JP5282619B2 - ガラス溶融炉 - Google Patents

ガラス溶融炉 Download PDFInfo

- Publication number

- JP5282619B2 JP5282619B2 JP2009073733A JP2009073733A JP5282619B2 JP 5282619 B2 JP5282619 B2 JP 5282619B2 JP 2009073733 A JP2009073733 A JP 2009073733A JP 2009073733 A JP2009073733 A JP 2009073733A JP 5282619 B2 JP5282619 B2 JP 5282619B2

- Authority

- JP

- Japan

- Prior art keywords

- raw material

- glass

- furnace

- melting furnace

- glass melting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03B—MANUFACTURE, SHAPING, OR SUPPLEMENTARY PROCESSES

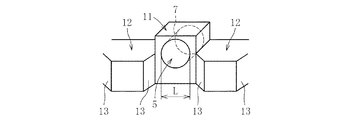

- C03B3/00—Charging the melting furnaces

- C03B3/005—Charging the melting furnaces using screw feeders

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Glass Melting And Manufacturing (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009073733A JP5282619B2 (ja) | 2009-03-25 | 2009-03-25 | ガラス溶融炉 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009073733A JP5282619B2 (ja) | 2009-03-25 | 2009-03-25 | ガラス溶融炉 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010222217A JP2010222217A (ja) | 2010-10-07 |

| JP2010222217A5 JP2010222217A5 (enExample) | 2011-09-29 |

| JP5282619B2 true JP5282619B2 (ja) | 2013-09-04 |

Family

ID=43039822

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009073733A Active JP5282619B2 (ja) | 2009-03-25 | 2009-03-25 | ガラス溶融炉 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5282619B2 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20200052249A (ko) | 2017-09-13 | 2020-05-14 | 니폰 덴키 가라스 가부시키가이샤 | 유리 물품의 제조 방법 |

| US11492281B2 (en) | 2017-06-28 | 2022-11-08 | Corning Incorporated | Melters for glass forming apparatuses |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102010035893B3 (de) * | 2010-08-31 | 2012-01-19 | Beteiligungen Sorg Gmbh & Co. Kg | Beschickungsvorrichtung für Glasschmelzanlagen und Verfahren zum Einlegen von partikelförmigem Beschickungsgut |

| CN103339072B (zh) * | 2011-02-07 | 2016-04-06 | 旭硝子株式会社 | 玻璃熔融炉、熔融玻璃的制造方法、玻璃制品的制造方法及玻璃制品的制造装置 |

| US9822027B2 (en) * | 2014-04-25 | 2017-11-21 | Owens-Brockway Glass Container Inc. | Glass furnace with bottom material feed |

| JP6792810B2 (ja) * | 2016-05-12 | 2020-12-02 | 日本電気硝子株式会社 | ガラス製造装置 |

| KR102500724B1 (ko) * | 2016-08-26 | 2023-02-16 | 코닝 인코포레이티드 | 유리 물품 제조를 위한 장치 및 방법 |

| CN106946439A (zh) * | 2017-04-28 | 2017-07-14 | 中建材(宜兴)新能源有限公司 | 一种大型玻璃熔窑投料装置 |

| US11613487B2 (en) * | 2017-09-13 | 2023-03-28 | Nippon Electric Glass Co., Ltd. | Method for producing glass article |

| CN110563311B (zh) * | 2019-08-27 | 2021-11-05 | 彩虹集团(邵阳)特种玻璃有限公司 | 一种投料机更换保证池炉内对流稳定的方法 |

| JP7519025B2 (ja) * | 2020-06-17 | 2024-07-19 | 日本電気硝子株式会社 | ガラス溶融炉 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS52135323A (en) * | 1976-05-10 | 1977-11-12 | Shibata Hario Glass Kk | Apparatus for charging glass material in electric melting furnace |

| JPH10316433A (ja) * | 1997-05-13 | 1998-12-02 | Nippon Electric Glass Co Ltd | ガラス原料供給装置 |

| US7926301B2 (en) * | 2007-08-16 | 2011-04-19 | Corning Incorporated | Method and apparatus for controlling the level of a molten material in a glass manufacturing system |

-

2009

- 2009-03-25 JP JP2009073733A patent/JP5282619B2/ja active Active

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11492281B2 (en) | 2017-06-28 | 2022-11-08 | Corning Incorporated | Melters for glass forming apparatuses |

| KR20200052249A (ko) | 2017-09-13 | 2020-05-14 | 니폰 덴키 가라스 가부시키가이샤 | 유리 물품의 제조 방법 |

| US11225428B2 (en) | 2017-09-13 | 2022-01-18 | Nippon Electric Glass Co., Ltd. | Glass article manufacturing method |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2010222217A (ja) | 2010-10-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5282619B2 (ja) | ガラス溶融炉 | |

| KR102292737B1 (ko) | 유리를 가공하기 위한 방법 및 장치 | |

| US8936454B2 (en) | Resin extrusion die and extrusion method using the same | |

| US20020093118A1 (en) | Twin-screw continuous kneading apparatus and kneading method using the same | |

| JPH11513971A (ja) | フロートガラス製造装置及び製造方法 | |

| TWI889692B (zh) | 製造玻璃帶的設備和方法 | |

| JP5638882B2 (ja) | 熱可塑性樹脂組成物の押出成形方法 | |

| CN1237193C (zh) | 用于将粉末材料均匀输送到悬浮冶炼炉的精矿燃烧器内的装置 | |

| CN104736488B (zh) | 玻璃板的成形方法、及玻璃板的成形装置 | |

| WO2007077716A1 (ja) | 溶融ガラス供給装置及びガラス成形品の製造方法 | |

| JP6568542B2 (ja) | 複合ガラス製品を製造する装置及び方法 | |

| JP5741074B2 (ja) | シート押出成形機およびシート押出製造方法 | |

| JP2014091320A (ja) | 押出成形機用スクリュー | |

| CN214088242U (zh) | 一种基板玻璃生产池炉投料口结构 | |

| CN209636365U (zh) | 一种石英坩埚的加料器 | |

| JP2010090028A (ja) | 溶融ガラス供給装置及びガラス成形品の製造方法 | |

| JP2009221105A (ja) | 溶融ガラス供給装置及びガラス成形品の製造方法 | |

| JP4001596B2 (ja) | シリンダホッパ | |

| JP2009184303A (ja) | 二軸スクリュ押出機における脱揮成分の分離方法及び装置 | |

| JP7392910B2 (ja) | ガラス溶融装置、ガラス物品の製造方法 | |

| JP5601444B2 (ja) | ガラス薄片の製造方法とその製造装置 | |

| JP7533895B2 (ja) | ガラス製品の製造装置、ガラス製品の製造方法 | |

| JP2016050148A (ja) | ガラス板の製造方法、及び、ガラス板の製造装置 | |

| CN209580075U (zh) | 防止堵料的链板秤料斗 | |

| CN210480050U (zh) | 落料集中的导料靴落料体系 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110817 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110817 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20121206 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20121212 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130212 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130430 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130513 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5282619 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |