JP2011523372A - プロセス強化のための流体力学的キャビテーション反応装置を設計する方法 - Google Patents

プロセス強化のための流体力学的キャビテーション反応装置を設計する方法 Download PDFInfo

- Publication number

- JP2011523372A JP2011523372A JP2011509082A JP2011509082A JP2011523372A JP 2011523372 A JP2011523372 A JP 2011523372A JP 2011509082 A JP2011509082 A JP 2011509082A JP 2011509082 A JP2011509082 A JP 2011509082A JP 2011523372 A JP2011523372 A JP 2011523372A

- Authority

- JP

- Japan

- Prior art keywords

- cavitation

- cavity

- cavity generator

- circular

- generator

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000000034 method Methods 0.000 title claims abstract description 58

- 230000001052 transient effect Effects 0.000 claims abstract description 68

- 238000006243 chemical reaction Methods 0.000 claims abstract description 43

- 238000001311 chemical methods and process Methods 0.000 claims abstract description 21

- 239000012736 aqueous medium Substances 0.000 claims abstract description 19

- 239000012457 nonaqueous media Substances 0.000 claims abstract description 19

- 239000012530 fluid Substances 0.000 claims abstract description 14

- 239000007788 liquid Substances 0.000 claims description 57

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 claims description 36

- 238000011144 upstream manufacturing Methods 0.000 claims description 23

- 230000009466 transformation Effects 0.000 claims description 20

- 230000001965 increasing effect Effects 0.000 claims description 17

- 230000006378 damage Effects 0.000 claims description 15

- 230000003647 oxidation Effects 0.000 claims description 15

- 238000007254 oxidation reaction Methods 0.000 claims description 15

- 229910052799 carbon Inorganic materials 0.000 claims description 11

- 239000002245 particle Substances 0.000 claims description 11

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 10

- 230000015556 catabolic process Effects 0.000 claims description 10

- 238000006731 degradation reaction Methods 0.000 claims description 10

- 230000000813 microbial effect Effects 0.000 claims description 10

- PYWVYCXTNDRMGF-UHFFFAOYSA-N rhodamine B Chemical compound [Cl-].C=12C=CC(=[N+](CC)CC)C=C2OC2=CC(N(CC)CC)=CC=C2C=1C1=CC=CC=C1C(O)=O PYWVYCXTNDRMGF-UHFFFAOYSA-N 0.000 claims description 10

- 235000014113 dietary fatty acids Nutrition 0.000 claims description 9

- 229930195729 fatty acid Natural products 0.000 claims description 9

- 239000000194 fatty acid Substances 0.000 claims description 9

- 150000004665 fatty acids Chemical class 0.000 claims description 9

- 238000000844 transformation Methods 0.000 claims description 9

- 239000012071 phase Substances 0.000 claims description 8

- 230000032050 esterification Effects 0.000 claims description 6

- 238000005886 esterification reaction Methods 0.000 claims description 6

- 230000021715 photosynthesis, light harvesting Effects 0.000 claims description 6

- 239000002028 Biomass Substances 0.000 claims description 5

- 230000001580 bacterial effect Effects 0.000 claims description 4

- 238000004945 emulsification Methods 0.000 claims description 4

- 239000002002 slurry Substances 0.000 claims description 4

- 239000000126 substance Substances 0.000 claims description 4

- 230000003247 decreasing effect Effects 0.000 claims description 3

- 239000000839 emulsion Substances 0.000 claims description 3

- 230000001133 acceleration Effects 0.000 claims description 2

- 239000007791 liquid phase Substances 0.000 claims description 2

- 238000005457 optimization Methods 0.000 claims description 2

- 239000000243 solution Substances 0.000 claims description 2

- 230000036962 time dependent Effects 0.000 claims description 2

- 238000010297 mechanical methods and process Methods 0.000 claims 1

- 238000013461 design Methods 0.000 abstract description 34

- 230000000694 effects Effects 0.000 abstract description 21

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 16

- 238000004659 sterilization and disinfection Methods 0.000 description 15

- 210000004027 cell Anatomy 0.000 description 10

- 230000007423 decrease Effects 0.000 description 8

- 230000000875 corresponding effect Effects 0.000 description 6

- 239000000376 reactant Substances 0.000 description 6

- 230000001105 regulatory effect Effects 0.000 description 6

- 238000001816 cooling Methods 0.000 description 5

- 239000006185 dispersion Substances 0.000 description 5

- 230000002925 chemical effect Effects 0.000 description 4

- 230000000704 physical effect Effects 0.000 description 4

- 230000002829 reductive effect Effects 0.000 description 4

- 238000004088 simulation Methods 0.000 description 4

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 3

- -1 alkyl arenes Chemical class 0.000 description 3

- 238000013459 approach Methods 0.000 description 3

- 230000001143 conditioned effect Effects 0.000 description 3

- 230000008602 contraction Effects 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 239000002699 waste material Substances 0.000 description 3

- 241001120493 Arene Species 0.000 description 2

- 102000004190 Enzymes Human genes 0.000 description 2

- 108090000790 Enzymes Proteins 0.000 description 2

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 2

- 239000003651 drinking water Substances 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 230000000977 initiatory effect Effects 0.000 description 2

- 150000004702 methyl esters Chemical class 0.000 description 2

- 238000011084 recovery Methods 0.000 description 2

- 239000010802 sludge Substances 0.000 description 2

- 241000894006 Bacteria Species 0.000 description 1

- 239000004215 Carbon black (E152) Substances 0.000 description 1

- 241000195493 Cryptophyta Species 0.000 description 1

- 241000233866 Fungi Species 0.000 description 1

- GRYLNZFGIOXLOG-UHFFFAOYSA-N Nitric acid Chemical compound O[N+]([O-])=O GRYLNZFGIOXLOG-UHFFFAOYSA-N 0.000 description 1

- 238000013019 agitation Methods 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 150000004982 aromatic amines Chemical class 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 235000012206 bottled water Nutrition 0.000 description 1

- 210000002421 cell wall Anatomy 0.000 description 1

- 238000003889 chemical engineering Methods 0.000 description 1

- 239000000356 contaminant Substances 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 230000002596 correlated effect Effects 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000000249 desinfective effect Effects 0.000 description 1

- 238000004090 dissolution Methods 0.000 description 1

- 235000020188 drinking water Nutrition 0.000 description 1

- 238000005265 energy consumption Methods 0.000 description 1

- 230000002708 enhancing effect Effects 0.000 description 1

- 230000001747 exhibiting effect Effects 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- 230000003834 intracellular effect Effects 0.000 description 1

- 230000000670 limiting effect Effects 0.000 description 1

- 238000013507 mapping Methods 0.000 description 1

- 239000002609 medium Substances 0.000 description 1

- AUHZEENZYGFFBQ-UHFFFAOYSA-N mesitylene Substances CC1=CC(C)=CC(C)=C1 AUHZEENZYGFFBQ-UHFFFAOYSA-N 0.000 description 1

- 125000001827 mesitylenyl group Chemical group [H]C1=C(C(*)=C(C([H])=C1C([H])([H])[H])C([H])([H])[H])C([H])([H])[H] 0.000 description 1

- 244000005700 microbiome Species 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 239000002105 nanoparticle Substances 0.000 description 1

- 229910017604 nitric acid Inorganic materials 0.000 description 1

- 230000003534 oscillatory effect Effects 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 238000012552 review Methods 0.000 description 1

- 239000013535 sea water Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 238000005728 strengthening Methods 0.000 description 1

- 239000011885 synergistic combination Substances 0.000 description 1

- 238000003786 synthesis reaction Methods 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- 238000005809 transesterification reaction Methods 0.000 description 1

- 238000002604 ultrasonography Methods 0.000 description 1

- 235000015112 vegetable and seed oil Nutrition 0.000 description 1

- 239000008158 vegetable oil Substances 0.000 description 1

- 238000004065 wastewater treatment Methods 0.000 description 1

- 239000008096 xylene Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J19/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J19/008—Processes for carrying out reactions under cavitation conditions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/40—Static mixers

- B01F25/45—Mixers in which the materials to be mixed are pressed together through orifices or interstitial spaces, e.g. between beads

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/40—Static mixers

- B01F25/45—Mixers in which the materials to be mixed are pressed together through orifices or interstitial spaces, e.g. between beads

- B01F25/452—Mixers in which the materials to be mixed are pressed together through orifices or interstitial spaces, e.g. between beads characterised by elements provided with orifices or interstitial spaces

- B01F25/4521—Mixers in which the materials to be mixed are pressed together through orifices or interstitial spaces, e.g. between beads characterised by elements provided with orifices or interstitial spaces the components being pressed through orifices in elements, e.g. flat plates or cylinders, which obstruct the whole diameter of the tube

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Dispersion Chemistry (AREA)

- Organic Chemistry (AREA)

- Physical Or Chemical Processes And Apparatus (AREA)

- Physical Water Treatments (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IN1045/MUM/2008 | 2008-05-15 | ||

| IN1045MU2008 | 2008-05-15 | ||

| PCT/IN2009/000280 WO2010089759A2 (en) | 2008-05-15 | 2009-05-13 | Method of designing hydrodynamic cavitation reactors for process intensification |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2011523372A true JP2011523372A (ja) | 2011-08-11 |

| JP2011523372A5 JP2011523372A5 (enExample) | 2012-06-07 |

Family

ID=42542460

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011509082A Pending JP2011523372A (ja) | 2008-05-15 | 2009-05-13 | プロセス強化のための流体力学的キャビテーション反応装置を設計する方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20110070639A1 (enExample) |

| EP (1) | EP2285482A2 (enExample) |

| JP (1) | JP2011523372A (enExample) |

| KR (1) | KR20110017866A (enExample) |

| CN (1) | CN102026718A (enExample) |

| WO (1) | WO2010089759A2 (enExample) |

| ZA (1) | ZA201008928B (enExample) |

Families Citing this family (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20120018386A1 (en) * | 2007-08-02 | 2012-01-26 | Mcguire Dennis | Deepwater oil recovery process |

| US8865452B2 (en) * | 2009-06-15 | 2014-10-21 | Aurora Algae, Inc. | Systems and methods for extracting lipids from wet algal biomass |

| US9101942B2 (en) * | 2009-06-16 | 2015-08-11 | Aurora Algae, Inc. | Clarification of suspensions |

| US8747930B2 (en) * | 2009-06-29 | 2014-06-10 | Aurora Algae, Inc. | Siliceous particles |

| DE102009034977B4 (de) * | 2009-07-28 | 2011-07-21 | Technische Universität München, 80333 | Kavitationsreaktor sowie ein Verfahren zur hydrodynamischen Erzeugung homogener, oszillierender Kavitationsblasen in einem Fluid, ein Verfahren zur Desinfektion eines Fluids und ein Verfahren zum Emulgieren oder zum Suspendieren oder zur Reaktionsbegünstigung zumindest zweier Stoffe |

| US8765983B2 (en) * | 2009-10-30 | 2014-07-01 | Aurora Algae, Inc. | Systems and methods for extracting lipids from and dehydrating wet algal biomass |

| US20110172137A1 (en) | 2010-01-13 | 2011-07-14 | Francesc Corominas | Method Of Producing A Fabric Softening Composition |

| US8926844B2 (en) * | 2011-03-29 | 2015-01-06 | Aurora Algae, Inc. | Systems and methods for processing algae cultivation fluid |

| US8569530B2 (en) | 2011-04-01 | 2013-10-29 | Aurora Algae, Inc. | Conversion of saponifiable lipids into fatty esters |

| US10190188B2 (en) * | 2012-11-25 | 2019-01-29 | Turbulent Technologies Ltd. | Mixing method and device for solvent extraction, especially in hydrometallurgical processes |

| US20160122701A1 (en) * | 2013-02-01 | 2016-05-05 | Carnegie Mellon University | Methods, Devices and Systems for Algae Lysis and Content Extraction |

| US9266973B2 (en) | 2013-03-15 | 2016-02-23 | Aurora Algae, Inc. | Systems and methods for utilizing and recovering chitosan to process biological material |

| CN103343089B (zh) * | 2013-07-10 | 2014-10-01 | 中国石油大学(华东) | 一种水力空化细胞破壁装置 |

| CN103449527A (zh) * | 2013-08-09 | 2013-12-18 | 华南理工大学 | 一种水力空化活化制备高铁酸盐的方法 |

| US10233132B2 (en) * | 2015-10-19 | 2019-03-19 | Oleksandr Galaka | Organic or organo-mineral fertilizers, method of producing thereof and production unit therefor |

| CN105718630B (zh) * | 2016-01-04 | 2019-07-09 | 中国人民解放军91550部队 | 一种垂直潜射飞行器肩空泡出水溃灭过程分析方法 |

| CN106739866B (zh) * | 2016-12-20 | 2019-02-22 | 石昌远 | 汽车轮胎降温装置 |

| DK179484B1 (en) * | 2017-05-26 | 2018-12-17 | Hans Jensen Lubricators A/S | Method for lubricating large two-stroke engines using controlled cavitation in the injector nozzle |

| CN107594597B (zh) * | 2017-07-31 | 2020-05-12 | 浙江新和成股份有限公司 | 一种脂溶性营养素微胶囊及其制备方法 |

| CN110296912B (zh) * | 2019-06-19 | 2020-07-21 | 北京理工大学 | 基于超声的粉尘云团扩散动态湍流动能的检测系统及方法 |

| US10934180B1 (en) | 2020-03-31 | 2021-03-02 | KD Enterprises LLC | Hydrodynamic cavitation device |

| CN112495592B (zh) * | 2020-12-11 | 2021-11-02 | 山东大学 | 空化与起泡一体化尾矿浮选装置 |

| IT202200007307A1 (it) * | 2022-04-13 | 2023-10-13 | Hyres S R L | Apparato per regolare dinamicamente i processi di cavitazione idrodinamica e relativo procedimento |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4123800A (en) * | 1977-05-18 | 1978-10-31 | Mazzei Angelo L | Mixer-injector |

| WO1994013392A1 (fr) | 1991-11-29 | 1994-06-23 | Ki N Proizv Ob | Procede et dispositif permettant d'obtenir un systeme a libre dispersion |

| ATE224013T1 (de) | 1996-02-15 | 2002-09-15 | Oleg Vyacheslavovich Kozyuk | Verfahren und vorrichtung zur herstellung eines frei dispersen systems in einer flüssigkeit |

| US5937906A (en) | 1997-05-06 | 1999-08-17 | Kozyuk; Oleg V. | Method and apparatus for conducting sonochemical reactions and processes using hydrodynamic cavitation |

| US5863128A (en) * | 1997-12-04 | 1999-01-26 | Mazzei; Angelo L. | Mixer-injectors with twisting and straightening vanes |

| JP4009035B2 (ja) * | 1999-03-05 | 2007-11-14 | 株式会社フジキン | 静止型混合攪拌装置 |

| US6502979B1 (en) * | 2000-11-20 | 2003-01-07 | Five Star Technologies, Inc. | Device and method for creating hydrodynamic cavitation in fluids |

| US7207712B2 (en) | 2004-09-07 | 2007-04-24 | Five Star Technologies, Inc. | Device and method for creating hydrodynamic cavitation in fluids |

| CN101370736A (zh) | 2005-11-08 | 2009-02-18 | 科学与工业研究委员会 | 一种用于海水/船舶压舱水的灭菌设备及其方法 |

-

2009

- 2009-05-13 JP JP2011509082A patent/JP2011523372A/ja active Pending

- 2009-05-13 US US12/992,038 patent/US20110070639A1/en not_active Abandoned

- 2009-05-13 WO PCT/IN2009/000280 patent/WO2010089759A2/en not_active Ceased

- 2009-05-13 CN CN2009801175157A patent/CN102026718A/zh active Pending

- 2009-05-13 KR KR1020107026702A patent/KR20110017866A/ko not_active Ceased

- 2009-05-13 EP EP09839572A patent/EP2285482A2/en not_active Withdrawn

-

2010

- 2010-12-10 ZA ZA2010/08928A patent/ZA201008928B/en unknown

Also Published As

| Publication number | Publication date |

|---|---|

| WO2010089759A2 (en) | 2010-08-12 |

| EP2285482A2 (en) | 2011-02-23 |

| CN102026718A (zh) | 2011-04-20 |

| KR20110017866A (ko) | 2011-02-22 |

| ZA201008928B (en) | 2012-01-25 |

| US20110070639A1 (en) | 2011-03-24 |

| WO2010089759A9 (en) | 2010-11-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2011523372A (ja) | プロセス強化のための流体力学的キャビテーション反応装置を設計する方法 | |

| Gogate et al. | Cavitation reactors: efficiency assessment using a model reaction | |

| Yi et al. | Degradation of organic wastewater by hydrodynamic cavitation combined with acoustic cavitation | |

| Ozonek | Application of hydrodynamic cavitation in environmental engineering | |

| Gogate | Cavitational reactors for process intensification of chemical processing applications: a critical review | |

| Zlokarnik | Stirring: Theory and practice | |

| Tao et al. | Application of hydrodynamic cavitation to wastewater treatment | |

| Rehman et al. | Fluidic oscillator-mediated microbubble generation to provide cost effective mass transfer and mixing efficiency to the wastewater treatment plants | |

| Gogate et al. | Engineering design methods for cavitation reactors II: hydrodynamic cavitation | |

| Kuppa et al. | Physical features of ultrasound-enhanced heterogeneous permanganate oxidation | |

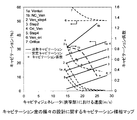

| Sharma et al. | Modeling of hydrodynamic cavitation reactors based on orifice plates considering hydrodynamics and chemical reactions occurring in bubble | |

| Thaker et al. | Emulsions using a vortex-based cavitation device: influence of number of passes, pressure drop, and device scale on droplet size distributions | |

| Li et al. | Insights into gas flow behavior in venturi aerator by CFD-PBM model and verification of its efficiency in sludge reduction through O3 aeration | |

| Ranade | Modeling of hydrodynamic cavitation reactors: Reflections on present status and path forward | |

| Jiang et al. | HiGee microbubble generator:(II) controllable preparation of microbubbles | |

| Cheng et al. | Three-stage shear-serrated aerator broke CO2 bubbles to promote mass transfer and microalgal growth | |

| Jiang et al. | HiGee microbubble generator:(I) mathematical modeling and experimental verification of the energy dissipation rate | |

| Shuai et al. | Structural design and performance of a jet-impinging type microbubble generator | |

| Wu et al. | Microbubble dispersion process intensification using novel internal baffles | |

| Ozonek et al. | Effect of different design features of the reactor on hydrodynamic cavitation process | |

| Zhang et al. | Analysis of the influencing factors of the hydroxyl radical yield in a hydrodynamic cavitation bubble of a chitosan solution based on a numerical simulation | |

| Yang et al. | Numerical simulation of the effect of jet small orifice structure on cavitation characteristic and jet impact flow field | |

| Wang et al. | Investigation of hydrodynamic performance in a staggered multistage internal airlift loop reactor | |

| Gogate et al. | Cavitation generation and usage without ultrasound: hydrodynamic cavitation | |

| Liu et al. | Computational fluid dynamics based modeling of gas absorption process: a state-of-the-art review |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110120 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20120209 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120419 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120622 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120703 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20121002 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20121010 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121105 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130115 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130415 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130423 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130515 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130522 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130617 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20131217 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140417 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20140618 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20140815 |