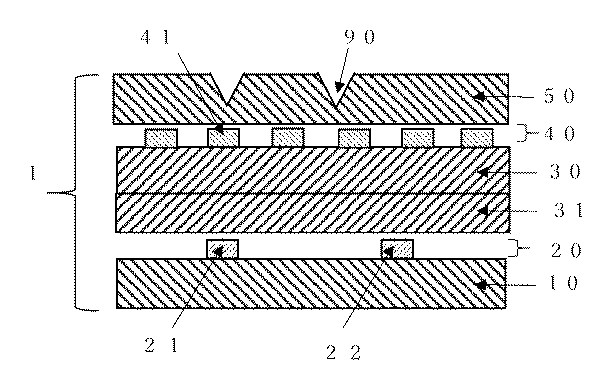

以下、本発明の実施の一形態を、図面に基づき説明する。本発明の圧力センサーシート1は、基板10上に第一電極20が形成され、前記第一電極20上に複数の絶縁層30、31が形成され、前記絶縁層31上に第二電極40が形成され、前記第二電極40上に保護層50が形成され、前記保護層50上から加わるせん断力60を算出できる圧力センサーシートである(図1参照)。なお、第一電極20と第二電極40とを入れ替えてもよい。すなわち、基板10上に第二電極40を形成し、絶縁層30上に第一電極20を形成してもよい。

この複数の層からなる絶縁層は、弾性率が高い絶縁層31の上に弾性率が低い絶縁層30が積層構成されていることが好ましい。弾性率が低い絶縁層30では押圧したせん断力60のたわみに応じた変形が感度良くなされ、弾性率が高い絶縁層31ではそのせん断力60のたわみに応じた変形が過度になることを抑制し、その下にある第一電極20が破損・劣化しないよう保護する。また、せん断方向の過度なずれはせん断方向測定値の誤差の原因となるため、それを軽減することは結果的に圧力方向だけでなくせん断方向の測定値もより正確に計測することができる。そして、その測定精度が向上すれば結果としてサンプリング速度が速くなる効果もある。

なお、本発明でいう弾性率とは引張弾性率のことであり、絶縁層30および絶縁層31をダンベル1号試験片の形状にカットし、微小な変位測定が可能な非接触方式の伸び幅計を使用して、JIS K 7127およびJIS K 7161に準拠した引張試験の方法にて、絶縁層30および絶縁層31が受けた引張応力を絶縁層30および絶縁層31に生じたひずみで除した値のことを指す。

この複数の層からなる絶縁層は上記に示した二層の場合だけでなく、三層以上形成された層であってもよい。また、上記絶縁層の弾性率の高い低いは、あくまでも絶縁層全体における相対的比較であって、単に絶縁層30の弾性率が絶縁層31の弾性率と比較して低いということを表しているだけであって、個々の層の弾性率の絶対的な数値の高い低いを表しているのではない。

すなわち、絶縁層が二層から積層構成される場合、例えば絶縁層30の弾性率が2GPaで絶縁層31の弾性率が1GPaであってもよいし。絶縁層30の弾性率が0.3GPaで絶縁層31の弾性率が0.01GPaであってもよい。絶縁層30の弾性率/絶縁層31の弾性率の比率は、1.1〜200の範囲になるよう設定するとよい。絶縁層30の弾性率/絶縁層31の弾性率の比率が1.1未満であると、せん断力60によって生じた変形が絶縁層を通り越して基板10上の第一電極20にまで達し、第一電極が劣化または破損しやすくなるという問題が生じる。一方、200を越えると、せん断力60によって生じた変形を絶縁層31のみで吸収して、そのが累積的な負荷により機械的強度が低下し、絶縁層31の耐久性が低下するという問題が生じる。

絶縁層が三層以上の場合は、第一電極20に接する絶縁層30と複数の電極40に接する絶縁層31の弾性率の比率を、上記二層の場合と同じように2〜2000の範囲になるよう設定し、絶縁層30と絶縁層31の間の絶縁層の弾性率は、絶縁層30の弾性率と絶縁層31の弾性率の中間値になるよう設定するとよい。また、絶縁層30と絶縁層31の材質や厚みが同一であっても、絶縁層30の表面にザグリ状の凹凸をつけて絶縁層30の弾性率を絶縁層31の弾性率より高くすることもできる。ザグリ状の凹凸の形状は絶縁層30の材質や厚みによって適宜選択するとよい。

絶縁層30、絶縁層31の材質としては、シリコーン、フッ素、ウレタン、エポキシ、エチレン酢酸ビニル共重合体、ポリエチレン、ポリプロピレン、ポリスチレン、ブタジエンゴムなどの弾性力を有する合成樹脂シートや伸縮性のある不織布シートなどが挙げられる。とくに、シリコーンゲル、シリコンエラストマーなどのシリコーン樹脂系の弾性体シートは、低温から高温まで幅広い温度域で耐久性に優れ、かつ弾性力も優れているので、より好ましい。また、絶縁層30、絶縁層31には、絶縁性を維持できる範囲の割合でカーボンブラック、金、銀、ニッケルなどの導電粒子を添加してもよい。絶縁層30、絶縁層31が押圧された際、含有されていた導電粒子間の距離が接近して第一電極20と第二電極40との間の静電容量値が急上昇するため、それにより後述するせん断力60の算出方法によって圧力およびせん断力の感度が向上する効果があるからである。導電粒子の平均粒径は絶縁層30、絶縁層31の厚みの10分の1以下が好ましい。

なお、絶縁層30、絶縁層31は押出成形などの一般的なシート成形法によりシート化されたものに限定されるわけでなく、印刷やコーターなどによって形成されたコーティング層であってもよい。厚みは20μm〜5mmの範囲で適宜選択すると良い。また、絶縁層30と絶縁層31の積層方法は、別々に用意したものを単に接着剤層等を介して貼り合わせする方法であってもよいし、共押し出し法のようにシート化する際に同時に積層してもよい。

シリコーンゲルは、オルガノポリシロキサンなどを主成分とする硬化後にゲル状になる材料であって、耐久性・高安全衛生性といったシリコーン特有の性質と、柔軟性・衝撃吸収性・耐湿性といった低架橋密度(鎖状高分子の相互間を化学的に結合させた網目構造の密度が低い)から生じる特性をもつ。シリコーンゲルで絶縁層30や絶縁層31を製造する方法としては、シリコーンゲル材料に硬化促進作用のある触媒とシリコーンゴム材料を添加して配合原料とし、リップコーター、コンマコーター、リバースコーター、ナイフコーターなどの各種コーターでシート化する方法や、予め用意したシリコーンゴムシート上にシリコーンゲル材料を前記各種コーターで塗布して一体成形する方法が挙げられる。

シリコンエラストマーは、直鎖状のシリコーンゴムコンパウンドあるいは液状シリコーンゴムを加硫剤や触媒により架橋させた熱硬化性シリコーンエラストマーのほか、ウレタン系などの他のエラストマーにシリコーンオイルをブレンドしたり、反応性シリコーンオイルと共重合させた熱可塑性のシリコーン変性エラストマーがある。シリコンエラストマーで絶縁層30、絶縁層31を製造する方法としては、上記シリコーン原料に補強剤や加硫剤を入れ撹拌混合し、所定の厚みの圧延機にかけシート化する圧延成形が挙げられる。その他、所定の型に流し込んで熱および圧力をかけて加硫するプレス成形や、押出機にかけシート化する押出成形、カレンダーロールを用い幅広の長尺シートに成形するカレンダー成形、コーティング装置を用いてガラスクロスなどの基材へ塗工するコーティング成形、インジェクション成形、巻きむし成形などが挙げられる。

絶縁層30と絶縁層31の弾性率が異なるように形成するための方法としては、各々を異なる材質で形成する方法が挙げられる。たとえば、絶縁層30をポリスチレン、ポリプロピレン、ポリカーボネート、エポキシ、ポリエチレンテレフタレート、ポリアセタールなどの合成樹脂シートで形成し、絶縁層31をシリコーンゴム、アクリルゴム、ブタジエンゴム、ウレタンゴムなどの合成樹脂シートにする組み合わせや、絶縁層30を不織布シートや、ポリスチレン、ポリアセタールなどの合成樹脂シートで形成し、絶縁層31をフッ素、ポリエチレンなどの合成樹脂シートにする組み合わせなどが挙げられる。

絶縁層30と絶縁層31の厚みの比率は特に限定されないが、絶縁層31の方を絶縁層30よりも厚く形成した方が好ましい。絶縁層31はせん断力60を感知するメインの層であるため、変形できるだけのある程度の厚みが必要になるためである。また、絶縁層31のみを発泡体にしたり、絶縁層30と絶縁層31とで発泡体の気泡のサイズを異ならせたり、発泡体の気泡の密度を異ならせたりして、絶縁層30と絶縁層31の弾性率が異なるように形成する方法もある。

この場合、絶縁層30、絶縁層31は全く同じ材質、厚みで形成されていてもよい。発泡体は合成樹脂中にガスを細かく分散させ、発泡状または多孔質形状に成形されたものであり。とくに、ポリエチレン、ポリプロピレン、ポリスチレンなどは、それ自体のシートのみでは弾性力が弱く発泡体にすることにより弾性力が向上するので、これらの合成樹脂を絶縁層31の材質として選択する場合は、発泡体にするのが好ましい。

発泡体の製造方法は、アゾジカーボンアミドや炭酸水素塩などの熱分解型発泡剤やフロンや炭化水素などを熱可塑性樹脂カプセルでくるんだ熱膨張性マイクロカプセル発泡剤を前記合成樹脂中に分散させ、熱が加わるビーズ発泡、バッチ発泡、プレス発泡、常圧二次発泡、射出発泡、押出発泡、発泡ブローなどの成形方法で製造する方法が挙げられる。

絶縁層30、絶縁層31の気泡の密度をほぼ同じにする場合、泡の平均体積サイズを絶縁層30よりも絶縁層31の方が平均1.3倍以上大きくなるようにすると、絶縁層30の弾性率/絶縁層31の弾性率の比率を1.1以上にすることができ、好ましい。また、絶縁層30、絶縁層31の気泡の平均体積サイズをほぼ同じにする場合、泡の密度を絶縁層30よりも絶縁層31の方が平均1.3倍以上大きくなるようにすると、絶縁層30の弾性率/絶縁層31の弾性率の比率を1.1以上にすることができ、好ましい。

所望の気泡の平均体積サイズにしたり所望の気泡の密度にするための方法としては、適した大きさのマイクロカプセル発泡剤を選択し適した量配合する方法のほか、発泡の過程で雰囲気圧力(外気圧)を一定の圧力に減圧または加圧して気泡の成長を促進または阻害することで得る方法もある。

発泡体の中でも、材質がシリコーン系樹脂から構成されているシリコーンフォームが好ましい。温度による弾性変化が少なく低温下での測定にも対応できるメリットがあり、耐久性が高いため、大きな変位による歪や応力が繰り返し加わったとしても、破断、変形を防ぐことができる。その結果、タイヤのよう荷重が大きな物を測定する場合から、靴底などのような荷重が小さな物を測定する場合など、あらゆる分野での接地状態を測定するための装置に使用できる。

シリコーンフォームはシリコーンゴムを独立発泡または半独立発泡させた発泡体であり、前述したように発泡剤をシリコーンゴム中に添加し加熱発泡させるタイプのほか、二成分型の液状シリコーンからなる自己発泡反応タイプなどが挙げられる。自己発泡反応タイプシリコーンフォームで絶縁層30を製造する方法としては、液状のシリコーンゴム原料を二枚のキャリアシートでサンドイッチ状とし、それをカレンダーロールの間を通して分出しシート形状にして加硫発泡させるカレンダー成形法、液状のシリコーンゴム原料をシートの上などに規制を受けない形でチャージし加硫発泡させるフリー発泡法、金型の中にシリコーン液状の原料を注ぎこみ加硫発泡させる注型成形法などが挙げられる。

また、絶縁層30、絶縁層31のいずれかのみを電気粘性流体で構成してもよい。あるいは、絶縁層30と絶縁層31の両方とも電気粘性流体で構成し、粘弾性の異なるよう構成してもよい。電気粘性流体は電界を印加したり除去したりすることによって粘弾性特性が可逆的に変化する流体のことであり、液晶などの単一物質からなる均一系電気粘性流体や、絶縁液体などに粒子を分散させた分散系電気粘性流体などが挙げられる。とくに、分散系電気粘性流体の場合は、電界の有無によって固液相変化が可能であり、より好ましい。

絶縁層30、絶縁層31を粘弾性の異なる複数の電気粘性流体で構成した場合、たとえば粘弾性が高い上側の絶縁層31では押圧した際のたわみに応じた絶縁層31の変形が感度良くなされ、粘弾性が低い下側の絶縁層31ではその変形が過度になることを抑制し、その下にある第一電極が破損・劣化しないよう保護する効果を持たすことができる。また、斜め方向のせん断力の測定値の誤差の原因となるずれを軽減するため、Z軸方向の圧力だけでなくXY軸方向のせん断力の測定値もより正確に計測することができる。

分散系電気粘性流体に使用する粒子としては、炭素質や絶縁質からなる多孔質な微粒子が挙げられる。微粒子の平均粒径は5μm〜30μmが好ましい。分散系電気粘性流体に使用する絶縁液体としては、シリコーンオイルなどが挙げられる。また、絶縁液体に架橋剤や白金触媒などを添加し熱処理を施して、電気粘性流体をゲル化してもよい。分散系電気粘性流体の製造方法は、乾燥後の多孔質粒子を電気絶縁性液体の分解温度以上に維持したまま攪拌しながら電気絶縁性液体に添加することにより、多孔質粒子の近傍に存在する電気絶縁性液体を分解させて低分子量の有機化合物を生成させ、その有機化合物を多孔質粒子の表面に均一に吸着させる方法が挙げられる。

第二電極40の材質は特に限定されないが、例えば、金、銀、銅、白金、パラジウム、アルミニウム、ロジウム等の金属膜のほか、これらの金属粒子を樹脂バインダーに分散させた導電ペースト膜あるいはポリへキシルチオフェン、ポリジオクチルフルオレン、ペンタセン、テトラベンゾポルフィリンなどの有機半導体などが挙げられる。第二電極40の製造方法は、前者の場合、メッキ法、スパッタリング法、真空蒸着法、イオンプレーティング法等で導電膜を全面形成した後にエッチングによりパターニングする方法が挙げられ、後者の場合、スクリーン、グラビア、オフセットなどの印刷法等で直接パターン形成する方法が挙げられる。

第二電極40は、絶縁層30または絶縁層31の上部に形成し、一層のみでもよいし二層以上の多層から成り立っていてもよい。絶縁層30および絶縁層31の両方に形成されていてもよい。第二電極40のパターンとしては、丸状、角状、線状などいずれの形状であってもよい。第二電極40の厚みは、0.1μm〜100μmの範囲内で適宜選択するとよい。第二電極40の各々からは配線パターンが接続され、外部にあるコントローラーと電気接続される。そして、前記第一電極20と前記複数の第二電極40との間で発生する静電容量値の変化を検出することにより、前記保護層50上から加わるせん断力60を算出できる。

第一電極20も、金、銀、銅、白金、パラジウム、アルミニウム、ロジウム等の金属膜のほか、これらの金属粒子を樹脂バインダーに分散させた導電ペースト膜、あるいはポリへキシルチオフェン、ポリジオクチルフルオレン、ペンタセン、テトラベンゾポルフィリンなどの有機半導体などが挙げられるが、特に限定されない。形成方法は、第二電極40と同様の方法で形成できるが、絶縁層30の下部に位置する基板10上に形成する。。基板10としては、ガラスエポキシ基板、ポリイミド基板、ポリブチレンテレフタレート樹脂基板などが挙げられるが、特に限定されない。厚みは0.1mm〜3mmの間ぐらいで適宜選択するとよい。

保護層50は、上部から加わるせん断力60から、下部にある第一電極20や前記第二電極40を保護するための層である。保護層50の材質としては、アクリル、ウレタン、フッ素、ポリエステル、ポリカーボネート、ポリアセタール、ポリアミド、オレフィンなどの熱可塑性または熱硬化性樹脂シートのほか、シアノアクリレートなどの紫外線硬化型樹脂シートなどが挙げられるが、とくに限定されない。

しかし、保護層50は、せん断力60を絶縁層30に的確に伝えるための役割も果たす層であるため、保護膜としての特性とともに圧力伝達体としての特性も有している必要がある。そのため、好ましいのは、アクリルゴム成分を10%以上含むアクリル系樹脂、ウレタン系樹脂、フッ素系樹脂、ポリエチレンテレフタレートなどのポリエステル樹脂である。保護層50の厚みは、材質によって異なるものの30μm〜5mmの間で適宜選択するとよい。

保護層50の上から加わるせん断力60はいずれの方式で算出しても構わないが、例えば、前記第一電極20と前記複数の第二電極40との間で発生する静電容量値の変化を検出することにより算出する方式が挙げられる。すなわち、せん断力60の押圧力によって、保護層50および絶縁層30が凹状に変形し、それによって絶縁層上に形成されていた複数の第二電極40と基板10上に形成されていた第一電極20との距離が変化する。その距離の変化は、せん断力60の押圧力および複数の第二電極40と第一電極20との間の静電容量値の変化と相関性がある。したがって、複数の第二電極40と第一電極20との間の静電容量値の変化を測定すれば、間接的にせん断力60の押圧力が測定できる。

そして、斜めの方向からせん断力60が加わった場合(すなわちZ軸方向の圧力のみでなく、XY軸方向のせん断力の成分がある場合)、たとえば複数の第二電極40のうちの一点の第二電極41は、その真下にある一点の第一電極21だけではなく、第一電極21の隣の第一電極22との間の距離も変化する(図2、図3参照)。すなわち、第二電極41と第一電極21との間の静電容量値の変化と第二電極41と第一電極22との間の静電容量値の変化とを測定すれば、斜めの方向のせん断力60の強さを測定できる。

この点は従来技術として掲げた特許文献1(特開2018−72041号公報)にない本発明の長所であり、実際、タイヤや靴底などの接地状態での圧力は保護層50の真上から加わるZ軸方向のみの圧力だけではなく、斜め方向から加わるXY軸方向の力の成分がある場合が常なため、本発明は、実製品での接地状態に則した発明であると言える。

なお、この一点の第二電極41のXY方向の変位が、周縁のほかの第二電極に影響を与え、それがノイズとなって測定したい静電容量値の感度に影響を与えないようにするために、表面に切り目を入れてもよい(図4参照)。すなわち、第二電極40各々が独立して動き、一点の第二電極41の変位が周囲のその他の第二電極40には影響を与えないようにする。この切り目を入れる場合は、絶縁層30の厚みは、やや厚めの500μm〜5mmの範囲にするのが好ましい。

切り目の形態としては、例えば点線状、破線状、長鎖線状、一点鎖線状、長二点鎖線状などが挙げられる。切れ目は一本の線であってもよいし複数の線であってもよい。切れ目の深さは、完全に貫通していてもよいし、途中までのハーフカット状であってもよい。切り目の形成方法としては、例えばトムソン刃の打ち抜き方法などが挙げられる。

以下、本発明の実施例1として、タイヤの接地状態測定装置に用いた場合の圧力センサーシートについて記載する。実施例1の圧力センサーシートは、以下の手順で製造した。液状シリコーンゴム、加硫架橋剤、トリエチルアミン触媒、フェノール誘導体の安定剤およびメタン内包マイクロカプセル発泡剤を重量比10:4:0.3:0.1:0.2の割合で配合・撹拌させた絶縁層原料および液状シリコーンゴム、加硫架橋剤、トリエチルアミン触媒、フェノール誘導体の安定剤およびメタン内包マイクロカプセル発泡剤を重量比10:4:0.3:0.1:0.4の割合で配合・撹拌させた絶縁層原料を、それぞれ別々に125μm厚のポリエステル製キャリアシート上に、0.3mm厚の間隙をもたせたカレンダーロールの間を通して順次分出しをし、絶縁層を作成した。次いで、120℃の加熱炉を通すことで、液状シリコーンゴムを架橋させシート状にするとともに、マイクロカプセルを発砲させたところ、それぞれ気泡の平均体積サイズが5μmのシリコーンフォームからなる絶縁層と気泡の平均体積サイズが30μmのシリコーンフォームからなる絶縁層(両方とも幅40cm、長さ2m)とが形成された。

この絶縁層をダンベル1号試験片の形状にカットし、非接触方式の伸び幅計を使用して、JIS K 7127およびJIS K 7161に準拠した引張試験の方法にて弾性率を計測したところ、気泡の平均体積サイズが5μmのシリコーンフォームからなる絶縁層は0.2であり、気泡の平均体積サイズが30μmのシリコーンフォームからなる絶縁層は0.05であった。前者の絶縁層上に、ピッチが1.5mm間隔でパターンが1mm正方形状の銀ペーストからなる第二電極を、スクリーン印刷法にて絶縁層に形成し、ウレタン接着剤を介して後者の絶縁層を積層した。次いで、後者の絶縁層の上面に、ポリカーボネート系樹脂からなる厚さ0.5mmの保護層を、ウレタン系接着剤を介して積層し、絶縁層の下面には、35μm厚の第一電極が形成された1mm厚のガラスエポキシ樹脂基板を積層して、圧力センサーシートを得た。上記複数の第二電極および第一電極は、引き出し配線を通じて静電容量値の変化を検出できるコントローラーに接続した。

上記製造された圧力センサーシートを用いて、―40℃、10℃、60℃の各環境温度下において、タイヤ幅195mm、偏平率65%、ホイールサイズ15インチからなるラジアルタイヤの走行速度40km/時における圧力をテストした。その測定結果は以下の通りであり、Z軸方向圧力のみならずXY軸方向せん断力も測定できた。また、低温環境下では、XY軸方向せん断圧力が増加する傾向が見られ、せん断圧力の測定の意義が確認された。また、このような広い環境温度で測定できるシリコーンフォームの絶縁層で形成される圧力センサーシートの意義も確認できた。

以下、本発明の実施例2として、靴底の接地状態測定装置に用いた場合の圧力センサーシートについて記載する。実施例2の圧力センサーシートは、以下の手順で製造した。ポリカーボネート樹脂からなる厚さ500μmの絶縁層を押出成形によってシート化した。このシート化した絶縁層をダンベル1号試験片の形状にカットし、非接触方式の伸び幅計を使用して、JIS K 7127およびJIS K 7161に準拠した引張試験の方法にて弾性率を計測したところ2.3であった。次いでこの絶縁層をカレンダーロールの間を通し、同時にウレタンゴム原料を供給して、厚さ500μmポリカーボネート樹脂と厚さ700μmのウレタンゴム樹脂からなる総厚0.12mmからなる絶縁層積層体(幅40cm、長さ2m)を作成した。このウレタンゴム樹脂からなる絶縁層単体での弾性率を、予め別途計測したところ0.2であった。なお、作成した絶縁層積層体の弾性率は2.0であった。

この絶縁層積層体のウレタンゴム樹脂絶縁層上に、ピッチが1.5mm間隔でパターンが1mm正方形状の銅からなる複数の第二電極を、部分メッキ法にて絶縁層の全面に形成した。次いで、絶縁層の上面に、アクリル系樹脂からなる厚さ0.05mmの保護層をシリコーン系接着剤を介して積層し、絶縁層の下面には、35μm厚の第一電極が形成された0.1mm厚のポリイミド樹脂フィルム基板を積層して、圧力センサーシートを得た。上記複数の第二電極および第一電極は、引き出し配線を通じて静電容量値の変化を検出できるコントローラーに接続した。

上記製造された圧力センサーシートを用いて、20℃の環境温度下において、サイズ27cmで圧力センサーシートが取り付けられた靴を履いた試験者に歩行速度2km/時、4km/時、6km/時で歩行してもらい、各歩行速度における圧力をテストした。その測定結果は以下の通りであり、Z軸方向圧力のみならずXY軸方向せん断力も測定できた。また、歩行速度が高いほど、靴底に掛かるXY軸方向せん断力が増加する傾向が見られ、せん断圧力の測定の意義が確認された。

以下、本発明の実施例3として、パーソナルコンピューターのトラックパットに用いた場合の圧力センサーシートについて記載する。実施例3の圧力センサーシートは、以下の手順で製造した。ポリスチレン樹脂材料中にアゾジカーボンアミド発泡剤および平均粒径30μmのカーボンブラックを重量比10:0.6:0.1の割合で分散させ、0.5mm厚の間隙をもたせた押出成形機の間を通してシート状の絶縁層を二枚形成した。次いで、熱を加えてビーズ発泡させながら圧力を加えて、二枚のうち一枚には表面にザグリ状の凹凸を付けた。このザグリ状の凹凸を付けた側を上にして、二枚の絶縁層をエポキシ樹脂接着剤を介して貼り合わせて、総厚1.1mmからなる絶縁層積層体(5mm角)を作成した。この発泡ポリスチレン樹脂からなる絶縁層単体での弾性率を、予め別途計測したところ0.21と0.25であった。なお、作成した絶縁層積層体の弾性率は0.22であった。

この絶縁層積層体の発泡ポリスチレン樹脂絶縁層上に、ピッチが0.3mm間隔でパターンが0.6mm正方形状の銅からなる複数の第二電極を、部分メッキ法にて絶縁層の全面に形成した。次いで、絶縁層の上面に、アクリル系樹脂からなる厚さ0.05mmの保護層をシリコーン系接着剤を介して積層し、絶縁層の下面には、35μm厚の第一電極が形成された0.1mm厚のポリイミド樹脂フィルム基板を積層して、圧力センサーシートを得た。上記複数の第二電極および第一電極は、引き出し配線を通じて静電容量値の変化を検出できるコントローラーに接続した。

上記製造された圧力センサーシートを用いて、20℃の環境温度下において、サイズ半径2mmで圧力センサーシートが取り付けられたトラックパットを試験者に速度2mm/秒、10mm/秒、40mm/秒でなぞってもらい、各速度における圧力をテストした。その測定結果は以下の通りであり、X軸方向圧力のみならずY軸方向のせん断力も測定できた。また、なぞる速度が高いほど、トラックパットに掛かるXY軸方向のせん断力が増加する傾向が見られ、せん断力の測定の意義が確認された。