JP5037253B2 - Developing device, image forming apparatus - Google Patents

Developing device, image forming apparatus Download PDFInfo

- Publication number

- JP5037253B2 JP5037253B2 JP2007196352A JP2007196352A JP5037253B2 JP 5037253 B2 JP5037253 B2 JP 5037253B2 JP 2007196352 A JP2007196352 A JP 2007196352A JP 2007196352 A JP2007196352 A JP 2007196352A JP 5037253 B2 JP5037253 B2 JP 5037253B2

- Authority

- JP

- Japan

- Prior art keywords

- developer

- supply

- conveyance path

- developing device

- conveyance

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Description

本発明は、複写機、ファクシミリ、プリンタ等に用いられる現像装置並びにこれを用いた画像形成装置に関するものである。 The present invention relates to a developing device used for a copying machine, a facsimile, a printer, and the like, and an image forming apparatus using the developing device.

従来から、トナーと磁性キャリアとを含む二成分の現像剤を用いた現像装置を備える画像形成装置が広く用いられている。この種の画像形成装置として、現像に伴ってトナーを消費する現像装置内の現像剤に対して、必要に応じてトナー収容器からトナーを補給することで、現像剤のトナー濃度を所定範囲内に維持するものがある。かかる構成では、現像剤内のキャリアは殆ど消費されず繰り返し使用されるため、画像を出力するにしたがってキャリアの表層のコート層が磨耗したり逆にコート層にトナー樹脂や添加剤が付着したりする。これにより、キャリアのトナーを帯電させる能力が徐々に低下して、キャリアが劣化した状態となる。キャリアの劣化が進行するとトナーの帯電量が低下し、地肌部汚れやトナー飛散などを引き起こすため、この種の画像形成装置では定期的にサービスマンがユーザーを訪問してキャリアの交換を行っていた。このために、メンテナンス費用がかかり画像形成の単価が高くなってしまっていた。 Conventionally, an image forming apparatus including a developing device using a two-component developer including toner and a magnetic carrier has been widely used. As an image forming apparatus of this type, the toner density of the developer is kept within a predetermined range by supplying toner from the toner container as necessary to the developer in the developing apparatus that consumes toner with development. There is something to keep in. In such a configuration, the carrier in the developer is hardly consumed and is repeatedly used. As the image is output, the coat layer on the surface of the carrier wears out, and conversely, toner resin and additives adhere to the coat layer. To do. As a result, the ability of the carrier to charge the toner gradually decreases, and the carrier is in a deteriorated state. As the deterioration of the carrier progresses, the charge amount of the toner decreases, causing background stains and toner scattering. Therefore, in this type of image forming apparatus, a service person visits the user regularly to replace the carrier. . For this reason, maintenance costs are incurred, and the unit price for image formation is high.

特許文献1には、キャリアとトナーとを混合したプレミックス現像剤を現像装置内の現像剤に補給してトナー濃度の回復を図りながら、増加量分の現像剤を現像装置から排出させる現像装置が記載されている。かかる構成では、現像剤の排出によって古くなったキャリアを少しずつ現像装置内から排出しつつ、プレミックス現像剤中の新しいキャリアを現像装置内の現像剤に補給する。そして、このような排出と補給とによって現像剤中のキャリアを少しずつ新たなものに交換していくことで、キャリアの交換作業を省くことができる。

また、特許文献1の現像装置では、現像剤を現像ローラに供給しながら現像ローラの軸方向に現像剤を搬送する供給搬送路の所定の高さに現像剤を装置外に排出する現像剤排出手段としての現像剤排出口を備えている。この現像装置では、プレミックス現像剤が供給され、現像装置内の現像剤量が増加すると、供給搬送路内の現像剤の嵩が高くなる。このとき、現像剤排出口を設けた位置で、現像剤排出口の高さまで到達した現像剤は現像剤排出口から現像装置外部へ排出される。

Further, in the developing device disclosed in

しかしながら、特許文献1の現像装置では、供給搬送路内で現像ローラに現像剤を供給する現像剤供給領域の途中に現像剤排出口を設けている。

供給搬送路内を搬送される現像剤は移動する勢いや、現像剤に搬送力を与える搬送部材が搬送スクリュの場合はその回転する力などによって飛び跳ねて、現像剤排出口から排出されることがある。現像剤が飛び跳ねて排出される場合、供給搬送路内を搬送される現像剤が適正な量の状態や、適正な量を下回る状態であっても、飛び跳ねた現像剤が排出されるおそれがある。これは、現像装置内の現像剤量が増加していないにもかかわらず現像剤が排出される状態である。そして、現像剤が適正な量以下の状態であるにもかかわらず現像剤排出口から現像剤が排出されると、現像装置内の現像剤量が必要量を下回り、潜像担持体への現像剤の供給が不安定になるおそれがあった。潜像担持体への現像剤の供給が不安定になると、画像抜けなどの異常画像が発生するおそれがある。

このような問題は、二成分現像剤を用いた現像装置に限るものではなく、現像剤補給手段によって現像剤の補給が成され、現像装置内の現像剤の増加量分を現像剤排出手段によって排出する構成を備えた現像装置であれば一成分現像剤を用いる現像装置であっても生じ得る問題である。

However, in the developing device of

The developer transported in the supply transport path jumps by the momentum to move, and when the transport member that imparts transport force to the developer is a transport screw, it can be ejected and discharged from the developer discharge port. is there. When the developer jumps and is discharged, even if the developer transported in the supply transport path is in an appropriate amount state or less than the appropriate amount, the jumped developer may be discharged. . This is a state in which the developer is discharged even though the amount of developer in the developing device has not increased. If the developer is discharged from the developer discharge port even though the developer is in an appropriate amount or less, the amount of developer in the developing device falls below the required amount, and the development on the latent image carrier is performed. The supply of the agent might become unstable. If the supply of the developer to the latent image carrier becomes unstable, abnormal images such as missing images may occur.

Such a problem is not limited to the developing device using the two-component developer, but the developer is replenished by the developer replenishing means, and the amount of the developer in the developing device is increased by the developer discharging means. This is a problem that may occur even in a developing device that uses a one-component developer as long as the developing device has a configuration for discharging.

本発明は、以上の問題に鑑みなされたものであり、その目的とするところは、飛び跳ねた現像剤が排出されることを防止し、現像装置内の現像剤量が増加していないにも関わらず現像剤が排出されることを防止することによって、潜像担持体に安定した現像剤の供給を行うことができる現像装置、並びにこの現像装置を備えた画像形成装置を提供することである。 The present invention has been made in view of the above problems, and the object of the present invention is to prevent the splashed developer from being discharged and to prevent the developer amount in the developing device from increasing. Accordingly, it is an object of the present invention to provide a developing device capable of stably supplying the developer to the latent image carrier by preventing the developer from being discharged, and an image forming apparatus including the developing device.

上記目的を達成するために、請求項1の発明は、現像剤を表面上に担持して回転し、潜像担持体と対向する箇所で該潜像担持体の表面の潜像にトナーを供給して現像する現像剤担持体と、装置内に現像剤を補給する現像剤補給手段と、該現像剤担持体に現像剤を供給しながら該現像剤担持体の軸線方向に沿って現像剤を搬送する供給搬送部材を備えた供給搬送路と、該供給搬送路の搬送方向下流側に到達した現像剤を該供給搬送路の搬送方向上流側に搬送する循環搬送部材を備えた循環搬送路とを有する現像装置において、該供給搬送路の搬送方向下流側の現像剤の嵩が所定の高さを越えた場合に該供給搬送路の搬送方向下流側の現像剤の一部を排出する現像剤排出手段を有し、該供給搬送路の現像剤搬送方向下流部に、該供給搬送部材とは逆方向の搬送力を発生させる逆搬送部材を備え、該供給搬送部材と該逆搬送部材との境界部に、該供給搬送部材の搬送方向に垂直で、且つ、その法線方向が該供給搬送部材の搬送方向と反対方向となり、現像剤の搬送方向への移動を妨げる壁面を備えることを特徴とするものである。

また、請求項2の発明は、請求項1の現像装置において、上記現像剤排出手段は、上記供給搬送路の搬送方向下流側で仕切り壁を挟んで該供給搬送路と隣り合うように配置され、該供給搬送路から排出される現像剤を搬送する排出搬送路と、該排該仕切り壁の所定の高さに該排出搬送路と該供給搬送路とを連通するように設けられた開口である現像剤排出口とを有し、該現像剤排出口の高さまで到達した現像剤を該現像剤排出口から該排出搬送路へ排出することを特徴とするものである。

また、請求項3の発明は、請求項2の現像装置において、上記供給搬送路と上記循環搬送路とは供給循環仕切り壁を挟んで隣り合うように配置され、該供給搬送路の搬送方向下流側の該供給循環仕切り壁に供給搬送路と該循環搬送路とを連通する開口部として供給循環連通口を設け、該供給搬送路の搬送方向下流側に到達した現像剤が、該供給循環連通口を通って、該循環搬送路へ移動可能に構成されていることを特徴とするものである。

また、請求項4の発明は、請求項3の現像装置において、上記現像剤排出口は上記供給搬送路の現像剤搬送方向について、上記供給循環連通口と同じ位置にあることを特徴とするものである。

また、請求項5の発明は、請求項3または4の現像装置において、上記現像剤排出口は上記供給循環連通口よりも上方に配置されていることを特徴とするものである。

また、請求項6の発明は、請求項1、2、3、4または5の現像装置において、上記循環搬送部材は、上記供給搬送路の搬送方向下流端に到達した現像剤を該供給搬送路の搬送方向上流端に搬送し、上記現像剤排出手段は、該供給搬送路の搬送方向下流端近傍の現像剤の嵩が所定の高さを越えた場合に該供給搬送路の搬送方向下流端近傍の現像剤の一部を排出することを特徴とするものである。

また、請求項7の発明は、請求項1、2、3、4、5または6の現像装置において、上記供給搬送部材及び上記逆搬送部材は、回転軸と該回転軸に螺旋状に設けられた羽部とを備え、回転することにより該回転軸方向に現像剤を搬送するスクリュ状の供給スクリュ及び逆スクリュであり、該供給スクリュよりも該逆スクリュのスクリュピッチを短くしたことを特徴とするものである。

また、請求項8の発明は、請求項1、2、3、4、5、6または7の現像装置において、上記供給搬送部材及び上記逆搬送部材は、回転軸と該回転軸に螺旋状に設けられた羽部とを備え、回転することにより該回転軸方向に現像剤を搬送するスクリュ状の供給スクリュ及び逆スクリュであり、該供給スクリュよりも該逆スクリュの羽部の外径を小さくしたことを特徴とするものである。

また、請求項9の発明は、請求項1、2、3、4、5、6、7または8の現像装置において、上記現像剤排出手段は通過した現像剤が排出される現像剤排出口を供給搬送路に備え、上記壁面の上端は該現像剤排出口の下端よりも上方であることを特徴とするものである。

また、請求項10の発明は、請求項1、2、3、4、5、6、7、8または9の現像装置において、上記現像剤排出手段は通過した現像剤が排出される現像剤排出口を供給搬送路に備え、上記現像剤排出口の上記供給搬送路の搬送方向下流端である排出口下流端縁部の該供給搬送路の搬送方向についての位置と、上記壁面の該供給搬送路の搬送方向についての位置とが一致することを特徴とするものである。

また、請求項11の発明は、請求項1、2、3、4、5、6、7、8、9または10の現像装置において、上記現像剤排出手段は通過した現像剤が排出される現像剤排出口を供給搬送路に備え、上記供給搬送部材は、回転軸と該回転軸に螺旋状に設けられた羽部とを備え、回転することにより該回転軸方向に現像剤を搬送するスクリュ状の供給スクリュであり、該現像剤排出口の下端は、該供給スクリュの羽部の上端よりも上方であることを特徴とするものである。

また、請求項12の発明は、請求項1、2、3、4、5、6、7、8、9、10または11の現像装置において、現像剤として磁性キャリアとトナーとからなる二成分現像剤を備え、上記潜像担持体と対向する箇所を通過後の上記現像剤担持体上から回収された現像剤を該現像剤担持体の軸線方向に沿って、且つ、上記供給搬送部材と同方向に搬送する回収搬送部材を備えた回収搬送路を有し、上記循環搬送路は、現像に用いられずに該供給搬送路の搬送方向の最下流側まで搬送された現像剤と、該回収搬送路の搬送方向の最下流側まで搬送された現像剤との供給を受け、該現像剤担持体の軸線方向に沿って、且つ、現像剤を攪拌しながら該供給搬送部材とは逆方向に搬送する上記循環搬送部材としての攪拌搬送部材を備え、攪拌後の現像剤を該供給搬送路に供給する攪拌搬送路であり、上記現像剤補給手段は該攪拌搬送路に現像剤を補給することを特徴とするものである。

また、請求項13の発明は、少なくとも潜像担持体と、該潜像担持体表面を帯電させるための帯電手段と、該潜像担持体上に静電潜像を形成するための潜像形成手段と、該静電潜像を現像してトナー像化するための現像手段とを有する画像形成装置において、該現像手段として、請求項1、2、3、4、5、6、7、8、9、10、11または12に記載の現像装置を用いることを特徴とするものである。

また、請求項14の発明は、現像剤を表面上に担持して回転し、潜像担持体と対向する箇所で該潜像担持体の表面の潜像にトナーを供給して現像する現像剤担持体と、装置内に現像剤を補給する現像剤補給手段と、該現像剤担持体に現像剤を供給しながら該現像剤担持体の軸線方向に沿って現像剤を搬送する供給搬送部材を備えた供給搬送路と、該供給搬送路の搬送方向下流側に到達した現像剤を該供給搬送路の搬送方向上流側に搬送する循環搬送部材を備えた循環搬送路とを有する現像装置において、該供給搬送路と該循環搬送路とを含む現像剤搬送路中の現像剤の一部を該現像剤搬送路の外部に排出する現像剤排出口と、該現像剤搬送路中を通過する現像剤の量を規制する現像剤搬送量規制手段とを備え、該現像剤搬送量規制手段によって規制され、滞留した現像剤の量が所定量を越えた場合に該現像剤排出口から現像剤が排出されるように、該現像剤排出口を配置することを特徴とするものである。

また、請求項15の発明は、請求項14の現像装置において、上記循環搬送部材は、上記供給搬送路の搬送方向下流端に到達した現像剤を該供給搬送路の搬送方向上流端に搬送することを特徴とするものである。

In order to achieve the above object, the invention according to

Further, the invention of

According to a third aspect of the present invention, in the developing device of the second aspect , the supply conveyance path and the circulation conveyance path are disposed adjacent to each other with a supply circulation partition wall interposed therebetween, and the supply conveyance path is downstream in the conveyance direction. The supply circulation partition wall is provided with a supply circulation communication port as an opening that communicates the supply conveyance path and the circulation conveyance path, and the developer that has reached the downstream side in the conveyance direction of the supply conveyance path is It is configured to be movable to the circulation conveyance path through the mouth.

According to a fourth aspect of the present invention, in the developing device of the third aspect , the developer discharge port is located at the same position as the supply circulation communication port in the developer transport direction of the supply transport path. It is.

According to a fifth aspect of the present invention, in the developing device according to the third or fourth aspect , the developer discharge port is disposed above the supply circulation communication port.

The invention of

Further, an invention according to

According to an eighth aspect of the present invention, in the developing device according to the first, second, third , fourth, fifth, sixth, or seventh aspect , the supply conveyance member and the reverse conveyance member are spirally formed on the rotation shaft and the rotation shaft. A screw-like supply screw and a reverse screw that convey the developer in the direction of the rotation axis by rotating, and the outer diameter of the wing portion of the reverse screw is smaller than that of the supply screw. It is characterized by that.

According to a ninth aspect of the present invention, in the developing device of the first, second, third , fourth, fifth , sixth, seventh or eighth aspect , the developer discharging means has a developer discharge port through which the developer passed therethrough is discharged. provided in the supply path, the upper end of the wall is characterized in that the lower end of the developer discharge port is upward.

The tenth aspect of the present invention is the developing device according to the first, second, third , fourth, fifth , sixth, seventh, eighth or ninth aspect , wherein the developer discharging means discharges the developer discharged therethrough. an outlet to the supply conveyance path, the position of the conveyance direction of the supply conveyance path of the outlet downstream end edge a downstream end in the conveyance direction of the supply conveyance path of the developer discharge port, on Kikabe surface of the The position of the supply conveyance path in the conveyance direction is the same.

According to an eleventh aspect of the present invention, in the developing device according to the first, second, third , fourth, fifth , sixth, seventh , eighth, ninth or tenth development, the developer discharging means discharges the developer that has passed through A screw discharge port is provided in the supply conveyance path, and the supply conveyance member includes a rotation shaft and a wing portion spirally provided on the rotation shaft, and rotates to screw the developer in the rotation axis direction. The lower end of the developer discharge port is above the upper end of the wing portion of the supply screw.

The invention of

The invention of claim 13 provides at least a latent image carrier, charging means for charging the surface of the latent image carrier, and formation of a latent image for forming an electrostatic latent image on the latent image carrier. And a developing unit for developing the electrostatic latent image into a toner image, wherein the developing unit is defined as

According to a fourteenth aspect of the present invention, there is provided a developer that rotates by supporting a developer on the surface, supplying toner to the latent image on the surface of the latent image carrier, and developing the developer at a location facing the latent image carrier. A carrier, a developer replenishing means for replenishing the developer in the apparatus, and a supply conveying member that conveys the developer along the axial direction of the developer carrier while supplying the developer to the developer carrier. A developing device having a supply conveyance path and a circulation conveyance path provided with a circulation conveyance member that conveys the developer that has reached the downstream side in the conveyance direction of the supply conveyance path to the upstream side in the conveyance direction of the supply conveyance path; A developer discharge port for discharging a part of the developer in the developer conveyance path including the supply conveyance path and the circulation conveyance path to the outside of the developer conveyance path , and development passing through the developer conveyance path Developer transport amount regulating means for regulating the amount of developer, and the developer transport amount regulating means. Is restricted, the amount of retained the developer is characterized in that the developer from the developer discharge port to be discharged, arranging the developer discharge port when it exceeds a predetermined amount.

The invention of

上記請求項1乃至13の現像装置においては、現像剤排出手段が、供給搬送路の搬送方向下流側の現像剤の嵩が所定の高さを越えた場合にその一部を排出するものであるので、供給搬送路の搬送方向下流側に、所定の高さを越えない程度の現像剤が存在する状態で現像装置内の現像量が安定した状態となる。

現像装置内に現像剤補給手段によって現像剤が供給されて現像装置内の現像剤量が増加すると、供給搬送路から循環搬送路に受け渡される現像剤量よりも供給搬送路を搬送されその搬送方向下流側に到達する現像剤量の方が多くなり、供給搬送路の搬送方向下流側に滞留する現像剤の量が増加し嵩が増す。従って、滞留する現像剤が所定の高さを越した場合に、その嵩が所定の高さとなるように滞留する現像剤の一部を現像剤排出手段が排出される。ここで、滞留する現像剤は現像剤が常に移動している箇所の現像剤よりも飛び跳ねにくいので、滞留した箇所の現像剤の嵩は現像装置内の現像剤量の増減に合わせて適正に変化する。よって、現像装置内の現像剤量の必要量を確保することができる。

また、上記請求項14及び15の現像装置においては、現像剤排出口が現像剤搬送量規制手段で規制された現像剤が、所定量を超えた場合にその一部を排出するものであるので、現像剤搬送量規制手段の近傍では所定量を超えない程度の現像剤が存在する状態で現像装置内の現像剤量が安定した状態となる。

現像装置内に現像剤補給手段によって現像剤が供給されて現像装置内の現像剤量が増加すると、現像剤搬送量規制手段によって規制される位置を通過する現像剤量よりもこの規制される位置に到達する現像剤量の方が多くなり、現像剤搬送量規制手段で滞留する現像剤の量が増加する。従って、滞留する現像剤が所定量を超えた場合に、その現像剤量が所定量となるように滞留する現像剤の一部を現像剤排出口から排出する。ここで、滞留する現像剤は現像剤が常に移動している箇所の現像剤よりも飛び跳ねにくいので、滞留した箇所の現像剤量は現像装置内の現像剤量の増減に合わせて適正に変化する。よって、現像装置内の現像剤量の必要量を確保することができる。

Those in the developing apparatus of the

When the developer is supplied into the developing device by the developer replenishing means and the amount of the developer in the developing device increases, the developer is transported through the supply transport path more than the developer amount delivered from the supply transport path to the circulation transport path. is higher in the amount of developer reaches a downstream side, the amount is increased the bulk of the developer staying in the conveying direction downstream side of the supply conveyance path is increased. Therefore, when the staying developer exceeds a predetermined height, the developer discharge means discharges a part of the staying developer so that the bulk becomes a predetermined height. Here, the stagnant developer is less likely to jump than the developer where the developer is constantly moving, so the bulk of the developer at the stagnant location changes appropriately according to the increase or decrease in the amount of developer in the developing device. To do. Therefore, a necessary amount of developer in the developing device can be ensured.

In the developing device according to the fourteenth and fifteenth aspects, a part of the developer whose developer discharge port is regulated by the developer transport amount regulating means is discharged when it exceeds a predetermined amount . Thus, in the vicinity of the developer transport amount regulating means , the developer amount in the developing device becomes stable in a state where the developer does not exceed the predetermined amount.

When the developer is supplied into the developing device by the developer replenishing means and the amount of the developer in the developing device increases, this regulated position is more than the amount of developer passing through the position regulated by the developer transport amount regulating means. The amount of the developer that reaches is increased, and the amount of the developer staying in the developer transport amount regulating means is increased. Therefore, when the staying developer exceeds a predetermined amount, a part of the staying developer is discharged from the developer discharge port so that the developer amount becomes a predetermined amount. Here, the staying developer is less likely to jump than the developer where the developer is constantly moving, so that the amount of developer at the staying location appropriately changes according to the increase or decrease in the amount of developer in the developing device. . Therefore, a necessary amount of developer in the developing device can be ensured.

請求項1乃至13の発明によれば、現像剤が飛び跳ねにくい現像剤が滞留する箇所である供給搬送路の搬送方向下流側の現像剤を排出することにより、飛び跳ねた現像剤が排出されることを防止し、現像装置内の現像剤量が増加していないにも関わらず現像剤が排出されることを防止することことができる。このため、現像装置内の現像剤量として必要量を確保することができ、現像剤担持体から潜像担持体に安定した現像剤の供給を行うことができるという優れた効果がある。

また、請求項14及び15の発明によれば、現像剤搬送量規制手段によって規制されて滞留し、飛び跳ねにくくなった現像剤を排出することにより、飛び跳ねた現像剤が排出されることを防止し、現像装置内の現像剤量が増加していないにも関わらず現像剤が排出されることを防止することことができる。このため、現像装置内の現像剤量として必要量を確保することができ、現像剤担持体から潜像担持体に安定した現像剤の供給を行うことができるという優れた効果がある。

According to the first to thirteenth aspects of the present invention, the developer that has jumped off is discharged by discharging the developer on the downstream side in the transport direction of the supply transport path, where the developer is unlikely to jump. It is possible to prevent the developer from being discharged even though the amount of the developer in the developing device has not increased. For this reason, a necessary amount can be ensured as the amount of developer in the developing device, and there is an excellent effect that the developer can be stably supplied from the developer carrier to the latent image carrier.

Further, according to the inventions of

以下、本発明を適用した画像形成装置として、複数の感光体が並行配設されたタンデム型のカラーレーザー複写機(以下、単に「複写機」という)の一実施形態について説明する。

図1は、本実施形態に係る複写機の概略構成図である。この複写機はプリンタ部100、これを載せる給紙装置200、プリンタ部100の上に固定されたスキャナ300などを備えている。また、このスキャナ300の上に固定された原稿自動搬送装置400なども備えている。

Hereinafter, as an image forming apparatus to which the present invention is applied, an embodiment of a tandem type color laser copying machine (hereinafter simply referred to as “copying machine”) in which a plurality of photoconductors are arranged in parallel will be described.

FIG. 1 is a schematic configuration diagram of a copying machine according to the present embodiment. The copier includes a

プリンタ部100は、イエロー(Y)、マゼンダ(M)、シアン(C)、黒(K)の各色の画像を形成するための4組のプロセスカートリッジ18Y,M,C,Kからなる画像形成ユニット20を備えている。各符号の数字の後に付されたY,M,C,Kは、イエロー、シアン、マゼンダ、ブラック用の部材であることを示している(以下同様)。プロセスカートリッジ18Y,M,C,Kの他には、光書込ユニット21、中間転写ユニット17、二次転写装置22、レジストローラ対49、ベルト定着方式の定着装置25などが配設されている。

The

光書込ユニット21は、図示しない光源、ポリゴンミラー、f−θレンズ、反射ミラーなどを有し、画像データに基づいて後述の感光体の表面にレーザ光を照射する。

The

プロセスカートリッジ18Y,M,C,Kは、ドラム状の感光体1、帯電器、現像装置4、ドラムクリーニング装置、除電器などを有している。

The process cartridges 18Y, 18M, 18C, and 18K include a drum-shaped

以下、イエロー用のプロセスカートリッジ18について説明する。

帯電手段たる帯電器によって、感光体1Yの表面は一様帯電される。帯電処理が施された感光体1Yの表面には、光書込ユニット21によって変調及び偏向されたレーザ光が照射される。すると、照射部(露光部)の電位が減衰する。この減衰により、感光体1Y表面にY用の静電潜像が形成される。形成されたY用の静電潜像は現像手段たる現像装置4Yによって現像されてYトナー像となる。

Y用の感光体1Y上に形成されたYトナー像は、後述の中間転写ベルト110に一次転写される。一次転写後の感光体1Yの表面は、ドラムクリーニング装置によって転写残トナーがクリーニングされる。

Y用のプロセスカートリッジ18Yにおいて、ドラムクリーニング装置によってクリーニングされた感光体1Yは、除電器によって除電される。そして、帯電器によって一様帯電せしめられて、初期状態に戻る。以上のような一連のプロセスは、他のプロセスカートリッジ18M,C,Kについても同様である。

Hereinafter, the yellow process cartridge 18 will be described.

The surface of the photoreceptor 1Y is uniformly charged by a charger as charging means. The surface of the

The Y toner image formed on the Y photoconductor 1Y is primarily transferred to an intermediate transfer belt 110 described later. The surface of the photoreceptor 1Y after the primary transfer is cleaned of the transfer residual toner by a drum cleaning device.

In the Y process cartridge 18Y, the photoconductor 1Y cleaned by the drum cleaning device is discharged by the charge eliminator. Then, it is uniformly charged by the charger and returns to the initial state. The series of processes as described above is the same for the other process cartridges 18M, 18C, and 18K.

次に、中間転写ユニットについて説明する。

中間転写ユニット17は、中間転写ベルト110やベルトクリーニング装置90などを有している。また、張架ローラ14、駆動ローラ15、二次転写バックアップローラ16、4つの一次転写バイアスローラ62Y,M,C,Kなども有している。

中間転写ベルト110は、張架ローラ14を含む複数のローラによってテンション張架されている。そして、図示しないベルト駆動モータによって駆動される駆動ローラ15の回転によって図中時計回りに無端移動せしめられる。

4つの一次転写バイアスローラ62Y,M,C,Kは、それぞれ中間転写ベルト110の内周面側に接触するように配設され、図示しない電源から一次転写バイアスの印加を受ける。また、中間転写ベルト110をその内周面側から感光体1Y,M,C,Kに向けて押圧してそれぞれ一次転写ニップを形成する。各一次転写ニップには、一次転写バイアスの影響により、感光体と一次転写バイアスローラとの間に一次転写電界が形成される。

Y用の感光体1Y上に形成された上述のYトナー像は、この一次転写電界やニップ圧の影響によって中間転写ベルト110上に一次転写される。このYトナー像の上には、M,C,K用の感光体1M,C,K上に形成されたM,C,Kトナー像が順次重ね合わせて一次転写される。この重ね合わせの一次転写により、中間転写ベルト110上には多重トナー像たる4色重ね合わせトナー像(以下、4色トナー像という)が形成される。

中間転写ベルト110上に重ね合わせ転写された4色トナー像は、後述の二次転写ニップで図示しない記録体たる転写紙に二次転写される。二次転写ニップ通過後の中間転写ベルト110の表面に残留する転写残トナーは、図中左側の駆動ローラ15との間にベルトを挟み込むベルトクリーニング装置90によってクリーニングされる。

Next, the intermediate transfer unit will be described.

The intermediate transfer unit 17 includes an intermediate transfer belt 110, a belt cleaning device 90, and the like. Further, it also includes a tension roller 14, a driving

The intermediate transfer belt 110 is tensioned by a plurality of rollers including the tension roller 14. Then, it is endlessly moved clockwise in the drawing by the rotation of the driving

The four primary transfer bias rollers 62Y, 62M, 62C, and 62K are disposed so as to be in contact with the inner peripheral surface side of the intermediate transfer belt 110, respectively, and receive primary transfer bias from a power source (not shown). Further, the intermediate transfer belt 110 is pressed toward the photoreceptors 1Y, 1M, 1C, and 1K from the inner peripheral surface side to form primary transfer nips. In each primary transfer nip, a primary transfer electric field is formed between the photosensitive member and the primary transfer bias roller due to the influence of the primary transfer bias.

The above-described Y toner image formed on the Y photoconductor 1Y is primarily transferred onto the intermediate transfer belt 110 due to the influence of the primary transfer electric field and nip pressure. On the Y toner image, the M, C, K toner images formed on the M, C, K photoconductors 1M, C, K are sequentially superposed and primarily transferred. By this primary transfer of superposition, a four-color superposed toner image (hereinafter referred to as a four-color toner image) that is a multiple toner image is formed on the intermediate transfer belt 110.

The four-color toner image superimposed and transferred onto the intermediate transfer belt 110 is secondarily transferred onto a transfer sheet (not shown) as a recording medium at a secondary transfer nip described later. Transfer residual toner remaining on the surface of the intermediate transfer belt 110 after passing through the secondary transfer nip is cleaned by a belt cleaning device 90 that sandwiches the belt with the driving

次に、二次転写装置22について説明する。

中間転写ユニット17の図中下方には、2本の張架ローラ23によって紙搬送ベルト24を張架している二次転写装置22が配設されている。紙搬送ベルト24は、少なくとも何れか一方の張架ローラ23の回転駆動に伴って、図中反時計回りに無端移動せしめられる。2本の張架ローラ23のうち、図中右側に配設された一方のローラは、中間転写ユニット17の二次転写バックアップローラ16との間に、中間転写ベルト110及び紙搬送ベルト24を挟み込んでいる。この挟み込みにより、中間転写ユニット17の中間転写ベルト110と、二次転写装置22の紙搬送ベルト24とが接触する二次転写ニップが形成されている。そして、この一方の張架ローラ23には、トナーと逆極性の二次転写バイアスが図示しない電源によって印加される。この二次転写バイアスの印加により、二次転写ニップには中間転写ユニット17の中間転写ベルト110上の4色トナー像をベルト側からこの一方の張架ローラ23側に向けて静電移動させる二次転写電界が形成される。後述のレジストローラ対49によって中間転写ベルト110上の4色トナー像に同期するように二次転写ニップに送り込まれた転写紙には、この二次転写電界やニップ圧の影響を受けた4色トナー像が二次転写せしめられる。なお、このように一方の張架ローラ23に二次転写バイアスを印加する二次転写方式に代えて、転写紙を非接触でチャージさせるチャージャを設けてもよい。

Next, the secondary transfer device 22 will be described.

Below the intermediate transfer unit 17 in the figure, a secondary transfer device 22 is disposed in which a paper conveying belt 24 is stretched by two stretching

複写機本体の下部に設けられた給紙装置200には、内部に複数の転写紙を紙束の状態で複数枚重ねて収容可能な給紙カセット44が、鉛直方向に複数重なるように配設されている。それぞれの給紙カセット44は、紙束の一番上の転写紙に給紙ローラ42を押し当てている。そして、給紙ローラ42を回転させることにより、一番上の転写紙を給紙路46に向けて送り出される。

In the

給紙カセット44から送り出された転写紙を受け入れる給紙路46は、複数の搬送ローラ対47と、その路内の末端付近に設けられたレジストローラ対49とを有している。そして、転写紙をレジストローラ対49に向けて搬送する。レジストローラ対49に向けて搬送された転写紙は、レジストローラ対49のローラ間に挟まれる。一方、中間転写ユニット17において、中間転写ベルト110上に形成された4色トナー像は、ベルトの無端移動に伴って上記二次転写ニップに進入する。レジストローラ対49は、ローラ間に挟み込んだ転写紙を二次転写ニップにて4色トナー像に密着させ得るタイミングで送り出す。これにより、二次転写ニップでは、中間転写ベルト110上の4色トナー像が転写紙に密着する。そして、転写紙上に二次転写されて、白色の転写紙上でフルカラー画像となる。このようにしてフルカラー画像が形成された転写紙は、紙搬送ベルト24の無端移動に伴って二次転写ニップを出た後、紙搬送ベルト24上から定着装置25に送られる。

The

定着装置25は、定着ベルト26を2本のローラによって張架しながら無端移動せしめるベルトユニットと、このベルトユニットの一方のローラに向けて押圧される加圧ローラ27とを備えている。これら定着ベルト26と加圧ローラ27とは互いに当接して定着ニップを形成しており、紙搬送ベルト24から受け取った転写紙をここに挟み込む。ベルトユニットにおいける2本のローラのうち、加圧ローラ27から押圧される方のローラは、内部に図示しない熱源を有しており、これの発熱によって定着ベルト26を加圧する。加圧された定着ベルト26は、定着ニップに挟み込まれた転写紙を加熱する。この加熱やニップ圧の影響により、フルカラー画像が転写紙に定着せしめられる。

The fixing

定着装置25内で定着処理が施された転写紙は、プリンタ筐体の図中左側板の外側に設けたスタック部57上にスタックされるか、もう一方の面にもトナー像を形成するために上述の二次転写ニップに戻されるかする。

The transfer paper subjected to the fixing process in the fixing

図示しない原稿のコピーがとられる際には、例えばシート原稿の束が原稿自動搬送装置400の原稿台30上セットされる。但し、その原稿が本状に閉じられている片綴じ原稿である場合には、コンタクトガラス32上にセットされる。このセットに先立ち、複写機本体に対して原稿自動搬送装置400が開かれ、スキャナ300のコンタクトガラス32が露出される。この後、閉じられた原稿自動搬送装置400によって片綴じ原稿が押さえられる。

When a document (not shown) is copied, for example, a bundle of sheet documents is set on the document table 30 of the

このようにして原稿がセットされた後、図示しないコピースタートスイッチが押下されると、スキャナ300による原稿読取動作がスタートする。但し、原稿自動搬送装置400にシート原稿がセットされた場合には、この原稿読取動作に先立って、原稿自動搬送装置400がシート原稿をコンタクトガラス32まで自動移動させる。原稿読取動作では、まず、第1走行体33と第2走行体34とがともに走行を開始し、第1走行体33に設けられた光源から光が発射される。そして、原稿面からの反射光が第2走行体34内に設けられたミラーによって反射せしめられ、結像レンズ35を通過した後、読取センサ36に入射される。読取センサ36は、入射光に基づいて画像情報を構築する。

When a copy start switch (not shown) is pressed after the document is set in this way, the document reading operation by the

このような原稿読取動作と並行して、各プロセスカートリッジ18Y,M,C,K内の各機器や、中間転写ユニット17、二次転写装置22、定着装置25がそれぞれ駆動を開始する。そして、読取センサ36によって構築された画像情報に基づいて、光書込ユニット21が駆動制御されて、各感光体40Y,M,C,K上に、Y,M,C,Kトナー像が形成される。これらトナー像は、中間転写ベルト110上に重ね合わせ転写された4色トナー像となる。

In parallel with such a document reading operation, each device in each of the process cartridges 18Y, 18M, 18C, 18K, the intermediate transfer unit 17, the secondary transfer device 22, and the fixing

また、原稿読取動作の開始とほぼ同時に、給紙装置200内では給紙動作が開始される。この給紙動作では、給紙ローラ42の1つが選択回転せしめられ、ペーパーバンク43内に多段に収容される給紙カセット44の1つから転写紙が送り出される。送り出された転写紙は、分離ローラ45で1枚ずつ分離されて反転給紙路46に進入した後、搬送ローラ対47によって二次転写ニップに向けて搬送される。このような給紙カセット44からの給紙に代えて、手差しトレイ51からの給紙が行われる場合もある。この場合、手差し給紙ローラ50が選択回転せしめられて手差しトレイ51上の転写紙を送り出した後、分離ローラ52が転写紙を1枚ずつ分離してプリンタ部100の手差し給紙路53に給紙する。

Further, almost simultaneously with the start of the document reading operation, the paper feeding operation is started in the

本複写機は、2色以上のトナーからなる他色画像を形成する場合には、中間転写ベルト110をその上部張架面がほぼ水平になる姿勢で張架して、上部張架面に全ての感光体1Y,M,C,Kを接触させる。これに対し、Kトナーのみからなるモノクロ画像を形成する場合には、図示しない機構により、中間転写ベルト110を図中左下に傾けるような姿勢にして、その上部張架面をY,M,C用の感光体1Y,M,Cから離間させる。そして、4つの感光体1Y,M,C,Kのうち、K用の感光体1Kだけを図中反時計回りに回転させて、Kトナー像だけを作像する。この際、Y,M,Cについては、感光体1だけでなく、現像器も駆動を停止させて、感光体や現像剤の不要な消耗を防止する。

In the case of forming another color image composed of two or more colors of toner, the copying machine stretches the intermediate transfer belt 110 so that the upper stretched surface thereof is substantially horizontal, Photoconductors 1Y, 1M, 1C, and 1K are brought into contact with each other. On the other hand, when forming a monochrome image consisting of only K toner, the intermediate transfer belt 110 is tilted to the lower left in the drawing by a mechanism (not shown) and the upper stretched surface is set to Y, M, C. The photoconductors 1Y, 1M, and 1C are separated. Of the four photoconductors 1Y, 1M, 1C, and 1K, only the K photoconductor 1K is rotated counterclockwise in the drawing to form only the K toner image. At this time, for Y, M, and C, not only the

本複写機は、複写機内の下記機器の制御を司るCPU等から構成される図示しない制御部と、液晶ディスプレイや各種キーボタン等などから構成される図示しない操作表示部とを備えている。操作者は、この操作表示部に対するキー入力操作により、制御部に対して命令を送ることで、転写紙の片面だけに画像を形成するモードである片面プリントモードについて、3つのモードの中から1つを選択することができる。この3つの片面プリントモードとは、ダイレクト排出モードと、反転排出モードと、反転デカール排出モードとからなる。 The copying machine includes a control unit (not shown) configured by a CPU or the like that controls the following devices in the copying machine, and an operation display unit (not shown) configured by a liquid crystal display, various key buttons, and the like. The operator sends a command to the control unit by a key input operation on the operation display unit, so that one of the three modes is selected from the three-sided print mode, which is a mode for forming an image only on one side of the transfer paper. You can choose one. The three single-sided printing modes include a direct discharge mode, a reverse discharge mode, and a reverse decal discharge mode.

図2は、4つプロセスカートリッジ18Y,M,C,Kのうちの1つが備える現像装置4及び感光体1を示す拡大構成図である。4つのプロセスカートリッジ18Y,M,C,Kは、それぞれ扱うトナーの色が異なる点の他がほぼ同様の構成になっているので、同図では「4」に付すY,M,C,Kという添字を省略している。

図2に示すように感光体1は図中矢印G方向に回転しながら、その表面を不図示の帯電装置により帯電される。帯電された感光体1の表面は不図示の露光装置より照射されたレーザ光により静電潜像を形成された潜像に現像装置4からトナーを供給され、トナー像を形成する。

FIG. 2 is an enlarged configuration diagram illustrating the developing

As shown in FIG. 2, the surface of the

現像装置4は、図中矢印I方向に表面移動しながら感光体1の表面の潜像にトナーを供給し、現像する現像剤担持体としての現像ローラ5を有している。また、現像ローラ5に現像剤を供給しながら図2の奥方向に現像剤を搬送する供給搬送部材としての供給スクリュ8を有している。

現像ローラ5の供給スクリュ8との対向部から表面移動方向下流側には、現像ローラ5に供給された現像剤を現像に適した厚さに規制する現像剤規制部材としての現像ドクタ12を備えている。

現像ローラ5の感光体1との対向部である現像部から表面移動方向下流側には、現像部を通過した現像済みの現像剤を回収し、回収した回収現像剤を供給スクリュ8と同方向に搬送する回収搬送部材としての回収スクリュ6を備えている。供給スクリュ8を備えた供給搬送路9は現像ローラ5の横方向に、回収スクリュ6を備えた回収搬送路としての回収搬送路7は現像ローラ5の下方に並設されている。

The developing

A developing

The developed developer that has passed through the developing section is collected downstream from the developing section, which is the facing portion of the developing

現像装置4は、供給搬送路9の下方で回収搬送路7に並列して、攪拌搬送路10を設けている。攪拌搬送路10は、現像剤を攪拌しながら供給スクリュ8とは逆方向である図中手前側に搬送する攪拌搬送部材としての攪拌スクリュ11を備えている。

供給搬送路9と攪拌搬送路10とは仕切り部材としての第一仕切り壁133によって仕切られている。第一仕切り壁133の供給搬送路9と攪拌搬送路10とを仕切る箇所は図中手前側と奥側との両端は開口部となっており、供給搬送路9と攪拌搬送路10とが連通している。

なお、供給搬送路9と回収搬送路7とも第一仕切り壁133によって仕切られているが、第一仕切り壁133の供給搬送路9と回収搬送路7とを仕切る箇所には開口部を設けていない。

また、攪拌搬送路10と回収搬送路7との2つの搬送路は仕切り部材としての第二仕切り壁134によって仕切られている。第二仕切り壁134は、図中手前側が開口部となっており、攪拌搬送路10と回収搬送路7とが連通している。

現像剤搬送部材のうちの供給搬送部材である供給スクリュ8、回収スクリュ6及び攪拌スクリュ11は樹脂もしくは金属のスクリュからなっており各スクリュ径は全てφ22[mm]でスクリュピッチは供給スクリュが50[mm]の2条巻き、回収スクリュ6及び攪拌スクリュ11が25[mm]の1条巻き、回転数は全て約600[rpm]に設定している。

The developing

The

The

Further, the two conveyance paths of the stirring

The

現像ローラ5上にステンレスからなる現像ドクタ12によって薄層化された現像剤を感光体1との対抗部である現像領域まで搬送し現像を行う。現像ローラ5の表面はV溝あるいはサンドブラスト処理されておりφ25[mm]のAlもしくはSUS素管からなり、現像ドクタ12及び感光体1とのギャップは0.3[mm]程度となっている。

現像後の現像剤は回収搬送路7にて回収を行い、図2中の断面手前側に搬送され、非画像領域部に設けられた第一仕切り壁133の開口部で、攪拌搬送路10へ現像剤が移送される。なお、攪拌搬送路10における現像剤搬送方向上流側の第一仕切り壁133の開口部の付近で攪拌搬送路10の上側に設けられたトナー補給口から攪拌搬送路10にトナーが供給される。

The developer thinned by the developing

The developer after the development is collected in the

次に、3つの現像剤搬送路内での現像剤の循環について説明する。

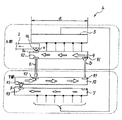

図3は現像剤搬送路内の現像剤の流れを説明する現像装置4の斜視断面図である。図中の各矢印は現像剤の移動方向を示している。

また、図4は、現像装置4内の現像剤の流れの模式図であり、図3と同様、図中の各矢印は現像剤の移動方向を示している。

Next, the circulation of the developer in the three developer conveyance paths will be described.

FIG. 3 is a perspective sectional view of the developing

4 is a schematic diagram of the flow of the developer in the developing

攪拌搬送路10から現像剤の供給を受けた供給搬送路9では、現像ローラ5に現像剤を供給しながら、供給スクリュ8の搬送方向下流側に現像剤を搬送する。そして、現像ローラ5に供給され現像に用いられず供給搬送路9の搬送方向下流端まで搬送された余剰現像剤は第一仕切り壁133の余剰開口部92より攪拌搬送路10に供給される(図4中矢印E)。

現像ローラ5から回収搬送路7に送られ、回収スクリュ6によって回収搬送路7の搬送方向下流端まで搬送された回収現像剤は第二仕切り壁134の回収開口部93より攪拌搬送路10に供給される(図4中矢印F)。

そして、攪拌搬送路10は、供給された余剰現像剤と回収現像剤とを攪拌し、攪拌スクリュ11の搬送方向下流側であり、供給スクリュ8の搬送方向上流側に搬送し、第一仕切り壁133の供給開口部91より供給搬送路9に供給される(図4中矢印D)。

攪拌搬送路10では攪拌スクリュ11によって、回収現像剤、余剰現像剤及び移送部で必要に応じて補給されるトナーを、回収搬送路7及び供給搬送路9の現像剤と逆方向に攪拌搬送する。そして、搬送方向下流側で連通している供給搬送路9の搬送方向上流側に攪拌された現像剤を移送する。なお、攪拌搬送路10の下方には、不図示のトナー濃度センサが設けられ、センサ出力により不図示のトナー補給制御装置を作動し、不図示のトナー収容部からトナー補給を行っている。

In the

The collected developer that is sent from the developing

The agitating and conveying

In the agitating and conveying

図4に示す現像装置4では、供給搬送路9と回収搬送路7とを備え、現像剤の供給と回収とを異なる現像剤搬送路で行うので、現像済みの現像剤が供給搬送路9に混入することがない。よって、供給搬送路9の搬送方向下流側ほど現像ローラ5に供給される現像剤のトナー濃度が低下することを防止することができる。また、回収搬送路7と攪拌搬送路10とを備え、現像剤の回収と攪拌とを異なる現像剤搬送路で行うので、現像済みの現像剤が攪拌の途中に落ちることがない。よって、十分に攪拌がなされた現像剤が供給搬送路9に供給されるため、供給搬送路9に供給されるの現像剤が攪拌不足となることを防止することができる。このように、供給搬送路9内の現像剤のトナー濃度が低下することを防止し、供給搬送路9内の現像剤が攪拌不足となることを防止することができるので現像時の画像濃度を一定にすることができる。

In the developing

なお、図4に示すように、現像装置4の下部から上部への現像剤の移動は矢印Dのみである。矢印Dで示す現像剤の移動は、攪拌スクリュ11の回転で現像剤を押し込むことにより、現像剤を盛り上がらせて供給搬送路9に現像剤を供給するものである。

このような現像剤の移動は、現像剤に対してストレスを与えることになり、現像剤の寿命低下の一因となる。

このような、現像剤を下方から上方に持ち上げる際に現像剤にストレスがかかり現像剤中のキャリアの膜削れやトナーのスペント化がその個所で発生し、それに伴い画像品質の安定性が保たれなくなってしまう。

よって、矢印Dで示す現像剤の移動における現像剤のストレスを軽減することで現像剤の長寿命化を図ることが出来る。現像剤の長寿命化を図ることにより、現像剤の劣化を防止して常に画像濃度ムラの無い画像品質の安定した現像装置を提供することができる。

As shown in FIG. 4, the developer moves from the lower part to the upper part of the developing

Such movement of the developer gives stress to the developer and contributes to a decrease in the life of the developer.

When the developer is lifted from the bottom to the top, stress is applied to the developer, and the carrier film in the developer is scraped off and the toner is spent on the spot. Accordingly, the stability of the image quality is maintained. It will disappear.

Therefore, the life of the developer can be extended by reducing the stress of the developer in the movement of the developer indicated by the arrow D. By prolonging the life of the developer, it is possible to provide a developing device that prevents deterioration of the developer and is always stable in image quality without image density unevenness.

本実施形態の現像装置4では、図2に示すように、供給搬送路9を攪拌搬送路10の斜め上方になるように配置している。斜め上方に配置することにより、供給搬送路9を攪拌搬送路10の垂直上方に設け現像剤を持ち上げるものに比べて、矢印Dで示す現像剤の移動における現像剤のストレスを軽減することができる。

さらに、現像装置4では、供給搬送路9と攪拌搬送路10とを斜めに配置することで、図2に示すように、攪拌搬送路10の上部壁面が供給搬送路9の下部壁面よりも高い位置となるように配置している。

供給搬送路9を攪拌搬送路10に対して垂直上方に持ち上げることは、重力に逆らって現像剤を攪拌スクリュ11の圧によって持ち上げるので現像剤にストレスがかかる。一方、攪拌搬送路10の上部壁面が供給搬送路9の下部壁面よりも高い位置となるように配置することで、攪拌搬送路10の最高点に存在する現像剤が供給搬送路9の最下点に重力に逆らわず流れ込むことができるので、現像剤にかかるストレスを低減することができる。

なお、攪拌搬送路10の現像剤搬送路下流側の、攪拌搬送路10と供給搬送路9とが連通している部分の攪拌スクリュ11の軸にフィン部材を設けても良い。このフィン部材は攪拌スクリュ11の軸方向に平行な辺と、攪拌スクリュの軸方向に垂直な辺とから構成される板状の部材である。このフィン部材で現像剤を掻き上げることにより、攪拌搬送路10から供給搬送路9へ、より効率的な現像剤の受渡しを行うことができる。

In the developing

Further, in the developing

Lifting the

Note that a fin member may be provided on the shaft of the stirring

また、現像装置4では、現像ローラ5と供給搬送路9との中心間距離Aが、現像ローラ5と攪拌搬送路10との中心間距離Bよりも短くなるように、供給搬送路9と攪拌搬送路10とを配置している。これにより供給搬送路9から現像ローラ5に現像剤を無理無く供給することができ、装置の小型化を図ることもできる。

また、攪拌スクリュ11は、図2中の手前側から見て反時計回り方向(図中矢印C方向)に回転しており、現像剤は攪拌スクリュ11の形状に沿って現像剤を持ち上げて供給搬送路9に移送させている。これにより、現像剤を効率良く持ち上げることが可能となり現像剤にかかるストレスもより低減することができる。

Further, in the developing

Further, the stirring

図5は、現像装置4の供給スクリュ8の回転中心における断面を図3中の矢印J方向から見た断面説明図である。図中Hは、現像剤担持体である現像ローラ5が、潜像担持体である感光体1にトナーを供給する現像領域を示している。この現像領域Hの現像ローラ5の回転軸の軸線方向の幅が現像領域幅αである。

図5に示すように、現像装置4は攪拌搬送路10から供給搬送路9に現像剤を持ち上げる箇所である供給開口部91と、供給搬送路9から攪拌搬送路10に現像剤を落下させる余剰開口部92とがともに現像領域幅α内に設けられている。

FIG. 5 is a cross-sectional explanatory view of the cross section at the rotation center of the

As shown in FIG. 5, the developing

図6は、図4とは異なる構成の現像装置4内の現像剤の流れの模式図である。

図6に示す現像装置4は、供給開口部91と余剰開口部92とを現像領域幅αの外側に設けている。供給開口部91を現像領域幅αの外側に設けているため、供給搬送路9の搬送方向上流側は現像ローラ5よりも供給搬送路上流側領域β分長くなっている。また、余剰開口部92を現像領域幅αの外側に設けているため、供給搬送路9の搬送方向下流側は現像ローラ5よりも供給搬送路下流側領域γ分長くなっている。

FIG. 6 is a schematic diagram of the developer flow in the developing

The developing

一方、図4に示す構成の現像装置4では、供給開口部91を現像領域幅α内に設けているため、供給搬送路9の搬送方向上流側は図6の現像装置4よりも供給搬送路上流側領域β分短くすることができる。また、余剰開口部92を現像領域幅α内に設けているため、供給搬送路9の搬送方向下流側は図6の現像装置4よりも供給搬送路下流側領域γ分短くすることができる。

このように、図4の現像装置4は供給開口部91と余剰開口部92とを現像領域幅α内に設けているため、図6に示す現像装置4に比べて、現像装置4の上部の省スペース化を図ることが出来る。

On the other hand, in the developing

4 is provided with the

次に、現像装置4の供給搬送路9、攪拌搬送路10及び回収搬送路7からなる現像剤搬送路へのトナーを補給する位置について説明する。図7は、現像装置4の外観斜視図である。

図7に示すように、トナーを補給するトナー補給口95を攪拌スクリュ11を備える攪拌搬送路10の搬送方向上流端部の上方に設けている。このトナー補給口95は現像ローラ5の幅方向端部よりも外側に設けてあるので、現像領域幅αよりも外側となっている。

この、トナー補給口95を設けた箇所は供給搬送路9の搬送方向の延長線上であり、図6における供給搬送路下流側領域γの空いたスペースに該当する。余剰開口部92を現像領域幅α内に設けることで空いたスペースにトナー補給口95を設けることにより、現像装置4の小型化を図ることが出来る。

また、トナー補給口95としては、攪拌搬送路10の搬送方向上流端部の上方に限らず、回収搬送路7の下流端部の上方に設けても良い。

さらに、回収搬送路7から攪拌搬送路10へ現像剤の受渡しを行う箇所である回収開口部93の真上にトナー補給口95を設けるようにしても良い。回収開口部93の真上のスペースも余剰開口部92を現像領域幅α内に設けることで空いたスペースであるので、この位置にトナー補給口95を設けることにより、現像装置4の小型化を図ることができる。さらに、受渡し部である回収開口部93では現像剤が混ざりやすいため、この位置で補給を行うことによりより効率よく現像剤の攪拌を行うことができる。

Next, the position at which toner is supplied to the developer conveyance path including the

As shown in FIG. 7, a

The portion where the

Further, the

Further, a

図4を用いて説明した現像装置4のように、攪拌搬送路10の搬送方向下流端から供給搬送路9の搬送方向上流端に現像剤を受け渡す供給開口部91と、供給搬送路9の下流端から攪拌搬送路10の搬送方向上流端に現像剤を受け渡す余剰開口部92とを現像領域幅α内に設けているため、従来の現像装置4に比べて、現像装置4の上部の省スペース化を図ることが出来、現像装置4全体の省スペース化を図ることが出来る。

また、余剰開口部92を現像領域幅α内に設けることで空いたスペースにトナー補給口95を設けることにより、現像装置4の小型化を図ることが出来る。

また、回収搬送路7から攪拌搬送路10への現像剤の受渡し部である回収開口部93の上方からトナー補給を行うことによりより効率よく現像剤の攪拌を行うことができる。

また、画像形成装置としての複写機のプリンタ部100の現像手段として、現像装置4を備えることにより、装置全体の省スペース化を図ることが出来る。

As in the developing

Also, by providing the

Further, the developer can be more efficiently stirred by replenishing the toner from above the

Further, by providing the developing

次に、本実施形態の現像装置4の特徴部について説明する。

現像剤補給手段である不図示のトナー補給制御装置は、不図示のトナー収容部内のトナーをトナー補給口95から現像装置4に補給する。本実施形態の現像装置4では現像装置4のトナー補給口95からトナーとキャリアとを含む現像剤が補給される。以降、現像装置4に補給されるトナーとキャリアとが混合された現像剤をプレミックストナーと称する。

また、供給搬送路9には、供給搬送路9内の現像剤が所定の嵩を越えた場合にその一部を現像装置4の外部に排出する現像剤排出手段として、排出搬送路2と現像剤排出口94とを有する。排出搬送路2は、供給搬送路9の搬送方向下流側で仕切り壁135を挟んで供給搬送路9と隣り合うように配置され、現像剤排出口94は供給搬送路9と排出搬送路2とを連通するように仕切り壁135に設けられた開口である。

そして、本実施形態の現像装置4は、図4に示すように、供給搬送路9の搬送方向下流端近傍に現像剤排出口94を配置して、供給搬送路9の搬送方向下流端近傍の現像剤が所定量の嵩を越えた場合にその一部を排出する。

なお、供給搬送路9の搬送方向下流端近傍とは、例えば、供給搬送路9から攪拌搬送路10へと現像剤が受け渡される現像剤受渡し部と供給搬送路9の搬送方向で同位置となる箇所である。言い換えると、供給スクリュ8による搬送力が終了するところであり、後述する逆スクリュによる搬送力がかかる直前部分のことである。ここに現像剤排出口94を設けることにより、供給スクリュ8によって搬送された後、逆スクリュの搬送力により受け止められ、最終的にたまった現像剤を現像剤排出口94から排出することが可能になる。また、現像装置4では逆スクリュがついているが、供給スクリュ8によって搬送された現像剤が現像剤排出口94の位置で溜まるように搬送力が途切れれば良いため、供給搬送路9の最下流側端面は壁状となっていてもかまわない。

Next, the characteristic part of the developing

A toner replenishment control device (not shown) that is a developer replenishing unit replenishes toner in a toner storage unit (not shown) to the developing

Further, the

In the developing

The vicinity of the downstream end of the

図8は、現像装置4から攪拌スクリュ11、回収スクリュ6、及び、現像ドクタ12を取り外した状態の手前側端部近傍の斜視説明図である。また、図9は、現像装置4について図8の状態からさらに供給スクリュ8を取り外した状態の手前側近傍を図9とは異なる方向から見た斜視説明図である。さらに、図10は、現像装置4について図9の状態からさらに現像ローラ5を取り外した状態の斜視説明図である。また、図11は、現像装置4について図10と同じ状態の現像装置4を図3と略同じ方向から見た場合の斜視説明図である。

FIG. 8 is an explanatory perspective view of the vicinity of the front end portion in a state where the stirring

供給スクリュ8の回転方向は、図2でいうところの右回り(矢印Mの方向)であって、現像ローラ5に対して現像剤を下方から持ち上げて供給する方向に回転している。ここで、供給スクリュ8の回転方向を左回りにし、現像剤を上から振り掛けるようにして現像ローラ5に現像剤を供給すると、現像剤が飛び散りながら現像ローラ5に供給される。一方、供給スクリュ8の回転方向を図2に示すように右回りにすると、現像剤がたまっている供給搬送路9の下方から現像剤を持ち上げるようにして現像ローラ5に現像剤が供給されるようになる。現像剤が飛び散りながら供給するよりも、下方から持ち上げるようにして供給するほうが現像剤の供給性が安定するため、現像装置4では供給スクリュ8の回転方向を図2でいうところの右回りに設定している。

特に本実施形態の現像装置4のように現像ローラ5に供給した現像剤を供給搬送路9へ戻さず、回収搬送路7へ回収するものでは、現像剤量は供給搬送路9の下流に行くにしたがって減少していく。このため、現像剤がたまっている下方からくみ上げて現像ローラ5に供給するもののほうが現像剤の供給性の面では優れている。

The rotation direction of the

In particular, in the case where the developer supplied to the developing

ここで、供給搬送路9内では、搬送されることで供給搬送路9内を移動する勢いや、現像剤搬送スクリュである供給スクリュ8の回転する力によって供給搬送路9内の現像剤は飛び跳ねる。そして、現像剤搬送路である供給搬送路9の所定の高さに現像剤排出口94を設けただけの構成であると、飛び跳ねた現像剤が飛翔して現像剤排出口94を通過して排出されることがある。現像剤が飛び跳ねて排出される場合、供給搬送路9内の現像剤排出口94を設けた位置を搬送される現像剤が適正な量の状態や、適正な量を下回る状態であっても、飛び跳ねた現像剤が排出されるおそれがある。このように飛び跳ねた現像剤が排出される状態であると、現像装置4内の現像剤が適正な量以下の状態であるにもかかわらず現像剤排出口から現像剤が排出されることがあり、現像装置4内の現像剤量が必要量を下回り、感光体1への現像剤の供給が不安定になるおそれがある。そして、感光体1への現像剤の供給が不安定になると画像抜けなどの異常画像が発生する。

Here, in the

このような不具合を防止するために、現像装置4は、現像剤搬送部材のうちの供給搬送部材である供給スクリュ8が現像剤を搬送するために回転することによって飛翔した現像剤が現像剤排出口94に向かう経路を塞ぐ飛翔現像剤排出防止部材として、ブロック部材3を備えている。ブロック部材3を備え、供給スクリュ8の搬送動作によって飛翔した現像剤が現像剤排出口94へ向かう経路を塞ぐため、飛び跳ねた現像剤が排出されることを防止し、現像装置4内の現像剤量が増加していないにもかかわらず現像剤が排出されることを防止することができる。このため、現像装置4内の現像剤の必要量を確保することができ、感光体1に安定した現像剤の供給を行うことができる。これにより、感光体1上の静電潜像を良好にトナー像化することができ、画像抜けなどの異常画像の発生を防止し、良好な画像形成を行うことができる。

In order to prevent such inconvenience, the developing

ブロック部材3は、その底面が供給搬送路9の上部に供給スクリュ8の形状に沿ったR形状の樹脂製の部材である。供給スクリュ8の形状に沿ったR形状であることにより、供給スクリュ8全体を覆うようにブロック部材3の底面を全体的に供給スクリュ8に近接させることが可能になる。このため、現像剤の跳ね上げを起こす供給スクリュ8の上方を覆い、供給スクリュ8によって跳ね上げられた現像剤が現像剤排出口94へ飛翔することを防止することができる。

The

また、図11に示すように、供給搬送路9の現像剤排出口94周辺でブロック部材3が突出した形状となっているため、ブロック部材3に対して供給スクリュ8の搬送方向上流側の供給搬送路9よりも、ブロック部材3を設けた箇所の供給搬送路が狭くなっている。このため、ブロック部材3を設けた位置に対して搬送方向上流側よりも、ブロック部材3を設けた位置の方が供給搬送路9の容量に対する現像剤量が多くなる。そのため、現像剤に対して搬送力の付与が無くなる供給搬送路9の搬送方向下流端部近傍で、ブロック部材3の側壁と、仕切り壁135との間に現像剤がせり上がる状態となる。これにより、供給スクリュ8が現像剤に埋まるような状態となり、供給スクリュ8の回転による現像剤の跳ね上げが抑えられるとともに、供給スクリュ8の羽部の上部が現像剤の剤面から出ているときに発生する供給スクリュの跳ね上げによる剤面の変化が現像剤排出口94付近では緩和される。このため、現像装置4内の現像剤の増減に対して感度の良い排出が望めるようになる。

このようなブロック部材3を備えることで、現像剤の供給により嵩が上昇した場合、増加した分に相当する現像剤が現像剤排出口94より溢れ出す構成となっている。

Further, as shown in FIG. 11, since the

By providing such a

図12及び図13は、現像装置4内の現像剤量が少ない状態、すなわち、供給搬送路9の搬送方向下流端近傍の現像剤の嵩が所定の高さに到達していない状態の現像装置4の現像剤の流れを示す説明図である。図12は、図2と同じ方向から見た供給搬送路9の搬送方向下流端近傍の現像装置4の断面説明図であり、図13は、図5と同じ方向から見た側方断面説明図である。図中Pは現像剤を示す。

図12及び図13に示すように、現像装置4内の現像剤量が少ない場合は供給搬送路9から循環搬送路である攪拌搬送路10への現像剤の供給がスムーズに行われる。その結果、供給搬送路9と攪拌搬送路10との境界である供給循環仕切り壁である第一仕切り壁133に設けられた開口部である供給循環連通口としての余剰開口部92で現像剤Pが溢れることが無い。このため、現像装置4外へ現像剤Pを排出する現像剤排出口94へ現像剤はほとんど導かれず、現像剤量が少ない状態で現像剤が排出されることを防止することができる。

12 and 13 show the developing device in a state where the amount of developer in the developing

As shown in FIGS. 12 and 13, when the amount of developer in the developing

図14及び図15は現像装置4内の現像剤量が多い状態、すなわち、供給搬送路9の搬送方向下流端近傍の現像剤Pの嵩が所定の高さに越えた状態の現像装置4の現像剤Pの流れを示す説明図である。図14は、図2と同じ方向から見た供給搬送路9の搬送方向下流端近傍の現像装置4の断面説明図であり、図15は、図5と同じ方向から見た側方断面説明図である。

図14及び図15に示すように、現像装置4内の現像剤量が多い場合は、供給搬送路9から攪拌搬送路10へ現像剤Pが移動する余剰開口部92の近傍で現像剤Pが滞留してしまう。その結果、供給搬送路9の搬送方向最下流部の現像剤Pは行き場が無くなり上方向に嵩が上昇して行く。そして、現像剤排出口94の高さまで嵩が上昇すると現像剤Pが排出搬送路2へと排出され、排出搬送路2内の排出搬送部材である排出搬送スクリュ2aによって現像装置4の外部に排出されることになる。

14 and 15 show the state of the developing

As shown in FIGS. 14 and 15, when the amount of developer in the developing

現像装置4は、供給搬送路9の搬送方向下流端近傍の現像剤の嵩が現像剤排出口94の高さを越えた場合に、現像剤排出口94の高さまで到達した現像剤を排出するものであるので、現像剤排出口94からの現像剤の排出によって供給搬送路9を搬送する現像剤が不足することを防止することができる。これにより、供給搬送路9から現像ローラ5へ必要量の現像剤を供給することができ、現像ローラ5から感光体1に安定した現像剤の供給を行うことができる。このため、感光体1上の静電潜像を良好にトナー像化することができ、画像抜けなどの異常画像の発生を防止し、良好な画像形成を行うことができる。

The developing

図13では、現像装置4内の現像剤が少ない状態について説明したが、現像装置4内の現像剤が排出されず、現像剤量が安定した状態では、供給搬送路9の搬送方向下流端近傍に現像剤が滞留した状態となっている。以下、この状態の詳細について説明する。

現像装置4は、現像剤排出手段が、供給搬送路9の搬送方向下流端近傍の現像剤の嵩が所定の高さを越えた場合にその一部を排出する構成である。すなわち、現像剤排出手段である現像剤排出口94及び排出搬送路2は、供給搬送路9の搬送方向下流端近傍の現像剤の嵩が、現像剤排出口94の高さまで到達した現像剤を排出するものである。よって、供給搬送路9の搬送方向下流端近傍に、現像剤排出口94の高さに到達しない程度の嵩で現像剤が存在する状態で現像装置4内の現像量が安定した状態となる。これは、供給搬送路9を搬送されその搬送方向下流端に到達する現像剤量と、供給搬送路9余剰開口部92を通って攪拌搬送路10に受け渡される現像剤量との均衡により、供給搬送路9の搬送方向下流端近傍に現像剤排出口94の高さに到達しない程度の嵩で現像剤が滞留している状態である。

In FIG. 13, the state in which the developer in the developing

In the developing

この状態からトナー補給制御装置によってプレミックストナーが供給されて現像装置4内の現像剤量が増加すると、供給搬送路9から攪拌搬送路10に受け渡される現像剤量よりも、供給搬送路9を搬送されその搬送方向下流端に到達する現像剤量の方が多くなる。このとき、供給搬送路9の搬送方向下流端近傍に滞留する現像剤の量が増加し、その嵩が上昇する。これにより、滞留する現像剤の嵩が現像剤排出口94に到達した場合に、その嵩が現像剤排出口94の位置よりも低くなるように滞留する現像剤の一部として、現像剤排出口94に到達した現像剤を排出する。

滞留する現像剤は飛び跳ねにくく、現像装置4内の現像剤量の増減に合わせて現像剤の嵩が変化する。そして、その嵩が所定の高さを越えたときに現像剤を排出することにより、現像装置4内の現像剤量が増加したときに増加量分の現像剤が排出されるため、現像装置4内の現像剤量を精度良く一定の範囲内に維持することができる。

これにより、供給搬送路9を搬送される現像剤量が安定するため、供給搬送路を搬送する現像剤が不足することを防止することができ、供給搬送路9から現像ローラ5へ必要量の現像剤を供給することができる。このため、現像ローラ5から感光体1に安定した現像剤の供給を行うことができ、感光体1上の静電潜像を良好にトナー像化することができるため、画像抜けなどの異常画像の発生を防止し、良好な画像形成を行うことができる。

When the premix toner is supplied by the toner replenishment control device from this state and the amount of developer in the developing

The staying developer is unlikely to jump, and the volume of the developer changes according to the increase or decrease of the developer amount in the developing

As a result, the amount of developer conveyed through the

現像装置4において、プレミックストナーが補給されたときの攪拌スクリュ11による現像剤の搬送量の変化や攪拌搬送路10から供給搬送路9への現像剤の受渡し量の変化によって現像剤の現像剤の動向は異なる。

例えば、プレミックストナーが補給された状態でも攪拌スクリュ11による現像剤の搬送量があまり変化しない場合は、供給搬送路9の搬送方向上流側に供給される現像剤の量もあまり変化しない。また、攪拌搬送路10から供給搬送路9へ現像剤を受け渡す構成が、図12や図13に示す状態で時間当りに受け渡せる量の上限に近い状態である場合も供給搬送路9の搬送方向上流側に供給される現像剤の量もあまり変化しない。これらの構成は、現像装置4内の現像剤量が増加することで攪拌搬送路10内の現像剤量が増加し、攪拌搬送路10内に時間当りに供給される現像剤量が増加する量に比べて、攪拌搬送路から供給搬送路9へと時間当りに移動する現像剤量の増加する量が少なくなる構成である。

In the developing

For example, when the amount of developer transported by the stirring

このような構成の現像装置4では、プレミックストナーが補給されても、供給搬送路9を搬送される現像剤量も変化せず、供給搬送路9から現像ローラ5に供給される現像剤量も略一定であるので、供給スクリュ8によって時間当りに供給搬送路9の搬送方向下流端近傍に到達する現像剤の量もほとんど変化しない。

一方、攪拌搬送路10の搬送量があまり変化しない場合は、トナー補給口95からプレミックストナーが補給されると、増加した現像剤は攪拌搬送路10の搬送方向上流端近傍で滞留する。また、攪拌搬送路10から供給搬送路9への受渡し量が変化しない場合は、増加した分の現像剤は攪拌搬送路10内で滞留し、搬送方向上流端近傍にも滞留する。

搬送方向上流端近傍に現像剤が滞留すると、供給搬送路9から攪拌搬送路10へ現像剤を受け渡す余剰開口部92を攪拌搬送路10側で現像剤によって塞ぐ状態となる。余剰開口部92が現像剤によって塞がれると供給搬送路9から攪拌搬送路10への現像剤の移動ができなくなるが、供給スクリュ8によって現像剤が搬送され続けるため、供給搬送路9の搬送方向下流端近傍で現像剤が滞留し、その嵩は増加する。そして、供給搬送路9の搬送方向下流端近傍の現像剤の嵩が、現像剤排出口94の高さまで上昇すると現像剤Pが排出搬送路2へと排出され、排出搬送路2を通って現像装置4の外部に排出される。

この構成では、攪拌搬送路10内に現像剤が充満状態のときに、現像に用いられずに供給搬送路9の搬送方向の最下流まで搬送された余剰現像剤を攪拌搬送路10に供給搬送する余剰開口部92が現像剤で溢れる状態とすることにより、供給搬送路9から攪拌搬送路10への現像剤の移動を規制することができその結果行き場を失った現像剤は現像剤排出口94へと導かれ、現像剤を排出ことが可能となる。

このように、現像装置4内の現像剤量が増加しても攪拌搬送路10から供給搬送路9へ時間当りに供給される現像剤量があまり変化しない構成であっても、供給搬送路9の搬送方向下流端に現像剤排出口94を配置することにより、現像装置4内の現像剤の入れ替えを行うことができる。

In the developing

On the other hand, when the conveyance amount of the

When the developer stays in the vicinity of the upstream end in the transport direction, the surplus opening 92 that delivers the developer from the

In this configuration, when the developer in the

As described above, even if the developer amount in the developing

また、プレミックストナーが補給されると、それに併せて供給搬送路9の搬送方向上流側に供給される現像剤の量が増加するが、供給搬送路9から攪拌搬送路10への現像剤の受渡し量に上限があるものがある構成もある。この構成は、現像装置4内の現像剤量が増加することで供給搬送路9内の現像剤量が増加し、供給スクリュ8の搬送によって供給搬送路9の搬送方向下流端近傍に時間当りに搬送される現像剤量が増加する量に比べて、供給搬送路9の搬送方向下流端から攪拌搬送路10へと時間当りに移動する現像剤量の増加する量が少なくなるように構成されている。

このような構成の現像装置4では、プレミックストナーが補給されると、現像剤の増化に合わせて攪拌搬送路10の搬送量が増加し、攪拌搬送路10から供給搬送路9への現像剤の受渡し量も増加する。これにより、供給搬送路9の搬送方向上流端部に供給される現像剤量が増加し、供給搬送路9内を搬送する現像剤量も増加する。しかし、供給搬送路9から現像ローラ5に供給される現像剤量は変化しないため、時間当りに供給搬送路9の搬送方向下流端近傍に到達する現像剤量は増加する。そして、時間当りに供給搬送路9の搬送方向下流端近傍に到達する現像剤量が、供給搬送路9から攪拌搬送路10への現像剤の時間当りの受渡し量の上限を越えると、供給搬送路9の搬送方向下流端近傍で現像剤が滞留し、その嵩は増加する。そして、供給搬送路9の搬送方向下流端近傍の現像剤の嵩が、現像剤排出口94の高さまで上昇すると現像剤Pが排出搬送路2へと排出され、排出搬送路2を通って現像装置4の外部に排出される。

このように、現像装置4内の現像剤量が増加すると攪拌搬送路10から供給搬送路9へ時間当りに供給される現像剤量も増加する構成であっても、供給搬送路9の搬送方向下流端に現像剤排出口94を配置することにより、現像装置4内の現像剤の入れ替えを行うことができる。

In addition, when the premix toner is replenished, the amount of the developer supplied to the upstream side of the

In the developing

As described above, even when the developer amount in the developing

また、現像装置4内の現像剤量の変化によって現像剤の嵩が変化する箇所である供給搬送路9の搬送方向下流端近傍であふれた現像剤を、仕切り壁135に設けた現像剤排出口94によって現像剤を排出する構成であるため、簡単な構成で精度よく現像装置4内の現像剤を入れ替えることができる。

また、供給搬送路9と循環搬送路である攪拌搬送路10とが供給循環仕切り壁である第一仕切り壁133を挟んで、上下で隣り合うように配置され、供給搬送路9の搬送方向下流端に到達した現像剤は、供給搬送路9と攪拌搬送路10とを連通するように設けられた開口である余剰開口部92を通って、攪拌搬送路10へ移動する構成である。そして、供給搬送路9の搬送方向下流端近傍の現像剤の嵩は、供給スクリュ8によってその下流端まで時間当りに搬送される現像剤量と、余剰開口部92を時間当りに通過する現像剤量との差によって変化する。供給スクリュ8によって搬送される現像剤量または余剰開口部92を時間当りに通過する現像剤量は、現像装置4内の現像剤量の変化によって変わり、現像装置4内の現像剤量が増加すると供給搬送路9の搬送方向下流端近傍の現像剤の嵩が上昇するため、簡単な構成で精度よく現像装置4内の現像剤を入れ替えることができる。

Further, the developer discharge port provided in the

Further, the

図4、図13及び図15に示すように、現像剤排出口94と余剰開口部92とが、供給搬送路9の現像剤搬送方向について同じ位置にあることにより、供給搬送路9から攪拌搬送路10に受け渡す現像剤量と、現像装置4の外に排出する現像剤量のバランスをとることが容易となる。

また、現像剤排出口94は余剰開口部92よりも上方に配置されているため、現像装置4内の現像剤量が適正量である状態では、供給搬送路9の搬送方向下流端に到達した現像剤は、下方にある余剰開口部92のみを通過し、攪拌搬送路10に移動して現像装置4内を循環する。そして、現像装置4内の現像剤量が増加し、搬送方向下流端の現像剤の嵩が上方にある現像剤排出口94の高さまで到達すると、その高さを越える現像剤が現像剤排出口94を通過して、現像装置4の外部に排出される。この構成では、現像剤排出口94は余剰開口部92よりも上方に配置するという簡易な構成で、攪拌搬送路10に供給すべき現像剤量が攪拌搬送路10に供給されない状態で現像剤が現像装置4の外に排出されることを防止しつつ、現像装置4内の現像剤量が所定量を越えた場合は、装置の外に排出することができる。これにより、余剰開口部92を介して現像剤を循環させつつ、現像剤排出口94で増加した分の現像剤を精度良く排出して現像剤を入れ替える構成を実現することができる。

As shown in FIGS. 4, 13, and 15, the

Further, since the

現像装置4は、供給搬送路9の搬送方向最下流端に、供給スクリュ8とは逆方向の搬送力を発生させる逆搬送部材として、逆スクリュ部8aを備えている。逆スクリュ部8aは、供給スクリュ8の回転軸の端部に供給スクリュ8の羽部とは逆巻きの羽部を取り付けたものである。

そして、供給スクリュ8が回転することにより、逆スクリュ部8aでは供給スクリュ8とは逆方向の搬送力が発生する。これにより、供給スクリュ8の搬送によって現像剤排出口94及び余剰開口部92を配置した位置を通り過ぎた現像剤を、逆スクリュ部8aによって現像剤排出口94及び余剰開口部92の位置に向かわせることができる。現像剤排出口94及び余剰開口部92を配置した位置を通り過ぎた現像剤が供給スクリュ8の搬送方向にさらに搬送されると、供給スクリュ8の回転軸の軸受に現像剤が入り込み、軸受を破損させるおそれがある。このような問題に対して、逆スクリュ部8aを配置し、現像剤排出口94及び余剰開口部92を配置した位置を通り過ぎた現像剤を押し戻すことにより、軸受に現像剤が入り込むことを防止し、軸受の破損を防止することができる。

The developing

As the

次に、逆スクリュ部8aと供給搬送路9の搬送方向下流端の壁面との好適な位置関係について説明する。

図16は本実施形態の現像装置4に適用可能な供給搬送路9の下流端近傍の拡大説明図である。

図16に示すように、供給搬送部材である供給スクリュ8と逆搬送部材である逆スクリュ部8aとの境界部に、供給搬送路9を形成するケーシングの内側の下流側の端面である下流側端面39が位置するように配置する。下流側端面39は、供給スクリュ8の搬送方向に垂直で、その法線方向が供給スクリュ8の搬送方向(図中矢印s方向)とは反対方向となり、下流側端面39よりも供給スクリュ8の搬送方向下流側へ現像剤が移動することを妨げるものである。

Next, a preferred positional relationship between the

FIG. 16 is an enlarged explanatory view in the vicinity of the downstream end of the

As shown in FIG. 16, the downstream side which is the downstream end surface inside the casing forming the

供給スクリュ8によって搬送された現像剤Tは、下流側端面39によって搬送方向への移動が妨げられるため、その上流側で搬送力が低下し、下流側端面39の近傍で供給スクリュ8の搬送方向への移動は停止したような状態となる。これは、現像剤の各粒子は供給スクリュ8や逆スクリュ部8bによって搬送力を付与され移動するものの、供給搬送路9内の現像剤全体の動きとしては下流側端面39の近傍で停止した状態となっている。この搬送力が低下する箇所に供給搬送路9の搬送方向上流側から現像剤が搬送されてくるため、図16に示すように下流側端面39の上流側で現像剤が滞留し、下流側端面39を伝って現像剤がせり上がる。そして、せり上がった現像剤のうち現像剤排出口94の高さまで到達した現像剤が現像剤排出口94を通って排出搬送路2に移動し、排出搬送路2内を搬送されて現像装置4の外へ排出される。

また、供給スクリュ8と逆スクリュ部8aとの境界部は、搬送方向が正反対の現像剤の流れがぶつかる位置であるので、供給スクリュ8によって搬送された現像剤が壁面にぶつかる場合と同様に現像剤が上方にせり上がる。

このため、供給スクリュ8と逆スクリュ部8aとの境界部と、下流側端面39とを図16のような位置関係にすることにより、下流端壁面39を伝って現像剤がせり上がるのを補助し、現像剤排出口94から現像剤を効率良く排出させることができるようになる。また、供給搬送路9の搬送方向下流端近傍でせり上がった現像剤が所定量の嵩を越えた場合に排出するものであるので、現像装置4内の現像剤量が増加していないにもかかわらず現像剤が排出されることを防止することができる。

Since the developer T transported by the

Further, since the boundary portion between the

For this reason, the boundary portion between the

また、供給スクリュ8のスクリュピッチよりも、逆スクリュ部8aのスクリュピッチの方が狭くなるように設定する。

逆スクリュ部8aは供給スクリュ8の軸部の現像装置4に対する位置決めをする軸受部8bに現像剤が入り込み、軸受部8bが損傷することを防止するものである。逆スクリュ部8aのスクリュピッチが長すぎると羽部の傾斜が緩やかになり、供給スクリュ8の搬送力によって逆スクリュ部8aまで到達した現像剤が、逆スクリュ部8aの羽部をすり抜けて軸受部8bに到達し、損傷させるおそれがある。一方、逆スクリュ部8aのスクリュピッチを供給スクリュ8のスクリュピッチよりも狭くすることにより、逆スクリュ部8aの羽部が供給スクリュ8の羽部よりも軸部に対して垂直に近い状態となる。逆スクリュ部8aの羽部を垂直に近い状態とすることにより、現像剤が軸受部8bに到達することをより確実に防止することができる。

Further, the screw pitch of the

The

供給搬送路9の下流側端部は、供給スクリュ8の搬送方向に対して垂直な壁面があれば、現像剤を滞留させることができ、現像剤が壁面に沿ってせり上がり、現像剤排出口94から現像剤を排出することができる。そして、現像剤排出口94から現像剤を排出する点のみを考えると、供給搬送路9の下流側端部は壁面であることが望ましい。しかし、現像剤が衝突する壁面に供給スクリュ8の軸受部8bを設けると上述したように、軸受部8bに現像剤が入り込み、軸受部8bを損傷するおそれがある。このため、逆スクリュ部8aを設けているが、壁面の方がより確実に現像剤をせり上げることができるので、軸受部8bに現像剤が到達することを防止できるものであれば、逆スクリュ部8aの外径は小さい方が望ましい。逆スクリュ部8aの外径を小さくすることにより、逆スクリュ部8aを設けた筒状の空間9eの径も小さくすることができ、下流側端面39をより広く形成することができる。このため、逆スクリュ部8aの外径を供給スクリュ8の外径よりも小さくすることで、下流側端面39の下端がより低い位置となるように形成することができる。下流側端面39の下端の位置を低くすることで、より効率よく現像剤をせり上げることができる。さらに、逆スクリュ部8aの外径を小さくすることで筒状の空間9eも小さくすることができ、現像装置4の省スペース化を図ることができる。

If the downstream end of the

また、図16に示す現像装置4は、下流端壁面39の上端は現像剤排出口94の下端よりも上方にある。これにより、現像装置4内の現像剤量が増加したときに、現像剤が下流側壁面39に沿ってせり上がって下流側壁面39の上端に到達する前に現像剤排出口94の下端に到達するため、確実に排出させることができる。

In the developing

また、図16に示す現像装置4は、現像剤排出口94の搬送方向下流端の排出口下流端縁部94eと、下流端壁面39との供給搬送路9の現像剤搬送方向についての位置が一致する。この現像装置4では、現像剤排出口94の排出口下流端縁部94eでの仕切り壁135の厚み分の平面と、下流端壁面39とが連続した平面として隙間なく形成されている。このため、下流端壁面39をせり上がった現像剤はスムーズに現像剤排出口94を通過することができる。

Further, in the developing

また、現像装置4は、図16に示すように現像剤排出口94の下端が、供給スクリュ8の羽部の上端よりも上方である。これにより、現像剤が滞留して現像剤排出口94に到達する状態の現像剤が滞留している部分では、供給スクリュ8は現像剤に埋まった状態となるため、供給スクリュ8の回転によって現像剤が跳ね上がることを防止することができる。このため、現像装置4内の現像剤量が増加していないにもかかわらず現像剤が排出されることを防止することができる。

Further, in the developing

また、供給搬送路9、攪拌搬送路10及び回収搬送路7を備える一方向循環の現像装置4では、供給搬送路9の搬送方向下流端に到達する現像剤は現像に寄与しなかった余剰現像剤である。一方向循環の現像装置4では、この余剰現像剤が滞留する位置で、プレミックストナーの補給によって増加した現像剤を排出することが適している。これは、以下の理由による。

回収搬送路7は、現像ローラ5に担持され現像領域を通過した現像剤を搬送するため、現像装置4内の現像剤量が変化しても回収搬送路7内を搬送される現像剤はほとんど変化せず、現像剤の嵩の上昇によって現像剤を排出することができない。

攪拌搬送路10は、現像装置4内の現像剤量が増加すると、搬送する現像剤量が増加してその嵩も上昇する。しかし、搬送される現像剤の飛び跳ねや搬送量のムラによって、現像剤量が増加しなくても現像剤が排出され、供給搬送路9に必要量の現像剤を受け渡すことができなくなるおそれがある。このため、攪拌搬送路10内での現像剤の嵩の上昇によって現像剤を排出することは不適である。さらに、供給搬送路9の途中で排出する構成も、現像装置4内の現像剤量が増加していなくても、現像剤の嵩が増加することがあり、排出した位置よりも搬送方向下流側で現像剤が不足するおそれがあるので不適である。

このような理由により、一方向循環の現像装置4では、供給搬送路9の搬送方向下流端に到達する現像剤が滞留する位置で、プレミックストナーの補給によって増加した分の現像剤を排出することが適している。

Further, in the one-way

Since the

As the amount of developer in the developing

For this reason, the one-way circulating developing

実施形態の現像装置4では、余剰開口部92が現像剤排出口94よりも大きな開口となっているが、現像剤排出口94が余剰開口部92よりも大きな開口としても良い。

また、上述の実施形態では、現像剤排出手段が、供給搬送路9の搬送方向下流端近傍の現像剤の嵩が所定の高さを越えた場合にその一部を排出する構成を図4に示す構成の現像装置4に適用した構成について説明した。本発明の特徴部を適用することができる構成は図4に示すものに限るものではなく、図6に示す構成の現像装置4に同様に適用することができる。

また、上述の実施形態では、現像剤として、キャリアとトナーとからなる二成分現像剤を用いる現像装置について説明した。本発明の特徴部を適用する現像装置としては、二成分現像剤を用いた現像装置に限るものではない。現像剤補給手段によって現像剤の補給が成され、現像装置内の現像剤の増加量分を現像剤排出手段によって排出する構成を備えた現像装置であれば一成分現像剤を用いる現像装置であっても適用可能である。

In the developing

Further, in the above-described embodiment, FIG. 4 shows a configuration in which the developer discharging means discharges a part of the developer when the volume of the developer near the downstream end in the transport direction of the

In the above-described embodiment, the developing device using the two-component developer composed of the carrier and the toner as the developer has been described. The developing device to which the feature of the present invention is applied is not limited to a developing device using a two-component developer. A developing device using a one-component developer can be used as long as the developer is replenished by the developer replenishing unit and the developer discharging unit discharges the increased amount of developer in the developing device. Is applicable.

以上、本実施形態によれば、供給搬送路9の搬送方向下流側の現像剤の嵩が現像剤排出口94の高さを越えた場合に、現像剤排出口94の高さまで到達した現像剤を、現像剤排出手段である現像剤排出口94及び排出搬送路2によって現像装置4の外に排出するものであるので、現像剤排出口94からの現像剤の排出によって供給搬送路9を搬送する現像剤が不足することを防止することができる。これにより、供給搬送路9から現像ローラ5へ必要量の現像剤を供給することができ、現像ローラ5から感光体1に安定した現像剤の供給を行うことができる。このため、感光体1上の静電潜像を良好にトナー像化することができ、画像抜けなどの異常画像の発生を防止し、良好な画像形成を行うことができる。

また、供給搬送路9の搬送方向下流側の現像剤の嵩が現像剤排出口94の高さを越えた現像剤を排出する構成であれば、現像装置4内の現像剤量が増加しても循環搬送路である攪拌搬送路10から供給搬送路9へと移動する現像剤量はあまり変化せず、攪拌搬送路10内の現像剤量が増加することによって、攪拌搬送路10内で現像剤が滞留して余剰開口部92を塞いで、供給搬送路9から攪拌搬送路10への現像剤の移動を妨げる構成であっても現像装置4内の現像量の増加に応じて、現像剤の排出を行うことができる。

また、供給搬送路9の搬送方向下流側の現像剤の嵩が現像剤排出口94の高さを越えた現像剤を排出する構成であれば、現像装置4内の現像剤量が増加すると攪拌搬送路10から供給搬送路9へと移動する現像剤量が増加し、供給搬送路9から余剰開口部92を通って攪拌搬送路10へと移動する現像剤量があまり変化しない構成であっても、現像装置4内の現像量の増加に応じて、現像剤の排出を行うことができる。

また、現像剤排出手段が、供給搬送路9の搬送方向下流側で仕切り壁135を挟んで供給搬送路9と隣り合うように配置され、供給搬送路9から排出された現像剤を搬送する排出搬送路2と、排出搬送路2と供給搬送路9とを連通するように仕切り壁に設けられた開口である現像剤排出口94とから構成することにより、簡単な構成で精度よく現像装置4内の現像剤を入れ替えることができる。

また、供給搬送路9と攪拌搬送路10とは、供給搬送路9の搬送方向下流側で供給循環仕切り壁である第一仕切り壁133を挟んで隣り合うように配置され、供給搬送路9の搬送方向下流側に到達した現像剤は、供給搬送路9と攪拌搬送路10とを連通するように第一仕切り壁133に設けられた開口である供給循環連通口である余剰開口部92を通って、攪拌搬送路10へ移動する構成であり、供給スクリュ8によって搬送される現像剤量または余剰開口部92を時間当りに通過する現像剤量は、現像装置4内の現像剤量の変化によって変わり、現像装置4内の現像剤量が増加すると供給搬送路9の搬送方向下流側の現像剤の嵩が上昇するため、簡単な構成で精度よく現像装置4内の現像剤を入れ替えることができる。

また、現像剤排出口94と余剰開口部92とが、供給搬送路9の現像剤搬送方向について同じ位置にあることにより、供給搬送路9から攪拌搬送路10に受け渡す現像剤量と、現像装置4の外に排出する現像剤量のバランスをとることが容易となる。

また、現像剤排出口94は余剰開口部92よりも上方に配置する簡易な構成で、現像剤排出口94は余剰開口部92よりも上方に配置するという簡易な構成で、攪拌搬送路10に供給すべき現像剤量が攪拌搬送路10に供給されない状態で現像剤が現像装置4の外に排出されることを防止しつつ、現像装置4内の現像剤量が所定量を越えた場合は、装置の外に排出することができる。これにより、余剰開口部92を介して現像剤を循環させつつ、現像剤排出口94で増加した分の現像剤を精度良く排出して現像剤を入れ替える構成を実現することができる。

また、供給搬送路9の搬送方向最下流端に、供給搬送部材である供給スクリュ8とは逆方向の搬送力を発生させる逆搬送部材としての逆スクリュ部8aを備えることにより、供給スクリュ8の回転軸の軸受に現像剤が入り込むことを防止し、軸受の破損を防止することができる。

また、供給搬送部材である供給スクリュ8と逆搬送部材である逆スクリュ部8aとの境界部に、供給スクリュ8の搬送方向に垂直で、且つ、その法線方向が供給スクリュ8の搬送方向と反対方向となり、現像剤の搬送方向への移動を妨げる下流端壁面39を備えることにより、下流端壁面39を伝って現像剤がせり上がるのを補助し、現像剤排出口94から現像剤を効率良く排出させることができるようになる。さらに、供給搬送路9の搬送方向下流端近傍でせり上がった現像剤が所定量の嵩を越えた場合に排出するものであるので、現像装置4内の現像剤量が増加していないにもかかわらず現像剤が排出されることを防止することができる。

また、供給搬送部材及び逆搬送部材は、回転軸と回転軸に螺旋状に設けられた羽部とを備え、回転することにより回転軸方向に現像剤を搬送するスクリュ状の供給スクリュ8及び逆スクリュ部8aであり、供給スクリュ8よりも逆スクリュ部8aのスクリュピッチを短くしたことにより、供給スクリュ8と逆スクリュ部8aとの軸部を受ける軸受部8bの損傷を防止することができる。

また、供給搬送部材及び逆搬送部材は、回転軸と回転軸に螺旋状に設けられた羽部とを備え、回転することにより回転軸方向に現像剤を搬送するスクリュ状の供給スクリュ8及び逆スクリュ部8aであり、供給スクリュ8よりも逆スクリュ部8aの羽部の外径を小さくしたことにより、下流側端面39の下端の位置を低くすることができ、より効率よく現像剤をせり上げることができる。

また、現像剤排出手段は通過した現像剤が排出される現像剤排出口94を供給搬送路9に備え、下流端壁面39の上端が現像剤排出口94の下端よりも上方であることによって、現像剤が下流側壁面39に沿ってせり上がって下流側壁面39の上端に到達する前に現像剤排出口94の下端に到達するため、確実に排出させることができる。

また、現像剤排出手段は通過した現像剤が排出される現像剤排出口94を供給搬送路9に備え、現像剤排出口94の供給搬送路9の搬送方向下流端である排出口下流端縁部94eの供給搬送路9の搬送方向についての位置と、下流端壁面39の供給搬送路9の搬送方向についての位置とが一致することにより、現像剤排出口94の排出口下流端縁部94eでの仕切り壁135の厚み分の平面と、下流端壁面39とを連続した平面として隙間なく形成することができる。このため、下流端壁面39をせり上がった現像剤はスムーズに現像剤排出口94を通過することができる。

また、現像剤排出手段は通過した現像剤が排出される現像剤排出口94を供給搬送路9に備え、供給搬送部材は、回転軸と回転軸に螺旋状に設けられた羽部とを備え、回転することにより回転軸方向に現像剤を搬送するスクリュ状の供給スクリュ8であり、現像剤排出口94の下端は、供給スクリュ8の羽部の上端よりも上方であることにより、供給スクリュ8が回転することで現像剤が跳ね上がることを防止し、現像装置4内の現像剤量が増加していないにもかかわらず現像剤が排出されることを防止することができる。

また、供給搬送路9、攪拌搬送路10及び回収搬送路7を備える一方向循環の現像装置4の、供給搬送路9の搬送方向下流端に到達する現像剤が滞留する位置で現像剤を排出することにより、プレミックストナーの補給によって増加した分の現像剤を適切に排出することができる。

また、画像形成装置としての複写機の現像手段として、現像装置4を備えることにより、現像剤を入れ替えることで現像手段の寿命を延ばしつつ、画像抜けなどの異常画像の発生を防止し、良好な画像形成を行うことができる。

As described above, according to the present embodiment, when the bulk of the developer on the downstream side in the transport direction of the

Further, if the developer is discharged so that the volume of the developer on the downstream side in the conveyance direction of the

Further, if the developer is discharged so that the volume of the developer on the downstream side in the transport direction of the

In addition, the developer discharge means is disposed adjacent to the

Further, the

Further, since the

Further, the

Further, by providing a

Further, the boundary between the

The supply conveyance member and the reverse conveyance member include a rotation shaft and a wing portion spirally provided on the rotation shaft, and rotate to rotate the screw-shaped

The supply conveyance member and the reverse conveyance member include a rotation shaft and a wing portion spirally provided on the rotation shaft, and rotate to rotate the screw-shaped

Further, the developer discharge means includes a

Further, the developer discharge means includes a

Further, the developer discharge means includes a

In addition, the developer is discharged at a position where the developer that reaches the downstream end in the transport direction of the

Further, by providing the developing

〔変形例1〕

なお、上述した実施形態の現像装置4は、供給搬送路9を攪拌搬送路10及び回収搬送路7よりも上方に設けた構成である。図4のように現像装置4の上部の省スペース化を図る構成を適用可能な現像装置4はこの構成に限るものではない。以下、変形例1として、供給搬送路9、攪拌搬送路10及び回収搬送路7からなる3つの現像剤搬送路を略同じ高さに設けた現像装置について説明する。なお、現像装置4の形状以外は実施形態と共通するので、相違点である現像装置4についてのみ説明する。

[Modification 1]

The developing

図17は変形例1にかかる現像装置4の概略構成図である。

図17に示すように感光体1は図中矢印G方向に回転しながら、その表面をスコロトロンチャージャ103により帯電される。帯電された感光体1の表面は不図示の露光装置より照射されたレーザ光Lにより静電潜像を形成された潜像に現像装置4からトナーを供給され、トナー像を形成する。

FIG. 17 is a schematic configuration diagram of the developing

As shown in FIG. 17, the surface of the

現像装置4は、図中矢印I方向に表面移動しながら感光体1の表面の潜像にトナーを供給し、現像する現像剤担持体としての現像ローラ5を有している。また、現像ローラ5に現像剤を供給しながら図17の奥方向に現像剤を搬送する供給搬送部材としての供給スクリュ8を有している。

現像ローラ5の供給スクリュ8との対向部から表面移動方向下流側には、現像ローラ5に供給された現像剤を現像に適した厚さに規制する現像剤規制部材としての現像ドクタ12を備えている。

現像ローラ5の感光体1との対向部である現像部から表面移動方向下流側には、現像部を通過した現像済みの現像剤を回収し、回収した回収現像剤を供給スクリュ8と同方向に搬送する回収搬送部材としての回収スクリュ6を備えている。供給スクリュ8を備えた供給搬送路9と回収スクリュ6を備えた回収搬送路7とは現像ローラ5の下方に並設されている。供給搬送路9と回収搬送路7との2つの搬送路は仕切り部材としての第二仕切り壁134によって仕切られている。

The developing

A developing

The developed developer that has passed through the developing section is collected downstream from the developing section, which is the facing portion of the developing

現像装置4は、供給搬送路9の回収搬送路7の反対側に並列して、攪拌搬送路10を設けている。攪拌搬送路10は、現像剤を攪拌しながら供給スクリュ8とは逆方向である図中手前側に搬送する攪拌搬送部材としての攪拌スクリュ11を備えている。供給搬送路9と攪拌搬送路10とは仕切り部材としての第一仕切り壁133によって仕切られている。第一仕切り壁133の図中手前側と奥側との両端は開口部となっており、供給搬送路9と攪拌搬送路10とが連通している。供給搬送路9内に供給され現像に用いられず供給搬送路9の搬送方向下流端まで搬送された余剰現像剤と、回収スクリュ6によって回収搬送路7の搬送方向下流端まで搬送された回収現像剤とは攪拌搬送路10に供給される。攪拌搬送路10は、供給された余剰現像剤と回収現像剤とを攪拌し、攪拌スクリュ11の搬送方向下流側に搬送する。そして、第一仕切り壁133に設けられた供給開口部より供給スクリュ8の搬送方向上流側の供給搬送路9内に現像剤を供給する。

The developing

第二仕切り壁134には回収スクリュ6の搬送方向最下流側である図中奥方向の端が開口部となっており、供給搬送路9と回収搬送路7とが連通している。回収スクリュ6の搬送方向下流端と、供給スクリュ8の搬送方向下流端と、攪拌スクリュ11の搬送方向上流端とで3つの搬送路が連通している。

そして、回収搬送路7の搬送方向下流端まで搬送された回収現像剤は供給搬送路9に移送される。また、回収現像剤と供給スクリュ8で搬送される現像ローラ5に供給されなかった現像剤は、連通している攪拌搬送路10に移送される。

攪拌搬送路10では攪拌スクリュ11によって、回収現像剤、余剰現像剤及び移送部で必要に応じて補給されるトナーを、回収搬送路7及び供給搬送路9の現像剤と逆方向に攪拌搬送する。そして、搬送方向下流側で連通している供給搬送路9の搬送方向上流側に攪拌された現像剤を移送する。なお、攪拌搬送路10の下方には、トナー濃度センサ127が設けられ、センサ出力によりトナー補給制御装置(図示せず)を作動し、不図示のトナーボトルから移送部へのトナー補給を行っている。

現像装置4のケーシングは3つの搬送スクリュの軸部で上下に分かれる一体成型された下ケーシング112及び上ケーシング113からなる。第一仕切り壁133は下ケーシング112の一部であり、第二仕切り壁134は、上ケーシング113に保持され、下ケーシング112と勘合する。

なお、上述のトナー補給制御装置として、公知のモーノポンプを用いる方式のものが採用できる。この方式によればトナーカートリッジの設置場所の制約が少ないため、画像形成装置内部のスペース配分に対し有利である。またトナーを適時補給できるため、現像装置4に大きなトナー貯留スペースを設けなくてすみ、現像装置4の小型化がはかれる。

The

Then, the recovered developer transported to the downstream end in the transport direction of the

In the agitating and conveying

The casing of the developing

As the above-described toner replenishment control device, a system using a known MONO pump can be employed. According to this method, there are few restrictions on the installation location of the toner cartridge, which is advantageous for space allocation in the image forming apparatus. Further, since the toner can be replenished in a timely manner, it is not necessary to provide a large toner storage space in the developing

図17に示すように、供給部材の最上部である供給スクリュ8のスクリュ頂点114が現像ローラ5の回転中心115よりも下方になるように配置されている。現像装置4では現像ローラ5の回転中心115とスクリュ頂点114とを結んだ直線と、回転中心115を通る水平な直線との角度θ1を30[°]に設定した。この角度θ1は供給スクリュ8の直径にも左右されるが、現像装置4の小型化からレイアウト上10[°]〜40[°]が望ましい。

現像ローラ5への現像剤の供給は現像ローラ5内に設けられた磁極が現像剤中の磁性キャリアをひきつけることによって行われる。上述のように、スクリュ頂点114が現像ローラ5の回転中心115よりも下方となるように配置することにより、現像剤の自重が現像ローラ5への現像剤の供給量に影響せず、磁力の大きさが現像剤の供給量に寄与する。これにより、供給搬送路9で搬送される現像剤の上部から確実に供給されるため、供給スクリュ8の搬送方向で供給搬送路9内の現像剤の嵩が均一でなくても、現像ローラ5に適正な量の現像剤を供給することができる。

As shown in FIG. 17, the screw apex 114 of the

The developer is supplied to the developing

従来の3つの現像剤搬送路を同じ高さに設けた現像装置では、攪拌搬送路10から供給搬送路9に現像剤を受け渡す供給開口部を現像領域幅よりも外側に設けていた。これにより、攪拌搬送路10及び供給搬送路9が、現像ローラ5及び回収搬送路7に比べて供給搬送路9の搬送方向上流端部が突き出した状態となっていた。

変形例1の現像装置4では、供給開口部を現像領域幅内に設けているので、現像ローラ5及び回収搬送路7に比べて攪拌搬送路10及び供給搬送路9が突き出していた部分がなくなり、現像装置4の省スペース化を図ることが出来る。

また、変形例1の現像装置4のように、回収搬送路7、攪拌搬送路10、及び供給搬送路9を略同じ高さに設けることにより、現像剤にかかるストレスを軽減し、現像剤の長寿命化を図ることができる。すなわち、3つの現像剤搬送経路を同じ高さに設けることにより、現像剤搬送経路内で現像剤を上方に持ち上げる必要がないため、現像剤に与えるストレスを軽減することができる。これにより、現像剤の劣化を抑制し、安定した画像品質を維持することができるようになる。

In the conventional developing device in which the three developer transport paths are provided at the same height, the supply opening for delivering the developer from the stirring

In the developing

Further, like the developing

〔変形例2〕

上述の実施形態では、供給搬送路9の搬送方向下流端近傍に供給搬送路9の搬送方向下流端近傍に現像剤排出口94を配置して、供給搬送路9の搬送方向下流端近傍の現像剤が所定量の嵩を越えた場合にその一部を排出する構成である。現像剤排出口94の位置としては供給搬送路9の下流端近傍に限るものではない。

供給搬送路9、攪拌搬送路10及び回収搬送路7を含む現像剤搬送路中の規制位置を通過する現像剤量を規制する現像剤搬送量規制手段を備え、現像剤搬送量規制手段によって規制され、滞留した現像剤の量が所定量を越えた場合に現像剤排出口94から現像剤が排出されるように、現像剤排出口94を配置すればよい。現像剤搬送量規制手段としては、一つの搬送路の途中に搬送路を狭めて通過量を規制する搬送量規制部材や、余剰開口部94などが上げられる。

上述の実施形態では余剰開口部92が現像剤搬送量規制手段として作用し、余剰開口部92の大きさによって余剰開口部92を通過して、供給搬送路9から攪拌搬送路10への受け渡される現像剤量が規制される。この受渡しのときに規制され供給搬送路9の搬送方向下流端近傍に滞留した現像剤が、所定量を越えて、所定の高さを越えたときに現像剤排出口94から所定量となるように排出が成される。

[Modification 2]

In the above-described embodiment, the

A developer conveyance amount regulating means for regulating the amount of developer passing through the regulation position in the developer conveyance path including the

In the above-described embodiment, the surplus opening 92 acts as a developer transport amount regulating means, passes through the surplus opening 92 depending on the size of the

以下、変形例2として、現像剤排出口94を供給搬送路9の下流端近傍以外の箇所に設けた構成について説明する。

図18は、一つの搬送路の途中に搬送路を狭めて通過量を規制する規制部材として、供給搬送路9の途中に搬送量規制壁48を設けた変形例2の構成の模式図である。

図18に示す供給搬送路9では、搬送量規制壁48の下端部である規制部材先端部48aと供給搬送路9の底面9aとの間が供給搬送路9の他の位置よりも断面積が狭く、現像剤の通過量を規制する規制部を形成している。そして、規制部を時間当りに通過できる現像剤の量よりも多くの現像剤が搬送量規制壁48の上流側に到達すると、規制部を通過できる現像剤量を越えた分の現像剤は規制部を通過することができず、規制部の上流側で滞留する。搬送量規制壁48は現像剤排出口94の下流に供給搬送路9の上面から壁が突出した形状となっており、搬送量規制壁48で規制された分の現像剤が搬送量規制壁48の壁面の上流側に滞留する。そして、現像装置4内の現像剤量が増加することでこの規制部の上流側で滞留する現像剤量が増加し、現像剤排出口94に到達する現像剤量となったときに現像剤が排出され始める。現像剤排出口94は、滞留した現像剤の嵩が設定された量となったときに排出されるように配置する高さや、開口の大きさが規定されている。

このように、搬送量規制部材48が規制して滞留した現像剤が現像剤排出口94から排出されるように現像剤排出口94の高さや幅を設定することにより、規制位置の近傍では現像剤排出口94の高さまで到達しない程度の現像剤が存在する状態で現像装置4内の現像剤量が安定した状態となる。また、滞留する現像剤は現像剤が常に移動している箇所の現像剤よりも飛び跳ねにくいので、滞留した箇所の現像剤量は現像装置4内の現像剤量の増減に合わせて適正に変化する。このため、滞留した現像剤を排出するものである変形例2では現像装置4内の現像剤量の必要量を確保することができる。

変形例2では、搬送量規制部材48を供給搬送路8の途中に設ける構成について説明したが、搬送量規制部材48を設ける位置としてはこれに限らず、現像装置4内の現像剤量の増減に応じて、搬送する現像剤の嵩の高さが変化する箇所であればよい。

Hereinafter, as a second modification, a configuration in which the

FIG. 18 is a schematic diagram of a configuration of

In the

Thus, by setting the height and width of the

In the second modification, the configuration in which the conveyance

1 感光体

2 排出搬送路

2a 排出搬送スクリュ

4 現像装置

5 現像ローラ

6 回収スクリュ

7 回収搬送路

8 供給スクリュ

8a 逆スクリュ部

9 供給搬送路

10 攪拌搬送路

11 攪拌スクリュ

12 現像ドクタ

14 張架ローラ

15 駆動ローラ

16 二次転写バックアップローラ

17 中間転写ユニット

18 プロセスカートリッジ

20 画像形成ユニット

21 光書込ユニット

22 二次転写装置

23 張架ローラ

24 紙搬送ベルト

25 定着装置

26 定着ベルト

27 加圧ローラ

90 ベルトクリーニング装置

91 供給開口部

92 余剰開口部

93 回収開口部

94 現像剤排出口

95 トナー補給口

100 プリンタ部

110 中間転写ベルト

133 第一仕切り壁

134 第二仕切り壁

135 仕切り壁

DESCRIPTION OF

Claims (15)

装置内に現像剤を補給する現像剤補給手段と、

該現像剤担持体に現像剤を供給しながら該現像剤担持体の軸線方向に沿って現像剤を搬送する供給搬送部材を備えた供給搬送路と、

該供給搬送路の搬送方向下流側に到達した現像剤を該供給搬送路の搬送方向上流側に搬送する循環搬送部材を備えた循環搬送路とを有する現像装置において、

該供給搬送路の搬送方向下流側の現像剤の嵩が所定の高さを越えた場合に該供給搬送路の搬送方向下流側の現像剤の一部を排出する現像剤排出手段を有し、

該供給搬送路の現像剤搬送方向下流部に、該供給搬送部材とは逆方向の搬送力を発生させる逆搬送部材を備え、

該供給搬送部材と該逆搬送部材との境界部に、該供給搬送部材の搬送方向に垂直で、且つ、その法線方向が該供給搬送部材の搬送方向と反対方向となり、現像剤の搬送方向への移動を妨げる壁面を備えることを特徴とする現像装置。 A developer carrying member that rotates by carrying a developer on the surface, and supplies toner to the latent image on the surface of the latent image carrying member at a position facing the latent image carrying member;

Developer replenishing means for replenishing developer in the apparatus;

A supply conveyance path provided with a supply conveyance member for conveying the developer along the axial direction of the developer carrier while supplying the developer to the developer carrier;

A developing device having a circulation conveyance path provided with a circulation conveyance member that conveys the developer that has reached the downstream side in the conveyance direction of the supply conveyance path to the upstream side in the conveyance direction of the supply conveyance path;

Have a developer discharging means for discharging a portion of the supply conveyance path downstream side of the developer when the bulk of the downstream side of the developer of the supply conveyance path exceeds a predetermined height,

A reverse conveyance member that generates a conveyance force in a direction opposite to that of the supply conveyance member at a downstream portion in the developer conveyance direction of the supply conveyance path;

At the boundary between the supply conveyance member and the reverse conveyance member, the direction perpendicular to the conveyance direction of the supply conveyance member and the normal direction thereof is opposite to the conveyance direction of the supply conveyance member, and the developer conveyance direction A developing device comprising a wall surface that prevents movement of the developing device .

上記現像剤排出手段は、

上記供給搬送路の搬送方向下流側で仕切り壁を挟んで該供給搬送路と隣り合うように配置され、該供給搬送路から排出される現像剤を搬送する排出搬送路と、

該排該仕切り壁の所定の高さに該排出搬送路と該供給搬送路とを連通するように設けられた開口である現像剤排出口とを有し、

該現像剤排出口の高さまで到達した現像剤を該現像剤排出口から該排出搬送路へ排出することを特徴とする現像装置。 The developing device 請 Motomeko 1,

The developer discharging means is

A discharge conveyance path that is disposed adjacent to the supply conveyance path across the partition wall on the downstream side in the conveyance direction of the supply conveyance path, and conveys the developer discharged from the supply conveyance path;

A developer discharge port which is an opening provided to communicate the discharge conveyance path and the supply conveyance path at a predetermined height of the discharge partition wall;

A developing device that discharges the developer that has reached the height of the developer discharge port from the developer discharge port to the discharge conveyance path.

上記供給搬送路と上記循環搬送路とは供給循環仕切り壁を挟んで隣り合うように配置され、

該供給搬送路の搬送方向下流側の該供給循環仕切り壁に供給搬送路と該循環搬送路とを連通する開口部として供給循環連通口を設け、

該供給搬送路の搬送方向下流側に到達した現像剤が、該供給循環連通口を通って、該循環搬送路へ移動可能に構成されていることを特徴とする現像装置。 The developing device according to claim 2 .

The supply conveyance path and the circulation conveyance path are arranged adjacent to each other across the supply circulation partition wall,

A supply circulation communication port is provided as an opening communicating the supply conveyance path and the circulation conveyance path on the supply circulation partition wall on the downstream side in the conveyance direction of the supply conveyance path,

3. A developing device, wherein the developer that has reached the downstream side of the supply conveyance path in the conveyance direction is configured to be movable to the circulation conveyance path through the supply circulation communication port.

上記現像剤排出口は上記供給搬送路の現像剤搬送方向について、上記供給循環連通口と同じ位置にあることを特徴とする現像装置。 The developing device according to claim 3 .

The developing device, wherein the developer discharge port is located at the same position as the supply circulation communication port in the developer transport direction of the supply transport path.

上記現像剤排出口は上記供給循環連通口よりも上方に配置されていることを特徴とする現像装置。 The developing device according to claim 3 or 4 ,

The developing device, wherein the developer discharge port is disposed above the supply circulation communication port.

上記循環搬送部材は、上記供給搬送路の搬送方向下流端に到達した現像剤を該供給搬送路の搬送方向上流端に搬送し、

上記現像剤排出手段は、該供給搬送路の搬送方向下流端近傍の現像剤の嵩が所定の高さを越えた場合に該供給搬送路の搬送方向下流端近傍の現像剤の一部を排出することを特徴とする現像装置。 The developing device according to claim 1, 2, 3, 4 or 5,

The circulating transport member transports the developer that has reached the downstream end in the transport direction of the supply transport path to the upstream end in the transport direction of the supply transport path,

The developer discharging means discharges a part of the developer near the downstream end in the transport direction of the supply transport path when the bulk of the developer near the downstream end in the transport direction of the supply transport path exceeds a predetermined height. A developing device.

上記供給搬送部材及び上記逆搬送部材は、回転軸と該回転軸に螺旋状に設けられた羽部とを備え、回転することにより該回転軸方向に現像剤を搬送するスクリュ状の供給スクリュ及び逆スクリュであり、

該供給スクリュよりも該逆スクリュのスクリュピッチを短くしたことを特徴とする現像装置。 Claim 1, 2, 3, 4, 5 or in the developing device 6,

Upper Symbol supply conveying member and the reverse conveying member, and a wing portion provided in a spiral shape on the rotary shaft and the rotary shaft, the screw-shaped feeding screw for conveying the developer in the rotation axis direction by rotating And a reverse screw,

A developing device characterized in that the screw pitch of the reverse screw is shorter than that of the supply screw.

上記供給搬送部材及び上記逆搬送部材は、回転軸と該回転軸に螺旋状に設けられた羽部とを備え、回転することにより該回転軸方向に現像剤を搬送するスクリュ状の供給スクリュ及び逆スクリュであり、

該供給スクリュよりも該逆スクリュの羽部の外径を小さくしたことを特徴とする現像装置。 The developing device according to claim 1, 2, 3, 4, 5, 6 or 7 .

The supply conveyance member and the reverse conveyance member each include a rotation shaft and a wing portion spirally provided on the rotation shaft, and a screw-shaped supply screw that conveys the developer in the rotation axis direction by rotating. Reverse screw,

A developing device characterized in that an outer diameter of a wing portion of the reverse screw is made smaller than that of the supply screw.

上記現像剤排出手段は通過した現像剤が排出される現像剤排出口を供給搬送路に備え、

上記壁面の上端は該現像剤排出口の下端よりも上方であることを特徴とする現像装置。 The developing device according to claim 1, 2, 3, 4, 5, 6, 7 or 8 .

The developer discharging means includes a developer discharge port for discharging the passed developer in the supply conveyance path,

The developing device according to claim 1, wherein an upper end of the wall surface is above a lower end of the developer discharge port.

上記現像剤排出手段は通過した現像剤が排出される現像剤排出口を供給搬送路に備え、

上記現像剤排出口の上記供給搬送路の搬送方向下流端である排出口下流端縁部の該供給搬送路の搬送方向についての位置と、上記壁面の該供給搬送路の搬送方向についての位置とが一致することを特徴とする現像装置。 The developing device according to claim 1, 2, 3, 4, 5, 6, 7, 8, or 9 .

The developer discharging means includes a developer discharge port for discharging the passed developer in the supply conveyance path,

The position of the conveyance direction of the supply conveyance path of the outlet downstream end edge a downstream end in the conveyance direction of the supply conveyance path of the developer discharge port, the conveyance direction of the supply conveyance path of the upper Kikabe surface of A developing device having a matching position.

上記現像剤排出手段は通過した現像剤が排出される現像剤排出口を供給搬送路に備え、

上記供給搬送部材は、回転軸と該回転軸に螺旋状に設けられた羽部とを備え、回転することにより該回転軸方向に現像剤を搬送するスクリュ状の供給スクリュであり、

該現像剤排出口の下端は、該供給スクリュの羽部の上端よりも上方であることを特徴とする現像装置。 The developing device according to claim 1, 2, 3, 4, 5, 6, 7, 8, 9 or 10 .

The developer discharging means includes a developer discharge port for discharging the passed developer in the supply conveyance path,

The supply conveyance member is a screw-shaped supply screw that includes a rotation shaft and a wing provided spirally on the rotation shaft, and conveys the developer in the rotation shaft direction by rotating,

The developing device, wherein a lower end of the developer discharge port is above an upper end of a wing portion of the supply screw.

現像剤として磁性キャリアとトナーとからなる二成分現像剤を備え、

上記潜像担持体と対向する箇所を通過後の上記現像剤担持体上から回収された現像剤を該現像剤担持体の軸線方向に沿って、且つ、上記供給搬送部材と同方向に搬送する回収搬送部材を備えた回収搬送路を有し、

上記循環搬送路は、現像に用いられずに該供給搬送路の搬送方向の最下流側まで搬送された現像剤と、該回収搬送路の搬送方向の最下流側まで搬送された現像剤との供給を受け、該現像剤担持体の軸線方向に沿って、且つ、現像剤を攪拌しながら該供給搬送部材とは逆方向に搬送する上記循環搬送部材としての攪拌搬送部材を備え、攪拌後の現像剤を該供給搬送路に供給する攪拌搬送路であり、

上記現像剤補給手段は該攪拌搬送路に現像剤を補給することを特徴とする現像装置。 The developing device according to claim 1,2,3,4,5,6,7,8,9,1 0 or 11,

A two- component developer comprising a magnetic carrier and a toner is provided as a developer,

The developer recovered from the developer carrier after passing through the portion facing the latent image carrier is transported along the axial direction of the developer carrier and in the same direction as the supply transport member. It has a collection conveyance path with a collection conveyance member,

The circulation conveyance path includes a developer conveyed to the most downstream side in the conveyance direction of the supply conveyance path without being used for development, and a developer conveyed to the most downstream side in the conveyance direction of the recovery conveyance path. A stirring and conveying member serving as the circulation conveying member that receives the supply and conveys the developer in the direction opposite to the supply and conveying member while stirring the developer along the axial direction of the developer carrying member, A stirring conveyance path for supplying the developer to the supply conveyance path;

The developing device, wherein the developer replenishing means replenishes the developer to the agitation transport path.

該潜像担持体表面を帯電させるための帯電手段と、

該潜像担持体上に静電潜像を形成するための潜像形成手段と、

該静電潜像を現像してトナー像化するための現像手段とを有する画像形成装置において、

該現像手段として、請求項1、2、3、4、5、6、7、8、9、10、11または12に記載の現像装置を用いることを特徴とする画像形成装置。 At least a latent image carrier;

Charging means for charging the surface of the latent image carrier;

Latent image forming means for forming an electrostatic latent image on the latent image carrier;

In an image forming apparatus having developing means for developing the electrostatic latent image into a toner image,

As developing means, claim 1,2,3,4,5,6,7,8,9,10,1 was 1 or an image forming apparatus which comprises using a developing device according to 12.

装置内に現像剤を補給する現像剤補給手段と、

該現像剤担持体に現像剤を供給しながら該現像剤担持体の軸線方向に沿って現像剤を搬送する供給搬送部材を備えた供給搬送路と、

該供給搬送路の搬送方向下流側に到達した現像剤を該供給搬送路の搬送方向上流側に搬送する循環搬送部材を備えた循環搬送路とを有する現像装置において、

該供給搬送路と該循環搬送路とを含む現像剤搬送路中の現像剤の一部を該現像剤搬送路の外部に排出する現像剤排出口と、該現像剤搬送路中を通過する現像剤の量を規制する現像剤搬送量規制手段とを備え、

該現像剤搬送量規制手段によって規制され、滞留した現像剤の量が所定量を越えた場合に該現像剤排出口から現像剤が排出されるように、該現像剤排出口を配置することを特徴とする現像装置。 A developer carrying member that rotates by carrying a developer on the surface, and supplies toner to the latent image on the surface of the latent image carrying member at a position facing the latent image carrying member;

Developer replenishing means for replenishing developer in the apparatus;