JP4944908B2 - Harvesting machine - Google Patents

Harvesting machine Download PDFInfo

- Publication number

- JP4944908B2 JP4944908B2 JP2009002688A JP2009002688A JP4944908B2 JP 4944908 B2 JP4944908 B2 JP 4944908B2 JP 2009002688 A JP2009002688 A JP 2009002688A JP 2009002688 A JP2009002688 A JP 2009002688A JP 4944908 B2 JP4944908 B2 JP 4944908B2

- Authority

- JP

- Japan

- Prior art keywords

- headlamp

- lens

- harvesting machine

- self

- valves

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000003306 harvesting Methods 0.000 title claims description 14

- 238000012794 pre-harvesting Methods 0.000 claims description 12

- 230000001678 irradiating effect Effects 0.000 claims description 6

- 244000025254 Cannabis sativa Species 0.000 claims description 3

- 241000209504 Poaceae Species 0.000 claims description 2

- 238000005520 cutting process Methods 0.000 description 28

- 238000009333 weeding Methods 0.000 description 21

- 235000013339 cereals Nutrition 0.000 description 13

- 210000000078 claw Anatomy 0.000 description 8

- 238000005286 illumination Methods 0.000 description 8

- 241000196324 Embryophyta Species 0.000 description 6

- 238000007781 pre-processing Methods 0.000 description 6

- 230000003028 elevating effect Effects 0.000 description 3

- 244000291564 Allium cepa Species 0.000 description 2

- 235000002732 Allium cepa var. cepa Nutrition 0.000 description 2

- 244000000626 Daucus carota Species 0.000 description 2

- 235000002767 Daucus carota Nutrition 0.000 description 2

- 240000007594 Oryza sativa Species 0.000 description 2

- 235000007164 Oryza sativa Nutrition 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 235000009566 rice Nutrition 0.000 description 2

- 208000019300 CLIPPERS Diseases 0.000 description 1

- 241000209140 Triticum Species 0.000 description 1

- 235000021307 Triticum Nutrition 0.000 description 1

- 208000021930 chronic lymphocytic inflammation with pontine perivascular enhancement responsive to steroids Diseases 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

Images

Description

本発明は、自走機体に搭乗型の運転部を設け、前記自走機体の前部に収穫前処理部を設けた収穫機に関する。 The present invention relates to a harvesting machine in which a self-propelled airframe is provided with a boarding type driving unit, and a pre-harvest processing unit is provided in front of the self-propelled airframe.

従来、例えば特許文献1に示されるように、運転部5の前面部に前照灯6を設け、その上方に作業灯8を設けたものがあった。

また、特許文献2に示されるように、刈取装置1(収穫前処理部に相当)の穀稈搬送部

2上方を覆う防塵カバー3を、前部カバー4と後部カバー5に分割し、前部カバー4を固定するとともに前部カバー4の前端部に前照灯33を取付け、後部カバー5を前方側の開放位置にスライドさせると、後部カバー5が前照灯33の上部を覆い、前照灯33が、通常の前方への照射領域に加えて、後部カバー5の内面で反射する照射領域により分草体25近傍を照射することができるものがあった。

Conventionally, for example, as shown in

Moreover, as shown in

収穫機によって夜間に作業をする際、前方を前後方向に広い範囲にわたって照明することができると、収穫前処理部の前端付近もさらにその前方も照明されて収穫前処理部を作物に対して位置合わせしやすくなるとともに走行先の状況を確認しやすくなり、作業が行いやすくなる。 When working at night with a harvester, if the front can be illuminated in a wide range in the front-rear direction, the front end of the pre-harvest processing unit is also illuminated in front of it, and the pre-harvest processing unit is positioned with respect to the crop. This makes it easier to match and makes it easier to check the status of the destination, making work easier.

上記した従来の技術を採用して照明範囲を広くすると、照明灯を数多く装備したり、照明装置以外の部材に優れた反射器機能を備えさせたりする必要があり、構造面やコスト面で不利になりがちであった。

また、特許文献2に示される技術を採用すると、収穫前処理部の前端付近が照明されるようにすると、後部カバーを開放位置にすることから、防塵カバーによる防塵作用が低下する問題があった。

If the above-mentioned conventional technology is adopted to widen the illumination range, it is necessary to equip many illumination lamps or to provide an excellent reflector function to members other than the illumination device, which is disadvantageous in terms of structure and cost. Tended to be.

Moreover, when the technique shown in

本発明の目的は、広い照明範囲を構造面やコスト面で有利に確保することができ、かつ、作業に支障が出ないようにして確保することができる収穫機を提供することにある。 An object of the present invention is to provide a harvester that can advantageously ensure a wide illumination range in terms of structure and cost, and that can be ensured without impeding work.

本第1発明にあっては、

自走機体に搭乗型の運転部が設けられ、

前記自走機体の前部に、茎稈引起し装置と分草具と前方を照射する前照灯装置とを有する収穫前処理部が設けられ、

前記分草具及び前記前照灯装置が前記収穫前処理部の右及び左の横側部に設けられ、

前記前照灯装置に、複数のバルブと、前記複数のバルブを覆う正面視で縦長のレンズと、が備えられ、

前記レンズは、機体側面視で前記レンズの前面が前記茎稈引起し装置の前面に沿うように構成されている。

In the first invention ,

Operation of the riding type are provided in the own run airframe,

The front of the front Symbol self airframe, pre-harvest processing unit is provided with a headlight device for irradiating the front and stems稈引cause device and minute grass tool,

Before SL min grasses instrument and said headlamp apparatus is provided next to the side of the right and left of the pre-harvest processing unit,

The headlamp device includes a plurality of bulbs, and a vertically long lens in front view covering the plurality of bulbs,

The lens is configured such that the front surface of the lens is raised from the side of the fuselage and is along the front surface of the device.

本第2発明にあっては、In the second invention,

前記レンズは、機体側面視で前記茎稈引起し装置の上部と重複するように構成されている。The lens is configured to overlap with the upper part of the stem raising device in a side view of the body.

本第3発明にあっては、In the third invention,

前記レンズは、機体前方に向く前面部と、前記前面部と連続的に形成され、機体横外方向に向く側面部とを備えている。The lens includes a front portion facing the front of the body and a side portion formed continuously with the front portion and facing the lateral direction of the body.

本第4発明にあっては、

前記レンズは、側面視で縦長に形成されている。

In the fourth invention ,

The lens is formed vertically long in a side view.

本第5発明にあっては、In the fifth invention,

前記レンズのうち前記前面部と前記側面部とに亘る部分が、湾曲した形状に形成されている。A portion of the lens that extends between the front surface portion and the side surface portion is formed in a curved shape.

本第6発明にあっては、In the sixth invention,

前記レンズ全体が、湾曲した形状に形成されている。The entire lens is formed in a curved shape.

本第7発明にあっては、

前記複数のバルブの夫々は、上下方向に並べて設けられている。

In the seventh invention ,

Each of the plurality of valves is provided side by side in the vertical direction.

本第8発明にあっては、In the eighth invention,

前記バルブの夫々に対応する複数のリフレクタを備え、前記複数のリフレクタは一体的に形成されている。A plurality of reflectors corresponding to each of the valves are provided, and the plurality of reflectors are integrally formed.

本第9発明にあっては、In the ninth invention,

一体的に形成された前記リフレクタは、前記茎稈引起し装置の傾きに沿うように構成されている。The integrally formed reflector is configured so as to follow the inclination of the stem raising device.

本第10発明にあっては、In the tenth invention,

前記複数のバルブの夫々は、最も下側のバルブが最も前方に位置するように、上下方向に並べて設けられている。Each of the plurality of valves is provided side by side in the vertical direction so that the lowermost valve is positioned forward.

本第11発明にあっては、In the eleventh invention,

前記複数のバルブの夫々は、上側になるほど機体後方に位置するように、上下方向に並べて設けられている。Each of the plurality of valves is arranged side by side in the vertical direction so as to be located at the rear of the machine body as it goes upward.

本第12発明にあっては、In the twelfth invention,

前記バルブの夫々に対応する複数のリフレクタを備え、A plurality of reflectors corresponding to each of the valves;

前記複数のバルブの光の夫々が異なる方向に向けて照射されるように、前記複数のバルブ向きと前記複数のリフレクタの向きとが設定されている。The direction of the plurality of bulbs and the direction of the plurality of reflectors are set so that each of the light from the plurality of bulbs is irradiated in different directions.

以下、本発明の実施例を図面に基づいて説明する。

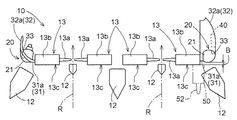

図1,2に示すように、クローラ走行装置1によって自走する自走機体の横方向での一端側の前部に、運転座席2などが装備された搭乗型の運転部3、及び、運転座席2の下方に位置するエンジンが装備された原動部を設け、前記自走機体の機体フレーム4の前部に、刈取り前処理部10の前処理部フレーム本体11の基部を回動自在に連結するとともに、この前処理部フレーム本体11にリフトシリンダ5を連動させ、前記機体フレーム4の後部側に脱穀装置6及び穀粒タンク7を設けて、稲、麦などを収穫するコンバインを構成してある。

Embodiments of the present invention will be described below with reference to the drawings.

As shown in FIGS. 1 and 2, a riding-

すなわち、リフトシリンダ5を伸縮操作すると、このリフトシリンダ5が前処理部フレーム本体11を機体フレーム4に対して上下に揺動操作し、刈取り前処理部10を分草具12や刈取装置14などが地面上近くに位置した下降作業状態と、分道具12などが地面上から高く上昇した上昇非作業状態とに自走機体に対して揺動昇降操作する。刈取り前処理部10を下降作業状態にして自走機体を走行させると、刈取り前処理部10は、自走機体横方向に並ぶ複数個の前記分草具12によって植立穀稈を刈取り対象と非刈取り対象とに分草するとともに刈取り対象の植立穀稈を茎稈引起し経路Rに導入し、各分草具12からの植立穀稈をこの穀稈に対応する茎稈引起し装置13によって引起し処理するとともに一つの前記刈取装置14によって刈取り処理し、刈取装置14からの刈取穀稈を供給装置15によって機体後方向きに搬送して脱穀装置6の脱穀フィードチェーン6aの始端部に供給する。脱穀装置6は、脱穀フィードチェーン6aによって刈取穀稈の株元側を機体後方側に挟持搬送しながらその穂先側を扱室(図示せず)に供給して脱穀処理する。穀粒タンク7は、脱穀装置6からの脱穀粒を回収して貯留していく。

That is, when the

刈取り前処理部10についてさらに詳述すると、この刈取り前処理部10は、図1,3などに示す如く構成してある。

すなわち、自走機体前後向きの前記前処理部フレーム本体11、この前処理部フレーム本体11の前端部に中間部が連結された自走機体横向きの支持部材17、この支持部材17の自走機体横方向での複数箇所から自走機体前方向きに延出された分草杆18などによって前処理部フレームを構成し、前記各分草杆18の先端部に前記分草具12を固定し、隣り合う一対の分草杆18どうしの間に前記茎稈引起し経路Rを設けるとともに、各茎稈引起し経路Rの横一端側に、前記茎稈起し装置13を上端側ほど自走機体後方側に位置した傾斜状態で設け、前記分草杆18の基端部にバリカン形の前記刈取装置14を設け、前記引起し装置13の後方に前記供給装置15を設けて構成してある。

The

That is, the pretreatment

図1に示すように、刈取り前処理部10の両横側に、茎稈引起し装置13の後側の横側方を覆う横カバー30、供給装置15の上方を覆う防塵カバー19を設けてある。図3,4などに示すように、左右いずれの横カバー30も、自走機体前方向きの前向き面31aを有した前側板部31と、自走機体横外側方向きの横向き面32aを有した横側板部32とを備えるように屈曲成形した屈曲板金で成り、自走機体横方向に並ぶ前記複数個の茎稈引起し装置13のうちの最も横外側に位置する茎稈引起し装置13の引起しケース13bの横外側に連設してある。左右いずれの横カバー30も、これの前記前向き面31aが引起しケース13bの自走機体前方向きの前面13cに沿った状態になるように構成してある。左右いずれの横カバー30の前記前向き面31aも、引起しケース13bの前記前面13cも、上端側ほど自走機体後方側に位置する状態に傾斜した傾斜面になっている。

As shown in FIG. 1, on both sides of the

図4に破線で示すように、前記各茎稈引起し装置13は、前記引起しケース13bの内部に、無端式の引起しチェーン13dを駆動スプロケット13eと遊転輪体13fとに巻回して設けて構成してある。

As shown by the broken lines in FIG. 4, each of the

引起しチェーン13dが前記駆動スプロケット13eによって回動駆動されると、引起しチェーン13dの複数箇所に起伏揺動自在に設けある引起し爪13aが順次に、引起しケース13bの自走機体横方向での一端側の引起し側を上昇移動し、引起しケース13bの自走機体横方向での他端側の戻り側を下降移動する。引起し側を上昇移動する引起し爪13aは、引起しケース13bの内部に位置する起立ガイド(図示せず)による起立操作のために引起しチェーン13dに対して起立した姿勢になって引起し爪13aの先端側が引起しケース13bからその横外側に突出した状態で上昇移動する。引起し爪13aが引起し側の終端部に到達すると、引起しケース13bの内部に位置する倒伏ガイド(図示せず)が倒伏操作するのであり、引起し爪13aは、起立姿勢から倒伏姿勢に姿勢変化して戻り側に移動して引起しケース13bの内部を倒伏姿勢で下降移動し、引起しケース13bの下端部で戻り側から引起し側に戻るようになっている。

When the elevating

これにより、各茎稈引起し装置13は、引起しケース13bの下端部で戻り側から引起し側に戻って起立姿勢になった引起し爪13aを分草具12からの植立穀稈に係止させ、この植立穀稈を引起しケース13bから自走機体横向きに突出した起立姿勢で上昇移動する引起し爪13aによって引起し処理する。

As a result, each stem-pick-up

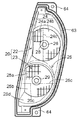

図3,4などに示すように、刈取り前処理部10の両横端の角部に、前照灯装置20を茎稈引起し装置13の上端部のやや横外側に位置するように配置して設けてある。 As shown in FIG. It is provided.

左右いずれの前照灯装置20も、図3,4に示す如く前記横カバー30の前記前側板部31と前記横側板部32とによって形成される角部に設けた前照灯装置組み付け凹部33に自走機体上下方向に並べて配置した一対の前照灯22,23を備えて構成してある。

As shown in FIGS. 3 and 4, the left and

左右いずれの前照灯装置20においても、次の如く構成してある。

すなわち、横カバー30の前側板部31の前向き面31aは、茎稈引起し装置13の引起しケース13bの前記前面13cに沿って傾斜していることから、前照灯装置組み付け凹部33は、自走機体上方側ほど自走機体後方側に位置する状態に傾斜した傾斜部分に位置している。また、前照灯装置組み付け凹部33は、横カバー30の前記前側板部31と前記横側板部32とにわたって切欠きを設けることによって構成してあることから、自走機体前方向きにも、自走機体横外側向きにも開口した凹部になっており、前照灯装置20は、自走機体の前方向きに照射する他、自走機体横外側向きにも照射しやすくなっている。

Both the left and

That is, since the forward facing

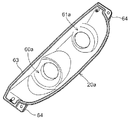

図7,9などに示すように、上下一対の前照灯22,23のうちの上側前照灯22も下側前照灯23も、前記前照灯装置組み付け凹部33の内部で前記横カバー30に固定された前照灯ケース20a、この前照灯ケース20aに止着されたリフレクタ24,25、このリフレクタ24,25の底部に位置するバルブ支持部26,27に支持されたバルブ28,29、前照灯ケース20a前側に装着されたレンズ21を備えて構成してある。上側前照灯22の前照灯ケース20aと、下側前照灯23の前照灯ケース20aとは、一体部品に成形してある。上側前照灯22のリフレクタ24と、下側前照灯23のリフレクタ25とは、一体部品に成形してある。上側前照灯22のレンズ21と、下側前照灯23のレンズ21とは、一体部品に成形してあって、全体として正面視でも側面視でも縦長となっている。そして、図7に示すように、レンズ21は、機体前方に向く前面部121aと、前面部121aと連続的に形成され、機体横外方向に向く側面部121bと、を備えている。図7に示すごとく、レンズ21のうち前面部121aと側面部121bとに亘る部分は、湾曲した形状に形成され、図7及び図9に示すごとく、レンズ21は、全体として湾曲した形状に形成されている。

As shown in FIGS. 7, 9, etc., the

図9,10,11に示すように、下側前照灯23のリフレクタ25に、反射特性が異なる2種のリフレクタ部25a,25bを境界線25cで自走機体上下方向に分かれて位置するようにして設け、上側前照灯22のリフレクタ24に、反射特性が異なる2種のリフレクタ部24a,24bを境界線24cで自走機体横方向に分かれて位置するようにして設けてある。下側前照灯23の2種のリフレクタ部25,25bも、上側前照灯22の2種のリフレクタ部24a,24bも不連続な3次元面を利用して構成してある。

As shown in FIGS. 9, 10, and 11, the

下側前照灯23の2種のリフレクタ部25a,25bの反射特性は、下側前照灯23のバルブ29から出て2種のリフレクタ部25a,25bのうちの上側リフレクタ部25aで反射して自走機体前方向きに照射される光が自走機体下方向きの照射向きで、かつ最も横端に位置する分草具12の先端部が照射範囲に入る状態に照射され、下側前照灯23のバルブ29から出て2種のリフレクタ部25a,25bのうちの下側リフレクタ部25bで反射して自走機体前方向きに照射される光が上側リフレクタ部25aによる照射向きよりも自走機体上向きの照射向きで照射され、刈取り前処理部10が下降作業状態にあれば、下側リフレクタ部25bで自走機体前方向きに照射される光が地面に対して平行又はそれに近い光になる反射特性に設定してある。

The reflection characteristics of the two types of

上側前照灯22の2種のリフレクタ部24a,24bの反射特性は、上側前照灯22のバルブ28から出て2種のリフレクタ部24a,24bのうちの内側リフレクタ部24aで反射して自走機体前方向きに照射される光がほぼ直前方向きの照射向きで照射されて刈取り前処理部10の自走機体横方向での中心よりやや自走機体横外側で前方を照射し、上側前照灯22のバルブ28から出て2種のリフレクタ部24a,24bのうちの外側リフレクタ部24bで反射して自走機体前方向きに照射される光が内側リフレクタ部24aによる照射向きよりも自走機体横方向での内側向きの照射向きで照射される反射特性に設定してある。

The reflection characteristics of the two types of

図9,10に示すように、前記両リフレクタ24,25を構成しているリフレクタ部材の下部に上向き反射舌部25dを設けてあるとともに、この上向き反射舌部25dは、バルブ29からの光の一部をリフレクタ部25a,25bによる反射向きよりも上向きに反射させ、これにより、刈取り前処理部10を上昇非作業状態に上昇させた状態において、バルブ29からの光の一部が対向車に向けて照射されないようにしている。

As shown in FIGS. 9 and 10, an upward reflecting

図1に示す如く下側前照灯23のバルブ29の光軸29aが最も横端に位置する分草具12の先端12aを通るようにして前照灯装置20を組み付けてある。

As shown in FIG. 1, the

左側の前照灯装置20において、図7に示すように、上側前照灯22及び下側前照灯23のバルブ28,29は、自走機体の前後向きに対して約15度の傾斜角度Aで左横外向きに傾斜した取り付け姿勢で支持されている。図示しないが、右側の前照灯装置20において、上側前照灯22及び下側前照灯23のバルブ28,29は、自走機体の前後向きに対して約15度の傾斜角度Aで右横外向きに傾斜した取り付け姿勢で支持されている。

In the

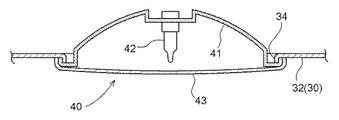

図1に示すように、刈取り前処理部10の両横側のうち、運転部3に対して遠い方の横側に、側照灯40を設けてある。

As shown in FIG. 1,

図8に示すように、前記側照灯40は、前記横カバー30の前記横側板部32に貫通孔を備えさせて設けた側照灯組み付け凹部34に配置して横カバー30に固定されたリフレクタ41と、このリフレクタ41に支持されたバルブ42と、リフレクタ41の前部に止着されたレンズ43とを備えて構成してある。

As shown in FIG. 8, the

これにより、図2に側照灯40による照射範囲を示し、図2に刈取り前処理部10が下降作業状態に下降された際に左右の前照灯装置20によって照射される自走機体平面視での照射範囲を示し、図6(a)に刈取り前処理部10が下降作業状態に下降された際に左右の前照灯装置20が照射する自走機体側面視での照射範囲を示し、図6(b)に刈取り前処理部10がストロークエンドまで上昇した上昇非作業状態に上昇された際に左右の前照灯装置20が照射する自走機体側面視での照射範囲を示すように、収穫作業を行なう際、夜間であっても、刈取り前処理部10を下降作業状態に下降させることから、左側の前照灯装置20の上側前照灯22と下側前照灯23とによって車体横方向に並ぶ前記分草具12のうちの最も車体左横外側に位置する分草具12の先端部、及びこの分草具12の左横外側方と前方の地面上を照射する照射範囲LDを照射しながら、右側の前照灯装置20の上側前照灯22と下側前照灯23とによって車体横方向に並ぶ前記分草具12のうちの最も車体右横外側に位置する分草具12の先端部、及びこの分草具12の右横外側方と前方の地面上を照射する照射範囲RDを照射しながら作業を行なうことができる。このとき、左側の前照灯装置20の上側前照灯22や下側前照灯23による自走機体横外側向きの照明に併せ、側照灯40による照明範囲Sの照明によっても刈取り前処理部10の横端付近で未刈り穀稈を照明し、殊に未刈り穀稈の株元付近を照明し、分草具12を未刈り穀稈に対して位置合わせしやすくなっている。

2 shows the irradiation range by the

路上走行など非作業状態で走行する際、夜間であっても、刈取り前処理部10をストロークエンドまで上昇させた上昇非作業状態に上昇させることにより、左側の前照灯装置20の上側前照灯22と下側前照灯23とにより、刈取り前処理部10が下降作業状態にある場合の前記照射範囲LDよりも自走機体から前方に離れた地面上を照射する照射範囲LUを照射しながら、右側の前照灯装置20の上側前照灯22と下側前照灯23とにより、刈取り前処理部10が下降作業状態にある場合の前記照射範囲RDよりも自走機体から前方に離れた地面上を照射する照射範囲RUを照射しながら走行することができる。このとき、前記上向き反射舌部25dによる上向き反射により、対向車に眩しさを与えにくいように前方を照明しながら走行することができる。

When traveling in a non-working state such as on the road, the upper headlight of the

左右いずれの前照灯装置20においても、図5に示すように、上側前照灯22も下側前照灯23も茎稈引起し装置13の引起しケース13bの前記前面13cよりも自走機体後方側に後退差Bだけ後退して位置した状態になるように、両前照灯22,23のレンズ21の外側面が引起しケース13bの前面13cよりもやや自走機体後方側に後退して位置するようにして前照灯装置20を前照灯装置組み付け凹部33に組み付けてある。これにより、図4,5に二点鎖線で示す如く最も横端に位置する茎稈引起し装置13の前側に強制分草装置50を装着する際、前照灯装置20が障害物になりにくくて強制分草装置50が茎稈引起し装置13の引起しケース13bの前面13cに接近して沿いやすくなっている。

強制分草装置50は、分草ケース51から自走機体前方側に突出した状態で上昇移動する分草爪52によって植立穀稈を刈取り対象と非刈取り対象とに分草するものである。

In both the left and

The forced

尚、図1,3に示すように、左右いずれの横カバー30も、一対のキャッチャー35を係合状態と係合解除状態とに切換え操作するだけで操作容易に脱着することができるように構成した下部カバー30aと、この下部カバー30aとは別部品になっているとともに前記前照灯装置20及び側照灯40を備えた上部カバー30bとによって構成してある。

As shown in FIGS. 1 and 3, the left and right lateral covers 30 can be easily detached by simply switching the pair of

図9,13に示すように、前記前照灯ケース20aの裏面側に、下側前照灯23のリフレクタ25が入り込む前向き凹部60aの裏側に位置する凹部60、上側前照灯22のリフレクタ24が入り込む前向き凹部61aの裏側に位置する凹部61、一方の凹部61を挟んで前照灯装置上下方向に並んだ状態で突出する一対の取り付け脚部62,62を設けてある。各取り付け脚部62は、前照灯装置20を横カバー30の支持部(図示せず)に連結するものである。図12に示すように、前記前照灯ケース20aの表面側に、レンズ21の全周囲での端部が当て付けられるレンズ当て部63を閉ループ形状に形成して設け、前照灯ケース20aの前記レンズ当て部63の外側に位置する角部に、レンズ21が締め付け連結されるレンズ連結部64を設けてある。これにより、前照灯ケース20a及び前照灯装置20は、剛性が向上した構造を備えた状態になっている。

As shown in FIGS. 9 and 13, the

〔別実施形態〕

図14は、別の実施形態を備えた前照灯装置20を示し、この前照灯装置20にあっては、レンズ21に、上側前照灯22のバルブ28に対応する上側屈折投光部21a、及び、下側前照灯23のバルブ29に対応する下側屈折投光部21bを設けてある。

上側屈折投光部21aには、バルブ28から出て上側屈折投光部21aから照射される光が前記2種のリフレクタ部24a,24bを備えた上側前照灯22による照射範囲と同様の照射範囲に照射されるように、バルブ28からの光を屈折投光する屈折特性を備えてある。下側屈折投光部21bには、バルブ29から出て下側屈折投光部21bから照射される光が前記2種のリフレクタ部25a,25bを備えた下側前照灯23による照射範囲と同様の照射範囲に照射されるように、バルブ29からの光を屈折投光する屈折特性を備えてある。

[Another embodiment]

FIG. 14 shows a

On the upper

この左右の前照灯装置20にあっては、前照灯装置20の照射範囲がレンズ21の上側屈折投光部21a及び下側屈折投光部21bによる屈折特性によって設定されており、これにより、リフレクタ部24a,24b,25a,25bを備えた前照灯装置20と同様に分草具12の先端部及び分草具12の前方を照明する。

In the left and

リフレクタ24,25の反射特性と、レンズ21の屈折特性との組み合わせによって前照灯装置20の照射範囲が所定の照射範囲に設定されるように構成して実施してもよい。

この場合も、本発明の目的を達成することができる。従って、リフレクタ部25a及び下側屈折投光部21bを総称して下方照射手段25a,21bと呼称し、リフレクタ部25b及び下側屈折投光部21bを総称して上方照射手段25b,21bと呼称し、リフレクタ部24a及び上側屈折投光部21aを総称して前方照射手段24a,21aと呼称し、リフレクタ部24b及び上側屈折投光部21aを総称して内側照射手段24b,21aと呼称する。

It may be configured and implemented such that the irradiation range of the

Also in this case, the object of the present invention can be achieved. Accordingly, the

図15は、別の実施形態を備えたコンバインを示し、このコンバインにあっては、刈取り前処理部10の茎稈引起し装置13の引起しケース13bの前面に前照灯装置20を設けてある。

FIG. 15 shows a combine provided with another embodiment. In this combine, a

コンバインの他、玉ねぎ、人参など各種の作物を収穫する作業機にも本発明を適用することができる。従って、刈取り前処理部10を「収穫前処理部」と呼称し、玉ねぎ、人参などを収穫する作業機やコンバインなどを総称して収穫機と呼称する。

In addition to the combine, the present invention can be applied to a working machine that harvests various crops such as onions and carrots. Therefore, mowing and referred to the

3 運転部

10 刈取り前処理部(収穫前処理部)

12 分草具

13 茎稈引起し装置

20 前照灯装置

21 レンズ

24 リフレクタ

25 リフレクタ

28 バルブ

29 バルブ(最も下側のバルブ)

121a 前面部

121b 側面部

3 driving

12th grass

13

21 Lens

24 reflector

25 Reflector

28 Valve

29 Valve (lowermost valve)

121a Front part

121b Side surface

Claims (12)

前記自走機体の前部に、茎稈引起し装置と分草具と前方を照射する前照灯装置とを有する収穫前処理部が設けられ、

前記分草具及び前記前照灯装置が前記収穫前処理部の右及び左の横側部に設けられ、

前記前照灯装置に、複数のバルブと、前記複数のバルブを覆う正面視で縦長のレンズと、が備えられ、

前記レンズは、機体側面視で前記レンズの前面が前記茎稈引起し装置の前面に沿うように構成されている収穫機。 Operation of the boarding type is provided on self-propelled aircraft,

The front of the front Symbol self airframe, pre-harvest processing unit is provided with a headlight device for irradiating the front and stems稈引cause device and minute grass tool,

Before SL min grasses instrument and said headlamp apparatus is provided next to the side of the right and left of the pre-harvest processing unit,

The headlamp device includes a plurality of bulbs, and a vertically long lens in front view covering the plurality of bulbs,

The said lens is a harvesting machine comprised so that the front surface of the said lens may raise the stalk and may follow the front surface of an apparatus by a body side view .

前記複数のバルブの光の夫々が異なる方向に向けて照射されるように、前記複数のバルブ向きと前記複数のリフレクタの向きとが設定されている請求項1から11の何れか一項に記載の収穫機。The direction of the plurality of bulbs and the direction of the plurality of reflectors are set so that each of the light from the plurality of bulbs is irradiated in different directions. Harvesting machine.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009002688A JP4944908B2 (en) | 2009-01-08 | 2009-01-08 | Harvesting machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009002688A JP4944908B2 (en) | 2009-01-08 | 2009-01-08 | Harvesting machine |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004241247A Division JP4713108B2 (en) | 2004-08-20 | 2004-08-20 | Harvesting machine |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2009065989A JP2009065989A (en) | 2009-04-02 |

| JP2009065989A5 JP2009065989A5 (en) | 2009-09-10 |

| JP4944908B2 true JP4944908B2 (en) | 2012-06-06 |

Family

ID=40602898

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009002688A Expired - Fee Related JP4944908B2 (en) | 2009-01-08 | 2009-01-08 | Harvesting machine |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4944908B2 (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5245814B2 (en) * | 2008-12-26 | 2013-07-24 | 市光工業株式会社 | Vehicle lighting |

| JP5752377B2 (en) * | 2010-09-09 | 2015-07-22 | ヤンマー株式会社 | Combine |

| JP2015065920A (en) * | 2013-09-30 | 2015-04-13 | 三菱農機株式会社 | Cockpit of work vehicle |

| JP6460725B2 (en) * | 2014-10-29 | 2019-01-30 | 三菱マヒンドラ農機株式会社 | Combine |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS55109043A (en) * | 1979-02-13 | 1980-08-21 | Fujitsu Ltd | Call piling system for optical data transmission |

| JPS62204442A (en) * | 1986-03-03 | 1987-09-09 | Toshiba Corp | Optical recording medium and its recording method |

| JPS6392533A (en) * | 1987-09-17 | 1988-04-23 | Minolta Camera Co Ltd | Automatic original feeding device |

| JPS6487937A (en) * | 1987-09-30 | 1989-04-03 | Bando Chemical Ind | Belt with heat resistant teeth |

| JP3579915B2 (en) * | 1994-04-26 | 2004-10-20 | 井関農機株式会社 | Combine harvester |

| JP2002373510A (en) * | 2001-06-14 | 2002-12-26 | Ichikoh Ind Ltd | Head lamp |

| JP4122771B2 (en) * | 2002-01-08 | 2008-07-23 | 市光工業株式会社 | head lamp |

| JP4185827B2 (en) * | 2002-09-24 | 2008-11-26 | ヤンマー農機株式会社 | Work vehicle lights |

-

2009

- 2009-01-08 JP JP2009002688A patent/JP4944908B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2009065989A (en) | 2009-04-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4944908B2 (en) | Harvesting machine | |

| JP2009065989A5 (en) | ||

| JP4046711B2 (en) | Harvesting machine | |

| JP5612804B2 (en) | Harvesting machine | |

| JP5379420B2 (en) | Harvesting machine | |

| JP4713108B2 (en) | Harvesting machine | |

| JP2014045694A (en) | Combine | |

| JP2006055094A (en) | Harvester | |

| JP2006006319A (en) | Harvester | |

| JP2006055092A (en) | Harvester | |

| JP7018761B2 (en) | combine | |

| KR100693976B1 (en) | Harvester | |

| JP4107608B2 (en) | Harvester | |

| JP6887372B2 (en) | combine | |

| JP6991055B2 (en) | combine | |

| JP5033251B2 (en) | Harvesting machine | |

| JP4675423B2 (en) | Mowing harvester | |

| JP2008237061A (en) | Lighting structure of harvester | |

| JP4825193B2 (en) | Harvesting machine | |

| JP5400923B2 (en) | Harvesting machine | |

| WO2022190832A1 (en) | Harvesting machine | |

| JP5033250B2 (en) | Harvesting machine | |

| JP2016054674A (en) | Combine-harvester | |

| WO2016038849A1 (en) | Combine | |

| JP2008131868A (en) | Combine harvester |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090129 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090728 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20111110 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120110 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120202 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120302 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4944908 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150309 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |