVGKMLS-UHFFFAOYSA-N 0.000 description 4

- 239000003054 catalyst Substances 0.000 description 4

- 230000000739 chaotic effect Effects 0.000 description 4

- 239000011248 coating agent Substances 0.000 description 4

- 238000000576 coating method Methods 0.000 description 4

- 229940125904 compound 1 Drugs 0.000 description 4

- 229920001577 copolymer Polymers 0.000 description 4

- AFYCEAFSNDLKSX-UHFFFAOYSA-N coumarin 460 Chemical compound CC1=CC(=O)OC2=CC(N(CC)CC)=CC=C21 AFYCEAFSNDLKSX-UHFFFAOYSA-N 0.000 description 4

- 230000007423 decrease Effects 0.000 description 4

- 235000013870 dimethyl polysiloxane Nutrition 0.000 description 4

- 239000006185 dispersion Substances 0.000 description 4

- 239000003814 drug Substances 0.000 description 4

- 238000004945 emulsification Methods 0.000 description 4

- 238000005538 encapsulation Methods 0.000 description 4

- GNBHRKFJIUUOQI-UHFFFAOYSA-N fluorescein Chemical compound O1C(=O)C2=CC=CC=C2C21C1=CC=C(O)C=C1OC1=CC(O)=CC=C21 GNBHRKFJIUUOQI-UHFFFAOYSA-N 0.000 description 4

- 230000002068 genetic effect Effects 0.000 description 4

- 239000011521 glass Substances 0.000 description 4

- DCAYPVUWAIABOU-UHFFFAOYSA-N hexadecane Chemical compound CCCCCCCCCCCCCCCC DCAYPVUWAIABOU-UHFFFAOYSA-N 0.000 description 4

- 230000002401 inhibitory effect Effects 0.000 description 4

- NOESYZHRGYRDHS-UHFFFAOYSA-N insulin Chemical group N1C(=O)C(NC(=O)C(CCC(N)=O)NC(=O)C(CCC(O)=O)NC(=O)C(C(C)C)NC(=O)C(NC(=O)CN)C(C)CC)CSSCC(C(NC(CO)C(=O)NC(CC(C)C)C(=O)NC(CC=2C=CC(O)=CC=2)C(=O)NC(CCC(N)=O)C(=O)NC(CC(C)C)C(=O)NC(CCC(O)=O)C(=O)NC(CC(N)=O)C(=O)NC(CC=2C=CC(O)=CC=2)C(=O)NC(CSSCC(NC(=O)C(C(C)C)NC(=O)C(CC(C)C)NC(=O)C(CC=2C=CC(O)=CC=2)NC(=O)C(CC(C)C)NC(=O)C(C)NC(=O)C(CCC(O)=O)NC(=O)C(C(C)C)NC(=O)C(CC(C)C)NC(=O)C(CC=2NC=NC=2)NC(=O)C(CO)NC(=O)CNC2=O)C(=O)NCC(=O)NC(CCC(O)=O)C(=O)NC(CCCNC(N)=N)C(=O)NCC(=O)NC(CC=3C=CC=CC=3)C(=O)NC(CC=3C=CC=CC=3)C(=O)NC(CC=3C=CC(O)=CC=3)C(=O)NC(C(C)O)C(=O)N3C(CCC3)C(=O)NC(CCCCN)C(=O)NC(C)C(O)=O)C(=O)NC(CC(N)=O)C(O)=O)=O)NC(=O)C(C(C)CC)NC(=O)C(CO)NC(=O)C(C(C)O)NC(=O)C1CSSCC2NC(=O)C(CC(C)C)NC(=O)C(NC(=O)C(CCC(N)=O)NC(=O)C(CC(N)=O)NC(=O)C(NC(=O)C(N)CC=1C=CC=CC=1)C(C)C)CC1=CN=CN1 NOESYZHRGYRDHS-UHFFFAOYSA-N 0.000 description 4

- 238000002372 labelling Methods 0.000 description 4

- 239000003068 molecular probe Substances 0.000 description 4

- 229960002378 oftasceine Drugs 0.000 description 4

- 229920001184 polypeptide Polymers 0.000 description 4

- 229920001296 polysiloxane Polymers 0.000 description 4

- 239000000376 reactant Substances 0.000 description 4

- 238000011084 recovery Methods 0.000 description 4

- 238000007789 sealing Methods 0.000 description 4

- 238000012360 testing method Methods 0.000 description 4

- MPLHNVLQVRSVEE-UHFFFAOYSA-N texas red Chemical compound [O-]S(=O)(=O)C1=CC(S(Cl)(=O)=O)=CC=C1C(C1=CC=2CCCN3CCCC(C=23)=C1O1)=C2C1=C(CCC1)C3=[N+]1CCCC3=C2 MPLHNVLQVRSVEE-UHFFFAOYSA-N 0.000 description 4

- WYXZAXRGDHVGTN-UHFFFAOYSA-N 3-[4-(difluorooxyphosphorylmethyl)phenyl]propanoic acid Chemical compound OC(=O)CCC1=CC=C(CP(=O)(OF)OF)C=C1 WYXZAXRGDHVGTN-UHFFFAOYSA-N 0.000 description 3

- 108010043121 Green Fluorescent Proteins Proteins 0.000 description 3

- SJRJJKPEHAURKC-UHFFFAOYSA-N N-Methylmorpholine Chemical compound CN1CCOCC1 SJRJJKPEHAURKC-UHFFFAOYSA-N 0.000 description 3

- 108010001441 Phosphopeptides Proteins 0.000 description 3

- 102000045595 Phosphoprotein Phosphatases Human genes 0.000 description 3

- 108700019535 Phosphoprotein Phosphatases Proteins 0.000 description 3

- 239000004809 Teflon Substances 0.000 description 3

- 239000012190 activator Substances 0.000 description 3

- 230000004075 alteration Effects 0.000 description 3

- 150000001408 amides Chemical class 0.000 description 3

- 238000013459 approach Methods 0.000 description 3

- 150000004982 aromatic amines Chemical class 0.000 description 3

- 230000003851 biochemical process Effects 0.000 description 3

- 229960002685 biotin Drugs 0.000 description 3

- 235000020958 biotin Nutrition 0.000 description 3

- 239000011616 biotin Substances 0.000 description 3

- 239000003990 capacitor Substances 0.000 description 3

- 238000006555 catalytic reaction Methods 0.000 description 3

- 238000003776 cleavage reaction Methods 0.000 description 3

- 230000002860 competitive effect Effects 0.000 description 3

- 230000001419 dependent effect Effects 0.000 description 3

- 230000030609 dephosphorylation Effects 0.000 description 3

- 238000006209 dephosphorylation reaction Methods 0.000 description 3

- 238000009792 diffusion process Methods 0.000 description 3

- 239000004205 dimethyl polysiloxane Substances 0.000 description 3

- 229940079593 drug Drugs 0.000 description 3

- 239000003596 drug target Substances 0.000 description 3

- 230000005670 electromagnetic radiation Effects 0.000 description 3

- 239000003995 emulsifying agent Substances 0.000 description 3

- 239000000835 fiber Substances 0.000 description 3

- 238000005206 flow analysis Methods 0.000 description 3

- 125000002485 formyl group Chemical group [H]C(*)=O 0.000 description 3

- 238000000338 in vitro Methods 0.000 description 3

- 230000002779 inactivation Effects 0.000 description 3

- 230000001939 inductive effect Effects 0.000 description 3

- 238000000465 moulding Methods 0.000 description 3

- UWEYRJFJVCLAGH-UHFFFAOYSA-N perfluorodecalin Chemical compound FC1(F)C(F)(F)C(F)(F)C(F)(F)C2(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C21F UWEYRJFJVCLAGH-UHFFFAOYSA-N 0.000 description 3

- 238000012545 processing Methods 0.000 description 3

- 230000035484 reaction time Effects 0.000 description 3

- 230000007017 scission Effects 0.000 description 3

- 229940119265 sepp Drugs 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 239000002904 solvent Substances 0.000 description 3

- 238000004611 spectroscopical analysis Methods 0.000 description 3

- 238000013519 translation Methods 0.000 description 3

- 238000003041 virtual screening Methods 0.000 description 3

- SIGZHCRJKAFRED-UHFFFAOYSA-N 11-(perfluorooctyl)undecyl dimorpholinophosphinate Chemical compound C1COCCN1P(=O)(OCCCCCCCCCCCC(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)F)N1CCOCC1 SIGZHCRJKAFRED-UHFFFAOYSA-N 0.000 description 2

- MYBBGZZXDFIZGU-UHFFFAOYSA-N 355017-64-0 Chemical compound COC1=CC(CO)=C([N+]([O-])=O)C=C1OCCCC(O)=O MYBBGZZXDFIZGU-UHFFFAOYSA-N 0.000 description 2

- LLENVBUPWUQAGL-UHFFFAOYSA-N 6,8-difluoro-7-hydroxy-4-methylcoumarin Chemical compound FC1=C(O)C(F)=CC2=C1OC(=O)C=C2C LLENVBUPWUQAGL-UHFFFAOYSA-N 0.000 description 2

- LKLWLDOUZJEHDY-UHFFFAOYSA-N 7-hydroxy-2-oxochromene-3-carboxylic acid Chemical compound C1=C(O)C=C2OC(=O)C(C(=O)O)=CC2=C1 LKLWLDOUZJEHDY-UHFFFAOYSA-N 0.000 description 2

- 108010041952 Calmodulin Proteins 0.000 description 2

- 102000000584 Calmodulin Human genes 0.000 description 2

- HEDRZPFGACZZDS-UHFFFAOYSA-N Chloroform Chemical compound ClC(Cl)Cl HEDRZPFGACZZDS-UHFFFAOYSA-N 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 2

- 108020004414 DNA Proteins 0.000 description 2

- PIICEJLVQHRZGT-UHFFFAOYSA-N Ethylenediamine Chemical compound NCCN PIICEJLVQHRZGT-UHFFFAOYSA-N 0.000 description 2

- 102000005744 Glycoside Hydrolases Human genes 0.000 description 2

- 108010031186 Glycoside Hydrolases Proteins 0.000 description 2

- 102000004144 Green Fluorescent Proteins Human genes 0.000 description 2

- 102000004877 Insulin Human genes 0.000 description 2

- 108090001061 Insulin Proteins 0.000 description 2

- 102000016267 Leptin Human genes 0.000 description 2

- 108010092277 Leptin Chemical group 0.000 description 2

- TWRXJAOTZQYOKJ-UHFFFAOYSA-L Magnesium chloride Chemical compound [Mg+2].[Cl-].[Cl-] TWRXJAOTZQYOKJ-UHFFFAOYSA-L 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- 208000008589 Obesity Diseases 0.000 description 2

- 102000004203 Phosphoric Triester Hydrolases Human genes 0.000 description 2

- 108090000754 Phosphoric Triester Hydrolases Proteins 0.000 description 2

- 239000004952 Polyamide Substances 0.000 description 2

- 239000004698 Polyethylene Substances 0.000 description 2

- 239000004365 Protease Substances 0.000 description 2

- 102000001253 Protein Kinase Human genes 0.000 description 2

- 238000001069 Raman spectroscopy Methods 0.000 description 2

- 229910052581 Si3N4 Inorganic materials 0.000 description 2

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 2

- 238000002835 absorbance Methods 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 2

- 230000001070 adhesive effect Effects 0.000 description 2

- 239000000443 aerosol Substances 0.000 description 2

- 125000003277 amino group Chemical group 0.000 description 2

- 210000004102 animal cell Anatomy 0.000 description 2

- 239000000427 antigen Substances 0.000 description 2

- 102000036639 antigens Human genes 0.000 description 2

- 108091007433 antigens Proteins 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 239000002199 base oil Substances 0.000 description 2

- 238000005842 biochemical reaction Methods 0.000 description 2

- IISBACLAFKSPIT-UHFFFAOYSA-N bisphenol A Chemical compound C=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1 IISBACLAFKSPIT-UHFFFAOYSA-N 0.000 description 2

- 238000000423 cell based assay Methods 0.000 description 2

- 238000004113 cell culture Methods 0.000 description 2

- 238000012512 characterization method Methods 0.000 description 2

- 125000004218 chloromethyl group Chemical group [H]C([H])(Cl)* 0.000 description 2

- HVYWMOMLDIMFJA-DPAQBDIFSA-N cholesterol Chemical compound C1C=C2C[C@@H](O)CC[C@]2(C)[C@@H]2[C@@H]1[C@@H]1CC[C@H]([C@H](C)CCCC(C)C)[C@@]1(C)CC2 HVYWMOMLDIMFJA-DPAQBDIFSA-N 0.000 description 2

- 238000002983 circular dichroism Methods 0.000 description 2

- 239000000084 colloidal system Substances 0.000 description 2

- 239000003086 colorant Substances 0.000 description 2

- 230000006957 competitive inhibition Effects 0.000 description 2

- 230000001276 controlling effect Effects 0.000 description 2

- 229910052802 copper Inorganic materials 0.000 description 2

- 239000010949 copper Substances 0.000 description 2

- XHXMPURWMSJENN-UHFFFAOYSA-N coumarin 480 Chemical compound C12=C3CCCN2CCCC1=CC1=C3OC(=O)C=C1C XHXMPURWMSJENN-UHFFFAOYSA-N 0.000 description 2

- 238000005686 cross metathesis reaction Methods 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- DIOQZVSQGTUSAI-UHFFFAOYSA-N decane Chemical compound CCCCCCCCCC DIOQZVSQGTUSAI-UHFFFAOYSA-N 0.000 description 2

- 230000001934 delay Effects 0.000 description 2

- ZBCBWPMODOFKDW-UHFFFAOYSA-N diethanolamine Chemical compound OCCNCCO ZBCBWPMODOFKDW-UHFFFAOYSA-N 0.000 description 2

- LOKCTEFSRHRXRJ-UHFFFAOYSA-I dipotassium trisodium dihydrogen phosphate hydrogen phosphate dichloride Chemical compound P(=O)(O)(O)[O-].[K+].P(=O)(O)([O-])[O-].[Na+].[Na+].[Cl-].[K+].[Cl-].[Na+] LOKCTEFSRHRXRJ-UHFFFAOYSA-I 0.000 description 2

- 231100000673 dose–response relationship Toxicity 0.000 description 2

- 239000000975 dye Substances 0.000 description 2

- 238000002848 electrochemical method Methods 0.000 description 2

- 239000007772 electrode material Substances 0.000 description 2

- 238000000572 ellipsometry Methods 0.000 description 2

- 230000002255 enzymatic effect Effects 0.000 description 2

- 238000001317 epifluorescence microscopy Methods 0.000 description 2

- 238000005530 etching Methods 0.000 description 2

- 239000004744 fabric Substances 0.000 description 2

- 238000002875 fluorescence polarization Methods 0.000 description 2

- 238000001943 fluorescence-activated cell sorting Methods 0.000 description 2

- 235000013305 food Nutrition 0.000 description 2

- 125000000524 functional group Chemical group 0.000 description 2

- 229910021397 glassy carbon Inorganic materials 0.000 description 2

- 239000005090 green fluorescent protein Substances 0.000 description 2

- 229930195733 hydrocarbon Natural products 0.000 description 2

- 150000002430 hydrocarbons Chemical class 0.000 description 2

- 230000005660 hydrophilic surface Effects 0.000 description 2

- 230000005661 hydrophobic surface Effects 0.000 description 2

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 2

- 150000002466 imines Chemical class 0.000 description 2

- 238000003018 immunoassay Methods 0.000 description 2

- AMGQUBHHOARCQH-UHFFFAOYSA-N indium;oxotin Chemical compound [In].[Sn]=O AMGQUBHHOARCQH-UHFFFAOYSA-N 0.000 description 2

- 229940125396 insulin Drugs 0.000 description 2

- 230000001788 irregular Effects 0.000 description 2

- 238000002356 laser light scattering Methods 0.000 description 2

- 239000004816 latex Substances 0.000 description 2

- 229920000126 latex Polymers 0.000 description 2

- NRYBAZVQPHGZNS-ZSOCWYAHSA-N leptin Chemical group O=C([C@H](CO)NC(=O)[C@H](CC(C)C)NC(=O)[C@H](CC(O)=O)NC(=O)[C@H](CC(C)C)NC(=O)[C@H](CCC(N)=O)NC(=O)[C@H](CC=1C2=CC=CC=C2NC=1)NC(=O)[C@H](CC(C)C)NC(=O)[C@@H](NC(=O)[C@H](CC(O)=O)NC(=O)[C@H](CCC(N)=O)NC(=O)[C@H](CC(C)C)NC(=O)[C@H](CO)NC(=O)CNC(=O)[C@H](CCC(N)=O)NC(=O)[C@@H](N)CC(C)C)CCSC)N1CCC[C@H]1C(=O)NCC(=O)N[C@@H](CS)C(O)=O NRYBAZVQPHGZNS-ZSOCWYAHSA-N 0.000 description 2

- 229940039781 leptin Drugs 0.000 description 2

- 239000004005 microsphere Substances 0.000 description 2

- 239000002480 mineral oil Substances 0.000 description 2

- 235000010446 mineral oil Nutrition 0.000 description 2

- 239000002736 nonionic surfactant Substances 0.000 description 2

- 235000020824 obesity Nutrition 0.000 description 2

- 238000000424 optical density measurement Methods 0.000 description 2

- 239000013307 optical fiber Substances 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 230000000144 pharmacologic effect Effects 0.000 description 2

- JTJMJGYZQZDUJJ-UHFFFAOYSA-N phencyclidine Chemical compound C1CCCCN1C1(C=2C=CC=CC=2)CCCCC1 JTJMJGYZQZDUJJ-UHFFFAOYSA-N 0.000 description 2

- 239000002953 phosphate buffered saline Substances 0.000 description 2

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 2

- 238000000711 polarimetry Methods 0.000 description 2

- 229920003229 poly(methyl methacrylate) Polymers 0.000 description 2

- 229920002647 polyamide Polymers 0.000 description 2

- 229920000573 polyethylene Polymers 0.000 description 2

- 239000004926 polymethyl methacrylate Substances 0.000 description 2

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 2

- 239000004810 polytetrafluoroethylene Substances 0.000 description 2

- 229920002102 polyvinyl toluene Polymers 0.000 description 2

- 235000019833 protease Nutrition 0.000 description 2

- 125000006239 protecting group Chemical group 0.000 description 2

- 108060006633 protein kinase Proteins 0.000 description 2

- 239000010453 quartz Substances 0.000 description 2

- 230000002829 reductive effect Effects 0.000 description 2

- 238000012827 research and development Methods 0.000 description 2

- 230000000717 retained effect Effects 0.000 description 2

- 239000012266 salt solution Substances 0.000 description 2

- 230000035945 sensitivity Effects 0.000 description 2

- 230000019491 signal transduction Effects 0.000 description 2

- 239000000377 silicon dioxide Substances 0.000 description 2

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 2

- 229910052814 silicon oxide Inorganic materials 0.000 description 2

- 229920002545 silicone oil Polymers 0.000 description 2

- 229920002379 silicone rubber Polymers 0.000 description 2

- 238000010532 solid phase synthesis reaction Methods 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- BDHFUVZGWQCTTF-UHFFFAOYSA-M sulfonate Chemical compound [O-]S(=O)=O BDHFUVZGWQCTTF-UHFFFAOYSA-M 0.000 description 2

- 230000001360 synchronised effect Effects 0.000 description 2

- 229920001897 terpolymer Polymers 0.000 description 2

- HQHCYKULIHKCEB-UHFFFAOYSA-N tetradecanedioic acid Chemical compound OC(=O)CCCCCCCCCCCCC(O)=O HQHCYKULIHKCEB-UHFFFAOYSA-N 0.000 description 2

- 230000001225 therapeutic effect Effects 0.000 description 2

- 125000002088 tosyl group Chemical group [H]C1=C([H])C(=C([H])C([H])=C1C([H])([H])[H])S(*)(=O)=O 0.000 description 2

- 238000007056 transamidation reaction Methods 0.000 description 2

- 238000003260 vortexing Methods 0.000 description 2

- ZORQXIQZAOLNGE-UHFFFAOYSA-N 1,1-difluorocyclohexane Chemical compound FC1(F)CCCCC1 ZORQXIQZAOLNGE-UHFFFAOYSA-N 0.000 description 1

- JYEUMXHLPRZUAT-UHFFFAOYSA-N 1,2,3-triazine Chemical compound C1=CN=NN=C1 JYEUMXHLPRZUAT-UHFFFAOYSA-N 0.000 description 1

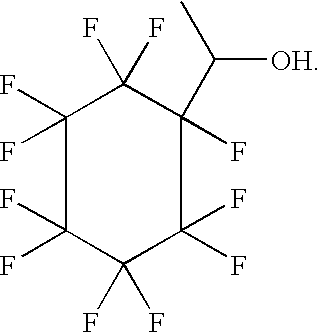

- SVQLLPOUSBWFHB-UHFFFAOYSA-N 1-(1,2,2,3,3,4,4,5,5,6,6-undecafluorocyclohexyl)ethanol Chemical compound CC(O)C1(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C1(F)F SVQLLPOUSBWFHB-UHFFFAOYSA-N 0.000 description 1

- IIBCXMVHDVUGFI-UHFFFAOYSA-N 2-(2-phenoxyethoxy)decan-2-ol Chemical compound CCCCCCCCC(C)(O)OCCOC1=CC=CC=C1 IIBCXMVHDVUGFI-UHFFFAOYSA-N 0.000 description 1

- QKNYBSVHEMOAJP-UHFFFAOYSA-N 2-amino-2-(hydroxymethyl)propane-1,3-diol;hydron;chloride Chemical compound Cl.OCC(N)(CO)CO QKNYBSVHEMOAJP-UHFFFAOYSA-N 0.000 description 1

- FPQQSJJWHUJYPU-UHFFFAOYSA-N 3-(dimethylamino)propyliminomethylidene-ethylazanium;chloride Chemical compound Cl.CCN=C=NCCCN(C)C FPQQSJJWHUJYPU-UHFFFAOYSA-N 0.000 description 1

- FHVDTGUDJYJELY-UHFFFAOYSA-N 6-{[2-carboxy-4,5-dihydroxy-6-(phosphanyloxy)oxan-3-yl]oxy}-4,5-dihydroxy-3-phosphanyloxane-2-carboxylic acid Chemical compound O1C(C(O)=O)C(P)C(O)C(O)C1OC1C(C(O)=O)OC(OP)C(O)C1O FHVDTGUDJYJELY-UHFFFAOYSA-N 0.000 description 1

- QTBSBXVTEAMEQO-UHFFFAOYSA-N Acetic acid Chemical compound CC(O)=O QTBSBXVTEAMEQO-UHFFFAOYSA-N 0.000 description 1

- 241000251468 Actinopterygii Species 0.000 description 1

- 241000224489 Amoeba Species 0.000 description 1

- 108090001008 Avidin Proteins 0.000 description 1

- 108050001427 Avidin/streptavidin Proteins 0.000 description 1

- 241000894006 Bacteria Species 0.000 description 1

- 241000283690 Bos taurus Species 0.000 description 1

- QTSLLLOCJZMSKN-UHFFFAOYSA-N CC(C)C1(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C1(F)F Chemical compound CC(C)C1(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C1(F)F QTSLLLOCJZMSKN-UHFFFAOYSA-N 0.000 description 1

- RDRBIXSNGAYLPT-UHFFFAOYSA-N CC1=CC=C(COC2=CC3=C(C=C2)C(NC(=O)OCC2C4=C(C=CC=C4)C4=C2C=CC=C4)C2=C(O3)C=CC=C2)C=C1 Chemical compound CC1=CC=C(COC2=CC3=C(C=C2)C(NC(=O)OCC2C4=C(C=CC=C4)C4=C2C=CC=C4)C2=C(O3)C=CC=C2)C=C1 RDRBIXSNGAYLPT-UHFFFAOYSA-N 0.000 description 1

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 description 1

- 241000283707 Capra Species 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 239000004215 Carbon black (E152) Substances 0.000 description 1

- 239000005046 Chlorosilane Substances 0.000 description 1

- 239000004821 Contact adhesive Substances 0.000 description 1

- 241000699802 Cricetulus griseus Species 0.000 description 1

- 241000195493 Cryptophyta Species 0.000 description 1

- 102000052510 DNA-Binding Proteins Human genes 0.000 description 1

- 108700020911 DNA-Binding Proteins Proteins 0.000 description 1

- 241000252212 Danio rerio Species 0.000 description 1

- 241000588724 Escherichia coli Species 0.000 description 1

- IAYPIBMASNFSPL-UHFFFAOYSA-N Ethylene oxide Chemical compound C1CO1 IAYPIBMASNFSPL-UHFFFAOYSA-N 0.000 description 1

- SYSKNHZYRAGVHA-UHFFFAOYSA-N FC1(F)C(F)(F)C(F)(F)C2(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C2(F)(F)C1(F)F Chemical compound FC1(F)C(F)(F)C(F)(F)C2(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C2(F)(F)C1(F)F SYSKNHZYRAGVHA-UHFFFAOYSA-N 0.000 description 1

- 241000282326 Felis catus Species 0.000 description 1

- 241000287227 Fringillidae Species 0.000 description 1

- 102000003688 G-Protein-Coupled Receptors Human genes 0.000 description 1

- 108090000045 G-Protein-Coupled Receptors Proteins 0.000 description 1

- 241000237858 Gastropoda Species 0.000 description 1

- 229910004373 HOAc Inorganic materials 0.000 description 1

- 108010093488 His-His-His-His-His-His Proteins 0.000 description 1

- ROHFNLRQFUQHCH-YFKPBYRVSA-N L-leucine Chemical compound CC(C)C[C@H](N)C(O)=O ROHFNLRQFUQHCH-YFKPBYRVSA-N 0.000 description 1

- 241000270322 Lepidosauria Species 0.000 description 1

- ROHFNLRQFUQHCH-UHFFFAOYSA-N Leucine Natural products CC(C)CC(N)C(O)=O ROHFNLRQFUQHCH-UHFFFAOYSA-N 0.000 description 1

- 229920001367 Merrifield resin Polymers 0.000 description 1

- 241001465754 Metazoa Species 0.000 description 1

- 108060004795 Methyltransferase Proteins 0.000 description 1

- 102000016397 Methyltransferase Human genes 0.000 description 1

- 239000000020 Nitrocellulose Substances 0.000 description 1

- 108091005461 Nucleic proteins Proteins 0.000 description 1

- 241000282320 Panthera leo Species 0.000 description 1

- 102000003992 Peroxidases Human genes 0.000 description 1

- 239000002202 Polyethylene glycol Substances 0.000 description 1

- 108010039918 Polylysine Proteins 0.000 description 1

- 241000288906 Primates Species 0.000 description 1

- 102000044126 RNA-Binding Proteins Human genes 0.000 description 1

- 108700020471 RNA-Binding Proteins Proteins 0.000 description 1

- 230000004570 RNA-binding Effects 0.000 description 1

- 241000283984 Rodentia Species 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- HVUMOYIDDBPOLL-XWVZOOPGSA-N Sorbitan monostearate Chemical compound CCCCCCCCCCCCCCCCCC(=O)OC[C@@H](O)[C@H]1OC[C@H](O)[C@H]1O HVUMOYIDDBPOLL-XWVZOOPGSA-N 0.000 description 1

- 210000001744 T-lymphocyte Anatomy 0.000 description 1

- 241000255588 Tephritidae Species 0.000 description 1

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 1

- 102000040945 Transcription factor Human genes 0.000 description 1

- 108091023040 Transcription factor Proteins 0.000 description 1

- 239000013504 Triton X-100 Substances 0.000 description 1

- 229920004890 Triton X-100 Polymers 0.000 description 1

- FJWGYAHXMCUOOM-QHOUIDNNSA-N [(2s,3r,4s,5r,6r)-2-[(2r,3r,4s,5r,6s)-4,5-dinitrooxy-2-(nitrooxymethyl)-6-[(2r,3r,4s,5r,6s)-4,5,6-trinitrooxy-2-(nitrooxymethyl)oxan-3-yl]oxyoxan-3-yl]oxy-3,5-dinitrooxy-6-(nitrooxymethyl)oxan-4-yl] nitrate Chemical compound O([C@@H]1O[C@@H]([C@H]([C@H](O[N+]([O-])=O)[C@H]1O[N+]([O-])=O)O[C@H]1[C@@H]([C@@H](O[N+]([O-])=O)[C@H](O[N+]([O-])=O)[C@@H](CO[N+]([O-])=O)O1)O[N+]([O-])=O)CO[N+](=O)[O-])[C@@H]1[C@@H](CO[N+]([O-])=O)O[C@@H](O[N+]([O-])=O)[C@H](O[N+]([O-])=O)[C@H]1O[N+]([O-])=O FJWGYAHXMCUOOM-QHOUIDNNSA-N 0.000 description 1

- 230000003213 activating effect Effects 0.000 description 1

- 230000004913 activation Effects 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 229940072056 alginate Drugs 0.000 description 1

- 235000010443 alginic acid Nutrition 0.000 description 1

- 229920000615 alginic acid Polymers 0.000 description 1

- 238000003491 array Methods 0.000 description 1

- 210000003719 b-lymphocyte Anatomy 0.000 description 1

- 210000003651 basophil Anatomy 0.000 description 1

- 238000002306 biochemical method Methods 0.000 description 1

- 230000004071 biological effect Effects 0.000 description 1

- 239000013060 biological fluid Substances 0.000 description 1

- 239000012620 biological material Substances 0.000 description 1

- 150000001615 biotins Chemical class 0.000 description 1

- 210000000601 blood cell Anatomy 0.000 description 1

- 239000007853 buffer solution Substances 0.000 description 1

- 210000004899 c-terminal region Anatomy 0.000 description 1

- 229910052793 cadmium Inorganic materials 0.000 description 1

- BDOSMKKIYDKNTQ-UHFFFAOYSA-N cadmium atom Chemical compound [Cd] BDOSMKKIYDKNTQ-UHFFFAOYSA-N 0.000 description 1

- 239000011575 calcium Substances 0.000 description 1

- 229910052791 calcium Inorganic materials 0.000 description 1

- 150000001720 carbohydrates Chemical class 0.000 description 1

- 235000014633 carbohydrates Nutrition 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 210000002421 cell wall Anatomy 0.000 description 1

- 230000004715 cellular signal transduction Effects 0.000 description 1

- 229940085262 cetyl dimethicone Drugs 0.000 description 1

- 125000003636 chemical group Chemical group 0.000 description 1

- 238000005229 chemical vapour deposition Methods 0.000 description 1

- VNJCDDZVNHPVNM-UHFFFAOYSA-N chloro(ethyl)silane Chemical class CC[SiH2]Cl VNJCDDZVNHPVNM-UHFFFAOYSA-N 0.000 description 1

- YGZSVWMBUCGDCV-UHFFFAOYSA-N chloro(methyl)silane Chemical class C[SiH2]Cl YGZSVWMBUCGDCV-UHFFFAOYSA-N 0.000 description 1

- NBWIIOQJUKRLKW-UHFFFAOYSA-N chloro(phenyl)silane Chemical class Cl[SiH2]C1=CC=CC=C1 NBWIIOQJUKRLKW-UHFFFAOYSA-N 0.000 description 1

- KOPOQZFJUQMUML-UHFFFAOYSA-N chlorosilane Chemical class Cl[SiH3] KOPOQZFJUQMUML-UHFFFAOYSA-N 0.000 description 1

- 235000012000 cholesterol Nutrition 0.000 description 1

- 238000010668 complexation reaction Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000012864 cross contamination Methods 0.000 description 1

- 238000004132 cross linking Methods 0.000 description 1

- 150000004292 cyclic ethers Chemical group 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 229960003964 deoxycholic acid Drugs 0.000 description 1

- KXGVEGMKQFWNSR-LLQZFEROSA-N deoxycholic acid Chemical compound C([C@H]1CC2)[C@H](O)CC[C@]1(C)[C@@H]1[C@@H]2[C@@H]2CC[C@H]([C@@H](CCC(O)=O)C)[C@@]2(C)[C@@H](O)C1 KXGVEGMKQFWNSR-LLQZFEROSA-N 0.000 description 1

- 238000005137 deposition process Methods 0.000 description 1

- 206010012601 diabetes mellitus Diseases 0.000 description 1

- 230000004069 differentiation Effects 0.000 description 1

- GYZLOYUZLJXAJU-UHFFFAOYSA-N diglycidyl ether Chemical class C1OC1COCC1CO1 GYZLOYUZLJXAJU-UHFFFAOYSA-N 0.000 description 1

- 201000010099 disease Diseases 0.000 description 1

- 208000037265 diseases, disorders, signs and symptoms Diseases 0.000 description 1

- BFMYDTVEBKDAKJ-UHFFFAOYSA-L disodium;(2',7'-dibromo-3',6'-dioxido-3-oxospiro[2-benzofuran-1,9'-xanthene]-4'-yl)mercury;hydrate Chemical compound O.[Na+].[Na+].O1C(=O)C2=CC=CC=C2C21C1=CC(Br)=C([O-])C([Hg])=C1OC1=C2C=C(Br)C([O-])=C1 BFMYDTVEBKDAKJ-UHFFFAOYSA-L 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000007876 drug discovery Methods 0.000 description 1

- 239000013536 elastomeric material Substances 0.000 description 1

- 238000003487 electrochemical reaction Methods 0.000 description 1

- 238000007786 electrostatic charging Methods 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 210000002889 endothelial cell Anatomy 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000002532 enzyme inhibitor Substances 0.000 description 1

- 229940125532 enzyme inhibitor Drugs 0.000 description 1

- 210000003979 eosinophil Anatomy 0.000 description 1

- 125000003700 epoxy group Chemical group 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 210000002950 fibroblast Anatomy 0.000 description 1

- MHMNJMPURVTYEJ-UHFFFAOYSA-N fluorescein-5-isothiocyanate Chemical compound O1C(=O)C2=CC(N=C=S)=CC=C2C21C1=CC=C(O)C=C1OC1=CC(O)=CC=C21 MHMNJMPURVTYEJ-UHFFFAOYSA-N 0.000 description 1

- 238000002189 fluorescence spectrum Methods 0.000 description 1

- 239000012634 fragment Substances 0.000 description 1

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 1

- 229910052737 gold Inorganic materials 0.000 description 1

- 239000010931 gold Substances 0.000 description 1

- 210000002064 heart cell Anatomy 0.000 description 1

- 238000012188 high-throughput screening assay Methods 0.000 description 1

- 210000003630 histaminocyte Anatomy 0.000 description 1

- 235000014304 histidine Nutrition 0.000 description 1

- 125000000487 histidyl group Chemical class [H]N([H])C(C(=O)O*)C([H])([H])C1=C([H])N([H])C([H])=N1 0.000 description 1

- 238000000265 homogenisation Methods 0.000 description 1

- 108091008039 hormone receptors Proteins 0.000 description 1

- 238000009396 hybridization Methods 0.000 description 1

- 210000002865 immune cell Anatomy 0.000 description 1

- 230000001900 immune effect Effects 0.000 description 1

- 238000007373 indentation Methods 0.000 description 1

- 230000000977 initiatory effect Effects 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 238000001746 injection moulding Methods 0.000 description 1

- 238000010255 intramuscular injection Methods 0.000 description 1

- 239000007927 intramuscular injection Substances 0.000 description 1

- 239000002563 ionic surfactant Substances 0.000 description 1

- 210000002510 keratinocyte Anatomy 0.000 description 1

- 150000002611 lead compounds Chemical class 0.000 description 1

- 238000012886 linear function Methods 0.000 description 1

- 150000002632 lipids Chemical class 0.000 description 1

- 239000002502 liposome Substances 0.000 description 1

- 239000007791 liquid phase Substances 0.000 description 1

- 108010026228 mRNA guanylyltransferase Proteins 0.000 description 1

- 229920002521 macromolecule Polymers 0.000 description 1

- 210000002540 macrophage Anatomy 0.000 description 1

- 229910001629 magnesium chloride Inorganic materials 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 210000004962 mammalian cell Anatomy 0.000 description 1

- 230000013011 mating Effects 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 230000001404 mediated effect Effects 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 230000005499 meniscus Effects 0.000 description 1

- 230000004060 metabolic process Effects 0.000 description 1

- 238000002493 microarray Methods 0.000 description 1

- 244000005700 microbiome Species 0.000 description 1

- 238000005459 micromachining Methods 0.000 description 1

- 239000011859 microparticle Substances 0.000 description 1

- 238000000386 microscopy Methods 0.000 description 1

- 230000005012 migration Effects 0.000 description 1

- 238000013508 migration Methods 0.000 description 1

- 230000006961 mixed inhibition Effects 0.000 description 1

- 238000010369 molecular cloning Methods 0.000 description 1

- 230000009456 molecular mechanism Effects 0.000 description 1

- 210000000663 muscle cell Anatomy 0.000 description 1

- 210000003061 neural cell Anatomy 0.000 description 1

- 230000003472 neutralizing effect Effects 0.000 description 1

- 210000000440 neutrophil Anatomy 0.000 description 1

- 239000002547 new drug Substances 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 229920001220 nitrocellulos Polymers 0.000 description 1

- 230000006959 non-competitive inhibition Effects 0.000 description 1

- 229920003986 novolac Polymers 0.000 description 1

- 239000002773 nucleotide Substances 0.000 description 1

- 125000003729 nucleotide group Chemical group 0.000 description 1

- 239000003960 organic solvent Substances 0.000 description 1

- 210000004409 osteocyte Anatomy 0.000 description 1

- 230000002611 ovarian Effects 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 230000037361 pathway Effects 0.000 description 1

- 229950011087 perflunafene Drugs 0.000 description 1

- 230000035699 permeability Effects 0.000 description 1

- 108040007629 peroxidase activity proteins Proteins 0.000 description 1

- 230000002186 photoactivation Effects 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 238000000053 physical method Methods 0.000 description 1

- 238000004987 plasma desorption mass spectroscopy Methods 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 229920000058 polyacrylate Polymers 0.000 description 1

- 229920001223 polyethylene glycol Polymers 0.000 description 1

- 229920000656 polylysine Polymers 0.000 description 1

- 239000012704 polymeric precursor Substances 0.000 description 1

- 238000006116 polymerization reaction Methods 0.000 description 1

- 239000000244 polyoxyethylene sorbitan monooleate Substances 0.000 description 1

- 235000010482 polyoxyethylene sorbitan monooleate Nutrition 0.000 description 1

- 229920000053 polysorbate 80 Polymers 0.000 description 1

- 230000003334 potential effect Effects 0.000 description 1

- 230000003389 potentiating effect Effects 0.000 description 1

- 239000002243 precursor Substances 0.000 description 1

- 150000003141 primary amines Chemical class 0.000 description 1

- 125000002924 primary amino group Chemical group [H]N([H])* 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 230000001902 propagating effect Effects 0.000 description 1

- 238000000159 protein binding assay Methods 0.000 description 1

- 238000000746 purification Methods 0.000 description 1

- 150000003254 radicals Chemical group 0.000 description 1

- 239000011541 reaction mixture Substances 0.000 description 1

- 108020003175 receptors Proteins 0.000 description 1

- 102000005962 receptors Human genes 0.000 description 1

- 230000007261 regionalization Effects 0.000 description 1

- 230000012385 regulation of binding Effects 0.000 description 1

- 238000000820 replica moulding Methods 0.000 description 1

- 230000000241 respiratory effect Effects 0.000 description 1

- 239000000523 sample Substances 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 229940126586 small molecule drug Drugs 0.000 description 1

- NRHMKIHPTBHXPF-TUJRSCDTSA-M sodium cholate Chemical compound [Na+].C([C@H]1C[C@H]2O)[C@H](O)CC[C@]1(C)[C@@H]1[C@@H]2[C@@H]2CC[C@H]([C@@H](CCC([O-])=O)C)[C@@]2(C)[C@@H](O)C1 NRHMKIHPTBHXPF-TUJRSCDTSA-M 0.000 description 1

- JAJWGJBVLPIOOH-IZYKLYLVSA-M sodium taurocholate Chemical compound [Na+].C([C@H]1C[C@H]2O)[C@H](O)CC[C@]1(C)[C@@H]1[C@@H]2[C@@H]2CC[C@H]([C@@H](CCC(=O)NCCS([O-])(=O)=O)C)[C@@]2(C)[C@@H](O)C1 JAJWGJBVLPIOOH-IZYKLYLVSA-M 0.000 description 1

- 239000011343 solid material Substances 0.000 description 1

- 238000000935 solvent evaporation Methods 0.000 description 1

- 238000000638 solvent extraction Methods 0.000 description 1

- 239000001593 sorbitan monooleate Substances 0.000 description 1

- 235000011069 sorbitan monooleate Nutrition 0.000 description 1

- 229940035049 sorbitan monooleate Drugs 0.000 description 1

- 239000001587 sorbitan monostearate Substances 0.000 description 1

- 235000011076 sorbitan monostearate Nutrition 0.000 description 1

- 229940035048 sorbitan monostearate Drugs 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

- 230000003595 spectral effect Effects 0.000 description 1

- 238000004528 spin coating Methods 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 238000010561 standard procedure Methods 0.000 description 1

- 210000000130 stem cell Anatomy 0.000 description 1

- 239000004575 stone Substances 0.000 description 1

- 230000008093 supporting effect Effects 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

- 238000002560 therapeutic procedure Methods 0.000 description 1

- 229920001169 thermoplastic Polymers 0.000 description 1

- 229920001187 thermosetting polymer Polymers 0.000 description 1

- 229910052718 tin Inorganic materials 0.000 description 1

- 239000011135 tin Substances 0.000 description 1

- 210000001519 tissue Anatomy 0.000 description 1

- 238000013518 transcription Methods 0.000 description 1

- 230000035897 transcription Effects 0.000 description 1

- 239000012780 transparent material Substances 0.000 description 1

- 230000032258 transport Effects 0.000 description 1

- 230000001960 triggered effect Effects 0.000 description 1

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 1

- 229910052721 tungsten Inorganic materials 0.000 description 1

- 239000010937 tungsten Substances 0.000 description 1

- 208000001072 type 2 diabetes mellitus Diseases 0.000 description 1

- 229960003732 tyramine Drugs 0.000 description 1

- 238000002604 ultrasonography Methods 0.000 description 1

- 230000006967 uncompetitive inhibition Effects 0.000 description 1

- 238000010200 validation analysis Methods 0.000 description 1

- LSGOVYNHVSXFFJ-UHFFFAOYSA-N vanadate(3-) Chemical compound [O-][V]([O-])([O-])=O LSGOVYNHVSXFFJ-UHFFFAOYSA-N 0.000 description 1

- 230000035899 viability Effects 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

- 210000005253 yeast cell Anatomy 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N33/00—Investigating or analysing materials by specific methods not covered by groups G01N1/00 - G01N31/00

- G01N33/48—Biological material, e.g. blood, urine; Haemocytometers

- G01N33/50—Chemical analysis of biological material, e.g. blood, urine; Testing involving biospecific ligand binding methods; Immunological testing

- G01N33/53—Immunoassay; Biospecific binding assay; Materials therefor

- G01N33/543—Immunoassay; Biospecific binding assay; Materials therefor with an insoluble carrier for immobilising immunochemicals

- G01N33/54313—Immunoassay; Biospecific binding assay; Materials therefor with an insoluble carrier for immobilising immunochemicals the carrier being characterised by its particulate form

- G01N33/5432—Liposomes or microcapsules

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/40—Mixing liquids with liquids; Emulsifying

- B01F23/41—Emulsifying

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/20—Jet mixers, i.e. mixers using high-speed fluid streams

- B01F25/23—Mixing by intersecting jets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/40—Static mixers

- B01F25/42—Static mixers in which the mixing is affected by moving the components jointly in changing directions, e.g. in tubes provided with baffles or obstructions

- B01F25/43—Mixing tubes, e.g. wherein the material is moved in a radial or partly reversed direction

- B01F25/433—Mixing tubes wherein the shape of the tube influences the mixing, e.g. mixing tubes with varying cross-section or provided with inwardly extending profiles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/40—Static mixers

- B01F25/42—Static mixers in which the mixing is affected by moving the components jointly in changing directions, e.g. in tubes provided with baffles or obstructions

- B01F25/43—Mixing tubes, e.g. wherein the material is moved in a radial or partly reversed direction

- B01F25/433—Mixing tubes wherein the shape of the tube influences the mixing, e.g. mixing tubes with varying cross-section or provided with inwardly extending profiles

- B01F25/4331—Mixers with bended, curved, coiled, wounded mixing tubes or comprising elements for bending the flow

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/40—Static mixers

- B01F25/42—Static mixers in which the mixing is affected by moving the components jointly in changing directions, e.g. in tubes provided with baffles or obstructions

- B01F25/43—Mixing tubes, e.g. wherein the material is moved in a radial or partly reversed direction

- B01F25/433—Mixing tubes wherein the shape of the tube influences the mixing, e.g. mixing tubes with varying cross-section or provided with inwardly extending profiles

- B01F25/4338—Mixers with a succession of converging-diverging cross-sections, i.e. undulating cross-section

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F33/00—Other mixers; Mixing plants; Combinations of mixers

- B01F33/30—Micromixers

- B01F33/301—Micromixers using specific means for arranging the streams to be mixed, e.g. channel geometries or dispositions

- B01F33/3011—Micromixers using specific means for arranging the streams to be mixed, e.g. channel geometries or dispositions using a sheathing stream of a fluid surrounding a central stream of a different fluid, e.g. for reducing the cross-section of the central stream or to produce droplets from the central stream

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F33/00—Other mixers; Mixing plants; Combinations of mixers

- B01F33/30—Micromixers

- B01F33/302—Micromixers the materials to be mixed flowing in the form of droplets

- B01F33/3021—Micromixers the materials to be mixed flowing in the form of droplets the components to be mixed being combined in a single independent droplet, e.g. these droplets being divided by a non-miscible fluid or consisting of independent droplets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F33/00—Other mixers; Mixing plants; Combinations of mixers

- B01F33/30—Micromixers

- B01F33/3031—Micromixers using electro-hydrodynamic [EHD] or electro-kinetic [EKI] phenomena to mix or move the fluids

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J19/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J19/0046—Sequential or parallel reactions, e.g. for the synthesis of polypeptides or polynucleotides; Apparatus and devices for combinatorial chemistry or for making molecular arrays

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L3/00—Containers or dishes for laboratory use, e.g. laboratory glassware; Droppers

- B01L3/50—Containers for the purpose of retaining a material to be analysed, e.g. test tubes

- B01L3/502—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures

- B01L3/5027—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures by integrated microfluidic structures, i.e. dimensions of channels and chambers are such that surface tension forces are important, e.g. lab-on-a-chip

- B01L3/502761—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures by integrated microfluidic structures, i.e. dimensions of channels and chambers are such that surface tension forces are important, e.g. lab-on-a-chip specially adapted for handling suspended solids or molecules independently from the bulk fluid flow, e.g. for trapping or sorting beads, for physically stretching molecules

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L3/00—Containers or dishes for laboratory use, e.g. laboratory glassware; Droppers

- B01L3/50—Containers for the purpose of retaining a material to be analysed, e.g. test tubes

- B01L3/502—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures

- B01L3/5027—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures by integrated microfluidic structures, i.e. dimensions of channels and chambers are such that surface tension forces are important, e.g. lab-on-a-chip

- B01L3/502769—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures by integrated microfluidic structures, i.e. dimensions of channels and chambers are such that surface tension forces are important, e.g. lab-on-a-chip characterised by multiphase flow arrangements

- B01L3/502784—Containers for the purpose of retaining a material to be analysed, e.g. test tubes with fluid transport, e.g. in multi-compartment structures by integrated microfluidic structures, i.e. dimensions of channels and chambers are such that surface tension forces are important, e.g. lab-on-a-chip characterised by multiphase flow arrangements specially adapted for droplet or plug flow, e.g. digital microfluidics

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12Q—MEASURING OR TESTING PROCESSES INVOLVING ENZYMES, NUCLEIC ACIDS OR MICROORGANISMS; COMPOSITIONS OR TEST PAPERS THEREFOR; PROCESSES OF PREPARING SUCH COMPOSITIONS; CONDITION-RESPONSIVE CONTROL IN MICROBIOLOGICAL OR ENZYMOLOGICAL PROCESSES

- C12Q1/00—Measuring or testing processes involving enzymes, nucleic acids or microorganisms; Compositions therefor; Processes of preparing such compositions

- C12Q1/34—Measuring or testing processes involving enzymes, nucleic acids or microorganisms; Compositions therefor; Processes of preparing such compositions involving hydrolase

- C12Q1/42—Measuring or testing processes involving enzymes, nucleic acids or microorganisms; Compositions therefor; Processes of preparing such compositions involving hydrolase involving phosphatase

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N15/00—Investigating characteristics of particles; Investigating permeability, pore-volume or surface-area of porous materials

- G01N15/10—Investigating individual particles

- G01N15/14—Optical investigation techniques, e.g. flow cytometry

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N21/00—Investigating or analysing materials by the use of optical means, i.e. using sub-millimetre waves, infrared, visible or ultraviolet light

- G01N21/62—Systems in which the material investigated is excited whereby it emits light or causes a change in wavelength of the incident light

- G01N21/63—Systems in which the material investigated is excited whereby it emits light or causes a change in wavelength of the incident light optically excited

- G01N21/64—Fluorescence; Phosphorescence

- G01N21/6428—Measuring fluorescence of fluorescent products of reactions or of fluorochrome labelled reactive substances, e.g. measuring quenching effects, using measuring "optrodes"

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N33/00—Investigating or analysing materials by specific methods not covered by groups G01N1/00 - G01N31/00

- G01N33/48—Biological material, e.g. blood, urine; Haemocytometers

- G01N33/50—Chemical analysis of biological material, e.g. blood, urine; Testing involving biospecific ligand binding methods; Immunological testing

- G01N33/5005—Chemical analysis of biological material, e.g. blood, urine; Testing involving biospecific ligand binding methods; Immunological testing involving human or animal cells

- G01N33/5008—Chemical analysis of biological material, e.g. blood, urine; Testing involving biospecific ligand binding methods; Immunological testing involving human or animal cells for testing or evaluating the effect of chemical or biological compounds, e.g. drugs, cosmetics

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N33/00—Investigating or analysing materials by specific methods not covered by groups G01N1/00 - G01N31/00

- G01N33/48—Biological material, e.g. blood, urine; Haemocytometers

- G01N33/50—Chemical analysis of biological material, e.g. blood, urine; Testing involving biospecific ligand binding methods; Immunological testing

- G01N33/5005—Chemical analysis of biological material, e.g. blood, urine; Testing involving biospecific ligand binding methods; Immunological testing involving human or animal cells

- G01N33/5008—Chemical analysis of biological material, e.g. blood, urine; Testing involving biospecific ligand binding methods; Immunological testing involving human or animal cells for testing or evaluating the effect of chemical or biological compounds, e.g. drugs, cosmetics

- G01N33/5044—Chemical analysis of biological material, e.g. blood, urine; Testing involving biospecific ligand binding methods; Immunological testing involving human or animal cells for testing or evaluating the effect of chemical or biological compounds, e.g. drugs, cosmetics involving specific cell types

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N33/00—Investigating or analysing materials by specific methods not covered by groups G01N1/00 - G01N31/00

- G01N33/48—Biological material, e.g. blood, urine; Haemocytometers

- G01N33/50—Chemical analysis of biological material, e.g. blood, urine; Testing involving biospecific ligand binding methods; Immunological testing

- G01N33/53—Immunoassay; Biospecific binding assay; Materials therefor

- G01N33/573—Immunoassay; Biospecific binding assay; Materials therefor for enzymes or isoenzymes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/40—Mixing liquids with liquids; Emulsifying

- B01F23/41—Emulsifying

- B01F23/414—Emulsifying characterised by the internal structure of the emulsion

- B01F23/4143—Microemulsions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/40—Mixing liquids with liquids; Emulsifying

- B01F23/41—Emulsifying

- B01F23/414—Emulsifying characterised by the internal structure of the emulsion

- B01F23/4145—Emulsions of oils, e.g. fuel, and water

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2219/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J2219/00274—Sequential or parallel reactions; Apparatus and devices for combinatorial chemistry or for making arrays; Chemical library technology

- B01J2219/00277—Apparatus

- B01J2219/0054—Means for coding or tagging the apparatus or the reagents

- B01J2219/00572—Chemical means

- B01J2219/00576—Chemical means fluorophore

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2219/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J2219/00274—Sequential or parallel reactions; Apparatus and devices for combinatorial chemistry or for making arrays; Chemical library technology

- B01J2219/00583—Features relative to the processes being carried out

- B01J2219/00596—Solid-phase processes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2219/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J2219/00274—Sequential or parallel reactions; Apparatus and devices for combinatorial chemistry or for making arrays; Chemical library technology

- B01J2219/00583—Features relative to the processes being carried out

- B01J2219/00599—Solution-phase processes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2219/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J2219/00274—Sequential or parallel reactions; Apparatus and devices for combinatorial chemistry or for making arrays; Chemical library technology

- B01J2219/00583—Features relative to the processes being carried out

- B01J2219/00603—Making arrays on substantially continuous surfaces

- B01J2219/00657—One-dimensional arrays

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2219/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J2219/00274—Sequential or parallel reactions; Apparatus and devices for combinatorial chemistry or for making arrays; Chemical library technology

- B01J2219/00583—Features relative to the processes being carried out

- B01J2219/00603—Making arrays on substantially continuous surfaces

- B01J2219/00664—Three-dimensional arrays

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2219/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J2219/00274—Sequential or parallel reactions; Apparatus and devices for combinatorial chemistry or for making arrays; Chemical library technology

- B01J2219/00583—Features relative to the processes being carried out

- B01J2219/00603—Making arrays on substantially continuous surfaces

- B01J2219/00664—Three-dimensional arrays

- B01J2219/00666—One-dimensional arrays within three-dimensional arrays

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2219/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J2219/00274—Sequential or parallel reactions; Apparatus and devices for combinatorial chemistry or for making arrays; Chemical library technology

- B01J2219/0068—Means for controlling the apparatus of the process

- B01J2219/00702—Processes involving means for analysing and characterising the products

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2200/00—Solutions for specific problems relating to chemical or physical laboratory apparatus

- B01L2200/06—Fluid handling related problems

- B01L2200/0647—Handling flowable solids, e.g. microscopic beads, cells, particles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2200/00—Solutions for specific problems relating to chemical or physical laboratory apparatus

- B01L2200/06—Fluid handling related problems

- B01L2200/0647—Handling flowable solids, e.g. microscopic beads, cells, particles

- B01L2200/0652—Sorting or classification of particles or molecules

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2200/00—Solutions for specific problems relating to chemical or physical laboratory apparatus

- B01L2200/06—Fluid handling related problems

- B01L2200/0673—Handling of plugs of fluid surrounded by immiscible fluid

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2300/00—Additional constructional details

- B01L2300/08—Geometry, shape and general structure

- B01L2300/0809—Geometry, shape and general structure rectangular shaped

- B01L2300/0816—Cards, e.g. flat sample carriers usually with flow in two horizontal directions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2300/00—Additional constructional details

- B01L2300/08—Geometry, shape and general structure

- B01L2300/0861—Configuration of multiple channels and/or chambers in a single devices

- B01L2300/0864—Configuration of multiple channels and/or chambers in a single devices comprising only one inlet and multiple receiving wells, e.g. for separation, splitting

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2300/00—Additional constructional details

- B01L2300/08—Geometry, shape and general structure

- B01L2300/0861—Configuration of multiple channels and/or chambers in a single devices

- B01L2300/0867—Multiple inlets and one sample wells, e.g. mixing, dilution

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2400/00—Moving or stopping fluids

- B01L2400/04—Moving fluids with specific forces or mechanical means

- B01L2400/0403—Moving fluids with specific forces or mechanical means specific forces

- B01L2400/0406—Moving fluids with specific forces or mechanical means specific forces capillary forces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2400/00—Moving or stopping fluids

- B01L2400/04—Moving fluids with specific forces or mechanical means

- B01L2400/0403—Moving fluids with specific forces or mechanical means specific forces

- B01L2400/0415—Moving fluids with specific forces or mechanical means specific forces electrical forces, e.g. electrokinetic

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L2400/00—Moving or stopping fluids

- B01L2400/04—Moving fluids with specific forces or mechanical means

- B01L2400/0475—Moving fluids with specific forces or mechanical means specific mechanical means and fluid pressure

- B01L2400/0487—Moving fluids with specific forces or mechanical means specific mechanical means and fluid pressure fluid pressure, pneumatics

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12Q—MEASURING OR TESTING PROCESSES INVOLVING ENZYMES, NUCLEIC ACIDS OR MICROORGANISMS; COMPOSITIONS OR TEST PAPERS THEREFOR; PROCESSES OF PREPARING SUCH COMPOSITIONS; CONDITION-RESPONSIVE CONTROL IN MICROBIOLOGICAL OR ENZYMOLOGICAL PROCESSES

- C12Q2563/00—Nucleic acid detection characterized by the use of physical, structural and functional properties

- C12Q2563/159—Microreactors, e.g. emulsion PCR or sequencing, droplet PCR, microcapsules, i.e. non-liquid containers with a range of different permeability's for different reaction components

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12Q—MEASURING OR TESTING PROCESSES INVOLVING ENZYMES, NUCLEIC ACIDS OR MICROORGANISMS; COMPOSITIONS OR TEST PAPERS THEREFOR; PROCESSES OF PREPARING SUCH COMPOSITIONS; CONDITION-RESPONSIVE CONTROL IN MICROBIOLOGICAL OR ENZYMOLOGICAL PROCESSES

- C12Q2565/00—Nucleic acid analysis characterised by mode or means of detection

- C12Q2565/10—Detection mode being characterised by the assay principle