JP5836645B2 - 煙道ガス再循環を備えるコンバインドサイクル発電プラント - Google Patents

煙道ガス再循環を備えるコンバインドサイクル発電プラント Download PDFInfo

- Publication number

- JP5836645B2 JP5836645B2 JP2011117927A JP2011117927A JP5836645B2 JP 5836645 B2 JP5836645 B2 JP 5836645B2 JP 2011117927 A JP2011117927 A JP 2011117927A JP 2011117927 A JP2011117927 A JP 2011117927A JP 5836645 B2 JP5836645 B2 JP 5836645B2

- Authority

- JP

- Japan

- Prior art keywords

- flue gas

- gas

- fuel

- combustion

- oxygen

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C3/00—Gas-turbine plants characterised by the use of combustion products as the working fluid

- F02C3/34—Gas-turbine plants characterised by the use of combustion products as the working fluid with recycling of part of the working fluid, i.e. semi-closed cycles with combustion products in the closed part of the cycle

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01K—STEAM ENGINE PLANTS; STEAM ACCUMULATORS; ENGINE PLANTS NOT OTHERWISE PROVIDED FOR; ENGINES USING SPECIAL WORKING FLUIDS OR CYCLES

- F01K17/00—Using steam or condensate extracted or exhausted from steam engine plant

- F01K17/04—Using steam or condensate extracted or exhausted from steam engine plant for specific purposes other than heating

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01K—STEAM ENGINE PLANTS; STEAM ACCUMULATORS; ENGINE PLANTS NOT OTHERWISE PROVIDED FOR; ENGINES USING SPECIAL WORKING FLUIDS OR CYCLES

- F01K23/00—Plants characterised by more than one engine delivering power external to the plant, the engines being driven by different fluids

- F01K23/02—Plants characterised by more than one engine delivering power external to the plant, the engines being driven by different fluids the engine cycles being thermally coupled

- F01K23/06—Plants characterised by more than one engine delivering power external to the plant, the engines being driven by different fluids the engine cycles being thermally coupled combustion heat from one cycle heating the fluid in another cycle

- F01K23/10—Plants characterised by more than one engine delivering power external to the plant, the engines being driven by different fluids the engine cycles being thermally coupled combustion heat from one cycle heating the fluid in another cycle with exhaust fluid of one cycle heating the fluid in another cycle

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C3/00—Gas-turbine plants characterised by the use of combustion products as the working fluid

- F02C3/20—Gas-turbine plants characterised by the use of combustion products as the working fluid using a special fuel, oxidant, or dilution fluid to generate the combustion products

- F02C3/26—Gas-turbine plants characterised by the use of combustion products as the working fluid using a special fuel, oxidant, or dilution fluid to generate the combustion products the fuel or oxidant being solid or pulverulent, e.g. in slurry or suspension

- F02C3/28—Gas-turbine plants characterised by the use of combustion products as the working fluid using a special fuel, oxidant, or dilution fluid to generate the combustion products the fuel or oxidant being solid or pulverulent, e.g. in slurry or suspension using a separate gas producer for gasifying the fuel before combustion

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C6/00—Plural gas-turbine plants; Combinations of gas-turbine plants with other apparatus; Adaptations of gas-turbine plants for special use

- F02C6/003—Gas-turbine plants with heaters between turbine stages

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C9/00—Controlling gas-turbine plants; Controlling fuel supply in air- breathing jet-propulsion plants

- F02C9/16—Control of working fluid flow

- F02C9/24—Control of the pressure level in closed cycles

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E20/00—Combustion technologies with mitigation potential

- Y02E20/16—Combined cycle power plant [CCPP], or combined cycle gas turbine [CCGT]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E20/00—Combustion technologies with mitigation potential

- Y02E20/32—Direct CO2 mitigation

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Engine Equipment That Uses Special Cycles (AREA)

Description

2 周囲空気

3 圧縮機入口ガス

4 燃焼器

5 GTのための煙道ガス

6 ガスタービンGT

7 タービン

8 ガスタービンからの高温煙道ガス

9 HRSG(熱回収蒸気発生器)

10 (CO2捕捉システムへの)第2の部分流のための煙道ガスブロワ

11 第1の部分流のための煙道ガスブロワ(煙道ガス再循環)

12 バイパスフラップ又は弁

13 蒸気タービン

14 凝縮器

15 CO2捕捉のための蒸気抽出部

16 給水部

17 凝縮物戻しライン

18 CO2捕捉システム

19 HRSGからの煙道ガス

20 第2の部分流(CO2捕捉システムへの煙道ガスライン)

21 第1の部分流(煙道ガス再循環)

22 CO2除去された煙道ガス

23 (第2の部分流のための)煙道ガス冷却器

24 煙突への煙道ガスバイパス

25 第1の発電機

26 第2の発電機

27 (第1の部分流のための)再循環煙道ガス再冷却器

28 圧縮機出口圧力又は出口温度測定装置

29 煙道ガス分割装置

30 生蒸気

31 捕捉されたCO2

32 煙突

33 高圧タービン

34 第2の燃焼器

35 低圧タービン

36 入口空気CO2及び/又はO2測定装置

37 ガスタービン煙道ガスCO2及び/又はO2測定装置

38 HRSG煙道ガスCO2及び/又はO2測定装置

39 マニホールド

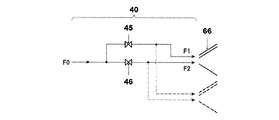

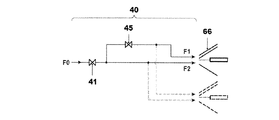

40 燃料分配システム

41 主燃料制御弁

45,46,47 制御弁

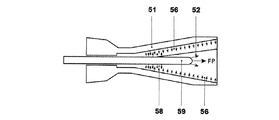

51 旋回ボディ

52 包囲空気

53 バーナ長手方向軸線

55 第1の供給導管

56 出口開口の第1のグループ

57 第2の供給導管

58 出口開口の第2のグループ

59 燃料ランス

60 燃料供給部

61 第1のバーナグループのためのマニホールド

62 第2のバーナグループのためのマニホールド

63 第1のバーナグループのための燃料制御弁

64 第2のバーナグループのための燃料制御弁

65 単一バーナ制御弁

66 バーナ

CCPP コンバインドサイクル発電プラント

F0 合計燃料量

F1,F2 燃料量

FP パイロット燃料量

n1 第1のグループにおける出口開口の数

n2 第2のグループにおける出口開口の数

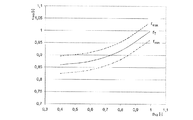

pk2 圧縮機出口圧力

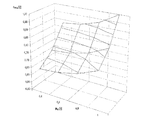

rFRG 煙道ガス再循環率

ri 課された燃焼不均一性比

rT 目標再循環率

rmin 最小再循環率

rmax 最大再循環率

Thot 高温ガス温度

Claims (15)

- ガスタービン(6)と、煙道ガス再循環システムを備えた熱回収蒸気発生器(9)とを有するコンバインドサイクル発電プラント(CCPP)を運転する方法において、煙道ガス再循環システムによってガスタービン(6)の圧縮機入口ガス(3)に再循環される煙道ガスの煙道ガス再循環率(rFRG)に関連して、課された燃焼不均一性比(ri)を制御することを特徴とする、コンバインドサイクル発電プラント(CCPP)を運転する方法。

- 前記課された燃焼不均一性比(ri)をさらに、燃焼器における高温ガス温度(Thot)に関連して制御しかつ/又は燃焼圧力(pk2)に関連して制御する、請求項1記載の方法。

- より高い煙道ガス再循環率(rFRG)を許容するためにガスタービン(6)のガスタービン圧縮機(1)の圧縮機入口ガス(3)及び/又はガスタービン(6)の燃焼器(4)に酸素又は酸素富化空気を混合する、請求項1又は2記載の方法。

- 圧縮機入口ガス(3)における目標酸素濃度を、課された燃焼不均一性比(ri)に関連して与え、圧縮機入口ガスにおける酸素濃度を、煙道ガス再循環率(rFRG)の変化及び/又は酸素又は酸素富化空気の混合によって制御する、請求項1から3までのいずれか1項記載の方法。

- 課された燃焼不均一性比(ri)及び/又は酸素又は酸素富化空気の混合を、測定されたCO及び/又は未燃炭化水素排出量に関連して調節する、請求項1から4までのいずれか1項記載の方法。

- 課された燃焼不均一性比(ri)を、測定された燃焼器脈動に関連して調節する、請求項1から5までのいずれか1項記載の方法。

- CO2捕捉システム(18)を通る所要の最小流量を保証するために煙道ガス再循環率(rFRG)を最大値よりも低く維持する、請求項1から6までのいずれか1項記載の方法。

- ガスタービン(6)の目標圧縮機入口温度を、相対負荷に関連して与え、圧縮機入口温度を、ガスタービン(6)の圧縮機入口ガス(3)へ再循環させられる、冷却された煙道ガスの再冷却温度(Trecool)を調節することによって制御する、請求項1から7までのいずれか1項記載の方法。

- 請求項1から8までのいずれか1項記載の運転方法のために設計されたコンバインドサイクル発電プラント(CCPP)において、ガスタービン(6)と、熱回収蒸気発生器(9)と、蒸気タービン(13)と、再循環煙道ガス再冷却器(27)を備えた煙道ガス再循環ラインと、少なくとも1つの圧縮機出口圧力及び/又は圧縮機出口温度測定装置と、再循環される煙道ガスと周囲空気との混合箇所とガスタービン(6)の圧縮機(1)との間の少なくとも1つの酸素及び/又はCO2測定装置(36)、及び/又はガスタービン(6)及び燃焼器(4,34)の下流に設けられた少なくとも1つの酸素及び/又はCO2測定装置(37,38)及び/又は少なくとも1つのCO及び/又は未燃炭化水素測定装置と、制御された燃焼不均一性を課すために構成された燃料分配システムを有することを特徴とする、コンバインドサイクル発電プラント(CCPP)。

- 少なくとも1つの燃焼器(4,34)におけるパイロット段及び/又は多段予混合ガス噴射を備えたガスタービン(6)が設けられている、請求項9記載のコンバインドサイクル発電プラント(CCPP)。

- 多段バーナグループを備えた少なくとも1つの燃焼器(4,34)を備えたガスタービン(6)が設けられている、請求項9または10記載のコンバインドサイクル発電プラント(CCPP)。

- 26よりも大きな設計圧縮機圧力比を備えるガスタービン(6)が設けられている、請求項9から11までのいずれか1項記載のコンバインドサイクル発電プラント(CCPP)。

- 15baraよりも大きな第2の燃焼器(34)の設計圧力を備える、順次燃焼ガスタービン(6)が設けられている、請求項9から12までのいずれか1項記載のコンバインドサイクル発電プラント(CCPP)。

- 再循環のための変速煙道ガスブロワ(11)及び/又はCO2捕捉システム(18)が設けられており、再循環率の制御のためのCO2捕捉システム(18)に送られる煙道ガスのためのCO2捕捉システム(10)への変速煙道ガスブロワが設けられている、請求項9から13までのいずれか1項記載のコンバインドサイクル発電プラント(CCPP)。

- 圧縮機(1)の圧縮機入口ガス(3)及び/又は燃焼器(4,34)又は圧縮機プレナムに酸素又は酸素富化空気を噴射するための噴射ポートが設けられている、請求項9から14までのいずれか1項記載のコンバインドサイクル発電プラント(CCPP)。

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH00841/10A CH703218A1 (de) | 2010-05-26 | 2010-05-26 | Verfahren zum Betreiben eines Gas-und-Dampf-Kombikraftwerk mit Rauchgasrezirkulation sowie Kraftwerk. |

| CH00841/10 | 2010-05-26 | ||

| CH01925/10 | 2010-11-17 | ||

| CH01925/10A CH704118A1 (de) | 2010-11-17 | 2010-11-17 | Verfahren zum Betreiben eines Kraftwerks mit kombiniertem Zyklus und mit Abgasrückführung. |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2011247265A JP2011247265A (ja) | 2011-12-08 |

| JP2011247265A5 JP2011247265A5 (ja) | 2015-05-14 |

| JP5836645B2 true JP5836645B2 (ja) | 2015-12-24 |

Family

ID=44924931

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011117927A Expired - Fee Related JP5836645B2 (ja) | 2010-05-26 | 2011-05-26 | 煙道ガス再循環を備えるコンバインドサイクル発電プラント |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US9828912B2 (ja) |

| JP (1) | JP5836645B2 (ja) |

| DE (1) | DE102011102720B4 (ja) |

Families Citing this family (44)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH703218A1 (de) | 2010-05-26 | 2011-11-30 | Alstom Technology Ltd | Verfahren zum Betreiben eines Gas-und-Dampf-Kombikraftwerk mit Rauchgasrezirkulation sowie Kraftwerk. |

| US9903316B2 (en) * | 2010-07-02 | 2018-02-27 | Exxonmobil Upstream Research Company | Stoichiometric combustion of enriched air with exhaust gas recirculation |

| SG186156A1 (en) * | 2010-07-02 | 2013-01-30 | Exxonmobil Upstream Res Co | Stoichiometric combustion with exhaust gas recirculation and direct contact cooler |

| SG186158A1 (en) * | 2010-07-02 | 2013-01-30 | Exxonmobil Upstream Res Co | Low emission power generation systems and methods |

| EP2568127B1 (en) * | 2011-09-07 | 2015-02-25 | Alstom Technology Ltd | Method for operating a power plant |

| EP2578839A1 (de) * | 2011-10-06 | 2013-04-10 | Alstom Technology Ltd | Verfahren zum Betrieb eines Gasturbinenkraftwerks mit Abgasrezirkulation und entsprechendes Gasturbinenkraftwerk |

| EP2795084B1 (en) * | 2011-12-19 | 2020-02-05 | Ansaldo Energia IP UK Limited | Control of the gas composition in a gas turbine power plant with flue gas recirculation |

| CH706150A1 (de) * | 2012-02-29 | 2013-08-30 | Alstom Technology Ltd | Verfahren zum Betriebe eines Gasturbinenkraftwerkes mit Abgasrezirkulation sowie Gasturbinentriebwerk. |

| ITCO20120008A1 (it) | 2012-03-01 | 2013-09-02 | Nuovo Pignone Srl | Metodo e sistema per monitorare la condizione di un gruppo di impianti |

| EP2642097A1 (de) | 2012-03-21 | 2013-09-25 | Alstom Technology Ltd | Verfahren zum Betrieb einer Gasturbine sowie Gasturbine zur Durchführung des Verfahrens |

| EP2642098A1 (de) * | 2012-03-24 | 2013-09-25 | Alstom Technology Ltd | Gasturbinenkraftwerk mit inhomogenem Eintrittsgas |

| US20130255267A1 (en) * | 2012-03-30 | 2013-10-03 | General Electric Company | System and method of improving emission performance of a gas turbine |

| US20130269358A1 (en) * | 2012-04-12 | 2013-10-17 | General Electric Company | Methods, systems and apparatus relating to reheat combustion turbine engines with exhaust gas recirculation |

| CN104428516B (zh) * | 2012-07-13 | 2017-08-18 | 通用电器技术有限公司 | 具有烟道气再循环的燃气涡轮功率装置及其运行方法 |

| EP2703607A1 (en) * | 2012-09-04 | 2014-03-05 | Alstom Technology Ltd | A method of increasing electricity output during high demand |

| US10215412B2 (en) * | 2012-11-02 | 2019-02-26 | General Electric Company | System and method for load control with diffusion combustion in a stoichiometric exhaust gas recirculation gas turbine system |

| US9567913B2 (en) * | 2013-01-28 | 2017-02-14 | General Electric Company | Systems and methods to extend gas turbine hot gas path parts with supercharged air flow bypass |

| EP2829705A1 (en) * | 2013-07-24 | 2015-01-28 | Alstom Technology Ltd | Gas turbine and method of controlling gas turbine |

| US9903588B2 (en) * | 2013-07-30 | 2018-02-27 | General Electric Company | System and method for barrier in passage of combustor of gas turbine engine with exhaust gas recirculation |

| EP2835516A1 (en) * | 2013-08-08 | 2015-02-11 | Alstom Technology Ltd | Gas turbine with improved part load emissions behavior |

| EP2837778A1 (en) | 2013-08-15 | 2015-02-18 | ALSTOM Technology Ltd | Operation of a gas turbine power plant with carbon dioxide separation |

| EP2853719A1 (en) * | 2013-09-25 | 2015-04-01 | Alstom Technology Ltd | Gas turbine with staged fuel injection |

| EP2894405B1 (en) * | 2014-01-10 | 2016-11-23 | General Electric Technology GmbH | Sequential combustion arrangement with dilution gas |

| US9492780B2 (en) | 2014-01-16 | 2016-11-15 | Bha Altair, Llc | Gas turbine inlet gas phase contaminant removal |

| US10060359B2 (en) * | 2014-06-30 | 2018-08-28 | General Electric Company | Method and system for combustion control for gas turbine system with exhaust gas recirculation |

| US10502136B2 (en) | 2014-10-06 | 2019-12-10 | Bha Altair, Llc | Filtration system for use in a gas turbine engine assembly and method of assembling thereof |

| US10253690B2 (en) * | 2015-02-04 | 2019-04-09 | General Electric Company | Turbine system with exhaust gas recirculation, separation and extraction |

| US10316746B2 (en) * | 2015-02-04 | 2019-06-11 | General Electric Company | Turbine system with exhaust gas recirculation, separation and extraction |

| AU2017223264B2 (en) * | 2016-02-26 | 2019-08-29 | 8 Rivers Capital, Llc | Systems and methods for controlling a power plant |

| DE102016218347A1 (de) | 2016-09-23 | 2018-03-29 | Siemens Aktiengesellschaft | Kraftwerksanlage |

| EP3620620A1 (de) * | 2018-09-07 | 2020-03-11 | Siemens Aktiengesellschaft | Abgasrezirkulation in gas- und dampfturbinenanlagen |

| US11156164B2 (en) | 2019-05-21 | 2021-10-26 | General Electric Company | System and method for high frequency accoustic dampers with caps |

| US11174792B2 (en) | 2019-05-21 | 2021-11-16 | General Electric Company | System and method for high frequency acoustic dampers with baffles |

| EP3822469B1 (en) * | 2019-11-18 | 2023-01-04 | Ansaldo Energia Switzerland AG | Gas turbine engine with alternating patterns of active burners and method of controlling a gas turbine engine |

| WO2022094605A1 (en) * | 2020-10-30 | 2022-05-05 | Colorado State University Research Foundation | Synergistic heat pumped thermal storage and flexible carbon capture system |

| CN112923771B (zh) * | 2021-04-02 | 2022-08-30 | 山东大学 | 一种根据排烟温度控制喷淋的湿烟气源热泵系统 |

| CN113091477B (zh) * | 2021-04-02 | 2022-02-22 | 山东大学 | 一种控制输入烟气压力的湿烟气源热泵系统 |

| CN112923770B (zh) * | 2021-04-02 | 2022-02-22 | 山东大学 | 一种集水及余热回收、污染物脱除的新型湿烟气源热泵系统 |

| WO2023287926A1 (en) * | 2021-07-13 | 2023-01-19 | Pts Power Inc. | Exhaust gas path heat energy utilization system and method |

| CN113417741A (zh) * | 2021-08-12 | 2021-09-21 | 华北电力大学(保定) | 一种改造的燃气-蒸汽联合循环机组及其控制方式 |

| US11852074B1 (en) * | 2022-07-12 | 2023-12-26 | General Electric Company | Combined cycle power plants with exhaust gas recirculation intercooling |

| WO2024141148A1 (en) * | 2022-12-26 | 2024-07-04 | General Electric Technology Gmbh | Systems for stabilizing gas turbine engine output during grid events |

| WO2025133001A1 (en) * | 2023-12-22 | 2025-06-26 | Technip Energies France | Carbon capture system with a blowerless configuration |

| EP4574242A1 (en) * | 2023-12-22 | 2025-06-25 | Technip Energies France | Carbon capture system with a blowerless configuration |

Family Cites Families (46)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3546882A (en) * | 1968-04-24 | 1970-12-15 | Gen Electric | Gas turbine engines |

| US3703807A (en) | 1971-01-15 | 1972-11-28 | Laval Turbine | Combined gas-steam turbine power plant |

| US3785145A (en) | 1971-11-10 | 1974-01-15 | Gen Motors Corp | Gas turbine power plant |

| DE2731387A1 (de) | 1976-07-19 | 1978-01-26 | Hydragon Corp | Gasturbinen-kraftmaschine mit abgas-rezirkulation |

| JPS5773827A (en) | 1980-10-24 | 1982-05-08 | Hitachi Ltd | Nox reducing device |

| US4441435A (en) * | 1981-10-21 | 1984-04-10 | Hitachi, Ltd. | Fluidizing gas control system in fluidized-bed incinerator |

| US5402631A (en) | 1991-05-10 | 1995-04-04 | Praxair Technology, Inc. | Integration of combustor-turbine units and integral-gear pressure processors |

| US5235814A (en) * | 1991-08-01 | 1993-08-17 | General Electric Company | Flashback resistant fuel staged premixed combustor |

| JP2954456B2 (ja) | 1993-07-14 | 1999-09-27 | 株式会社日立製作所 | 排気再循環型コンバインドプラント |

| US5794431A (en) | 1993-07-14 | 1998-08-18 | Hitachi, Ltd. | Exhaust recirculation type combined plant |

| DE4446610A1 (de) | 1994-12-24 | 1996-06-27 | Abb Management Ag | Verfahren zum Betrieb einer Gasturbogruppe |

| US6256976B1 (en) | 1997-06-27 | 2001-07-10 | Hitachi, Ltd. | Exhaust gas recirculation type combined plant |

| EP0953748B1 (de) | 1998-04-28 | 2004-01-28 | ALSTOM (Switzerland) Ltd | Kraftwerksanlage mit einem CO2-Prozess |

| US6260400B1 (en) | 1998-12-14 | 2001-07-17 | Gohysu Corporation | Full enclosed forging apparatus |

| JP3614751B2 (ja) * | 2000-03-21 | 2005-01-26 | 東京電力株式会社 | コンバインド発電プラントの熱効率診断方法および装置 |

| CA2409700C (en) | 2000-05-12 | 2010-02-09 | Clean Energy Systems, Inc. | Semi-closed brayton cycle gas turbine power systems |

| AU2001272682A1 (en) | 2000-06-15 | 2001-12-24 | Alstom Power N.V. | Method for operating a burner and burner with stepped premix gas injection |

| US6430914B1 (en) * | 2000-06-29 | 2002-08-13 | Foster Wheeler Energy Corporation | Combined cycle power generation plant and method of operating such a plant |

| GB2399600B (en) | 2001-10-26 | 2005-12-14 | Alstom Technology Ltd | Gas turbine adapted to operate with a high exhaust gas recirculation rate and a method for operation thereof |

| US6962055B2 (en) * | 2002-09-27 | 2005-11-08 | United Technologies Corporation | Multi-point staging strategy for low emission and stable combustion |

| JP3702266B2 (ja) * | 2002-11-13 | 2005-10-05 | 三菱重工業株式会社 | デュアル燃料型一軸コンバインドプラントにおける蒸気タービン出力推定装置 |

| US7191587B2 (en) | 2002-11-13 | 2007-03-20 | American Air Liquide, Inc. | Hybrid oxygen-fired power generation system |

| DK1576266T3 (en) | 2002-11-15 | 2014-12-01 | Clean Energy Systems Inc | Low pollutant energy generation system with air separation using an ion transfer membrane |

| EP1583893A1 (en) * | 2002-12-12 | 2005-10-12 | Ebara Corporation | Gas turbine apparatus |

| WO2004072453A1 (de) * | 2003-02-11 | 2004-08-26 | Alstom Technology Ltd | Verfahren zum betrieb einer gasturbogruppe |

| DE112004000994T5 (de) | 2003-06-06 | 2006-06-14 | Precision Combustion, Inc., North Haven | Verfahren zum Erhalten ultraniedriger NOx-Emissionen von mit hohen Turbineneinlasstemperaturen arbeitenden Gasturbinen |

| US7007487B2 (en) * | 2003-07-31 | 2006-03-07 | Mes International, Inc. | Recuperated gas turbine engine system and method employing catalytic combustion |

| DE10360951A1 (de) | 2003-12-23 | 2005-07-28 | Alstom Technology Ltd | Wärmekraftanlage mit sequentieller Verbrennung und reduziertem CO2-Ausstoß sowie Verfahren zum Betreiben einer derartigen Anlage |

| DE102004015187A1 (de) | 2004-03-29 | 2005-10-20 | Alstom Technology Ltd Baden | Brennkammer für eine Gasturbine und zugehöriges Betriebsverfahren |

| DE102004036911A1 (de) | 2004-07-29 | 2006-03-23 | Alstom Technology Ltd | Betriebsverfahren für eine Feuerungsanlage |

| DE102004039164A1 (de) * | 2004-08-11 | 2006-03-02 | Alstom Technology Ltd | Verfahren zur Erzeugung von Energie in einer eine Gasturbine umfassenden Energieerzeugungsanlage sowie Energieerzeugungsanlage zur Durchführung des Verfahrens |

| NO20044456L (no) | 2004-10-20 | 2005-03-03 | Norsk Hydro As | Fremgangsmate for fjerning og gjenvinning av C02 fra eksosgass |

| DE102005015151A1 (de) | 2005-03-31 | 2006-10-26 | Alstom Technology Ltd. | Gasturbinenanlage |

| US7950217B2 (en) * | 2005-08-12 | 2011-05-31 | American Air Liquide, Inc. | Oxygen-enriched air assisting system for improving the efficiency of cogeneration system |

| WO2007087907A1 (de) | 2006-01-11 | 2007-08-09 | Alstom Technology Ltd | Verfahren zum betreiben einer feuerungsanlage |

| GB2434437B (en) * | 2006-01-19 | 2011-01-26 | Siemens Ag | Improvements in or relating to combustion apparatus |

| US7805922B2 (en) * | 2006-02-09 | 2010-10-05 | Siemens Energy, Inc. | Fuel flow tuning for a stage of a gas turbine engine |

| US20080076080A1 (en) * | 2006-09-22 | 2008-03-27 | Tailai Hu | Method and apparatus for optimizing high fgr rate combustion with laser-based diagnostic technology |

| US8046986B2 (en) | 2007-12-10 | 2011-11-01 | General Electric Company | Method and system for controlling an exhaust gas recirculation system |

| US7536252B1 (en) | 2007-12-10 | 2009-05-19 | General Electric Company | Method and system for controlling a flowrate of a recirculated exhaust gas |

| US8051638B2 (en) | 2008-02-19 | 2011-11-08 | General Electric Company | Systems and methods for exhaust gas recirculation (EGR) for turbine engines |

| US9297306B2 (en) | 2008-09-11 | 2016-03-29 | General Electric Company | Exhaust gas recirculation system, turbomachine system having the exhaust gas recirculation system and exhaust gas recirculation control method |

| EP2246532A1 (en) | 2008-12-24 | 2010-11-03 | Alstom Technology Ltd | Power plant with CO2 capture |

| EP2248999A1 (en) | 2008-12-24 | 2010-11-10 | Alstom Technology Ltd | Power plant with CO2 capture |

| CH703218A1 (de) | 2010-05-26 | 2011-11-30 | Alstom Technology Ltd | Verfahren zum Betreiben eines Gas-und-Dampf-Kombikraftwerk mit Rauchgasrezirkulation sowie Kraftwerk. |

| US8915733B2 (en) * | 2010-11-11 | 2014-12-23 | Air Products And Chemicals, Inc. | Selective adjustment of heat flux for increased uniformity of heating a charge material in a tilt rotary furnace |

-

2011

- 2011-05-20 DE DE102011102720.7A patent/DE102011102720B4/de active Active

- 2011-05-26 US US13/116,486 patent/US9828912B2/en active Active

- 2011-05-26 JP JP2011117927A patent/JP5836645B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2011247265A (ja) | 2011-12-08 |

| US20110289899A1 (en) | 2011-12-01 |

| DE102011102720B4 (de) | 2021-10-28 |

| DE102011102720A1 (de) | 2011-12-01 |

| US9828912B2 (en) | 2017-11-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5836645B2 (ja) | 煙道ガス再循環を備えるコンバインドサイクル発電プラント | |

| JP5836644B2 (ja) | 煙道ガス再循環を備えるコンバインドサイクル発電プラント | |

| US20220282668A1 (en) | System and method for load control with diffusion combustion in a stoichiometric exhaust gas recirculation gas turbine system | |

| CN102265004B (zh) | 具有co2捕捉的动力设备 | |

| US10100741B2 (en) | System and method for diffusion combustion with oxidant-diluent mixing in a stoichiometric exhaust gas recirculation gas turbine system | |

| JP4735548B2 (ja) | 高湿分空気利用ガスタービン及びその運転方法 | |

| JP2015518540A (ja) | 量論的egrガスタービンシステムのためのシステム及び方法 | |

| US10151487B2 (en) | Sequential combustion arrangement with dilution gas | |

| JP2011153624A (ja) | ガスタービンの運転方法およびガスタービン | |

| JP5480792B2 (ja) | ガスタービンシステム及びガスタービンの加湿制御方法 | |

| US20130160456A1 (en) | System and method for controlling oxygen emissions from a gas turbine | |

| WO2024205604A1 (en) | System and method having oxidant supply for duct burner of heat recovery steam generator | |

| CN104421003B (zh) | 燃气轮机燃烧系统 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20140106 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20141219 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150105 |

|

| A524 | Written submission of copy of amendment under section 19 (pct) |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20150330 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20151005 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20151104 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5836645 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| LAPS | Cancellation because of no payment of annual fees |