KR20140122688A - 인터리브된 평면의 유도성 장치와 그의 제조 및 사용 방법 - Google Patents

인터리브된 평면의 유도성 장치와 그의 제조 및 사용 방법 Download PDFInfo

- Publication number

- KR20140122688A KR20140122688A KR1020140043164A KR20140043164A KR20140122688A KR 20140122688 A KR20140122688 A KR 20140122688A KR 1020140043164 A KR1020140043164 A KR 1020140043164A KR 20140043164 A KR20140043164 A KR 20140043164A KR 20140122688 A KR20140122688 A KR 20140122688A

- Authority

- KR

- South Korea

- Prior art keywords

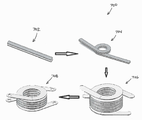

- flat coil

- coil windings

- inductive device

- terminals

- interleaved

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000000034 method Methods 0.000 title claims abstract description 36

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 26

- 230000001939 inductive effect Effects 0.000 title claims description 79

- 238000004804 winding Methods 0.000 claims abstract description 134

- 238000010168 coupling process Methods 0.000 claims description 9

- 230000008878 coupling Effects 0.000 claims description 8

- 238000005859 coupling reaction Methods 0.000 claims description 8

- 238000003780 insertion Methods 0.000 claims description 2

- 230000037431 insertion Effects 0.000 claims description 2

- 239000000306 component Substances 0.000 description 13

- 230000008569 process Effects 0.000 description 11

- 230000009467 reduction Effects 0.000 description 8

- 239000000463 material Substances 0.000 description 7

- 230000008901 benefit Effects 0.000 description 4

- 230000003750 conditioning effect Effects 0.000 description 4

- 238000010586 diagram Methods 0.000 description 4

- 238000002955 isolation Methods 0.000 description 4

- 229910000679 solder Inorganic materials 0.000 description 4

- 238000003466 welding Methods 0.000 description 4

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 3

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 3

- 239000000956 alloy Substances 0.000 description 3

- 230000000712 assembly Effects 0.000 description 3

- 238000000429 assembly Methods 0.000 description 3

- 238000013461 design Methods 0.000 description 3

- 229920006332 epoxy adhesive Polymers 0.000 description 3

- 229920000642 polymer Polymers 0.000 description 3

- 238000005476 soldering Methods 0.000 description 3

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 2

- 230000006978 adaptation Effects 0.000 description 2

- 229910045601 alloy Inorganic materials 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 239000004020 conductor Substances 0.000 description 2

- 229910052802 copper Inorganic materials 0.000 description 2

- 239000010949 copper Substances 0.000 description 2

- 230000007547 defect Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000004806 packaging method and process Methods 0.000 description 2

- 229920000052 poly(p-xylylene) Polymers 0.000 description 2

- 238000006467 substitution reaction Methods 0.000 description 2

- 239000000758 substrate Substances 0.000 description 2

- 229910000859 α-Fe Inorganic materials 0.000 description 2

- 229910000976 Electrical steel Inorganic materials 0.000 description 1

- 239000004593 Epoxy Substances 0.000 description 1

- 229910000640 Fe alloy Inorganic materials 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 239000003990 capacitor Substances 0.000 description 1

- 239000000969 carrier Substances 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 239000000356 contaminant Substances 0.000 description 1

- 239000008358 core component Substances 0.000 description 1

- 238000012937 correction Methods 0.000 description 1

- 239000008367 deionised water Substances 0.000 description 1

- 229910021641 deionized water Inorganic materials 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000007598 dipping method Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000005496 eutectics Effects 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 230000004907 flux Effects 0.000 description 1

- 239000000383 hazardous chemical Substances 0.000 description 1

- 230000006698 induction Effects 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 238000001746 injection moulding Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- UGKDIUIOSMUOAW-UHFFFAOYSA-N iron nickel Chemical compound [Fe].[Ni] UGKDIUIOSMUOAW-UHFFFAOYSA-N 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- ORQBXQOJMQIAOY-UHFFFAOYSA-N nobelium Chemical compound [No] ORQBXQOJMQIAOY-UHFFFAOYSA-N 0.000 description 1

- 239000012811 non-conductive material Substances 0.000 description 1

- 230000010363 phase shift Effects 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 230000008439 repair process Effects 0.000 description 1

- 230000011218 segmentation Effects 0.000 description 1

- 238000005245 sintering Methods 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 239000012899 standard injection Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000004506 ultrasonic cleaning Methods 0.000 description 1

- 238000007740 vapor deposition Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F27/00—Details of transformers or inductances, in general

- H01F27/28—Coils; Windings; Conductive connections

- H01F27/30—Fastening or clamping coils, windings, or parts thereof together; Fastening or mounting coils or windings on core, casing, or other support

- H01F27/306—Fastening or mounting coils or windings on core, casing or other support

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F27/00—Details of transformers or inductances, in general

- H01F27/28—Coils; Windings; Conductive connections

- H01F27/2847—Sheets; Strips

- H01F27/2852—Construction of conductive connections, of leads

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49002—Electrical device making

- Y10T29/4902—Electromagnet, transformer or inductor

- Y10T29/49071—Electromagnet, transformer or inductor by winding or coiling

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Coils Or Transformers For Communication (AREA)

- Manufacturing & Machinery (AREA)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201361810654P | 2013-04-10 | 2013-04-10 | |

| US61/810,654 | 2013-04-10 | ||

| US14/243,786 | 2014-04-02 | ||

| US14/243,786 US20140340186A1 (en) | 2013-04-10 | 2014-04-02 | Interleaved planar inductive device and methods of manufacture and use |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20140122688A true KR20140122688A (ko) | 2014-10-20 |

Family

ID=51895334

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020140043164A Ceased KR20140122688A (ko) | 2013-04-10 | 2014-04-10 | 인터리브된 평면의 유도성 장치와 그의 제조 및 사용 방법 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20140340186A1 (enExample) |

| KR (1) | KR20140122688A (enExample) |

| IN (1) | IN2014DE00992A (enExample) |

| TW (1) | TW201505049A (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR200487142Y1 (ko) * | 2017-05-31 | 2018-08-10 | 주식회사 에이치에스씨 | 2차코일이 일체로 형성된 트랜스포머용 가이더 |

| KR20200000140A (ko) * | 2018-06-22 | 2020-01-02 | 엘지이노텍 주식회사 | 트랜스포머 |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102013101768A1 (de) * | 2013-02-22 | 2014-08-28 | Intel Mobile Communications GmbH | Transformator und elektrische Schaltung |

| US20170345545A1 (en) * | 2016-05-31 | 2017-11-30 | Cooper Technologies Company | Low profile power inductor |

| JP7160438B2 (ja) | 2016-08-31 | 2022-10-25 | ヴィシェイ デール エレクトロニクス エルエルシー | 低い直流抵抗を有す高電流コイルを備えた誘導子 |

| CN106253532A (zh) * | 2016-08-31 | 2016-12-21 | 江门市蓬江区硕泰电器有限公司 | 一种双线绕组线圈及电机 |

| DE102017208655B4 (de) * | 2017-05-22 | 2020-10-01 | Würth Elektronik eiSos Gmbh & Co. KG | Induktives Bauteil und Verfahren zum Herstellen eines induktiven Bauteils |

| WO2020043664A1 (en) * | 2018-08-29 | 2020-03-05 | Qi Suxia | Inductive chargeable energy storage device |

| US12165798B2 (en) | 2019-07-09 | 2024-12-10 | Murata Manufacturing Co., Ltd. | Surface-mounted magnetic-component module |

| CN114080654A (zh) | 2019-07-09 | 2022-02-22 | 株式会社村田制作所 | 表面安装的磁性组件模块 |

| CN112820510A (zh) * | 2019-11-18 | 2021-05-18 | 台达电子(东莞)有限公司 | 电感及其制作方法 |

| US11309123B2 (en) * | 2020-01-07 | 2022-04-19 | Schneider Electric It Corporation | Fully integrated inversely weakly coupled power inductor |

| USD1034462S1 (en) | 2021-03-01 | 2024-07-09 | Vishay Dale Electronics, Llc | Inductor package |

| US11948724B2 (en) | 2021-06-18 | 2024-04-02 | Vishay Dale Electronics, Llc | Method for making a multi-thickness electro-magnetic device |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2474395A (en) * | 1945-09-20 | 1949-06-28 | Gen Motors Corp | High-frequency transformer |

| US2535554A (en) * | 1949-01-24 | 1950-12-26 | Shell Dev | Close-coupled electrical transformer |

| US4901048A (en) * | 1985-06-10 | 1990-02-13 | Williamson Windings Inc. | Magnetic core multiple tap or windings devices |

| US5331536A (en) * | 1992-11-05 | 1994-07-19 | Opt Industries, Inc. | Low leakage high current transformer |

| US6335671B1 (en) * | 1999-08-20 | 2002-01-01 | Tyco Electronics Logistics Ag | Surface mount circuit assembly |

-

2014

- 2014-04-02 US US14/243,786 patent/US20140340186A1/en not_active Abandoned

- 2014-04-07 IN IN992DE2014 patent/IN2014DE00992A/en unknown

- 2014-04-09 TW TW103112988A patent/TW201505049A/zh unknown

- 2014-04-10 KR KR1020140043164A patent/KR20140122688A/ko not_active Ceased

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR200487142Y1 (ko) * | 2017-05-31 | 2018-08-10 | 주식회사 에이치에스씨 | 2차코일이 일체로 형성된 트랜스포머용 가이더 |

| KR20200000140A (ko) * | 2018-06-22 | 2020-01-02 | 엘지이노텍 주식회사 | 트랜스포머 |

Also Published As

| Publication number | Publication date |

|---|---|

| IN2014DE00992A (enExample) | 2015-06-05 |

| US20140340186A1 (en) | 2014-11-20 |

| TW201505049A (zh) | 2015-02-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20140122688A (ko) | 인터리브된 평면의 유도성 장치와 그의 제조 및 사용 방법 | |

| US9378885B2 (en) | Flat coil windings, and inductive devices and electronics assemblies that utilize flat coil windings | |

| KR101466418B1 (ko) | 소형 차폐된 자기소자 | |

| KR101555398B1 (ko) | 자기 전기적 장치 | |

| CN101553891B (zh) | 电子部件及与该电子部件有关的方法 | |

| CN102449708A (zh) | 微型经屏蔽的磁性部件及制造方法 | |

| US10679783B2 (en) | Network transformer apparatus and methods of making and using the same | |

| US20120176214A1 (en) | Flatwire planar transformer | |

| CN1307661C (zh) | 带有线圈末端的电子元件磁芯 | |

| WO2014088893A1 (en) | Choke coil devices and methods of making and using the same | |

| JPH04144212A (ja) | プリント配線板を使用した高周波用トランスおよびコイル | |

| US20150130577A1 (en) | Insulation planar inductive device and methods of manufacture and use | |

| CN107924751A (zh) | 具有分离器的电感装置以及其制造和使用方法 | |

| JP2017147321A (ja) | コイル部品、コイル部品を内蔵した回路基板、並びに、コイル部品を備える電源回路 | |

| CN101620916A (zh) | 磁性元件 | |

| CN104103399A (zh) | 交错式平面电感装置及其制造和使用方法 | |

| JP2009218530A (ja) | 多連インダクタ及びその製造方法 | |

| TWI447759B (zh) | 表面安裝磁性元件總成 | |

| JPH02224212A (ja) | インダクタンス部品 | |

| CN214505184U (zh) | 贴片式电感 | |

| TWM556915U (zh) | 電感元件 | |

| CN103489576A (zh) | 微型屏蔽磁性部件 | |

| KR20230089665A (ko) | 전기자동차용 커먼모드 노이즈필터 | |

| HK1073529B (en) | Component core with coil terminations | |

| JP2006196607A (ja) | 基板コイル |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| PA0109 | Patent application |

Patent event code: PA01091R01D Comment text: Patent Application Patent event date: 20140410 |

|

| PA0201 | Request for examination | ||

| PG1501 | Laying open of application | ||

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20150306 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20151223 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20150306 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |