KR20110017866A - 프로세스 강화를 위한 유체역학적 공동 반응기 설계방법 - Google Patents

프로세스 강화를 위한 유체역학적 공동 반응기 설계방법 Download PDFInfo

- Publication number

- KR20110017866A KR20110017866A KR1020107026702A KR20107026702A KR20110017866A KR 20110017866 A KR20110017866 A KR 20110017866A KR 1020107026702 A KR1020107026702 A KR 1020107026702A KR 20107026702 A KR20107026702 A KR 20107026702A KR 20110017866 A KR20110017866 A KR 20110017866A

- Authority

- KR

- South Korea

- Prior art keywords

- cavitation

- cavity

- hole

- flow

- ven

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000000034 method Methods 0.000 title claims abstract description 71

- 230000008569 process Effects 0.000 title claims abstract description 18

- 238000013461 design Methods 0.000 title abstract description 34

- 238000001311 chemical methods and process Methods 0.000 claims abstract description 12

- 230000001052 transient effect Effects 0.000 claims description 60

- 239000007788 liquid Substances 0.000 claims description 51

- 238000006243 chemical reaction Methods 0.000 claims description 39

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 claims description 33

- 230000009466 transformation Effects 0.000 claims description 28

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 28

- 238000011144 upstream manufacturing Methods 0.000 claims description 20

- 230000006378 damage Effects 0.000 claims description 16

- 230000003647 oxidation Effects 0.000 claims description 15

- 238000007254 oxidation reaction Methods 0.000 claims description 15

- 230000001965 increasing effect Effects 0.000 claims description 14

- 239000012530 fluid Substances 0.000 claims description 12

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 11

- 229910052799 carbon Inorganic materials 0.000 claims description 11

- 230000015556 catabolic process Effects 0.000 claims description 11

- 238000006731 degradation reaction Methods 0.000 claims description 11

- 230000000813 microbial effect Effects 0.000 claims description 11

- PYWVYCXTNDRMGF-UHFFFAOYSA-N rhodamine B Chemical compound [Cl-].C=12C=CC(=[N+](CC)CC)C=C2OC2=CC(N(CC)CC)=CC=C2C=1C1=CC=CC=C1C(O)=O PYWVYCXTNDRMGF-UHFFFAOYSA-N 0.000 claims description 11

- 239000002245 particle Substances 0.000 claims description 10

- 239000006185 dispersion Substances 0.000 claims description 9

- 235000014113 dietary fatty acids Nutrition 0.000 claims description 8

- 229930195729 fatty acid Natural products 0.000 claims description 8

- 239000000194 fatty acid Substances 0.000 claims description 8

- 150000004665 fatty acids Chemical class 0.000 claims description 8

- 230000032050 esterification Effects 0.000 claims description 7

- 238000005886 esterification reaction Methods 0.000 claims description 7

- 238000005728 strengthening Methods 0.000 claims description 6

- 239000002028 Biomass Substances 0.000 claims description 5

- 241000894006 Bacteria Species 0.000 claims description 4

- 238000011109 contamination Methods 0.000 claims description 4

- 238000004945 emulsification Methods 0.000 claims description 4

- 238000005457 optimization Methods 0.000 claims description 4

- 230000001133 acceleration Effects 0.000 claims description 3

- 239000008135 aqueous vehicle Substances 0.000 claims description 3

- 239000000839 emulsion Substances 0.000 claims description 3

- 239000000463 material Substances 0.000 claims description 3

- 239000002687 nonaqueous vehicle Substances 0.000 claims description 3

- 230000009467 reduction Effects 0.000 claims description 3

- 239000002002 slurry Substances 0.000 claims description 3

- 239000007791 liquid phase Substances 0.000 claims description 2

- 230000004083 survival effect Effects 0.000 claims description 2

- 230000036962 time dependent Effects 0.000 claims description 2

- 230000000694 effects Effects 0.000 abstract description 25

- 239000012736 aqueous medium Substances 0.000 abstract description 2

- 239000012457 nonaqueous media Substances 0.000 abstract description 2

- 238000004659 sterilization and disinfection Methods 0.000 description 17

- 230000001954 sterilising effect Effects 0.000 description 16

- 230000006399 behavior Effects 0.000 description 11

- 210000004027 cell Anatomy 0.000 description 10

- 230000007423 decrease Effects 0.000 description 9

- 238000000844 transformation Methods 0.000 description 9

- 239000012071 phase Substances 0.000 description 7

- 239000000376 reactant Substances 0.000 description 6

- 238000001816 cooling Methods 0.000 description 5

- 239000000126 substance Substances 0.000 description 5

- 230000008859 change Effects 0.000 description 4

- 230000008602 contraction Effects 0.000 description 4

- 238000004088 simulation Methods 0.000 description 4

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 3

- 230000002925 chemical effect Effects 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 230000000704 physical effect Effects 0.000 description 3

- 102000004190 Enzymes Human genes 0.000 description 2

- 108090000790 Enzymes Proteins 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 239000003651 drinking water Substances 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 150000004702 methyl esters Chemical class 0.000 description 2

- 239000011148 porous material Substances 0.000 description 2

- 230000002829 reductive effect Effects 0.000 description 2

- 239000010802 sludge Substances 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 238000003786 synthesis reaction Methods 0.000 description 2

- 239000002699 waste material Substances 0.000 description 2

- 241000195493 Cryptophyta Species 0.000 description 1

- 241000588724 Escherichia coli Species 0.000 description 1

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 150000007513 acids Chemical class 0.000 description 1

- 150000001298 alcohols Chemical class 0.000 description 1

- 125000002947 alkylene group Chemical group 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 150000004982 aromatic amines Chemical class 0.000 description 1

- -1 aryl carboxylic acid Chemical class 0.000 description 1

- 230000001580 bacterial effect Effects 0.000 description 1

- KCXMKQUNVWSEMD-UHFFFAOYSA-N benzyl chloride Chemical compound ClCC1=CC=CC=C1 KCXMKQUNVWSEMD-UHFFFAOYSA-N 0.000 description 1

- 239000003225 biodiesel Substances 0.000 description 1

- 239000003181 biological factor Substances 0.000 description 1

- 235000012206 bottled water Nutrition 0.000 description 1

- 210000002421 cell wall Anatomy 0.000 description 1

- 238000003889 chemical engineering Methods 0.000 description 1

- 239000000356 contaminant Substances 0.000 description 1

- 238000005202 decontamination Methods 0.000 description 1

- 230000003588 decontaminative effect Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000002845 discoloration Methods 0.000 description 1

- 239000002612 dispersion medium Substances 0.000 description 1

- 238000004090 dissolution Methods 0.000 description 1

- 235000020188 drinking water Nutrition 0.000 description 1

- 238000005265 energy consumption Methods 0.000 description 1

- 230000002708 enhancing effect Effects 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 230000000977 initiatory effect Effects 0.000 description 1

- 230000003834 intracellular effect Effects 0.000 description 1

- 230000000670 limiting effect Effects 0.000 description 1

- 238000013507 mapping Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 239000002609 medium Substances 0.000 description 1

- AUHZEENZYGFFBQ-UHFFFAOYSA-N mesitylene Substances CC1=CC(C)=CC(C)=C1 AUHZEENZYGFFBQ-UHFFFAOYSA-N 0.000 description 1

- 125000001827 mesitylenyl group Chemical group [H]C1=C(C(*)=C(C([H])=C1C([H])([H])[H])C([H])([H])[H])C([H])([H])[H] 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 239000002105 nanoparticle Substances 0.000 description 1

- 239000006070 nanosuspension Substances 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 230000019612 pigmentation Effects 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 238000011002 quantification Methods 0.000 description 1

- 238000011084 recovery Methods 0.000 description 1

- 239000003507 refrigerant Substances 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 238000012552 review Methods 0.000 description 1

- 239000013535 sea water Substances 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 238000002604 ultrasonography Methods 0.000 description 1

- 235000015112 vegetable and seed oil Nutrition 0.000 description 1

- 239000008158 vegetable oil Substances 0.000 description 1

- 238000004065 wastewater treatment Methods 0.000 description 1

- 239000008096 xylene Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J19/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J19/008—Processes for carrying out reactions under cavitation conditions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/40—Static mixers

- B01F25/45—Mixers in which the materials to be mixed are pressed together through orifices or interstitial spaces, e.g. between beads

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/40—Static mixers

- B01F25/45—Mixers in which the materials to be mixed are pressed together through orifices or interstitial spaces, e.g. between beads

- B01F25/452—Mixers in which the materials to be mixed are pressed together through orifices or interstitial spaces, e.g. between beads characterised by elements provided with orifices or interstitial spaces

- B01F25/4521—Mixers in which the materials to be mixed are pressed together through orifices or interstitial spaces, e.g. between beads characterised by elements provided with orifices or interstitial spaces the components being pressed through orifices in elements, e.g. flat plates or cylinders, which obstruct the whole diameter of the tube

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Dispersion Chemistry (AREA)

- Organic Chemistry (AREA)

- Physical Or Chemical Processes And Apparatus (AREA)

- Physical Water Treatments (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IN1045/MUM/2008 | 2008-05-15 | ||

| IN1045MU2008 | 2008-05-15 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20110017866A true KR20110017866A (ko) | 2011-02-22 |

Family

ID=42542460

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020107026702A Ceased KR20110017866A (ko) | 2008-05-15 | 2009-05-13 | 프로세스 강화를 위한 유체역학적 공동 반응기 설계방법 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20110070639A1 (enExample) |

| EP (1) | EP2285482A2 (enExample) |

| JP (1) | JP2011523372A (enExample) |

| KR (1) | KR20110017866A (enExample) |

| CN (1) | CN102026718A (enExample) |

| WO (1) | WO2010089759A2 (enExample) |

| ZA (1) | ZA201008928B (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT202200007307A1 (it) * | 2022-04-13 | 2023-10-13 | Hyres S R L | Apparato per regolare dinamicamente i processi di cavitazione idrodinamica e relativo procedimento |

Families Citing this family (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20120018386A1 (en) * | 2007-08-02 | 2012-01-26 | Mcguire Dennis | Deepwater oil recovery process |

| US8865452B2 (en) * | 2009-06-15 | 2014-10-21 | Aurora Algae, Inc. | Systems and methods for extracting lipids from wet algal biomass |

| US9101942B2 (en) * | 2009-06-16 | 2015-08-11 | Aurora Algae, Inc. | Clarification of suspensions |

| US8747930B2 (en) * | 2009-06-29 | 2014-06-10 | Aurora Algae, Inc. | Siliceous particles |

| DE102009034977B4 (de) * | 2009-07-28 | 2011-07-21 | Technische Universität München, 80333 | Kavitationsreaktor sowie ein Verfahren zur hydrodynamischen Erzeugung homogener, oszillierender Kavitationsblasen in einem Fluid, ein Verfahren zur Desinfektion eines Fluids und ein Verfahren zum Emulgieren oder zum Suspendieren oder zur Reaktionsbegünstigung zumindest zweier Stoffe |

| US8765983B2 (en) * | 2009-10-30 | 2014-07-01 | Aurora Algae, Inc. | Systems and methods for extracting lipids from and dehydrating wet algal biomass |

| US20110172137A1 (en) | 2010-01-13 | 2011-07-14 | Francesc Corominas | Method Of Producing A Fabric Softening Composition |

| US8926844B2 (en) * | 2011-03-29 | 2015-01-06 | Aurora Algae, Inc. | Systems and methods for processing algae cultivation fluid |

| US8569530B2 (en) | 2011-04-01 | 2013-10-29 | Aurora Algae, Inc. | Conversion of saponifiable lipids into fatty esters |

| US10190188B2 (en) * | 2012-11-25 | 2019-01-29 | Turbulent Technologies Ltd. | Mixing method and device for solvent extraction, especially in hydrometallurgical processes |

| US20160122701A1 (en) * | 2013-02-01 | 2016-05-05 | Carnegie Mellon University | Methods, Devices and Systems for Algae Lysis and Content Extraction |

| US9266973B2 (en) | 2013-03-15 | 2016-02-23 | Aurora Algae, Inc. | Systems and methods for utilizing and recovering chitosan to process biological material |

| CN103343089B (zh) * | 2013-07-10 | 2014-10-01 | 中国石油大学(华东) | 一种水力空化细胞破壁装置 |

| CN103449527A (zh) * | 2013-08-09 | 2013-12-18 | 华南理工大学 | 一种水力空化活化制备高铁酸盐的方法 |

| US10233132B2 (en) * | 2015-10-19 | 2019-03-19 | Oleksandr Galaka | Organic or organo-mineral fertilizers, method of producing thereof and production unit therefor |

| CN105718630B (zh) * | 2016-01-04 | 2019-07-09 | 中国人民解放军91550部队 | 一种垂直潜射飞行器肩空泡出水溃灭过程分析方法 |

| CN106739866B (zh) * | 2016-12-20 | 2019-02-22 | 石昌远 | 汽车轮胎降温装置 |

| DK179484B1 (en) * | 2017-05-26 | 2018-12-17 | Hans Jensen Lubricators A/S | Method for lubricating large two-stroke engines using controlled cavitation in the injector nozzle |

| CN107594597B (zh) * | 2017-07-31 | 2020-05-12 | 浙江新和成股份有限公司 | 一种脂溶性营养素微胶囊及其制备方法 |

| CN110296912B (zh) * | 2019-06-19 | 2020-07-21 | 北京理工大学 | 基于超声的粉尘云团扩散动态湍流动能的检测系统及方法 |

| US10934180B1 (en) | 2020-03-31 | 2021-03-02 | KD Enterprises LLC | Hydrodynamic cavitation device |

| CN112495592B (zh) * | 2020-12-11 | 2021-11-02 | 山东大学 | 空化与起泡一体化尾矿浮选装置 |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4123800A (en) * | 1977-05-18 | 1978-10-31 | Mazzei Angelo L | Mixer-injector |

| WO1994013392A1 (fr) | 1991-11-29 | 1994-06-23 | Ki N Proizv Ob | Procede et dispositif permettant d'obtenir un systeme a libre dispersion |

| ATE224013T1 (de) | 1996-02-15 | 2002-09-15 | Oleg Vyacheslavovich Kozyuk | Verfahren und vorrichtung zur herstellung eines frei dispersen systems in einer flüssigkeit |

| US5937906A (en) | 1997-05-06 | 1999-08-17 | Kozyuk; Oleg V. | Method and apparatus for conducting sonochemical reactions and processes using hydrodynamic cavitation |

| US5863128A (en) * | 1997-12-04 | 1999-01-26 | Mazzei; Angelo L. | Mixer-injectors with twisting and straightening vanes |

| JP4009035B2 (ja) * | 1999-03-05 | 2007-11-14 | 株式会社フジキン | 静止型混合攪拌装置 |

| US6502979B1 (en) * | 2000-11-20 | 2003-01-07 | Five Star Technologies, Inc. | Device and method for creating hydrodynamic cavitation in fluids |

| US7207712B2 (en) | 2004-09-07 | 2007-04-24 | Five Star Technologies, Inc. | Device and method for creating hydrodynamic cavitation in fluids |

| CN101370736A (zh) | 2005-11-08 | 2009-02-18 | 科学与工业研究委员会 | 一种用于海水/船舶压舱水的灭菌设备及其方法 |

-

2009

- 2009-05-13 JP JP2011509082A patent/JP2011523372A/ja active Pending

- 2009-05-13 US US12/992,038 patent/US20110070639A1/en not_active Abandoned

- 2009-05-13 WO PCT/IN2009/000280 patent/WO2010089759A2/en not_active Ceased

- 2009-05-13 CN CN2009801175157A patent/CN102026718A/zh active Pending

- 2009-05-13 KR KR1020107026702A patent/KR20110017866A/ko not_active Ceased

- 2009-05-13 EP EP09839572A patent/EP2285482A2/en not_active Withdrawn

-

2010

- 2010-12-10 ZA ZA2010/08928A patent/ZA201008928B/en unknown

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT202200007307A1 (it) * | 2022-04-13 | 2023-10-13 | Hyres S R L | Apparato per regolare dinamicamente i processi di cavitazione idrodinamica e relativo procedimento |

| EP4260934A1 (en) * | 2022-04-13 | 2023-10-18 | Hyres S.r.l. | Apparatus for dynamically regulating hydrodynamic cavitation processes and related process |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2011523372A (ja) | 2011-08-11 |

| WO2010089759A2 (en) | 2010-08-12 |

| EP2285482A2 (en) | 2011-02-23 |

| CN102026718A (zh) | 2011-04-20 |

| ZA201008928B (en) | 2012-01-25 |

| US20110070639A1 (en) | 2011-03-24 |

| WO2010089759A9 (en) | 2010-11-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20110017866A (ko) | 프로세스 강화를 위한 유체역학적 공동 반응기 설계방법 | |

| Gogate et al. | Hydrodynamic cavitation reactors: a state of the art review | |

| Carpenter et al. | Hydrodynamic cavitation: an emerging technology for the intensification of various chemical and physical processes in a chemical process industry | |

| Rehman et al. | Fluidic oscillator-mediated microbubble generation to provide cost effective mass transfer and mixing efficiency to the wastewater treatment plants | |

| Huang et al. | A review on bubble generation and transportation in Venturi-type bubble generators | |

| Zlokarnik | Stirring: Theory and practice | |

| Tao et al. | Application of hydrodynamic cavitation to wastewater treatment | |

| Gogate | Cavitational reactors for process intensification of chemical processing applications: a critical review | |

| Kuppa et al. | Physical features of ultrasound-enhanced heterogeneous permanganate oxidation | |

| Ozonek | Application of hydrodynamic cavitation in environmental engineering | |

| Chatzi et al. | Drop size distributions in high holdup fraction dispersion systems: effect of the degree of hydrolysis of PVA stabilizer | |

| Petersen et al. | Hydrodynamic and mass transfer characteristics of three-phase gaslift bioreactor systems | |

| Mohseni et al. | Bubble generation by micro-orifices with application on activated sludge wastewater treatment | |

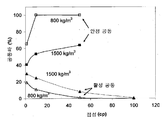

| Kumar et al. | Flow regime maps and optimization thereby of hydrodynamic cavitation reactors | |

| Li et al. | Insights into gas flow behavior in venturi aerator by CFD-PBM model and verification of its efficiency in sludge reduction through O3 aeration | |

| Gogate et al. | Cavitation generation and usage without ultrasound: hydrodynamic cavitation | |

| Hongprasith et al. | Study of different flexible aeration tube diffusers: Characterization and oxygen transfer performance | |

| Gogate | Application of hydrodynamic cavitation for food and bioprocessing | |

| Amini et al. | Investigating the effect of sparger configuration on the hydrodynamics of a full-scale membrane bioreactor using computational fluid dynamics | |

| Qin et al. | Review of Micronano Bubbles: Stability, Mass Transfer Performance, and Application | |

| Pirdashti et al. | Effects of height to diameter ratio and aeration rate on liquid mixing and hydrodynamic properties in a bubble column | |

| Lee et al. | Bubble column reactors | |

| Hooshyar | Hydrodynamics of structured slurry bubble columns | |

| Ryan | Novel venturi technology for the purpose of gas-liquid mass transfer | |

| Terasaka et al. | Submilli-bubble dispersion from a slit orifice into water |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20101129 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| A201 | Request for examination | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20140509 Comment text: Request for Examination of Application |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20150904 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20151112 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20150904 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |