JP5719584B2 - Knitting method of knitted fabric with multilayer structure - Google Patents

Knitting method of knitted fabric with multilayer structure Download PDFInfo

- Publication number

- JP5719584B2 JP5719584B2 JP2010288587A JP2010288587A JP5719584B2 JP 5719584 B2 JP5719584 B2 JP 5719584B2 JP 2010288587 A JP2010288587 A JP 2010288587A JP 2010288587 A JP2010288587 A JP 2010288587A JP 5719584 B2 JP5719584 B2 JP 5719584B2

- Authority

- JP

- Japan

- Prior art keywords

- knitted fabric

- knitting

- needle bed

- fabric portion

- needle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B1/00—Weft knitting processes for the production of fabrics or articles not dependent on the use of particular machines; Fabrics or articles defined by such processes

- D04B1/22—Weft knitting processes for the production of fabrics or articles not dependent on the use of particular machines; Fabrics or articles defined by such processes specially adapted for knitting goods of particular configuration

- D04B1/24—Weft knitting processes for the production of fabrics or articles not dependent on the use of particular machines; Fabrics or articles defined by such processes specially adapted for knitting goods of particular configuration wearing apparel

- D04B1/246—Upper torso garments, e.g. sweaters, shirts, leotards

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2501/00—Wearing apparel

- D10B2501/06—Details of garments

- D10B2501/061—Piped openings (pockets)

Description

本発明は、筒状の外側編地部と、その内側に無縫製で接合される内側編地部とを備える多層構造の編地を編成する多層構造の編地の編成方法に関する。 The present invention relates to a knitting method for a knitted fabric having a multilayer structure, in which a knitted fabric having a multilayer structure including a cylindrical outer knitted fabric portion and an inner knitted fabric portion joined without sewing to the inside is knitted.

従来から、筒状の外側編地部と、その内側に無縫製で接合される内側編地部とを備える多層構造のニットウェア(編地)が知られている。例えば、ポケットを有するセーターは、そのポケットの位置で厚み方向に3層構造となったニットウェアの代表例である。また、着用者の胴回りに相当する部分にベルト通しを設けたニットワンピースは、そのベルト通しの位置で厚み方向に4層構造となったニットウェアである。その他、裏立てジャカードで編成されたニットウェアも多層構造のニットウェアの代表例である。 Conventionally, a knitwear (knitted fabric) having a multilayer structure including a cylindrical outer knitted fabric portion and an inner knitted fabric portion joined without sewing to the inside is known. For example, a sweater having a pocket is a typical example of knitwear having a three-layer structure in the thickness direction at the pocket. Moreover, the knit dress which provided the belt loop in the part corresponded to a wearer's waist is the knitwear which became the 4 layer structure in the thickness direction in the position of the belt loop. In addition, knitwear knitted with lining jacquard is a typical example of multi-layer knitwear.

上述したような多層構造の編地を編成するには、前後一対の針床を上下に2段備える4枚ベッド横編機を用いる。例えば、特許文献1には、2重に形成された裾を備えるセーター、つまり裾の位置で厚み方向に4層構造となったセーターを編成する方法が開示されている。この特許文献1の技術では、まずセーターの前身裾ゴム部の編出し部と後身裾ゴム部の編出し部を、下段の前後の針床に編成する。次いで、各編出し部の1目おきの編目をセーターの外側に配置される編地部の編目とし、当該編出し部の残りの編目をセーターの内側に配置される編地部の編目とする。そして、下段の針床に加えて上段の針床も利用することで、前身裾ゴム部の2つの編地部と、後身裾ゴム部の2つの編地部、つまり合計4つの編地部の編成コース数を増して行く。

In order to knit a knitted fabric having a multilayer structure as described above, a four-bed flat knitting machine having a pair of front and rear needle beds in two stages is used. For example,

上記特許文献1の編成方法では、編針の大きさに対応した適切な大きさの編目を形成できない。適切な大きさの編目を形成するには、総針状態(編地部の隣接する編目間に空針がない状態)で編地部を編成すれば良いが、特許文献1では、多層構造となっている部分の全ての編地部を針抜き状態(編地部の隣接する編目間に1針以上の空針がある状態)で編成しているからである。特許文献1において針抜き状態で編地部を編成しているのは、下段の前後の針床に総針状態で編地部を係止させておくと、上段の前後の針床に係止される編地部が妨げとなって、総針状態の編地部を編成することができないため、編成の妨げとなる編地部を逃がすための空針を確保する必要があるからである。そこで、少なくとも外部から見える外側編地部について、適切な大きさの編目を形成できる総針状態で編成できる多層構造の編地の編成方法が望まれているものの、現在のところそのような編成方法は提案されていない。

In the knitting method of

本発明は、上記の事情に鑑みてなされたものであり、その目的の一つは、外側編地部と内側編地部とを備える多層構造の編地を編成するにあたり、外側編地部を総針状態で編成できる多層構造の編地の編成方法を提供することにある。 The present invention has been made in view of the above circumstances, and one of its purposes is to form an outer knitted fabric portion when knitting a multi-layered knitted fabric including an outer knitted fabric portion and an inner knitted fabric portion. An object of the present invention is to provide a knitting method of a knitted fabric having a multilayer structure that can be knitted in a total needle state.

本発明多層構造の編地の編成方法は、前後一対の針床を上下に2段備える4枚ベッド横編機を用いて、筒状に編成された外側編地部と、この外側編地部の筒内部で編成され、外側編地部に無縫製で接合される内側編地部と、を備える多層構造の編地を編成する多層構造の編地の編成方法である。この本発明多層構造の編地の編成方法は、外側編地部が下部前針床と下部後針床に総針状態で係止され、内側編地部が上部前針床と上部後針床の少なくとも一方に針抜き状態で係止される標準配置から前後いずれかの針床の外側編地部の編成コース数を増すにあたり、前後の針床のうち、内側編地部が係止され、かつ編成コース数を増す外側編地部が係止される側の針床を基準側の針床、この基準側に対向する側の針床を対向側の針床としたときに、次の工程を繰り返すことを特徴とする。 A knitting method of a knitted fabric having a multilayer structure according to the present invention includes an outer knitted fabric portion knitted in a cylindrical shape using a four-bed flat knitting machine having a pair of front and rear needle beds in two stages, and the outer knitted fabric portion. Is a knitted method of a knitted fabric having a multilayer structure, in which a knitted fabric having a multilayer structure is knitted with an inner knitted fabric portion that is knitted inside and joined to the outer knitted fabric portion without sewing. In the knitting method of the knitted fabric having a multilayer structure according to the present invention, the outer knitted fabric portion is locked to the lower front needle bed and the lower rear needle bed in the total needle state, and the inner knitted fabric portion is the upper front needle bed and the upper rear needle bed. In increasing the number of knitting courses of the outer knitted fabric portion of either the front or back needle bed from the standard arrangement locked in the needle-extracted state at least one of the inner knitted fabric portion of the front and back needle beds is locked, and when the outer knitted fabric portion to increase the number of knitting courses has needle bed on the reference side of the needle bed of locked by side, the needle bed on the side opposite to the reference side and the needle bed on the opposite side, the next step It is characterized by repeating.

(工程α) 基準側の下部針床に係止される外側編地部の編目の一部を、対向側の上部針床に目移しする。

(工程β) 対向側の下部針床に係止される外側編地部の編目の一部を、前記工程αで空針となった基準側の下部針床の編針を利用して、対向側の上部針床に目移しする。

(工程γ) 前記工程αで目移しした編目を、目移しの前にもともと係止されていた基準側の下部針床の編針に戻す。

(工程δ) 基準側から内側編地部の編目の全てを、前記工程βで空針となった対向側の下部針床の編針に目移しする。ここで、内側編地部の編目の目移しは、一度に行っても良いし、複数回に分けて行っても良い。

(工程ε) 工程γを経て基準側の下部針床に係止された状態にある外側編地部の編成コース数を増す、または、工程γを経て基準側の下部針床に係止された状態にある外側編地部の編目を基準側の下部針床と対向側の上部針床に振り分けた上で外側編地部の編成コース数を増した後、対向側の上部針床で編成した編目を基準側の下部針床に目移しする。

(工程ζ) 対向側の下部針床にある内側編地部の編目を、基準側の上部針床に目移しする。

(工程η) 前記工程εで編成した外側編地部の編目の一部を、対向側の上部針床に目移しする。

(工程θ) 前記工程βで目移しした編目を、前記工程ηで空針となった基準側の下部針床の編針を利用して、目移しの前にもともと係止されていた対向側の下部針床の編針に戻す。

(工程ι) 前記工程ηで目移しした編目を、目移し前にもともと係止されていた基準側の下部針床の編針に戻す。

(Step α) A part of the stitches of the outer knitted fabric portion locked to the lower needle bed on the reference side is transferred to the upper needle bed on the opposite side.

(Step β) A part of the stitches of the outer knitted fabric portion that is locked to the lower needle bed on the opposite side is formed on the opposite side using the knitting needles on the lower needle bed on the reference side that has become empty needles in the step α. Transfer to the upper needle bed.

(Step γ) The stitch transferred in the step α is returned to the knitting needle of the lower needle bed on the reference side that was originally locked before the transfer.

(Step δ) Transfer all the stitches of the inner knitted fabric portion from the reference side to the knitting needles of the lower needle bed on the opposite side that became empty needles in the step β. Here, the transfer of the stitches in the inner knitted fabric portion may be performed at a time or may be performed in a plurality of times.

To increase the number of knitting courses of the outer knitted fabric portion located (step epsilon) Engineering enough through the γ to state of being locked at the lower needle bed on the reference side, or the locking in the lower needle bed on the reference side through the steps γ After the number of knitting courses of the outer knitted fabric portion is increased after the stitches of the outer knitted fabric portion in the formed state are distributed to the lower needle bed on the reference side and the upper needle bed on the opposite side, Transfer the knitted stitch to the lower needle bed on the reference side.

(Step ζ) The stitches of the inner knitted fabric portion on the opposite lower needle bed are transferred to the upper needle bed on the reference side.

(Step η) Part of the stitches of the outer knitted fabric portion knitted in the step ε is transferred to the upper needle bed on the opposite side.

(Step θ) Using the knitting needle of the lower needle bed on the reference side, which has become a blank needle in the step η, the stitch transferred in the step β is used for the opposite side that was originally locked before the transfer. Return to the knitting needle on the lower needle bed.

(Step ι) The stitch transferred in the step η is returned to the knitting needle of the lower needle bed on the reference side that was originally locked before the transfer.

ここで、内側編地部の編成コース数を増すタイミングは適宜選択することができる。下部針床に総針状態で係止される外側編地部を編成するにあたり、上部針床に係止される内側編地部が妨げとなることはあっても、内側編地部を編成するにあたり、外側編地部が妨げとなることはないからである。そのため、内側編地部の編成コース数は、編地が完成するまでの間に任意のタイミングで増すことができる。その観点からすれば、外側編地部と内側編地部の編成コース数を同じとすることもできるし、異ならせることもできる。外側編地部と内側編地部の編成コース数を同じとする場合、例えば、後述する実施形態1に示すように、工程ε(S5)で外側編地部を編成することに伴い内側編地部も編成すると、編成効率が良い。

Here, the timing at which the number of knitting courses of the inner knitted fabric portion is increased can be appropriately selected. In knitting the outer knitted fabric portion that is locked to the lower needle bed in the full needle state, the inner knitted fabric portion that is locked to the upper needle bed is obstructed, but the inner knitted fabric portion is knitted. This is because the outer knitted fabric portion does not become an obstacle. Therefore, the number of knitting courses in the inner knitted fabric portion can be increased at an arbitrary timing until the knitted fabric is completed. From this point of view, the number of knitting courses of the outer knitted fabric portion and the inner knitted fabric portion can be the same or different. When the number of knitting courses of the outer knitted fabric portion and the inner knitted fabric portion is the same, for example, as shown in

本発明多層構造の編地の編成方法の一形態として、外側編地部が総針状態で係止された状態から新たに内側編地部を作りだして標準配置を形成するために、以下の工程を繰り返すことが好ましい。ここで、内側編地部を作り出す側を基準側、この基準側に対向する側を対向側とする。例えば、前針床に内側編地部が係止された標準配置を形成する場合、前針床は基準側、後針床は対向側となる。 In order to form a standard arrangement by newly creating an inner knitted fabric portion from a state in which the outer knitted fabric portion is locked in the total needle state as one form of the knitting method of the knitted fabric having a multilayer structure of the present invention, the following steps are performed. Is preferably repeated. Here, the side that creates the inner knitted fabric portion is the reference side, and the side that faces the reference side is the opposing side. For example, when forming a standard arrangement in which the inner knitted fabric portion is locked to the front needle bed, the front needle bed is the reference side and the rear needle bed is the opposite side.

(工程κ) 対向側の下部針床に係止される外側編地部の編目を、基準側の上部針床に目移しする。

(工程λ) 前記工程κで目移しした編目がもともと係止されていた編針に対向する位置にある基準側の下部針床に係止される対象編目に対して割増やしを行う。その場合、前記工程κで空針となった編針に対象編目が目移しされると共に、その対象編目から引き出された割増やし目が、対象編目が係止されていた編針に、外側編地部の編目として形成される。

(工程μ) 前記工程λで割増やしに伴い対向側の下部針床に目移しされた対象編目を、内側編地部の編目として、基準側の上部針床に目移しする。

(工程ν) 前記工程κで目移しした編目を、目移し前にもともと係止されていた対向側の下部針床に戻す。

(Step κ) The stitches of the outer knitted fabric portion that is locked to the lower needle bed on the opposite side are transferred to the upper needle bed on the reference side.

(Step λ) The target stitch that is locked to the lower needle bed on the reference side at the position facing the knitting needle that was originally locked by the stitch transferred in the step κ is increased. In that case, the target stitch is transferred to the knitting needle that has become an empty needle in the step κ, and the additional stitch pulled out from the target stitch is connected to the outer knitted fabric portion on the knitting needle on which the target stitch is locked. Formed as a stitch.

(Process μ) The target stitch transferred to the lower needle bed on the opposite side in accordance with the increase in the step λ is transferred to the upper needle bed on the reference side as the stitch of the inner knitted fabric portion.

(Step ν) The stitch transferred in the step κ is returned to the lower needle bed on the opposite side that was originally locked before the transfer.

本発明多層構造の編地の編成方法の一形態として、前後いずれか一方の上部針床に内側編地部を形成する場合、つまり3層構造の編地を編成する場合、当該内側編地部は、隣接する編目間に1つ以上の空針を設けて編成することが好ましい。 As an embodiment of the knitting method of the knitted fabric having a multilayer structure according to the present invention, when forming the inner knitted fabric portion on either one of the upper and lower upper needle beds, that is, when knitting a three-layer knitted fabric, the inner knitted fabric portion Is preferably knitted by providing one or more empty needles between adjacent stitches.

本発明多層構造の編地の編成方法の一形態として、前後両方の上部針床に内側編地部を形成する場合、つまり4層構造の編地を編成する場合、当該内側編地部は、隣接する編目間に3つ以上の空針を設けて編成することが好ましい。 As one form of the knitting method of the knitted fabric having a multilayer structure of the present invention, when forming the inner knitted fabric portion on both the upper and lower needle beds, that is, when knitting a knitted fabric having a four-layer structure, the inner knitted fabric portion is It is preferable that three or more empty needles are provided between adjacent stitches for knitting.

本発明編地の編成方法によれば、総針状態で編成された筒状の外側編地部と、その外側編地部の内側に配置され、外側編地部に無縫製で接合される針抜き状態で編成された内側編地部と、を備える編地を編成できる。 According to the knitting method of the knitted fabric of the present invention, a cylindrical outer knitted fabric portion knitted in a total needle state, and a needle that is disposed inside the outer knitted fabric portion and joined to the outer knitted fabric portion without sewing. A knitted fabric comprising an inner knitted fabric portion knitted in a punched state can be knitted.

以下、本発明の実施形態を図面に基づいて説明する。実施形態に記載の編成はいずれも、左右方向に延び、かつ、前後方向に互いに対向する下部前針床(以下、FD)と下部後針床(以下、BD)、およびこれらFDとBDの上方に設けられ、下部の針床と同ピッチで多数の編針が列設された上部前針床(以下、FU)と上部後針床(以下、BU)を備える4枚ベッド横編機を用いた編成例を説明する。この横編機は、前後の針床間で編目の目移しが可能であり、しかも横編機に備わるBD,BUは左右にラッキング可能である。なお、現行市販されている横編機では、FDとBDとの間、FDとBUとの間、およびBDとFUとの間で目移し可能であるが、FUとBUとの間では目移しできない構造になっている。 Hereinafter, embodiments of the present invention will be described with reference to the drawings. All of the knitting described in the embodiment extend in the left-right direction and face each other in the front-rear direction, the lower front needle bed (hereinafter referred to as FD) and the lower rear needle bed (hereinafter referred to as BD), and above these FD and BD. A four-bed flat knitting machine provided with an upper front needle bed (hereinafter referred to as FU) and an upper rear needle bed (hereinafter referred to as BU) in which a large number of knitting needles are arranged at the same pitch as the lower needle bed is used. An example of organization will be described. This flat knitting machine can transfer stitches between the front and back needle beds, and the BD and BU provided in the flat knitting machine can be racked left and right. In the flat knitting machine currently on the market, it is possible to transfer between FD and BD, between FD and BU, and between BD and FU, but between FU and BU. The structure is not possible.

<実施形態1>

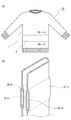

実施形態1では、図1に示すように、筒状の身頃(外側編地部1)の内側に、さらに筒状の内側編地部2を設けたセーター10を編成する。外側編地部1は、前針床で編成される前側編地部(以下、外前部1F)と、後針床で編成される後側編地部(以下、外後部1B)とに分けられる。内側編地部2も、前針床で編成される前側編地部(以下、内前部2F)と、後針床で編成される後側編地部(以下、内後部2B)とに分けられる。以下、この4層になった部分の編成を図2,3の編成工程図に基づいて説明する。

<

In the first embodiment, as shown in FIG. 1, a

図2,3の編成工程図では、説明の便宜上、針床の一部のみを示し、編地の編目の数も、実際の編成に使用される数よりも少なくし、BD,BUのラッキング動作は省略している。これらの図の「アルファベット+数字」は編成工程の番号を、大文字アルファベットは編針の編幅方向の位置を示す。また、図中の丸印は編針に係止される編目を、黒塗り丸印はその編成工程において新たに形成される編目を、矢印は目移しの方向を示し、各編成工程で行われた操作は太線で示す。さらに、図中の外前部1Fの編目にはV印、外後部1Bの編目には逆V印、内前部2Fの編目にはバツ印、内後部2Bの編目には十字印を付している。

In the knitting process diagrams of FIGS. 2 and 3, for convenience of explanation, only a part of the needle bed is shown, and the number of stitches of the knitted fabric is made smaller than the number used for the actual knitting, and the BD and BU racking operations are performed. Is omitted. In these drawings, “alphabet + number” indicates the number of the knitting process, and the capital letter indicates the position of the knitting needle in the knitting width direction. In addition, the circles in the figure indicate stitches that are locked to the knitting needles, the black circles indicate stitches that are newly formed in the knitting process, and the arrows indicate the direction of transfer, and were performed in each knitting process. The operation is indicated by a bold line. Further, in the drawing, the

S1には、FDの編針B〜Qに外前部1Fが、BDの編針B〜Qに外後部1Bが、FUの編針D,H,L,Pに内前部2Fが、BUの編針C,G,K,Oに内後部2Bが係止された状態(標準配置)が示されている。この編目の係止状態は、図1(B)において2層の編地部が4層の編地部に分かれ始める部分に相当し、外前部1Fと内前部2Fとは編糸を介して繋がっており、外後部1Bと内後部2Bとは編糸を介して繋がっている。ここで、内前部2F(内後部2B)における隣接する編目同士が互いに4針離れているのは、他部2B(2F),1F,1Bの編目を目移しするためのスペースを確保するためである。

In S1, the

このS1の状態から、S2〜S8の編成により外前部1Fと内前部2Fの編成コース数を増し、S9〜S15の編成により外後部1Bと内後部2Bの編成コース数を増す。ここで、編成コース数を増す外側編地部が係止される側を基準側、その反対側を対向側とし、それぞれ囲み文字の符号8,9を付して図面上に示す。図2では、FD,FUは基準側8の針床、BD,BUは対向側9の針床である。

From the state of S1, the number of knitting courses of the outer

S2では、FDの編針E,I,M,Qに係止される外前部1Fの一部の編目を、対向するBUの編針F,J,N,Rに目移しし、FDの編針E,I,M,Qを空針にする(工程α)。

In S2, some stitches of the

S3では、BDの編針C,G,K,Oに係止される外後部1Bの一部を構成する編目をそれぞれ、FDの編針A,E,I,Mに目移しした後、さらにBUの編針A,E,I,Mに目移しする(工程β)。BDに係止される編目を一旦FDに目移ししてからBUに目移ししているのは、BDから直接BUに目移しすることができないからである。

In S3, the stitches constituting part of the outer

S4では、FUの編針D,H,L,Pに係止される内前部2Fの編目を、S3の目移しによって空針となったBDの編針C,G,K,Oに目移しする(工程δ)と共に、S2において目移しした外前部1Fの編目を、BUの編針F,J,N,RからFDの空針(FDの編針E,I,M,Q)に目移しする(工程γ)。S4が終了した時点で、S2においてFDからBUに目移しした外前部1Fの一部の編目は、再びFDの同じ編針に戻っているので、外前部1Fの編目は、S1のときと同じ状態でFDに係止されている。

In S4, the stitches of the

S5では、給糸口を編地の編幅方向の一方へ移動させる間に、BDの編針C,G,K,Oに係止される内前部2Fを1コース分編成し、続いて給糸口を他方へ移動させる間に、FDの編針Q〜Bに係止される外前部1Fを1コース分編成する(工程ε)。

In S5, while the yarn feeder is moved to one side in the knitting width direction of the knitted fabric, the

なお、内前部2Fを編成するタイミングは、この工程εに限定されるわけではなく、任意に選択することができる。例えば、S1とS2の間に行っても良いし、後述するS8と図3のS9の間に行っても良い。また、内前部2Fの編成コース数を増さないという選択もある。その場合、外前部1Fを複数コース分編成するごとに内前部2Fを1コース分編成し、外前部1Fの編成コース数を、内前部2Fの編成コース数よりも多くすることで、編地に凹凸を持たすことも可能である。

The timing for knitting the

S6では、S5において編成された外前部1Fの編目のうち、FDの編針C,G,K,Oに係止される外前部1Fの編目を、BUの編針B,F,J,Nに目移しする(工程η)と共に、S5においてBDの編針C,G,K,Oで編成した内前部2Fの編目を、FUの編針D,H,L,Pに戻す(工程ζ)。

In S6, among the stitches of the

S7では、S3においてBUの編針A,E,I,Mに目移ししておいた外後部1Bの編目を、S6の目移しにより空針となったFDの編針C,G,K,Oを経由させ、BDの編針C,G,K,Oに戻す(工程θ)。このS7が終了した時点で、BDには外後部1Bの編目のみが係止された状態(S1と同じ状態)となる。

In S7, the knitting needles C, G, K, and O of the FD that have been transferred to the knitting needles A, E, I, and M of the BU in S3 and become empty needles by the transfer of S6 are transferred. Return to the knitting needles C, G, K, and O of the BD (step θ). When S7 ends, only the stitches of the outer

S8では、S6においてBUの編針B,F,J,Nに目移ししておいた外前部1Fの編目を、FDの編針C,G,K,Oに戻す(工程ι)。S8が終了した時点の各部1F,1B,2F,2Bの係止状態を見ると、S1と全く同じ標準配置となっている。

In S8, the stitches of the

上記S2〜S8により、外前部1Fと内前部2Fが1コース分ずつ編成される。続いて、図3のS9以降に示す編成工程に従って、外後部1Bと内後部2Bを1コース分ずつ編成する。その編成工程の基本的な考え方はS2〜S8と同様であるので、簡単に説明する。但し、編成コース数を増す外側編地部(外後部1B)が係止される針床は後針床であるので、図3ではBD,BUが基準側8、FD,FUが対向側9の針床になる。

By the above S2 to S8, the

図3のS9に示すように、まず、BDの編針B,F,J,Nに係止される外後部1Bの編目を、FUの編針A,E,I,Mに目移しする(工程α)。次いで、FDの編針C,G,K,Oに係止される外前部1Fの編目を、BDを経由させ、FUの編針B,F,J,Nに目移しする(S10:工程β)。そして、S9においてFUの編針A,E,I,Mに目移ししておいた外後部1Bの編目を、もともと係止されていたBDの編針B,F,J,Nに戻す(工程γ)と共に、BUの編針C,G,K,Oに係止される内後部2Bの編目を、FDの編針C,G,K,Oに目移しする(S11:工程δ)。

As shown in S9 of FIG. 3, first, the stitches of the outer

S11が終了することによって、外後部1Bと内後部2Bの編成コースを増すための外後部1Bと内後部2Bの配置が整うので、S12では、外後部1Bと内後部2Bの編成コース数を増す。具体的には、FDの編針C,G,K,Oに目移ししておいた内後部2Bを1コース分編成し、BDの編針Q〜Bに係止される外後部1Bを1コース分編成する(工程ε)。

Since the arrangement of the outer

次いで、S12においてFDの編針C,G,K,Oに編成した内後部2Bの編目を、BUの編針C,G,K,Oに目移しする(工程ζ)と共に、BDの編針B,F,J,Nに係止される外後部1Bの編目を、FUの編針A,E,I,Mに目移しする(S13:工程η)。そして、S10においてFUの編針B,F,J,Nに預けておいた外前部1Fの編目を、BDを経由させて、もともと係止されていたFDの編針C,G,K,Oに戻す(S14:工程θ)。最後に、S13においてFUの編針A,E,I,Mに預けておいた外後部1Bの編目を、もともと係止されていたBDの編針B,F,J,Nに戻す(S15:工程ι)。

Next, the stitches of the inner

上記S9〜S15により、外後部1Bと内後部2Bが1コース分ずつ編成される。つまり、S2〜S15を経ることによって、図1の外側編地部1と内側編地部2とが1コースずつ編成されたことになる。ここで、図3のS15における各部1F,1B,2F,2Bの係止状態を見ると、図2のS1と同じ標準配置となっていることがわかる。従って、さらに外側編地部1と内側編地部2の編成コース数を増していく場合、S2〜S15と同様の編成を繰り返せば良い。そして、図1に示すように内側編地部2をウエール方向の上端まで編成すれば、内側編地部2の編目を外側編地部1の編目に重ね合わせて両編地部1,2を接合すると良い。

By S9 to S15, the outer

以上説明した実施形態1の編成方法によれば、図1のセーター10の外側編地部1は総針状態で編成されることになるので、外側編地部1の編目を、使用する横編機に備わる編針の大きさに対応した大きさとすることができる。一方、内側編地部2の編目は、針抜き状態で編成されるので外側編地部1に比べて大きくなるものの、セーター10の外側から見えない。

According to the knitting method of the first embodiment described above, the outer knitted

<実施形態2>

実施形態1では、外側編地部1を天竺編みしたが、リブ編みすることもできる。その場合、図2のS5(図3のS12)において、外前部1F(外後部1B)の編目をFDとBUに振り分けた上で、外前部1F(外後部1B)の編成コース数を増せば良い。

<

In the first embodiment, the outer knitted

<実施形態3>

実施形態3では、実施形態1と同様の技術思想に基づいて図1のS1に示す編目の係止状態とする編成方法を図4に基づいて編成する。図4の見方は図2,3と同様である。

<

In the third embodiment, based on the same technical idea as in the first embodiment, the knitting method for setting the stitches shown in S1 of FIG. 4 is the same as that shown in FIGS.

T1には、総針状態で編成された外前部1Fと外後部1BがFDとBDに係止された状態が示されている。以降の編成では、このT1の状態から内前部2Fの編目を形成していく。ここで、内前部2Fを形成する予定のFUがある前針床の側が基準側8、後針床の側が対向側9である。

T1 shows a state in which the

まず、T2では、BDの編針Dに係止される外後部1Bの編目を、FUの編針Eに目移しする(工程κ)。そして、T3では、T2においてFDの編針B,Cに係止される編目に続く新たな編目を形成すると共に、T2においてFDの編針Dに係止される編目(対象編目)に対して割増やしを行って、内前部2Fを編出す(工程λ)。

First, at T2, the stitch of the outer

ここで、割増やしとは、例えば、特開平4−73245号公報に記載のように、前後一方の針床に係止される編目(対象編目)を、対向する他方の針床の編針に目移ししつつ、その対象編目から引き出されるように新たな編目(割増やし目)を一方の針床の編針に形成する編成動作である。割増やし目は、上記対象編目がもともと係止されていた編針に係止される。つまり、T3においてBDの編針Dに係止される内前部2Fの編目は、T1,T2においてFDの編針Dに係止されていた外前部1Fの編目である。また、T3においてFDの編針Dに係止される外前部1Fの編目はもともと、BDの編針Dに形成される編目から引き出された割増やし目である。このような割増やしを行うことにより、外前部1Fと内前部2Fとが繋がった状態で、内前部2Fを編出すことができる。

Here, for example, as described in Japanese Patent Application Laid-Open No. 4-73245, an increase in splitting means that a stitch (target stitch) locked to one of the front and back needle beds is connected to a knitting needle on the other facing needle bed. In this knitting operation, a new stitch (split stitch) is formed on the knitting needle of one needle bed so as to be pulled out from the target stitch. The split stitch is locked to the knitting needle in which the target stitch was originally locked. That is, the stitch of the

T4では、T3を経て内前部2Fの編目となったBDの編針Dに係止される編目を、FUの編針Dに目移しし(工程μ)、続くT5では、T2においてFUの編針Eに目移ししておいた外後部1Bの編目を、目移し前にもともと係止されていたBDの編針Dに戻す(工程ν)。

At T4, the stitch that is locked to the knitting needle D of the BD that has become the stitch of the

以降は、T6に例示するように、T4において形成した内前部2Fから4針隣の位置で、T2〜T5と同様の編成を行って、内前部2Bを完成させる(T7参照)。また、図示しないが、内後部についてもT2〜T5と同様の技術思想に基づいて形成することができる。

Thereafter, as illustrated in T6, knitting similar to T2 to T5 is performed at a position adjacent to four needles from the

以上説明した実施形態3の編成工程に従えば、総針状態で編成された外側編地部に無縫製で接合された状態で筒状の内側編地部を編出すことができる。

If the knitting process of

<実施形態4>

本発明多層構造の編地の編成方法によれば、上記実施形態1〜3と異なり、3層構造の編地を編成することもできる。例えば、外側編地部に対して内前部のみを備える3層構造の編地を編成する場合、図2のS2〜S8と同様の編成を行えば良いし、外側編地部に対して内後部のみを備える3層構造の編地を編成する場合、図3のS9〜S15と同様の編成を行えば良い。但し、3層構造の編地の場合、内側編地部における隣接する編目同士は、互いに2針以上離れていれば良い。それは、内側編地部における編目同士の間に目移しのスペースが1針分あれば十分であるからである。

<

According to the knitting method of a knitted fabric having a multilayer structure of the present invention, unlike the first to third embodiments, a knitted fabric having a three-layer structure can be knitted. For example, when a knitted fabric having a three-layer structure including only the inner front portion is knitted with respect to the outer knitted fabric portion, knitting similar to S2 to S8 in FIG. When knitting a knitted fabric having a three-layer structure including only the rear portion, knitting similar to S9 to S15 in FIG. 3 may be performed. However, in the case of a knitted fabric having a three-layer structure, adjacent stitches in the inner knitted fabric portion may be separated from each other by two or more stitches. This is because it is sufficient if there is a space for transferring one stitch between stitches in the inner knitted fabric portion.

<実施形態5>

実施形態3では、標準配置を作り出すために、本発明多層構造の編地の編成方法を利用した。しかし、上記標準配置は、本発明多層構造の編地の編成方法を利用しなくても作り出すことができる。例えば、図4のT1の状態から、給糸口を紙面右方向に移動させる間に、FDの編針B,C,E〜G,I〜K,M〜O,Qに外前部1Fの編目を形成すると共に、FUの編針D,H,L,Pに掛け目からなる内前部2Fの編目を形成すると良い。但し、内側編地部を編出した後は、実施形態1に示すように、本発明の編成方法を利用する必要がある。

<

In the third embodiment, the knitting method of the knitted fabric having the multilayer structure of the present invention is used to create a standard arrangement. However, the standard arrangement can be created without using the knitting method of the knitted fabric having the multilayer structure of the present invention. For example, the stitches of the

なお、本発明の実施形態は上述した実施形態に限定されるわけではなく、本発明の要旨を逸脱しない範囲で適宜変更することができる。例えば、実施形態では外側編地部の一部に内側編地部を接合したが、外側編地部の全体にわたって内編地部を形成しても良い。また、前後の編針を使用して編成し、前後の編目が離れずに一体化した単層のように見えるゴムジャカードや袋ジャカード、裏立てジャカードなどの組織を備える編地も本発明における多層構造の編地に含まれる。 The embodiment of the present invention is not limited to the above-described embodiment, and can be appropriately changed without departing from the gist of the present invention. For example, in the embodiment, the inner knitted fabric portion is joined to a part of the outer knitted fabric portion, but the inner knitted fabric portion may be formed over the entire outer knitted fabric portion. Further, the present invention also relates to a knitted fabric having a structure such as a rubber jacquard, a bag jacquard, or a back jacquard that is knitted using front and rear knitting needles and looks like a single layer in which the front and rear stitches are integrated without separation. It is included in the knitted fabric of the multilayer structure.

10 セーター

1 身頃(外側編地部)

1F 外前部 1B 外後部

2 内側編地部

2F 内前部 2B 内後部

8 基準側

9 対向側

10

1F outer

Claims (4)

外側編地部が下部前針床と下部後針床に総針状態で係止され、内側編地部が上部前針床と上部後針床の少なくとも一方に針抜き状態で係止される標準配置から前後いずれかの針床の外側編地部の編成コース数を増すにあたり、

前後の針床のうち、内側編地部が係止され、かつ編成コース数を増す外側編地部が係止される側の針床を基準側の針床、この基準側に対向する側の針床を対向側の針床としたときに、

基準側の下部針床に係止される外側編地部の編目の一部を、対向側の上部針床に目移しする工程αと、

対向側の下部針床に係止される外側編地部の編目の一部を、前記工程αで空針となった基準側の下部針床の編針を利用して、対向側の上部針床に目移しする工程βと、

前記工程αで目移しした編目を、目移しの前にもともと係止されていた基準側の下部針床の編針に戻す工程γと、

基準側から内側編地部の編目を、前記工程βで空針となった対向側の下部針床の編針に目移しする工程δと、

工程γを経て基準側の下部針床に係止された状態にある外側編地部の編成コース数を増す、または、工程γを経て基準側の下部針床に係止された状態にある外側編地部の編目を基準側の下部針床と対向側の上部針床に振り分けた上で外側編地部の編成コース数を増した後、対向側の上部針床で編成した編目を基準側の下部針床に目移しする工程εと、

対向側の下部針床にある内側編地部の編目を、基準側の上部針床に目移しする工程ζと、

前記工程εで編成した外側編地部の編目の一部を、対向側の上部針床に目移しする工程ηと、

前記工程βで目移しした編目を、前記工程ηで空針となった基準側の下部針床の編針を利用して、目移しの前にもともと係止されていた対向側の下部針床の編針に戻す工程θと、

前記工程ηで目移しした編目を、目移し前にもともと係止されていた基準側の下部針床の編針に戻す工程ιと、

を備えることを特徴とする多層構造の編地の編成方法。 Using a four-bed flat knitting machine having a pair of front and rear needle beds, the outer knitted fabric portion is knitted in a cylindrical shape, and the outer knitted fabric portion is knitted inside the outer knitted fabric portion. A knitting method of a knitted fabric of a multilayer structure, knitting a knitted fabric of a multilayer structure comprising an inner knitted fabric portion joined without sewing,

A standard in which the outer knitted fabric is locked to the lower front needle bed and the lower rear needle bed in a full needle state, and the inner knitted fabric portion is locked to at least one of the upper front needle bed and the upper rear needle bed in a needle-free state. In increasing the number of knitting courses of the outer knitted fabric part of the needle bed either before or after placement,

Of the front and back needle beds, locked inner knitted fabric portion and the reference side of the needle bed on the side where the outer knitted fabric portion to increase the number of knitting courses is engaged needle bed, on the side opposite to the reference side When the needle bed is the opposite needle bed ,

A step α of transferring a part of the stitches of the outer knitted fabric portion locked to the lower needle bed on the reference side to the upper needle bed on the opposite side;

A part of the stitches of the outer knitted fabric portion that is locked to the lower needle bed on the opposite side, using the knitting needles on the lower needle bed on the reference side that has become empty needles in the step α, Step β to transfer to,

A step γ for returning the stitch transferred in the step α to the knitting needle of the lower needle bed on the reference side that was originally locked before the transfer;

A step δ of transferring the stitches of the inner knitted fabric portion from the reference side to the knitting needles of the lower needle bed on the opposite side that has become empty needles in the step β;

To increase the number of knitting courses of the outer knitted fabric portion in Engineering enough through the γ to locked state to the lower needle bed on the reference side, or, in the locked state in the lower needle bed on the reference side through the steps γ After the number of knitting courses of the outer knitted fabric portion is increased after the stitches of an outer knitted fabric portion are distributed to the lower needle bed on the reference side and the upper needle bed on the opposite side, the stitches knitted on the upper needle bed on the opposite side Step ε for transferring to the lower needle bed on the reference side,

A step ζ of transferring the stitches of the inner knitted fabric portion in the lower needle bed on the opposite side to the upper needle bed on the reference side;

A step η of transferring a part of the stitches of the outer knitted fabric portion knitted in the step ε to the upper needle bed on the opposite side;

Using the knitting needle of the lower needle bed on the reference side that has become the empty needle in the step η, the stitch transferred in the step β is used for the lower side needle bed on the opposite side that was originally locked before the transfer. A process θ to return to the knitting needle,

Step ι for returning the stitch transferred in the step η to the knitting needle of the lower needle bed on the reference side that was originally locked before the transfer, and

A knitting method for a knitted fabric having a multilayer structure.

内側編地部を作り出す側を基準側、この基準側に対向する側を対向側としたときに、

対向側の下部針床に係止される外側編地部の編目を、基準側の上部針床に目移しする工程κと、

前記工程κで目移しした編目がもともと係止されていた編針に対向する位置にある基準側の下部針床に係止される対象編目に対して割増やしを行って、前記工程κで空針となった編針に対象編目を目移しすると共に、その対象編目から引き出された割増やし目を、対象編目が係止されていた編針に、外側編地部の編目として形成する工程λと、

前記工程λで割増やしに伴い対向側の下部針床に目移しされた対象編目を、内側編地部の編目として、基準側の上部針床に目移しする工程μと、

前記工程κで目移しした編目を、目移し前にもともと係止されていた対向側の下部針床に戻す工程νと、

を繰り返すことを特徴とする請求項1に記載の多層構造の編地の編成方法。 In forming a standard arrangement by creating a new inner knitted fabric portion from a state in which the outer knitted fabric portion is locked in the total needle state,

When the side that creates the inner knitted fabric portion is the reference side, and the side that faces this reference side is the opposite side,

A step κ of transferring the stitches of the outer knitted fabric portion locked to the lower needle bed on the opposite side to the upper needle bed on the reference side;

The target stitch that is locked to the lower needle bed on the reference side at the position opposite to the knitting needle that was originally locked in the step κ is increased, and the empty needle in the step κ Transferring the target stitch to the resulting knitting needle, and forming the additional stitch pulled out from the target stitch as a stitch of the outer knitted fabric portion on the knitting needle on which the target stitch is locked;

The step μ of transferring the target stitch transferred to the lower needle bed on the opposite side with the split in the step λ to the upper needle bed on the reference side as the stitch of the inner knitted fabric portion,

A step ν of returning the stitch transferred in the step κ to the lower needle bed on the opposite side originally locked before the transfer,

The knitting method for a knitted fabric having a multilayer structure according to claim 1, wherein:

当該内側編地部は、隣接する編目間に1つ以上の空針を設けて編成することを特徴とする請求項1または2に記載の多層構造の編地の編成方法。 When forming the inner knitted fabric part on the upper needle bed of either the front or back,

The method for knitting a multi-layered knitted fabric according to claim 1 or 2, wherein the inner knitted fabric portion is knitted by providing one or more empty needles between adjacent stitches.

当該内側編地部は、隣接する編目間に3つ以上の空針を設けて編成することを特徴とする請求項1または2に記載の多層構造の編地の編成方法。 When forming the inner knitted fabric part on both upper and lower needle beds,

The knitting method for a knitted fabric having a multilayer structure according to claim 1 or 2, wherein the inner knitted fabric portion is knitted by providing three or more empty needles between adjacent stitches.

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010288587A JP5719584B2 (en) | 2010-12-24 | 2010-12-24 | Knitting method of knitted fabric with multilayer structure |

| EP11010165.6A EP2468934B1 (en) | 2010-12-24 | 2011-12-23 | Knitting method of knitted fabric having multilayered structure |

| CN201110437702.2A CN102534972B (en) | 2010-12-24 | 2011-12-23 | Knitting method of knitted fabric having multilayered structure |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010288587A JP5719584B2 (en) | 2010-12-24 | 2010-12-24 | Knitting method of knitted fabric with multilayer structure |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2012136793A JP2012136793A (en) | 2012-07-19 |

| JP2012136793A5 JP2012136793A5 (en) | 2014-01-09 |

| JP5719584B2 true JP5719584B2 (en) | 2015-05-20 |

Family

ID=45444361

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010288587A Expired - Fee Related JP5719584B2 (en) | 2010-12-24 | 2010-12-24 | Knitting method of knitted fabric with multilayer structure |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP2468934B1 (en) |

| JP (1) | JP5719584B2 (en) |

| CN (1) | CN102534972B (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103132220A (en) * | 2012-06-12 | 2013-06-05 | 盐城纺织职业技术学院 | Flat knitting machine local tubular structure and series of products of flat knitting machine |

| JP2014227611A (en) * | 2013-05-17 | 2014-12-08 | 株式会社島精機製作所 | Method for knitting fabric having rib pattern appearance and knitted fabric having rib pattern appearance |

| JP6501824B2 (en) * | 2017-05-29 | 2019-04-17 | 株式会社島精機製作所 | Bonding method of knitted fabric |

| CN108823772B (en) * | 2018-08-09 | 2020-04-07 | 福建荣荣新材料股份有限公司 | Flat knitting machine fabric with multilayer structure and method for knitting multilayer fabric by double-needle bed flat knitting machine |

| CN109594185B (en) * | 2019-02-08 | 2023-09-22 | 嘉兴市蒂维时装有限公司 | Edge-covering strip structure of knitted fabric piece and knitting method thereof |

| CN113279128A (en) * | 2021-05-21 | 2021-08-20 | 无锡太平针织有限公司 | Side face rotary weaving manufacturing process of four-needle bed full-forming protective sports connecting clothes and hat |

| GB2617060A (en) * | 2022-02-25 | 2023-10-04 | Prevayl Innovations Ltd | Fabric article and method of making the same |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0473245A (en) | 1990-07-13 | 1992-03-09 | Shima Seiki Mfg Ltd | Method for setting up and knit fabric thereby |

| JP2514489B2 (en) * | 1991-07-04 | 1996-07-10 | 株式会社島精機製作所 | Knitted fabric having quadruple structure and knitting method thereof |

| JPH0781228B2 (en) * | 1991-07-05 | 1995-08-30 | 株式会社島精機製作所 | Cylindrical knitted fabric having a three-dimensional silhouette and knitting method thereof |

| JP3148997B2 (en) * | 1991-09-21 | 2001-03-26 | 株式会社島精機製作所 | Needle retraction mechanism in 4-bed flat knitting machine |

| DE4419985C2 (en) * | 1994-06-08 | 1996-04-04 | Univ Dresden Tech | Multi-layer knitted fabric and process for its manufacture |

| JP3494487B2 (en) * | 1994-11-15 | 2004-02-09 | 株式会社島精機製作所 | Knitting method of tubular knitted fabric |

| JP3010480B2 (en) * | 1996-08-01 | 2000-02-21 | 株式会社島精機製作所 | Method of knitting woven jacquard consisting of double jersey organization on tubular knitted fabric |

| DE19717415A1 (en) * | 1997-04-25 | 1998-10-29 | Stoll & Co H | Process for the production of spatial, single or multi-surface knitted pieces on a flat knitting machine |

| DE10027534A1 (en) * | 2000-06-02 | 2001-12-13 | Stoll & Co H | Knitting of a tubular garment with circular band sections on a flatbed knitter uses four knitting planes and selective use of alternating needles in the two opposing needle beds |

| JP3888868B2 (en) * | 2001-08-29 | 2007-03-07 | 株式会社島精機製作所 | Rib knitted fabric knitting method |

| JP4336307B2 (en) * | 2004-12-28 | 2009-09-30 | 株式会社島精機製作所 | Knitting method of double tubular knitted fabric |

| JP2008163528A (en) * | 2006-12-29 | 2008-07-17 | Shima Seiki Mfg Ltd | Method for knitting knitwear |

-

2010

- 2010-12-24 JP JP2010288587A patent/JP5719584B2/en not_active Expired - Fee Related

-

2011

- 2011-12-23 EP EP11010165.6A patent/EP2468934B1/en not_active Not-in-force

- 2011-12-23 CN CN201110437702.2A patent/CN102534972B/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| EP2468934A3 (en) | 2015-09-16 |

| EP2468934B1 (en) | 2016-10-26 |

| CN102534972B (en) | 2015-05-13 |

| JP2012136793A (en) | 2012-07-19 |

| CN102534972A (en) | 2012-07-04 |

| EP2468934A2 (en) | 2012-06-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5719584B2 (en) | Knitting method of knitted fabric with multilayer structure | |

| WO2002070800A1 (en) | Knitted fabric having opening portion and knitting method therefor | |

| JP5349268B2 (en) | Knitting method of knitted fabric and knitted fabric | |

| JP3968100B2 (en) | Method for knitting tubular knitted fabric | |

| JP5567565B2 (en) | Knitwear having sleeves and body and knitting method thereof | |

| JP5980098B2 (en) | Method for knitting tubular knitted fabric, and tubular knitted fabric | |

| JP5603779B2 (en) | Inside increase method and knitted fabric | |

| KR101449913B1 (en) | Knitting method of knitted fabric | |

| JP2012082564A (en) | Binding off method | |

| JP6153551B2 (en) | How to create a knitted fabric | |

| JP4374309B2 (en) | Knitwear knitted by a flat knitting machine and its knitting method | |

| JP3251521B2 (en) | Knitted garment having two-layer structure and knitting method thereof | |

| JP5905221B2 (en) | Joining method of knitted fabric and knitted fabric | |

| WO2003057958A1 (en) | Neck forming method | |

| JP2012202006A (en) | Cylindrical fabric having partition and method for knitting the same | |

| JP6280991B2 (en) | Knitting method of knitted fabric | |

| WO2007020829A1 (en) | Knitting method of fabric having piping portion, and its fabric | |

| JP2015004150A (en) | Method for knitting knitted fabric in which lateral end part is strengthened | |

| JP6518549B2 (en) | Method of knitting shoe upper and shoe upper | |

| JP2020063545A (en) | Method for knitting tubular knitted fabric and tubular knitted fabric | |

| JP2013036122A (en) | Method for knitting fabric | |

| KR101384192B1 (en) | Knit wear | |

| JP6104080B2 (en) | Method for knitting a tubular knitted fabric having a slit | |

| JP5372914B2 (en) | Knitting method of knitted fabric having double stitches and knitted fabric | |

| JP2012001860A (en) | Method of knitting fabric in which fabric expressing colored design is overlapped and fabric |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20131118 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20131118 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20140821 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140825 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150316 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20150323 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5719584 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |