JP4895237B2 - Small closure structure for architectural louvers - Google Patents

Small closure structure for architectural louvers Download PDFInfo

- Publication number

- JP4895237B2 JP4895237B2 JP2009247562A JP2009247562A JP4895237B2 JP 4895237 B2 JP4895237 B2 JP 4895237B2 JP 2009247562 A JP2009247562 A JP 2009247562A JP 2009247562 A JP2009247562 A JP 2009247562A JP 4895237 B2 JP4895237 B2 JP 4895237B2

- Authority

- JP

- Japan

- Prior art keywords

- louver

- small

- fitting

- fixed

- hollow portion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000463 material Substances 0.000 claims description 102

- 239000002537 cosmetic Substances 0.000 claims description 14

- 210000001061 forehead Anatomy 0.000 description 5

- 210000003128 head Anatomy 0.000 description 5

- 229910052751 metal Inorganic materials 0.000 description 5

- 239000002184 metal Substances 0.000 description 5

- 229910000831 Steel Inorganic materials 0.000 description 4

- 239000010959 steel Substances 0.000 description 4

- 230000001771 impaired effect Effects 0.000 description 2

- 230000013011 mating Effects 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229920003002 synthetic resin Polymers 0.000 description 1

- 239000000057 synthetic resin Substances 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Landscapes

- Grates (AREA)

- Specific Sealing Or Ventilating Devices For Doors And Windows (AREA)

- Building Awnings And Sunshades (AREA)

Description

本発明は、小口の処理と取り付け作業を改良した建築用ルーバーの小口塞ぎ構造に関するものである。 The present invention relates to a small-mouth closing structure for a building louver with improved small-mouth processing and attachment work.

この種の建築用ルーバーの小口塞ぎ構造に関する技術として、中空の羽板(ルーバー材)に形鋼を貫通し、形鋼の両端部に支持腕部の先端に設けられた固着板を溶着する構成のものが知られている(特許文献1参照)。支持腕部は羽板の小口を覆うに十分な大きさを有し、その先端から直角に突設された固着板は、羽板の中空部に挿入されて形鋼に溶着されている。したがって、羽板の両端小口は支持腕部に覆われるから、別途小口蓋を取り付ける必要はない。また、上記構造を工場で予め組み立てておき、現場では支持腕部の基部を建築物の躯体に固定すればよいので、作業を迅速に行うことができるというメリットがある。 As a technology related to this type of louver for building louvers, a structure in which a hollow slat (louver material) penetrates a section steel and welds a fixing plate provided at the end of the support arm to both ends of the section steel. Are known (see Patent Document 1). The support arm portion has a size sufficient to cover the ostium of the slats, and a fixing plate protruding perpendicularly from the tip thereof is inserted into the hollow part of the slats and welded to the shape steel. Therefore, since the fore-edges of both ends of the slat are covered with the support arm portion, it is not necessary to attach a separate fore-mouth cover. Moreover, since the said structure is assembled beforehand in a factory and the base part of a support arm part should just be fixed to the housing of a building on the spot, there exists an advantage that work can be performed rapidly.

しかしながら、その半面、形鋼と固着板とを溶着する作業が必要となるほか、固着板は支持腕部の先端部に突設されるものであるから、部品コストがかかるという問題がある。 However, on the other hand, there is a problem that the work of welding the shape steel and the fixing plate is necessary, and the fixing plate protrudes from the tip end portion of the support arm portion, so that there is a problem that the parts cost is increased.

また、ルーバー本体の小口をカバー材でカバーすることは従来から行われているが、カバー材を固定する際、ビス、釘等の止め具を表側から打ち込むので、止め具の頭が外部に露出し、意匠性が損なわれるという問題があった。 In addition, covering the mouthpiece of the louver body with a cover material has been conventionally performed, but when fixing the cover material, a stopper such as a screw or nail is driven from the front side, so the head of the stopper is exposed to the outside. However, there is a problem that the designability is impaired.

本発明は、上記問題点を解消し、部品点数を節減でき、作業も簡単であるとともに、意匠性にも優れる建築用ルーバーの小口塞ぎ構造を提供することをその課題とする。 An object of the present invention is to solve the above-described problems, to reduce the number of parts, to simplify the work, and to provide a small-closure structure for a building louver that is excellent in design.

前記課題を解決するため、請求項1に係る発明は、建物躯体に取付部材を固定し、この取付部材に固定した固定部材に、中空部と該中空部の一側に形成されたアリ溝状取付部とを有するルーバー材を固定するとともに、このルーバー材の小口を小口化粧材によって塞ぐ建築用ルーバーの小口塞ぎ構造であって、

上記ルーバー材の中空部の互いに対向する内壁面の長手方向に沿って1対の突条を形成し、上記ルーバー材の小口を塞ぐ小口化粧材の背面側には上記各内壁面の突条に対応する嵌合片を2個平行に突出形成し、両側の嵌合片の先端間の間隔は、上記突条の幅よりわずかに小さい程度に形成するとともに、上記ルーバー材の両端の小口に小口化粧材を当て、上記2個の嵌合片の間に上記突条を嵌合させて固定したことを特徴とする。

In order to solve the above-mentioned problem, the invention according to

A pair of protrusions are formed along the longitudinal direction of the inner wall surfaces of the hollow portion of the louver material facing each other, and the protrusions of the inner wall surfaces are formed on the back side of the edge decorative material that closes the edge of the louver material. Two corresponding fitting pieces are formed so as to protrude in parallel, and the interval between the tips of the fitting pieces on both sides is formed to be slightly smaller than the width of the ridge, and a small edge is formed on the small edge on both ends of the louver material. A decorative material is applied, and the protrusion is fitted and fixed between the two fitting pieces .

請求項2に係る発明は、請求項1において、上記嵌合片を2個形成することに代えて1個を形成し、上記突条の中央には嵌合溝が形成され、該嵌合溝の内側に上記嵌合片を嵌合させて固定したことを特徴とする。 According to a second aspect of the present invention, in the first aspect, instead of forming the two fitting pieces, one is formed, a fitting groove is formed in the center of the protrusion, and the fitting groove The above-mentioned fitting piece is fitted inside and fixed.

請求項3に係る発明は、請求項1〜3のいずれかにおいて、上記小口化粧材の背面側には上記ルーバー材の取付部の壁に係合する係合部を突出形成し、該係合部から上記ルーバー材の中空部の壁にビス止めしたことを特徴とする。 According to a third aspect of the present invention, in any one of the first to third aspects, an engagement portion that engages with a wall of the attachment portion of the louver material is formed on the back side of the small cosmetic material, and the engagement The screw is fixed to the wall of the hollow portion of the louver material from the portion.

請求項4に係る発明は、請求項1〜4のいずれかにおいて、上記ルーバー材及び小口化粧材の表面に、適宜の模様を施したシートを貼着したことを特徴とする。

The invention according to

請求項1に係る発明によれば、建物躯体に固定した取付部材に断面L字形の固定部材の一方の片を固定したことにより、固定部材の他方の片は建物躯体の外表面と平行になる。そして、ルーバー材を取り付けるときは、上記他方の片からボルトを挿通し、このボルトを、ルーバー材の中空部の一側に設けられた取付部内の受け金具に螺着固定する構成であるから、上記ボルトの頭部は固定部材の背面側に隠れ、外側からは見えない。また、ルーバー材の両端部には小口化粧材が嵌合して装着されているので、ネジ頭が露出せず意匠性に優れる建築用外装ルーバーを提供することができる。 According to the first aspect of the present invention, by fixing one piece of the L-shaped fixing member to the mounting member fixed to the building housing, the other piece of the fixing member is parallel to the outer surface of the building housing. . And when attaching the louver material, it is a configuration in which a bolt is inserted from the other piece, and this bolt is screwed and fixed to a receiving metal fitting in an attachment portion provided on one side of the hollow portion of the louver material. The head of the bolt is hidden behind the fixing member and is not visible from the outside. In addition, since the forehead decorative material is fitted and attached to both ends of the louver material, it is possible to provide an exterior louver for architecture that is excellent in design without exposing the screw head.

また、ルーバー材の両端部には小口化粧材が装着されるが、小口化粧材はルーバー材の端部に嵌合により装着されているので、作業が簡単であるとともに、特別の部材を使わないので、部品点数を節減してコストを抑えることができる。 In addition, small cosmetics are attached to both ends of the louver material, but the cosmetics are attached to the end of the louver material by fitting, so the work is simple and no special members are used. Therefore, the number of parts can be reduced and the cost can be suppressed.

さらに、ルーバー材の中空部の互いに対向する内壁面の長手方向に沿って1対の突条を形成し、上記ルーバー材の小口を塞ぐ小口化粧材の背面側には上記各内壁面の突条に対応する嵌合片を2個平行に突出形成し、両側の嵌合片の先端間の間隔は、上記突条の幅よりわずかに小さい程度に形成するとともに、上記ルーバー材の両端の小口に小口化粧材を当て、上記2個の嵌合片の間に上記突条を嵌合させて固定する構成であるから、2個の嵌合片の間に上記突条を嵌合させたとき、両側の嵌合片の先端間の間隔は、上記突条の幅よりわずかに小さい程度に形成されているから、きつく嵌合され、小口化粧材はガタつきがなく、しっかりと固定される。 Furthermore, a pair of protrusions are formed along the longitudinal direction of the inner wall surfaces of the hollow portion of the louver material facing each other, and the protrusions of the inner wall surfaces are formed on the back side of the edge decorative material that closes the edge of the louver material. Two fitting pieces corresponding to the above are formed to protrude in parallel, and the distance between the tips of the fitting pieces on both sides is formed to be slightly smaller than the width of the ridge, and at both ends of the louver material, applying a small decorative material, because it is to affix structure by fitting the ridges between the two mating pieces, when the projection is fitted between two mating pieces Since the distance between the tips of the fitting pieces on both sides is formed to be slightly smaller than the width of the protrusion, the fitting pieces are tightly fitted, and the fore edge decorative material is not loose and is firmly fixed.

請求項2に係る発明によれば、突条の中央には嵌合溝が形成され、該嵌合溝の内側に上記嵌合片を嵌合させるようにして固定するものであるから、いずれの場合も、ガタつきがなく、小口化粧材の嵌合作業を容易かつ確実に行うことができる。

According to the invention of

請求項3に係る発明によれば、小口化粧材の背面側には上記ルーバー材の取付部の壁に係合する係合部を突出形成し、係合部から挿通したビスを上記係合部の内側を挿通させて上記ルーバー材の中空部の壁に螺着したことにより、小口化粧材をより強固に固定することができるとともに、上記係合部をアリ溝状取付部の底壁に係合させることにより、ビスの頭部もアリ溝状取付部の内側にあって外部からは隠れているので、美観が損なわれることがない。

According to the invention which concerns on

請求項4に係る発明によれば、例えば木目模様のシートを貼着すると、外観が全く異なるルーバーが得ることができる。しかも、小口化粧材とルーバー材の表面にはネジ頭が露出していないので、貼着されたシートの表面が滑らかである。したがって、意匠性を高めることができる。

According to the invention which concerns on

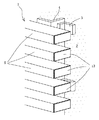

図1は、本発明に係る建築用外装ルーバーの一方の小口側をメインにした斜視図であり、図2はその縦断面図である。図1及び図2において、符号1は外装ルーバーで、この外装ルーバー1は建物躯体2の外表面に固定した複数個の取付部材3に固定部材4を固定し、さらにこの固定部材4に複数のルーバー材5を水平に固定したものである。

FIG. 1 is a perspective view mainly showing one small edge side of an exterior louver for building according to the present invention, and FIG. 2 is a longitudinal sectional view thereof. 1 and 2,

取付部材3は断面L字形の短尺の部材で、一方の片は固定ボルト6により建物躯体2に、他方の片もボルト7により固定部材4に固定されている。

The

固定部材4は断面L字形のアングル材で、一方の片4aは取付部材3に固定され、他方の片4bにはルーバー材5が固定されている。建物躯体2の外面には複数の固定部材4が上下方向に沿って互いに平行に配設されている。

The

ルーバー材5は、中空の押出形材よりなり中空部8の下部に断面L字形の側片部9を一対で延長形成し、両側の側片部9の内側にアリ溝状の取付部10を形成したもので、取付部10内には受け金具11が配置され、受け金具11には雌ネジが形成されている。ルーバー材5は、固定部材4の上記他方の片4bから挿通したボルト12を受け金具11に螺着することにより固定されている。同様にして、複数のルーバー材5が固定部材4に水平に配設されている。そして、ルーバー材5の両端部にはルーバー材5の小口を塞ぐ小口化粧材13が装着されている。

The

ルーバー材5と小口化粧材13の装着態様は次のとおりである。

The wearing mode of the

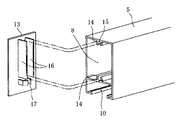

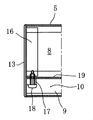

ルーバー材5には、図3に示されるように、中空部8の互いに対向する内壁面の長手方向に沿って上下1対の突条14が形成されている。突条14はビスホールと同様に断面円弧状に形成され、中央には嵌合溝15が形成されている。

As shown in FIG. 3, the

小口化粧材13はアルミニウム等の金属によって構成され、ルーバー材5の断面形状の外形と同じ長方形状を有し、その背面側の中央のやや上部には1対の嵌合片16が平行に突出形成されている。嵌合片16は板状で小口化粧材13をルーバー材5の小口に当てたときにルーバー材5の中空部8内の突条14に嵌合できる位置に形成され、また中空部8に嵌合できる程度の大きさに形成されているとともに、両側の嵌合片16の先端間の間隔は、ルーバー材5の突条14の幅よりわずかに小さい程度に形成されている。

The fore edge

次に、嵌合片16の下部には係合部17が形成されている。係合部17は先端が内側に屈曲した2個の係合片からなり、内側にはビスが挿通できる程度の空間が形成されている。また、嵌合片16と係合部17との間の間隔は、ルーバー材5の中空部8の下部の壁19の肉厚と略同じに形成されている。したがって、嵌合片16の端部は中空部8の下部の壁19に、係合部17はルーバー材5の取付部10の壁に係合する。

Next, an

上記構成の小口化粧材13をルーバー材5の小口に装着するときは、まず図3のように小口化粧材13の嵌合片16の間にルーバー材5の突条14が嵌合するように押し込んで固定する。しかも、図4に示されるように、アリ溝状の取付部10の両側の側片部9の間の開口部からビス18を挿通し、小口化粧材13の係合部17の内側を通って中空部8の壁19に螺着して固定する。ビス18は係合部17を介してルーバー材5の中空部8に圧接した状態で固定されるとともに、係合部17の先端部は内側に屈曲してビスを抱えるようになるため、小口化粧材13はビス18によってさらに確実に固定される。

When the small-sized

上述のように、ルーバー材5を固定するボルト12の頭部は固定部材4の背面側に隠れ、小口化粧材13をルーバー材5に固定するビス18の頭部はアリ溝の内側に隠れ、外側からは見えない。また、ルーバー材5の両端部には小口化粧材13が嵌合して装着され、ビスを使用していないので、意匠性に優れる建築用外装ルーバーを提供することができる。

As described above, the head of the bolt 12 that fixes the

また、ルーバー材5の両端部には小口化粧材13が装着されるが、小口化粧材13はルーバー材5の端部に嵌合により装着されているので、作業が簡単であるとともに、特別の部材を使わないので、部品点数を節減してコストを抑えることができる。

Further, the small edge

また、嵌合片16自体もルーバー材5の中空部8内の突条14に嵌合するので、取付後にがたつきが生じることはない。

Further, since the

なお、係合部17は必ずしも必要ではない。次に示す実施形態では係合部17を省略している。もちろん、この実施形態の場合も係合部を設けてもよい。

Note that the engaging

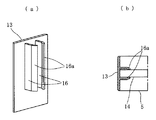

図5(a)(b)は小口化粧材13の取付けの他の実施形態を示すもので、嵌合片16の先端16aを内側に屈曲して先端部間の間隔をルーバー材5の突条14の幅よりも小さくしておけばよい。

5 (a) and 5 (b) show another embodiment of attachment of the fore edge

上記構成によれば、小口化粧材13をルーバー材5の小口に装着するときは、小口化粧材13の嵌合片16の間にルーバー材5の突条14がきつく嵌合するように押し込んで固定すればよい。嵌合片16の先端16aが内側に屈曲しているので、嵌合片16の固有弾性により先端部がルーバー材5の突条14を強く押圧するので、係合部17がなくても小口化粧材13は確実に固定される。

According to the above configuration, when the small

次に、嵌合片16は突条14の外側に嵌合する形態に限定されない。たとえば、図6(a)(b)に示されるように、嵌合片16を左右に交互にジグザグ状に折れ曲がる1枚の板状片によって形成し、これをルーバー材5の断面円弧状の突条14の内側の嵌合溝15に嵌合するようにしてもよい。この場合も、嵌合片16の折れ曲がり部の山部20が突条14の内面を押圧する。また、嵌合片16はジグザグ状に折れ曲がっているので、両側に突出する各山部20が突条14の嵌合溝15の内側面に当接するので、小口化粧材13は確実に固定される。

Next, the

ルーバー材5は上記実施形態のように水平方向に配置してもよいが、上下方向に配置してもよい。また、ルーバー材5の突条14の位置も図示したものに限定されない。

The

なお、図示はしないが、上記ルーバー材5及び小口化粧材13の表面に、適宜の模様を施した合成樹脂製等のシートを貼着してもよい。これによれば、例えば木目模様のシートを貼着すると、外観が全く異なるルーバーが得ることができる。しかも、小口化粧材とルーバー材の表面にはネジ頭が露出していないので、貼着されたシートの表面が滑らかである。したがって、意匠性を高めることができる。

Although not shown, a sheet made of synthetic resin or the like having an appropriate pattern may be attached to the surfaces of the

シートを貼着するときは、小口化粧材とルーバー材のそれぞれに又は個別に貼着してもよく、あるいは一体に貼着してもよい。 When sticking a sheet, it may be stuck to each of the small cosmetic material and the louver material or individually, or may be stuck together.

1 外装用ルーバー

2 建物躯体

5 ルーバー材

8 中空部

10 取付部

11 受け金具

13 小口化粧材

14 突条

15 嵌合溝

16 嵌合片

17 係合部

DESCRIPTION OF

Claims (4)

上記ルーバー材の中空部の互いに対向する内壁面の長手方向に沿って1対の突条を形成し、上記ルーバー材の小口を塞ぐ小口化粧材の背面側には上記各内壁面の突条に対応する嵌合片を2個平行に突出形成し、両側の嵌合片の先端間の間隔は、上記突条の幅よりわずかに小さい程度に形成するとともに、上記ルーバー材の両端の小口に小口化粧材を当て、上記2個の嵌合片の間に上記突条を嵌合させて固定したことを特徴とする建築用ルーバーの小口塞ぎ構造。 A mounting member is fixed to the building frame, and a louver material having a hollow portion and a dovetail mounting portion formed on one side of the hollow portion is fixed to the fixing member fixed to the mounting member. A small closure structure of a building louver that closes the small edge with a small cosmetic material,

A pair of protrusions are formed along the longitudinal direction of the inner wall surfaces of the hollow portion of the louver material facing each other, and the protrusions of the inner wall surfaces are formed on the back side of the edge decorative material that closes the edge of the louver material. Two corresponding fitting pieces are formed so as to protrude in parallel, and the interval between the tips of the fitting pieces on both sides is formed to be slightly smaller than the width of the ridge, and a small edge is formed on the small edge on both ends of the louver material. A small-closure structure for a building louver, wherein a decorative material is applied and the protrusions are fitted and fixed between the two fitting pieces .

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009247562A JP4895237B2 (en) | 2009-10-28 | 2009-10-28 | Small closure structure for architectural louvers |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009247562A JP4895237B2 (en) | 2009-10-28 | 2009-10-28 | Small closure structure for architectural louvers |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011156950A Division JP2011252380A (en) | 2011-07-15 | 2011-07-15 | Cut end closing structure of construction louver |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2011094344A JP2011094344A (en) | 2011-05-12 |

| JP2011094344A5 JP2011094344A5 (en) | 2011-06-23 |

| JP4895237B2 true JP4895237B2 (en) | 2012-03-14 |

Family

ID=44111560

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009247562A Active JP4895237B2 (en) | 2009-10-28 | 2009-10-28 | Small closure structure for architectural louvers |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4895237B2 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101522109B1 (en) * | 2013-12-05 | 2015-05-20 | 김진호 | Finishing material for screen louver |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5659400B2 (en) * | 2009-12-07 | 2015-01-28 | 株式会社トッパン・コスモ | Architectural louver |

| JP6043527B2 (en) * | 2012-07-17 | 2016-12-14 | 株式会社Uacj金属加工 | Louver assembly |

| KR101376822B1 (en) * | 2012-12-19 | 2014-03-20 | 김진호 | Ceiling finishing material having lighting apparatus |

| KR101355362B1 (en) * | 2012-12-24 | 2014-02-04 | 김진호 | Ceiling finishing material |

| JP7535916B2 (en) | 2020-11-16 | 2024-08-19 | 理研軽金属工業株式会社 | Closing structure for architectural louvers |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH04366268A (en) * | 1991-06-14 | 1992-12-18 | San Rail:Kk | Fitting method of hand rail |

| JP2669800B2 (en) * | 1995-04-11 | 1997-10-29 | 株式会社ナカムラ | How to install the grid |

| JPH10220435A (en) * | 1997-02-07 | 1998-08-21 | Miwa Lock Co Ltd | End cap mounting structure for tube body |

| JP2002308319A (en) * | 2001-04-09 | 2002-10-23 | Masaharu Kitamura | Hole closing lid member |

| JP4520206B2 (en) * | 2004-04-21 | 2010-08-04 | 三菱樹脂株式会社 | End cap and fixing structure thereof |

| JP2006219879A (en) * | 2005-02-09 | 2006-08-24 | Sanyo Industries Ltd | Mounting structure of louver material |

| JP4332521B2 (en) * | 2005-11-15 | 2009-09-16 | 理研軽金属工業株式会社 | Architectural exterior louver |

| JP2009091717A (en) * | 2007-10-03 | 2009-04-30 | Shin Nikkei Co Ltd | Header cap for deck material |

-

2009

- 2009-10-28 JP JP2009247562A patent/JP4895237B2/en active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101522109B1 (en) * | 2013-12-05 | 2015-05-20 | 김진호 | Finishing material for screen louver |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2011094344A (en) | 2011-05-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2011252380A (en) | Cut end closing structure of construction louver | |

| JP4895237B2 (en) | Small closure structure for architectural louvers | |

| JP2011094344A5 (en) | ||

| JP5631582B2 (en) | Joinery and picture frames | |

| JP2013503785A (en) | Vehicle door mechanism and method for assembling vehicle door mechanism | |

| JP5659400B2 (en) | Architectural louver | |

| JP5822216B2 (en) | Architectural louver | |

| JP2008095374A (en) | Connection frame and corner joint member for frame | |

| JP6682419B2 (en) | Frame and fittings | |

| KR20180082865A (en) | Handle for sliding door of built-in wardrobe | |

| JP6754192B2 (en) | Outer wall panel support structure | |

| JP2020007740A (en) | Connecting device for exterior louver | |

| JP4520206B2 (en) | End cap and fixing structure thereof | |

| JP5478301B2 (en) | Panel mounting structure, panel mounting tool and panel assembly | |

| JP5358815B2 (en) | Spandrel border | |

| KR101671843B1 (en) | Side contact type skin plate for building | |

| KR20090009024U (en) | A fixture of interior decoration board for buliding | |

| JP2004245525A (en) | Door body assembly structure for hinged double doors type refrigerator door | |

| JP2005068801A (en) | Temporary panel | |

| JP6722725B2 (en) | Corner cap, parting structure, and decorative panel body | |

| JP3187630U (en) | Panel frame and panel kit | |

| JP2004225272A (en) | Sash frame, opening structure, and building | |

| JP4972057B2 (en) | Panel outer frame structure | |

| JP6978056B2 (en) | Panel with grid | |

| JP5200757B2 (en) | Elevator mirror device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110407 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110407 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20110407 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20110502 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110517 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110715 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110927 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111128 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20111214 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20111215 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4895237 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150106 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313115 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |