JP6364027B2 - 補強構造部品を作製するプロセス及び機構 - Google Patents

補強構造部品を作製するプロセス及び機構 Download PDFInfo

- Publication number

- JP6364027B2 JP6364027B2 JP2015557398A JP2015557398A JP6364027B2 JP 6364027 B2 JP6364027 B2 JP 6364027B2 JP 2015557398 A JP2015557398 A JP 2015557398A JP 2015557398 A JP2015557398 A JP 2015557398A JP 6364027 B2 JP6364027 B2 JP 6364027B2

- Authority

- JP

- Japan

- Prior art keywords

- adhesive

- reinforcing support

- structural member

- robot

- structural

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims description 54

- 230000008569 process Effects 0.000 title claims description 51

- 230000007246 mechanism Effects 0.000 title claims description 20

- 239000000853 adhesive Substances 0.000 claims description 145

- 230000001070 adhesive effect Effects 0.000 claims description 144

- 230000003014 reinforcing effect Effects 0.000 claims description 119

- 239000011324 bead Substances 0.000 claims description 49

- 239000000463 material Substances 0.000 claims description 33

- 238000003825 pressing Methods 0.000 claims description 17

- 238000001746 injection moulding Methods 0.000 claims description 14

- 230000033001 locomotion Effects 0.000 claims description 12

- 238000003860 storage Methods 0.000 claims description 12

- 238000010422 painting Methods 0.000 claims description 5

- 229920001187 thermosetting polymer Polymers 0.000 claims description 3

- 238000005304 joining Methods 0.000 claims description 2

- 239000003795 chemical substances by application Substances 0.000 claims 2

- 230000007423 decrease Effects 0.000 claims 1

- 238000007373 indentation Methods 0.000 claims 1

- 239000000758 substrate Substances 0.000 claims 1

- 230000002787 reinforcement Effects 0.000 description 14

- 239000012790 adhesive layer Substances 0.000 description 6

- 239000012779 reinforcing material Substances 0.000 description 4

- 238000012546 transfer Methods 0.000 description 4

- 239000011248 coating agent Substances 0.000 description 3

- 238000000576 coating method Methods 0.000 description 3

- 238000013461 design Methods 0.000 description 3

- 230000008901 benefit Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 239000010410 layer Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 239000004831 Hot glue Substances 0.000 description 1

- 229920001730 Moisture cure polyurethane Polymers 0.000 description 1

- 230000002776 aggregation Effects 0.000 description 1

- 238000004220 aggregation Methods 0.000 description 1

- 230000003466 anti-cipated effect Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 239000011230 binding agent Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 210000000078 claw Anatomy 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000003822 epoxy resin Substances 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 238000010097 foam moulding Methods 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000012432 intermediate storage Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000008520 organization Effects 0.000 description 1

- 239000003973 paint Substances 0.000 description 1

- 229920000647 polyepoxide Polymers 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000008439 repair process Effects 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 239000000565 sealant Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 239000003351 stiffener Substances 0.000 description 1

- 239000012745 toughening agent Substances 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/48—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding

- B29C65/52—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding characterised by the way of applying the adhesive

- B29C65/524—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding characterised by the way of applying the adhesive by applying the adhesive from an outlet device in contact with, or almost in contact with, the surface of the part to be joined

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J9/00—Programme-controlled manipulators

- B25J9/16—Programme controls

- B25J9/1656—Programme controls characterised by programming, planning systems for manipulators

- B25J9/1664—Programme controls characterised by programming, planning systems for manipulators characterised by motion, path, trajectory planning

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J9/00—Programme-controlled manipulators

- B25J9/16—Programme controls

- B25J9/1679—Programme controls characterised by the tasks executed

- B25J9/1687—Assembly, peg and hole, palletising, straight line, weaving pattern movement

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/48—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding

- B29C65/4805—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding characterised by the type of adhesives

- B29C65/483—Reactive adhesives, e.g. chemically curing adhesives

- B29C65/4835—Heat curing adhesives

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/48—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding

- B29C65/52—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor using adhesives, i.e. using supplementary joining material; solvent bonding characterised by the way of applying the adhesive

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/78—Means for handling the parts to be joined, e.g. for making containers or hollow articles, e.g. means for handling sheets, plates, web-like materials, tubular articles, hollow articles or elements to be joined therewith; Means for discharging the joined articles from the joining apparatus

- B29C65/7841—Holding or clamping means for handling purposes

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J5/00—Adhesive processes in general; Adhesive processes not provided for elsewhere, e.g. relating to primers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/301—Three-dimensional joints, i.e. the joined area being substantially non-flat

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/50—General aspects of joining tubular articles; General aspects of joining long products, i.e. bars or profiled elements; General aspects of joining single elements to tubular articles, hollow articles or bars; General aspects of joining several hollow-preforms to form hollow or tubular articles

- B29C66/51—Joining tubular articles, profiled elements or bars; Joining single elements to tubular articles, hollow articles or bars; Joining several hollow-preforms to form hollow or tubular articles

- B29C66/53—Joining single elements to tubular articles, hollow articles or bars

- B29C66/532—Joining single elements to the wall of tubular articles, hollow articles or bars

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/50—General aspects of joining tubular articles; General aspects of joining long products, i.e. bars or profiled elements; General aspects of joining single elements to tubular articles, hollow articles or bars; General aspects of joining several hollow-preforms to form hollow or tubular articles

- B29C66/61—Joining from or joining on the inside

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/50—General aspects of joining tubular articles; General aspects of joining long products, i.e. bars or profiled elements; General aspects of joining single elements to tubular articles, hollow articles or bars; General aspects of joining several hollow-preforms to form hollow or tubular articles

- B29C66/65—General aspects of joining tubular articles; General aspects of joining long products, i.e. bars or profiled elements; General aspects of joining single elements to tubular articles, hollow articles or bars; General aspects of joining several hollow-preforms to form hollow or tubular articles with a relative motion between the article and the welding tool

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/30—Vehicles, e.g. ships or aircraft, or body parts thereof

- B29L2031/3044—Bumpers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/30—Vehicles, e.g. ships or aircraft, or body parts thereof

- B29L2031/3055—Cars

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/30—Vehicles, e.g. ships or aircraft, or body parts thereof

- B29L2031/3067—Ships

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/30—Vehicles, e.g. ships or aircraft, or body parts thereof

- B29L2031/3076—Aircrafts

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2301/00—Additional features of adhesives in the form of films or foils

- C09J2301/20—Additional features of adhesives in the form of films or foils characterized by the structural features of the adhesive itself

- C09J2301/204—Additional features of adhesives in the form of films or foils characterized by the structural features of the adhesive itself the adhesive coating being discontinuous

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16B—DEVICES FOR FASTENING OR SECURING CONSTRUCTIONAL ELEMENTS OR MACHINE PARTS TOGETHER, e.g. NAILS, BOLTS, CIRCLIPS, CLAMPS, CLIPS OR WEDGES; JOINTS OR JOINTING

- F16B11/00—Connecting constructional elements or machine parts by sticking or pressing them together, e.g. cold pressure welding

- F16B11/006—Connecting constructional elements or machine parts by sticking or pressing them together, e.g. cold pressure welding by gluing

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S901/00—Robots

- Y10S901/02—Arm motion controller

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/10—Methods of surface bonding and/or assembly therefor

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Robotics (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Automatic Assembly (AREA)

- Application Of Or Painting With Fluid Materials (AREA)

- Standing Axle, Rod, Or Tube Structures Coupled By Welding, Adhesion, Or Deposition (AREA)

- Adhesives Or Adhesive Processes (AREA)

Description

3a,3b 接着剤ビード

3’ 接着剤

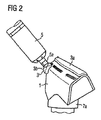

5 接着剤吐出ユニット

5a ノズル

7 ロボット

7a ロボットハンド

9 補強構造部品

9’ 基本構造部品

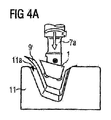

11 組立てブロック

11a キャビティ

100 機構

101 射出成形機

103 補強用支持材保管部

105 構造部品保管部

107 搬送手段

109 硬化塗装オーブン

111 ロボット及び吐出ユニットの動作制御ユニット

Claims (18)

- 基本構造部品(9’)及び補強用支持材(1)を含み、前記補強用支持材を前記基本構造部品に構造的に接合するために、接着剤ビード(3a)及び/又は複数の接着剤プロットが前記補強用支持材の外面と前記基本構造部品の接触面との間に配置される補強構造部品(9)を作製するプロセスであって、

該プロセスは、

ロボット(7)を用いて前記補強用支持材を取り上げるステップと、

前記ロボットを対応して動作させることによって、前記補強用支持材を接着剤吐出ユニット(5)の近くに運ぶステップと、

前記ロボットを対応して動作させることによって、前記補強用支持材を前記接着剤吐出ユニットに沿って所定の経路に従って移動させるとともに、前記補強用支持材の移動に適時対応して、前記接着剤吐出ユニットから1回あたりの所定量の接着剤を放出して、1又は複数の前記接着剤ビード及び/又は複数の前記接着剤プロットを、前記補強用支持材の前記外面上の所定の場所に塗布し、これにより、1又は複数の前記接着剤ビード又は複数の前記接着剤プロットが所定の形状に形成されるように前記ロボット及び前記接着剤吐出ユニットを制御するステップと、

1又は複数の前記接着剤ビード又は複数の前記接着剤プロットが塗布された前記補強用支持材を、作業空間に配置されている前記基本構造部品のところに移動させるとともに、1又は複数の前記接着剤ビード及び/又は複数の前記接着剤プロットが、前記基本構造部品の前記接触面上の所定の場所に接触かつ接着して機械的に安定な結合を形成するように、前記ロボットを対応して動作させることによって、前記補強用支持材を前記基本構造部品に押し込むステップと、

前記補強用支持材を解放して開始位置に戻り、次の補強用支持材を取り出して該プロセスを再開するように、前記ロボットを操作するステップと、を含むプロセス。 - 前記補強構造部品が、自動車若しくは他の車両又は航空機又は船舶の一部を形成する請求項1に記載のプロセス。

- 前記基本構造部品と前記補強用支持材との間の接合部は、前記押し込みによって専ら実現される請求項1又は2に記載のプロセス。

- 前記基本構造部品と前記補強用支持材との間の接合部は、前記補強用支持材を保持する前記ロボットが、前記補強用支持材を介して前記基本構造部品を取り上げることができるようになっている請求項1〜3のいずれか1項に記載のプロセス。

- 前記補強用支持材を前記接着剤吐出ユニットに沿って移動させるとともに、1又は複数の前記接着剤ビード及び/又は複数の前記接着剤プロットを、前記補強用支持材に塗布するステップは、前記所定の経路に沿って一定量の接着剤が塗布されるように、前記ロボット及び前記吐出ユニットを制御することを含む請求項1〜4のいずれか1項に記載のプロセス。

- 前記補強用支持材を前記接着剤吐出ユニットに沿って移動させるとともに、1又は複数の前記接着剤ビード及び/又は複数の前記接着剤プロットを、前記補強用支持材に塗布するステップは、前記所定の経路に沿って可変量の接着剤が塗布され、前記接着剤ビード及び/又は前記接着剤プロットのそれぞれの断面が、前記接着剤ビード及び/又は前記接着剤プロットの所定の幾何形状に従って変化するように、前記ロボット及び前記吐出ユニットを制御することを含む請求項1〜5のいずれか1項に記載のプロセス。

- 前記補強構造部品は、少なくとも第1の構造部材及び第2の構造部材を含み、

該プロセスは、

1又は複数の前記接着剤ビード及び/又は複数の前記接着剤プロットが施された前記補強用支持材を前記第1の構造部材のところに移動させるとともに、前記ロボットを対応して動作させることによって、前記補強用支持材を前記第1の構造部材に押し込むステップと、

前記ロボットを対応して動作させることによって、前記補強用支持材及び前記補強用支持材に接着している前記第1の構造部材を組み立て位置に移動させるステップと、

1又は複数の前記接着剤ビード及び/又は複数の前記接着剤プロットが施された前記第1の構造部材を、前記組み立て位置で待機している前記第2の構造部材に押し付けるように、前記ロボットを操作するステップ、又は、前記第1の構造部材が前記組み立て位置において解放され、前記ロボットが、前記第2の構造部材が待機している保管位置に移動し、前記第2の構造部材を取り出して前記組み立て位置に移送するとともに、前記第2の構造部材を、1又は複数の前記接着剤ビード及び/又は複数の前記接着剤プロットが施された前記第1の構造部材に押し付けるように、前記ロボットを操作するステップと、を含み、

前記第1の構造部材を前記第2の構造部材に押し付けること又は前記第2の構造部材を前記第1の構造部材に押し付けることは、1又は複数の前記接着剤ビード又は複数の前記接着剤プロットを未硬化状態で前記第2の構造部材の表面に接触させ前記第2の構造部材に接着させるようにして行われる請求項1〜6のいずれか1項に記載のプロセス。 - 1又は複数の前記接着剤ビード又は複数の前記接着剤プロットが施された前記補強用支持材を前記基本構造部品又は前記第1の構造部材に押し付けること、及び必要に応じて、前記第1の構造部材を前記第2の構造部材に押し付けることは、前記補強用支持材又は前記第1の構造部材を保持する前記ロボットの並進運動において実行され、及び/又は、

1又は複数の前記接着剤ビード又は複数の前記接着剤プロットが施された前記補強用支持材を前記基本構造部品又は前記第1の構造部材に押し付けること、及び必要に応じて、前記第1の構造部材を前記第2の構造部材に押し付けることは、前記補強用支持材又は前記第1の構造部材を保持する前記ロボットの並進運動と回転運動との組み合わせによって実行される請求項7に記載のプロセス。 - 前記補強用支持材を前記基本構造部品又は前記第1の構造部材に押し込むステップ、及び必要に応じて、1又は複数の前記接着剤ビード及び/又は複数の前記接着剤プロットが施された前記第1の構造部材を前記第2の構造部材に互いに押し付けるステップにおいて、前記接着剤ビード又は前記接着剤プロットの側方延長部が拡張され、その一方で、前記側方延長部の前記ビードは、所定の範囲に減少する請求項8に記載のプロセス。

- 計量ユニットに結合されている空間的に固定されたノズル(5a)を備える前記接着剤吐出ユニットを用いて、前記補強用支持材又は前記構造部材上の接着剤が塗布される場所が、前記ロボットの運動によって専ら制御されるようにし、及び/又は、

熱硬化性接着剤を用いて、前記補強用支持材に接着剤(3’)を塗布して、接着剤ビード及び/又は複数の接着剤プロットを前記補強用支持材上に形成するステップの後、前記プロセスを中断し、その後再開する請求項1〜9のいずれか1項に記載のプロセス。 - 前記補強用支持材を射出成形機(101)において射出成形によって作成する請求項1〜10のいずれか1項に記載のプロセス。

- 前記ロボットが前記射出成形機の出口において前記補強用支持材を取り出す請求項11に記載のプロセス。

- 前記組み立てられた補強構造部品を、硬化場所に移送して所定の時間入れておき、1又は複数の前記接着剤ビード及び/又は複数の前記接着剤プロットを硬化させる請求項1〜12のいずれか1項に記載のプロセス。

- 前記硬化場所がコート塗装オーブン(109)であり、前記組み立てられた補強構造部品を前記コート塗装オーブンに移送し、前記コート塗装オーブンに所定の時間入れておき、1又は複数の前記接着剤ビード及び/又は複数の前記接着剤プロットを硬化させる請求項13に記載のプロセス。

- 前記補強用支持材及び/又は前記第1の構造部材前記第2の構造部材に、ロボット操作のための操作部を設けることを含む請求項1〜14のいずれか1項に記載のプロセス。

- 請求項1〜15のいずれか1項に記載のプロセスを実施する機構であって、

該機構は、

補強用支持材(1)と、必要に応じて第1の構造部材及び/又は第2の構造部材とを取り出して移動させるようになっているロボット(7)と、

前記補強用支持材のそれぞれの表面、又は必要に応じて、前記第1の構造部材のそれぞれの表面に、1回あたりの所定量の接着剤(3’)を放出するようになっている接着剤吐出ユニット(5)と、

基本構造部品(9’)、又は前記第1の構造部材若しくは前記第2の構造部材をそれぞれ保管するようになっている保管部(105)と、

前記ロボットの取り出し動作、解放動作及び運動、及び、所定の接着剤構成に従った前記補強用支持材又は必要に応じて前記第1の構造部材のそれぞれの表面に対する前記接着剤吐出ユニットからの前記接着剤の放出を制御するロボット及び吐出ユニットの動作制御ユニット(111)と、を備える機構。 - 該機構は、前記補強用支持材を保管するようになっている保管部(103)又は前記補強用支持材をインラインで供給する射出成形機(101)を備え、

前記ロボットは、前記保管部(103)又は前記射出成形機の出口から前記補強用支持材を取り出すように構成されているとともに動作可能である請求項16に記載の機構。 - 前記接着剤吐出ユニットは、固定ノズル(5a)を備える請求項16又は17に記載の機構。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP13155497.4 | 2013-02-15 | ||

| EP13155497 | 2013-02-15 | ||

| PCT/EP2014/052607 WO2014124924A1 (en) | 2013-02-15 | 2014-02-11 | Process and arrangement for making a reinforced structural member |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2016516560A JP2016516560A (ja) | 2016-06-09 |

| JP2016516560A5 JP2016516560A5 (ja) | 2017-03-09 |

| JP6364027B2 true JP6364027B2 (ja) | 2018-07-25 |

Family

ID=47710045

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2015557398A Active JP6364027B2 (ja) | 2013-02-15 | 2014-02-11 | 補強構造部品を作製するプロセス及び機構 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US9962884B2 (ja) |

| EP (1) | EP2956680B1 (ja) |

| JP (1) | JP6364027B2 (ja) |

| KR (1) | KR102239399B1 (ja) |

| CN (1) | CN105074233B (ja) |

| WO (1) | WO2014124924A1 (ja) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT517912B1 (de) * | 2015-10-21 | 2019-03-15 | Hubert Ing Rapperstorfer | Fertigungsanlage zum Fertigen von Bewehrungselementen |

| DE102017203368B4 (de) * | 2017-03-02 | 2023-07-06 | Volkswagen Aktiengesellschaft | Verfahren und Vorrichtung zum Versteifen von Metallbauteilen mittels eines robotergeführten Applikationskopfes |

| IT201700053837A1 (it) * | 2017-05-18 | 2018-11-18 | Sapa S R L | Metodo di produzione di una seduta per un sedile di un qualsiasi veicolo stradale e prodotto così ottenuto. |

| EP3421331B1 (de) | 2017-06-29 | 2021-06-16 | Sika Technology Ag | System eines verstärkten strukturelementes eines kraftfahrzeugs |

| EP3466800B1 (de) | 2017-10-06 | 2024-03-13 | Sika Technology Ag | Verstärkungsvorrichtung zur verstärkung eines strukturelementes in einem kraftfahrzeug |

| ES2949793T3 (es) | 2018-08-31 | 2023-10-03 | Sika Tech Ag | Dispositivo para reforzar, sellar o amortiguar un elemento estructural |

| KR102618225B1 (ko) | 2018-08-31 | 2023-12-27 | 시카 테크놀러지 아게 | 구조 요소를 차폐시키기 위한 시스템 |

| WO2024052276A1 (en) | 2022-09-05 | 2024-03-14 | Zephyros, Inc. | Curable polymer composition having improved wash-off resistance |

Family Cites Families (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3558361B2 (ja) * | 1994-01-31 | 2004-08-25 | 豊田工機株式会社 | モールの装着方法およびその装置 |

| DE10013224A1 (de) | 2000-03-17 | 2001-09-20 | Cd Design Gmbh | Verfahren und Vorrichtung zum Aufbringen von selbstklebenden Folienzuschnitten, insbesondere auf Kfz-Karosserieteile |

| JP2002047457A (ja) * | 2000-07-31 | 2002-02-12 | Ricoh Co Ltd | 貼付部材剥離装置および貼付部材剥離方法 |

| JP4497468B2 (ja) | 2004-09-14 | 2010-07-07 | 株式会社不二越 | シーリング・システム |

| JP2006341291A (ja) * | 2005-06-09 | 2006-12-21 | Kanto Auto Works Ltd | ヘミング装置 |

| CN100467266C (zh) * | 2005-12-26 | 2009-03-11 | 东莞宏威数码机械有限公司 | 用于制造dvd光盘的粘合方法和装置 |

| EP1916270A1 (de) | 2006-10-24 | 2008-04-30 | Sika Technology AG | Hitzehärtende Epoxidharzzusammensetzung mit blockiertem Polyurethanprepolymer |

| EP1916269A1 (de) | 2006-10-24 | 2008-04-30 | Sika Technology AG | Blockierte Polyurethanprepolymere und hitzehärtende Epoxidharzzusammensetzungen |

| EP1916285A1 (de) | 2006-10-24 | 2008-04-30 | Sika Technology AG | Derivatisiertes Epoxid-Festharz und dessen Verwendungen |

| EP1916272A1 (de) | 2006-10-24 | 2008-04-30 | Sika Technology AG | Hitzehärtende Epoxidharzzusammensetzung enthaltend ein blockiertes und ein epoxidterminiertes Polyurethanprepolymer |

| EP1946995A1 (de) | 2006-12-22 | 2008-07-23 | Sika Technology AG | Verstärkungssystem zur Verstärkung eines Hohlraumes eines Bauelements |

| JP4945262B2 (ja) * | 2007-02-14 | 2012-06-06 | 本田技研工業株式会社 | 車両用ガラス取付装置及び車両用ガラスの移動方法 |

| GB2446718B (en) | 2007-02-14 | 2009-04-29 | Honda Motor Co Ltd | Automotive glass attachment apparatus |

| EP1972646A1 (de) | 2007-03-20 | 2008-09-24 | Sika Technology AG | Epoxidgruppen terminierte Polymer, deren Zusammensetzungen und deren Verwendung als Schlagzähigkeitsmodifikatoren |

| JP4746002B2 (ja) * | 2007-05-07 | 2011-08-10 | リンテック株式会社 | 移載装置及び移載方法 |

| US8028559B2 (en) | 2007-08-06 | 2011-10-04 | Hirotec America, Inc. | Flying roller hemming anvil process |

| US8361589B2 (en) | 2008-02-29 | 2013-01-29 | Sika Technology Ag | Structural reinforcement system |

| JP5392455B2 (ja) * | 2008-03-24 | 2014-01-22 | マツダ株式会社 | 被塗装物品の接着組立方法 |

| DE102008039869B4 (de) | 2008-08-27 | 2016-11-03 | Benteler Sgl Gmbh & Co. Kg | Verfahren zum Herstellen von Leichtbauteilen |

| EP2159136A1 (en) * | 2008-09-01 | 2010-03-03 | Sika Technology AG | Bonding with adhesive beads or plots |

| EP2159109A1 (en) | 2008-09-01 | 2010-03-03 | Sika Technology AG | Reinforcement with channel design |

| JP2010076417A (ja) * | 2008-09-01 | 2010-04-08 | Oshima Denki Seisakusho:Kk | 射出成形体の製造装置 |

| EP2251250A1 (en) | 2009-05-05 | 2010-11-17 | Sika Technology AG | Bonding with adhesive beads or plots |

| GB201007793D0 (en) * | 2010-05-10 | 2010-06-23 | Zephyros Inc | Improvements in or relating to structural adhesives |

| EP2463180B1 (en) * | 2010-12-07 | 2015-10-07 | Sika Technology AG | Reinforcer with pre-applied bonding material |

| EP2537642A1 (en) | 2011-06-23 | 2012-12-26 | Raytheon BBN Technologies Corp. | Robot fabricator |

-

2014

- 2014-02-11 US US14/767,845 patent/US9962884B2/en active Active

- 2014-02-11 KR KR1020157019921A patent/KR102239399B1/ko active IP Right Grant

- 2014-02-11 CN CN201480008830.7A patent/CN105074233B/zh active Active

- 2014-02-11 EP EP14705995.0A patent/EP2956680B1/en active Active

- 2014-02-11 WO PCT/EP2014/052607 patent/WO2014124924A1/en active Application Filing

- 2014-02-11 JP JP2015557398A patent/JP6364027B2/ja active Active

Also Published As

| Publication number | Publication date |

|---|---|

| WO2014124924A1 (en) | 2014-08-21 |

| KR20150117649A (ko) | 2015-10-20 |

| US20150367562A1 (en) | 2015-12-24 |

| EP2956680B1 (en) | 2020-04-08 |

| CN105074233A (zh) | 2015-11-18 |

| KR102239399B1 (ko) | 2021-04-13 |

| EP2956680A1 (en) | 2015-12-23 |

| CN105074233B (zh) | 2018-05-25 |

| US9962884B2 (en) | 2018-05-08 |

| JP2016516560A (ja) | 2016-06-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6364027B2 (ja) | 補強構造部品を作製するプロセス及び機構 | |

| JP2016516560A5 (ja) | ||

| US9114568B2 (en) | Extrusion of adhesives for composite structures | |

| US9579713B2 (en) | Method for producing a vehicle body or a vehicle body module | |

| US20090071609A1 (en) | Method and systems for the automated manufacture of composite doors | |

| US10870241B2 (en) | Machine system for producing a hybrid component | |

| WO2006046974A2 (en) | Method of making and using shape memory polymer composite patches | |

| CA2932506A1 (en) | Apparatus and method for continuously manufacturing components from fibre-reinforced composites, and mould set | |

| US8808479B2 (en) | Method of making and using shape memory polymer composite patches | |

| JP6577608B2 (ja) | 樹脂補強金属部品の製造方法 | |

| JP7510248B2 (ja) | 複合材プリフォームの連続製造 | |

| WO2020230797A1 (ja) | 板金部材成形方法および板金部材成形装置 | |

| JP2020114661A (ja) | 被覆マンドレルパッケージ | |

| CN102869560B (zh) | 用于连接部件的方法 | |

| JP6329548B2 (ja) | 物品の製造システム、物品の製造方法およびパレット | |

| CN105899345B (zh) | 用于胶合车辆内饰件的方法和生产系统 | |

| US20180319099A1 (en) | Method for Increasing the Rigidity of Nonwoven Moldings by Way of Additive Manufacturing | |

| WO2021199696A1 (ja) | 繊維束貼り付け装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170202 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20170202 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20171204 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20171212 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180309 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20180605 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20180629 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6364027 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |