JP6284765B2 - 波状の構造物 - Google Patents

波状の構造物 Download PDFInfo

- Publication number

- JP6284765B2 JP6284765B2 JP2013529513A JP2013529513A JP6284765B2 JP 6284765 B2 JP6284765 B2 JP 6284765B2 JP 2013529513 A JP2013529513 A JP 2013529513A JP 2013529513 A JP2013529513 A JP 2013529513A JP 6284765 B2 JP6284765 B2 JP 6284765B2

- Authority

- JP

- Japan

- Prior art keywords

- sheet

- strain

- shape

- corrugated shape

- strained

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 claims description 31

- 230000035882 stress Effects 0.000 claims description 28

- 239000000463 material Substances 0.000 claims description 17

- 238000004891 communication Methods 0.000 claims description 13

- 238000004519 manufacturing process Methods 0.000 claims description 10

- 230000001939 inductive effect Effects 0.000 claims description 9

- 230000002829 reductive effect Effects 0.000 claims description 4

- 238000005096 rolling process Methods 0.000 claims description 4

- 238000009987 spinning Methods 0.000 claims description 3

- 230000006355 external stress Effects 0.000 claims description 2

- 239000012530 fluid Substances 0.000 description 52

- 230000007246 mechanism Effects 0.000 description 17

- 230000002093 peripheral effect Effects 0.000 description 12

- 230000006870 function Effects 0.000 description 11

- 238000010438 heat treatment Methods 0.000 description 11

- 238000010586 diagram Methods 0.000 description 10

- 230000036961 partial effect Effects 0.000 description 10

- 230000008901 benefit Effects 0.000 description 9

- 239000007787 solid Substances 0.000 description 9

- 230000007935 neutral effect Effects 0.000 description 8

- 239000012781 shape memory material Substances 0.000 description 7

- 230000008569 process Effects 0.000 description 6

- 230000001629 suppression Effects 0.000 description 6

- 230000009471 action Effects 0.000 description 5

- 230000008859 change Effects 0.000 description 5

- 238000013519 translation Methods 0.000 description 5

- 238000005452 bending Methods 0.000 description 4

- 238000013461 design Methods 0.000 description 4

- 239000004033 plastic Substances 0.000 description 4

- 241000251468 Actinopterygii Species 0.000 description 3

- 238000009826 distribution Methods 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 229920001971 elastomer Polymers 0.000 description 3

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- 230000001133 acceleration Effects 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 2

- 230000001070 adhesive effect Effects 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 238000005304 joining Methods 0.000 description 2

- 239000003550 marker Substances 0.000 description 2

- 239000012778 molding material Substances 0.000 description 2

- 230000004044 response Effects 0.000 description 2

- 230000002441 reversible effect Effects 0.000 description 2

- 230000003068 static effect Effects 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 230000001131 transforming effect Effects 0.000 description 2

- 230000032258 transport Effects 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 238000003462 Bender reaction Methods 0.000 description 1

- 241000218645 Cedrus Species 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 229920001131 Pulp (paper) Polymers 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- 230000004913 activation Effects 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 210000004690 animal fin Anatomy 0.000 description 1

- 230000002238 attenuated effect Effects 0.000 description 1

- 230000006399 behavior Effects 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 238000012937 correction Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000001723 curing Methods 0.000 description 1

- 238000013016 damping Methods 0.000 description 1

- 230000007812 deficiency Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000001066 destructive effect Effects 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 239000000806 elastomer Substances 0.000 description 1

- 238000010292 electrical insulation Methods 0.000 description 1

- 229920001746 electroactive polymer Polymers 0.000 description 1

- 230000002708 enhancing effect Effects 0.000 description 1

- 230000003628 erosive effect Effects 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 238000007654 immersion Methods 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 238000009940 knitting Methods 0.000 description 1

- 230000000670 limiting effect Effects 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 238000013017 mechanical damping Methods 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 230000003446 memory effect Effects 0.000 description 1

- 230000007334 memory performance Effects 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 238000012552 review Methods 0.000 description 1

- 238000005480 shot peening Methods 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 239000010936 titanium Substances 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

- 239000002918 waste heat Substances 0.000 description 1

- 238000009941 weaving Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B06—GENERATING OR TRANSMITTING MECHANICAL VIBRATIONS IN GENERAL

- B06B—METHODS OR APPARATUS FOR GENERATING OR TRANSMITTING MECHANICAL VIBRATIONS OF INFRASONIC, SONIC, OR ULTRASONIC FREQUENCY, e.g. FOR PERFORMING MECHANICAL WORK IN GENERAL

- B06B3/00—Methods or apparatus specially adapted for transmitting mechanical vibrations of infrasonic, sonic, or ultrasonic frequency

- B06B3/02—Methods or apparatus specially adapted for transmitting mechanical vibrations of infrasonic, sonic, or ultrasonic frequency involving a change of amplitude

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B19/00—Machines or pumps having pertinent characteristics not provided for in, or of interest apart from, groups F04B1/00 - F04B17/00

- F04B19/20—Other positive-displacement pumps

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B06—GENERATING OR TRANSMITTING MECHANICAL VIBRATIONS IN GENERAL

- B06B—METHODS OR APPARATUS FOR GENERATING OR TRANSMITTING MECHANICAL VIBRATIONS OF INFRASONIC, SONIC, OR ULTRASONIC FREQUENCY, e.g. FOR PERFORMING MECHANICAL WORK IN GENERAL

- B06B1/00—Methods or apparatus for generating mechanical vibrations of infrasonic, sonic, or ultrasonic frequency

- B06B1/10—Methods or apparatus for generating mechanical vibrations of infrasonic, sonic, or ultrasonic frequency making use of mechanical energy

- B06B1/12—Methods or apparatus for generating mechanical vibrations of infrasonic, sonic, or ultrasonic frequency making use of mechanical energy operating with systems involving reciprocating masses

- B06B1/14—Methods or apparatus for generating mechanical vibrations of infrasonic, sonic, or ultrasonic frequency making use of mechanical energy operating with systems involving reciprocating masses the masses being elastically coupled

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F03—MACHINES OR ENGINES FOR LIQUIDS; WIND, SPRING, OR WEIGHT MOTORS; PRODUCING MECHANICAL POWER OR A REACTIVE PROPULSIVE THRUST, NOT OTHERWISE PROVIDED FOR

- F03G—SPRING, WEIGHT, INERTIA OR LIKE MOTORS; MECHANICAL-POWER PRODUCING DEVICES OR MECHANISMS, NOT OTHERWISE PROVIDED FOR OR USING ENERGY SOURCES NOT OTHERWISE PROVIDED FOR

- F03G7/00—Mechanical-power-producing mechanisms, not otherwise provided for or using energy sources not otherwise provided for

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F03—MACHINES OR ENGINES FOR LIQUIDS; WIND, SPRING, OR WEIGHT MOTORS; PRODUCING MECHANICAL POWER OR A REACTIVE PROPULSIVE THRUST, NOT OTHERWISE PROVIDED FOR

- F03G—SPRING, WEIGHT, INERTIA OR LIKE MOTORS; MECHANICAL-POWER PRODUCING DEVICES OR MECHANISMS, NOT OTHERWISE PROVIDED FOR OR USING ENERGY SOURCES NOT OTHERWISE PROVIDED FOR

- F03G7/00—Mechanical-power-producing mechanisms, not otherwise provided for or using energy sources not otherwise provided for

- F03G7/025—Mechanical-power-producing mechanisms, not otherwise provided for or using energy sources not otherwise provided for characterised by its use

- F03G7/0254—Mechanical-power-producing mechanisms, not otherwise provided for or using energy sources not otherwise provided for characterised by its use pumping or compressing fluids, e.g. microfluidic devices

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F03—MACHINES OR ENGINES FOR LIQUIDS; WIND, SPRING, OR WEIGHT MOTORS; PRODUCING MECHANICAL POWER OR A REACTIVE PROPULSIVE THRUST, NOT OTHERWISE PROVIDED FOR

- F03G—SPRING, WEIGHT, INERTIA OR LIKE MOTORS; MECHANICAL-POWER PRODUCING DEVICES OR MECHANISMS, NOT OTHERWISE PROVIDED FOR OR USING ENERGY SOURCES NOT OTHERWISE PROVIDED FOR

- F03G7/00—Mechanical-power-producing mechanisms, not otherwise provided for or using energy sources not otherwise provided for

- F03G7/06—Mechanical-power-producing mechanisms, not otherwise provided for or using energy sources not otherwise provided for using expansion or contraction of bodies due to heating, cooling, moistening, drying or the like

- F03G7/061—Mechanical-power-producing mechanisms, not otherwise provided for or using energy sources not otherwise provided for using expansion or contraction of bodies due to heating, cooling, moistening, drying or the like characterised by the actuating element

- F03G7/0614—Mechanical-power-producing mechanisms, not otherwise provided for or using energy sources not otherwise provided for using expansion or contraction of bodies due to heating, cooling, moistening, drying or the like characterised by the actuating element using shape memory elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F03—MACHINES OR ENGINES FOR LIQUIDS; WIND, SPRING, OR WEIGHT MOTORS; PRODUCING MECHANICAL POWER OR A REACTIVE PROPULSIVE THRUST, NOT OTHERWISE PROVIDED FOR

- F03G—SPRING, WEIGHT, INERTIA OR LIKE MOTORS; MECHANICAL-POWER PRODUCING DEVICES OR MECHANISMS, NOT OTHERWISE PROVIDED FOR OR USING ENERGY SOURCES NOT OTHERWISE PROVIDED FOR

- F03G7/00—Mechanical-power-producing mechanisms, not otherwise provided for or using energy sources not otherwise provided for

- F03G7/06—Mechanical-power-producing mechanisms, not otherwise provided for or using energy sources not otherwise provided for using expansion or contraction of bodies due to heating, cooling, moistening, drying or the like

- F03G7/065—Mechanical-power-producing mechanisms, not otherwise provided for or using energy sources not otherwise provided for using expansion or contraction of bodies due to heating, cooling, moistening, drying or the like using a shape memory element

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B43/00—Machines, pumps, or pumping installations having flexible working members

- F04B43/0009—Special features

- F04B43/0054—Special features particularities of the flexible members

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16H—GEARING

- F16H35/00—Gearings or mechanisms with other special functional features

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49826—Assembling or joining

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T74/00—Machine element or mechanism

- Y10T74/18—Mechanical movements

- Y10T74/18888—Reciprocating to or from oscillating

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Dispersion Chemistry (AREA)

- Reciprocating Pumps (AREA)

- General Electrical Machinery Utilizing Piezoelectricity, Electrostriction Or Magnetostriction (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

- User Interface Of Digital Computer (AREA)

- Aerials With Secondary Devices (AREA)

- Micromachines (AREA)

Description

波型形状を有する歪みシートと、

歪みシートを波状様式に変形させるために歪みシートと連通する1つ又はそれ以上の作業入力要素であって、波型形状上の一連の点のそれぞれが、少なくとも部分的に、共通の座標系に対して8字形状経路に沿って移動する、1つ又はそれ以上の作業入力要素と、を備える。

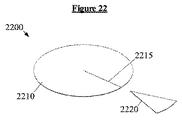

鞍点を有する歪みシートであって、鞍点に隣接する歪みシートの或る区分は、鞍形状を有する、歪みシートと、

歪みシートを変形させることで鞍点に対して前述の区分の鞍形状を回転可能に再度方向付けるように働く歪みシートの区分に接続される1つ又はそれ以上の作業入力要素と、を備える。

これらの実施形態では、歪みシートは、機械と連通する、1つ又はそれ以上の作業入力要素と1つ又はそれ以上の本体との間に機械的利点を提供するように作られた機械式変圧器として働き得る。

歪み応力をその中に誘発することで柔軟性シートに波型形状を形成する段階と、

波型形状上の一連の点のそれぞれが、少なくとも部分的に、共通の座標系に対して8字形状経路に沿って移動するようにさせるために、柔軟性シートと連通する少なくとも1つの作業入力要素を提供する段階と、を備える。

図5Bは、作動中の装置500の動作を示しており、動きの時系列510が歪みシート110の変形経路を示す。

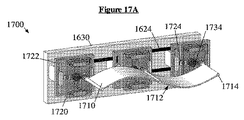

歪み細片1010は、線形区分から見ると波型形状1014を有しており、これは、縦方向縁部1012から横方向の振幅を大きくする。図示する実施形態では、歪み細片1010には波型形状1014があり、2つの波長を有しているが、別の実施形態では、非整数値を含む異なる数の波長を有していてもよい。構造物1000は、中に埋め込まれる、又は代替実施形態では歪み細片1010の面に取り付けられる複数の周期的に作動可能な抵抗加熱要素1030を更に備える。歪み細片1010の形状記憶部分は、歪み細片1010を波状様式に変形するための作業入力要素として働くために、加熱要素1030によって特有の様式で活性化され得る。歪み細片1010と連通する流体1040は、熱だめとして働く。この熱だめは、加熱要素1030によって活発に加熱されていない歪み細片1010の一部を冷却することによって歪み細片1010の形状記憶を局部的に不活性にするためのものである。流体1040は、歪み細片1010が変形される場合にその上で作業を実行することができる本体として働いてもよい。随意的に、加熱要素1030は、図21を参照して後で説明するように、歪み細片1010から電気的に絶縁されてもよい。

歪み細片1010を観察すると、正弦波形状1014の各半波長の3分の1が残りの3分の2と比べて比較的直線的であることが分かる。これに対応して、加熱要素1030は、形状記憶効果を用いて局部的な歪み取り応力を生み出すために、波長の6分の1ごとの間隔で歪み細片1010中に作られているので、歪み細片1010を波状様式に変形することができる。一連の電気波形1110は、第1位相1120、第2位相1130及び第3位相1140を備えており、これらの位相は、電気コネクタ1150を通る、歪み細片1010の各半波長の第3、第2及び第1の加熱要素1030への接続に関するものである。

様々な目的で、位相1120、1130及び1140のこの基本的形状に変形を加えることができ、目的として、エネルギー効率の最大化、円滑な周波中の電力供給、過熱保護、及び過大応力保護が含まれる。前述の変形には、パルス幅変調、振幅変調、及び位相1120、1130及び1140間の順次処理の前進又は遅延のための時間変化1160が、これらに限定するわけではないが含まれる。示している構造物1000の実施形態では、一連の電気波形1110は、歪み細片1010の開ループ制御を提供するが、温度又は位置に関するフィードバック等のフィードバックは、閉ループ制御用に含まれる。

Claims (18)

- 構造物において、

波型形状を有する歪みシート、及び

前記歪みシートを波状様式に変形させるために前記歪みシートと連通する少なくとも3つの作業入力要素であって、前記歪みシートの前記波型形状上の少なくとも3つの点の自由度を抑制する、前記少なくとも3つの作業入力要素により、前記波型形状上の一連の点のそれぞれが、少なくとも部分的に、8字形状経路に沿って移動する、少なくとも3つの作業入力要素、

を備える構造物。 - 前記歪みシートは、等方性機械的特性を有する材料を備える、請求項1に記載の構造物。

- 前記歪みシートは、正弦波形状である波型形状を有する、請求項1に記載の構造物。

- 前記歪みシートは、前記歪みシートの或る区分から見て波型形状を有し、前記区分は、円周の、線形の、及び曲線状の、から成る群から選択される形状を有する、請求項1に記載の構造物。

- 前記歪みシートは、前記歪みシートの或る区分から見ると波型形状を有し、前記波型形状は振幅を有し、前記振幅は、記区分から垂直に伸びる方向において、実質的に一定の、単調な、及び波形に変化する、から成る群から選択される方法で特徴付けられる、請求項1に記載の構造物。

- 構造物において、

波型形状を有する歪みシートであり、前記波型形状は変化する振幅を有し、前記変化する振幅は前記歪みシート上の静止位置においてゼロに減少し、前記歪みシートは、前記静止位置において支持部に固定的に接続される、歪みシート、及び

前記歪みシートを波状様式に変形させるために前記歪みシートと連通する1つ又はそれ以上の作業入力要素であって、前記波型形状上の一連の点のそれぞれが、少なくとも部分的に、8字形状経路に沿って移動する、1つ又はそれ以上の作業入力要素、

を備える構造物。 - 構造物において、

鞍点を有する歪みシートであって、前記鞍点に隣接する前記歪みシートの区分が鞍形状を有する、歪みシート、及び

前記歪みシートを変形させることで前記鞍点に対して前記区分の鞍形状を回転可能に再度方向付けるように働く前記鞍形状を有する前記歪みシートの前記区分に接続される1つ又はそれ以上の作業入力要素、

を備える構造物。 - 前記歪みシートは、前記歪みシートの中心において支持シャフトに固定的に接続される、請求項7に記載の構造物。

- 前記歪みシートは、実質的に一定の総歪みエネルギーで波状様式に変形可能であるので、前記歪みシートが弾性復元力の大きな抵抗なく変形され得る、請求項1から8の何れかに記載の構造物。

- 前記構造物は、以下に示す、変換器、アクチュエータ、センサー、発電機、ファン、ポンプ、拡声器、熱機関、及び推進システムのうちの1つの形態である、請求項1から9の何れかに記載の構造物。

- 前記構造物は機械であり、前記機械は、前記歪みシートが波状様式に変形された結果として、前記歪みシートと連通する1つ又はそれ以上の本体上で作業を実行する、請求項1から9の何れかに記載の構造物。

- 前記歪みシートは、前記作業入力要素と前記1つ又はそれ以上の本体との間に機械的倍率を提供するように作られる機械式変圧器である、請求項11に記載の構造物。

- 構造物を製作する方法において、

歪み応力をその中に誘発することで柔軟性シートに波型形状を形成する段階、及び

前記歪みシートの前記波型形状上の少なくとも3つの点の自由度を抑制する、少なくとも3つの作業入力要素により、前記波型形状上の一連の点のそれぞれが、8字形状経路を移動するようにさせるために、前記柔軟性シートと連通する少なくとも3つの作業入力要素を提供する段階、

を含む方法。 - 前記波型形状は変化する振幅を有して形成され、前記変化する振幅は前記柔軟性シート上の静止位置においてゼロに低下し、

当該方法は、前記柔軟性シートを、前記静止位置において支持部に固定的に接続する段階を更に備える、請求項13に記載の方法。 - 弾性的に前記柔軟性シートの均衡を取る段階を更に備える、請求項13に記載の方法。

- 柔軟性シートに波型形状を形成する前記段階は、前記柔軟性シートに外部から応力を加える前記段階を備える、請求項13に記載の方法。

- 柔軟性シートに波型形状を形成する前記段階は、前記柔軟性シートに残留応力を誘発する前記段階を備える、請求項13に記載の方法。

- 前記柔軟性シートに残留応力を誘発する前記段階は、圧延、ピーニング、及びスピニングの前記群から選択される形成工程のうちの1つ又はそれ以上を含む、請求項17に記載の方法。

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AU2010904340 | 2010-09-27 | ||

| AU2010904340A AU2010904340A0 (en) | 2010-09-27 | Saddle-shaped mechanical transformers | |

| AU2011901482A AU2011901482A0 (en) | 2011-04-20 | Undulatory Machines | |

| AU2011901482 | 2011-04-20 | ||

| PCT/AU2011/001237 WO2012040775A1 (en) | 2010-09-27 | 2011-09-26 | Undulatory structures |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2013537950A JP2013537950A (ja) | 2013-10-07 |

| JP2013537950A5 JP2013537950A5 (ja) | 2014-11-06 |

| JP6284765B2 true JP6284765B2 (ja) | 2018-02-28 |

Family

ID=45891717

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013529513A Active JP6284765B2 (ja) | 2010-09-27 | 2011-09-26 | 波状の構造物 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US9744563B2 (ja) |

| EP (1) | EP2622219B1 (ja) |

| JP (1) | JP6284765B2 (ja) |

| CN (1) | CN103249947B (ja) |

| AU (1) | AU2011308078B2 (ja) |

| BR (1) | BR112013006386B1 (ja) |

| CA (1) | CA2813000C (ja) |

| WO (1) | WO2012040775A1 (ja) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20130093256A (ko) * | 2012-02-14 | 2013-08-22 | 서울대학교산학협력단 | 플래핑 기반 수중 로봇 |

| WO2014113666A1 (en) * | 2013-01-18 | 2014-07-24 | Lord Corporation | Devices, systems, and methods for active vibration control force, speed and vibration monitoring and control |

| US10284117B2 (en) | 2014-05-05 | 2019-05-07 | Genesis Advanced Technology Inc. | Buckling wave disk |

| JP2018513325A (ja) | 2015-04-15 | 2018-05-24 | ジェネシス ロボティクス エルエルピー | ウェーブアクチュエータ |

| US10288220B2 (en) * | 2015-08-27 | 2019-05-14 | City University Of Hong Kong | Multistable structure and a method for making thereof |

| WO2018130295A1 (en) * | 2017-01-13 | 2018-07-19 | MAX-PLANCK-Gesellschaft zur Förderung der Wissenschaften e.V. | Method of actuating a shape changeable member, shape changeable member and actuating system |

| US10148199B1 (en) * | 2017-05-15 | 2018-12-04 | Baoxiang Shan | Loop-band devices configured for motion |

| US10148142B1 (en) | 2017-05-15 | 2018-12-04 | Baoxiang Shan | Buckling loop rotary motor |

| US10487817B1 (en) | 2018-11-02 | 2019-11-26 | Baoxiang Shan | Methods for creating an undulating structure |

| CN110304223B (zh) * | 2019-07-04 | 2020-09-29 | 中国科学院自动化研究所 | 仿生机器蝠鲼 |

| CN110702152A (zh) * | 2019-11-11 | 2020-01-17 | 单保祥 | 创建起伏结构的方法 |

Family Cites Families (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3019834A (en) * | 1958-01-31 | 1962-02-06 | Cie De Pont A Mousson | Sheet-bending method and machine for the production of tubular elements |

| US3227598A (en) | 1960-12-02 | 1966-01-04 | Wayne F Robb | Core structure |

| US3316415A (en) * | 1965-07-01 | 1967-04-25 | John E Taylor | Solid medium thermal engines |

| US3343655A (en) | 1966-12-12 | 1967-09-26 | Thomas E Howard | Undulatory conveyor |

| GB1302541A (ja) * | 1969-02-07 | 1973-01-10 | ||

| US4010612A (en) | 1974-12-13 | 1977-03-08 | Dante J. Sandoval | Thermal motor |

| US3964316A (en) * | 1974-12-23 | 1976-06-22 | Rohr Industries, Inc. | Wave motion simulator |

| US4183153A (en) * | 1977-10-26 | 1980-01-15 | Dickson Lawrence J | Hyperbolic geometry model |

| CA1208269A (en) | 1982-02-25 | 1986-07-22 | Toshiiku Sashida | Motor device utilizing ultrasonic oscillation |

| US5431634A (en) * | 1992-03-06 | 1995-07-11 | Baxter International Inc. | Ambulatory pump |

| US5471721A (en) | 1993-02-23 | 1995-12-05 | Research Corporation Technologies, Inc. | Method for making monolithic prestressed ceramic devices |

| US5632841A (en) | 1995-04-04 | 1997-05-27 | The United States Of America As Represented By The Administrator Of The National Aeronautics And Space Administration | Thin layer composite unimorph ferroelectric driver and sensor |

| JPH0932719A (ja) | 1995-07-24 | 1997-02-04 | Furukawa Electric Co Ltd:The | 進行波発生装置および進行波発生方法 |

| GB2314591B (en) * | 1996-06-26 | 1999-10-27 | Poss Limited | Flexible tube pump |

| WO1998045677A2 (en) | 1997-02-28 | 1998-10-15 | The Penn State Research Foundation | Transducer structure with differing coupling coefficients feature |

| US6029294A (en) * | 1998-07-23 | 2000-02-29 | Saringer Research Inc. | Mechanism for generating wave motion |

| US6362559B1 (en) | 1999-02-12 | 2002-03-26 | Face International Corp. | Piezoelectric transformer with segmented electrodes |

| EP1179139B1 (de) * | 1999-05-17 | 2003-08-13 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Mikromechanische pumpe |

| JP3261458B2 (ja) * | 2000-02-22 | 2002-03-04 | 独立行政法人産業技術総合研究所 | 光駆動型アクチュエータ |

| JP4799795B2 (ja) * | 2000-05-22 | 2011-10-26 | 有限会社三輪サイエンス研究所 | 超音波照射装置 |

| US6655035B2 (en) | 2000-10-20 | 2003-12-02 | Continuum Photonics, Inc. | Piezoelectric generator |

| US7823682B2 (en) * | 2004-06-09 | 2010-11-02 | Gm Global Technology Operations, Inc. | Hood lift mechanisms utilizing active materials and methods of use |

| US7321185B2 (en) | 2005-03-04 | 2008-01-22 | United States Of America As Represented By The Administrator Of The National Aeronautics And Space Administration | Active multistable twisting device |

| US7626319B2 (en) | 2005-03-21 | 2009-12-01 | Artificial Muscle, Inc. | Three-dimensional electroactive polymer actuated devices |

| GB0612558D0 (en) | 2006-06-23 | 2006-08-02 | Univ Cambridge Tech | Multistable structural member and method for forming a multistable structural member |

| TWI485863B (zh) * | 2006-09-06 | 2015-05-21 | Univ Illinois | 半導互連及奈米薄膜中用於可延伸電子元件之控制彎曲結構 |

| CN203131450U (zh) | 2013-02-28 | 2013-08-14 | 宁波天瑞电器有限公司 | 一种工作灯 |

-

2011

- 2011-09-26 AU AU2011308078A patent/AU2011308078B2/en active Active

- 2011-09-26 EP EP11827812.6A patent/EP2622219B1/en active Active

- 2011-09-26 WO PCT/AU2011/001237 patent/WO2012040775A1/en active Application Filing

- 2011-09-26 JP JP2013529513A patent/JP6284765B2/ja active Active

- 2011-09-26 CN CN201180046617.1A patent/CN103249947B/zh active Active

- 2011-09-26 BR BR112013006386-6A patent/BR112013006386B1/pt active IP Right Grant

- 2011-09-26 CA CA2813000A patent/CA2813000C/en active Active

- 2011-09-26 US US13/824,333 patent/US9744563B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CA2813000C (en) | 2018-09-04 |

| CA2813000A1 (en) | 2012-04-05 |

| AU2011308078B2 (en) | 2015-10-01 |

| EP2622219A1 (en) | 2013-08-07 |

| AU2011308078A1 (en) | 2013-03-28 |

| BR112013006386B1 (pt) | 2020-12-15 |

| EP2622219A4 (en) | 2017-05-31 |

| US20130220074A1 (en) | 2013-08-29 |

| WO2012040775A1 (en) | 2012-04-05 |

| BR112013006386A2 (pt) | 2016-07-05 |

| CN103249947A (zh) | 2013-08-14 |

| JP2013537950A (ja) | 2013-10-07 |

| EP2622219B1 (en) | 2021-08-11 |

| CN103249947B (zh) | 2017-03-29 |

| US9744563B2 (en) | 2017-08-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6284765B2 (ja) | 波状の構造物 | |

| US7915790B2 (en) | Electroactive polymer transducers biased for increased output | |

| US6543110B1 (en) | Electroactive polymer fabrication | |

| US6781284B1 (en) | Electroactive polymer transducers and actuators | |

| US6583533B2 (en) | Electroactive polymer electrodes | |

| Wang et al. | Design, analysis and experimental performance of a novel stick-slip type piezoelectric rotary actuator based on variable force couple driving | |

| EP1848046B1 (en) | Transducers of electroactive polymers | |

| US7468575B2 (en) | Electroactive polymer electrodes | |

| WO2001006575A1 (en) | Improved electroactive polymers | |

| Nishioka et al. | Development of a pneumatic soft actuator with pleated inflatable structures | |

| Berselli et al. | Design of a single-acting constant-force actuator based on dielectric elastomers | |

| Jia et al. | A novel traveling wave piezoelectric actuated wheeled robot: design, theoretical analysis, and experimental investigation | |

| Glenn et al. | Development of a two-sided piezoelectric rotary ultrasonic motor for high torque | |

| Pirrotta et al. | Evaluation of the effect of preload force on resonance frequencies for a traveling wave ultrasonic motor | |

| Li et al. | Modeling of a micropump membrane with electrostatic actuator | |

| JP2007239717A (ja) | 熱発電装置 | |

| Kanada et al. | Flexible ultrasonic motor using an output coil spring slider | |

| Zhang et al. | Two-joint robot finger design based on multi-degree-of-freedom ultrasonic motors | |

| TWI404321B (zh) | 一種具有預壓元件之三自由度球狀超音波馬達裝置 | |

| WANG et al. | A Novel Dual-Rotor Ultrasonic Motor Applied for Underwater Propulsion | |

| JPH10113887A (ja) | マイクロマニピュレータとその駆動方法 | |

| Xu et al. | Torque for an electromechanical integrated harmonic piezodrive system | |

| Chen et al. | Analysis and Design of Stator of Traveling Wave Type Rotary Ultrasonic Motor | |

| Cheng et al. | A novel universal joint with PZT-driven cyclic symmetric stator | |

| CN105897041A (zh) | 一种具有半弯月形弹性体的定向驱动器 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140919 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20140919 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20150828 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150901 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20151130 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20160510 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160902 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20160914 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20161104 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20170919 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20171019 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20171114 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20180131 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6284765 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |