JP6339395B2 - Welding method for resin molded products - Google Patents

Welding method for resin molded products Download PDFInfo

- Publication number

- JP6339395B2 JP6339395B2 JP2014065038A JP2014065038A JP6339395B2 JP 6339395 B2 JP6339395 B2 JP 6339395B2 JP 2014065038 A JP2014065038 A JP 2014065038A JP 2014065038 A JP2014065038 A JP 2014065038A JP 6339395 B2 JP6339395 B2 JP 6339395B2

- Authority

- JP

- Japan

- Prior art keywords

- component

- plane

- welding

- resin molded

- molded product

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/02—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure

- B29C65/08—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure using ultrasonic vibrations

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/10—Particular design of joint configurations particular design of the joint cross-sections

- B29C66/12—Joint cross-sections combining only two joint-segments; Tongue and groove joints; Tenon and mortise joints; Stepped joint cross-sections

- B29C66/124—Tongue and groove joints

- B29C66/1244—Tongue and groove joints characterised by the male part, i.e. the part comprising the tongue

- B29C66/12449—Tongue and groove joints characterised by the male part, i.e. the part comprising the tongue being asymmetric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/10—Particular design of joint configurations particular design of the joint cross-sections

- B29C66/12—Joint cross-sections combining only two joint-segments; Tongue and groove joints; Tenon and mortise joints; Stepped joint cross-sections

- B29C66/124—Tongue and groove joints

- B29C66/1246—Tongue and groove joints characterised by the female part, i.e. the part comprising the groove

- B29C66/12469—Tongue and groove joints characterised by the female part, i.e. the part comprising the groove being asymmetric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/32—Measures for keeping the burr form under control; Avoiding burr formation; Shaping the burr

- B29C66/322—Providing cavities in the joined article to collect the burr

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/32—Measures for keeping the burr form under control; Avoiding burr formation; Shaping the burr

- B29C66/324—Avoiding burr formation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/50—General aspects of joining tubular articles; General aspects of joining long products, i.e. bars or profiled elements; General aspects of joining single elements to tubular articles, hollow articles or bars; General aspects of joining several hollow-preforms to form hollow or tubular articles

- B29C66/51—Joining tubular articles, profiled elements or bars; Joining single elements to tubular articles, hollow articles or bars; Joining several hollow-preforms to form hollow or tubular articles

- B29C66/54—Joining several hollow-preforms, e.g. half-shells, to form hollow articles, e.g. for making balls, containers; Joining several hollow-preforms, e.g. half-cylinders, to form tubular articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/80—General aspects of machine operations or constructions and parts thereof

- B29C66/83—General aspects of machine operations or constructions and parts thereof characterised by the movement of the joining or pressing tools

- B29C66/832—Reciprocating joining or pressing tools

- B29C66/8322—Joining or pressing tools reciprocating along one axis

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/18—Heat-exchangers or parts thereof

Description

本発明は、樹脂製の第1部品と第2部品とを超音波溶着機によって接合する接合方法に関する。 The present invention relates to a joining method in which a first part made of resin and a second part are joined by an ultrasonic welding machine.

一例として、樹脂製ラジエータキャップは、弁本体とキャップ本体とを夫々樹脂成形品で形成し、両者を嵌着し、その接合部を超音波溶着により接合することができる。

第1部品と第2部品とが夫々複雑な形状をしている場合、各部品ごとに成形し、両部品を接合することにより、より複雑な部品を完成することができる。

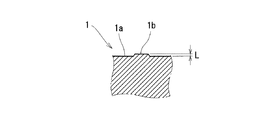

図6〜図8は従来の樹脂成形品の溶着方法であり、図6はその第1部品1の平面図、図7は同縦断面図である。

上記のような環状の第1部品1を射出成形により形成するには、図7に示す如く、成形用金型の中心から溶融した樹脂7を内部に注入し、それを図6に示す如く、複数の架橋部8を介して半径方向外側に導くことになる。

As an example, the resin-made radiator cap can form a valve main body and a cap main body by a resin molded product, respectively, can fit both, and can join the junction part by ultrasonic welding.

When the first part and the second part have complicated shapes, a more complicated part can be completed by molding each part and joining both parts.

6 to 8 show a conventional method of welding a resin molded product. FIG. 6 is a plan view of the

In order to form the annular

ところが、複数の架橋部8を介して溶融する樹脂7を環状部に供給するとき、その端面1aの表面に、僅かな凸部1bが形成されることがある。その凸部1bの高さは、一例として0.02mm(図3参照)程度で極めて僅かである。

ところが、その第1部品1の端面1aに超音波溶接機のホーン4(またはコーンともいう)を当接し、超音波振動を与えると、僅かな凸部1bが平坦に押圧され、図8の如く、凸部1bの端部が端面1aの外周に溶融部5として付着する。そのため、第1部品1の外周が不体裁になると共に、その溶融部5が分離して部品の各部に付着するおそれがある。

上記のような成形品が弁ユニットを内部に有するラジエータキャップであった場合であり、分離した溶融部5が部品内部に浸入したときは、その分離した溶融部5の侵入によりキャップ内に設けられる弁ユニットが動作不良を起こし、ラジエータキャップのシール性を損なうおそれがある。

そこで、本発明はこのような凸部1bが端面1aの表面に形成されても、超音波振動の際にそれが外部に飛び出さないようにして、体裁が良く、且つ溶着不良が生じ難い成形品を提供することを課題とする。

However, when the

However, when the horn 4 (or cone) of the ultrasonic welder is brought into contact with the

This is a case where the molded product as described above is a radiator cap having a valve unit therein, and when the separated melted

Therefore, even if such a

請求項1に記載の本発明は、それぞれ樹脂成形品よりなる第1部品1と第2部品2とを超音波溶着機により、互いに接合する方法において、

第1部品1の軸線に直行する端面1aが、略環状の平面に形成され、その平面に対して僅かに突出する凸部1bが前記軸線に対して放射状に互いに離間して、その平面上に複数存在するものであって、

前記端面1aの外周縁又は内周縁の少なくとも一方に、前記平面に対して凹陥する環状の段部3を形成しておく工程と、

前記第1部品1と前記第2部品2とを接触させ、溶着機のホーン4を第1部品1の前記端面1aに当接し、複数の各凸部1bを押圧しつつ、前記第1部品1および前記第2部品2間に超音波振動を与える溶着工程と、

を、具備し、

前記各凸部1bが超音波振動により平面に押込まれて平面に面一に形成され、各凸部1bの変形に伴い、前記各凸部1bの端部から生じる溶融樹脂を前記段部3内に留まるように溶着して、凸部1bの端部から生じる溶融樹脂が第1部品の端面の外周縁又は内周縁の少なくとも一方から、半径方向の外側又は内側の少なくとも一方に突出しないようにした樹脂成形品の溶着方法である。

The present invention according to

An

On at least the outer periphery or the inner periphery of the

Contacting the

Comprising

Each

請求項2に記載の本発明は、請求項1に記載の樹脂成形品の溶着方法において、

前記第1部品(1)は、ラジエータキャップの弁本体であり、

前記第2部品(2)は、ラジエータキャップのキャップ本体であり、

前記段部(3)を、前記第1部品(1)である弁本体の端面(1a)の外周縁および内周縁に、予め環状に形成しておいたことを特徴とする樹脂成形品の溶着方法である。

According to a second aspect of the present invention, in the method for welding a resin molded product according to the first aspect,

The first part (1) is a valve body of a radiator cap;

The second part (2) is a cap body of a radiator cap,

The step (3) is formed in a ring shape in advance on the outer and inner peripheral edges of the end surface (1a) of the valve body which is the first component (1). Is the method.

本発明の樹脂成形品の溶着方法によれば、ホーン4が当接する第1部品の端面1aの凸部1bが溶着されるとき、その端部から生じる溶融樹脂が段部3内に留まるように収納され、その凸部1bの端部から生じる溶融樹脂が部品の外周に押し出されることを防止し、体裁のよい樹脂成形品となる。即ち、溶着工程で、第1部品1の端面1aの凸部1bが、端面1aと面一に形成されたとき、その凸部1bの端部から生じる溶融樹脂が、周縁に設けた段部3に溶着され、それが外部に飛び出ることがない。また、このように凸部1bの端部から生じる溶融樹脂を段部3に溶着した場合、その凸部1bの端部から生じる溶融樹脂が分離して部品の内部に浸入することを防止することができるため、溶着不良が生じ難い樹脂成型品を提供できる。

一例として、ラジエータキャップの場合は、凸部1bの端部から生じうる溶融部5が内部に侵入することを防止できるため、そのシール性が損なわれることを効果的に防止しうる。

According to the welding method of the resin molded product of the present invention, when the

As an example, in the case of a radiator cap, it is possible to prevent the melted

請求項2に記載の樹脂成形品の溶着方法によれば、段部3を、前記第1部品1である弁本体の端面1aの外周縁および内周縁に、予め環状に形成しておいたので、凸部1bの端部から生じる溶融樹脂を、周縁に設けた段部3に確実に溶着することができる。

According to the welding method of the resin molded article according to

次に、図面に基づいて本発明の実施の形態につき説明する。

本実施例は、一例として、ラジエータ等のフィラーネック部に着脱自在に装着され、一対の分割体からなるラジエータキャップについて説明する。

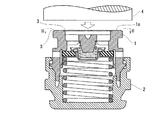

図1は、第1部品1としてラジエータの弁本体と、第2部品2として同キャップ本体とを、図示しない超音波溶接機を介して接合する説明図である。

先ず、第1部品1と第2部品2とを嵌着する。それらの間には、予め、弁ユニットが介装されている。この弁ユニットは、図1の如く、負圧弁と正圧弁が環状の弁座を介して対向しており、それらの弁が負圧スプリングと正圧スプリングにより付勢されている。この時点では、第1部品1と第2部品2とは固定されていない。

その第1部品1の端面1aの表面には、凸部1bが放射方向に複数形成されている。この凸部1bは、図3に示す如く、その高さが一例として0.02mm程度の極めて僅かなものである。

Next, embodiments of the present invention will be described with reference to the drawings.

In the present embodiment, as an example, a description will be given of a radiator cap that is detachably attached to a filler neck portion such as a radiator and includes a pair of divided bodies.

FIG. 1 is an explanatory view for joining a valve body of a radiator as a

First, the

On the surface of the

次に、この発明では、第1部品1の端面1aの外周及び内周には、僅かな段差である段部3が図1及び図2に示す如く形成されている。そして、図示しない超音波溶着機のホーン4を第1部品1の端面1aに当接し、第1部品1及び第2部品2間に超音波振動を与える。

前述の僅かな凸部1bはその振動によって、端面1aの平面内に押し込まれて平坦に形成される。それと共に、図4又は図5の如く、その凸部1bの両端部から生じうる溶融部5は段部3に溶着し、そこに溶融部5が保持される。そのため、超音波振動時に第1部品1の内周側及び外周側に流出した溶融部5は、そこから外部に飛び出ることがない。それにより、体裁の良い溶着が行われる。さらに、ラジエータキャップの内部に溶融部5が侵入することを防止することができるため、弁ユニットの動作に影響を及ぼすことがない。

このとき、図1において第1部品1の下端部は環状の凸部に形成され、第2部品2の上端部は環状の溝部に形成され、両者が同図の如く嵌着している。そして超音波振動によって、両者の嵌着部が溶着する。それにより、第1部品1と第2部品2とは一体化される。

Next, in the present invention,

The

At this time, in FIG. 1, the lower end portion of the

さらに、図1に記載の如く、第1部品1の端面1aの位置は、負スプリングが載置されるスプリング座の端面と架橋部8の端面の位置から高さをずらして設けられている(この図では、端面1aの位置がスプリング座の端面より上方に環状に突出している、これに対し、従来技術の図7では、端面1aとスプリング座と架橋部8が略面一に形成されている。)。このような構造とした場合、ホーン4の当接する面が端面1aのみとなるので、端面1aに段部3の加工を行えばよく、樹脂製ラジエータキャップの製造が容易となり、且つ、凸部1bの端部から生じうる溶融部5を確実に段部3に溶着することが可能となる。

Furthermore, as shown in FIG. 1, the position of the

1 第1部品

1a 端面

1b 凸部

2 第2部品

3 段部

4 ホーン

5 溶融部

6 樹脂流れ

7 樹脂

8 架橋部

1 First part

1a End face

Claims (2)

第1部品(1)の軸線に直行する端面(1a)が、略環状の平面に形成され、その平面に対して僅かに突出する凸部(1b)が前記軸線に対して放射状に互いに離間して、その平面上に複数存在するものであって、

前記端面(1a)の外周縁又は内周縁の少なくとも一方に、前記平面に対して凹陥する環状の段部(3)を形成しておく工程と、

前記第1部品(1)と前記第2部品(2)とを接触させ、溶着機のホーン(4)を第1部品(1)の前記端面(1a)に当接し、複数の各凸部(1b)を押圧しつつ、前記第1部品(1)および前記第2部品(2)間に超音波振動を与える溶着工程と、

を、具備し、

前記各凸部(1b)が超音波振動により平面に押込まれて平面に面一に形成され、各凸部(1b)の変形に伴い、前記各凸部(1b)の端部から生じる溶融樹脂を前記段部(3)内に留まるように溶着して、凸部(1b)の端部から生じる溶融樹脂が第1部品の端面の外周縁又は内周縁の少なくとも一方から、半径方向の外側又は内側の少なくとも一方に突出しないようにした樹脂成形品の溶着方法。 In a method of joining the first part (1) and the second part (2) each made of a resin molded product to each other by an ultrasonic welding machine,

An end face (1a) perpendicular to the axis of the first component (1) is formed in a substantially annular plane, and convex portions (1b) slightly projecting from the plane are radially separated from the axis. And there are multiple on the plane,

At least one of the outer periphery or inner periphery of said end face (1a), a step to be formed a stepped portion of the annular shape recessed to (3) to the plane,

Wherein the first component (1) and the second part (2) and brought into contact with the end face (1a) in contact with a plurality of the convex portions of the horn (4) of the welding machine first component (1) ( while pressing the 1b), and the welding step of Ru applying ultrasonic vibrations while said first component (1) and the second part (2),

Comprising

Wherein each of the convex portions (1b) is formed flush to the plane to the plane pushed by the ultrasonic vibration, with the deformation of the convex portions (1b), the molten resin resulting from the end of each protrusion (1b) Is welded so as to remain in the step (3), and the molten resin generated from the end of the convex portion (1b) is radially outward from the outer periphery or the inner periphery of the end surface of the first part, A method of welding a resin molded product so as not to protrude to at least one of the inner sides.

前記第1部品(1)は、ラジエータキャップの弁本体であり、

前記第2部品(2)は、ラジエータキャップのキャップ本体であり、

前記段部(3)を、前記第1部品(1)である弁本体の端面(1a)の外周縁および内周縁に、予め環状に形成しておいたことを特徴とする樹脂成形品の溶着方法。 In the welding method of the resin molded product according to claim 1,

The first part (1) is a valve body of a radiator cap;

The second part (2) is a cap body of a radiator cap,

The step (3) is formed in a ring shape in advance on the outer and inner peripheral edges of the end surface (1a) of the valve body which is the first component (1). Method.

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014065038A JP6339395B2 (en) | 2014-03-27 | 2014-03-27 | Welding method for resin molded products |

| PCT/JP2015/056573 WO2015146530A1 (en) | 2014-03-27 | 2015-02-26 | Welding method for resin molding |

| CN201580016059.2A CN106132667B (en) | 2014-03-27 | 2015-02-26 | The welding process of resin forming product |

| TW104109171A TWI613062B (en) | 2014-03-27 | 2015-03-23 | Welding method of resin molded article |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014065038A JP6339395B2 (en) | 2014-03-27 | 2014-03-27 | Welding method for resin molded products |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2015186872A JP2015186872A (en) | 2015-10-29 |

| JP2015186872A5 JP2015186872A5 (en) | 2017-04-27 |

| JP6339395B2 true JP6339395B2 (en) | 2018-06-06 |

Family

ID=54195059

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014065038A Active JP6339395B2 (en) | 2014-03-27 | 2014-03-27 | Welding method for resin molded products |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JP6339395B2 (en) |

| CN (1) | CN106132667B (en) |

| TW (1) | TWI613062B (en) |

| WO (1) | WO2015146530A1 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2016022995A (en) * | 2014-07-25 | 2016-02-08 | 株式会社カネカ | Airtight pressure-resistant container |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2527238B2 (en) * | 1989-05-30 | 1996-08-21 | 株式会社小糸製作所 | Ultrasonic welding method, ultrasonic horn, and ultrasonic welder |

| JPH1110742A (en) * | 1997-06-24 | 1999-01-19 | Fuji Photo Film Co Ltd | Method and apparatus of welding reel for magnetic tape cartridge |

| JP4132353B2 (en) * | 1999-02-22 | 2008-08-13 | 株式会社小糸製作所 | Vehicle lighting lens |

| JP2003137205A (en) * | 2001-11-06 | 2003-05-14 | Ricoh Co Ltd | Ultrasonic welding method and toner case |

| JP2005007623A (en) * | 2003-06-17 | 2005-01-13 | Aisan Ind Co Ltd | Welded structure of three members |

| JP2005169721A (en) * | 2003-12-09 | 2005-06-30 | Kojima Press Co Ltd | Vibration welding apparatus and vibration welding method |

| CN2894917Y (en) * | 2006-01-13 | 2007-05-02 | 陈岳文 | Translational welding type ultrasonic welded template |

| GB2446385A (en) * | 2007-02-12 | 2008-08-13 | Inbev Sa | Laser welding valve assembly to beer keg |

| JP2008238437A (en) * | 2007-03-26 | 2008-10-09 | Toray Ind Inc | Method for manufacturing container |

| JP5302056B2 (en) * | 2009-03-11 | 2013-10-02 | オリンパス株式会社 | Pipe joining method and pipe joining structure |

| DE102011005997A1 (en) * | 2011-03-23 | 2012-09-27 | Robert Bosch Gmbh | Method for attaching an opening and closing device to a tubular bag by means of ultrasonic welding |

-

2014

- 2014-03-27 JP JP2014065038A patent/JP6339395B2/en active Active

-

2015

- 2015-02-26 CN CN201580016059.2A patent/CN106132667B/en active Active

- 2015-02-26 WO PCT/JP2015/056573 patent/WO2015146530A1/en active Application Filing

- 2015-03-23 TW TW104109171A patent/TWI613062B/en active

Also Published As

| Publication number | Publication date |

|---|---|

| WO2015146530A1 (en) | 2015-10-01 |

| CN106132667A (en) | 2016-11-16 |

| CN106132667B (en) | 2018-07-27 |

| TWI613062B (en) | 2018-02-01 |

| JP2015186872A (en) | 2015-10-29 |

| TW201600315A (en) | 2016-01-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2008155587A (en) | Manufacturing method of hollow resin molded product | |

| JP6339395B2 (en) | Welding method for resin molded products | |

| KR101418914B1 (en) | fusion welding structure of components in door trim | |

| JP5426143B2 (en) | Manufacturing method of injection molded body | |

| JP2019535359A (en) | Integrated razor cartridge | |

| JP6513759B2 (en) | Resin tank | |

| JP2012192604A (en) | Injection molding method | |

| KR101795577B1 (en) | Weldind structure of vehicle interior | |

| WO2017141385A1 (en) | Welded joint structure for automotive interior parts | |

| US10981616B2 (en) | Resin-made fuel tank | |

| JP2015186872A5 (en) | ||

| JP5656896B2 (en) | Joining method of plastic parts | |

| JP5122828B2 (en) | Manufacturing method of injection molded body and injection molded body manufactured thereby | |

| JP6393552B2 (en) | Bonding structure of synthetic resin parts | |

| TWI687273B (en) | Diffuser for fluid-operated pump and method of manufacturing the same | |

| KR101774088B1 (en) | Plastic tank, method and system for welding palstic tank | |

| JP6598656B2 (en) | Diaphragm valve and manufacturing method thereof | |

| WO2018092851A1 (en) | Resin product | |

| JP6379992B2 (en) | Resin welded structure and manufacturing method thereof | |

| JP4905005B2 (en) | Member joining structure to fuel tank, fuel tank manufacturing method, and member joining method to fuel tank | |

| JP2019081301A (en) | Joined body and manufacturing method of joined body | |

| JP6704885B2 (en) | Resin fuel tank | |

| US20190337236A1 (en) | Plastic Containing Assembly Having Filler Material Arrangement for Welding | |

| JP5369081B2 (en) | Fuel tank component joining method | |

| TH69333B (en) | Welding method for resin molding |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170322 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20170322 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20180320 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180413 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20180508 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20180510 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6339395 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |