JP5509837B2 - Method for joining plate-like parts and joining member - Google Patents

Method for joining plate-like parts and joining member Download PDFInfo

- Publication number

- JP5509837B2 JP5509837B2 JP2009289629A JP2009289629A JP5509837B2 JP 5509837 B2 JP5509837 B2 JP 5509837B2 JP 2009289629 A JP2009289629 A JP 2009289629A JP 2009289629 A JP2009289629 A JP 2009289629A JP 5509837 B2 JP5509837 B2 JP 5509837B2

- Authority

- JP

- Japan

- Prior art keywords

- plate

- component

- sheet

- joining member

- protruding layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000005304 joining Methods 0.000 title claims description 173

- 238000000034 method Methods 0.000 title claims description 62

- 230000002093 peripheral effect Effects 0.000 claims description 48

- 238000002360 preparation method Methods 0.000 claims description 30

- 238000010030 laminating Methods 0.000 claims description 13

- 239000010410 layer Substances 0.000 description 131

- 239000004973 liquid crystal related substance Substances 0.000 description 61

- 239000000758 substrate Substances 0.000 description 17

- 239000004820 Pressure-sensitive adhesive Substances 0.000 description 14

- 230000001681 protective effect Effects 0.000 description 13

- 230000004048 modification Effects 0.000 description 10

- 238000012986 modification Methods 0.000 description 10

- 239000012788 optical film Substances 0.000 description 7

- 239000000853 adhesive Substances 0.000 description 6

- 230000001070 adhesive effect Effects 0.000 description 6

- 239000010408 film Substances 0.000 description 5

- 238000004519 manufacturing process Methods 0.000 description 3

- 230000005674 electromagnetic induction Effects 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- 239000003566 sealing material Substances 0.000 description 2

- 238000010521 absorption reaction Methods 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 238000005401 electroluminescence Methods 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 239000005341 toughened glass Substances 0.000 description 1

Images

Landscapes

- Liquid Crystal (AREA)

- Electroluminescent Light Sources (AREA)

- Adhesive Tapes (AREA)

- Adhesives Or Adhesive Processes (AREA)

- Devices For Indicating Variable Information By Combining Individual Elements (AREA)

Description

この発明は、板状部品の接合方法及び接合部材に関する。 The present invention relates to a method for joining plate-like components and a joining member.

例えば表示パネルの前側(観察側)に表示パネル保護板を配置した表示装置として、前記表示パネルと前記表示パネル保護板とを、両面粘着シート等のシート状接合部材により貼合わせたものがある(特許文献1参照)。 For example, as a display device in which a display panel protection plate is arranged on the front side (observation side) of the display panel, there is one in which the display panel and the display panel protection plate are bonded together by a sheet-like joining member such as a double-sided adhesive sheet ( Patent Document 1).

しかし、前記表示パネルと前記表示パネル保護板とをシート状接合部材により貼合わせる場合、前記保護板の前記表示パネルに対する貼付け面の所定部分、例えば前記表示パネルの画面エリア外の領域に対応する部分に、印刷層等の厚みをもった突出層が形成されていると、前記接合部材の前記突出層に重なった部分が押し潰されて応力を発生し、貼合わせ部に剥離等を生じさせる原因になる。 However, when the display panel and the display panel protection plate are bonded together by a sheet-like joining member, a predetermined portion of the bonding surface of the protection plate to the display panel, for example, a portion corresponding to an area outside the screen area of the display panel In addition, when a protruding layer having a thickness such as a printed layer is formed, the portion of the joining member that overlaps the protruding layer is crushed and generates stress, causing peeling or the like in the bonded portion become.

これは、前記表示パネルと保護板との接合に限らず、第1の板状部品と、前記第1の板状部品に対する貼付け面の所定部分に突出層が形成された第2の板状部品とをシート状接合部材により貼合わせる場合にも言える。 This is not limited to the joining of the display panel and the protective plate, but the first plate-like component and the second plate-like component in which the protruding layer is formed at a predetermined portion of the affixing surface to the first plate-like component. It can be said also when pasting together with a sheet-like joining member.

この発明は、第1の板状部品と前記第1の板状部品に対する貼付け面の所定部分に突出層が形成された第2の板状部品とを貼合せるためのシート状接合部材の前記突出層に重なった部分に生じる応力を低減しつつ前記第1の板状部品と第2の板状部品とを貼合わせることができる板状部品の接合方法及びそのための前記シート状接合部材を提供することを目的としたものである。 According to the present invention, the protrusion of the sheet-like joining member for bonding the first plate-like component and the second plate-like component having a protrusion layer formed on a predetermined portion of the attachment surface for the first plate-like component. Provided is a method for joining plate-like components capable of bonding the first plate-like component and the second plate-like component while reducing stress generated in a portion overlapping the layer, and the sheet-like joining member therefor. It is for the purpose.

請求項1に記載の発明は、第1の板状部品と、前記第1の板状部品に対する貼付け面の所定部分に突出層が形成された第2の板状部品とをシート状接合部材により貼合わせて接合する方法であって、

前記第1の板状部品を準備する第1部品準備工程と、

前記突出層が形成された前記第2の板状部品を準備する第2部品準備工程と、

前記第1の板状部品と前記第2の板状部品との間に前記突出層の一部と重なった状態で挟持される形状に形成され、且つ前記突出層と重なる部分の全域に、その重なり部を部分的に欠落させて前記突出層との接触面積を小さくした応力緩和部が形成されたシート状接合部材を準備する接合部材準備工程と、

前記第2の板状部品に、前記シート状接合部材を、前記突出層に前記応力緩和部が重なるように位置決めして貼付ける接合部材貼付け工程と、

前記第1の板状部品と前記第2の板状部品とを前記シート状接合部材を介して重ねて加圧し、前記第1の板状部品と前記第2の板状部品とを前記シート状接合部材により貼合わせる部品貼合わせ工程と、

を含むことを特徴とする。

According to the first aspect of the present invention, the first plate-like component and the second plate-like component in which the protruding layer is formed at a predetermined portion of the affixing surface to the first plate-like component are formed by a sheet-like joining member. A method of bonding and joining,

A first component preparation step of preparing the first plate-shaped component;

A second component preparation step of preparing the second plate-shaped component on which the protruding layer is formed;

Formed in a shape that is sandwiched between the first plate-like component and the second plate-like component in a state where it overlaps with a part of the protruding layer, and over the entire area overlapping the protruding layer, A joining member preparation step of preparing a sheet-like joining member in which a stress relaxation portion in which an overlapping portion is partially lost and the contact area with the protruding layer is reduced is formed;

A bonding member bonding step for positioning and bonding the sheet-shaped bonding member to the second plate-shaped component so that the stress relaxation portion overlaps the protruding layer;

The first plate-like component and the second plate-like component are overlapped and pressed through the sheet-like joining member, and the first plate-like component and the second plate-like component are put into the sheet-like shape. Component bonding process to be bonded by the joining member;

It is characterized by including.

請求項2に記載の発明は、第1の板状部品と、前記第1の板状部品に対する貼付け面の所定部分に突出層が形成された第2の板状部品とをシート状接合部材により貼合わせて接合する方法であって、

前記第1の板状部品を準備する第1部品準備工程と、

前記突出層が形成された前記第2の板状部品を準備する第2部品準備工程と、

前記第1の板状部品と前記第2の板状部品との間に前記突出層の一部と重なった状態で挟持される形状に形成され、且つ前記突出層と重なる部分の全域に、その重なり部を部分的に欠落させて前記突出層との接触面積を小さくした応力緩和部が形成されたシート状接合部材を準備する接合部材準備工程と、

前記第1の板状部品に前記シート状接合部材を貼付ける接合部材貼付け工程と、

前記第1の板状部品と前記第2の板状部品とを、前記突出層に前記応力緩和部が重なるように位置決めして、前記シート状接合部材を介して重ねて加圧し、前記第1の板状部品と前記第2の板状部品とを前記シート状接合部材により貼合わせる部品貼合わせ工程と、

を含むことを特徴とする。

According to a second aspect of the present invention, the first plate-like component and the second plate-like component in which the protruding layer is formed at a predetermined portion of the affixing surface to the first plate-like component are formed by a sheet-like joining member. A method of bonding and joining,

A first component preparation step of preparing the first plate-shaped component;

A second component preparation step of preparing the second plate-shaped component on which the protruding layer is formed;

Formed in a shape that is sandwiched between the first plate-like component and the second plate-like component in a state where it overlaps with a part of the protruding layer, and over the entire area overlapping the protruding layer, A joining member preparation step of preparing a sheet-like joining member in which a stress relaxation portion in which an overlapping portion is partially lost and the contact area with the protruding layer is reduced is formed;

A joining member attaching step of attaching the sheet-like joining member to the first plate-like component;

The first plate-like component and the second plate-like component are positioned so that the stress relieving portion overlaps the protruding layer, and the first plate-like component and the second plate-like component are overlapped and pressurized via the sheet-like joining member, Component laminating step of laminating the plate-shaped component and the second plate-shaped component with the sheet-shaped joining member

It is characterized by including.

請求項3に記載の発明は、前記請求項1または2に記載の板状部品の接合方法において、第1周縁部に枠形状の突出層が形成された前記第2の板状部品を準備し、前記接合部材準備工程で、第2周縁部が前記突出層の少なくとも内周側の縁部と重なる形状に形成され、且つ前記第2周縁部に、前記突出層と重なる部分の全域にわたって前記応力緩和部が形成されたシート状接合部材を準備することを特徴とする。 According to a third aspect of the present invention, in the method for joining plate-like components according to the first or second aspect, the second plate-like component having a frame-shaped protruding layer formed on the first peripheral edge is prepared. In the joining member preparing step, the second peripheral edge portion is formed in a shape overlapping with at least the inner peripheral edge of the protruding layer, and the stress is applied to the second peripheral edge portion over the entire area overlapping with the protruding layer. A sheet-like joining member in which a relaxation portion is formed is prepared.

請求項4に記載の発明は、前記請求項1から3の何れかに記載の板状部品の接合方法において、前記部品貼合わせ工程を、真空圧下で行うことを特徴とする。 According to a fourth aspect of the present invention, in the method for joining plate-shaped components according to any of the first to third aspects, the component laminating step is performed under vacuum pressure.

請求項5に記載の発明は、前記請求項1から4の何れかに記載の板状部品の接合方法において、前記部品貼合わせ工程後に、前記第1の板状部品と前記第2の板状部品とに対して熱と圧力とを一定時間付与するオートクレーブを行うオートクレーブ工程をさらに含むことを特徴とする。

The invention according to

請求項6に記載の発明は、前記請求項5に記載の板状部品の接合方法において、前記接合部材準備工程で、前記周縁部に、その外周縁から前記突出層と重なる部分の全幅にわたる形状の複数の切欠部を所定のピッチで形成した応力緩和部が形成されたシート状接合部材を準備することを特徴とする。

The invention described in claim 6 is the method of bonding the plate-like component according to

請求項7に記載の発明は、前記請求項5に記載の板状部品の接合方法において、前記接合部材準備工程で、前記周縁部に、その外周縁を前記突出層と重なる部分の全幅にわたる振幅をもった波形状に形成した応力緩和部が形成されたシート状接合部材を準備することを特徴とする。

The invention described in

請求項8に記載の発明は、前記請求項5に記載の板状部品の接合方法において、前記接合部材準備工程で、前記周縁部の前記突出層と重なる部分に、複数の貫通孔を所定のピッチで設けた応力緩和部が形成されたシート状接合部材を準備することを特徴とする。

The invention according to

請求項9に記載の発明は、第1の板状部品と、前記第1の板状部品に対する貼付け面の所定部分に突出層が形成された第2の板状部品とを貼合わせるためのシート状接合部材であって、前記第1の板状部品と前記第2の板状部品との間に前記突出層の一部と重なった状態で挟持される平面形状に形成され、前記突出層と重なる部分の全域に、その重なり部を部分的に欠落させて前記突出層との接触面積を小さくした応力緩和部が形成されたシート部材からなることを特徴とする。

The invention according to

この発明によれば、第1の板状部品と前記第1の板状部品に対する貼付け面の所定部分に突出層が形成された第2の板状部品とを貼合せるための前記シート状接合部材の前記突出層に重なった部分に生じる応力を低減しつつ前記第1の板状部品と第2の板状部品とを貼合わせることができる。 According to this invention, the sheet-like joining member for laminating the first plate-like component and the second plate-like component having a protruding layer formed on a predetermined portion of the affixing surface to the first plate-like component. The first plate-like component and the second plate-like component can be bonded together while reducing the stress generated in the portion overlapping the protruding layer.

[実施例1]

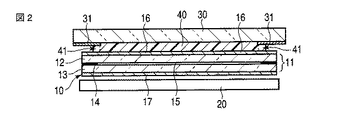

まず、図2に示した表示装置について説明すると、この表示装置は、表示パネル10と、この表示パネル10の前側(観察側)に、透明なシート状接合部材40により前記表示パネル10と貼合わせて配置された透明な表示パネル保護板30とを備えている。

[Example 1]

First, the display device shown in FIG. 2 will be described. This display device is bonded to the

この実施例において、前記表示パネル10は液晶表示パネルであり、図1及び図2のように、対向配置された2枚の透明基板12,13間に液晶層15が設けられた表示パネル本体11と、前記表示パネル本体11の各基板12,13の外面にそれぞれ貼付けられた前側光学フィルム16及び後側光学フィルム17とからなっている。

In this embodiment, the

前記表示パネル本体11は、TFT(薄膜トランジスタ)をアクティブイブ素子としたアクティブイブ型のものであり、図では省略しているが、前記2枚の透明基板12,13のうちの一方の基板、例えば後側基板13の液晶層15と対向する面に、行方向及び列方向に配列された複数の画素電極と、これらの画素電極にそれぞれ対応させて配置された複数のTFTと、各行の複数のTFTにゲート信号を供給する複数の走査線と、各列の複数のTFTにデータ信号を供給する複数のデータ線とが設けられ、他方の基板、つまり前側基板12の液晶層15と対向する面に、前記複数の画素電極と対向する一枚膜状の共通電極が設けられている。

The

さらに、他方の基板13の液晶層15と対向する面には、前記複数の画素電極と前記共通電極とが互いに対向する領域からなる複数の画素にそれぞれ対応させて、赤、緑、青の三色のカラーフィルタが設けられている。なお、前記共通電極は、前記カラーフィルタの前記液晶層15側の面上に形成されている。

Further, on the surface of the

そして、前記2枚の基板12,13は、前記複数の画素の配列領域からなる画面エリア11aを囲む枠状のシール材14を介して接合されており、これらの基板12,13間の間隙の前記シール材14で囲まれた領域に液晶層15が設けられている。

The two

この表示パネル本体11は、例えばTN(ツイステッドネマティック)型のものであり、前記液晶層15の液晶分子は、各基板12,13にそれぞれ前記各画素電極及び共通電極を覆って設けられた配向膜によりそれぞれの基板12,13面における配向方向を規定され、前記基板12,13において略90の捩れ角でツイスト配向している。

The

また、前側光学フィルム16及び後側光学フィルム17はそれぞれ偏光板であり、これらの偏光板16,17は、それぞれの吸収軸を互いに直交させるか、或いは互いに平行にして配置されている。

Further, the front

さらに、前記液晶表示パネル10の後側には、図2のように、前記液晶表示パネル10の画面エリア11aに向けて光を照射する面光源20が配置されている。なお、図では前記面光源20を簡略化しているが、この面光源20は、その一端面に光を入射させる入射端面が形成され、二つの板面の一方に前記入射端面から入射した光の出射面が形成され、他方の板面に前記入射端面から入射した光を前記出射面に向けて反射する反射面が形成された導光板と、前記導光板の入射端面に対向させて配置されたLED(発光ダイオード)等からなる複数の発光素子とを含む。そして、この面光源20は、前記導光板の出射面を前記液晶表示パネル10の後面に対向させて配置されている。

Further, as shown in FIG. 2, a

一方、前記表示パネル保護板30は、強化ガラスまたは硬質樹脂からなっており、前記液晶表示パネル10に対する貼付け面の所定部分に、印刷層等からなる突出層31が形成されている。この実施例において、前記突出層31は、任意の色の着色層であり、前記液晶表示パネル10の画面エリア11aに対向する領域の外側に、前記画面エリア11aを囲む枠形状に形成されている。

On the other hand, the display

なお、前記表示パネル保護板30は、前記液晶表示パネル10の前面の面積よりもある程度大きい面積を有する矩形形状に形成されており、前記突出層31は、前記画面エリア10aの周縁に対向する位置から前記表示パネル保護板30の外周縁にわたって形成されている。

The display

また、前記液晶表示パネル10と前記表示パネル保護板30とを貼合わせるための前記シート状接合部材40は、可撓性及び圧縮変形性をもった透明なシート部材からなっている。この実施例のシート状接合部材40は、両面粘着シートからなっている。

Further, the sheet-like joining

なお、図に示したシート状接合部材40は、粘着剤をシート状に成形した両面粘着シートであるが、前記シート状接合部材40は、ベースフィルムの両面にそれぞれ粘着剤層を設けた両面粘着シートでもよい。

The sheet-

このシート状接合部材40は、前記液晶表示パネル10と表示パネル保護板30との間に、前記突出層31の一部と重なった状態で挟持される平面形状に形成されている。この実施例において、前記シート状接合部材40は、その外形が前記液晶表示パネル10の前面の外形よりも小さく、且つ周縁部が、前記表示パネル保護板30に形成された前記突出層31の内周側の縁部と重なる形状に形成されている。

The sheet-like joining

そして、前記シート状接合部材40の前記突出層31の周縁部には、図1〜図3のように、前記突出層31と重なる部分の略全域にわたって、その重なり部を部分的に欠落させて前記突出層31との接触面積を小さくした応力緩和部41が形成されている。この際、表示パネル保護板30側から見たシート状接合部材40の面積が、シート状接合部材40の全体を取り囲む最小の閉曲線で囲まれる領域の面積よりも小さくなるように、シート状接合部材40の突出層31との重なり部を部分的に欠落させることにより、突出層31との接触面積を小さくした応力緩和部41が形成される。

And in the peripheral part of the said

この実施例のシート状接合部材40の応力緩和部41は、前記シート状接合部材40の外周縁から前記突出層31と重なる部分の略全幅にわたる形状の複数の切欠部42を所定のピッチで形成した凹凸縁部からなっている。

The

前記複数の切欠部42は、できるだけ小さいピッチ、好ましくは5mm以下、より好ましくは2〜3mm以下のピッチで形成するのが望ましい。

The plurality of

この実施例で、シート状接合部材40に、台形形状の複数の切欠部42を隣り合う切欠部42,42間に三角形状の切り残し部43を形成するピッチで設けた応力緩和部41を形成している。

In this embodiment, a

なお、前記両面粘着シートからなるシート状接合部材40は、図4及び図5のように、その両面をセパレータ(剥離紙)45a,45bにより保護されており、前記液晶表示パネル10と表示パネル保護板30とを貼合わせるときに、前記セパレータ45a,45bを剥ぎ取って使用される。

The sheet-like joining

上記表示装置の製造において、前記液晶表示パネル10と、前記突出層31が形成された前記表示パネル保護板30との貼合わせは、第1部品準備工程、第2部品準備工程、接合部材準備工程、接合部材貼付け工程及び部品貼合わせ工程と、前記部品貼合わせ工程後に行うオートクレーブ工程とを含む次のような接合方法で行う。

In the production of the display device, the liquid

(第1部品準備工程)

第1の板状部品として、前記液晶表示パネル10を準備する。

(First part preparation process)

The liquid

(第2部品準備工程)

第2の板状部品として、前記液晶表示パネル10の画面エリア11aに対向する領域の外側に前記突出層31が形成された前記表示パネル保護板30を準備する。

(Second part preparation process)

As the second plate-like component, the display

(接合部材準備工程)

前記両面粘着シートからなり、周縁部のうち、前記表示パネル保護板30の突出層31と重なる部分に前記応力緩和部41が形成された前記シート状接合部材40を準備する。

(Jointing member preparation process)

The sheet-like joining

(接合部材貼付け工程)

前記表示パネル保護板30に前記シート状接合部材40を、前記突出層31に前記応力緩和部41が重なるように位置決めして貼付ける。

(Jointing member pasting process)

The sheet-like joining

この実施例では、図6(a)のように、前記突出層31が形成された表示パネル保護板30の前記液晶表示パネル10に対する貼付け面(突出層31が形成された面)に、前記シート状接合部材40の一方の面を、この一方の面側のセパレータ45aを剥ぎ取って対向させ、前記シート状接合部材40を前記表示パネル保護板30の前記貼付け面及び突出層31に押付けることにより、図6(b)のように、前記シート状接合部材40を前記表示パネル保護板30の前記貼付け面に、前記突出層31に前記応力緩和部41に重ねて貼付ける。

In this embodiment, as shown in FIG. 6 (a), the display

この接合部材貼付け工程において、前記シート状接合部材40は可撓性をもっているため、このシート状接合部材40の周縁部を、前記突出層31の厚みに合わせて屈曲させ、前記表示パネル保護板30板面上と前記突出層31上との両方に当接した状態で貼付けることができる。

In the bonding member attaching step, since the sheet-

(部品貼合わせ工程)

次に、前記シート状接合部材40の他方の面側のセパレータ45bを剥ぎ取り、図6(c)のように、前記液晶表示パネル10と表示パネル保護板30とを前記シート状接合部材40を介して重ねて加圧することにより、図6(d)のように、前記液晶表示パネル10と表示パネル保護板30とを前記シート状接合部材40により貼合わせる。この実施例において、前記液晶表示パネル10と表示パネル保護板30との前記シート状接合部材40による貼合わせは、図示しない真空チャンバ等を利用して真空圧下において行う。ここで真空として例えば30Pa(2.961×10−4atm)以下程度にまで真空引きを行うことが好ましい。しかしながら、空気介在部が発生することを抑制できれば、必ずしも30Pa以下まで真空引きしなくてもよい。

(Parts bonding process)

Next, the

このように、前記液晶表示パネル10と表示パネル保護板30とを前記シート状接合部材40を介して重ねて加圧すると、前記シート状接合部材40の前記突出層31に重ねられた周縁部が押し潰されて前記シート状接合部材40がその全域において前記液晶表示パネル10と表示パネル保護板30とに密着し、前記液晶表示パネル10と表示パネル保護板30とが前記シート状接合部材40により貼合わされる。

Thus, when the liquid

この部品貼合わせ工程において、前記シート状接合部材40は、前記突出層31に重ねられた周縁部を押し潰されるため、このシート状接合部材40の押し潰された部分に応力が発生する。

In this component laminating step, the sheet-like joining

しかし、前記シート状接合部材40の前記突出層31と重なる部分には、上記のように、前記シート状接合部材40の外周縁から前記突出層31と重なる部分の略全幅にわたる深さの複数の切欠部42を周縁部の全周に所定のピッチで形成した凹凸縁部からなる応力緩和部41が形成されているため、前記シート状接合部材40の押し潰された部分に発生する応力を小さくすることができる。

However, as described above, the portion of the sheet-

すなわち、前記シート状接合部材40の押し潰された部分に発生する応力の大きさは、その押し潰された部分の面積に略比例する。前記シート状接合部材40は、前記突出層31と重なる部分に前記凹凸縁部からなる応力緩和部41を形成したものであるため、前記突出層31と重なって押し潰される部分の面積は、前記応力緩和部41のうちの前記複数の切欠部42,42の間の各切り残し部43の面積と略同じである。従って、前記シート状接合部材40の押し潰された部分に発生する応力を、各辺の縁部をそれぞれ前記複数の切欠部42の無い直線縁部に形成したシート状接合部材に発生する応力に比べて小さくすることができる。

That is, the magnitude of the stress generated in the crushed portion of the sheet-like joining

そのため、前記液晶表示パネル10と、前記突出層31が形成された前記表示パネル保護板30とを、前記シート状接合部材40の前記突出層31に重なった部分に大きな応力を生じさせることなく貼合わせることができる。

Therefore, the liquid

なお、前記接合部材貼付け工程において、前記シート状接合部材40は、図6(b)のように、その周縁部を屈曲させて前記表示パネル保護板30板面上から前記突出層31上にわたって貼付けるが、そのときに、前記表示パネル保護板30板面と前記突出層31の内周縁との間の段差部に、空気が閉じ込められることがある。

In the joining member pasting step, the sheet-like joining

また、前記部品貼合わせ工程において、前記液晶表示パネル10は、図6(c)のように、前記表示パネル保護板30に一方の面を貼付けられた前記シート状接合部材40の他方の面に押付けられるが、そのときに、前記シート状接合部材40の前記突出層31上に重なった周縁部で囲まれた部分と前記液晶表示パネル10との間の隙間に空気が閉じ込められる。なお、上記実施例では、前記液晶表示パネル10と表示パネル保護板30との貼合わせを真空圧下で行っているが、真空圧下での貼合わせでも、ある程度の量の空気が閉じ込められる。

Moreover, in the said component bonding process, the said liquid

前記表示パネル保護板30及び液晶表示パネル10と前記シート状接合部材40との間に閉じ込められた空気の殆んどは、図7のように、前記突出層31の内周に沿った部分(平行斜線を施した部分)に集まって空気溜まりAを形成する。

Most of the air trapped between the display

前記空気溜まりAができると、その部分の表示パネル保護板30とシート状接合部材40との密着力及び液晶表示パネル10とシート状接合部材40との密着力が弱くなる。また、前記空気溜まりAがあると、その部分を透過する光が屈折したり散乱したりするため、表示装置の表示品質を低下させてしまう。

When the air reservoir A is formed, the adhesion between the display

(オートクレーブ工程)

そのため、この実施例では、前記貼合わされた液晶表示パネル10と表示パネル保護板30とに対して熱と圧力とを一定時間付与するオートクレーブを行ない、前記接合部材貼付け工程及び前記部品貼合わせ工程において前記表示パネル保護板30及び液晶表示パネル10と前記シート状接合部材40との間に閉じ込められた空気を前記シート状接合部材40中に溶け込ませて前記空気溜まりAを消去している。

(Autoclave process)

Therefore, in this embodiment, an autoclave for applying heat and pressure to the bonded liquid

このように、上記接合方法は、前記液晶表示パネル10と、前記突出層31が形成された前記表示パネル保護板30とを、前記突出層31に重なる部分に前記応力緩和部41を形成したシート状接合部材40により接合しているため、前記液晶表示パネル10と表示パネル保護板30とを、前記シート状接合部材40の前記突出層31に重なった部分に大きな応力を生じさせることなく貼合わせることができ、従って、前記液晶表示パネル10と表示パネル保護板30との貼合わせ部に、前記応力による剥離等が生じるのを抑制することができる。

As described above, the bonding method includes a sheet in which the liquid

しかも、前記シート状接合部材40の応力緩和部41は、前記シート状接合部材40の外周縁から前記突出層31と重なる部分の略全幅にわたる形状の複数の切欠部42を所定のピッチで形成した凹凸縁部からなっているため、このシート状接合部材40の応力緩和部41においても、前記複数の切欠部42の間の各切り残し部43により、前記液晶表示パネル10と表示パネル保護板30とを充分な強度で貼合わせることができる。

In addition, the

また、上記接合方法は、前記液晶表示パネル10と表示パネル保護板30との貼合わせ後に、前記オートクレーブを行なっているため、前記表示パネル保護板30及び液晶表示パネル10と前記シート状接合部材40との間に空気が閉じ込められた場合には、その閉じ込められた空気を前記シート状接合部材40中に溶け込ませ、前記液晶表示パネル10と表示パネル保護板30との貼合わせ強度を、前記シート状接合部材40による貼合わせ領域の全域において高く維持すると共に、前記空気溜まりAによる透過光の屈折や散乱をなくし、高い表示品質の表示装置を得ることができる。

Moreover, since the said joining method is performing the said autoclave after bonding the said liquid

なお、上記第1実施例における表示パネル保護板30は、前記液晶表示パネル10の前面の面積よりもある程度大きい面積を有するものであるが、この表示パネル保護板30は、前記液晶表示パネル10の前面の面積と同程度の面積を有するものでもよい。

Note that the display

また、前記シート状接合部材40は、その周縁部が、前記表示パネル保護板30に形成された前記突出層31の略全幅にわたって重なる外形を有し、前記周縁部の前記突出層31と重なる部分に前記応力緩和部41が形成されたものでもよい。

In addition, the sheet-like joining

さらに、上記第1実施例における表示パネル保護板30は、その外周縁から前記突出層31と重なる部分の略全幅にわたる形状の複数の切欠部42を所定のピッチで形成した凹凸縁部からなる応力緩和部41を形成したものであるが、この応力緩和部は、前記突出層31との重なり部を部分的に欠落させて前記突出層31との接触面積を小さくした形状であれば、他の形状に形成してもよい。

Further, the display

またさらに、前記接合部材貼付け工程では、前記表示パネル保護板30に前記シート状接合部材40を前記突出層31に前記応力緩和部41が重なるように位置決めして貼付けたが、前記液晶表示パネル10に前記シート状接合部材40を貼付けてもよい。この場合、部品貼合わせ工程において、前記液晶表示パネル10と前記表示パネル保護板30とを、前記突出層31に前記応力緩和部41が重なるように位置決めして、前記シート状接合部材40を介して重ねて加圧し、前記液晶表示パネル10と前記表示パネル保護板30とを前記シート状接合部材40により貼合わせるとよい。

Furthermore, in the joining member attaching step, the sheet-like joining

図8に示した第1変形例のシート状接合部材40aは、両面粘着シートからなるシート部材の外周縁を、前記表示パネル保護板30に形成された突出層31と重なる部分の略全幅にわたる振幅をもった三角波形状に形成した波状縁部からなる応力緩和部41aを形成したものである。

The sheet-like joining

図9に示した第2変形例のシート状接合部材40bは、両面粘着シートからなるシート部材の外周縁を、前記表示パネル保護板30に形成された突出層31と重なる部分の略全幅にわたる振幅をもった矩形波形状に形成した波状縁部からなる応力緩和部41bを形成したものである。

The sheet-like joining

図10に示した第3変形例のシート状接合部材40cは、両面粘着シートからなるシート部材の外周縁を、前記表示パネル保護板30に形成された突出層31と重なる部分の略全幅にわたる振幅をもった正弦波形状に形成した波状縁部からなる応力緩和部41cを形成したものである。

The sheet-like joining

なお、上記第1〜第3変形例のシート状接合部材40a,40b,40cにおいて、前記応力緩和部41a,41b,41cは、できるだけ小さいピッチ、好ましくは5mm以下、より好ましくは2〜3mm以下のピッチの波形状に形成するのが望ましい。

In the sheet-like joining

また、第1乃至第3変形例ではシート状接合部材40bの外周縁を前記突出層31と重なる部分の略全幅にわたる振幅をもった形状に形成したが、前記外周縁を前記突出層31と重なる部分の一部の幅にわたる振幅をもった形状に形成してもよい。

In the first to third modifications, the outer peripheral edge of the sheet-like joining

図11に示した第4変形例のシート状接合部材40dは、両面粘着シートからなるシート部材の周縁部の前記突出層31と重なる部分に、複数の貫通孔44を所定のピッチで設けた孔配列部からなる応力緩和部41dを形成したものである。

The sheet-like joining

この第4変形例のシート状接合部材40dにおいて、前記応力緩和部41dの複数の貫通孔44は、できるだけ小さいピッチ、好ましくは5mm以下、より好ましくは2〜3mm以下のピッチで設けるのが望ましい。

In the sheet-like joining

また、上記実施例の接合方法は、液晶表示パネル10と突出層31が形成された表示パネル保護板30との貼合わせに限らず、基板上に有機EL(エレクトロルミネッセンス)発光層が設けられ、前記基板の外面に例えばプリズムシート等の光学フィルムが貼付けられた有機EL表示パネルと前記表示パネル保護板30との貼合わせにも適用することができる。その場合は、前記第1部品準備工程で、第1の板状部品として前記有機EL表示パネルを準備する。また、有機EL表示パネルの他にもプラズマ表示装置やフィールドエミッション表示装置等といった他の表示装置に適用してもよい。

In addition, the bonding method of the above embodiment is not limited to the bonding of the liquid

[実施例2]

図12に示したタッチ入力装置は、抵抗膜方式、静電容量方式、光学方式、電磁誘導方式または超音波方式の何れかのタッチパネル18と、前記タッチパネル18の前面に、シート状接合部材46により前記タッチパネル18と貼合わせて配置されたタッチパネル保護板32とを備えている。

[Example 2]

The touch input device shown in FIG. 12 has a resistive film type, a capacitance type, an optical type, an electromagnetic induction type or an ultrasonic

なお、この実施例において、前記タッチパネル18は、前記タッチパネル保護板32の貼付け面とは反対面に配置された表示パネル10を備えたものであり、前記表示パネル10は、上記第1実施例の液晶表示パネルからなっている。

In this embodiment, the

前記液晶表示パネル10は、その前面(前側偏光板16の外面)を図示しない透明な両面粘着シート等により前記タッチパネル18に貼付けて配置されており、この液晶表示パネル10の後側に、上記第1実施例と同様な面光源20が配置されている。

The liquid

このタッチ入力装置の製造において、前記タッチパネル18と前記タッチパネル保護板32との貼合わせは、第1部品準備工程、第2部品準備工程、接合部材準備工程、接合部材貼付け工程及び部品貼合わせ工程と、前記部品貼合わせ工程後に行うオートクレーブ工程とを含む次のような接合方法で行う。

In the manufacture of the touch input device, the bonding between the

(第1部品準備工程)

第1の板状部品として、前記タッチパネル保護板32の貼付け面とは反対面に前記液晶表示パネル10が配置されたタッチパネル18を準備する。

(First part preparation process)

As a first plate-like component, a

(第2部品準備工程)

第2の板状部品として、前記タッチパネル18の外形と略同じ形状に形成され、前記タッチパネル18に対する貼付け面の周縁部に、前記タッチパネル18のタッチエリア(図示せず)に対向する領域の外側に印刷層等からなる枠形状の突出層33が形成されたタッチパネル保護板32を準備する。

(Second part preparation process)

As a 2nd plate-shaped component, it is formed in the shape substantially the same as the external shape of the said

なお、この第2部品準備工程において、前記タッチパネル18がタッチ圧による抵抗膜同士の接触を検知する抵抗膜方式のタッチパネルである場合は、前記タッチパネル保護板32として可撓性保護板を準備する。また、前記タッチパネル18が静電容量方式または電磁誘導方式のタッチパネルである場合は、前記タッチパネル保護板32として誘電性保護板を準備する。さらに、前記タッチパネル18が光学方式のタッチパネルである場合は、前記タッチパネル保護板32として光の屈折性が小さい保護板を準備し、前記タッチパネル18が超音波方式のタッチパネルである場合は、前記タッチパネル保護板32として超音波伝達性の高い保護板を準備する。

In the second component preparation step, when the

(接合部材準備工程)

前記タッチパネル18と前記タッチパネル保護板32との間に前記突出層33の略全体と重なった状態で挟持される平面形状に形成され、前記突出層33と重なる部分に、その重なり部を部分的に欠落させて前記突出層33との接触面積を小さくした応力緩和部47が形成された両面粘着シートからなるシート状接合部材46を準備する。

(Jointing member preparation process)

A flat shape is formed between the

なお、このシート状接合部材46の応力緩和部47は、上記第1の実施例及びその第1〜第4変形例のシート状接合部材40,40a,40b,40c,40dの応力緩和部41,41a,41b,41c,41dの何れかと同じ形状に形成されている。

In addition, the

(接合部材貼付け工程)

前記タッチパネル18とタッチパネル保護板32の一方、望ましくは前記突出層33が形成されたタッチパネル保護板32に、前記シート状接合部材46を、前記突出層33に前記応力緩和部47が重なるように位置決めして貼付ける。

(Jointing member pasting process)

The sheet-like joining

(部品貼合わせ工程)

次に、真空圧下において、前記タッチパネル18とタッチパネル保護板32とを前記シート状接合部材46を介して重ねて加圧することにより、前記タッチパネル18とタッチパネル保護板32とを前記シート状接合部材46により貼合わせる。

(Parts bonding process)

Next, under the vacuum pressure, the

このように、前記タッチパネル18とタッチパネル保護板32とを前記シート状接合部材46を介して重ねて加圧すると、前記シート状接合部材46の前記突出層33に重ねられた周縁部が押し潰されて前記シート状接合部材46がその全域において前記タッチパネル18と前記タッチパネル保護板32とに密着し、前記タッチパネル18とタッチパネル保護板32とが前記シート状接合部材46により貼合わされる。

As described above, when the

このタッチパネル18とタッチパネル保護板32との貼合わせにおいて、前記シート状接合部材46の前記突出層31と重なる部分に前記応力緩和部47が形成されているため、前記タッチパネル18とタッチパネル保護板32とを、前記シート状接合部材46の前記突出層33に重なった部分に大きな応力を生じさせることなく貼合わせることができる。

In the bonding of the

(オートクレーブ工程)

次に、前記貼合わされたタッチパネル18とタッチパネル保護板32とに対して熱と圧力を一定時間付与するオートクレーブを行ない、前記接合部材貼付け工程及び前記部品貼合わせ工程において前記タッチパネル保護板32及びタッチパネル18と前記シート状接合部材46との間に閉じ込められた空気を前記シート状接合部材46中に溶け込ませる。

(Autoclave process)

Next, an autoclave for applying heat and pressure to the bonded

このように、上記接合方法は、前記タッチパネル18と、前記突出層33が形成された前記タッチパネル保護板32とを、前記突出層33に重なる部分に前記応力緩和部47を形成したシート状接合部材46により接合しているため、前記タッチパネル18とタッチパネル保護板32とを、前記シート状接合部材46の前記突出層33に重なった部分に大きな応力を生じさせることなく貼合わせることができ、従って、前記タッチパネル18とタッチパネル保護板32との貼合わせ部に、前記応力による剥離等が生じることを抑制することができる。

As described above, the joining method includes a sheet-like joining member in which the

しかも、前記シート状接合部材46の応力緩和部47は、前記突出層33と重なる部分に、その重なり部を部分的に欠落させて前記突出層33との接触面積を小さくした形状に形成されているため、このシート状接合部材46の応力緩和部47においても、前記タッチパネル18とタッチパネル保護板32とを充分な強度で貼合わせることができる。

In addition, the

また、上記接合方法は、前記タッチパネル18とタッチパネル保護板32との貼合わせ後に、前記オートクレーブを行なっているため、前記タッチパネル保護板32及びタッチパネル18と前記シート状接合部材46との間に閉じ込められた空気を前記シート状接合部材46中に溶け込ませ、前記タッチパネル18とタッチパネル保護板32との貼合わせ強度を、前記シート状接合部材46による貼合わせ領域の全域において高く維持することができる。

Moreover, since the said joining method is performing the said autoclave after bonding of the said

なお、この実施例の接合方法は、タッチパネル保護板32の貼付け面とは反対面に液晶表示パネル10が配置されたタッチパネル18と前記タッチパネル保護板32との貼合わせに限らず、タッチパネル保護板32の貼付け面とは反対面に前記有機EL表示パネルやプラズマ表示装置、フィールドエミッション表示装置等といった他の表示装置が配置されたタッチパネル18と前記タッチパネル保護板32との貼合わせにも適用することができる。

In addition, the joining method of this embodiment is not limited to the bonding of the

さらに、この実施例の接合方法は、タッチパネル保護板32の貼付け面とは反対面に表示パネル等を配置していない単体のタッチパネル18と前記タッチパネル保護板32との貼合わせにも適用することができる。

Furthermore, the joining method of this embodiment can be applied to bonding of the touch panel

[実施例3]

図13に示した液晶表示パネル10aは、上記第1及び第2実施例における液晶表示パネル10の2枚の偏光板16,17のうちの前側偏光板16の表示パネル本体11に対する貼付け面の周縁部に、印刷層等からなる突出層35を、前記表示パネル本体11の画面エリア11a(図1参照)を囲む枠形状に形成し、前記表示パネル本体11と前記前側偏光板16とを、シート状接合部材48により貼合わせたものである。

[Example 3]

The liquid

なお、前記液晶表示パネル10aの後側偏光板17は、前記突出層35等を形成しない偏光板であり、図示しない両面粘着シート等により前記表示パネル本体11の後面(後側基板13の外面)に貼付けられている。また、前記液晶表示パネル10aの後側には、上記第1実施例と同様な面光源20が配置されている。

The rear

この液晶表示パネル10aの製造において、前記表示パネル本体11と前記前側偏光板16との貼合わせは、第1部品準備工程、第2部品準備工程、接合部材準備工程、接合部材貼付け工程及び部品貼合わせ工程と、前記部品貼合わせ工程後に行うオートクレーブ工程とを含む次のような接合方法で行う。

In the manufacture of the liquid

(第1部品準備工程)

第1の板状部品として、対向配置された2枚の透明基板12,13間に液晶層15が設けられ、後面に前記後側偏光板17が貼付られた表示パネル本体11を準備する。

(First part preparation process)

As a first plate-like component, a

(第2部品準備工程)

第2の板状部品として、前記表示パネル本体11の外形と略同じ形状に形成され、前記表示パネル本体11に対する貼付け面の周縁部に前記突出層35が形成された前側偏光板16を準備する。

(Second part preparation process)

As the second plate-like component, a front

(接合部材準備工程)

前記表示パネル本体11と前記前側偏光板16との間に前記突出層33の略全体と重なった状態で挟持される平面形状に形成され、前記突出層35と重なる部分に、その重なり部を部分的に欠落させて前記突出層33との接触面積を小さくした応力緩和部49が形成された両面粘着シートからなるシート状接合部材48を準備する。

(Jointing member preparation process)

The planar shape is formed between the

なお、このシート状接合部材48の応力緩和部49は、上記第1の実施例及びその第1〜第4変形例のシート状接合部材40,40a,40b,40c,40dの応力緩和部41,41a,41b,41c,41dの何れかと同じ形状に形成されている。

In addition, the

(接合部材貼付け工程)

前記表示パネル本体11と前側偏光板16の一方、望ましくは前記突出層35が形成された前側偏光板16に、前記シート状接合部材48を、前記突出層35に前記応力緩和部49が重なるように位置決めして貼付ける。

(Jointing member pasting process)

One of the

(部品貼合わせ工程)

次に、真空圧下において、前記表示パネル本体11と前側偏光板16とを前記シート状接合部材48を介して重ねて加圧することにより、前記表示パネル本体11と前側偏光板16とを前記シート状接合部材48により貼合わせる。

(Parts bonding process)

Next, under vacuum pressure, the display panel

このように、前記表示パネル本体11と前側偏光板16とを前記シート状接合部材48を介して重ねて加圧すると、前記シート状接合部材48の前記突出層35に重ねられた周縁部が押し潰されて前記シート状接合部材48がその全域において前記表示パネル本体11と前側偏光板16とに密着し、前記表示パネル本体11と前側偏光板16とが前記シート状接合部材48により貼合わされる。

As described above, when the

この表示パネル本体11と前側偏光板16との貼合わせにおいて、前記シート状接合部材48の前記突出層35と重なる部分に前記応力緩和部49が形成されているため、前記表示パネル本体11と前側偏光板16とを、前記シート状接合部材48の前記突出層35に重なった部分に大きな応力を生じさせることなく貼合わせることができる。

In the bonding of the

(オートクレーブ工程)

次に、前記貼合わされた表示パネル本体11と前側偏光板16とに対して熱と圧力とを一定時間付与するオートクレーブを行ない、前記接合部材貼付け工程及び前記部品貼合わせ工程において前記表示パネル本体11及び前側偏光板16と前記シート状接合部材48との間に閉じ込められた空気を前記シート状接合部材48中に溶け込ませる。

(Autoclave process)

Next, an autoclave for applying heat and pressure to the bonded

このように、上記接合方法は、前記表示パネル本体11と、前記突出層35が形成された前記前側偏光板16とを、前記突出層35に重なる部分に前記応力緩和部49を形成したシート状接合部材48により接合しているため、前記表示パネル本体11と前側偏光板16とを、前記シート状接合部材48の前記突出層35に重なった部分に大きな応力を生じさせることなく貼合わせることができ、従って、前記表示パネル本体11と前側偏光板16との貼合わせ部に、前記応力による剥離等が生じることを抑制することができる。

As described above, the bonding method is a sheet-like structure in which the

しかも、前記シート状接合部材48の応力緩和部49は、前記突出層35と重なる部分に、その重なり部を部分的に欠落させて前記突出層35との接触面積を小さくした形状に形成されているため、このシート状接合部材48の応力緩和部49においても、前記表示パネル本体11と前側偏光板16とを充分な強度で貼合わせることができる。

In addition, the

また、上記接合方法は、前記表示パネル本体11と前側偏光板16との貼合わせ後に、前記オートクレーブを行なっているため、前記前側偏光板16及び表示パネル本体11と前記シート状接合部材48との間に閉じ込められた空気を前記シート状接合部材48中に溶け込ませ、前記表示パネル本体11と前側偏光板16との貼合わせ強度を、前記シート状接合部材48による貼合わせ領域の全域において高く維持することができる。

Moreover, since the said joining method is performing the said autoclave after bonding the said display panel

なお、この実施例の接合方法は、前記表示パネル本体11と前側偏光板16との貼合わせに限らず、基板上に有機EL発光層が設けられた表示パネル本体と、前記表示パネル本体に対する貼付け面の周縁部に突出層を形成したプリズムシート等の光学フィルムとの貼合わせにも適用することができる。また、有機EL表示パネルの他にもプラズマ表示装置やフィールドエミッション表示装置等といった他の表示装置に適用してもよい。

Note that the bonding method of this embodiment is not limited to the bonding of the

[他の実施例]

なお、上記各実施例においては、第1の板状部品と第2の板状部品とを貼合わせるためのシート状接合部材40,46,48として両面粘着シートを用いているが、前記シート状接合部材40,46,48は、両面粘着シートに限らず、例えば両面に熱重合性または光重合性接着剤を塗布した樹脂シート等でもよく、その場合は、前記オートクレーブ工程後に、前記熱重合性または光重合性接着剤を重合させればよい。

[Other embodiments]

In each of the above embodiments, a double-sided pressure-sensitive adhesive sheet is used as the sheet-like joining

また、前記第1の板状部品と前記第2の板状部品は、上記各実施例のものに限らず、他の板状部品でもよい。さらに、前記第2の板状部品は、周縁部に限らず、周縁部以外の部分(例えば表示パネルの画面エリア内に対向する部分)に突出層を形成したものでもよく、その場合は、シート状接合部材の前記突出層に重なる部分に、複数の貫通孔を所定のピッチで設けた応力緩和部を形成すればよい。 Further, the first plate-like component and the second plate-like component are not limited to those in the above embodiments, and may be other plate-like components. Furthermore, the second plate-like component is not limited to the peripheral portion, and may be a member in which a protruding layer is formed in a portion other than the peripheral portion (for example, a portion facing the screen area of the display panel). What is necessary is just to form the stress relaxation part which provided the several through-hole with the predetermined pitch in the part which overlaps with the said protrusion layer of a cylindrical joining member.

10…液晶表示パネル、11…表示パネル本体、11a…画面エリア、12,13…透明基板、15…液晶層、16,17…光学フィルム(偏光板)、18…タッチパネル、20…面光源、30…表示パネル保護板、32…タッチパネル保護板、31,33,35…突出層、40,40a,40b,40c,40d,46,48…シート状接合部材、41,41a,41b,41c,41d,47,49…応力緩和部、42…切欠部、43…切り残し部、44…貫通孔、45a,45b…セパレータ、A…空気溜まり

DESCRIPTION OF

Claims (9)

前記第1の板状部品を準備する第1部品準備工程と、

前記突出層が形成された前記第2の板状部品を準備する第2部品準備工程と、

前記第1の板状部品と前記第2の板状部品との間に前記突出層の一部と重なった状態で挟持される形状に形成され、且つ前記突出層と重なる部分の全域に、その重なり部を部分的に欠落させて前記突出層との接触面積を小さくした応力緩和部が形成されたシート状接合部材を準備する接合部材準備工程と、

前記第2の板状部品に、前記シート状接合部材を、前記突出層に前記応力緩和部が重なるように位置決めして貼付ける接合部材貼付け工程と、

前記第1の板状部品と前記第2の板状部品とを前記シート状接合部材を介して重ねて加圧し、前記第1の板状部品と前記第2の板状部品とを前記シート状接合部材により貼合わせる部品貼合わせ工程と、

を含むことを特徴とする板状部品の接合方法。 The first plate-shaped component and the second plate-shaped component in which a protruding layer is formed on a predetermined portion of the bonding surface for the first plate-shaped component are bonded and bonded together by a sheet-shaped bonding member. ,

A first component preparation step of preparing the first plate-shaped component;

A second component preparation step of preparing the second plate-shaped component on which the protruding layer is formed;

Formed in a shape that is sandwiched between the first plate-like component and the second plate-like component in a state where it overlaps with a part of the protruding layer, and over the entire area overlapping the protruding layer, A joining member preparation step of preparing a sheet-like joining member in which a stress relaxation portion in which an overlapping portion is partially lost and the contact area with the protruding layer is reduced is formed;

A bonding member bonding step for positioning and bonding the sheet-shaped bonding member to the second plate-shaped component so that the stress relaxation portion overlaps the protruding layer;

The first plate-like component and the second plate-like component are overlapped and pressed through the sheet-like joining member, and the first plate-like component and the second plate-like component are put into the sheet-like shape. Component bonding process to be bonded by the joining member;

The joining method of the plate-shaped components characterized by including.

前記第1の板状部品を準備する第1部品準備工程と、

前記突出層が形成された前記第2の板状部品を準備する第2部品準備工程と、

前記第1の板状部品と前記第2の板状部品との間に前記突出層の一部と重なった状態で挟持される形状に形成され、且つ前記突出層と重なる部分の全域に、その重なり部を部分的に欠落させて前記突出層との接触面積を小さくした応力緩和部が形成されたシート状接合部材を準備する接合部材準備工程と、

前記第1の板状部品に前記シート状接合部材を貼付ける接合部材貼付け工程と、

前記第1の板状部品と前記第2の板状部品とを、前記突出層に前記応力緩和部が重なるように位置決めして、前記シート状接合部材を介して重ねて加圧し、前記第1の板状部品と前記第2の板状部品とを前記シート状接合部材により貼合わせる部品貼合わせ工程と、

を含むことを特徴とする板状部品の接合方法。 The first plate-shaped component and the second plate-shaped component in which a protruding layer is formed on a predetermined portion of the bonding surface for the first plate-shaped component are bonded and bonded together by a sheet-shaped bonding member. ,

A first component preparation step of preparing the first plate-shaped component;

A second component preparation step of preparing the second plate-shaped component on which the protruding layer is formed;

Formed in a shape that is sandwiched between the first plate-like component and the second plate-like component in a state where it overlaps with a part of the protruding layer, and over the entire area overlapping the protruding layer, A joining member preparation step of preparing a sheet-like joining member in which a stress relaxation portion in which an overlapping portion is partially lost and the contact area with the protruding layer is reduced is formed;

A joining member attaching step of attaching the sheet-like joining member to the first plate-like component;

The first plate-like component and the second plate-like component are positioned so that the stress relieving portion overlaps the protruding layer, and the first plate-like component and the second plate-like component are overlapped and pressurized via the sheet-like joining member, Component laminating step of laminating the plate-shaped component and the second plate-shaped component with the sheet-shaped joining member

The joining method of the plate-shaped components characterized by including.

前記第1の板状部品と前記第2の板状部品との間に前記突出層の一部と重なった状態で挟持される平面形状に形成され、前記突出層と重なる部分の全域に、その重なり部を部分的に欠落させて前記突出層との接触面積を小さくした応力緩和部が形成されたシート部材からなることを特徴とするシート状接合部材。 A sheet-shaped joining member for bonding a first plate-shaped component and a second plate-shaped component in which a protruding layer is formed on a predetermined portion of a bonding surface for the first plate-shaped component,

Formed in a planar shape that is sandwiched between the first plate-like component and the second plate-like component in a state where it overlaps a part of the protruding layer, and over the entire area overlapping the protruding layer, A sheet-like joining member comprising a sheet member formed with a stress relaxation portion in which an overlapping portion is partially omitted to reduce a contact area with the protruding layer.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009289629A JP5509837B2 (en) | 2009-12-21 | 2009-12-21 | Method for joining plate-like parts and joining member |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009289629A JP5509837B2 (en) | 2009-12-21 | 2009-12-21 | Method for joining plate-like parts and joining member |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2011127072A JP2011127072A (en) | 2011-06-30 |

| JP2011127072A5 JP2011127072A5 (en) | 2012-12-13 |

| JP5509837B2 true JP5509837B2 (en) | 2014-06-04 |

Family

ID=44290014

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009289629A Expired - Fee Related JP5509837B2 (en) | 2009-12-21 | 2009-12-21 | Method for joining plate-like parts and joining member |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5509837B2 (en) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5982179B2 (en) * | 2012-05-28 | 2016-08-31 | 株式会社東芝 | Semiconductor light emitting device and manufacturing method thereof |

| JP6135902B2 (en) * | 2012-11-06 | 2017-05-31 | 株式会社ジャパンディスプレイ | Display device |

| JP6324045B2 (en) * | 2013-12-04 | 2018-05-16 | 三菱電機株式会社 | Display device |

| JP7280009B2 (en) * | 2016-04-18 | 2023-05-23 | 日東電工株式会社 | liquid crystal display |

| JP2017194672A (en) | 2016-04-18 | 2017-10-26 | 日東電工株式会社 | Liquid crystal display |

| KR102633523B1 (en) * | 2016-04-18 | 2024-02-06 | 닛토덴코 가부시키가이샤 | Liquid Crystal Display Device |

| WO2017183498A1 (en) * | 2016-04-18 | 2017-10-26 | 日東電工株式会社 | Liquid crystal display device |

| JP7280008B2 (en) * | 2016-04-18 | 2023-05-23 | 日東電工株式会社 | liquid crystal display |

| WO2017183499A1 (en) * | 2016-04-18 | 2017-10-26 | 日東電工株式会社 | Liquid crystal display device |

| CN111177962B (en) * | 2019-12-20 | 2023-04-07 | 惠州市华星光电技术有限公司 | Curved-surface display panel and gluing method thereof |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001027879A (en) * | 1999-07-14 | 2001-01-30 | Bando Chem Ind Ltd | Manufacture of laminated sheet for liquid crystal display panel and manufacture of liquid crystal display panel |

| DE10058956A1 (en) * | 2000-11-28 | 2002-06-06 | Tesa Ag | Adhesive tape for running reel changes, e.g. in paper splicing, has splitting carrier system with self-adhesive on both sides and notches along front edge where cleavage starts during splicing process |

| JP3827971B2 (en) * | 2001-06-15 | 2006-09-27 | コニシ株式会社 | Induction heating adhesive tape |

| JP4612337B2 (en) * | 2004-05-11 | 2011-01-12 | 三菱樹脂株式会社 | Method for manufacturing panel laminate |

| JP2008111040A (en) * | 2006-10-30 | 2008-05-15 | Kyocera Corp | Adhesive tape |

| JP2009263502A (en) * | 2008-04-25 | 2009-11-12 | Sekisui Chem Co Ltd | Adhesive sheet and display device using it |

-

2009

- 2009-12-21 JP JP2009289629A patent/JP5509837B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2011127072A (en) | 2011-06-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5509837B2 (en) | Method for joining plate-like parts and joining member | |

| JP4888532B2 (en) | Electronic member with protective plate | |

| KR101113289B1 (en) | Method for forming display panel with curved shape, display panel with curved shape using the method, and multi-layer image display device using the display panel | |

| TWI379261B (en) | Curved display panel and manufacturing method thereof | |

| JP4462317B2 (en) | Protection plate integrated display panel | |

| KR101113734B1 (en) | Method for manufacturing display panel with curved shape | |

| JP6122439B2 (en) | Curved display panel manufacturing method | |

| JP6070394B2 (en) | Liquid crystal display device and manufacturing method thereof | |

| KR20120013265A (en) | Method for forming display panel with curved shape, display panel with curved shape using the method, and multi-layer image display device using the display panel | |

| KR20120029090A (en) | Method for manufacturing display panel with curved shape | |

| JP2018120087A (en) | Method of manufacturing display device, and display device | |

| JP2007178758A (en) | Display device | |

| JP2010156784A (en) | Liquid crystal display apparatus | |

| JP5487915B2 (en) | Protective plate integrated type liquid crystal display panel manufacturing method | |

| CN107807750A (en) | Cover plate and the display device including cover plate | |

| JP5646744B2 (en) | Display module and display device including the module | |

| WO2013118475A1 (en) | Display apparatus | |

| JP5541707B2 (en) | Display module | |

| JP2013250900A (en) | Information processing apparatus and method of manufacturing the same | |

| JP5315965B2 (en) | Protective plate integrated display panel and manufacturing method thereof | |

| JP2012003177A (en) | Protection plate integrated liquid crystal display panel | |

| JP2010066706A (en) | Liquid crystal display | |

| JP2003337543A (en) | Display device | |

| JP2012008422A (en) | Polarizing plate, display panel, electronic apparatus, and method for manufacturing display panel | |

| WO2008026374A1 (en) | Polarizing plate, polarizing plate manufacturing method, display panel and display element |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121025 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20121025 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20131010 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20131203 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140124 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20140225 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140310 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5509837 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |