JP4953524B2 - 転送ロール - Google Patents

転送ロール Download PDFInfo

- Publication number

- JP4953524B2 JP4953524B2 JP2001208614A JP2001208614A JP4953524B2 JP 4953524 B2 JP4953524 B2 JP 4953524B2 JP 2001208614 A JP2001208614 A JP 2001208614A JP 2001208614 A JP2001208614 A JP 2001208614A JP 4953524 B2 JP4953524 B2 JP 4953524B2

- Authority

- JP

- Japan

- Prior art keywords

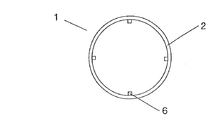

- transfer roll

- cylindrical

- members

- cylindrical members

- transfer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000012546 transfer Methods 0.000 title claims abstract description 73

- 239000000463 material Substances 0.000 claims abstract description 52

- 238000000034 method Methods 0.000 claims description 20

- 238000004519 manufacturing process Methods 0.000 claims description 12

- 238000003466 welding Methods 0.000 claims description 5

- 238000005304 joining Methods 0.000 claims description 4

- 206010036790 Productive cough Diseases 0.000 claims 2

- 210000003802 sputum Anatomy 0.000 claims 2

- 208000024794 sputum Diseases 0.000 claims 2

- 230000007423 decrease Effects 0.000 claims 1

- 238000007373 indentation Methods 0.000 claims 1

- 238000005259 measurement Methods 0.000 abstract description 18

- 230000008901 benefit Effects 0.000 description 10

- 229910052751 metal Inorganic materials 0.000 description 8

- 239000002184 metal Substances 0.000 description 8

- 238000012545 processing Methods 0.000 description 4

- 239000002699 waste material Substances 0.000 description 4

- 238000010586 diagram Methods 0.000 description 3

- 238000009826 distribution Methods 0.000 description 3

- 230000005540 biological transmission Effects 0.000 description 2

- 238000004364 calculation method Methods 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 230000002950 deficient Effects 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 238000013500 data storage Methods 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 239000000428 dust Substances 0.000 description 1

- 238000009760 electrical discharge machining Methods 0.000 description 1

- 239000004519 grease Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000000696 magnetic material Substances 0.000 description 1

- 230000005415 magnetization Effects 0.000 description 1

- 238000000691 measurement method Methods 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 238000012544 monitoring process Methods 0.000 description 1

- 239000000123 paper Substances 0.000 description 1

- 239000013618 particulate matter Substances 0.000 description 1

- 230000035699 permeability Effects 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 238000004886 process control Methods 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 229920002994 synthetic fiber Polymers 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G39/00—Rollers, e.g. drive rollers, or arrangements thereof incorporated in roller-ways or other types of mechanical conveyors

- B65G39/02—Adaptations of individual rollers and supports therefor

- B65G39/04—Adaptations of individual rollers and supports therefor the rollers comprising a number of roller forming elements mounted on a single axle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B38/00—Methods or devices for measuring, detecting or monitoring specially adapted for metal-rolling mills, e.g. position detection, inspection of the product

- B21B38/02—Methods or devices for measuring, detecting or monitoring specially adapted for metal-rolling mills, e.g. position detection, inspection of the product for measuring flatness or profile of strips

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B39/00—Arrangements for moving, supporting, or positioning work, or controlling its movement, combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills

- B21B39/008—Rollers for roller conveyors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H23/00—Registering, tensioning, smoothing or guiding webs

- B65H23/04—Registering, tensioning, smoothing or guiding webs longitudinally

- B65H23/044—Sensing web tension

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H27/00—Special constructions, e.g. surface features, of feed or guide rollers for webs

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C13/00—Rolls, drums, discs, or the like; Bearings or mountings therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2402/00—Constructional details of the handling apparatus

- B65H2402/60—Coupling, adapter or locking means

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Registering, Tensioning, Guiding Webs, And Rollers Therefor (AREA)

- Rolls And Other Rotary Bodies (AREA)

- Force Measurement Appropriate To Specific Purposes (AREA)

- Butt Welding And Welding Of Specific Article (AREA)

- Controlling Rewinding, Feeding, Winding, Or Abnormalities Of Webs (AREA)

- Sheets, Magazines, And Separation Thereof (AREA)

- Feeding And Guiding Record Carriers (AREA)

- Vending Machines For Individual Products (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SE0002558-5 | 2000-07-07 | ||

| SE0002558A SE517543C2 (sv) | 2000-07-07 | 2000-07-07 | Transportvals med givare och cylindrar sammansatta med medel med reducerat tvärsnitt samt tillverkning och system för mätning med denna |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2002122131A JP2002122131A (ja) | 2002-04-26 |

| JP2002122131A5 JP2002122131A5 (enExample) | 2008-08-28 |

| JP4953524B2 true JP4953524B2 (ja) | 2012-06-13 |

Family

ID=20280398

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2001208614A Expired - Fee Related JP4953524B2 (ja) | 2000-07-07 | 2001-07-09 | 転送ロール |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US6508115B2 (enExample) |

| EP (1) | EP1170240B1 (enExample) |

| JP (1) | JP4953524B2 (enExample) |

| AT (1) | ATE352506T1 (enExample) |

| DE (1) | DE60126194T2 (enExample) |

| ES (1) | ES2280285T3 (enExample) |

| SE (1) | SE517543C2 (enExample) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102707497B (zh) * | 2011-11-15 | 2014-08-06 | 京东方科技集团股份有限公司 | 一种摩擦布检查机及摩擦布检查方法 |

| WO2021030227A1 (en) * | 2019-08-09 | 2021-02-18 | Superior Industries, Inc. | Conveyor pulley apparatus, systems, and methods |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1573407B1 (de) * | 1965-10-05 | 1970-09-03 | Asea Ab | Anordnung bei Bandwalzwerken zum Messen der Verteilung des Bandzuges ueber die Bandbreite |

| FR2314471A1 (fr) * | 1975-06-13 | 1977-01-07 | Secim | Rouleau deflecteur pour la mesure et le controle de la planeite d'une tole tendue en deplacement |

| JPS5588918A (en) * | 1978-12-27 | 1980-07-05 | Kuroki Kogyosho:Kk | Carrier roll for hot metallic billet |

| DE2924315A1 (de) * | 1979-06-15 | 1980-12-18 | Betr Forsch Inst Angew Forsch | Vorrichtung zur messung der spannungsverteilung ueber die breite von biegsamen baendern |

| FR2468878A1 (fr) * | 1979-10-26 | 1981-05-08 | Secim | Dispositif de detection des defauts de planeite d'une bande tendue en deplacement |

| DE2944723A1 (de) * | 1979-11-06 | 1981-05-14 | Betriebsforschungsinstitut VDEh - Institut für angewandte Forschung GmbH, 4000 Düsseldorf | Vorrichtung zur messung der spannungsverteilung ueber die breite von biegsamen baendern |

| US4428244A (en) * | 1981-11-20 | 1984-01-31 | Sumitomo Light Metal Industries, Ltd. | Apparatus for measuring internal stress of strip during rolling process |

| JPS5985930A (ja) * | 1982-11-10 | 1984-05-18 | Hitachi Ltd | 形状検出装置 |

| JPS6084152A (ja) * | 1983-06-02 | 1985-05-13 | 株式会社 サタケ | 精穀機の押圧調整装置 |

| SE461298B (sv) * | 1988-06-02 | 1990-01-29 | Asea Brown Boveri | Planhetsmaetare foer valsade band |

| FR2684441A1 (fr) * | 1991-12-02 | 1993-06-04 | Siderurgie Fse Inst Rech | Rouleau mesureur de planeite d'une bande fabriquee en continu. |

| JPH09145503A (ja) * | 1995-11-27 | 1997-06-06 | Kawasaki Steel Corp | ストリップの形状検出装置 |

| FI105804B (fi) * | 1997-01-30 | 2000-10-13 | Valmet Corp | Ulosottotela, levitystela tai vastaava rainamaista materiaalia varten |

-

2000

- 2000-07-07 SE SE0002558A patent/SE517543C2/sv not_active IP Right Cessation

-

2001

- 2001-06-02 EP EP01113445A patent/EP1170240B1/en not_active Expired - Lifetime

- 2001-06-02 DE DE60126194T patent/DE60126194T2/de not_active Expired - Lifetime

- 2001-06-02 ES ES01113445T patent/ES2280285T3/es not_active Expired - Lifetime

- 2001-06-02 AT AT01113445T patent/ATE352506T1/de active

- 2001-06-15 US US09/880,785 patent/US6508115B2/en not_active Expired - Lifetime

- 2001-07-09 JP JP2001208614A patent/JP4953524B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| SE517543C2 (sv) | 2002-06-18 |

| ATE352506T1 (de) | 2007-02-15 |

| US20020005067A1 (en) | 2002-01-17 |

| EP1170240A2 (en) | 2002-01-09 |

| EP1170240A3 (en) | 2004-06-16 |

| DE60126194T2 (de) | 2007-12-13 |

| EP1170240B1 (en) | 2007-01-24 |

| SE0002558L (sv) | 2002-01-08 |

| US6508115B2 (en) | 2003-01-21 |

| SE0002558D0 (sv) | 2000-07-07 |

| ES2280285T3 (es) | 2007-09-16 |

| DE60126194D1 (de) | 2007-03-15 |

| JP2002122131A (ja) | 2002-04-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0537329B1 (en) | Control of web winding | |

| EP0301008B1 (en) | Shapemeter | |

| ITMI20092248A1 (it) | Metodo e apparato per la rilevazione della geometria di cilindri operativi | |

| JP4953524B2 (ja) | 転送ロール | |

| KR100245409B1 (ko) | 탠덤 냉간 압연 방법 및 탠덤 냉간 압연기 | |

| JP2008188647A (ja) | ディンプル付きチューブの製造方法 | |

| CN1645035A (zh) | 平直度测量辊 | |

| JP2009047665A (ja) | 膜厚分布測定装置および塗膜形成装置 | |

| KR20220157899A (ko) | 측정 롤러 위로 안내되는 스트립 형상 제품의 특성을 검출하기 위한 측정 롤러, 측정 롤러 위로 안내되는 스트립 형상 제품의 특성을 검출하기 위한 측정 롤러의 용도, 및 스트립 형상 제품의 스트립 에지의 위치를 결정하기 위한 방법 | |

| JP4372662B2 (ja) | 形状検出装置及び形状検出プログラム | |

| CN100402168C (zh) | 张力板形仪 | |

| JP3216320B2 (ja) | 鋼板の板厚変動測定装置 | |

| JP2011036890A (ja) | 厚板剪断設備および鋼板蛇行防止方法 | |

| JP2021133411A (ja) | 金属帯の圧延制御方法、圧延制御装置、及び製造方法 | |

| CN108543815B (zh) | 整辊式板形检测辊及其板形检测方法 | |

| JP2987744B2 (ja) | 形状センサーロール | |

| JP3512227B2 (ja) | 形状測定ローラ | |

| CN218430382U (zh) | 幅材生产设备及用于幅材生产设备的压辊 | |

| JP2978056B2 (ja) | 圧延機のロール間接触摩耗予測方法 | |

| JP2001183129A (ja) | 円周長情報自動測定方法及びその装置並びにシート状物巻取方法 | |

| JPH02223814A (ja) | ロールプロフィール測定方法 | |

| JPH0328962B2 (enExample) | ||

| Philipp Bratfisch et al. | Development and validation of a continuous production concept for thermoplastic honeycomb | |

| JPH04262812A (ja) | 圧延板の形状測定装置 | |

| JP6477629B2 (ja) | 鋼板表面の凹凸欠陥の検査装置および鋼板表面の凹凸欠陥の検査方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20080610 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080610 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110412 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110708 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20111025 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111227 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120214 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120313 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150323 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |