JP5200418B2 - Bearing unit - Google Patents

Bearing unit Download PDFInfo

- Publication number

- JP5200418B2 JP5200418B2 JP2007124832A JP2007124832A JP5200418B2 JP 5200418 B2 JP5200418 B2 JP 5200418B2 JP 2007124832 A JP2007124832 A JP 2007124832A JP 2007124832 A JP2007124832 A JP 2007124832A JP 5200418 B2 JP5200418 B2 JP 5200418B2

- Authority

- JP

- Japan

- Prior art keywords

- wheel

- wheel side

- hub

- flange

- bearing unit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C35/00—Rigid support of bearing units; Housings, e.g. caps, covers

- F16C35/04—Rigid support of bearing units; Housings, e.g. caps, covers in the case of ball or roller bearings

- F16C35/06—Mounting or dismounting of ball or roller bearings; Fixing them onto shaft or in housing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60B—VEHICLE WHEELS; CASTORS; AXLES FOR WHEELS OR CASTORS; INCREASING WHEEL ADHESION

- B60B3/00—Disc wheels, i.e. wheels with load-supporting disc body

- B60B3/14—Attaching disc body to hub ; Wheel adapters

- B60B3/16—Attaching disc body to hub ; Wheel adapters by bolts or the like

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/58—Raceways; Race rings

- F16C33/581—Raceways; Race rings integral with other parts, e.g. with housings or machine elements such as shafts or gear wheels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60B—VEHICLE WHEELS; CASTORS; AXLES FOR WHEELS OR CASTORS; INCREASING WHEEL ADHESION

- B60B27/00—Hubs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60B—VEHICLE WHEELS; CASTORS; AXLES FOR WHEELS OR CASTORS; INCREASING WHEEL ADHESION

- B60B2900/00—Purpose of invention

- B60B2900/10—Reduction of

- B60B2900/141—Corrosions

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/02—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows

- F16C19/14—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load

- F16C19/18—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls

- F16C19/181—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls with angular contact

- F16C19/183—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls with angular contact with two rows at opposite angles

- F16C19/184—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls with angular contact with two rows at opposite angles in O-arrangement

- F16C19/186—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls with angular contact with two rows at opposite angles in O-arrangement with three raceways provided integrally on parts other than race rings, e.g. third generation hubs

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2326/00—Articles relating to transporting

- F16C2326/01—Parts of vehicles in general

- F16C2326/02—Wheel hubs or castors

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Rolling Contact Bearings (AREA)

Description

本発明は、車輪を支えるフランジを備えた軸受ユニットに関する。 The present invention relates to a bearing unit including a flange that supports a wheel.

従来から、自動車の車輪(例えば、ディスクホイールDW)を車体(例えば、懸架装置(サスペンション))に対して回転自在に支持するための各種の軸受ユニットが知られている。

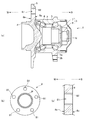

例えば図5に示された軸受ユニット1は、車体側に固定される外輪(静止輪)2と、外輪2の内側に対向して設けられ且つ車輪側に接続(固定)されて車輪と共に回転する内輪(回転輪)3と、外輪2と内輪3との間に複列(例えば2列)で回転可能に組み込まれた複数の転動体4,5とを備えている。

2. Description of the Related Art Conventionally, various bearing units for supporting a vehicle wheel (for example, a disc wheel DW) rotatably with respect to a vehicle body (for example, a suspension device (suspension)) are known.

For example, the

外輪2は、略円筒形に形成されるとともに、その内周面には、複数の外輪側軌道面を並設して備え、その外周面には、外方に向かって突出して一体成形された固定フランジ2aを備えている。その固定フランジ2aの固定孔2bには、固定用ボルト(図示しない)を挿入し、これを車体側のハウジング(図示しない)に締結することで、外輪2を図示しない懸架装置(ナックル)に固定することができる。

The

内輪3は、車輪側構成品(例えば自動車のディスクホイールやブレーキローター)を支持しつつ共に回転する略円筒形状のハブ6と、ハブ6の外周面の車体側(図中矢印B側)に嵌め合わされた内輪構成体7とを備え、その外周面に、複数の内輪側軌道面を並設して備えている。

また、前記外輪側軌道面と内輪側軌道面間には、複数の転動体4,5が配されている。

なお、ハブ6の車体側端部には締結ナットNが螺合することにより、前記内輪構成体7と一体に締結されるとともに、前記転動体4,5に予圧が付与されている。

The

Further, a plurality of

A fastening nut N is screwed to the end of the hub 6 on the vehicle body side, so that the hub 6 is fastened integrally with the inner ring constituting body 7 and a preload is applied to the

ハブ6の車輪側(図中矢印W側)からは、外輪2を越えて外方(ハブ6の半径方向外側)に向って延出された円板状のハブフランジ8が突設され、その延出縁付近には、周方向に沿って所定間隔で配置された複数のハブボルト孔81が設けられている。さらに、その複数のハブボルト孔81の内周面には雌ネジ82が刻設されている。

なお、車輪側構成品(ディスクホイールやブレーキローター)の取り付け孔に通されたハブボルト(図示しない)が、前記ハブボルト孔81に螺合して締結されることによって、ハブ6と車輪側構成品が一体に固定される。

また、ハブフランジ8の車輪側端面8aの中心側には、パイロット部Pが円筒状に延出して形成されている。

From the wheel side of the hub 6 (the arrow W side in the figure), a disk-

A hub bolt (not shown) passed through a mounting hole of a wheel side component (disc wheel or brake rotor) is screwed into the

A pilot portion P is formed in a cylindrical shape on the center side of the wheel

また、外輪2が回転輪となる例として、例えば、図6に示すハブユニット軸受では、車体側に固定される内輪(静止輪)3と、内輪3の外側に対向して設けられ且つ車輪側に接続(固定)されて車輪と共に回転する外輪(回転輪)2と、外輪2と内輪3との間に複列(例えば2列)で回転可能に組み込まれた複数の転動体4,5とを備えている。

Further, as an example in which the

外輪2は、略円筒形に形成されるとともに、その内周面には、複数の外輪側軌道面を並設して備えられている。また、外輪2の外周面の車輪側(図中矢印W側)からは、外輪2を越えて外方(外輪2の半径方向外側)に向って延出された円板状のハブフランジ8が突設され、その延出縁付近には、周方向に沿って所定間隔で配置された複数のハブボルト孔81が設けられている。このハブボルト孔81の内周面には雌ネジ82が刻設されており、ハブボルト孔81には、前述した内輪が回転輪となるハブユニット軸受と同様に、車輪側構成品(ディスクホイールやブレーキローター)を固定可能なハブボルトが螺合可能となっている。

また、ハブフランジ8の車輪側端面8aの中心側には、パイロット部Pが、車輪側に向けて、円筒状に延出して形成されている。このパイロット部Pの外径側は、車輪側構成品をハブフランジ8に固定する際に、車輪側構成品の内径側端部が引っ掛けられることにより、車輪側構成品の位置決めを容易にしている。

内輪3は、複数個の内輪構成体(6,7)で構成され、その外周面に、複数の内輪側軌道面を並設して備えている。さらに、前記外輪側軌道面と内輪側軌道面間に複数の転動体4,5が配されている。

The

A pilot portion P is formed on the center side of the wheel

The

上述した2例では、ハブボルト孔81にハブボルトが螺合することによって、車輪側構成品が挟持されて固定されているが、その他の例として、ハブボルト孔81にハブボルトが圧入されており、ハブボルトにハブナットが螺合することによって車輪側構成品を挟持して固定可能にする構成もある。

In the two examples described above, the hub bolt is screwed into the

ところで、従来から、自動車の操縦安定性向上のためには、懸架装置に懸架される部材の重量が軽くなること、つまり、バネ下荷重の軽減が効果的であることから、車輪側構成品をアルミやチタンなどの軽合金で形成する場合が多くなってきた。

一方、上述したハブフランジ軸受は、通常、鋼で形成されているので、軽合金と鋼の標準電位に大きな差が生じてしまう。このように標準電位に差がある材料同士が接触している場合において、その接触面に電導体である液体(例えば水)が介在すると、材料同士が電流をともなって著しく腐食する現象、いわゆる電食現象が発生する。

By the way, conventionally, in order to improve the driving stability of an automobile, the weight of a member suspended on a suspension device is reduced, that is, the reduction of unsprung load is effective. In many cases, it is formed of a light alloy such as aluminum or titanium.

On the other hand, since the hub flange bearing described above is usually formed of steel, a large difference occurs between the standard potentials of the light alloy and the steel. When materials having a difference in standard potential are in contact with each other as described above, if a liquid (for example, water) as a conductor is present on the contact surface, the material is significantly corroded with current, so-called electric current. An eating phenomenon occurs.

そこで、特許文献1では、軽金属製の車輪側構成品(アルミ合金製のブレーキローター)とハブフランジとの間に電食防止皮膜を設けて、電食現象を防止した技術が開示されている。この場合には、ブレーキローターとハブフランジとの間の電食現象は防止することができるが、鋼製のハブボルトを使用した場合には、ハブボルトと軽金属製の車輪側構成品との間で電食現象が生じてしまう。

また、軽金属製の車輪側構成品にアルマイト等で表面処理をして絶縁性をもたせた場合であっても、ハブボルトやナットで車輪側構成品を締結する際に、これらのハブボルトやナットが触る部分の表面処理が剥がされて、絶縁性が損なわれることにより上記の不都合が発生する場合がある。

Therefore,

In addition, even when light metal wheel side components are surface treated with alumite or the like to provide insulation, these hub bolts and nuts touch when fastening the wheel side components with hub bolts and nuts. The above-mentioned inconvenience may occur due to the surface treatment of the portion being peeled off and the insulation being impaired.

軽金属製の車輪側構成品とハブボルトとの間で電食現象が生じた場合には、まず、軽合金製の車輪側構成品の酸化現象が生じる。これにより、車輪側構成品の体積が増加することから、ハブボルトの軸力が上昇してしまう。このとき、熱処理や硬化処理が行なわれていないハブボルトであれば、水素イオンが蓄積されることによって脆弱化してしまう。また、酸化した軽金属イオンが流出した場合には、車輪側構成品がやせ細る現象が生じ、その結果、ハブボルトの軸力が低下して、緩みが生じてしまう。 When an electrolytic corrosion phenomenon occurs between the light metal wheel side component and the hub bolt, first, an oxidation phenomenon of the light alloy wheel side component occurs. Thereby, since the volume of the wheel side component increases, the axial force of the hub bolt increases. At this time, if the hub bolt is not subjected to heat treatment or hardening treatment, it is weakened by the accumulation of hydrogen ions. In addition, when oxidized light metal ions flow out, a phenomenon occurs in which the wheel-side components are thinned, resulting in a decrease in the axial force of the hub bolt and loosening.

そこで、軽金属製の車輪側構成品を取り付ける際に、硬化チタン等の軽金属製のハブボルトを使用することにより、車輪側構成品とハブボルトとの間の電食現象を防止することができると思われる。

ところが、軽金属製のハブボルトは、鋼製のハブフランジに取り付けられるので、ハブボルトとハブフランジとの間の電食現象を防止する必要に迫られることとなった。

この場合、ハブボルトがハブフランジのハブボルト取り付け孔に圧入されて、車輪側構成品をハブナットによって固定する構成であれば、ハブボルトの圧入部分に電食防止皮膜を介在させることによって電食現象を防止することが可能である。

しかし、ハブボルト孔81にハブボルトが螺合することによって、車輪側構成品が挟持されて固定される構成の場合には、雄ネジや雌ネジに電食防止皮膜を設けても、螺合時に高面圧となるため、電食防止皮膜が破壊され易く、電食現象を防止することが困難であった。そこで、ハブボルト孔81にハブボルトが螺合する構成において、電食現象を防止する技術が望まれるが、現在そのような技術は見当たらない。

Therefore, it seems that the electric corrosion phenomenon between the wheel side component and the hub bolt can be prevented by using a light metal hub bolt such as hardened titanium when mounting the light metal wheel side component. .

However, since light metal hub bolts are attached to steel hub flanges, it is necessary to prevent electrolytic corrosion between the hub bolts and the hub flange.

In this case, if the hub bolt is press-fitted into the hub bolt mounting hole of the hub flange and the wheel side component is fixed by the hub nut, the electrolytic corrosion phenomenon is prevented by interposing an electrolytic corrosion prevention film on the press-fitted portion of the hub bolt. it is possible.

However, in the case where the wheel side component is clamped and fixed by screwing the hub bolt into the

本発明の目的は、ハブボルト孔にハブボルトが螺合することによって、車輪側構成品が挟持されて固定される構成の軸受ユニットにおいて、ハブボルト孔とハブボルトとの間の電食現象を防止した軸受ユニットを提供することである。 An object of the present invention is to provide a bearing unit in which a wheel-side component is sandwiched and fixed by screwing a hub bolt into a hub bolt hole, in which the electrolytic corrosion phenomenon between the hub bolt hole and the hub bolt is prevented. Is to provide.

上記課題を達成するために、本発明が成した手段は、車体側に固定される静止輪と、静止輪に対向して設けられ且つ車輪側に配された車輪側構成品が固定されて車輪と共に回転する回転輪と、当該回転輪と静止輪のそれぞれの対向面に形成される軌道面間に転動自在に組み込まれた複数の転動体と、回転輪から外方に向かって延出された円板状のハブフランジとを備え、ハブフランジには、周方向に沿って所定間隔で孔が、当該フランジの車輪側から車体側にわたって貫通して形成されており、当該孔に対してハブボルトを車輪側から挿入することで、車輪側構成品をハブフランジに固定する軸受ユニットにおいて、孔には、前記ハブボルトが螺合可能な内径面を有する円筒部材が嵌合されているとともに、円筒部材は、ハブフランジの車体側の端面に加締め固定されており、前記車輪側構成品とハブボルトと円筒部材は、互いに同一の材質である軽合金で形成されていることを特徴とする軸受ユニットとしたことである。その円筒部材の車輪側の端面は、フランジの車輪側の端面と同一平面上に位置付けられている場合もあり、フランジの車輪側の端面から所定量だけ、車輪側に向けて突出している場合もあり、フランジの車輪側の端面に沿って延在し、互いに連結している場合もある。さらに、円筒部材の車輪側の端面には、車輪側構成品をハブフランジに固定する際の位置決めとして、車輪側に向けて延出した延出部が一体形成されている場合もある。また、ハブフランジの孔に嵌合する円筒部材の嵌合面には、絶縁防錆加工が施されている場合もある。

In order to achieve the above-mentioned object, the present invention comprises a stationary wheel fixed to the vehicle body side, and a wheel side component provided opposite to the stationary wheel and disposed on the wheel side to which the wheel is fixed. A rotating wheel that rotates together with each other, a plurality of rolling elements that are rotatably incorporated between raceway surfaces that are formed on opposite surfaces of the rotating wheel and the stationary wheel, and extending outward from the rotating wheel. A disc-shaped hub flange, and a hole is formed in the hub flange at predetermined intervals along the circumferential direction from the wheel side of the flange to the vehicle body side. by inserting from the wheel side, in the bearing unit to secure the wheel-side components to the hub flange, the hole, together with the hub bolts are fitted into the cylindrical member having a threaded inner diameter capable of surface, the cylindrical member The hub flange body Of being in the end face caulking, the wheel-side components and the hub bolts and the cylindrical member is to have the bearing unit, characterized in that it is formed by light alloy which is the same material with each other. The end surface on the wheel side of the cylindrical member may be positioned on the same plane as the end surface on the wheel side of the flange, or may protrude from the end surface on the wheel side of the flange by a predetermined amount toward the wheel side. Yes, it extends along the end face of the flange on the wheel side and may be connected to each other. Furthermore, an extension portion extending toward the wheel side may be integrally formed on the end surface of the cylindrical member on the wheel side as positioning when the wheel side component is fixed to the hub flange. In some cases , the mating surface of the cylindrical member that fits into the hole of the hub flange is subjected to insulation / rust prevention.

本発明によれば、ハブボルト孔にハブボルトが螺合することによって、車輪側構成品が挟持されて固定される構成の軸受ユニットにおいて、ハブボルト孔とハブボルトとの間の電食現象を防止した軸受ユニットを提供することができる。 According to the present invention, in a bearing unit in which a wheel side component is clamped and fixed by screwing a hub bolt into the hub bolt hole, a bearing unit that prevents an electrolytic corrosion phenomenon between the hub bolt hole and the hub bolt. Can be provided.

以下、本発明の一実施の形態に係る軸受ユニットについて、添付図面に基づいて説明する。なお、本実施形態の軸受ユニットは、ハブボルト孔の構成に特徴を有し、軸受ユニットの全体構成は、上述した従来の軸受ユニット(図5及び図6参照)の全体構成と同様であるので、同一の符号を用いることでその説明を省略し、ここではその特徴的な構成を中心に説明する。

本実施形態による軸受ユニット1では、図1(a)〜(c)に示すように、ハブフランジ8の周方向に沿って所定間隔で配置された複数のハブボルト孔81に、それぞれ、円筒部材(インサート)9が嵌合して配されている。

具体的には、インサート9の車輪側91の端面95は、ハブフランジ8の車輪側の端面8aと同一平面上に位置付けられている。一方、インサート9の車体側92は、ハブボルト孔81の車体側(図中矢印B側)端面8cから突出するとともに該端面8cに加締められて圧接固定されている。

Hereinafter, a bearing unit according to an embodiment of the present invention will be described with reference to the accompanying drawings. The bearing unit of the present embodiment is characterized by the configuration of the hub bolt hole, and the overall configuration of the bearing unit is the same as the overall configuration of the conventional bearing unit described above (see FIGS. 5 and 6). The description will be omitted by using the same reference numerals, and the characteristic configuration will be mainly described here.

In the

Specifically, the

インサート9は、ハブフランジ8の厚み寸法(車輪側端面8aから車体側端面8bまでの寸法)よりも大きな軸方法長寸法を有しており、その車輪側91には、インサート9の胴部94の外径よりも大径に形成された鍔部93が備えられている。

インサート9の胴部94の内径寸法は、ハブボルト径よりも僅かに小径に設定されるとともに、胴部94から鍔部93にわたる内径面にはハブボルト(図示しない)が螺合可能な雌ネジ82が形成されている。

一方、ハブボルト孔81の車輪側(図中矢印W側)には、鍔部93が嵌合可能な段部8bが形成されている。

The

The inner diameter dimension of the

On the other hand, on the wheel side of the hub bolt hole 81 (the arrow W side in the figure), a

ハブボルト孔81にインサート9を嵌合する場合には、車輪側から鍔部93が段部8bに当接するまでインサート9をハブボルト孔81に嵌め入れる。このとき、ハブボルト孔81から車体側(図中矢印B側)に突出したインサート9の車体側端部9aを加締めて、ハブフランジ8の車体側端面8cに圧接することで、インサート9がハブボルト孔81に回転不能かつ堅牢に固定される。

なお、本実施形態では、車輪側構成品とハブボルト及びインサート9は同一の材質、例えば軽合金で形成されており、ハブフランジ8は鋼で形成されている。この場合、ハブボルト孔81とインサート9との電食現象を防止するため、ハブボルト孔81とインサート9との嵌合面には、絶縁防錆加工が施される。その絶縁防錆加工は、例えば、ハブボルト孔81側に亜鉛ニッケルクロメート(Zn−Niクロメート)後のトップコートを塗布したり、ダクロ処理を施したりしても良い。或いは、インサート9の嵌合面にシーリング材を塗布しても良い。

When the

In the present embodiment, the wheel side component, the hub bolt and the

このように、ハブフランジ8の周方向に沿って所定間隔で形成された複数のハブボルト孔81に、それぞれ、インサート9が固定されたことにより、車輪側構成品とハブボルトとインサート9は、ともに軽金属製であって同一の材質であり、その標準電位の差が小さいので、ハブボルトとインサート9の間に電食現象が生じることがない。

この場合、軽金属製のインサート9と鋼製のハブフランジ8は、互いに異なる材質となり、その標準電位に大きな差が生じ得る状態となるが、ハブボルト孔81とインサート9との嵌合面は絶縁防錆加工が施されているので、ハブボルト孔81とインサート9の間に電食現象が生じることはない。

また、インサート9は、ハブボルト孔81に回転不能かつ堅牢に固定されているので、ハブボルトをインサート9に螺合させた際でも、その螺合力によってインサート9がハブボルト孔81に対して相対的に回転することがなく、ハブボルト孔81とインサート9と絶縁防錆加工の効果が損なわれることがない。

(変形例1)

As described above, since the

In this case, the

Further, since the

(Modification 1)

本変形例1として、図2(a)〜(c)に示すように、インサート9の車輪側の端面95をフランジ8の車輪側の端面8aから所定量だけ車輪側に向けて突出させても良い。ここでは、一例として、ハブボルト孔81に嵌合するインサート9の鍔部93を車輪側に向けて突出させている。なお、所定量については、例えば、フランジ8の大きさや内輪側構成品の形状や軸受の使用目的・使用環境に応じて任意に設定しているので、ここでは特に数値限定をしない。

As shown in FIGS. 2 (a) to 2 (c), as the first modification, the

このように、鍔部93を車輪側に突出させたことにより、ハブフランジ8に車輪側構成品を固定した場合には、車輪側構成品が、突出した鍔部93と当接することで、車輪側構成品のハブフランジ側の面(図示せず)と、ハブフランジ8の車輪側端面8aとの間には、鍔部93の突出量に応じた隙間が構成される。

これにより、鋼製のハブフランジ8と軽合金製の車輪側構成品が直接接触することがないので、ハブフランジ8と車輪側構成品との間に電食現象が生じることがない。

その他の構成及び効果は上述した実施形態と同様であるのでその説明は省略する。

(変形例2)

In this way, when the wheel side component is fixed to the

As a result, the

Since other configurations and effects are the same as those of the above-described embodiment, the description thereof is omitted.

(Modification 2)

本変形例2として、図3(a)〜(c)に示すように、上記変形例1で突出させた鍔部93の端面95をフランジ8の車輪側の端面8aに沿って延在させ、互いに連結させても良い。ここでは、一例として、突出させた鍔部93同士をフランジ8の車輪側の端面8aに沿って互いに連結させている。なお、連結させる形状としては、例えば円環状、直線状(矩形状)などとしてもよいが、一例として、円環状に連結させた場合には、当該鍔部93の端面95は、円環状の突出面となる。

この場合、円環状に連結された突出面95の範囲(領域)は、例えば、ハブフランジ8の車輪側端面8a全体にわたって延在させてもよいし、インサート9の径寸法(幅)だけを互いに連結させるようにしても良い。

As shown in FIGS. 3A to 3C, as the second modification, the

In this case, for example, the range (region) of the projecting

このように鍔部93を連結したことによって、ハブフランジ8に車輪側構成品を固定した場合には、車輪側構成品の車輪側の面は、鍔部93で形成された突出面95と当接し、ハブフランジ8とは接触しない。

このとき、車輪側構成品と突出面95は、ともに軽金属製であって同一の材質であり、その標準電位の差が小さいので、車輪側構成品と突出面95との間に電食現象が生じることがない。

これにより、鋼製のハブフランジ8の車輪側端面8aと軽合金製の車輪側構成品とは完全に絶縁され、直接接触することがないので、ハブフランジ8と車輪側構成品との間に電食現象が生じることがない。

その他の構成及び効果は上述した実施形態と同様であるのでその説明は省略する。

(変形例3)

When the wheel side component is fixed to the

At this time, the wheel-side component and the protruding

As a result, the wheel-

Since other configurations and effects are the same as those of the above-described embodiment, the description thereof is omitted.

(Modification 3)

本変形例3として、図4(a)〜(c)に示すように、上記変形例2で連続させた端面95に、車輪側構成品をハブフランジ8に固定する際の位置決めとして、車輪側に向けて延出した延出部を一体形成しても良い。ここでは、一例として、延出部P2は、鍔部93の円環状の突出面95の内径端から、車輪側に向けて円筒状に延出している。

この場合、延出部P2は、ハブフランジ8のパイロット部となるので、ハブフランジ8の車輪側端面8aの中心側にはパイロット部Pが不要となる(図4(a)参照)が、延出部P2の内径側にパイロット部Pを残しても良い。

As the third modification, as shown in FIGS. 4A to 4C, as the positioning when the wheel side component is fixed to the

In this case, since the extension part P2 becomes a pilot part of the

本変形例3では、変形例2の構成に加えて、延出部P2を設けたことで、車輪側構成品の車体側の面は、すべて、ハブフランジ8に接することはない。

具体的には、車輪側構成品の車体側の面は、前述の変形例2と同様に、前記円環状の突出面95と当接し、さらに、車輪側構成品の内径端は、延出部P2の外径周面に引っ掛けられて当接するが、車輪側構成品と突出面95と延出部P2は、ともに軽金属製であって同一の材質であり、その標準電位の差が小さいので、電食現象が生じることがない。

これにより、鋼製のハブフランジ8の車輪側端面8aと軽合金製の車輪側構成品とが完全に絶縁され、直接接触することがないので、ハブフランジ8と車輪側構成品との間に電食現象が生じることがない。

また、延出部P2を形成したことによって、ハブフランジ8に車輪側構成品を固定する場合には、円筒状の延出部P2の外径周面に車輪側構成品の内径側端部を引っ掛けて車輪側構成品の位置決めをすることができる。

In the third modification, in addition to the structure of the second modification, the extension portion P2 is provided, so that the vehicle body side surfaces of the wheel side components do not all come into contact with the

Specifically, the surface on the vehicle body side of the wheel-side component is in contact with the annular projecting

As a result, the wheel-

Further, when the wheel side component is fixed to the

なお、上述した各変形例では、インサート9の車輪側の端面95がフランジ8の車輪側の端面8aから所定量だけ車輪側に向けて突出した構成を示したが、これに限られず、上記変形例2及び変形例3で形成した端面(突出面)95の突出形状に合わせて、インサート9の車輪側の端面95を掘り込むことにより、端面(突出面)95が、ハブフランジ8の車輪側の端面8aと同一平面上に位置付けられるようにしても良い。

In addition, in each modification mentioned above, although the

また、上述した本実施形態および各変形例では、内輪回転の軸受ユニットを想定して説明したが、外輪回転の軸受ユニット(図6参照)にも適用可能である。また、上述した本実施形態および各変形例では、駆動輪側の軸受ユニットを想定して説明したが、従動輪側の軸受ユニットにも適用可能である。 Further, in the above-described embodiment and each modification, the bearing unit for rotating the inner ring has been described, but the present invention can also be applied to a bearing unit for rotating the outer ring (see FIG. 6). Further, in the above-described embodiment and each modification, the description has been made assuming the bearing unit on the driving wheel side, but the present invention can also be applied to the bearing unit on the driven wheel side.

1 軸受ユニット

2 外輪

3 内輪

4,5 複数の転動体

8 ハブフランジ

82 円筒部材(インサート)の内径面(雌ネジ)

9 円筒部材(インサート)

DESCRIPTION OF

9 Cylindrical member (insert)

Claims (6)

静止輪に対向して設けられ且つ車輪側に配された車輪側構成品が固定されて車輪と共に回転する回転輪と、

当該回転輪と静止輪のそれぞれの対向面に形成される軌道面間に転動自在に組み込まれた複数の転動体と、

回転輪から外方に向かって延出された円板状のハブフランジとを備え、ハブフランジには、周方向に沿って所定間隔で孔が、当該フランジの車輪側から車体側にわたって貫通して形成されており、当該孔に対してハブボルトを車輪側から挿入することで、車輪側構成品をハブフランジに固定する軸受ユニットにおいて、

孔には、前記ハブボルトが螺合可能な内径面を有する円筒部材が嵌合されているとともに、円筒部材は、ハブフランジの車体側の端面に加締め固定されており、前記車輪側構成品とハブボルトと円筒部材は、互いに同一の材質である軽合金で形成されていることを特徴とする軸受ユニット。 A stationary wheel fixed to the vehicle body side,

A rotating wheel that is provided facing the stationary wheel and that is disposed on the wheel side and that rotates together with the wheel.

A plurality of rolling elements incorporated in a freely rolling manner between the raceway surfaces formed on the opposing surfaces of the rotating wheel and the stationary wheel,

A disc-shaped hub flange extending outward from the rotating wheel, and the hub flange has holes extending from the wheel side to the vehicle body side at predetermined intervals along the circumferential direction. In the bearing unit for fixing the wheel side component to the hub flange by inserting the hub bolt from the wheel side into the hole,

A cylindrical member having an inner diameter surface into which the hub bolt can be screwed is fitted in the hole, and the cylindrical member is fixed by crimping to the end surface of the hub flange on the vehicle body side, and the wheel side component and The hub bolt and the cylindrical member are formed of a light alloy that is the same material as each other .

The bearing unit according to any one of claims 1 to 5 , wherein an insulating rust-proofing process is applied to a fitting surface of the cylindrical member fitted into the hole of the hub flange .

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007124832A JP5200418B2 (en) | 2007-05-09 | 2007-05-09 | Bearing unit |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007124832A JP5200418B2 (en) | 2007-05-09 | 2007-05-09 | Bearing unit |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2008279861A JP2008279861A (en) | 2008-11-20 |

| JP2008279861A5 JP2008279861A5 (en) | 2010-07-08 |

| JP5200418B2 true JP5200418B2 (en) | 2013-06-05 |

Family

ID=40141051

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007124832A Active JP5200418B2 (en) | 2007-05-09 | 2007-05-09 | Bearing unit |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5200418B2 (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITTO20121056A1 (en) * | 2012-12-07 | 2014-06-08 | Skf Ab | FLANGED BEARING RING FOR THE HUB OF THE WHEEL OF A MOTOR VEHICLE |

| JP6657631B2 (en) * | 2015-07-21 | 2020-03-04 | 株式会社ジェイテクト | Vehicle bearings |

| JP6094653B2 (en) * | 2015-10-28 | 2017-03-15 | 日本精工株式会社 | Rolling bearing unit for wheel support |

| EP3323629B1 (en) * | 2016-11-22 | 2019-06-12 | Georg Fischer GmbH | Wheel bearing assembly |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH02258402A (en) * | 1989-03-31 | 1990-10-19 | Koyo Seiko Co Ltd | Heat insulating hub unit bearing device |

| DE4227259C1 (en) * | 1992-08-18 | 1994-03-24 | Stahlschmidt & Maiworm | Arrangement to avoid contact corrosion on magnesium wheels |

| JPH0676726U (en) * | 1993-04-08 | 1994-10-28 | 日信工業株式会社 | Caliper mounting structure for vehicle disc brakes |

| JPH07228101A (en) * | 1994-02-17 | 1995-08-29 | Bridgestone Corp | Resin wheel and manufacture thereof |

| DE19754188A1 (en) * | 1997-12-06 | 1999-06-17 | Porsche Ag | Fastening device for a vehicle wheel consisting of an inner and outer wheel shell |

| JP2000346025A (en) * | 1999-06-01 | 2000-12-12 | Fotonikusu Kk | Galvanic corrosion preventive pitch diameter taper screw reinforced bush |

| JP2001158203A (en) * | 1999-12-01 | 2001-06-12 | Yamaha Motor Co Ltd | Fastening structure of stainless-steel material to be fastened |

| JP4581723B2 (en) * | 2005-02-08 | 2010-11-17 | 日本精工株式会社 | Hub unit and hub unit manufacturing method |

-

2007

- 2007-05-09 JP JP2007124832A patent/JP5200418B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2008279861A (en) | 2008-11-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5422868B2 (en) | Axle bearing device | |

| US6174117B1 (en) | Fastening structure including a bolt having a serration that is press-fit into a bolt hole of a flange | |

| JP5200418B2 (en) | Bearing unit | |

| US8221004B2 (en) | Method of making wheel support bearing | |

| JPH02278012A (en) | Rolling bearing | |

| JP3091990B2 (en) | Fastening structure | |

| JP4449356B2 (en) | Rolling bearing device for wheels | |

| US8142081B2 (en) | Wheel support bearing assembly | |

| JP2006336757A (en) | Bearing device for wheel | |

| JP4562461B2 (en) | Wheel bearing device | |

| CN112659812B (en) | Hub unit bearing with generator | |

| JP4326191B2 (en) | Pin type cage | |

| JP4519004B2 (en) | Wheel bearing device | |

| JP2005059832A (en) | Wheel bearing assembly | |

| JP2006105343A (en) | Bearing device for wheel | |

| JP4134872B2 (en) | Rolling bearing device | |

| JP2006118626A (en) | Bearing device for wheel | |

| JP4986512B2 (en) | Wheel bearing device | |

| JP4595580B2 (en) | Hub unit for vehicles | |

| JP2007327507A (en) | Wheel bearing device | |

| JP2008175573A (en) | Bearing arrangement for wheel | |

| WO2007051009A1 (en) | Sensor gasket | |

| JP2006144990A (en) | Rolling bearing device | |

| JP2007230492A (en) | Bearing unit | |

| JP2006151067A (en) | Rotation support device for wheel |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100506 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100506 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100622 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120427 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120529 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120706 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130115 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130128 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5200418 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20160222 Year of fee payment: 3 |