KR101441515B1 - Precast concrete slab of Inver-Teed Rib - Google Patents

Precast concrete slab of Inver-Teed Rib Download PDFInfo

- Publication number

- KR101441515B1 KR101441515B1 KR1020140018918A KR20140018918A KR101441515B1 KR 101441515 B1 KR101441515 B1 KR 101441515B1 KR 1020140018918 A KR1020140018918 A KR 1020140018918A KR 20140018918 A KR20140018918 A KR 20140018918A KR 101441515 B1 KR101441515 B1 KR 101441515B1

- Authority

- KR

- South Korea

- Prior art keywords

- rib

- slab

- plate

- concrete

- slabs

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000011178 precast concrete Substances 0.000 title description 15

- 230000002787 reinforcement Effects 0.000 claims abstract description 15

- 239000004567 concrete Substances 0.000 claims abstract description 11

- 230000003014 reinforcing effect Effects 0.000 claims description 8

- 230000008878 coupling Effects 0.000 claims description 2

- 238000010168 coupling process Methods 0.000 claims description 2

- 238000005859 coupling reaction Methods 0.000 claims description 2

- 230000000694 effects Effects 0.000 claims 1

- 238000011065 in-situ storage Methods 0.000 claims 1

- 238000010276 construction Methods 0.000 abstract description 8

- 239000010410 layer Substances 0.000 description 7

- 238000000034 method Methods 0.000 description 4

- 239000002131 composite material Substances 0.000 description 3

- 238000009413 insulation Methods 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 150000008282 halocarbons Chemical class 0.000 description 2

- 239000011796 hollow space material Substances 0.000 description 2

- 239000011150 reinforced concrete Substances 0.000 description 2

- 229920006328 Styrofoam Polymers 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 238000009415 formwork Methods 0.000 description 1

- 230000008014 freezing Effects 0.000 description 1

- 238000007710 freezing Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 239000011229 interlayer Substances 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000003892 spreading Methods 0.000 description 1

- 239000008261 styrofoam Substances 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B5/00—Floors; Floor construction with regard to insulation; Connections specially adapted therefor

- E04B5/02—Load-carrying floor structures formed substantially of prefabricated units

- E04B5/04—Load-carrying floor structures formed substantially of prefabricated units with beams or slabs of concrete or other stone-like material, e.g. asbestos cement

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B5/00—Floors; Floor construction with regard to insulation; Connections specially adapted therefor

- E04B5/16—Load-carrying floor structures wholly or partly cast or similarly formed in situ

- E04B5/17—Floor structures partly formed in situ

- E04B5/23—Floor structures partly formed in situ with stiffening ribs or other beam-like formations wholly or partly prefabricated

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B5/00—Floors; Floor construction with regard to insulation; Connections specially adapted therefor

- E04B5/48—Special adaptations of floors for incorporating ducts, e.g. for heating or ventilating

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Panels For Use In Building Construction (AREA)

Abstract

본 발명은 피씨 구조물용 인버티드 리브(Inver-Teed Rib) 슬래브에 관한 것이다.

이에 본 발명의 기술적 요지는 역 티(Tee) 구조의 상부 돌출형 지지리브를 갖는 피씨형 인버티드 리브 슬래브에 있어서, 상기 슬래브는 민자형 평판으로 인해 천정 마감이 평이하여 설비 등 마감 공사가 용이하도록 형성되고, 단열 공사비가 절감(냉동창고로 시공시)되며, 평평한 천정면으로 하여금 유효공간이 확대됨은 물론 판과 판(슬래브간) 연결부는 탑핑 콘크리트(T/C)의 유효 깊이(Depth)가 크게 확보되어 균열 발생을 현저하게 감소시키고, 버림 거푸집(가림판)을 지지리브 상단에 얹어 사용하도록 함으로써, 지지리브간 빈 공간으로 하여금 부재 자중이 현저하게 감소되어 구조 안전성과 시공중 안전사고 위험이 크게 감소되고, 특히 전단 보강 철근의 배근으로 인해 단면 성능이 증가되는 반면, 슬래브간 접합부의 연속성 및 일체성이 우수하며, 단면 감소로 인한 원가 절감을 통해 생산성과 경제성이 확보되는 것을 특징으로 한다.The present invention relates to an Inver-Teed Rib slab for PC structures.

Accordingly, the technical idea of the present invention is to provide a PC-type inverted rib slab having an upper protruding support rib having a Tee structure, wherein the slab has a flat ceiling due to a flat plate, (T / C) of the connecting portion between the plate and the plate (slab) is larger than the effective depth of the tapped concrete (T / C). (Blanking plate) is placed on the upper end of the support rib, and the empty space between the support ribs is remarkably reduced, so that the structural safety and the risk of safety accidents during construction are greatly reduced In particular, the cross-sectional performance is increased due to the shear reinforcement reinforcement, but the continuity and integrity of the joint between the slabs is excellent, And productivity and economical efficiency are ensured through cost reduction due to reduction in cost.

Description

본 발명은 역 티(Tee) 구조의 상부 돌출형 지지리브를 갖는 피씨형 인버티드 리브 슬래브에 있어서, 상기 슬래브는 민자형 평판으로 인해 천정 마감이 평이하여 설비 등 마감 공사가 용이하도록 형성되고, 단열 공사비가 절감(냉동창고로 시공시)되며, 평평한 천정면으로 하여금 유효공간이 확대됨은 물론 판과 판(슬래브간) 연결부는 탑핑 콘크리트(T/C)의 유효 깊이(Depth)가 크게 확보되어 균열 발생을 현저하게 감소시키고, 버림 거푸집(가림판)을 지지리브 상단에 얹어 사용하도록 함으로써, 지지리브간 빈 공간으로 하여금 부재 자중이 현저하게 감소되어 구조 안전성과 시공중 안전사고 위험이 크게 감소되고, 특히 전단 보강 철근의 배근으로 인해 단면 성능이 증가되는 반면, 슬래브간 접합부의 연속성 및 일체성이 우수하며, 단면 감소로 인한 원가 절감을 통해 생산성과 경제성이 확보되는 것을 특징으로 하는 피씨 구조물용 인버티드 리브(Inver-Teed Rib) 슬래브에 관한 것이다.

The present invention relates to a PC-type inverted rib slab having an upper protruding support rib having a Tee structure, wherein the slab is formed by a flat plate so that the ceiling finish is flat, (T / C) of the connecting portion between the plate and the plate (slab) is secured, and the crack is generated (Blanking plate) is placed on the upper end of the support rib, and the empty space between the support ribs is significantly reduced, so that the structural safety and the risk of safety accidents during installation are greatly reduced. Particularly, The shear reinforcement reinforcement increases the section performance, but the continuity and integrity of the joints between the slabs is excellent, The present invention relates to an inverted-ribbed (Inver-Teed) rib slab for a PC structure.

일반적으로 지하주차장을 포함한 공공시설물 또는 공공주택 등의 건축물을 시공하는 경우에는 많은 하중이 요구되므로, 특허출원 제10-2010-0084034호와 같이 피씨 부재를 제작하여 현장에서 맞춤 조립하도록 형성되고 있으며, 이러한 시공방법은 통상 하프 슬래브(Half PC Slab)를 이용한 PRC(Precast Reinforced Concrete Layer Construction Method) 복합화 공법 등이 실시되고 있다.Generally, when a building such as a public facility or a public house including an underground parking lot is installed, a large load is required. Therefore, a PC member is formed as shown in Patent Application No. 10-2010-0084034, Such a construction method is usually performed by a PRC (Precast Reinforced Concrete Layer Construction Method) composite method using a half slab (Half PC Slab).

즉, 이러한 PRC 복합화 공법은 철근 콘크리트 라멘(Rahmen) 구조의 건물을 PC(Precast Concrete)화하는 공법으로서, 공장에서 제작한 PC기둥, PC보, 하프 슬래브 등 PC부재를 현장으로 운송, 양중하여 조립한 후 부재 간 접합부와 하프 슬래브의 상부에 덧침 콘크리트를 현장에서 타설하여 구조체를 일체화시키도록 형성된다.In other words, this PRC composite method is a method of making a PC (Precast Concrete) of reinforced concrete Rahmen structure. It is used to transport PC materials such as PC columns, PC beams, and half slabs And is then formed so as to integrate the structural body by placing overburdened concrete in the field at the junction between the members and the upper part of the half slab.

이에, 최근에는 더블티 슬래브공법이 실시되고 있다. 즉, DTS 공법이라고도 하는데 더블티 슬래브는 바닥판에 깊은 보강리브를 설치하고 상기 보강리브의 하부에 스트랜드를 삽입하여 인장력을 가한 뒤 일체의 부재를 이루도록 형성하는 바, 이러한 더블티 슬래브는 스트랜드의 인장력으로 인해 더블티 슬래브의 몸판 중앙부가 소폭 치켜 올려지도록 형성되어 약 10m 이상의 장스팬으로 지상층 구조물에 주로 적용되고 있다.Accordingly, a double-slab method has recently been implemented. That is, the double slab is also referred to as the DTS method. In the double slab, deep reinforcing ribs are provided on the bottom plate, strands are inserted into the lower portion of the reinforcing ribs, and tensile force is applied to the reinforcing ribs. The center portion of the body of the double slab is slightly raised to be raised, and thus it is mainly applied to the ground layer structure with an elongation span of about 10 m or more.

그러나, 상술한 종래의 더블티 슬래브는 통상 보강을 위해 지지리브 내에 다수개의 매립 연결근을 심어 상부를 절곡시킨 후 덧침 콘크리트에 의해 지하층 또는 지상층의 천정부를 형성하도록 하고 있으나, 이러한 매립 연결근은 공장에서 피씨 슬래브를 제작시 작업자가 수작업으로 일일이 설정된 간격에 맞춰 끼워 넣어야 하는 바, 번거로운 작업에 의해 인건비의 상승과 작업성의 저하 결국 공기 지연으로 연결되는 문제가 발생되고 있다.

However, in the conventional double-tee slab described above, a plurality of buried connecting roots are usually embedded in the supporting ribs to reinforce the upper portions of the slabs to bend the upper portions of the supporting ribs to form a ceiling portion of the ground or ground floor. The operator must manually insert the PC slab in accordance with the interval set at the time of manufacture, and the troublesome work increases the labor cost and decreases the workability and eventually leads to air delay.

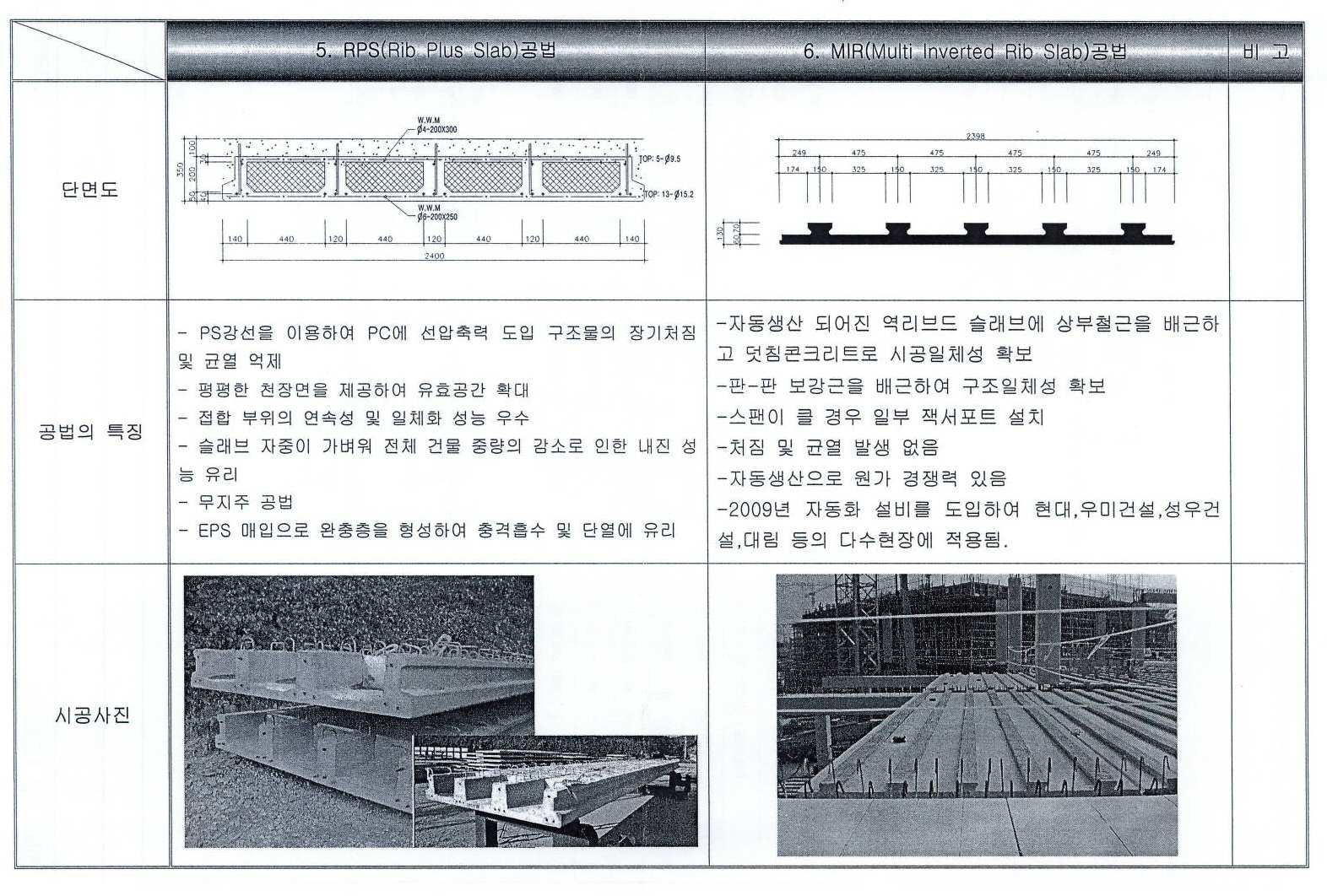

이에, 종래의 피씨 슬래브 종류와 해당 피씨 슬래브의 특장점을 살펴보면 아래 표와 같다.Accordingly, the conventional types of PC slabs and the characteristics of the PC slabs are as follows.

하향 분기식 TEE 슬래브와 너와 연결식 TEE 슬래브

Downward branching TEE slabs and TEE slabs connected to you

상기 표 1에서 보는 바와 같이, 종래의 MTS 슬래브나 RQS 슬래브는 천정 마감시 다수개의 지지리브(TEE)에 의해 설비 등 마감 공사가 번거롭고 어려우며, 단열 공사비가 상승(냉동창고로 시공시)되고, 낮은 천정면으로 하여금 유효공간이 축소되는 문제가 발생된다.

As shown in Table 1, the conventional MTS slabs or RQS slabs are complicated and difficult to finish due to a plurality of support ribs TEE at the time of ceiling finishing, increase in the cost of heat insulation (at the time of construction as a freezing warehouse) There arises a problem that the effective space is reduced for the ceiling surface.

속빈 할로코어 슬래브와 더블 TEE 슬래브

Double hollow TEE slab with hollow core

또한, 상기 표 2에서 보는 바와 같이, 종래의 할로코어 슬래브는 두께가 증가하여 층고가 높아지므로 고층건물에 적용시에는 문제가 있으며, 더블티형 하프 슬래브는 현장타설 콘크리트의 물량이 증가하고 리브가 하면에 돌출되어 있어 평면 구성에 제한을 받는다는 문제가 발생되고 있는 실정이다.

As shown in Table 2, the conventional halocarbon slab has a problem in that it is applied to a high-rise building because the thickness of the conventional halocarbon slab is increased to increase the floor height. In the double-tee type half slab, So that there is a problem that the planar configuration is limited.

속빈 리브 플러스 슬래브와 역 리브드 슬래브

Inside ribbed plus slabs and inverted ribbed slabs

또한, 상기 표 3에서 보는 바와 같이, 종래의 리브 플러스 슬래브는 구조 강성이 약하고 단열을 위한 내부 스티로폼에 의해 제조 원가가 상승되는 문제가 있으며, 역 리브드 슬래브는 층 두께(리브가 돌출된 높이-일명 리브춤)가 높은 단면에 적용하기 곤란함은 물론 전단보강철근 배근이 불가하여 현장타설 콘크리트와의 합성력이 저하되어 구조 안전성에 문제가 발생하고 있는 실정이다.

In addition, as shown in Table 3, the conventional rib plus slab has a problem that the structural stiffness is weak and the manufacturing cost is increased due to the internal styrofoam for heat insulation. The reverse ribbed slab has a problem that the layer thickness Rib dancing) is difficult to apply to a high section and the shear rebar reinforcement can not be installed. Therefore, the composite strength with the cast concrete is lowered, thereby causing a problem in structural safety.

본 발명은 상술한 문제점을 해결하기 위한 것으로, 그 기술적 요지는 역 티(Tee) 구조의 상부 돌출형 지지리브를 갖는 피씨형 인버티드 리브 슬래브에 있어서, 상기 슬래브는 민자형 평판으로 인해 천정 마감이 평이하여 설비 등 마감 공사가 용이하도록 형성되고, 단열 공사비가 절감(냉동창고로 시공시)되며, 평평한 천정면으로 하여금 유효공간이 확대됨은 물론 판과 판(슬래브간) 연결부는 탑핑 콘크리트(T/C)의 유효 깊이(Depth)가 크게 확보되어 균열 발생을 현저하게 감소시키고, 버림 거푸집(가림판)을 지지리브 상단에 얹어 사용하도록 함으로써, 지지리브간 빈 공간으로 하여금 부재 자중이 현저하게 감소되어 구조 안전성과 시공중 안전사고 위험이 크게 감소되고, 특히 전단 보강 철근의 배근으로 인해 단면 성능이 증가되는 반면, 슬래브간 접합부의 연속성 및 일체성이 우수하며, 단면 감소로 인한 원가 절감을 통해 생산성과 경제성이 확보되는 것을 특징으로 하는 피씨 구조물용 인버티드 리브(Inver-Teed Rib) 슬래브를 제공함에 그 목적이 있다.

SUMMARY OF THE INVENTION The present invention has been made to solve the above-mentioned problems, and it is a technical object of the present invention to provide a PC-type inverted rib slab having an upper protruding support rib having a Tee structure, wherein the slab has a flat ceiling, (T / C) connection between the plate and the plate (slab), as well as the effective space is enlarged by the flat ceiling face, (The cover plate) is placed on the upper end of the support rib to be used, the hollow space between the support ribs is significantly reduced in the weight of the member, While the safety and the risk of safety accidents during construction are greatly reduced, especially the section performance is increased due to the shear reinforcement reinforcement, And continuity and integrity of the solid, to provide an inverter for precast concrete structure through a cost reduction due to the reduced cross-section characterized in that the productivity and economy secured suited rib (Inver-Teed Rib) it is an object of the slab.

이러한 목적을 달성하기 위해 본 발명은 층간의 춤(층 두께: 리브가 돌출된 높이-일명 리브춤)이 높은 경우의 실시예로서, 지지리브(120)의 상단 모서리에 단턱(121)이 형성되고, 상기 단턱에는 가림판(300)의 외측단이 대응되면서 결합되도록 형성되어 지지리브(120) 사이마다 빈공간(180)이 형성되면 가림판(300) 상부에 현장 콘크리트(C)가 타설되도록 하는 것이 바람직하다.In order to attain this object, the present invention is an embodiment in which dancing between layers (layer thickness: rib protruding height - aka rib dancing) is high, the

이에, 상기 인버티드 리브 슬래브는 지지리브(120) 내부에 구조 강성을 위한 전단철근(122)이 매입되도록 하되, 상기 전단철근(122)은 상부 선단이 현장 콘크리트(C)와 합성되도록 지지리브(120) 상면으로부터 돌출되어 분기되도록 하는 것이 바람직하다.

In the inverted rib slab, a

이와 같이, 본 발명은 민자형 평판으로 인해 천정 마감이 평이하여 설비 등 마감 공사가 용이하도록 형성되고, 단열 공사비가 절감(냉동창고로 시공시)되며, 평평한 천정면으로 하여금 유효공간이 확대됨은 물론 판과 판(슬래브간) 연결부는 탑핑 콘크리트(T/C)의 유효 깊이(Depth)가 크게 확보되어 균열 발생을 현저하게 감소시키고, 버림 거푸집(가림판)을 지지리브 상단에 얹어 사용하도록 함으로써, 지지리브간 빈 공간으로 하여금 부재 자중이 현저하게 감소되어 구조 안전성과 시공중 안전사고 위험이 크게 감소되고, 특히 전단 보강 철근의 배근으로 인해 단면 성능이 증가되는 반면, 슬래브간 접합부의 연속성 및 일체성이 우수하며, 단면 감소로 인한 원가 절감을 통해 생산성과 경제성이 확보되는 효과가 있다.

As described above, according to the present invention, since the ceiling finish is flat due to the flat plate, it is possible to easily finish the facilities such as facilities, and the cost of the insulation is reduced (when the refrigerator is installed in the warehouse) And the plate (slab) connecting portion is provided with a large effective depth of the top concrete (T / C) to significantly reduce the occurrence of cracks, and by placing the abandoned formwork (cover plate) And the risk of safety accidents during construction is greatly reduced. In particular, the performance of the section is increased due to the shear reinforcement reinforcement, while the continuity and integrity of the joints between the slabs And it is effective to secure productivity and economy through cost reduction due to reduction in section.

도 1 내지 도 5는 본 발명에 따른 인버티드 리브 슬래브의 사용 예시 중 층간 높이(리브춤)가 높을 경우 마감판을 사용하여 슬래브에 빈공간을 형성한 후 현장 타설함으로써, 저중량 대비 구조 강성이 확보되도록 하는 것을 나타낸 예시도,

도 6 내지 도 9는 본 발명에 따른 인버티드 리브 슬래브의 시공상태를 나타낸 예시도이다.FIGS. 1 to 5 illustrate the use of an inverted rib slab according to the present invention, in which a hollow space is formed in a slab by using a finishing plate when the interlayer height (rib dancing) is high, Fig.

FIGS. 6 to 9 are views illustrating the construction of an inverted rib slab according to the present invention.

다음은 첨부된 도면을 참조하며 본 발명을 보다 상세히 설명하겠다.DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be described in detail below with reference to the accompanying drawings.

먼저, 도 1 내지 도 5에 도시된 바와 같이, 본 발명은 층의 춤(층 두께: 리브가 돌출된 높이-일명 리브춤)이 높은 경우의 실시예로서, 도 1 내지 도 5에 도시한 바와 같이, 지지리브(120)의 상단 모서리에 단턱(121)이 형성되고, 상기 단턱에는 가림판(300)의 외측단이 대응되면서 결합되도록 형성되어 지지리브(120) 사이마다 빈공간(180)이 형성되면 가림판(300) 상부에 현장 콘크리트(C)가 타설되도록 하는 것이 바람직하다.First, as shown in FIGS. 1 to 5, the present invention is an embodiment in which layer dancing (layer thickness: rib protruding height - aka rib dancing) is high, and as shown in FIGS. 1 to 5 A

이에, 상기 인버티드 리브 슬래브는 지지리브(120) 내부에 구조 강성을 위한 전단철근(122)이 매입되도록 하되, 상기 전단철근(122)은 상부 선단이 현장 콘크리트(C)와 합성되도록 지지리브(120) 상면으로부터 돌출되어 분기되도록 하는 것이 바람직하다.In the inverted rib slab, a

이때, 지지리브의 길이방향 양단부에는 마감턱(130)으로부터 구획된 공간부(140)가 형성되며, 상기 마감턱(130)은 일부가 매입되고 다른 일부가 분기된 철근(131)이 형성되고, 폭방향으로 이웃한 타측 슬래브의 평판 날개면(150)에는 이음부 접합 일체화를 위한 균열방지용 연결근(200)이 구성되어 이루어진다.At this time, a

이에, 상기 연결근(200)은 통상의 철선을 다수개가 엮인 상태로 고정되는 것으로, 상기 철선은 현장배근과 고정되거나 패널의 상면에 일정한 간격을 두고 일부 꺽인 다리를 통해 지지고정된 후 콘크리트에 의해 타설되도록 형성된다. The connecting

이때, 도 5에서 보이는 연결근(200)은 시공상태의 사시도에서 보여지는 수평 상태로서, 상기 철선은 미도시된 상태이다. 즉, 상기 연결근의 결합관계는 일반적인 철선 배근으로 하여금 고정되도록 형성되는 것이 바람직하다.At this time, the

이에 본 발명의 인버티드 리브 슬래브는 도 6 내지 도 9에 도시된 바와 같이, 피씨 기둥이 기립되면 피씨 보가 안착되고, 이후 피씨 슬래브가 걸침되면 토핑 콘크리트에 의해 타설되어 일체성이 확보되도록 형성된다.

As shown in FIGS. 6 to 9, the inverted rib slab of the present invention is formed such that when a PC column is erected, a PC substrate is seated, and when the PC slab is stuck thereon, the integrated slab is installed by topping concrete to ensure integrity.

본 발명은 상술한 특정의 바람직한 실시예에 한정되지 아니하며, 청구범위에서 청구하는 본 발명의 요지를 벗어남이 없이 당해 고안이 속하는 기술분야에서 통상의 지식을 가진 자라면 누구든지 다양한 변형실시가 가능한 것은 물론이고, 그와 같은 변경은 청구범위 기재의 범위 내에 있게 된다.

It will be understood by those skilled in the art that various changes in form and details may be made therein without departing from the spirit and scope of the present invention as defined by the appended claims and their equivalents. Of course, such modifications are within the scope of the claims.

100 ... 인버티드 리브 슬래브 110 ... 평판

120 ... 지지리브 130 ... 마감턱

140 ... 공간부 150 ... 날개면

160 ... 샌딩면 170 ... 펼침식 보강근

180 ... 빈공간 200 ... 연결근

300 ... 가림판100 ... Inverted rib slab 110 ... Flat plate

120

140

160 ... sanding surface 170 ... spreading type reinforcement bar

180 ...

300 ... clearance plate

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020140018918A KR101441515B1 (en) | 2014-02-19 | 2014-02-19 | Precast concrete slab of Inver-Teed Rib |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020140018918A KR101441515B1 (en) | 2014-02-19 | 2014-02-19 | Precast concrete slab of Inver-Teed Rib |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020130119642A Division KR101457070B1 (en) | 2013-10-08 | 2013-10-08 | Precast concrete slab of Inver-Teed Rib |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR101441515B1 true KR101441515B1 (en) | 2014-09-17 |

Family

ID=51760431

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020140018918A Active KR101441515B1 (en) | 2014-02-19 | 2014-02-19 | Precast concrete slab of Inver-Teed Rib |

Country Status (1)

| Country | Link |

|---|---|

| KR (1) | KR101441515B1 (en) |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104294983A (en) * | 2014-10-11 | 2015-01-21 | 上海建工四建集团有限公司 | Double-layer hollow sound insulation concrete slab and construction method thereof |

| CN104314211A (en) * | 2014-10-11 | 2015-01-28 | 上海建工四建集团有限公司 | Hollow concrete board with sound insulation effect and construction method thereof |

| KR101621188B1 (en) * | 2015-01-21 | 2016-05-13 | 아이에스동서 주식회사 | Headed Rib Precast Concrete Slab and Connection Method Using The Same |

| KR101745092B1 (en) * | 2015-05-29 | 2017-06-09 | 동진산업 주식회사 | Headed Rib Precast Concrete Slab Using Deck Plate |

| CN108560796A (en) * | 2018-04-17 | 2018-09-21 | 昆明理工大学 | A kind of concrete T type rib Covered with Angles prefabricated panel and its superimposed sheet of making |

| CN108590006A (en) * | 2018-04-17 | 2018-09-28 | 昆明理工大学 | A kind of double-T shaped armored concrete prefabricated panel and its superimposed sheet of making |

| CN109723184A (en) * | 2019-02-25 | 2019-05-07 | 上海城建建设实业(集团)有限公司 | Fragment integrated form T plate structure |

| CN112171884A (en) * | 2020-09-02 | 2021-01-05 | 中国建筑上海设计研究院有限公司 | Prefabricated ribbed concrete composite slab and preparation method thereof |

| KR102280675B1 (en) * | 2020-09-28 | 2021-07-23 | 유재천 | Libbed half PC slab |

| KR20220021161A (en) * | 2020-08-13 | 2022-02-22 | 권순웅 | Cover and slab comprising the same |

| KR102570239B1 (en) * | 2023-04-20 | 2023-08-25 | 홍종규 | PC pole construction method using non-thread terminator of anchoring tensile force reinforcement structure |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1034630A (en) * | 1996-07-29 | 1998-02-10 | Kazuhisa Kinoshita | Manufacturing of hollow precast floor board |

| JPH10110498A (en) * | 1996-10-07 | 1998-04-28 | Taisei Corp | Half precast slab and method of constructing hollow flat slab using the same |

-

2014

- 2014-02-19 KR KR1020140018918A patent/KR101441515B1/en active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1034630A (en) * | 1996-07-29 | 1998-02-10 | Kazuhisa Kinoshita | Manufacturing of hollow precast floor board |

| JPH10110498A (en) * | 1996-10-07 | 1998-04-28 | Taisei Corp | Half precast slab and method of constructing hollow flat slab using the same |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104294983A (en) * | 2014-10-11 | 2015-01-21 | 上海建工四建集团有限公司 | Double-layer hollow sound insulation concrete slab and construction method thereof |

| CN104314211A (en) * | 2014-10-11 | 2015-01-28 | 上海建工四建集团有限公司 | Hollow concrete board with sound insulation effect and construction method thereof |

| CN104314211B (en) * | 2014-10-11 | 2016-01-27 | 上海建工四建集团有限公司 | A kind of hollow concrete plate and construction method thereof with soundproof effect |

| CN104294983B (en) * | 2014-10-11 | 2016-03-23 | 上海建工四建集团有限公司 | A kind of double layer hollow vermex concrete plate and construction method thereof |

| KR101621188B1 (en) * | 2015-01-21 | 2016-05-13 | 아이에스동서 주식회사 | Headed Rib Precast Concrete Slab and Connection Method Using The Same |

| KR101745092B1 (en) * | 2015-05-29 | 2017-06-09 | 동진산업 주식회사 | Headed Rib Precast Concrete Slab Using Deck Plate |

| CN108560796A (en) * | 2018-04-17 | 2018-09-21 | 昆明理工大学 | A kind of concrete T type rib Covered with Angles prefabricated panel and its superimposed sheet of making |

| CN108590006A (en) * | 2018-04-17 | 2018-09-28 | 昆明理工大学 | A kind of double-T shaped armored concrete prefabricated panel and its superimposed sheet of making |

| CN109723184A (en) * | 2019-02-25 | 2019-05-07 | 上海城建建设实业(集团)有限公司 | Fragment integrated form T plate structure |

| KR20220021161A (en) * | 2020-08-13 | 2022-02-22 | 권순웅 | Cover and slab comprising the same |

| KR102406559B1 (en) * | 2020-08-13 | 2022-06-08 | 권순웅 | Cover and slab comprising the same |

| CN112171884A (en) * | 2020-09-02 | 2021-01-05 | 中国建筑上海设计研究院有限公司 | Prefabricated ribbed concrete composite slab and preparation method thereof |

| KR102280675B1 (en) * | 2020-09-28 | 2021-07-23 | 유재천 | Libbed half PC slab |

| KR102570239B1 (en) * | 2023-04-20 | 2023-08-25 | 홍종규 | PC pole construction method using non-thread terminator of anchoring tensile force reinforcement structure |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101441515B1 (en) | Precast concrete slab of Inver-Teed Rib | |

| KR101570484B1 (en) | Half-PC Column using lightweight Encased Inner Form And Manufacturing Method Thereof, And Construction Method Using The Same | |

| KR101001208B1 (en) | Structure construction method using sandwich PC-wall | |

| KR101182536B1 (en) | Prefabricated double wall precast concrete pannel having surface material, reinforcing rod according to the purpose | |

| CN105507470B (en) | A kind of periphery overlapping overall assembled floor and its construction method | |

| KR101776129B1 (en) | Built-up type precast double structure for slab and wall and double precast wall construction method using the same | |

| KR101429430B1 (en) | Double PC girder and construction method thereof | |

| KR101614842B1 (en) | frame system of buildings using the pc-column with overhanging beam applicable various span without increase of story-height | |

| KR101272601B1 (en) | A joint structure for sculpture of rooftop | |

| KR20140108353A (en) | Improving structure integrity with topping concrete and improved shear load carrying of hollow slab structure using shear reinforcing bar and constructing method using the same | |

| CN110820928A (en) | Connecting joint of wallboard and beam and construction method thereof | |

| KR101308053B1 (en) | Precast Concrete Column Connecting Structure Using The Low Bending Moment Zone | |

| CN206337655U (en) | A kind of assembly concrete wallboard and its soft rope anchor ring attachment structure of reinforcement | |

| KR101178168B1 (en) | Inverted multi tee slab | |

| KR101614722B1 (en) | The flat and Ribbed slab | |

| KR101459003B1 (en) | The wide PC girder and construction method thereof | |

| KR20220049720A (en) | Rapid Construction Structure of Core Part Using Multi-Story Precast Wall | |

| KR101303721B1 (en) | Headed rib precast slab and construction method therefor | |

| CN110644662A (en) | Prefabricated flat slab composite slab based on stress and splitting method thereof | |

| RU2441965C1 (en) | Multi-stored building of the frame-wall structural system from prefabricated and monolithic reinforced concrete | |

| CN206829461U (en) | After pour teeth groove and be linked and packed formula precast slab | |

| KR101324884B1 (en) | Hybrid building construction method combining dry type and wet type | |

| KR101576224B1 (en) | Prefabricated precast concrete girder for building construction | |

| KR101457070B1 (en) | Precast concrete slab of Inver-Teed Rib | |

| CN106088437A (en) | A kind of superimposed sheet strengthening two-way transmission force property |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0107 | Divisional application |

Comment text: Divisional Application of Patent Patent event date: 20140219 Patent event code: PA01071R01D Filing date: 20131008 Application number text: 1020130119642 |

|

| PA0201 | Request for examination | ||

| PA0302 | Request for accelerated examination |

Patent event date: 20140219 Patent event code: PA03022R01D Comment text: Request for Accelerated Examination |

|

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20140508 Patent event code: PE09021S01D |

|

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

Patent event code: PE07011S01D Comment text: Decision to Grant Registration Patent event date: 20140901 |

|

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

Comment text: Registration of Establishment Patent event date: 20140911 Patent event code: PR07011E01D |

|

| PR1002 | Payment of registration fee |

Payment date: 20140911 End annual number: 3 Start annual number: 1 |

|

| PG1601 | Publication of registration | ||

| FPAY | Annual fee payment |

Payment date: 20170616 Year of fee payment: 4 |

|

| PR1001 | Payment of annual fee |

Payment date: 20170616 Start annual number: 4 End annual number: 4 |

|

| FPAY | Annual fee payment |

Payment date: 20180626 Year of fee payment: 5 |

|

| PR1001 | Payment of annual fee |

Payment date: 20180626 Start annual number: 5 End annual number: 5 |

|

| FPAY | Annual fee payment |

Payment date: 20190612 Year of fee payment: 6 |

|

| PR1001 | Payment of annual fee |

Payment date: 20190612 Start annual number: 6 End annual number: 6 |

|

| PR1001 | Payment of annual fee |

Payment date: 20201027 Start annual number: 7 End annual number: 7 |

|

| PR1001 | Payment of annual fee |

Payment date: 20210615 Start annual number: 8 End annual number: 8 |

|

| PR1001 | Payment of annual fee |

Payment date: 20220802 Start annual number: 9 End annual number: 9 |

|

| PR1001 | Payment of annual fee |

Payment date: 20230828 Start annual number: 10 End annual number: 10 |

|

| PR1001 | Payment of annual fee |

Payment date: 20240808 Start annual number: 11 End annual number: 11 |