JP6889862B2 - コールドスプレーガン及びそれを備えたコールドスプレー装置 - Google Patents

コールドスプレーガン及びそれを備えたコールドスプレー装置 Download PDFInfo

- Publication number

- JP6889862B2 JP6889862B2 JP2017131921A JP2017131921A JP6889862B2 JP 6889862 B2 JP6889862 B2 JP 6889862B2 JP 2017131921 A JP2017131921 A JP 2017131921A JP 2017131921 A JP2017131921 A JP 2017131921A JP 6889862 B2 JP6889862 B2 JP 6889862B2

- Authority

- JP

- Japan

- Prior art keywords

- raw material

- material powder

- cold spray

- working gas

- flow path

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000007921 spray Substances 0.000 title claims description 100

- 239000000843 powder Substances 0.000 claims description 154

- 239000002994 raw material Substances 0.000 claims description 145

- 238000001816 cooling Methods 0.000 claims description 36

- 238000002844 melting Methods 0.000 claims description 26

- 230000008018 melting Effects 0.000 claims description 26

- 239000002826 coolant Substances 0.000 claims description 17

- 230000006835 compression Effects 0.000 claims description 14

- 238000007906 compression Methods 0.000 claims description 14

- 239000000463 material Substances 0.000 claims description 14

- 238000011144 upstream manufacturing Methods 0.000 claims description 5

- 239000007787 solid Substances 0.000 claims description 3

- 239000007789 gas Substances 0.000 description 153

- 238000000034 method Methods 0.000 description 17

- 229910045601 alloy Inorganic materials 0.000 description 11

- 239000000956 alloy Substances 0.000 description 11

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 10

- 229910052751 metal Inorganic materials 0.000 description 10

- 239000002184 metal Substances 0.000 description 10

- 239000000919 ceramic Substances 0.000 description 8

- 238000010438 heat treatment Methods 0.000 description 8

- 239000002245 particle Substances 0.000 description 7

- 239000002585 base Substances 0.000 description 6

- 239000000110 cooling liquid Substances 0.000 description 6

- 238000002156 mixing Methods 0.000 description 6

- 150000002739 metals Chemical class 0.000 description 5

- 229910052759 nickel Inorganic materials 0.000 description 5

- 238000007751 thermal spraying Methods 0.000 description 5

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 4

- MCMNRKCIXSYSNV-UHFFFAOYSA-N Zirconium dioxide Chemical compound O=[Zr]=O MCMNRKCIXSYSNV-UHFFFAOYSA-N 0.000 description 4

- 230000015572 biosynthetic process Effects 0.000 description 4

- 229910010293 ceramic material Inorganic materials 0.000 description 4

- 239000000470 constituent Substances 0.000 description 4

- 229910052802 copper Inorganic materials 0.000 description 4

- 239000010949 copper Substances 0.000 description 4

- 239000011521 glass Substances 0.000 description 4

- 239000005368 silicate glass Substances 0.000 description 4

- 229910052782 aluminium Inorganic materials 0.000 description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 3

- 238000007750 plasma spraying Methods 0.000 description 3

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 2

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 2

- 229910052910 alkali metal silicate Inorganic materials 0.000 description 2

- 229910052804 chromium Inorganic materials 0.000 description 2

- 239000011651 chromium Substances 0.000 description 2

- 239000001307 helium Substances 0.000 description 2

- 229910052734 helium Inorganic materials 0.000 description 2

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 2

- 229910000765 intermetallic Inorganic materials 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 2

- 229910010271 silicon carbide Inorganic materials 0.000 description 2

- 229910052709 silver Inorganic materials 0.000 description 2

- 239000004332 silver Substances 0.000 description 2

- 239000007790 solid phase Substances 0.000 description 2

- 239000010935 stainless steel Substances 0.000 description 2

- 229910001220 stainless steel Inorganic materials 0.000 description 2

- 239000010936 titanium Substances 0.000 description 2

- 229910052719 titanium Inorganic materials 0.000 description 2

- 229910052581 Si3N4 Inorganic materials 0.000 description 1

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 1

- 229910001315 Tool steel Inorganic materials 0.000 description 1

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 1

- 239000003570 air Substances 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- 229910052788 barium Inorganic materials 0.000 description 1

- DSAJWYNOEDNPEQ-UHFFFAOYSA-N barium atom Chemical compound [Ba] DSAJWYNOEDNPEQ-UHFFFAOYSA-N 0.000 description 1

- 239000005388 borosilicate glass Substances 0.000 description 1

- 238000005219 brazing Methods 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 239000000498 cooling water Substances 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 238000007772 electroless plating Methods 0.000 description 1

- 238000009713 electroplating Methods 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 238000007749 high velocity oxygen fuel spraying Methods 0.000 description 1

- 229910001026 inconel Inorganic materials 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 239000005355 lead glass Substances 0.000 description 1

- 150000004767 nitrides Chemical class 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 239000005307 potash-lime glass Substances 0.000 description 1

- 230000001568 sexual effect Effects 0.000 description 1

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 1

- 239000005361 soda-lime glass Substances 0.000 description 1

- 238000004544 sputter deposition Methods 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 229910052715 tantalum Inorganic materials 0.000 description 1

- GUVRBAGPIYLISA-UHFFFAOYSA-N tantalum atom Chemical compound [Ta] GUVRBAGPIYLISA-UHFFFAOYSA-N 0.000 description 1

- UONOETXJSWQNOL-UHFFFAOYSA-N tungsten carbide Chemical compound [W+]#[C-] UONOETXJSWQNOL-UHFFFAOYSA-N 0.000 description 1

- 238000007740 vapor deposition Methods 0.000 description 1

- 229910052725 zinc Inorganic materials 0.000 description 1

- 239000011701 zinc Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/16—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas incorporating means for heating or cooling the material to be sprayed

- B05B7/1606—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas incorporating means for heating or cooling the material to be sprayed the spraying of the material involving the use of an atomising fluid, e.g. air

- B05B7/1613—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas incorporating means for heating or cooling the material to be sprayed the spraying of the material involving the use of an atomising fluid, e.g. air comprising means for heating the atomising fluid before mixing with the material to be sprayed

- B05B7/162—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas incorporating means for heating or cooling the material to be sprayed the spraying of the material involving the use of an atomising fluid, e.g. air comprising means for heating the atomising fluid before mixing with the material to be sprayed and heat being transferred from the atomising fluid to the material to be sprayed

- B05B7/1626—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas incorporating means for heating or cooling the material to be sprayed the spraying of the material involving the use of an atomising fluid, e.g. air comprising means for heating the atomising fluid before mixing with the material to be sprayed and heat being transferred from the atomising fluid to the material to be sprayed at the moment of mixing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/14—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas designed for spraying particulate materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/14—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas designed for spraying particulate materials

- B05B7/1481—Spray pistols or apparatus for discharging particulate material

- B05B7/1486—Spray pistols or apparatus for discharging particulate material for spraying particulate material in dry state

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/16—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas incorporating means for heating or cooling the material to be sprayed

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C24/00—Coating starting from inorganic powder

- C23C24/02—Coating starting from inorganic powder by application of pressure only

- C23C24/04—Impact or kinetic deposition of particles

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Nozzles (AREA)

- Other Surface Treatments For Metallic Materials (AREA)

Description

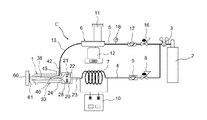

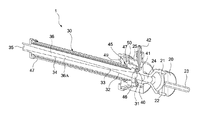

本発明に係るコールドスプレーガンは、搬送ガスにより搬送された原料粉末を、当該原料粉末の融点又は軟化点以下の温度に加熱した作動ガスと共に超音速流で噴出して、当該原料粉末を固相状態のまま基材に衝突させて皮膜を形成するものであって、前記作動ガスを収容するチャンバーと、入口から延在方向にわたって先細りの円錐状に形成された圧縮部と、当該圧縮部に続く狭小なスロート部と、当該スロート部から出口にわたって先広がりの円錐状に形成された膨張部とを備え、前記チャンバーから吐出した前記作動ガスを出口で超音速流とする作動ガス流路が形成されたコールドスプレー用ノズルと、前記作動ガス流路の流路方向でみたときに前記チャンバーの出口から前記スロート部の範囲に位置し、当該チャンバーから吐出した前記作動ガスに前記原料粉末を供給する原料粉末供給流路と、前記原料粉末供給流路の少なくとも出口部分を冷却する冷却手段とを備えることを特徴とする。

本発明に係るコールドスプレー装置は、上述したコールドスプレーガンを備えたことを特徴とする。

1 コールドスプレーガン

2 圧縮ガスボンベ(高圧ガス供給部)

3 ガス供給ライン

4 作動ガスライン

5 搬送ガスライン

6 原料粉末供給装置

7 ヒータ

13 搬送ガスライン

20 本体

21 チャンバー

22 作動ガス入口

23 作動ガス供給ノズル

24 チャンバー出口

25 ノズル接続部

30 コールドスプレー用ノズル

31 ノズル入口

32 圧縮部

33 スロート部

34 膨張部

35 ノズル出口

36 作動ガス流路

36A 内壁面

40 原料粉末供給流路

41 原料粉末流路構成部材

42 原料粉末供給ノズル

45 水冷式冷却部

46、47 冷却液流路

60 基材

61 皮膜

Claims (6)

- 搬送ガスにより搬送された原料粉末を、当該原料粉末の融点又は軟化点以下の温度に加熱した作動ガスと共に超音速流で噴出して、当該原料粉末を固相状態のまま基材に衝突させて皮膜を形成するコールドスプレーガンであって、

前記作動ガスを収容するチャンバーと、

入口から延在方向にわたって先細りの円錐状に形成された圧縮部と、当該圧縮部に続く狭小なスロート部と、当該スロート部から出口にわたって先広がりの円錐状に形成された膨張部とを備え、前記チャンバーから吐出した前記作動ガスを出口で超音速流とする作動ガス流路が形成されたコールドスプレー用ノズルと、

前記作動ガス流路の流路方向でみたときに前記チャンバーの出口から前記スロート部の範囲に位置し、当該チャンバーから吐出した前記作動ガスに前記原料粉末を供給する原料粉末供給流路と、

前記原料粉末供給流路の少なくとも出口部分を冷却する冷却手段とを備えることを特徴とするコールドスプレーガン。 - 前記冷却手段が、前記作動ガス流路を構成する内壁の冷却を同時に行うものである請求項1に記載のコールドスプレーガン。

- 前記原料粉末供給流路が、前記作動ガス流路の下流側に向けて傾斜して形成された請求項1又は請求項2に記載のコールドスプレーガン。

- 前記原料粉末供給流路が、前記作動ガス流路の上流側に向けて傾斜して形成された請求項1又は請求項2に記載のコールドスプレーガン。

- 前記冷却手段は、冷却液が循環する冷却液流路を備えた水冷式冷却部である請求項1〜請求項4のいずれか一項に記載のコールドスプレーガン。

- 請求項1〜請求項5のいずれか一項に記載のコールドスプレーガンを備えたことを特徴とするコールドスプレー装置。

Priority Applications (8)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017131921A JP6889862B2 (ja) | 2017-07-05 | 2017-07-05 | コールドスプレーガン及びそれを備えたコールドスプレー装置 |

| CN201880043474.0A CN110799669B (zh) | 2017-07-05 | 2018-06-29 | 冷喷枪及具备该冷喷枪的冷喷涂设备 |

| KR1020197037196A KR102310304B1 (ko) | 2017-07-05 | 2018-06-29 | 콜드 스프레이 건 및 이를 구비한 콜드 스프레이 장치 |

| AU2018297846A AU2018297846B2 (en) | 2017-07-05 | 2018-06-29 | Cold spray gun and cold spray apparatus equipped with the same |

| US16/628,304 US20200215559A1 (en) | 2017-07-05 | 2018-06-29 | Cold spray gun and cold spray apparatus equipped with the same |

| PCT/JP2018/024845 WO2019009206A1 (ja) | 2017-07-05 | 2018-06-29 | コールドスプレーガン及びそれを備えたコールドスプレー装置 |

| CA3067686A CA3067686C (en) | 2017-07-05 | 2018-06-29 | Cold spray gun and cold spray device equipped therewith |

| EP18828300.6A EP3650581B1 (en) | 2017-07-05 | 2018-06-29 | Cold spray gun and cold spray device equipped therewith |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017131921A JP6889862B2 (ja) | 2017-07-05 | 2017-07-05 | コールドスプレーガン及びそれを備えたコールドスプレー装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2019014929A JP2019014929A (ja) | 2019-01-31 |

| JP6889862B2 true JP6889862B2 (ja) | 2021-06-18 |

Family

ID=64950004

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017131921A Active JP6889862B2 (ja) | 2017-07-05 | 2017-07-05 | コールドスプレーガン及びそれを備えたコールドスプレー装置 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US20200215559A1 (ja) |

| EP (1) | EP3650581B1 (ja) |

| JP (1) | JP6889862B2 (ja) |

| KR (1) | KR102310304B1 (ja) |

| CN (1) | CN110799669B (ja) |

| AU (1) | AU2018297846B2 (ja) |

| CA (1) | CA3067686C (ja) |

| WO (1) | WO2019009206A1 (ja) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9335296B2 (en) | 2012-10-10 | 2016-05-10 | Westinghouse Electric Company Llc | Systems and methods for steam generator tube analysis for detection of tube degradation |

| US11161128B2 (en) | 2017-11-14 | 2021-11-02 | General Electric Company | Spray nozzle device for delivering a restorative coating through a hole in a case of a turbine engine |

| US11534780B2 (en) * | 2017-11-14 | 2022-12-27 | General Electric Company | Spray nozzle device for delivering a restorative coating through a hole in a case of a turbine engine |

| EP3951011A4 (en) * | 2019-03-29 | 2022-02-09 | NISSAN MOTOR Co., Ltd. | COLD SPRAY DEVICE |

| US11935662B2 (en) | 2019-07-02 | 2024-03-19 | Westinghouse Electric Company Llc | Elongate SiC fuel elements |

| CA3151605C (en) | 2019-09-19 | 2023-04-11 | Westinghouse Electric Company Llc | Apparatus for performing in-situ adhesion test of cold spray deposits and method of employing |

| JP7392391B2 (ja) * | 2019-10-25 | 2023-12-06 | 日産自動車株式会社 | コールドスプレー用ノズル |

| JP6960564B1 (ja) * | 2020-03-05 | 2021-11-05 | タツタ電線株式会社 | スプレーノズル、及び溶射装置 |

| KR102382221B1 (ko) * | 2020-07-30 | 2022-04-04 | 한국핵융합에너지연구원 | 코팅용 분체 에어로졸 증착용 마이크로웨이브 플라즈마 노즐 및 이를 이용하는 코팅용 분체 에어로졸에 의한 코팅 장치 |

| CN113414022B (zh) * | 2021-04-02 | 2025-04-25 | 国网宁夏电力有限公司检修公司 | 一种用于喷涂粉末的喷管及喷涂装置 |

| WO2023054464A1 (ja) * | 2021-10-01 | 2023-04-06 | タツタ電線株式会社 | 成膜装置 |

| KR102496105B1 (ko) | 2022-01-14 | 2023-02-07 | 이앤트레이딩(주) | 저반동 발포총 |

| CN114515660A (zh) * | 2022-03-02 | 2022-05-20 | 季华实验室 | 一种超音速喷管及喷枪 |

| JPWO2023188873A1 (ja) * | 2022-03-29 | 2023-10-05 | ||

| CN115652247A (zh) * | 2022-11-10 | 2023-01-31 | 扬州市松田液压机械有限公司 | 一种用于等离子喷涂的送粉套及防沉积结瘤的涂层制作方法 |

| CN116213153A (zh) * | 2023-05-05 | 2023-06-06 | 季华实验室 | 一种冷喷涂喷枪及冷喷涂装置 |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20070031591A1 (en) * | 2005-08-05 | 2007-02-08 | TDM Inc. | Method of repairing a metallic surface wetted by a radioactive fluid |

| DE102006014124A1 (de) | 2006-03-24 | 2007-09-27 | Linde Ag | Kaltgasspritzpistole |

| JP2007308737A (ja) * | 2006-05-16 | 2007-11-29 | Toyota Motor Corp | 溶接部の防食方法 |

| JP4999520B2 (ja) | 2007-04-02 | 2012-08-15 | プラズマ技研工業株式会社 | コールドスプレー用ノズル及びコールドスプレー装置 |

| CN201143468Y (zh) * | 2008-01-09 | 2008-11-05 | 中国船舶重工集团公司第七二五研究所 | 一种冷喷涂用的拉阀尔喷嘴 |

| US20130087633A1 (en) * | 2011-10-11 | 2013-04-11 | Hirotaka Fukanuma | Cold spray gun |

| CN104114746A (zh) * | 2011-12-22 | 2014-10-22 | 泰光科技有限公司 | 利用低温喷射的溅射靶的制造方法以及低温喷射装置 |

| JP2014156634A (ja) * | 2013-02-15 | 2014-08-28 | Toyota Motor Corp | コールドスプレー用粉末、その製造方法、およびこれを用いた銅系被膜の成膜方法 |

| KR101482412B1 (ko) * | 2013-06-25 | 2015-01-13 | 주식회사 포스코 | 분말분사 코팅장치 |

| DE102014205343A1 (de) * | 2014-03-21 | 2015-09-24 | Siemens Aktiengesellschaft | Kühlvorrichtung für eine Spritzdüse bzw. Spritzdüsenanordnung mit einer Kühlvorrichtung für das thermische Spritzen |

| JP6716204B2 (ja) * | 2015-06-24 | 2020-07-01 | 日本発條株式会社 | 成膜方法及び成膜装置 |

| US20190366361A1 (en) * | 2018-06-05 | 2019-12-05 | United Technologies Corporation | Cold spray deposition apparatus, system, and method |

| US20190366363A1 (en) * | 2018-06-05 | 2019-12-05 | United Technologies Corporation | Cold spray deposition apparatus, system, and method |

-

2017

- 2017-07-05 JP JP2017131921A patent/JP6889862B2/ja active Active

-

2018

- 2018-06-29 KR KR1020197037196A patent/KR102310304B1/ko not_active Expired - Fee Related

- 2018-06-29 US US16/628,304 patent/US20200215559A1/en not_active Abandoned

- 2018-06-29 AU AU2018297846A patent/AU2018297846B2/en active Active

- 2018-06-29 WO PCT/JP2018/024845 patent/WO2019009206A1/ja not_active Ceased

- 2018-06-29 CA CA3067686A patent/CA3067686C/en active Active

- 2018-06-29 CN CN201880043474.0A patent/CN110799669B/zh not_active Expired - Fee Related

- 2018-06-29 EP EP18828300.6A patent/EP3650581B1/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| EP3650581A4 (en) | 2021-03-03 |

| CA3067686C (en) | 2021-11-23 |

| EP3650581B1 (en) | 2022-05-18 |

| JP2019014929A (ja) | 2019-01-31 |

| CN110799669B (zh) | 2021-09-28 |

| AU2018297846B2 (en) | 2023-07-27 |

| AU2018297846A1 (en) | 2020-01-16 |

| CA3067686A1 (en) | 2019-01-10 |

| KR20200007949A (ko) | 2020-01-22 |

| CN110799669A (zh) | 2020-02-14 |

| WO2019009206A1 (ja) | 2019-01-10 |

| KR102310304B1 (ko) | 2021-10-06 |

| US20200215559A1 (en) | 2020-07-09 |

| EP3650581A1 (en) | 2020-05-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6889862B2 (ja) | コールドスプレーガン及びそれを備えたコールドスプレー装置 | |

| CN106457180B (zh) | 通过雾化以伸长部件的形式的原材料制造粉末粒子的方法和设备 | |

| JP5877590B2 (ja) | コールドスプレー用ノズル及びそのコールドスプレー用ノズルを用いたコールドスプレー装置 | |

| JP5035929B2 (ja) | コールドガス・スプレーガン | |

| JP5162621B2 (ja) | 温度調節装置、冷却装置、及び温度調節装置の製造方法 | |

| JP4973324B2 (ja) | コールドスプレー方法、コールドスプレー装置 | |

| US20100143700A1 (en) | Cold spray impact deposition system and coating process | |

| JP4999520B2 (ja) | コールドスプレー用ノズル及びコールドスプレー装置 | |

| CN110462099B (zh) | 冷喷枪及具备该冷喷枪的冷喷涂设备 | |

| US20160047052A1 (en) | Gas dynamic cold spray method and apparatus | |

| TW200938658A (en) | Nozzle used in cold sprayer and cold sprayer device | |

| WO2007091102A1 (en) | Kinetic spraying apparatus and method | |

| JP2012052186A (ja) | コールドスプレー装置用エジェクタノズル及びコールドスプレー装置 | |

| JP6426647B2 (ja) | スプレーノズル、皮膜形成装置、及び皮膜の形成方法 | |

| US7351450B2 (en) | Correcting defective kinetically sprayed surfaces | |

| HK40014258B (en) | Cold spray gun and cold spray device equipped therewith | |

| HK40014258A (en) | Cold spray gun and cold spray device equipped therewith | |

| HK40013663A (en) | Cold spray gun and cold spray apparatus equipped with same | |

| WO2022010651A1 (en) | Cooling system and fabrication method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20200323 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20210127 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20210326 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20210420 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20210506 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6889862 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |