JP5317990B2 - プロセス流中の微生物学的活性をモニタリングする方法 - Google Patents

プロセス流中の微生物学的活性をモニタリングする方法 Download PDFInfo

- Publication number

- JP5317990B2 JP5317990B2 JP2009549721A JP2009549721A JP5317990B2 JP 5317990 B2 JP5317990 B2 JP 5317990B2 JP 2009549721 A JP2009549721 A JP 2009549721A JP 2009549721 A JP2009549721 A JP 2009549721A JP 5317990 B2 JP5317990 B2 JP 5317990B2

- Authority

- JP

- Japan

- Prior art keywords

- flow cell

- probe

- process stream

- fluid

- opening

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims abstract description 243

- 230000008569 process Effects 0.000 title claims abstract description 201

- 230000002906 microbiologic effect Effects 0.000 title claims abstract description 72

- 238000012544 monitoring process Methods 0.000 title claims abstract description 29

- 230000004071 biological effect Effects 0.000 claims abstract description 4

- 239000000523 sample Substances 0.000 claims description 150

- 239000012530 fluid Substances 0.000 claims description 93

- 230000007246 mechanism Effects 0.000 claims description 59

- 238000005259 measurement Methods 0.000 claims description 56

- 238000004140 cleaning Methods 0.000 claims description 42

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 25

- 230000000694 effects Effects 0.000 claims description 11

- 238000009825 accumulation Methods 0.000 claims description 7

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 abstract description 22

- 239000001301 oxygen Substances 0.000 abstract description 22

- 229910052760 oxygen Inorganic materials 0.000 abstract description 22

- 230000000813 microbial effect Effects 0.000 description 24

- 230000015572 biosynthetic process Effects 0.000 description 20

- 239000003139 biocide Substances 0.000 description 19

- 230000003287 optical effect Effects 0.000 description 18

- 230000003115 biocidal effect Effects 0.000 description 17

- 244000005700 microbiome Species 0.000 description 15

- 239000002689 soil Substances 0.000 description 15

- 239000000126 substance Substances 0.000 description 15

- 230000000443 biocontrol Effects 0.000 description 9

- 238000012806 monitoring device Methods 0.000 description 8

- 239000000123 paper Substances 0.000 description 8

- 230000004044 response Effects 0.000 description 8

- 238000004458 analytical method Methods 0.000 description 6

- 238000011109 contamination Methods 0.000 description 6

- 239000007800 oxidant agent Substances 0.000 description 6

- 239000013049 sediment Substances 0.000 description 6

- 241000233866 Fungi Species 0.000 description 5

- 238000013459 approach Methods 0.000 description 5

- 230000008878 coupling Effects 0.000 description 5

- 238000010168 coupling process Methods 0.000 description 5

- 238000005859 coupling reaction Methods 0.000 description 5

- 238000010586 diagram Methods 0.000 description 5

- 241000894007 species Species 0.000 description 5

- ZKHQWZAMYRWXGA-KQYNXXCUSA-J ATP(4-) Chemical compound C1=NC=2C(N)=NC=NC=2N1[C@@H]1O[C@H](COP([O-])(=O)OP([O-])(=O)OP([O-])([O-])=O)[C@@H](O)[C@H]1O ZKHQWZAMYRWXGA-KQYNXXCUSA-J 0.000 description 4

- ZKHQWZAMYRWXGA-UHFFFAOYSA-N Adenosine triphosphate Natural products C1=NC=2C(N)=NC=NC=2N1C1OC(COP(O)(=O)OP(O)(=O)OP(O)(O)=O)C(O)C1O ZKHQWZAMYRWXGA-UHFFFAOYSA-N 0.000 description 4

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 4

- 241000894006 Bacteria Species 0.000 description 4

- QDHHCQZDFGDHMP-UHFFFAOYSA-N Chloramine Chemical compound ClN QDHHCQZDFGDHMP-UHFFFAOYSA-N 0.000 description 4

- KFSLWBXXFJQRDL-UHFFFAOYSA-N Peracetic acid Chemical compound CC(=O)OO KFSLWBXXFJQRDL-UHFFFAOYSA-N 0.000 description 4

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 description 4

- 239000005708 Sodium hypochlorite Substances 0.000 description 4

- 230000015556 catabolic process Effects 0.000 description 4

- 238000004891 communication Methods 0.000 description 4

- 238000006731 degradation reaction Methods 0.000 description 4

- 238000000151 deposition Methods 0.000 description 4

- OSVXSBDYLRYLIG-UHFFFAOYSA-N dioxidochlorine(.) Chemical compound O=Cl=O OSVXSBDYLRYLIG-UHFFFAOYSA-N 0.000 description 4

- 239000012528 membrane Substances 0.000 description 4

- SUKJFIGYRHOWBL-UHFFFAOYSA-N sodium hypochlorite Chemical compound [Na+].Cl[O-] SUKJFIGYRHOWBL-UHFFFAOYSA-N 0.000 description 4

- KZNICNPSHKQLFF-UHFFFAOYSA-N succinimide Chemical compound O=C1CCC(=O)N1 KZNICNPSHKQLFF-UHFFFAOYSA-N 0.000 description 4

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 3

- 230000008859 change Effects 0.000 description 3

- 239000013626 chemical specie Substances 0.000 description 3

- 230000008021 deposition Effects 0.000 description 3

- 239000000835 fiber Substances 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 230000001590 oxidative effect Effects 0.000 description 3

- 230000036284 oxygen consumption Effects 0.000 description 3

- 230000037361 pathway Effects 0.000 description 3

- 229920000642 polymer Polymers 0.000 description 3

- KEQGZUUPPQEDPF-UHFFFAOYSA-N 1,3-dichloro-5,5-dimethylimidazolidine-2,4-dione Chemical compound CC1(C)N(Cl)C(=O)N(Cl)C1=O KEQGZUUPPQEDPF-UHFFFAOYSA-N 0.000 description 2

- UUIVKBHZENILKB-UHFFFAOYSA-N 2,2-dibromo-2-cyanoacetamide Chemical compound NC(=O)C(Br)(Br)C#N UUIVKBHZENILKB-UHFFFAOYSA-N 0.000 description 2

- GUUULVAMQJLDSY-UHFFFAOYSA-N 4,5-dihydro-1,2-thiazole Chemical compound C1CC=NS1 GUUULVAMQJLDSY-UHFFFAOYSA-N 0.000 description 2

- YIROYDNZEPTFOL-UHFFFAOYSA-N 5,5-Dimethylhydantoin Chemical compound CC1(C)NC(=O)NC1=O YIROYDNZEPTFOL-UHFFFAOYSA-N 0.000 description 2

- KXDHJXZQYSOELW-UHFFFAOYSA-M Carbamate Chemical compound NC([O-])=O KXDHJXZQYSOELW-UHFFFAOYSA-M 0.000 description 2

- 239000004155 Chlorine dioxide Substances 0.000 description 2

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 2

- SXRSQZLOMIGNAQ-UHFFFAOYSA-N Glutaraldehyde Chemical compound O=CCCCC=O SXRSQZLOMIGNAQ-UHFFFAOYSA-N 0.000 description 2

- MHAJPDPJQMAIIY-UHFFFAOYSA-N Hydrogen peroxide Chemical compound OO MHAJPDPJQMAIIY-UHFFFAOYSA-N 0.000 description 2

- CBENFWSGALASAD-UHFFFAOYSA-N Ozone Chemical compound [O-][O+]=O CBENFWSGALASAD-UHFFFAOYSA-N 0.000 description 2

- XSQUKJJJFZCRTK-UHFFFAOYSA-N Urea Chemical compound NC(N)=O XSQUKJJJFZCRTK-UHFFFAOYSA-N 0.000 description 2

- 230000003213 activating effect Effects 0.000 description 2

- 230000001464 adherent effect Effects 0.000 description 2

- 230000004103 aerobic respiration Effects 0.000 description 2

- 150000001413 amino acids Chemical class 0.000 description 2

- 150000003863 ammonium salts Chemical class 0.000 description 2

- PQRDTUFVDILINV-UHFFFAOYSA-N bcdmh Chemical compound CC1(C)N(Cl)C(=O)N(Br)C1=O PQRDTUFVDILINV-UHFFFAOYSA-N 0.000 description 2

- 235000013361 beverage Nutrition 0.000 description 2

- 125000001246 bromo group Chemical group Br* 0.000 description 2

- 239000004202 carbamide Substances 0.000 description 2

- 239000003153 chemical reaction reagent Substances 0.000 description 2

- 239000000460 chlorine Substances 0.000 description 2

- 235000019398 chlorine dioxide Nutrition 0.000 description 2

- 239000000498 cooling water Substances 0.000 description 2

- 230000002596 correlated effect Effects 0.000 description 2

- 230000005284 excitation Effects 0.000 description 2

- 238000005111 flow chemistry technique Methods 0.000 description 2

- 230000005484 gravity Effects 0.000 description 2

- 230000010354 integration Effects 0.000 description 2

- ZFSLODLOARCGLH-UHFFFAOYSA-N isocyanuric acid Chemical compound OC1=NC(O)=NC(O)=N1 ZFSLODLOARCGLH-UHFFFAOYSA-N 0.000 description 2

- 239000004973 liquid crystal related substance Substances 0.000 description 2

- 230000007257 malfunction Effects 0.000 description 2

- 230000004060 metabolic process Effects 0.000 description 2

- 229910052757 nitrogen Inorganic materials 0.000 description 2

- 235000015097 nutrients Nutrition 0.000 description 2

- 230000003647 oxidation Effects 0.000 description 2

- 238000007254 oxidation reaction Methods 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 150000003856 quaternary ammonium compounds Chemical class 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 239000003381 stabilizer Substances 0.000 description 2

- 238000003860 storage Methods 0.000 description 2

- 229960002317 succinimide Drugs 0.000 description 2

- IIACRCGMVDHOTQ-UHFFFAOYSA-M sulfamate Chemical compound NS([O-])(=O)=O IIACRCGMVDHOTQ-UHFFFAOYSA-M 0.000 description 2

- 102000016938 Catalase Human genes 0.000 description 1

- 108010053835 Catalase Proteins 0.000 description 1

- 108010059892 Cellulase Proteins 0.000 description 1

- 238000007792 addition Methods 0.000 description 1

- 230000032770 biofilm formation Effects 0.000 description 1

- 229940106157 cellulase Drugs 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 238000012937 correction Methods 0.000 description 1

- 238000013480 data collection Methods 0.000 description 1

- 230000007812 deficiency Effects 0.000 description 1

- 229910052736 halogen Inorganic materials 0.000 description 1

- 150000002367 halogens Chemical class 0.000 description 1

- 238000011534 incubation Methods 0.000 description 1

- 239000008235 industrial water Substances 0.000 description 1

- 230000000977 initiatory effect Effects 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 230000002503 metabolic effect Effects 0.000 description 1

- 238000000386 microscopy Methods 0.000 description 1

- 239000011368 organic material Substances 0.000 description 1

- 239000011087 paperboard Substances 0.000 description 1

- 230000002085 persistent effect Effects 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 239000010453 quartz Substances 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- 238000010561 standard procedure Methods 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N33/00—Investigating or analysing materials by specific methods not covered by groups G01N1/00 - G01N31/00

- G01N33/18—Water

- G01N33/1806—Biological oxygen demand [BOD] or chemical oxygen demand [COD]

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12Q—MEASURING OR TESTING PROCESSES INVOLVING ENZYMES, NUCLEIC ACIDS OR MICROORGANISMS; COMPOSITIONS OR TEST PAPERS THEREFOR; PROCESSES OF PREPARING SUCH COMPOSITIONS; CONDITION-RESPONSIVE CONTROL IN MICROBIOLOGICAL OR ENZYMOLOGICAL PROCESSES

- C12Q1/00—Measuring or testing processes involving enzymes, nucleic acids or microorganisms; Compositions therefor; Processes of preparing such compositions

- C12Q1/02—Measuring or testing processes involving enzymes, nucleic acids or microorganisms; Compositions therefor; Processes of preparing such compositions involving viable microorganisms

- C12Q1/04—Determining presence or kind of microorganism; Use of selective media for testing antibiotics or bacteriocides; Compositions containing a chemical indicator therefor

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N33/00—Investigating or analysing materials by specific methods not covered by groups G01N1/00 - G01N31/00

- G01N33/18—Water

- G01N33/1893—Water using flow cells

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N33/00—Investigating or analysing materials by specific methods not covered by groups G01N1/00 - G01N31/00

- G01N33/48—Biological material, e.g. blood, urine; Haemocytometers

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N33/00—Investigating or analysing materials by specific methods not covered by groups G01N1/00 - G01N31/00

- G01N33/48—Biological material, e.g. blood, urine; Haemocytometers

- G01N33/50—Chemical analysis of biological material, e.g. blood, urine; Testing involving biospecific ligand binding methods; Immunological testing

- G01N33/53—Immunoassay; Biospecific binding assay; Materials therefor

- G01N33/569—Immunoassay; Biospecific binding assay; Materials therefor for microorganisms, e.g. protozoa, bacteria, viruses

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T436/00—Chemistry: analytical and immunological testing

- Y10T436/11—Automated chemical analysis

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T436/00—Chemistry: analytical and immunological testing

- Y10T436/11—Automated chemical analysis

- Y10T436/117497—Automated chemical analysis with a continuously flowing sample or carrier stream

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T436/00—Chemistry: analytical and immunological testing

- Y10T436/20—Oxygen containing

- Y10T436/207497—Molecular oxygen

- Y10T436/209163—Dissolved or trace oxygen or oxygen content of a sealed environment

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Immunology (AREA)

- Physics & Mathematics (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- Pathology (AREA)

- Molecular Biology (AREA)

- General Physics & Mathematics (AREA)

- Organic Chemistry (AREA)

- Food Science & Technology (AREA)

- Medicinal Chemistry (AREA)

- Biomedical Technology (AREA)

- Wood Science & Technology (AREA)

- Zoology (AREA)

- Proteomics, Peptides & Aminoacids (AREA)

- Urology & Nephrology (AREA)

- Biotechnology (AREA)

- Microbiology (AREA)

- Hematology (AREA)

- Biophysics (AREA)

- Toxicology (AREA)

- Bioinformatics & Cheminformatics (AREA)

- General Engineering & Computer Science (AREA)

- Genetics & Genomics (AREA)

- Emergency Medicine (AREA)

- Biodiversity & Conservation Biology (AREA)

- Tropical Medicine & Parasitology (AREA)

- Virology (AREA)

- Cell Biology (AREA)

- Measuring Or Testing Involving Enzymes Or Micro-Organisms (AREA)

- Apparatus Associated With Microorganisms And Enzymes (AREA)

- Investigating Or Analyzing Non-Biological Materials By The Use Of Chemical Means (AREA)

Description

「DO」は、溶存酸素を表す。

プロセス流中の微生物活動は、細胞が好気呼吸状態下で生成しているATPの量と溶存酸素の消費量が直接的に関連するため、溶存酸素の消費をモニタリングすることによって間接的に測定でき、細胞が生成するATPの量は前記プロセス流中の微生物活動のレベルと相関付けできる。本発明に記載の方法は、好気呼吸が微生物細胞中のエネルギ生成の主経路ではない場合の低レベルのDOを有するプロセス流に対しては好適ではない。

機構はプロセス流中の溶存酸素を実際に測定するために開発された。例えばORPプローブのような、他の分析装置はこの機構に付随してもよい。

プロセス流中のバルク型の(全体の)微生物学的活性をモニタリングする方法が開示される。バルク型の(全体の)微生物学的活性は、プロセス流中のプランクトン様の微生物及び固着性の微生物のような、バルク型のプロセス流中の微生物活動である。

表面結合型の微生物学的活性は、例えば生物膜のような、表面型微生物の微生物活動である。

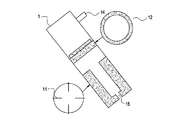

バルク型の微生物学的活性は、表面結合型の微生物学的活性と併用してモニタリングできる。プロセス流中のバルク型の微生物学的活性と、表面結合型の微生物学的活性とを測定する方法は、(a)機構を前記プロセス流に連結するステップであって、前記機構が、複数の開口を含むフローセルであって、少なくとも1の開口が前記プロセス流から引き込まれる流体用のフローセル入口であり、少なくとも1の開口が前記フローセルを出る流体用のフローセル出口であるフローセルと、前記開口のうちの1つに取付けられる1つのDOプローブと、選択的に前記開口のうちの1つに取付けられるORPプローブと、前記開口のうちの1つに取付けられる洗浄装置と、選択的にフローセル入口に取り付けられる第1の導管と、選択的にフローセル出口に取り付けられる第2の導管と、前記フローセルに付随するバルブとを含むステップと、(b)流体が前記フローセル内に引き込まれるのを可能にすべく、前記機構のバルブを開けるステップと、(c)前記プロセス流から前記フローセル内に前記流体を引き込むステップと、(d)前記DOプローブで前記プロセス流のDO濃度を少なくとも1回測定するステップであって、前記DOプローブは各測定前に洗浄されないステップと、(e)前記DOプローブの表面を洗浄するステップと、(f)前記DOプローブで前記機構内部の流体のDO濃度を少なくとも1回測定するステップであって、選択的に各測定前に前記DOプローブの表面が洗浄されるステップと、(g)更なる流体が前記フローセル内に引き込まれるのを防ぐために前記機構のバルブを閉じるステップと、(h)前記DOプローブで前記機構内部の流体のDO濃度を少なくとも1回測定するステップであって、各測定前に前記DOプローブの表面が洗浄されるステップと、(i)ステップ(f)とステップ(h)との間のΔDOの読取り値を計算し、前記ΔDOを前記プロセス流中の前記バルク型の微生物学的活性と少なくとも相関づけるステップと、(j)ステップ(d)とステップ(f)との間のΔDOの読取り値を計算し、前記ΔDOを前記プロセス流中の前記表面結合型の微生物学的活性と少なくとも相関づけるステップとを含む。

Claims (6)

- プロセス流中のバルク型の(全体の)微生物学的な水分活性をモニタリングするための方法であって、

a.機構をプロセス流に連結するステップであって、前記機構が、複数の開口を含むフローセルであって、少なくとも1の開口が前記プロセス流から引き込まれる流体用のフローセル入口であり、少なくとも1の開口が前記フローセルを出る流体用のフローセル出口であるフローセルと、前記開口のうちの1つに取付けられる1つのDOプローブと、前記開口のうちの1つに取付けられる洗浄装置と、前記フローセル入口に取り付けられる第1の導管と、前記フローセルに付随するバルブとを含むステップと、

b.流体が前記フローセル内に引き込まれるのを可能にすべく、前記機構のバルブを開けるステップと、

c.前記プロセス流から前記フローセル内に前記流体を引き込むステップと、

d.前記DOプローブで前記プロセス流のDO濃度を少なくとも1回測定するステップであって、各測定前に前記DOプローブの表面が洗浄されるステップと、

e.更なる流体が前記フローセル内に引き込まれるのを防ぐために前記機構のバルブを閉じるステップと、

f.前記流体が前記フローセル内に維持された流動停止状態で、前記DOプローブで前記機構内部の流体のDO濃度を少なくとも1回測定するステップであって、各測定前に前記DOプローブの表面が洗浄されるステップと、

g.ステップ(d)とステップ(f)との間のΔDOの読取り値を計算するステップと、

h.ステップ(g)中の前記ΔDOの値を、前記プロセス流中のバルク型の(全体の)微生物学的活性と少なくとも相関づけるステップと、

を含むことを特徴とする方法。 - 前記機構は、前記開口のうちの1つに取付けられるORPプローブと、前記フローセル出口に取り付けられる第2の導管と、を含むことを特徴とする請求項1記載の方法。

- プロセス流中の表面結合型の微生物学的活性をモニタリングする方法であって、

a.機構をプロセス流に連結するステップであって、前記機構が、複数の開口を含むフローセルであって、少なくとも1の開口が前記プロセス流から引き込まれる流体用のフローセル入口であり、少なくとも1の開口が前記フローセルを出る流体用のフローセル出口であるフローセルと、前記開口のうちの1つに取付けられる1つのDOプローブと、前記開口のうちの1つに取付けられる洗浄装置と、前記フローセル入口に取り付けられる第1の導管と、前記フローセルに付随するバルブとを含むステップと、

b.流体が前記フローセル内に引き込まれるのを可能にすべく、前記機構のバルブを開けるステップと、

c.前記プロセス流から前記フローセル内に前記流体を引き込むステップと、

d.前記DOプローブで前記プロセス流のDO濃度を少なくとも1回測定するステップであって、前記DOプローブは各測定前に洗浄されず、生体膜の蓄積が生じる時間が経過した後にDO濃度が測定されるステップと、

e.前記DOプローブの表面を洗浄するステップと、

f.前記DOプローブで前記機構内部の流体のDO濃度を少なくとも1回測定するステップであって、各測定前に前記DOプローブの表面が洗浄され、流動開始中の拭き取り直後にDO濃度が測定されるステップと、

g.ステップ(d)とステップ(f)との間のΔDOの読取り値を計算するステップと、

h.ステップ(g)中の前記ΔDOを表面結合型の生物学的活性と相関づけるステップと、

を含むことを特徴とする方法。 - 前記機構は、前記開口のうちの1つに取付けられるORPプローブと、前記フローセル出口に取り付けられる第2の導管と、を含むことを特徴とする請求項3記載の方法。

- プロセス流中のバルク型の微生物学的活性と表面結合型の微生物学的活性とをモニタリングする方法であって、

a.機構をプロセス流に連結するステップであって、前記機構が、複数の開口を含むフローセルであって、少なくとも1の開口が前記プロセス流から引き込まれる流体用のフローセル入口であり、少なくとも1の開口が前記フローセルを出る流体用のフローセル出口であるフローセルと、前記開口のうちの1つに取付けられる1つのDOプローブと、前記開口のうちの1つに取付けられる洗浄装置と、前記フローセル入口に取り付けられる第1の導管と、前記フローセルに付随するバルブとを含むステップと、

b.流体が前記フローセル内に引き込まれるのを可能にすべく、前記機構のバルブを

開けるステップと、

c.前記プロセス流から前記フローセル内に前記流体を引き込むステップと、

d.前記DOプローブで前記プロセス流のDO濃度を少なくとも1回測定するステップであって、前記DOプローブが各測定前に洗浄されず、生体膜の蓄積が生じる時間が経過した後にDO濃度が測定されるステップと、

e.前記DOプローブの表面を洗浄するステップと、

f.前記DOプローブで前記機構内部の流体のDO濃度を少なくとも1回測定するステップであって、各測定前に前記DOプローブの表面が洗浄され、流動開始中の拭き取り直後にDO濃度が測定されるステップと、

g.更なる流体が前記フローセル内に引き込まれるのを防ぐために前記機構のバルブを閉じるステップと、

h.前記流体が前記フローセル内に維持された流動停止状態で、前記DOプローブで前記機構内部の流体のDO濃度を少なくとも1回測定するステップであって、各測定前に前記DOプローブの表面が洗浄されるステップと、

i.ステップ(f)とステップ(h)との間のΔDOの読取り値を計算し、前記ΔDOを前記プロセス流中の前記バルク型の微生物学的活性と少なくとも相関づけるステップと、

j.ステップ(d)とステップ(f)との間のΔDOの読取り値を計算し、前記ΔDOを前記プロセス流中の前記表面結合型の微生物学的活性と少なくとも相関づけるステップと、

を含むことを特徴とする方法。 - 前記機構は、前記開口のうちの1つに取付けられるORPプローブと、前記フローセル出口に取り付けられる第2の導管と、を含むことを特徴とする請求項5記載の方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/675,726 | 2007-02-16 | ||

| US11/675,726 US8012758B2 (en) | 2007-02-16 | 2007-02-16 | Method of monitoring microbiological activity in process streams |

| PCT/US2008/053976 WO2008101089A2 (en) | 2007-02-16 | 2008-02-14 | A method of monitoring microbiological activity in process streams |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010518823A JP2010518823A (ja) | 2010-06-03 |

| JP2010518823A5 JP2010518823A5 (ja) | 2011-03-24 |

| JP5317990B2 true JP5317990B2 (ja) | 2013-10-16 |

Family

ID=39690795

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009549721A Active JP5317990B2 (ja) | 2007-02-16 | 2008-02-14 | プロセス流中の微生物学的活性をモニタリングする方法 |

Country Status (15)

| Country | Link |

|---|---|

| US (1) | US8012758B2 (ja) |

| EP (1) | EP2115157B1 (ja) |

| JP (1) | JP5317990B2 (ja) |

| KR (1) | KR101387036B1 (ja) |

| CN (1) | CN101245312B (ja) |

| AR (1) | AR071536A1 (ja) |

| AU (1) | AU2008216152B2 (ja) |

| BR (1) | BRPI0807325B1 (ja) |

| CA (1) | CA2678247C (ja) |

| CL (1) | CL2008000488A1 (ja) |

| MX (1) | MX2009008713A (ja) |

| NZ (1) | NZ579561A (ja) |

| RU (1) | RU2477320C2 (ja) |

| TW (3) | TWI493039B (ja) |

| WO (1) | WO2008101089A2 (ja) |

Families Citing this family (34)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7981679B2 (en) * | 2007-02-16 | 2011-07-19 | Nalco Company | Method of monitoring bulk (total) microbiological activity in process streams |

| US7949432B2 (en) * | 2007-02-16 | 2011-05-24 | Nalco Company | Method of monitoring surface associated microbiological activity in process streams |

| US20090242484A1 (en) | 2008-04-01 | 2009-10-01 | Ana-Mariana Urmenyi | Environmentally friendly hybrid microbiological control technologies for cooling towers |

| WO2009143511A1 (en) * | 2008-05-23 | 2009-11-26 | Kemira Oyj | Chemistry for effective microbe control with reduced gas phase corrosiveness in pulp & paper processing systems |

| US8429952B1 (en) * | 2010-02-02 | 2013-04-30 | Campbell Scientific, Inc. | Sensor with antifouling control |

| CA2793614C (en) * | 2010-03-19 | 2018-09-18 | Buckman Laboratories International, Inc. | Processes using antibiotic alternatives in bioethanol production |

| KR101813934B1 (ko) | 2011-06-02 | 2018-01-30 | 엘지이노텍 주식회사 | 발광 소자 및 발광 소자 패키지 |

| CN103053613A (zh) * | 2011-10-21 | 2013-04-24 | 纳尔科公司 | 通过使用氯-稳定剂混合物的改进的生物控制 |

| US9265259B2 (en) | 2011-10-21 | 2016-02-23 | Nalco Company | Use of sulfamic acid or its salts as stabilizers especially in combination with ammonium salt and/or ammine for bleach or other halogen containing biocides in the paper area |

| FI126240B (en) * | 2011-12-02 | 2016-08-31 | Kemira Oyj | Method and apparatus for monitoring and controlling the state of the process |

| CA3085086C (en) | 2011-12-06 | 2023-08-08 | Delta Faucet Company | Ozone distribution in a faucet |

| US8613837B2 (en) | 2012-01-24 | 2013-12-24 | Nalco Company | Detection and quantification of nucleic acid to assess microbial biomass in paper defects and machine felts |

| US9908796B2 (en) * | 2012-10-23 | 2018-03-06 | Ecolab Usa Inc. | Use of oxidizing and non-oxidizing biocides for control of bacteria tolerant to stabilized-oxidant treatment |

| US9410288B2 (en) | 2013-08-08 | 2016-08-09 | Ecolab Usa Inc. | Use of nanocrystaline cellulose and polymer grafted nanocrystaline cellulose for increasing retention in papermaking process |

| US9034145B2 (en) | 2013-08-08 | 2015-05-19 | Ecolab Usa Inc. | Use of nanocrystaline cellulose and polymer grafted nanocrystaline cellulose for increasing retention, wet strength, and dry strength in papermaking process |

| US9303360B2 (en) | 2013-08-08 | 2016-04-05 | Ecolab Usa Inc. | Use of nanocrystaline cellulose and polymer grafted nanocrystaline cellulose for increasing retention in papermaking process |

| US9834730B2 (en) | 2014-01-23 | 2017-12-05 | Ecolab Usa Inc. | Use of emulsion polymers to flocculate solids in organic liquids |

| US9909219B2 (en) | 2014-04-14 | 2018-03-06 | Ecolab Usa Inc. | Slurry biocide |

| US9810676B2 (en) * | 2015-01-12 | 2017-11-07 | Ecolab Usa Inc. | Apparatus for, system for and methods of maintaining sensor accuracy |

| US11608516B2 (en) | 2015-04-15 | 2023-03-21 | Ecolab Usa Inc. | Method for determination of diversity and viability thresholds used to assess microorganisms in process samples |

| US9696244B2 (en) * | 2015-06-11 | 2017-07-04 | Western Energy Support and Technology, Inc | Inline sampling for multi-phase flow |

| CA3001717A1 (en) | 2015-10-15 | 2017-04-20 | Ecolab Usa Inc. | Nanocrystalline cellulose and polymer-grafted nanocrystalline cellulose as rheology modifying agents for magnesium oxide and lime slurries |

| US10280714B2 (en) | 2015-11-19 | 2019-05-07 | Ecolab Usa Inc. | Solid chemicals injection system for oil field applications |

| CA3007437C (en) | 2015-12-21 | 2021-09-28 | Delta Faucet Company | Fluid delivery system including a disinfectant device |

| CA3064009A1 (en) | 2017-05-23 | 2018-11-29 | Ecolab Usa Inc. | Dilution skid and injection system for solid/high viscosity liquid chemicals |

| AR112058A1 (es) | 2017-05-23 | 2019-09-18 | Ecolab Usa Inc | Sistema de inyección para administración controlada de sustancias químicas sólidas de campos petrolíferos |

| FI128324B (en) * | 2017-06-21 | 2020-03-31 | Kemira Oyj | Process for making fiber web |

| US10822442B2 (en) | 2017-07-17 | 2020-11-03 | Ecolab Usa Inc. | Rheology-modifying agents for slurries |

| RU179657U1 (ru) * | 2017-08-25 | 2018-05-21 | Федеральное государственное бюджетное учреждение науки Институт теоретической и экспериментальной биофизики Российской академии наук (ИТЭБ РАН) | Устройство для биообрастания биопленки в просвете трубопроводов и воздействия дезинфицирующих средств на биопленки в проточных системах |

| WO2019070739A1 (en) * | 2017-10-03 | 2019-04-11 | Avails Medical, Inc. | APPARATUSES, SYSTEMS AND METHODS FOR DETERMINING THE CONCENTRATION OF MICROORGANISMS AND THE SENSITIVITY OF MICROORGANISMS TO ANTI-INFECTIOUS, BASED ON OXIDOREDUCTION REACTIONS |

| FI130064B (en) | 2017-12-08 | 2023-01-13 | Kemira Oyj | METHOD FOR PREDICTING OR CONTROLLING MICROSTATICITY IN THE MANUFACTURING PROCESS OF PAPER OR BOARD |

| RU194989U1 (ru) * | 2018-04-27 | 2020-01-10 | Федеральное государственное бюджетное учреждение науки Институт теоретической и экспериментальной биофизики Российской академии наук (ИТЭБ РАН) | Устройство для роста биопленки на внутренней поверхности трубопроводов и воздействия дезинфицирующих средств на биопленки в проточных циркуляционных системах |

| SG11202011157UA (en) | 2018-06-13 | 2020-12-30 | A Y Lab Ltd | System and method for monitoring process water treated with a biocide using an oxygen sensor |

| CN115230888B (zh) * | 2022-09-20 | 2023-02-14 | 广州映博智能科技有限公司 | 一种基于陀螺仪的远程操控机器人 |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3510406A (en) | 1964-11-17 | 1970-05-05 | Pennwalt Corp | Method and apparatus for measuring rate of consumption of dissolved gas in a liquid |

| US3510106A (en) | 1968-02-01 | 1970-05-05 | Tamper Inc | Liner assembly |

| US3731522A (en) | 1970-09-30 | 1973-05-08 | Robertshaw Controls Co | Method and apparatus for determining oxygen consumption rate in sewage |

| JPS5558461A (en) * | 1978-10-25 | 1980-05-01 | Hitachi Ltd | Oxygen utilizing analysis device |

| US5190728A (en) | 1991-10-21 | 1993-03-02 | Nalco Chemical Company | Apparatus for monitoring fouling in commercial waters |

| JP3120505B2 (ja) * | 1991-10-31 | 2000-12-25 | 株式会社島津製作所 | 好気性微生物の測定法および測定装置 |

| JP3144911B2 (ja) * | 1992-10-14 | 2001-03-12 | 株式会社ミツカングループ本社 | 微生物膜の活性化方法 |

| GB9206796D0 (en) | 1992-03-27 | 1992-05-13 | Thames Water Utilites Limited | Apparatus and method for monitoring condition of a biomass |

| US5552319A (en) | 1993-07-20 | 1996-09-03 | Biochem Technology, Inc. | Apparatus and method for monitoring and controlling biological activity in wastewater and controlling the treatment thereof |

| RU2053300C1 (ru) * | 1993-12-17 | 1996-01-27 | Государственный научно-исследовательский институт генетики и селекции промышленных микроорганизмов | Штамм бактерий rhodococcus rhodochrous - продуцент нитрилгидратазы |

| JPH08131161A (ja) * | 1994-11-08 | 1996-05-28 | Food Design Gijutsu Kenkyu Kumiai | 植物組織の指数関数的流加培養方法、培養物の生育係数算出方法および植物組織培養装置 |

| US5576481A (en) | 1995-10-02 | 1996-11-19 | Ashland, Inc. | Method and apparatus for detecting microbiological fouling in aqueous systems |

| MY129784A (en) * | 1996-01-22 | 2007-04-30 | Biochem Technology Inc | Method for monitoring biological activity in fluids |

| GB2312278B (en) * | 1996-04-19 | 1998-03-04 | Boghos Awanes Manook | Organic and/or biological pollution monitoring of liquids based on UV/visible light absorbtion/scatter and dissolved oxygen measurements |

| JP2002112761A (ja) * | 2000-10-06 | 2002-04-16 | Toshiba Corp | 微生物計測センサ |

| US6475394B2 (en) | 2000-12-13 | 2002-11-05 | Ondeo Nalco Company | Pseudo-fouling detector and use thereof to control an industrial water process |

| JP2003302392A (ja) * | 2002-04-05 | 2003-10-24 | Hitachi Ltd | 懸濁液の水質計測装置及び水質制御装置 |

| CA2532079C (en) | 2003-07-11 | 2010-02-09 | Pda Security Solutions, Inc. | Remote monitoring system for water supply network |

| JP4458469B2 (ja) * | 2004-06-04 | 2010-04-28 | 応用地質株式会社 | 嫌気性微生物の採取装置及び採取方法 |

| US7078201B2 (en) | 2004-12-01 | 2006-07-18 | Burmaster Brian M | Ethanol fermentation using oxidation reduction potential |

-

2007

- 2007-02-16 US US11/675,726 patent/US8012758B2/en active Active

- 2007-12-31 KR KR1020070141863A patent/KR101387036B1/ko active IP Right Grant

-

2008

- 2008-01-10 CN CN2008100004350A patent/CN101245312B/zh active Active

- 2008-02-14 EP EP08729874.1A patent/EP2115157B1/en active Active

- 2008-02-14 CA CA2678247A patent/CA2678247C/en active Active

- 2008-02-14 WO PCT/US2008/053976 patent/WO2008101089A2/en active Application Filing

- 2008-02-14 AU AU2008216152A patent/AU2008216152B2/en active Active

- 2008-02-14 BR BRPI0807325-2A patent/BRPI0807325B1/pt active IP Right Grant

- 2008-02-14 RU RU2009133045/10A patent/RU2477320C2/ru active

- 2008-02-14 MX MX2009008713A patent/MX2009008713A/es active IP Right Grant

- 2008-02-14 NZ NZ579561A patent/NZ579561A/en unknown

- 2008-02-14 JP JP2009549721A patent/JP5317990B2/ja active Active

- 2008-02-15 CL CL200800488A patent/CL2008000488A1/es unknown

- 2008-02-15 TW TW102137479A patent/TWI493039B/zh active

- 2008-02-15 AR ARP080100652A patent/AR071536A1/es unknown

- 2008-02-15 TW TW102137482A patent/TWI484036B/zh active

- 2008-02-15 TW TW097105284A patent/TWI426131B/zh active

Also Published As

| Publication number | Publication date |

|---|---|

| TW201406962A (zh) | 2014-02-16 |

| EP2115157B1 (en) | 2020-01-15 |

| KR20080076706A (ko) | 2008-08-20 |

| RU2009133045A (ru) | 2011-03-27 |

| AU2008216152A1 (en) | 2008-08-21 |

| JP2010518823A (ja) | 2010-06-03 |

| KR101387036B1 (ko) | 2014-04-18 |

| EP2115157A2 (en) | 2009-11-11 |

| BRPI0807325B1 (pt) | 2022-06-07 |

| WO2008101089A2 (en) | 2008-08-21 |

| TW201402824A (zh) | 2014-01-16 |

| US20080199901A1 (en) | 2008-08-21 |

| TWI484036B (zh) | 2015-05-11 |

| CA2678247C (en) | 2015-09-29 |

| AR071536A1 (es) | 2010-06-30 |

| TWI493039B (zh) | 2015-07-21 |

| CN101245312B (zh) | 2013-03-13 |

| NZ579561A (en) | 2011-11-25 |

| RU2477320C2 (ru) | 2013-03-10 |

| MX2009008713A (es) | 2009-10-19 |

| CL2008000488A1 (es) | 2008-08-29 |

| AU2008216152B2 (en) | 2013-05-02 |

| EP2115157A4 (en) | 2013-08-21 |

| TWI426131B (zh) | 2014-02-11 |

| US8012758B2 (en) | 2011-09-06 |

| WO2008101089A3 (en) | 2008-10-09 |

| CN101245312A (zh) | 2008-08-20 |

| TW200904990A (en) | 2009-02-01 |

| BRPI0807325A2 (pt) | 2018-09-25 |

| CA2678247A1 (en) | 2008-08-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5317990B2 (ja) | プロセス流中の微生物学的活性をモニタリングする方法 | |

| JP5384511B2 (ja) | プロセス流中のバルク型の(全体の)微生物学的活性をモニタリングする方法 | |

| JP5466165B2 (ja) | プロセス流中の表面結合型の微生物学的活性をモニタリングする方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20100315 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20100315 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20100315 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20100404 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20100405 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110117 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110117 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120222 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120306 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20120606 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20120613 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120614 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20130219 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130226 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20130311 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20130306 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130523 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130618 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130709 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5317990 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |