KR20220157504A - 압력 배관용 강관 - Google Patents

압력 배관용 강관 Download PDFInfo

- Publication number

- KR20220157504A KR20220157504A KR1020227038419A KR20227038419A KR20220157504A KR 20220157504 A KR20220157504 A KR 20220157504A KR 1020227038419 A KR1020227038419 A KR 1020227038419A KR 20227038419 A KR20227038419 A KR 20227038419A KR 20220157504 A KR20220157504 A KR 20220157504A

- Authority

- KR

- South Korea

- Prior art keywords

- steel pipe

- residual stress

- self

- pressure

- stress

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 229910000831 Steel Inorganic materials 0.000 title claims abstract description 149

- 239000010959 steel Substances 0.000 title claims abstract description 149

- 238000005728 strengthening Methods 0.000 claims abstract description 11

- 238000000034 method Methods 0.000 description 30

- 239000000446 fuel Substances 0.000 description 21

- 230000000670 limiting effect Effects 0.000 description 21

- 238000002347 injection Methods 0.000 description 18

- 239000007924 injection Substances 0.000 description 18

- 238000012360 testing method Methods 0.000 description 15

- 238000004458 analytical method Methods 0.000 description 13

- 238000005520 cutting process Methods 0.000 description 11

- 238000009661 fatigue test Methods 0.000 description 10

- 239000000463 material Substances 0.000 description 10

- 239000000047 product Substances 0.000 description 10

- 238000010438 heat treatment Methods 0.000 description 8

- 238000010586 diagram Methods 0.000 description 7

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 6

- 229910002804 graphite Inorganic materials 0.000 description 6

- 239000010439 graphite Substances 0.000 description 6

- 238000005259 measurement Methods 0.000 description 6

- 238000012545 processing Methods 0.000 description 6

- 230000000052 comparative effect Effects 0.000 description 5

- 238000007789 sealing Methods 0.000 description 5

- 238000003754 machining Methods 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 4

- 238000005498 polishing Methods 0.000 description 4

- 238000002485 combustion reaction Methods 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- 239000012043 crude product Substances 0.000 description 3

- 239000002344 surface layer Substances 0.000 description 3

- 238000009864 tensile test Methods 0.000 description 3

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 2

- 238000002441 X-ray diffraction Methods 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000002243 precursor Substances 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 238000010791 quenching Methods 0.000 description 2

- 230000000171 quenching effect Effects 0.000 description 2

- PZNPLUBHRSSFHT-RRHRGVEJSA-N 1-hexadecanoyl-2-octadecanoyl-sn-glycero-3-phosphocholine Chemical compound CCCCCCCCCCCCCCCCCC(=O)O[C@@H](COP([O-])(=O)OCC[N+](C)(C)C)COC(=O)CCCCCCCCCCCCCCC PZNPLUBHRSSFHT-RRHRGVEJSA-N 0.000 description 1

- 206010039509 Scab Diseases 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 238000003915 air pollution Methods 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 238000005422 blasting Methods 0.000 description 1

- 238000010622 cold drawing Methods 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000006356 dehydrogenation reaction Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000012467 final product Substances 0.000 description 1

- 238000005242 forging Methods 0.000 description 1

- 239000010720 hydraulic oil Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 238000000691 measurement method Methods 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 229910052755 nonmetal Inorganic materials 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 230000036961 partial effect Effects 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 230000002829 reductive effect Effects 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 238000005482 strain hardening Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 230000003746 surface roughness Effects 0.000 description 1

- 238000005496 tempering Methods 0.000 description 1

- 238000005979 thermal decomposition reaction Methods 0.000 description 1

- 238000010792 warming Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L9/00—Rigid pipes

- F16L9/02—Rigid pipes of metal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23P—METAL-WORKING NOT OTHERWISE PROVIDED FOR; COMBINED OPERATIONS; UNIVERSAL MACHINE TOOLS

- B23P9/00—Treating or finishing surfaces mechanically, with or without calibrating, primarily to resist wear or impact, e.g. smoothing or roughening turbine blades or bearings; Features of such surfaces not otherwise provided for, their treatment being unspecified

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D7/00—Modifying the physical properties of iron or steel by deformation

- C21D7/02—Modifying the physical properties of iron or steel by deformation by cold working

- C21D7/10—Modifying the physical properties of iron or steel by deformation by cold working of the whole cross-section, e.g. of concrete reinforcing bars

- C21D7/12—Modifying the physical properties of iron or steel by deformation by cold working of the whole cross-section, e.g. of concrete reinforcing bars by expanding tubular bodies

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/10—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of tubular bodies

- C21D8/105—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of tubular bodies of ferrous alloys

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/08—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for tubular bodies or pipes

- C21D9/14—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for tubular bodies or pipes wear-resistant or pressure-resistant pipes

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/001—Ferrous alloys, e.g. steel alloys containing N

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/002—Ferrous alloys, e.g. steel alloys containing In, Mg, or other elements not provided for in one single group C22C38/001 - C22C38/60

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/06—Ferrous alloys, e.g. steel alloys containing aluminium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/42—Ferrous alloys, e.g. steel alloys containing chromium with nickel with copper

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/44—Ferrous alloys, e.g. steel alloys containing chromium with nickel with molybdenum or tungsten

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/46—Ferrous alloys, e.g. steel alloys containing chromium with nickel with vanadium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/48—Ferrous alloys, e.g. steel alloys containing chromium with nickel with niobium or tantalum

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/50—Ferrous alloys, e.g. steel alloys containing chromium with nickel with titanium or zirconium

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M55/00—Fuel-injection apparatus characterised by their fuel conduits or their venting means; Arrangements of conduits between fuel tank and pump F02M37/00

- F02M55/02—Conduits between injection pumps and injectors, e.g. conduits between pump and common-rail or conduits between common-rail and injectors

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2221/00—Treating localised areas of an article

- C21D2221/10—Differential treatment of inner with respect to outer regions, e.g. core and periphery, respectively

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/12—Ferrous alloys, e.g. steel alloys containing tungsten, tantalum, molybdenum, vanadium, or niobium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/14—Ferrous alloys, e.g. steel alloys containing titanium or zirconium

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M2200/00—Details of fuel-injection apparatus, not otherwise provided for

- F02M2200/90—Selection of particular materials

- F02M2200/9053—Metals

- F02M2200/9061—Special treatments for modifying the properties of metals used for fuel injection apparatus, e.g. modifying mechanical or electromagnetic properties

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M37/00—Apparatus or systems for feeding liquid fuel from storage containers to carburettors or fuel-injection apparatus; Arrangements for purifying liquid fuel specially adapted for, or arranged on, internal-combustion engines

- F02M37/0011—Constructional details; Manufacturing or assembly of elements of fuel systems; Materials therefor

- F02M37/0017—Constructional details; Manufacturing or assembly of elements of fuel systems; Materials therefor related to fuel pipes or their connections, e.g. joints or sealings

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P10/00—Technologies related to metal processing

- Y02P10/20—Recycling

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Organic Chemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- General Engineering & Computer Science (AREA)

- Crystallography & Structural Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Combustion & Propulsion (AREA)

- Heat Treatment Of Articles (AREA)

- Rigid Pipes And Flexible Pipes (AREA)

- Fuel-Injection Apparatus (AREA)

Abstract

Description

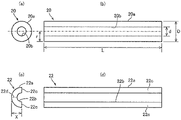

도 2는, 다변수 함수의 도출 방법을 설명하기 위한 도면이다.

도 3은, 다변수 함수의 도출 방법을 설명하기 위한 도면이다.

도 4는, 다변수 함수의 도출 방법을 설명하기 위한 도면이다.

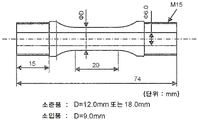

도 5는, 내압 피로 시험편의 형상을 설명하기 위한 도면이다.

20b: 내면 22: 반할 시료

22a: 외면 22b: 내면

22c: 절단면 22d: 중심부

40: 해석 모델 40a, 40b: 단부

40c: 내면 40d: 외면

Claims (1)

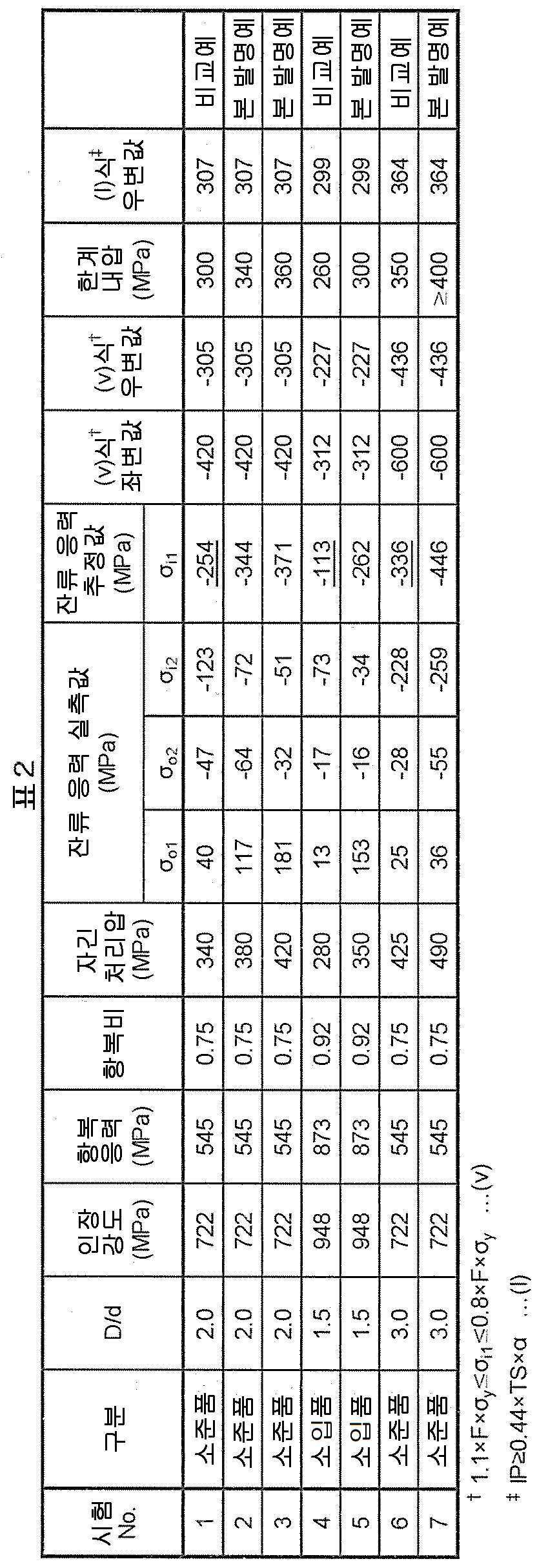

- 자긴(自緊) 처리가 실시된 압력 배관용 강관으로서,

상기 강관의 외경을 D(mm), 내경을 d(mm), 항복 응력을 σy(MPa)로 하고,

자긴 처리 후의 상기 강관의 외면의 잔류 응력의 실측값을 σo1(MPa), 자긴 처리 후 또한 반할(半割) 후의 상기 강관의 외면의 잔류 응력의 실측값을 σo2(MPa), 자긴 처리 후 또한 반할 후의 상기 강관의 내면의 잔류 응력의 실측값을 σi2(MPa)로 한 경우에,

D/d가 1.2 이상이며,

하기 (i)식~(iv)식에 의해 구해지는, 자긴 처리 후의 상기 강관의 내면의 잔류 응력의 추정값 σi1(MPa)가 하기 (v)식을 만족하는,

압력 배관용 강관.

σi1=(-σi2)/(A×(t/T)2-1) …(i)

t/T=((σo2-σo1)/(A×(σo2-σo1)-C×σi2))1/2 …(ii)

A=3.9829×exp(0.1071×(D/d)2) …(iii)

C=-3.3966×exp(0.0452×(D/d)2) …(iv)

1.1×F×σy≤σi1≤0.8×F×σy …(v)

단, 상기 (v)식 중의 F는 계수이며,

1.2≤D/d≤3.0의 경우는, F=(0.3×(3-D/d)2-1),

D/d>3.0의 경우는, F=-1로 한다.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020069080 | 2020-04-07 | ||

| JPJP-P-2020-069080 | 2020-04-07 | ||

| PCT/JP2021/014435 WO2021206034A1 (ja) | 2020-04-07 | 2021-04-05 | 圧力配管用鋼管 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20220157504A true KR20220157504A (ko) | 2022-11-29 |

| KR102686612B1 KR102686612B1 (ko) | 2024-07-19 |

Family

ID=78023229

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020227038419A Active KR102686612B1 (ko) | 2020-04-07 | 2021-04-05 | 압력 배관용 강관 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20230140650A1 (ko) |

| EP (1) | EP4134578A4 (ko) |

| JP (1) | JP7495636B2 (ko) |

| KR (1) | KR102686612B1 (ko) |

| CN (1) | CN115398136A (ko) |

| WO (1) | WO2021206034A1 (ko) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116162849B (zh) * | 2021-11-25 | 2024-11-12 | 宝山钢铁股份有限公司 | 一种油缸管及其制造方法 |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4417459A (en) * | 1981-07-30 | 1983-11-29 | National Distillers And Chemical Corporation | Autofrettage process |

| JPH0957329A (ja) | 1995-08-28 | 1997-03-04 | Nkk Corp | ディーゼルエンジン燃料噴射管用鋼管の製造方法 |

| KR20040020843A (ko) * | 2002-09-02 | 2004-03-09 | 우수이 고쿠사이 산교 가부시키가이샤 | 디젤 엔진용 커먼 레일 |

| WO2007119734A1 (ja) | 2006-04-13 | 2007-10-25 | Usui Kokusai Sangyo Kaisha, Ltd. | 燃料噴射管用鋼管 |

| WO2009008281A1 (ja) | 2007-07-10 | 2009-01-15 | Usui Kokusai Sangyo Kaisha, Ltd. | 燃料噴射管用鋼管およびその製造方法 |

| WO2015129617A1 (ja) | 2014-02-25 | 2015-09-03 | 臼井国際産業株式会社 | 燃料噴射管用鋼管およびそれを用いた燃料噴射管 |

| WO2016203924A1 (ja) | 2015-06-17 | 2016-12-22 | 臼井国際産業株式会社 | 燃料噴射管用鋼管およびその製造方法 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005201254A (ja) | 2003-12-16 | 2005-07-28 | Usui Kokusai Sangyo Kaisha Ltd | ディーゼルエンジン用高圧燃料配管 |

| JP7124744B2 (ja) * | 2019-02-08 | 2022-08-24 | 日本製鉄株式会社 | 残留応力推定装置、残留応力推定方法、プログラムおよび品質管理方法 |

| US20240093324A1 (en) * | 2021-02-04 | 2024-03-21 | Nippon Steel Corporation | Steel pipe for pressure piping and starting material for steel pipe |

-

2021

- 2021-04-05 KR KR1020227038419A patent/KR102686612B1/ko active Active

- 2021-04-05 CN CN202180025909.0A patent/CN115398136A/zh active Pending

- 2021-04-05 EP EP21785003.1A patent/EP4134578A4/en active Pending

- 2021-04-05 US US17/906,408 patent/US20230140650A1/en active Pending

- 2021-04-05 WO PCT/JP2021/014435 patent/WO2021206034A1/ja not_active Ceased

- 2021-04-05 JP JP2022514052A patent/JP7495636B2/ja active Active

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4417459A (en) * | 1981-07-30 | 1983-11-29 | National Distillers And Chemical Corporation | Autofrettage process |

| JPH0957329A (ja) | 1995-08-28 | 1997-03-04 | Nkk Corp | ディーゼルエンジン燃料噴射管用鋼管の製造方法 |

| KR20040020843A (ko) * | 2002-09-02 | 2004-03-09 | 우수이 고쿠사이 산교 가부시키가이샤 | 디젤 엔진용 커먼 레일 |

| JP2004092551A (ja) * | 2002-09-02 | 2004-03-25 | Usui Kokusai Sangyo Kaisha Ltd | ディーゼルエンジン用コモンレール |

| WO2007119734A1 (ja) | 2006-04-13 | 2007-10-25 | Usui Kokusai Sangyo Kaisha, Ltd. | 燃料噴射管用鋼管 |

| WO2009008281A1 (ja) | 2007-07-10 | 2009-01-15 | Usui Kokusai Sangyo Kaisha, Ltd. | 燃料噴射管用鋼管およびその製造方法 |

| WO2015129617A1 (ja) | 2014-02-25 | 2015-09-03 | 臼井国際産業株式会社 | 燃料噴射管用鋼管およびそれを用いた燃料噴射管 |

| WO2016203924A1 (ja) | 2015-06-17 | 2016-12-22 | 臼井国際産業株式会社 | 燃料噴射管用鋼管およびその製造方法 |

| US11203793B2 (en) * | 2015-06-17 | 2021-12-21 | Usui Co., Ltd. | Steel pipe for fuel injection pipe and method for producing the same |

Non-Patent Citations (2)

| Title |

|---|

| 나카야마 에이스케, 미야하라 미츠오, 오카무라 카즈오, 후지모토 히로키, 후쿠이 키요유키, 「초소형 시험편에 의한 자동차용 박판 스폿 용접 이음매의 피로 강도 예측」, 재료, 2004년 10월, 제53권, 제10호, p.1136-1142 |

| 사단법인 일본재료학회 편찬, 「X선 응력 측정법 표준(2002년판) -철강편」, 2002년 3월 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN115398136A (zh) | 2022-11-25 |

| US20230140650A1 (en) | 2023-05-04 |

| JPWO2021206034A1 (ko) | 2021-10-14 |

| KR102686612B1 (ko) | 2024-07-19 |

| EP4134578A1 (en) | 2023-02-15 |

| EP4134578A4 (en) | 2023-09-20 |

| WO2021206034A1 (ja) | 2021-10-14 |

| JP7495636B2 (ja) | 2024-06-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Hassani-Gangaraj et al. | Finite element approach toward an advanced understanding of deep rolling induced residual stresses, and an application to railway axles | |

| JP6530069B2 (ja) | 燃料噴射管用鋼管およびその製造方法 | |

| US20200240487A1 (en) | Helical compression spring and method for producing same | |

| Gerin et al. | Influence of surface integrity on the fatigue behaviour of a hot-forged and shot-peened C70 steel component | |

| Lyasota et al. | Identification of the tensile damage of degraded carbon steel and ferritic alloy-steel by acoustic emission with in situ microscopic investigations | |

| Trzepiecinski et al. | Experimental and numerical analysis of industrial warm forming of stainless steel sheet | |

| KR20220157504A (ko) | 압력 배관용 강관 | |

| JP7602151B2 (ja) | 圧力配管用鋼管および鋼管素材 | |

| Azadi et al. | Failure analysis of an intake valve in a gasoline engine | |

| Hu et al. | Computer modeling and optimization of swage autofrettage process of a thick-walled cylinder incorporating Bauschinger effect | |

| Togasaki et al. | Effect of UIT on fatigue life in web-gusset welded joints | |

| Zanni et al. | Development and validation of a probabilistic model for notch fatigue strength prediction of tool steels based on surface defects | |

| US20240035593A1 (en) | Threaded steel pipe or tube and production method therefor | |

| Nguyen et al. | Effects of Shot‐Blasting and Induction Hardening on the Fatigue Strength of Hot‐Forged Wheel Bearing Hubs | |

| Gerin et al. | Effect of cold forming on the high cycle fatigue behaviour of a 27MnCr5 steel | |

| Easton et al. | Residual stress in case hardened steel gears | |

| JP7167748B2 (ja) | 超音波疲労試験用試験片及び超音波疲労試験方法 | |

| Chernenkoff et al. | Increased fatigue strength of powder-forged connecting rods by optimized shot peening | |

| JP7516303B2 (ja) | 鋼材中の最大介在物のサイズの予測方法 | |

| Smaili | Influence of Microdefect on Fatigue Properties in Weld Fine Grain Heat Affected Zone on Nickel Molybdenum Alloy Steel | |

| Freborg | Investigating and Understanding the Role of Transformation Induced Residual Stress to Increase Fatigue Life of High Strength Steel Used in Transmission Gears | |

| Salehnasab et al. | Journal of Design Against Fatigue | |

| Hussain et al. | Defence Technology | |

| Salehnasab et al. | A predictive approach for thermal fatigue crack growth behaviour of shot peened Ni75 alloy | |

| Behrens et al. | Adjusting Mechanical Properties of Forging Dies Produced by Ausforming |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20221102 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PA0201 | Request for examination | ||

| PG1501 | Laying open of application | ||

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

Patent event code: PE07011S01D Comment text: Decision to Grant Registration Patent event date: 20240522 |

|

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

Comment text: Registration of Establishment Patent event date: 20240716 Patent event code: PR07011E01D |

|

| PR1002 | Payment of registration fee |

Payment date: 20240717 End annual number: 3 Start annual number: 1 |

|

| PG1601 | Publication of registration |