JP5105704B2 - Heating / cooling system and heating / cooling method for heat press or heating / cooling mold - Google Patents

Heating / cooling system and heating / cooling method for heat press or heating / cooling mold Download PDFInfo

- Publication number

- JP5105704B2 JP5105704B2 JP2004354583A JP2004354583A JP5105704B2 JP 5105704 B2 JP5105704 B2 JP 5105704B2 JP 2004354583 A JP2004354583 A JP 2004354583A JP 2004354583 A JP2004354583 A JP 2004354583A JP 5105704 B2 JP5105704 B2 JP 5105704B2

- Authority

- JP

- Japan

- Prior art keywords

- cooling

- mold

- heating

- medium

- temperature

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C35/00—Heating, cooling or curing, e.g. crosslinking or vulcanising; Apparatus therefor

- B29C35/007—Tempering units for temperature control of moulds or cores, e.g. comprising heat exchangers, controlled valves, temperature-controlled circuits for fluids

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/32—Component parts, details or accessories; Auxiliary operations

- B29C43/52—Heating or cooling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/32—Component parts, details or accessories; Auxiliary operations

- B29C43/58—Measuring, controlling or regulating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/72—Heating or cooling

- B29C45/73—Heating or cooling of the mould

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/76—Measuring, controlling or regulating

- B29C45/78—Measuring, controlling or regulating of temperature

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/32—Component parts, details or accessories; Auxiliary operations

- B29C43/58—Measuring, controlling or regulating

- B29C2043/5816—Measuring, controlling or regulating temperature

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76003—Measured parameter

- B29C2945/7604—Temperature

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76177—Location of measurement

- B29C2945/76254—Mould

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76494—Controlled parameter

- B29C2945/76531—Temperature

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76929—Controlling method

- B29C2945/76939—Using stored or historical data sets

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Oral & Maxillofacial Surgery (AREA)

- Thermal Sciences (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Molds, Cores, And Manufacturing Methods Thereof (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

Description

本発明は、熱プレス用又は加熱冷却用金型の加熱冷却システム及び加熱冷却方法に関するものである。 The present invention relates to a heating / cooling system and heating / cooling method for a hot press or heating / cooling mold.

従来、液晶バックパネル導光板のプリズムやディスクの信号部等を成形する場合、熱プレス成形方法で素材(プラスチックの板)に金型の成形面を熱転写させる際に、金型の温度コントロールを行うことが必須となる。 Conventionally, when molding the prism of a liquid crystal back panel light guide plate, the signal part of a disk, etc., the mold temperature is controlled when the molding surface of the mold is thermally transferred to the material (plastic plate) by the hot press molding method. It is essential.

熱プレス用又は加熱冷却用金型の加熱冷却システムは、熱プレス成形において、2種類の異なった温度の媒体を、同一の金型に、成形プロセスに応じて切り替えて流す方法を採用している。

具体的には、素材(プラスチックの板)を金型内に搬入し、金型を加熱(昇温)して金型を均等に加熱し、プレス機構により金型を下降してこの金型の成形面を素材に転写し、その後、金型を冷却し、金型を上昇して成形加工された素材を搬出するようにしている。

The heating / cooling system for a hot press or heating / cooling die employs a method in which two types of media having different temperatures are flowed to the same die in accordance with the molding process in hot press molding. .

Specifically, the material (plastic plate) is carried into the mold, the mold is heated (heated up) to uniformly heat the mold, and the mold is lowered by the press mechanism. The molding surface is transferred to the material, and then the mold is cooled, and the mold is raised to carry out the molded material.

ところで、従来の熱プレス用又は加熱冷却用金型の加熱冷却システムにおいては、加熱用媒体に油、冷却用媒体に油を使用したり、又は加熱用媒体に温水、冷却用媒体に水を使用する等、2種の媒体で金型の加熱冷却を行っている。 By the way, in a conventional heating and cooling system for a heat press or heating and cooling mold, oil is used as a heating medium, oil is used as a cooling medium, or hot water is used as a heating medium and water is used as a cooling medium. The mold is heated and cooled with two types of media.

しかし、熱プレス用又は加熱冷却用金型では、その温度上昇に熱エネルギーを多く必要とし、成形サイクルを早くするためには、設備費用、ランニング費用が多くかかるとともに、設備の規模も大きくなり、実用的ではないという問題を包含している。

また、複数の金型を使用する場合、これらに温度差を付けるには、個々の金型へ供給する加熱用媒体それぞれについて独立した温度調節装置が必要となるという問題を包含している。

However, molds for hot pressing or heating / cooling require a large amount of thermal energy to increase the temperature, and in order to speed up the molding cycle, equipment costs and running costs are high, and the scale of the equipment also increases. It includes the problem of being impractical.

Moreover, when using a some metal mold | die, in order to give a temperature difference to these, the problem that the temperature control apparatus independent for each heating medium supplied to each metal mold | die is needed is included.

特許文献1には、射出成形機と、昇温装置と、複数の金型とを用いて構成され、複数の金型を昇温装置にて昇温した後、複数の金型を順に射出成形機に移送し、各金型を個別に温度制御しつつ射出成形を行うようにした複数の金型を用いる成形方法が提案されている。

In

しかし、この特許文献1の成形方法の場合、複数の金型の射出成形機への順次移送、各金型の個別の温度制御等、複雑な構成、複雑な制御が必要になるという問題を包含している。

However, in the case of the molding method disclosed in

特許文献2には、固定金型、可動金型を有する射出成形機に対して、この射出成形機の複数の要部に、複数の温調装置から媒体を温度制御しながら圧送するように構成したディスク成形金型の温度制御機構が提案されている。 Japanese Patent Laid-Open No. 2004-228688 is configured to press and feed a medium from a plurality of temperature control devices to a plurality of main parts of the injection molding machine with respect to an injection molding machine having a fixed mold and a movable mold. There has been proposed a temperature control mechanism for a disc molding die.

しかし、この特許文献2の温度制御機構の場合も、成形機の複数の要部に、複数の温調装置から媒体を温度制御しながら圧送する構成であるため、やはり複雑な構成、複雑な制御が必要になるという問題を包含している。

解決しようとする問題点は、一台の温度調節装置を用いて、加熱用媒体に蒸気、冷却用媒体に水を使用し、金型の加熱、冷却の切り替えを短時間で、容易に行うことができる熱プレス用又は加熱冷却用金型の加熱冷却システムが存在しない点である。 The problem to be solved is that using a single temperature control device, steam is used for the heating medium and water is used for the cooling medium, and the heating and cooling of the mold can be easily switched in a short time. However, there is no heating / cooling system for a hot press or heating / cooling mold.

本発明は、複数の金型の加熱用媒体に蒸気、冷却用媒体に冷却水の2種類の異なる温度の媒体を使用し、これらを温度調節装置により金型の媒体路に切り替えて供給し、金型の加熱工程、成形品の成形、金型の冷却工程を繰り返すシステムで、前記金型の対になっている上プレートと下プレートに温度差が必要な時、加熱用媒体路、冷却用媒体路から当該各金型への蒸気、冷却水の供給を切り替えて温度差を調節するようにした熱プレス用又は加熱冷却用の金型の加熱冷却システムであって、前記加熱用媒体である蒸気を生成する加熱用ユニットと、前記冷却用媒体である冷却水の供給、循環を行うとともに、クーリングタワーを含む冷却用ユニットと、前記複数の金型に配置した複数の温度検出部と、蒸気が供給されるとともに、複数系統に分岐した媒体路に各々接続した空気圧で開閉作動する複数の切替弁を有し、前記複数の金型に蒸気を供給する加熱用媒体路と、前記クーリングタワーから冷却水が供給されるとともに、複数系統に分岐した媒体路に各々接続した空気圧で開閉作動する複数の切替弁を有し、前記複数の金型に冷却水を供給する冷却用媒体路と、エアー源、エアーフィルター、エアーレギュレータ、エアーアキュムレータータンク、調節弁、空気圧で開閉作動する切替弁、この切替弁の後段で複数系統に分岐した媒体路に各々接続した止め弁を有し、前記複数の金型にパージ用エアーを供給するエアー流路と、前記加熱用媒体路、冷却用媒体路及びエアー流路の出口側と、前記各複数の金型との間に接続した各々供給弁を含む複数系統の共通媒体路と、前記各金型からの複数系統の媒体路を流出する媒体を排出弁を経て1系統に纏めクーリングタワーに接続した排出弁に送る媒体路に接続した空気圧で開閉作動する切替弁と、前記冷却用媒体路の各切替弁の前段で分岐した媒体路に接続した空気圧で開閉作動する切替弁と、この切替弁の出口から複数系統に分岐した媒体路に接続され、吐出側を前記排出弁に接続したサイレントレジューサと、前記排出媒体路に接続した切替弁の入口手前で分岐し前記サイレントレジューサに接続した媒体路と、を有し、前記冷却水を冷却用ユニットに送る排出媒体路と、を備えるとともに、温度判定用プログラムを格納し前記各温度検出部による検出温度に基づき各金型の温度を判定して、前記加熱用媒体路の複数の切替弁、冷却用媒体路の複数の切替弁、エアー流路の切替弁を制御して各金型への蒸気、冷却水の切り替え供給制御及び各金型のパージを行い、前記各金型における成形動作制御を行う制御手段を備えた温度調節装置と、を具備し、前記複数の金型のパージ用エアー流路は、エアーパージを行う際には前記制御手段、バルブコントローラをもって前記エアー流路に設けた切替弁、排出媒体路に設けた切替弁及び冷却用媒体路の前段に設けた切替弁を開状態に制御し、前記加熱用媒体路に設けた各切替弁及び冷却用媒体路に設けた複数系統の切替弁を閉状態に制御して行うことにより、エアー源からのエアーは、エアーフィルター、エアーレギュレータ、エアーアキュムレータータンク、調節弁、切替弁、止め弁、共通媒体路の各系統の供給弁、金型に設けた各供給マニホールドを経て前記各金型に至りこれらの各金型内をパージした後、当該各金型を通過したエアーは、前記各金型に設けた各循環マニホールド、前記排出弁を経て前記温度調節装置に戻り、前記排出媒体路の切替弁を経た後、排出弁よりクーリングタワーへ循環する冷却水に混合するように構成し、前記制御手段に設定する温度判定用プログラムは、前記金型における任意の金型の加熱判定温度、冷却判定用温度の設定することができ、更に、前記金型における任意の金型をグループ分けしてグループでの温度判定の組み合わせを設定して、加熱判定温度によるプログラム動作にて、プレス部のプレススライドの下降やプレス保持時間のスタート制御可能とし、冷却判定温度によるプログラム動作にて、プレス部のプレススライドの上昇やプレス保持時間を制御可能とし、一台の温度調節装置を用いて、加熱用媒体に蒸気、冷却用媒体に水を使用し、金型の加熱、冷却の切り替えを短時間で容易に行うことができるようにしたことを最も主要な特徴とする。 The present invention uses a medium having two different temperatures for steam as a heating medium for a plurality of molds and cooling water for a cooling medium, and supplies them to a mold medium path by a temperature control device. In a system that repeats the heating process of the mold, the molding of the molded product, and the cooling process of the mold, when a temperature difference is required between the upper plate and the lower plate of the mold pair, the heating medium path, for cooling A heating / cooling system for a hot press or heating / cooling mold in which the temperature difference is adjusted by switching the supply of steam and cooling water from the medium path to each mold, which is the heating medium. A heating unit that generates steam, supply and circulation of cooling water as the cooling medium, a cooling unit that includes a cooling tower, a plurality of temperature detectors disposed in the plurality of molds, and steam Multiple systems are supplied A plurality of switching valves that open and close by air pressure respectively connected to the branched medium paths; a heating medium path that supplies steam to the plurality of molds; cooling water is supplied from the cooling tower; and a plurality of systems A cooling medium path for supplying cooling water to the plurality of molds, an air source, an air filter, an air regulator, and an air accumulator. Air that supplies purge air to the plurality of molds, including a regulator tank, a control valve, a switching valve that opens and closes by air pressure, and a stop valve that is connected to each of the media paths branched into a plurality of systems at the subsequent stage of the switching valve A plurality of common medium paths each including a flow path, an outlet side of the heating medium path, a cooling medium path and an air flow path, and each of the plurality of molds; A switching valve that opens and closes by air pressure connected to a medium path that sends a medium flowing out of a plurality of medium paths from a mold to a discharge valve connected to a cooling tower through a discharge valve, and each of the cooling medium paths A switching valve that opens and closes by air pressure connected to a medium path branched before the switching valve, and a silent reducer that is connected to a medium path branched into a plurality of systems from the outlet of the switching valve and has a discharge side connected to the discharge valve; A medium path branched before the switching valve connected to the discharge medium path and connected to the silent reducer, and a discharge medium path for sending the cooling water to a cooling unit. The temperature of each mold is determined based on the temperature detected by each temperature detection unit, a plurality of switching valves for the heating medium path, a plurality of switching valves for the cooling medium path, an air flow A temperature adjusting device comprising a control means for controlling the switching valve of the path to perform the switching supply control of steam and cooling water to each mold and purging each mold, and controlling the molding operation in each mold; The purge air flow paths of the plurality of molds, when performing the air purge, the control means, a switching valve provided in the air flow path with a valve controller, a switching valve provided in the discharge medium path, and The switching valve provided in the front stage of the cooling medium path is controlled to be in an open state, and the switching valves provided in the heating medium path and a plurality of switching valves provided in the cooling medium path are controlled to be closed. Therefore, the air from the air source passes through an air filter, an air regulator, an air accumulator tank, a control valve, a switching valve, a stop valve, a supply valve for each system of the common medium path, and each supply manifold provided in the mold. Each After purging the inside of the mold, these lead to mold, air which passes through the respective mold, the respective circulation manifold provided in each mold, returns to the temperature control device through the discharge valve, the discharge medium After passing through the path switching valve, the temperature determination program set in the control means is configured to mix with the cooling water circulated from the discharge valve to the cooling tower, the heating determination temperature of any mold in the mold, The temperature for cooling determination can be set, and further, any mold in the mold is grouped and a combination of temperature determination in the group is set. Enables start control of press slide descent and press hold time, and control of press slide rise and press hold time of the press section by program operation according to the cooling judgment temperature Using a single temperature control device, steam was used for the heating medium and water was used for the cooling medium so that the heating and cooling of the mold could be easily switched in a short time. The most important feature.

本発明によれば、以下の効果を奏する。

請求項1記載の発明によれば、複数の金型に温度検出部を配置し、温度調節装置の制御手段に温度判定用プログラムを格納して、前記温度検出部による検出温度に基づき複数の金型の温度を判定して、加熱用ユニットから加熱用媒体路を経た複数の金型への加熱用媒体、すなわち蒸気の供給、冷却用ユニットから冷却用媒体路を経た複数の金型への冷却用媒体、すなわち冷却水の供給の切り替え供給制御を行うとともに、前記複数の金型における成形動作制御を行うようにしたものであるから、一台の温度調節装置を用い、加熱用媒体に蒸気、冷却用媒体に水を使用し、複数の金型の加熱、冷却の切り替えを短時間で、容易に行うことができる効果に加え、複数の金型のパージをも行うことができる熱プレス用又は加熱冷却用金型の加熱冷却システムを提供することができる。

The present invention has the following effects.

According to the first aspect of the present invention, the temperature detection units are arranged in the plurality of molds, the temperature determination program is stored in the control means of the temperature control device, and the plurality of molds is based on the temperature detected by the temperature detection unit. Judging the temperature of the mold, heating medium from the heating unit to the plurality of molds through the heating medium path, that is, supply of steam, cooling from the cooling unit to the plurality of molds through the cooling medium path Medium, i.e., the cooling water supply switching supply control and the molding operation control in the plurality of molds are performed. In addition to the effect that water can be used as a cooling medium and switching between heating and cooling of a plurality of dies can be easily performed in a short time, a hot press for purging a plurality of dies or Heating and cooling molds for heating and cooling It is possible to provide a stem.

また、請求項2記載の発明によれば、請求項1記載の発明の効果に加え、各金型における各金型の加熱後のプレススライド下降による成形動作制御又は各金型のプレススライド下降後の加熱による成形動作制御を行うものであるから、異なる種類の成形素材に容易に対応できる熱プレス用又は加熱冷却用金型の加熱冷却システムを提供することができる。

Further , according to the invention described in

請求項3記載の発明によれば、金型に配置した温度検出部により複数の金型の温度を検出し、温度調節装置に予め格納した温度判定用プログラムにより温度検出部による検出温度を判定し、判定結果に基づき加熱用ユニットが生成する加熱用媒体すなわち蒸気、冷却用ユニットからの冷却用媒体すなわち冷却水の複数の金型への切り替え供給と、複数の金型における成形動作を行うことにより、一台の温度調節装置を用い、加熱用媒体に蒸気、冷却用媒体に水を使用し、金型の加熱、冷却の切り替えを短時間で、容易に行い複数の成形品を得ることができる効果に加え、複数の金型のパージをも行うことができる熱プレス用又は加熱冷却用金型の加熱冷却方法を提供することができる。 According to the third aspect of the present invention, the temperatures of the plurality of molds are detected by the temperature detection unit arranged in the mold, and the temperature detected by the temperature detection unit is determined by the temperature determination program stored in advance in the temperature control device. By switching and supplying the heating medium generated by the heating unit based on the determination result, that is, steam, the cooling medium from the cooling unit, that is, cooling water, to the plurality of molds, and performing the molding operation in the plurality of molds Using a single temperature control device, using steam as the heating medium and water as the cooling medium, switching between heating and cooling of the mold can be easily performed in a short time to obtain a plurality of molded products. In addition to the effect, it is possible to provide a heating / cooling method for a hot press or heating / cooling die capable of purging a plurality of dies .

更に、請求項4記載の発明によれば、請求項3記載の発明の効果に加え、各金型における各金型の加熱後のプレススライド下降による成形動作又は各金型のプレススライド下降後の加熱による成形動作を行う工程を含むことから、異なる種類の成形素材に容易に対応できる熱プレス用又は加熱冷却用金型の加熱冷却方法を提供することができる。

Further, according to the invention described in

本発明は、一台の温度調節装置を用い、加熱用媒体に蒸気、冷却用媒体に水を使用し、金型の加熱、冷却の切り替えを短時間で、容易に行うことができる熱プレス用又は加熱冷却用金型の加熱冷却システムを提供するという目的を、複数の金型の加熱用媒体に蒸気、冷却用媒体に冷却水の2種類の異なる温度の媒体を使用し、これらを温度調節装置により金型の媒体路に切り替えて供給し、金型の加熱工程、成形品の成形、金型の冷却工程を繰り返すシステムで、前記金型の対になっている上プレートと下プレートに温度差が必要な時、加熱用媒体路、冷却用媒体路から当該各金型への蒸気、冷却水の供給を切り替えて温度差を調節するようにした熱プレス用又は加熱冷却用の金型の加熱冷却システムであって、前記加熱用媒体である蒸気を生成する加熱用ユニットと、前記冷却用媒体である冷却水の供給、循環を行うとともに、クーリングタワーを含む冷却用ユニットと、前記複数の金型に配置した複数の温度検出部と、蒸気が供給されるとともに、複数系統に分岐した媒体路に各々接続した空気圧で開閉作動する複数の切替弁を有し、前記複数の金型に蒸気を供給する加熱用媒体路と、前記クーリングタワーから冷却水が供給されるとともに、複数系統に分岐した媒体路に各々接続した空気圧で開閉作動する複数の切替弁を有し、前記複数の金型に冷却水を供給する冷却用媒体路と、エアー源、エアーフィルター、エアーレギュレータ、エアーアキュムレータータンク、調節弁、空気圧で開閉作動する切替弁、この切替弁の後段で複数系統に分岐した媒体路に各々接続した止め弁を有し、前記複数の金型にパージ用エアーを供給するエアー流路と、前記加熱用媒体路、冷却用媒体路及びエアー流路の出口側と、前記各複数の金型との間に接続した各々供給弁を含む複数系統の共通媒体路と、前記各金型からの複数系統の媒体路を流出する媒体を排出弁を経て1系統に纏めクーリングタワーに接続した排出弁に送る媒体路に接続した空気圧で開閉作動する切替弁と、前記冷却用媒体路の各切替弁の前段で分岐した媒体路に接続した空気圧で開閉作動する切替弁と、この切替弁の出口から複数系統に分岐した媒体路に接続され、吐出側を前記排出弁に接続したサイレントレジューサと、前記排出媒体路に接続した切替弁の入口手前で分岐し前記サイレントレジューサに接続した媒体路と、を有し、前記冷却水を冷却用ユニットに送る排出媒体路と、を備えるとともに、温度判定用プログラムを格納し前記各温度検出部による検出温度に基づき各金型の温度を判定して、前記加熱用媒体路の複数の切替弁、冷却用媒体路の複数の切替弁、エアー流路の切替弁を制御して各金型への蒸気、冷却水の切り替え供給制御及び各金型のパージを行い、前記各金型における各金型の加熱後のプレススライド下降による成形動作制御又は各金型のプレススライド下降後の加熱による成形動作制御を行う制御手段を備えた温度調節装置と、を具備し、前記複数の金型のパージ用エアー流路は、エアーパージを行う際には前記制御手段、バルブコントローラをもって前記エアー流路に設けた切替弁、排出媒体路に設けた切替弁及び冷却用媒体路の前段に設けた切替弁を開状態に制御し、前記加熱用媒体路に設けた各切替弁及び冷却用媒体路に設けた複数系統の切替弁を閉状態に制御して行うことにより、エアー源からのエアーは、エアーフィルター、エアーレギュレータ、エアーアキュムレータータンク、調節弁、切替弁、止め弁、共通媒体路の各系統の供給弁、金型に設けた各供給マニホールドを経て前記各金型に至りこれらの各金型内をパージした後、当該各金型を通過したエアーは、当該各金型を通過したエアーは、前記各金型に設けた各循環マニホールド、前記排出弁を経て前記温度調節装置に戻り、前記排出媒体路の切替弁を経た後、排出弁よりクーリングタワーへ循環する冷却水に混合するように構成し、前記制御手段に設定する温度判定用プログラムは、前記金型における任意の金型の加熱判定温度、冷却判定用温度の設定することができ、更に、前記金型における任意の金型をグループ分けしてグループでの温度判定の組み合わせを設定して、加熱判定温度によるプログラム動作にて、プレス部のプレススライドの下降やプレス保持時間のスタート制御可能とし、冷却判定温度によるプログラム動作にて、プレス部のプレススライドの上昇やプレス保持時間を制御可能とし、一台の温度調節装置を用いて、加熱用媒体に蒸気、冷却用媒体に水を使用し、金型の加熱、冷却の切り替えを短時間で容易に行うことができるようにしたことにより実現した。 The present invention uses a single temperature control device, uses steam as a heating medium and water as a cooling medium, and can be used for hot presses that can be easily switched between heating and cooling of a mold in a short time. Alternatively, the purpose of providing a heating / cooling system for heating / cooling molds is to use two different temperature media of steam and cooling water as the heating media of a plurality of molds, and adjust the temperature of these. This is a system in which the device is switched to the mold medium path and supplied, and the heating process of the mold, the molding of the molded product, and the cooling process of the mold are repeated. When a difference is required, a hot press or heating / cooling mold that adjusts the temperature difference by switching the supply of steam and cooling water from the heating medium path and the cooling medium path to each mold. A heating / cooling system, wherein the heating medium is steam. The heating unit to be configured, the cooling water as the cooling medium to be supplied and circulated, the cooling unit including a cooling tower, the plurality of temperature detection units disposed in the plurality of molds, and steam are supplied. A heating medium path for supplying steam to the plurality of molds, and cooling water from the cooling tower. A cooling medium path for supplying cooling water to the plurality of molds, an air source, and an air filter. , An air regulator, an air accumulator tank, a control valve, a switching valve that opens and closes by air pressure, and a stop connected to each of the media paths branched into multiple systems at the subsequent stage of this switching valve An air flow path for supplying purge air to the plurality of molds, an outlet side of the heating medium path, a cooling medium path and the air flow path, and each of the plurality of molds. A plurality of common media paths including each connected supply valve, and a medium path that sends the media flowing out from the plurality of media paths from each mold into one system via a discharge valve and sends them to a discharge valve connected to a cooling tower. A switching valve that opens and closes with the connected air pressure, a switching valve that opens and closes with air pressure connected to the medium path branched before each switching valve of the cooling medium path, and a branch from the outlet of the switching valve to a plurality of systems A silent reducer connected to the medium path and having a discharge side connected to the discharge valve, and a medium path branched before the switching valve connected to the discharge medium path and connected to the silent reducer, and the cooling Unit for cooling water And a discharge medium path to be sent to the gas, and a temperature determination program is stored, the temperature of each mold is determined based on the temperature detected by each temperature detection unit, and a plurality of switching valves for the heating medium path, Controls a plurality of switching valves for the cooling medium path and a switching valve for the air flow path to perform switching supply control of steam and cooling water to each mold and purge each mold, and each mold in each mold And a temperature control device having a control means for performing molding operation control by lowering the press slide after heating or controlling molding operation by heating after lowering the press slide of each mold, and for purging the plurality of molds When air purge is performed, the air flow path includes the control means, a switching valve provided in the air flow path with a valve controller, a switching valve provided in the discharge medium path, and a switching valve provided in front of the cooling medium path. Control to open state By controlling each switching valve provided in the heating medium path and a plurality of switching valves provided in the cooling medium path in a closed state, the air from the air source is supplied with an air filter, an air regulator, and an air accumulator. After purging the respective molds through the supply tanks of the system tank, control valve, switching valve, stop valve, common medium path, supply manifolds provided in the molds, The air that has passed through each mold is returned to the temperature control device via each circulation manifold and each discharge valve provided in each mold, and the switching valve for the discharge medium path is turned on. after passing through, configured to mix a coolant circulating to the cooling tower from the discharge valve, the temperature determining program to be set in the control unit, the heating determination temperature of any of the mold in the mold, the cooling-format The temperature can be set, and any molds in the mold can be grouped to set a combination of temperature judgments in the group. Can be controlled and the press holding time can be controlled by the program operation according to the cooling judgment temperature, and the heating medium can be controlled by using one temperature control device. In addition, it was realized by using water as the cooling medium and cooling medium so that the heating and cooling of the mold can be easily switched in a short time.

以下に本発明の実施例を詳細に説明する。

本実施例に係る熱プレス成形用金型(以下「金型」という)の加熱冷却システムは、加熱用媒体に蒸気、冷却用媒体に冷却水の2種類の異なる温度の媒体を使用し、これらを温度調節装置10により金型の媒体路に切り替えて供給し、金型の加熱工程、成形品の成形、冷却工程を繰り返すシステムである。

Examples of the present invention will be described in detail below.

The heating and cooling system of the hot press molding die (hereinafter referred to as “die”) according to the present embodiment uses two different temperature media of steam and cooling water as the heating medium, and these. Is switched to the medium path of the mold by the

本実施例に係る金型の加熱冷却システムは、金型が4個、すなわち金型1乃至金型4からなり、金型1乃至金型4は2プレートで対になり、上プレートと下プレートに温度差が必要な時、加熱用媒体路、冷却用媒体路から金型1乃至金型4への蒸気、冷却水の供給を切り替えて温度差を調節するものである。

The mold heating / cooling system according to the present embodiment includes four molds, that is,

以下に本実施例に係る金型の加熱冷却システムについて詳述する。

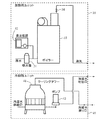

本実施例に係る金型の加熱冷却システムは、図1、図2に示すように、素材を成形加工する4個の金型1乃至金型4に対する加熱用媒体である蒸気、冷却用媒体である冷却水の切り替え供給を行う温度調節装置10と、温度調節装置10に対して蒸気を送り込む加熱用ユニット30、冷却水を送り込む冷却用ユニット40とを有している。

The mold heating / cooling system according to the present embodiment will be described in detail below.

As shown in FIGS. 1 and 2, the mold heating / cooling system according to the present embodiment is composed of steam and a cooling medium which are heating media for the four

前記加熱用ユニット30は、図2に示すように、原水を軟水器31により軟水とし、薬注装置32で防腐剤等の薬を注入した後ボイラー33に供給し、ボイラー33にて蒸気(例えば170℃の蒸気)として吐出弁34から温度調節装置10に供給するように構成している。

As shown in FIG. 2, the

また、前記冷却用ユニット40は、冷却水供給口に供給される冷却水をクーリングタワー41に導き、このクーリングタワー41にて熱交換される冷却水をポンプ42により温度調節装置10に送るとともに、温度調節装置10からの戻りの冷却水をクーリングタワー41の上部からその内部に散水し熱交換するようになっている。

In addition, the cooling

前記温度調節装置10は、加熱用媒体路11、冷却用媒体路12、エアー流路13、蒸気、冷却水及びエアーを各々流通させ金型1乃至金型4に供給するための共通媒体路14、金型1乃至金型4からの循環水(又は蒸気)を冷却用ユニット40に向けて排出する排出媒体路15を有している。

The

加熱用媒体路11は、加熱用ユニット30からの蒸気が供給される入口蒸気弁16と、入口蒸気弁16から4系統に分岐した媒体路に各々接続した4個の減圧弁R1乃至減圧弁R4と、4個の空気圧で開閉作動する切替弁D1乃至切替弁D4と、4個の流量調節弁H1乃至流量調節弁H4とを有している。

The

冷却用媒体路12は、前記クーリングタワー41より冷却水が供給される入口冷却水弁17と、入口冷却水弁17の後段に接続したY型ストレーナ18と、ポンプ19と、ポンプ19の吐出側で4系統に分岐した媒体路に各々接続した4個の空気圧で開閉作動する切替弁A1乃至切替弁A4と、流量調節弁E1乃至流量調節弁E4とを有している。前記ポンプ19の前段には圧力スイッチ20、後段には圧力計21を接続している。

The cooling

前記エアー流路13は、エアー源22と、エアーフィルター23と、エアーレギュレータ24と、エアーアキュムレータータンク29と、調節弁26と、空気圧で開閉作動する切替弁Mと、切替弁Mの吐出側で4系統に分岐した媒体路に各々接続した4個の止め弁27a乃至止め弁27dとを有している。

The

前記加熱用媒体路11、冷却用媒体路12、エアー流路13の4系統の出口側は、4系統の共通媒体路14に各々接続している。

The four outlets of the

前記排出媒体路15は、金型1乃至金型4からの4系統の循環水(又は蒸気)を1系統に纏め前記クーリングタワー41に接続した排出弁28に送る媒体路に接続した空気圧で開閉作動する切替弁Bと、前記冷却用媒体路12のポンプ19の後段で分岐した媒体路に接続した空気圧で開閉作動する切替弁Cと、この切替弁Cから2系統に分岐した媒体路に接続し、吐出側を排出弁28としたサイレントレジューサSR1、SR2と、前記切替弁Bの入口手前で分岐しサイレントレジューサSR1、SR2に接続した2系統の媒体路に接続した調節弁S1、S2とを有している。なお、図1中、Kは(媒体温度モニター用)温度センサである。

The

前記4個の金型1乃至金型4は、各々供給マニホールド1a乃至4a、循環マニホールド1b乃至4bを具備している。また、前記金型1乃至金型4は、各々内部の温度を検出する温度センサ5a乃至5dを具備している。

The four

また、前記4個の金型1乃至金型4に対しては、前記共通媒体路14から4個の供給弁6a乃至6dを経て蒸気、冷却水又はエアーが供給され、前記4個の金型1乃至金型4を通過した蒸気、冷却水又はエアーは4個の排出弁7a乃至7dを経て前記排出媒体路15へ排出されるようになっている。

Further, steam, cooling water, or air is supplied from the common

前記4個の金型1乃至金型4は、プレス部8を備え、このプレス部8に設けたプレススライドの図5に示すような金型1乃至金型4が一定温度まで上昇した時点からの下降動作でプレートを移動させて成形加工を行い、プレススライドの図5に示すような上昇動作の後成形品(製品)の搬出(取り出し)を行う。

The four

バルブコントローラ25は、前記切替弁A1乃至A4、切替弁D1乃至D4、切替弁B、切替弁C、切替弁Mにこれらの開閉動作用の信号を供給するようになっている。

The

次に、本実施例に係る金型の加熱冷却システムにおける温度調節装置10の制御系について図3を参照して説明する。

Next, a control system of the

前記温度調節装置10は、前記温度センサ5a乃至5dの検出信号を取り込み、予め設定した温度判定用プログラムによるプログラム動作にて前記バルブコントローラ25の動作制御を行うとともに、前記金型1乃至金型4用のプレス部8に制御信号を送りプレススライドの動作制御を行う制御手段50を有している。前記制御手段50、バルブコントローラ25は、図1に示すように、コントロールBOXに収納されている。

The

制御手段50に設定する温度判定用プログラムとしては、金型1乃至金型4の任意の加熱判定温度、及び冷却判定用温度の設定や、以下のようなグループでの温度判定の組み合わせ設定を挙げることができる。

Examples of the temperature determination program set in the control means 50 include setting of arbitrary heating determination temperatures and cooling determination temperatures of the

すなわち、金型1、金型2をAグループとし、金型1、金型2の各温度をT1、T2とするときのT1 AND T2又はT1 OR T2の判定の設定、金型3、金型4をBグループとし、金型3、金型4の温度をT3、T4とするときのT3 AND T4又はT3 OR T4の判定の設定を挙げることができる。

That is, the setting of the determination of T1 AND T2 or T1 OR T2 when the

また、Aグループ、Bグループで、A AND Bの判定、A OR Bの判定の組合わせの設定を挙げることができる。 Further, in the A group and the B group, a combination of A AND B determination and A OR B determination can be set.

そして、加熱判定温度によるプログラム動作にて、プレス部8のプレススライドの下降や、プレス保持時間のスタート制御を行ったり、冷却判定温度によるプログラム動作にて、プレス部8のプレススライドの上昇、プレス保持時間の制御を行ったりすることができる。 Then, the press slide of the press section 8 is lowered and the press holding time is controlled by the program operation based on the heating determination temperature, or the press slide is raised and pressed by the program operation based on the cooling determination temperature. The holding time can be controlled.

次に、本実施例に係る金型の加熱冷却システムの動作を、前記温度調節装置10による金型温度調節動作を主にし、各図とともに図4、図5も参照してスタンバイ時、加熱時、冷却時、パージ時に分けて説明する。

Next, the operation of the mold heating and cooling system according to the present embodiment is mainly performed by the mold temperature adjusting operation by the

(スタンバイ時)

スタンバイ時は、制御手段50、バルブコントローラ25の制御に基づき、図4に示すように温度調節装置10における切替弁Cのみが開、切替弁A1乃至A4、切替弁D1乃至D4、切替弁B、切替弁Mが閉状態となり、クーリングタワー41からの冷却水は、ポンプ19により圧送され切替弁Cを経てサイレントレジューサSR1、SR2を通過し、更に排出弁28よりクーリングタワー41へ循環する。

(Standby)

During standby, based on the control of the control means 50 and the

(加熱時)

金型1乃至金型4の加熱を行う際には、前記制御手段50、バルブコントローラ25により、図4に示すように切替弁D1乃至D4及び切替弁Cが開状態に制御、切替弁A1乃至A4、切替弁B及び切替弁Mが閉状態に制御される。

(When heating)

When the

これにより、加熱用ユニット30で生成した蒸気は、温度調節装置10の入口蒸気弁16より、加熱用媒体路11に設けた4系統の減圧弁R1乃至R4、切替弁D1乃至D4、流量調節弁H1乃至H4を通り、共通媒体路14を経た後、供給弁6a乃至6d、供給マニホールド1a乃至4aを経て金型1乃至金型4を図5に示すように加熱する。

As a result, the steam generated by the

このとき、金型1乃至4へ供給される蒸気は、金型1乃至4のすぐ側の供給マニホールド1a乃至4aにアキュムレートする形態で、各金型1乃至4に供給することにより、各金型1乃至4の表面の温度むらが抑えられる。前記4個の金型1乃至金型4においては、制御手段50による制御に基づきプレス部8に設けたプレススライドの図5に示すような金型1乃至金型4が一定温度まで上昇した時点からの下降動作でプレートを移動させて成形加工を行い、プレススライドの図5に示すような上昇動作の後成形品(製品)の搬出(取り出し)を行う。

At this time, the steam supplied to the

金型1乃至金型4を加熱し温度の下がった蒸気は、循環マニホールド1b乃至4b、排出弁7a乃至7dを経て温度調節装置10に戻り、排出媒体路15の調節弁S1、S2を経てサイレントレジューサSR1、SR2に送られ、ここで蒸気が水に置換され、更に排出弁28を経てクーリングタワー41へ送られる(循環する)。

The steam whose temperature has been lowered by heating the

このような金型1乃至金型4の加熱時においては、前記切替弁A1乃至A4は上述したように閉状態で、クーリングタワー41からの冷却水は、ポンプ19により圧送され切替弁Cを経てサイレントレジューサSR1、SR2を通過し、更に排出弁28を経てクーリングタワー41へ循環する。

When the

(冷却時)

金型1乃至金型4の冷却を行う際には、前記制御手段50、バルブコントローラ25により、切替弁A1乃至A4、切替弁Bが開状態に制御され、切替弁D1乃至D4、切替弁C、切替弁Mが閉状態に制御される。

(When cooling)

When the

これにより、クーリングタワー41からの冷却水は、入口冷却水弁17、Y型ストレーナ18を経てポンプ19により圧送され、切替弁A1乃至A4、流量調節弁E1乃至E4を通り、共通媒体路14を経た後、供給弁6a乃至6d、供給マニホールド1a乃至4aを経て図5に示すように金型1乃至金型4を冷却する。

Thereby, the cooling water from the

この場合も、金型1乃至4へ供給される冷却水は、金型1乃至4のすぐ側の供給マニホールド1a乃至4aにアキュムレートする形態で、各金型1乃至4に供給することにより、各金型1乃至4の表面の温度むらが抑えられる。

Also in this case, the cooling water supplied to the

金型1乃至金型4を冷却し温度の上がった冷却水は、循環マニホールド1b乃至4b、排出弁7a乃至7dを経て温度調節装置10に戻り、排出媒体路15の切替弁B、更に排出弁28を経てクーリングタワー41へ送られる(循環する)。

Cooling water that has cooled the

(パージ時)

金型1乃至金型4のパージを行う際には、前記制御手段50、バルブコントローラ25により、図4に示すように切替弁B、切替弁C及び切替弁Mが開状態に制御され、切替弁A1乃至A4、切替弁D1乃至D4が閉状態に制御される。

(When purging)

When purging the

これにより、エアー源22からのエアーは、エアーフィルター23、エアーレギュレータ24、エアーアキュムレータータンク29、調節弁26、切替弁M、4個の止め弁27a乃至27dを通り、更に共通媒体路14を経た後、供給弁6a乃至6d、供給マニホールド1a乃至4aを経て金型1乃至金型4に至り、これら金型1乃至金型4内をパージする。

Thereby, the air from the air source 22 passes through the air filter 23, the

金型1乃至金型4を通過したエアーは、循環マニホールド1b乃至4b、排出弁7a乃至7dを経て温度調節装置10に戻り、排出媒体路15の切替弁Bを経た後、スタンバイ時の場合と同様にポンプ19により圧送され切替弁Cを経てサイレントレジューサSR1、SR2を通過し、更に排出弁28よりクーリングタワー41ヘ循環する冷却水に混合する。The air that has passed through the

ここで、加熱冷却システムの装置サイズの具体例について考察すると、従来例のように、加熱用媒体に油又は温水を使用する装置では、熱媒体発生機のサイズは、mm単位で幅1000×奥行き2100×高さ2350のサイズで200kWのカロリが必要であり、金型が4個有れば、上記サイズの4倍の設置面積が必要となる。更に、これに温度調節装置(幅650×奥行き532×高さ500)の設置面積が必要となる。 Here, a specific example of the apparatus size of the heating / cooling system will be considered. In the apparatus using oil or hot water as the heating medium as in the conventional example, the size of the heat medium generator is 1000 × depth in mm units. A 2100 × 2350 size 200 kW calorie is required, and if there are four molds, an installation area four times the size is required. Furthermore, this requires an installation area of the temperature control device (width 650 × depth 532 × height 500).

しかし、本実施例のように加熱用媒体を蒸気とすることにより、加熱用ユニット30のサイズは、mm単位で幅1270×奥行2100×高さ2200で940kWの熱エネルギーを出力する構成とすることができ、これに温度調節装置のmm単位で幅750×奥行き1500×高さ1850を加えたサイズに収まることになり、省スペースを図ることができる。

However, by using steam as the heating medium as in this embodiment, the size of the

また、従来例において、複数の各金型に温度差を付けるには、加熱用媒体それぞれの独立した装置が必要であったが、本実施例によれば、加熱用蝶体である蒸気(170℃)を温度調節装置10に供給するだけで、4種の温度の蒸気を金型1乃至4へ供給することが容易にできる。すなわち、加熱用媒体路11においては、減圧弁R1乃至R4、温度判定により開閉動作する切替弁D1乃至D4、流量調節弁H1乃至H4を設けているので、これらにより4種の温度の蒸気を金型1乃至4へ供給することができる。また、冷却用媒体路12には、温度判定により開閉動作する切替弁A1乃至A4、流量調節弁E1乃至E4を設けているので、これらにより4種の温度の冷却水を金型1乃至4へ供給することができる。

Further, in the conventional example, in order to give a temperature difference to each of the plurality of molds, an independent device for each heating medium is necessary. However, according to the present embodiment, steam (170 4) can be easily supplied to the

また、本実施例によれば、設備費は80kWくらいが現実的なので、金型1乃至4におけるプレート1枚あたりの昇温スピードも約3倍は早くなる。

Further, according to the present embodiment, since the equipment cost is realistically about 80 kW, the temperature increase speed per plate in the

更に、本実施例によれば、大量の蒸気を金型1乃至4へ供給することができるため、プレートの表面の温度バラツキも抑えることが可能となる。

Furthermore, according to the present embodiment, since a large amount of steam can be supplied to the

図6は、前記各金型1乃至4における成形動作制御の他の例を示すものであり、前記4個の金型1乃至金型4による成形動作時に、制御手段50による制御に基づき素材を金型1乃至金型4に搬入後、直ちにプレス部8に設けたプレススライドの図6に示すように、下降動作を行い、金型1乃至金型4を加熱し成形加工を行い、更に冷却し、一定温度まで金型1乃至金型4が冷却した時点で、プレススライドを図6に示すように上昇動作させて、成形品(製品)の搬出(取り出し)を行うようにしたものである。

このような金型1乃至金型4における成形動作制御を行うことにより、図5に示す場合とは異なる種類の樹脂材料の成形加工にも容易に対応することができる。

FIG. 6 shows another example of molding operation control in each of the

By performing the molding operation control in the

本発明は、上述した熱プレス用又は加熱冷却用金型に適用する場合の他、複数の金型を含む成形システムに幅広く適用可能である。 The present invention can be widely applied to a molding system including a plurality of molds in addition to the above-described mold for hot pressing or heating / cooling.

1〜4 金型

1a〜4a 供給マニホールド

1b〜4b 循環マニホールド

5a〜5d 温度センサ

6a〜6d 供給弁

7a〜7d 排出弁

8 プレス部

10 温度調節装置

11 加熱用媒体路

12 冷却用媒体路

13 エアー流路

14 共通媒体路

15 排出媒体路

16 入口蒸気弁

17 入口冷却水弁

17 入口冷却水弁

18 Y型ストレーナ

19 ポンプ

20 圧力スイッチ

21 圧力計

22 エアー源

23 エアーフィルター

24 エアーレギュレータ

25 バルブコントローラ

26 調節弁

27a〜27d 止め弁

28 排出弁

29 エアーアキュムレータータンク

30 加熱用ユニット

31 軟水器

32 薬注装置

33 ボイラー

34 吐出弁

40 冷却用ユニット

41 クーリングタワー

42 ポンプ

50 制御手段

A1〜A4 切替弁

B 切替弁

C 切替弁

D1〜D4 切替弁

E1〜E4 流量調節弁

H1〜H4 流量調節弁

M 切替弁

R1〜R4 減圧弁

S1、S2 調節弁

SR1、SR2 サイレントレジューサ

K (媒体温度モニター用)温度センサ

1 to 4 Mold 1a to 4a Supply manifold 1b to

Claims (4)

前記加熱用媒体である蒸気を生成する加熱用ユニットと、

前記冷却用媒体である冷却水の供給、循環を行うとともに、クーリングタワーを含む冷却用ユニットと、

前記複数の金型に配置した複数の温度検出部と、

蒸気が供給されるとともに、複数系統に分岐した媒体路に各々接続した空気圧で開閉作動する複数の切替弁を有し、前記複数の金型に蒸気を供給する加熱用媒体路と、前記クーリングタワーから冷却水が供給されるとともに、複数系統に分岐した媒体路に各々接続した空気圧で開閉作動する複数の切替弁を有し、前記複数の金型に冷却水を供給する冷却用媒体路と、エアー源、エアーフィルター、エアーレギュレータ、エアーアキュムレータータンク、調節弁、空気圧で開閉作動する切替弁、この切替弁の後段で複数系統に分岐した媒体路に各々接続した止め弁を有し、前記複数の金型にパージ用エアーを供給するエアー流路と、前記加熱用媒体路、冷却用媒体路及びエアー流路の出口側と、前記各複数の金型との間に接続した各々供給弁を含む複数系統の共通媒体路と、前記各金型からの複数系統の媒体路を流出する媒体を排出弁を経て1系統に纏めクーリングタワーに接続した排出弁に送る媒体路に接続した空気圧で開閉作動する切替弁と、前記冷却用媒体路の各切替弁の前段で分岐した媒体路に接続した空気圧で開閉作動する切替弁と、この切替弁の出口から複数系統に分岐した媒体路に接続され、吐出側を前記排出弁に接続したサイレントレジューサと、前記媒体路に接続した切替弁の入口手前で分岐し前記サイレントレジューサに接続した媒体路と、を有し、前記冷却水を冷却用ユニットに送る排出媒体路と、を備えるとともに、温度判定用プログラムを格納し前記各温度検出部による検出温度に基づき各金型の温度を判定して、前記加熱用媒体路の複数の切替弁、冷却用媒体路の複数の切替弁、エアー流路の切替弁を制御して各金型への蒸気、冷却水の切り替え供給制御及び各金型のパージを行い、前記各金型における成形動作制御を行う制御手段を備えた温度調節装置と、

を具備し、

前記複数の金型のパージ用エアー流路は、エアーパージを行う際には前記制御手段、バルブコントローラをもって前記エアー流路に設けた切替弁、排出媒体路に設けた切替弁及び冷却用媒体路の前段に設けた切替弁を開状態に制御し、前記加熱用媒体路に設けた各切替弁及び冷却用媒体路に設けた複数系統の切替弁を閉状態に制御して行うことにより、エアー源からのエアーは、エアーフィルター、エアーレギュレータ、エアーアキュムレータータンク、調節弁、切替弁、止め弁、共通媒体路の各系統の供給弁、金型に設けた各供給マニホールドを経て前記各金型に至りこれらの各金型内をパージした後、当該各金型を通過したエアーは、前記各金型に設けた各循環マニホールド、前記排出弁を経て前記温度調節装置に戻り、前記排出媒体路の切替弁を経た後、排出弁よりクーリングタワーへ循環する冷却水に混合するように構成し、

前記制御手段に設定する温度判定用プログラムは、前記金型における任意の金型の加熱判定温度、冷却判定用温度の設定することができ、更に、前記金型における任意の金型をグループ分けしてグループでの温度判定の組み合わせを設定して、加熱判定温度によるプログラム動作にて、プレス部のプレススライドの下降やプレス保持時間のスタート制御可能とし、冷却判定温度によるプログラム動作にて、プレス部のプレススライドの上昇やプレス保持時間を制御可能とし、

一台の温度調節装置を用いて、加熱用媒体に蒸気、冷却用媒体に水を使用し、金型の加熱、冷却の切り替えを短時間で容易に行うことができるようにしたことを特徴とする熱プレス用又は加熱冷却用の金型の加熱冷却システム。 Two types of medium with different temperatures are used for the heating medium of the molds and the cooling medium is used for the cooling medium, and these are switched to the mold medium path by the temperature control device and supplied to the mold. When a temperature difference is required between the upper plate and lower plate of the mold pair, the system repeats the process, the molding of the molded product, and the cooling process of the mold. A heating / cooling system for a mold for heat pressing or heating / cooling, wherein the temperature difference is adjusted by switching the supply of steam and cooling water to each mold,

A heating unit that generates steam as the heating medium;

Supplying and circulating the cooling water as the cooling medium, and a cooling unit including a cooling tower;

A plurality of temperature detectors arranged in the plurality of molds;

A heating medium path that supplies steam to the plurality of molds and has a plurality of switching valves that are opened and closed by air pressure connected to each of the medium paths that are branched into a plurality of systems, while supplying steam, and the cooling tower A cooling medium path for supplying cooling water to the plurality of molds, and a plurality of switching valves that are opened and closed by air pressure connected to the medium paths branched into a plurality of systems, respectively, and supplied with cooling water; A source, an air filter, an air regulator, an air accumulator tank, a control valve, a switching valve that opens and closes by air pressure, a stop valve connected to each of the medium paths branched into a plurality of systems at the subsequent stage of the switching valve, An air flow path for supplying purge air to the mold, and each supply valve connected between the heating medium path, the cooling medium path and the outlet side of the air flow path, and the plurality of molds. Opening and closing operation by air pressure connected to the medium path of multiple systems, and the medium path that sends the media flowing out of the multiple systems of media paths from each mold to one system via the discharge valve and connected to the discharge valve connected to the cooling tower A switching valve that is opened and closed by air pressure connected to a medium path branched in the previous stage of each switching valve of the cooling medium path, and connected to a medium path branched into a plurality of systems from the outlet of the switching valve, A silent reducer having a discharge side connected to the discharge valve, and a medium path branched before the switching valve connected to the medium path and connected to the silent reducer, and sends the cooling water to the cooling unit. A discharge medium path, a temperature determination program is stored, the temperature of each mold is determined based on the temperature detected by each temperature detection unit, and a plurality of switching valves for the heating medium path, cooling Controls a plurality of switching valves for the medium path and a switching valve for the air flow path, performs switching supply control of steam and cooling water to each mold, and purges each mold, and performs molding operation control in each mold. A temperature control device comprising a control means;

Comprising

The purge air flow paths of the plurality of molds are, when performing air purge, the control means, a switching valve provided in the air flow path with a valve controller, a switching valve provided in a discharge medium path, and a cooling medium path. By switching the switching valve provided in the previous stage to the open state and controlling the switching valves provided in the heating medium path and the switching valves of the plurality of systems provided in the cooling medium path to the closed state, The air from the source passes through the air filter, air regulator, air accumulator tank, control valve, switching valve, stop valve, supply valve of each system of the common medium path, each supply manifold provided in the mold, and each mold after reach purged in each mold these, the air that has passed through the mold, each circulation manifold provided on each die, through the discharge valve back to the temperature adjusting device, wherein the discharge medium passage After passing through the switching valve, and configured to mix the coolant circulating to the cooling tower from the discharge valve,

The temperature determination program set in the control means can set a heating determination temperature and a cooling determination temperature for any mold in the mold, and further group the arbitrary molds in the mold. By setting the temperature judgment combination in the group, it is possible to control the press slide descent and press holding time start by the program operation by the heating judgment temperature, and the press part by the program operation by the cooling judgment temperature. The press slide rise and press holding time can be controlled,

Using a single temperature control device, steam is used for the heating medium and water is used for the cooling medium, so that the heating and cooling of the mold can be easily switched in a short time. Heating / cooling system for molds for heat press or heating / cooling.

前記加熱用媒体である蒸気を生成する加熱用ユニットと、

前記冷却用媒体である冷却水の供給、循環を行うとともに、クーリングタワーを含む冷却用ユニットと、

前記複数の金型に配置した複数の温度検出部と、

蒸気が供給されるとともに、複数系統に分岐した媒体路に各々接続した空気圧で開閉作動する複数の切替弁を有し、前記複数の金型に蒸気を供給する加熱用媒体路と、前記クーリングタワーから冷却水が供給されるとともに、複数系統に分岐した媒体路に各々接続した空気圧で開閉作動する複数の切替弁を有し、前記複数の金型に冷却水を供給する冷却用媒体路と、エアー源、エアーフィルター、エアーレギュレータ、エアーアキュムレータータンク、調節弁、空気圧で開閉作動する切替弁、この切替弁の後段で複数系統に分岐した媒体路に各々接続した止め弁を有し、前記複数の金型にパージ用エアーを供給するエアー流路と、前記加熱用媒体路、冷却用媒体路及びエアー流路の出口側と、前記各複数の金型との間に接続した各々供給弁を含む複数系統の共通媒体路と、前記各金型からの複数系統の媒体路を流出する媒体を排出弁を経て1系統に纏めクーリングタワーに接続した排出弁に送る媒体路に接続した空気圧で開閉作動する切替弁と、前記冷却用媒体路の各切替弁の前段で分岐した媒体路に接続した空気圧で開閉作動する切替弁と、この切替弁の出口から複数系統に分岐した媒体路に接続され、吐出側を前記排出弁に接続したサイレントレジューサと、前記排出媒体路に接続した切替弁の入口手前で分岐し前記サイレントレジューサに接続した媒体路と、を有し、前記冷却水を冷却用ユニットに送る排出媒体路と、を備えるとともに、温度判定用プログラムを格納し前記各温度検出部による検出温度に基づき各金型の温度を判定して、前記加熱用媒体路の複数の切替弁、冷却用媒体路の複数の切替弁、エアー流路の切替弁を制御して各金型への蒸気、冷却水の切り替え供給制御及び各金型のパージを行い、前記各金型における各金型の加熱後のプレススライド下降による成形動作制御又は各金型のプレススライド下降後の加熱による成形動作制御を行う制御手段を備えた温度調節装置と、

を具備し、

前記複数の金型のパージ用エアー流路は、エアーパージを行う際には前記制御手段、バルブコントローラをもって前記エアー流路に設けた切替弁、排出媒体路に設けた切替弁及び冷却用媒体路の前段に設けた切替弁を開状態に制御し、前記加熱用媒体路に設けた各切替弁及び冷却用媒体路に設けた複数系統の切替弁を閉状態に制御して行うことにより、エアー源からのエアーは、エアーフィルター、エアーレギュレータ、エアーアキュムレータータンク、調節弁、切替弁、止め弁、共通媒体路の各系統の供給弁、金型に設けた各供給マニホールドを経て前記各金型に至りこれらの各金型内をパージした後、当該各金型を通過したエアーは、前記各金型に設けた各循環マニホールド、前記排出弁を経て前記温度調節装置に戻り、前記排出媒体路の切替弁を経た後、排出弁よりクーリングタワーへ循環する冷却水に混合するように構成し、

前記制御手段に設定する温度判定用プログラムは、前記金型における任意の金型の加熱判定温度、冷却判定用温度の設定することができ、更に、前記金型における任意の金型をグループ分けしてグループでの温度判定の組み合わせを設定して、加熱判定温度によるプログラム動作にて、プレス部のプレススライドの下降やプレス保持時間のスタート制御可能とし、冷却判定温度によるプログラム動作にて、プレス部のプレススライドの上昇やプレス保持時間を制御可能とし、

一台の温度調節装置を用いて、加熱用媒体に蒸気、冷却用媒体に水を使用し、金型の加熱、冷却の切り替えを短時間で容易に行うことができるようにしたことを特徴とする熱プレス用又は加熱冷却用の金型の加熱冷却システム。 Two types of medium with different temperatures are used for the heating medium of the molds and the cooling medium is used for the cooling medium, and these are switched to the mold medium path by the temperature control device and supplied to the mold. When a temperature difference is required between the upper plate and lower plate of the mold pair, the system repeats the process, the molding of the molded product, and the cooling process of the mold. A heating / cooling system for a mold for heat pressing or heating / cooling, wherein the temperature difference is adjusted by switching the supply of steam and cooling water to each mold,

A heating unit that generates steam as the heating medium;

Supplying and circulating the cooling water as the cooling medium, and a cooling unit including a cooling tower;

A plurality of temperature detectors arranged in the plurality of molds;

A heating medium path that supplies steam to the plurality of molds and has a plurality of switching valves that are opened and closed by air pressure connected to each of the medium paths that are branched into a plurality of systems, while supplying steam, and the cooling tower A cooling medium path for supplying cooling water to the plurality of molds, and a plurality of switching valves that are opened and closed by air pressure connected to the medium paths branched into a plurality of systems, respectively, and supplied with cooling water; A source, an air filter, an air regulator, an air accumulator tank, a control valve, a switching valve that opens and closes by air pressure, a stop valve connected to each of the medium paths branched into a plurality of systems at the subsequent stage of the switching valve, An air flow path for supplying purge air to the mold, and each supply valve connected between the heating medium path, the cooling medium path and the outlet side of the air flow path, and the plurality of molds. Opening and closing operation by air pressure connected to the medium path of multiple systems, and the medium path that sends the media flowing out of the multiple systems of media paths from each mold to one system via the discharge valve and connected to the discharge valve connected to the cooling tower A switching valve that is opened and closed by air pressure connected to a medium path branched in the previous stage of each switching valve of the cooling medium path, and connected to a medium path branched into a plurality of systems from the outlet of the switching valve, A silent reducer having a discharge side connected to the discharge valve, and a medium path branched before the switching valve connected to the discharge medium path and connected to the silent reducer, and the cooling water is supplied to the cooling unit. A discharge medium path to be sent, a temperature determination program is stored, a temperature of each mold is determined based on a temperature detected by each temperature detection unit, and a plurality of switching valves for the heating medium path, Control each of the switching valves of the reject medium path and the switching valve of the air flow path to perform switching supply control of steam and cooling water to each mold and purge each mold, and each mold in each mold A temperature control device comprising a control means for performing molding operation control by lowering the press slide after heating or molding operation control by heating after lowering the press slide of each mold, and

Comprising

The purge air flow paths of the plurality of molds are, when performing air purge, the control means, a switching valve provided in the air flow path with a valve controller, a switching valve provided in a discharge medium path, and a cooling medium path. By switching the switching valve provided in the previous stage to the open state and controlling the switching valves provided in the heating medium path and the switching valves of the plurality of systems provided in the cooling medium path to the closed state, The air from the source passes through the air filter, air regulator, air accumulator tank, control valve, switching valve, stop valve, supply valve of each system of the common medium path, each supply manifold provided in the mold, and each mold after reach purged in each mold these, the air that has passed through the mold, each circulation manifold provided on each die, through the discharge valve back to the temperature adjusting device, wherein the discharge medium passage After passing through the switching valve, and configured to mix the coolant circulating to the cooling tower from the discharge valve,

The temperature determination program set in the control means can set a heating determination temperature and a cooling determination temperature for any mold in the mold, and further group the arbitrary molds in the mold. By setting the temperature judgment combination in the group, it is possible to control the press slide descent and press holding time start by the program operation by the heating judgment temperature, and the press part by the program operation by the cooling judgment temperature. The press slide rise and press holding time can be controlled,

Using a single temperature control device, steam is used for the heating medium and water is used for the cooling medium, so that the heating and cooling of the mold can be easily switched in a short time. Heating / cooling system for molds for heat press or heating / cooling.

前記加熱用媒体である蒸気を生成する加熱用ユニットと、

前記冷却用媒体である冷却水の供給、循環を行うとともに、クーリングタワーを含む冷却用ユニットと、

前記複数の金型に配置した複数の温度検出部と、

蒸気が供給されるとともに、複数系統に分岐した媒体路に各々接続した空気圧で開閉作動する複数の切替弁を有し、前記複数の金型に蒸気を供給する加熱用媒体路と、前記クーリングタワーから冷却水が供給されるとともに、複数系統に分岐した媒体路に各々接続した空気圧で開閉作動する複数の切替弁を有し、前記複数の金型に冷却水を供給する冷却用媒体路と、エアー源、エアーフィルター、エアーレギュレータ、エアーアキュムレータータンク、調節弁、空気圧で開閉作動する切替弁、この切替弁の後段で複数系統に分岐した媒体路に各々接続した止め弁を有し、前記複数の金型にパージ用エアーを供給するエアー流路と、前記加熱用媒体路、冷却用媒体路及びエアー流路の出口側と、前記各複数の金型との間に接続した各々供給弁を含む複数系統の共通媒体路と、前記各金型からの複数系統の媒体路を流出する媒体を排出弁を経て1系統に纏めクーリングタワーに接続した排出弁に送る媒体路に接続した空気圧で開閉作動する切替弁と、前記冷却用媒体路の各切替弁の前段で分岐した媒体路に接続した空気圧で開閉作動する切替弁と、この切替弁の出口から複数系統に分岐した媒体路に接続され、吐出側を前記排出弁に接続したサイレントレジューサと、前記排出媒体路に接続した切替弁の入口手前で分岐し前記サイレントレジューサに接続した媒体路と、を有し、前記冷却水を冷却用ユニットに送る排出媒体路と、を備えて構成し、

前記金型の対になっている上プレートと下プレートに温度差が必要な時、加熱用媒体路、冷却用媒体路から当該各金型への蒸気、冷却水の供給を切り替えて温度差を調節するようにした熱プレス用又は加熱冷却用の金型の加熱冷却方法であって、

前記複数の金型に配置した各温度検出部により各金型の温度を検出する工程と、

前記温度調節装置に予め格納した温度判定用プログラムにより各温度検出部による検出温度を判定する工程と、

前記判定結果に基づき各金型への蒸気、冷却水の切り替え供給制御、パージ用エアーの供給制御、前記各金型における成形動作制御を行う工程と、

を含み、

前記複数の金型のパージ用エアー流路のエアーパージを行う際には前記制御手段、バルブコントローラをもって前記エアー流路に設けた切替弁、排出媒体路に設けた切替弁及び冷却用媒体路の前段に設けた切替弁を開状態に制御し、前記加熱用媒体路に設けた各切替弁及び冷却用媒体路に設けた複数系統切替弁を閉状態に制御して行うことにより、エアー源からのエアーは、エアーフィルター、エアーレギュレータ、エアーアキュムレータータンク、調節弁、切替弁、止め弁、共通媒体路の各系統の供給弁、金型に設けた各供給マニホールドを経て前記各金型に至りこれらの各金型内をパージした後、当該各金型を通過したエアーは、前記各金型に設けた各循環マニホールド、前記排出弁を経て前記温度調節装置に戻り、前記排出媒体路の切替弁を経た後、排出弁よりクーリングタワーへ循環する冷却水に混合するように構成し、

前記制御手段に設定する温度判定用プログラムは、前記金型における任意の金型の加熱判定温度、冷却判定用温度の設定することができ、更に、前記金型における任意の金型をグループ分けしてグループでの温度判定の組み合わせを設定して、加熱判定温度によるプログラム動作にて、プレス部のプレススライドの下降やプレス保持時間のスタート制御可能とし、冷却判定温度によるプログラム動作にて、プレス部のプレススライドの上昇やプレス保持時間を制御可能とし、

一台の温度調節装置を用いて、加熱用媒体に蒸気、冷却用媒体に水を使用し、金型の加熱、冷却の切り替えを短時間で容易に行うことができるようにしたことを特徴とする熱プレス用又は加熱冷却用の金型の加熱冷却方法。 Two types of medium with different temperatures are used for the heating medium of the molds and the cooling medium is used for the cooling medium, and these are switched to the mold medium path by the temperature control device and supplied to the mold. A system that repeats the process, molding of molded products, and cooling process of the mold,

A heating unit that generates steam as the heating medium;

Supplying and circulating the cooling water as the cooling medium, and a cooling unit including a cooling tower;

A plurality of temperature detectors arranged in the plurality of molds;

A heating medium path that supplies steam to the plurality of molds and has a plurality of switching valves that are opened and closed by air pressure connected to each of the medium paths that are branched into a plurality of systems, while supplying steam, and the cooling tower A cooling medium path for supplying cooling water to the plurality of molds, and a plurality of switching valves that are opened and closed by air pressure connected to the medium paths branched into a plurality of systems, respectively, and supplied with cooling water; A source, an air filter, an air regulator, an air accumulator tank, a control valve, a switching valve that opens and closes by air pressure, a stop valve connected to each of the medium paths branched into a plurality of systems at the subsequent stage of the switching valve, An air flow path for supplying purge air to the mold, and each supply valve connected between the heating medium path, the cooling medium path and the outlet side of the air flow path, and the plurality of molds. Opening and closing operation by air pressure connected to the medium path of multiple systems, and the medium path that sends the media flowing out of the multiple systems of media paths from each mold to one system via the discharge valve and connected to the discharge valve connected to the cooling tower A switching valve that is opened and closed by air pressure connected to a medium path branched in the previous stage of each switching valve of the cooling medium path, and connected to a medium path branched into a plurality of systems from the outlet of the switching valve, A silent reducer having a discharge side connected to the discharge valve, and a medium path branched before the switching valve connected to the discharge medium path and connected to the silent reducer, and the cooling water is supplied to the cooling unit. A discharge medium path to be sent,

When a temperature difference is required between the upper plate and the lower plate of the mold pair, the supply of steam and cooling water from the heating medium path and cooling medium path to the respective molds is switched to reduce the temperature difference. A heating / cooling method of a mold for heat press or heating / cooling adapted to be adjusted,

Detecting the temperature of each mold by each temperature detector disposed in the plurality of molds;

Determining a temperature detected by each temperature detection unit using a temperature determination program stored in advance in the temperature control device;

A process of performing steam and cooling water switching supply control to each die based on the determination result, purge air supply control, and molding operation control in each die,

Including

When performing air purge of the purge air flow paths of the plurality of molds, the control means, a switching valve provided in the air flow path with a valve controller, a switching valve provided in the discharge medium path, and a cooling medium path By controlling the switching valve provided in the previous stage to the open state and controlling each switching valve provided in the heating medium path and the multiple system switching valve provided in the cooling medium path to the closed state, from the air source The air reaches the molds through an air filter, an air regulator, an air accumulator tank, a control valve, a switching valve, a stop valve, a supply valve for each system of the common medium path, and each supply manifold provided in the mold. after purging the inside of each of these molds, air which passes through the respective mold, the respective circulation manifold provided in each mold, returns to the discharge valve the temperature controller via a switching of the discharge medium passage After a valve, configured to mix a coolant circulating to the cooling tower from the discharge valve,

The temperature determination program set in the control means can set a heating determination temperature and a cooling determination temperature for any mold in the mold, and further group the arbitrary molds in the mold. By setting the temperature judgment combination in the group, it is possible to control the press slide descent and press holding time start by the program operation by the heating judgment temperature, and the press part by the program operation by the cooling judgment temperature. The press slide rise and press holding time can be controlled,

Using a single temperature control device, steam is used for the heating medium and water is used for the cooling medium, so that the heating and cooling of the mold can be easily switched in a short time. A method for heating and cooling a mold for hot pressing or heating and cooling.

前記加熱用媒体である蒸気を生成する加熱用ユニットと、

前記冷却用媒体である冷却水の供給、循環を行うとともに、クーリングタワーを含む冷却用ユニットと、

前記複数の金型に配置した複数の温度検出部と、

蒸気が供給されるとともに、複数系統に分岐した媒体路に各々接続した空気圧で開閉作動する複数の切替弁を有し、前記複数の金型に蒸気を供給する加熱用媒体路と、前記クーリングタワーから冷却水が供給されるとともに、複数系統に分岐した媒体路に各々接続した空気圧で開閉作動する複数の切替弁を有し、前記複数の金型に冷却水を供給する冷却用媒体路と、エアー源、エアーフィルター、エアーレギュレータ、エアーアキュムレータータンク、調節弁、空気圧で開閉作動する切替弁、この切替弁の後段で複数系統に分岐した媒体路に各々接続した止め弁を有し、前記複数の金型にパージ用エアーを供給するエアー流路と、前記加熱用媒体路、冷却用媒体路及びエアー流路の出口側と、前記各複数の金型との間に接続した各々供給弁を含む複数系統の共通媒体路と、前記各金型からの複数系統の媒体路を流出する媒体を排出弁を経て1系統に纏めクーリングタワーに接続した排出弁に送る媒体路に接続した空気圧で開閉作動する切替弁と、前記冷却用媒体路の各切替弁の前段で分岐した媒体路に接続した空気圧で開閉作動する切替弁と、この切替弁の出口から複数系統に分岐した媒体路に接続され、吐出側を前記排出弁に接続したサイレントレジューサと、前記排出媒体路に接続した切替弁の入口手前で分岐し前記サイレントレジューサに接続した媒体路と、を有し、前記冷却水を冷却用ユニットに送る排出媒体路と、を備えて構成し、

前記金型の対になっている上プレートと下プレートに温度差が必要な時、加熱用媒体路、冷却用媒体路から当該各金型への蒸気、冷却水の供給を切り替えて温度差を調節するようにした熱プレス用又は加熱冷却用の金型の加熱冷却方法であって、

前記複数の金型に配置した各温度検出部により各金型の温度を検出する工程と、

前記温度調節装置に予め格納した温度判定用プログラムにより各温度検出部による検出温度を判定する工程と、

前記判定結果に基づき加熱用媒体路の複数の切替弁、冷却用媒体路の複数の切替弁、エアー流路の切替弁を制御して各金型への蒸気、冷却水の切り替え供給制御、パージ用エアーの供給制御、前記各金型における各金型の加熱後のプレススライド下降による成形動作制御又は各金型のプレススライド下降後の加熱による成形動作制御を行う工程と、

を含み、

前記複数の金型のパージ用エアー流路のエアーパージを行う際には前記制御手段、バルブコントローラをもって前記エアー流路に設けた切替弁、排出媒体路に設けた切替弁及び冷却用媒体路の前段に設けた切替弁を開状態に制御し、前記加熱用媒体路に設けた各切替弁及び冷却用媒体路に設けた複数系統の切替弁を閉状態に制御して行うことにより、エアー源からのエアーは、エアーフィルター、エアーレギュレータ、エアーアキュムレータータンク、調節弁、切替弁、止め弁、共通媒体路の各系統の供給弁、金型に設けた各供給マニホールドを経て前記各金型に至りこれらの各金型内をパージした後、当該各金型を通過したエアーは、前記各金型に設けた各循環マニホールド、前記排出弁を経て前記温度調節装置に戻り、前記排出媒体路の切替弁を経た後、排出弁よりクーリングタワーへ循環する冷却水に混合するように構成し、

前記制御手段に設定する温度判定用プログラムは、前記金型における任意の金型の加熱判定温度、冷却判定用温度の設定することができ、更に、前記金型における任意の金型をグループ分けしてグループでの温度判定の組み合わせを設定して、加熱判定温度によるプログラム動作にて、プレス部のプレススライドの下降やプレス保持時間のスタート制御可能とし、冷却判定温度によるプログラム動作にて、プレス部のプレススライドの上昇やプレス保持時間を制御可能とし、

一台の温度調節装置を用いて、加熱用媒体に蒸気、冷却用媒体に水を使用し、金型の加熱、冷却の切り替えを短時間で容易に行うことができるようにしたことを特徴とする熱プレス用又は加熱冷却用の金型の加熱冷却方法。 Two types of medium with different temperatures are used for the heating medium of the molds and the cooling medium is used for the cooling medium, and these are switched to the mold medium path by the temperature control device and supplied to the mold. A system that repeats the process, molding of molded products, and cooling process of the mold,

A heating unit that generates steam as the heating medium;

Supplying and circulating the cooling water as the cooling medium, and a cooling unit including a cooling tower;

A plurality of temperature detectors arranged in the plurality of molds;

A heating medium path that supplies steam to the plurality of molds and has a plurality of switching valves that are opened and closed by air pressure connected to each of the medium paths that are branched into a plurality of systems, while supplying steam, and the cooling tower A cooling medium path for supplying cooling water to the plurality of molds, and a plurality of switching valves that are opened and closed by air pressure connected to the medium paths branched into a plurality of systems, respectively, and supplied with cooling water; A source, an air filter, an air regulator, an air accumulator tank, a control valve, a switching valve that opens and closes by air pressure, a stop valve connected to each of the medium paths branched into a plurality of systems at the subsequent stage of the switching valve, An air flow path for supplying purge air to the mold, and each supply valve connected between the heating medium path, the cooling medium path and the outlet side of the air flow path, and the plurality of molds. Opening and closing operation by air pressure connected to the medium path of multiple systems, and the medium path that sends the media flowing out of the multiple systems of media paths from each mold to one system via the discharge valve and connected to the discharge valve connected to the cooling tower A switching valve that is opened and closed by air pressure connected to a medium path branched in the previous stage of each switching valve of the cooling medium path, and connected to a medium path branched into a plurality of systems from the outlet of the switching valve, A silent reducer having a discharge side connected to the discharge valve, and a medium path branched before the switching valve connected to the discharge medium path and connected to the silent reducer, and the cooling water is supplied to the cooling unit. A discharge medium path to be sent,

When a temperature difference is required between the upper plate and the lower plate of the mold pair, the supply of steam and cooling water from the heating medium path and cooling medium path to the respective molds is switched to reduce the temperature difference. A heating / cooling method of a mold for heat press or heating / cooling adapted to be adjusted,

Detecting the temperature of each mold by each temperature detector disposed in the plurality of molds;

Determining a temperature detected by each temperature detection unit using a temperature determination program stored in advance in the temperature control device;

Based on the determination result, the control unit controls the plurality of switching valves for the heating medium path, the plurality of switching valves for the cooling medium path, and the switching valve for the air flow path to control supply and purge of steam and cooling water to each mold. A step of performing air supply control, control of molding operation by lowering the press slide after heating of each mold in each mold or molding operation control by heating after lowering of the press slide of each mold, and

Including

When performing air purge of the purge air flow paths of the plurality of molds, the control means, a switching valve provided in the air flow path with a valve controller, a switching valve provided in the discharge medium path, and a cooling medium path By controlling the switching valve provided in the previous stage to the open state and controlling each switching valve provided in the heating medium path and the switching valves of the plurality of systems provided in the cooling medium path to the closed state, the air source Air from the air filter, air regulator, air accumulator tank, control valve, switching valve, stop valve, supply valve of each system of common media path, each supply manifold provided in the mold, to each mold lead after purging the inside of each of these molds, air which passes through the respective mold, the respective circulation manifold provided in each mold, returns to the temperature control device through the discharge valve, the discharge medium passage After a Kawaben, configured to mix a coolant circulating to the cooling tower from the discharge valve,

The temperature determination program set in the control means can set a heating determination temperature and a cooling determination temperature for any mold in the mold, and further group the arbitrary molds in the mold. By setting the temperature judgment combination in the group, it is possible to control the press slide descent and press holding time start by the program operation by the heating judgment temperature, and the press part by the program operation by the cooling judgment temperature. The press slide rise and press holding time can be controlled,

Using a single temperature control device, steam is used for the heating medium and water is used for the cooling medium, so that the heating and cooling of the mold can be easily switched in a short time. A method for heating and cooling a mold for hot pressing or heating and cooling.

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004354583A JP5105704B2 (en) | 2004-12-07 | 2004-12-07 | Heating / cooling system and heating / cooling method for heat press or heating / cooling mold |

| KR1020050109062A KR100848865B1 (en) | 2004-12-07 | 2005-11-15 | Heating and cooling system and heating and cooling method of mold for thermal press or injection molding |

| CNA2005101286967A CN1785644A (en) | 2004-12-07 | 2005-11-25 | Metal mould heating and cooling system and its method for heat pressing |

| TW094142737A TWI275466B (en) | 2004-12-07 | 2005-12-05 | Heating and cooling system for hot press mold and method for heating and cooling hot press mold |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004354583A JP5105704B2 (en) | 2004-12-07 | 2004-12-07 | Heating / cooling system and heating / cooling method for heat press or heating / cooling mold |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2006159643A JP2006159643A (en) | 2006-06-22 |

| JP2006159643A5 JP2006159643A5 (en) | 2008-07-17 |

| JP5105704B2 true JP5105704B2 (en) | 2012-12-26 |

Family

ID=36662169

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004354583A Expired - Fee Related JP5105704B2 (en) | 2004-12-07 | 2004-12-07 | Heating / cooling system and heating / cooling method for heat press or heating / cooling mold |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JP5105704B2 (en) |

| KR (1) | KR100848865B1 (en) |

| CN (1) | CN1785644A (en) |

| TW (1) | TWI275466B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20210031412A1 (en) * | 2018-02-12 | 2021-02-04 | Harburg-Freudenberger Maschinenbau Gmbh | Valve control method and device |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5250223B2 (en) * | 2007-08-20 | 2013-07-31 | 三菱重工プラスチックテクノロジー株式会社 | Temperature control method and temperature control device for molding die |

| CN102137752A (en) * | 2008-08-29 | 2011-07-27 | 北川精机株式会社 | Press apparatus |

| JP5368884B2 (en) * | 2009-06-05 | 2013-12-18 | 株式会社日立産機システム | Heating / cooling control method and apparatus for transfer section in precision hot press apparatus |

| KR101269651B1 (en) | 2010-11-24 | 2013-05-30 | 유도썬스(주) | Injection Molding of Heating And Cooling System |

| KR101239359B1 (en) | 2010-11-24 | 2013-03-05 | 유도썬스(주) | Duble Injection-molding of Cooling System |

| US9676124B2 (en) | 2010-12-01 | 2017-06-13 | Plasan Carbon Composites, Inc. | Method and system for forming composite articles |

| JP6050351B2 (en) * | 2011-07-28 | 2016-12-21 | プレイザン カーボン コンポジティーズ,インコーポレイテッド | System and method for molding composite products |

| KR101330525B1 (en) * | 2013-01-04 | 2013-11-18 | 주식회사 어코드시스템 | Temperature adjusting apparatus for mold and the method thereof |

| CN103388830A (en) * | 2013-07-24 | 2013-11-13 | 芜湖市伟华泡塑有限公司 | Energy recycling system and method for foam plastic production |

| CN106439339A (en) * | 2016-08-30 | 2017-02-22 | 安徽双鹤药业有限责任公司 | Mould cooling water pipeline system capable of being quickly dismounted |

| CN107599260A (en) * | 2017-10-23 | 2018-01-19 | 天津蓝科机械有限公司 | A kind of Multifunctional mould temperature controller |

| TWI734618B (en) * | 2020-09-23 | 2021-07-21 | 大陸商漢達精密電子(昆山)有限公司 | Cooling system for a mold and method thereof |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4690789A (en) * | 1985-03-13 | 1987-09-01 | Dart Industries Inc. | Refrigerant cooled plastic molding, method and apparatus |

| JPS61215021A (en) * | 1985-03-22 | 1986-09-24 | Hitachi Ltd | Manufacture of mutilayer printed circuit board and its manufacturing device |

| JPH0513543Y2 (en) * | 1987-02-18 | 1993-04-09 | ||

| JPH0393920U (en) * | 1990-01-12 | 1991-09-25 | ||

| JPH0393921U (en) * | 1990-01-17 | 1991-09-25 | ||

| KR0138451Y1 (en) * | 1993-06-30 | 1999-04-01 | 김연수 | Side frame grounding length adjusting device for tracked heavy equipment |

| JPH08216217A (en) * | 1994-12-15 | 1996-08-27 | Ricoh Co Ltd | Die for molding optical disc substrate and system thereof as well as molding method |

| JPH08164566A (en) * | 1994-12-16 | 1996-06-25 | Olympus Optical Co Ltd | Injection molding method for lens barrel part |

| JP3480863B2 (en) * | 1995-02-15 | 2003-12-22 | 三井金属鉱業株式会社 | Injection molding method |

| JP3977565B2 (en) * | 1999-05-06 | 2007-09-19 | 小野産業株式会社 | Mold for synthetic resin molding, mold temperature control device and mold temperature control method |

| JP3777887B2 (en) * | 1999-07-26 | 2006-05-24 | 松下電工株式会社 | Manufacturing method of resin molded products |

| JP4121833B2 (en) * | 2002-11-07 | 2008-07-23 | 株式会社シスコ | Mold heating and cooling system |

| JP4219657B2 (en) | 2002-11-07 | 2009-02-04 | 株式会社シスコ | Mold heating and cooling system |

| JP4324370B2 (en) * | 2002-12-17 | 2009-09-02 | 株式会社積層金型 | Structure of laminated mold and manufacturing method thereof |

-

2004

- 2004-12-07 JP JP2004354583A patent/JP5105704B2/en not_active Expired - Fee Related

-

2005

- 2005-11-15 KR KR1020050109062A patent/KR100848865B1/en not_active IP Right Cessation

- 2005-11-25 CN CNA2005101286967A patent/CN1785644A/en active Pending

- 2005-12-05 TW TW094142737A patent/TWI275466B/en not_active IP Right Cessation

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20210031412A1 (en) * | 2018-02-12 | 2021-02-04 | Harburg-Freudenberger Maschinenbau Gmbh | Valve control method and device |

| US11738480B2 (en) * | 2018-02-12 | 2023-08-29 | Harburg-Freudenberger Maschinenbau Gmbh | Valve control method and device |

Also Published As

| Publication number | Publication date |

|---|---|

| TWI275466B (en) | 2007-03-11 |

| KR20060063659A (en) | 2006-06-12 |

| KR100848865B1 (en) | 2008-07-29 |

| TW200618983A (en) | 2006-06-16 |

| CN1785644A (en) | 2006-06-14 |

| JP2006159643A (en) | 2006-06-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR100848865B1 (en) | Heating and cooling system and heating and cooling method of mold for thermal press or injection molding | |

| JP2006159643A5 (en) | ||

| JP4785479B2 (en) | Molding equipment | |

| JP2010012682A (en) | Multi-heating/cooling system of mold | |

| KR101047832B1 (en) | Temperature control device and temperature control method for electronic devices | |

| JP2007533155A5 (en) | ||

| JP2007083502A5 (en) | ||

| KR100857264B1 (en) | Thermal control device of mold | |

| JP2008105271A (en) | Mold heating/cooling system using superheated steam | |

| CN100460196C (en) | Press and its control method | |

| JP3109224U (en) | Heating and cooling system for molds for heat press | |

| JP6257467B2 (en) | Mold temperature control device and mold temperature control method | |

| TWI422483B (en) | Pressing apparatus | |

| KR101147926B1 (en) | Heating and cooling cycle isolated type temperature control apparatus for chemical reactor | |

| JP2003154500A (en) | Method for controlling temperature of hot press | |

| KR100838729B1 (en) | Temperature maintenance apparatus of plating solution | |

| JP2010036588A (en) | Device for adjusting mold temperature | |

| JP3144868U (en) | Multi heating and cooling system for molds | |

| JP6140781B2 (en) | Molding apparatus using steam as heating medium and drain removal method for flow path of heated part | |

| JP5546176B2 (en) | Hot press apparatus and temperature control method for hot press apparatus | |

| JP2001009839A (en) | Plastic molding die temperature control device and molding die temperature control method | |

| JP6845201B2 (en) | Hot press device and temperature control method for hot press device | |

| JP6889748B2 (en) | Cooling control method of press equipment and press equipment | |

| JP3128598U (en) | Mold heating / cooling system using superheated steam | |

| KR100837513B1 (en) | Apparatus and method for controlling temperature of batch reactor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20071205 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080530 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100621 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100721 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100921 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110419 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110620 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110712 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110912 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120515 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120717 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120817 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20121002 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|