JP4858776B2 - LENS DEVICE AND IMAGING DEVICE - Google Patents

LENS DEVICE AND IMAGING DEVICE Download PDFInfo

- Publication number

- JP4858776B2 JP4858776B2 JP2007008865A JP2007008865A JP4858776B2 JP 4858776 B2 JP4858776 B2 JP 4858776B2 JP 2007008865 A JP2007008865 A JP 2007008865A JP 2007008865 A JP2007008865 A JP 2007008865A JP 4858776 B2 JP4858776 B2 JP 4858776B2

- Authority

- JP

- Japan

- Prior art keywords

- lens

- adjustment

- lens frame

- optical axis

- frame

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000003384 imaging method Methods 0.000 title claims description 25

- 230000003287 optical effect Effects 0.000 claims description 68

- 230000007246 mechanism Effects 0.000 claims description 46

- 238000006073 displacement reaction Methods 0.000 description 9

- 230000002093 peripheral effect Effects 0.000 description 8

- 210000000078 claw Anatomy 0.000 description 5

- 238000010586 diagram Methods 0.000 description 4

- 230000001154 acute effect Effects 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 1

- 230000004907 flux Effects 0.000 description 1

Images

Landscapes

- Lens Barrels (AREA)

Description

本発明はレンズ装置および撮像装置に関する。 The present invention relates to a lens apparatus and an imaging apparatus .

近年、デジタルスチルカメラ、デジタルビデオカメラ等の撮像装置として、ズーミング(変倍)を行なう撮影光学系を有するものが提供されている。

このような撮影光学系を構成するレンズ装置として、光軸方向の位置が固定された固定レンズ群と、光軸方向に移動可能な可動レンズ群とを有し、可動レンズ群を撮影光学系の光軸に沿って動かすことでズーミング動作を行なうものが提供されている。

前記レンズ装置では、可動レンズ群が広角側と望遠側とに移動した際に、撮影光学系全体としてのMTF(空間周波数)、言い換えれば解像度が変動するため、この変動が広角側と望遠側とでバランスのとれたものとなるように固定レンズ群の光軸位置の微調整を行なうことが必要となる。このような微調整は、撮像素子の高画素数化に伴って撮影光学系の光学的性能の向上を図る上で重要なものとなっている。

そのため、固定レンズ群の光軸と直交する方向の位置を微調整するための調整機構を有するレンズ装置が提案されている(特許文献1参照)。

このレンズ装置では、調整機構は、2つの調整部材と、1つの調整用付勢部材とで構成されており、2つの調整部材はそれらの軸心が固定レンズ群の中央で互いに鋭角をなして交差するように延在し、かつ、それらの先端が固定レンズ群の外周面の2箇所に当接して前記光軸に対して接離する方向に変位可能に設けられ、前記調整用付勢部材は、前記固定レンズ群を前記2つの調整部材に当接する方向に付勢するように構成されている。

As a lens apparatus that constitutes such a photographing optical system, it has a fixed lens group whose position in the optical axis direction is fixed, and a movable lens group that can move in the optical axis direction. There is provided a device that performs a zooming operation by moving along an optical axis.

In the lens apparatus, when the movable lens group moves to the wide angle side and the telephoto side, the MTF (spatial frequency) as the entire photographing optical system, in other words, the resolution fluctuates. Therefore, it is necessary to finely adjust the position of the optical axis of the fixed lens group so as to be balanced. Such fine adjustment is important for improving the optical performance of the photographing optical system as the number of pixels of the image sensor increases.

Therefore, a lens device having an adjustment mechanism for finely adjusting the position of the fixed lens group in the direction orthogonal to the optical axis has been proposed (see Patent Document 1).

In this lens device, the adjustment mechanism is composed of two adjustment members and one adjustment biasing member, and the two adjustment members have their axes centered at an acute angle at the center of the fixed lens group. The adjustment biasing member that extends so as to intersect with each other and that is displaceable in a direction in which its tip abuts against two places on the outer peripheral surface of the fixed lens group and is in contact with or away from the optical axis. Is configured to urge the fixed lens group in a direction in contact with the two adjustment members.

一方、近年では、レンズ装置のより一層の小型化が要求されていることから、調整機構と、該調整機構に隣接する他の機構(例えば絞り機構やフォーカス機構)とをより近接させて配置する必要がある。

しかしながら、上記従来装置では、2つの調整部材はそれらの軸心が固定レンズ群の中央で互いに鋭角をなして交差するように延在していることから、調整機構と隣接する他の機構とを近接させて配置するにも限界があり、特に光軸方向における小型化を図る上で不利があった。

本発明は、このような事情に鑑みなされたものであり、小型化を図る上で有利な撮像装置およびレンズ装置を提供することにある。

On the other hand, in recent years, there is a demand for further downsizing of the lens device, and therefore, the adjustment mechanism and other mechanisms (for example, a diaphragm mechanism and a focus mechanism) adjacent to the adjustment mechanism are arranged closer to each other. There is a need.

However, in the above-described conventional device, the two adjustment members extend so that their axial centers intersect at an acute angle at the center of the fixed lens group. There is a limit to disposing them close to each other, which is disadvantageous in reducing the size especially in the optical axis direction.

The present invention has been made in view of such circumstances, and it is an object of the present invention to provide an imaging device and a lens device that are advantageous in reducing the size.

上述の目的を達成するため、本発明は、レンズを支持するレンズ枠と、開口部を有する壁部と、前記レンズを前記開口部に臨ませて前記レンズ枠を前記レンズの光軸方向に移動不能に支持する支持機構と、前記レンズ枠を前記光軸と直交する面内で変位させる調整機構とを備えたレンズ装置であって、前記調整機構は、2つの調整部材と、1つの調整用付勢部材とで構成され、前記2つの調整部材はそれらの軸心の延長線が前記レンズの中心から離れた箇所で交差するように延在し、かつ、前記2つの調整部材は前記レンズ枠の互いに異なる2箇所に当接してそれらの軸心方向に変位可能に設けられ、前記調整用付勢部材は、前記レンズ枠の互いに異なる2箇所が前記2つの調整部材に当接する方向に前記レンズ枠を付勢し、前記調整用付勢部材は、前記壁部と前記レンズ枠とにわたって設けられたねじりばねで構成され、前記2つの調整部材の軸心の延長線は、前記レンズの半径方向の外側の箇所で交差するように延在し、かつ、前記光軸方向から見てそれら延長線で囲まれた領域の内側に前記レンズと前記ねじりばねが位置していることを特徴とする。

また本発明は、レンズを支持するレンズ枠と、開口部を有する壁部と、前記レンズを前記開口部に臨ませて前記レンズ枠を前記レンズの光軸方向に移動不能に支持する支持機構と、前記レンズ枠を前記光軸と直交する面内で変位させる調整機構と、前記レンズの後方に配置された撮像素子とを備えた撮像装置であって、前記調整機構は、2つの調整部材と、1つの調整用付勢部材とで構成され、前記2つの調整部材はそれらの軸心の延長線が前記レンズの中心から離れた箇所で交差するように延在し、かつ、前記2つの調整部材は前記レンズ枠の互いに異なる2箇所に当接してそれらの軸心方向に変位可能に設けられ、前記調整用付勢部材は、前記レンズ枠の互いに異なる2箇所が前記2つの調整部材に当接する方向に前記レンズ枠を付勢し、前記調整用付勢部材は、前記壁部と前記レンズ枠とにわたって設けられたねじりばねで構成され、前記2つの調整部材の軸心の延長線は、前記レンズの半径方向の外側の箇所で交差するように延在し、かつ、前記光軸方向から見てそれら延長線で囲まれた領域の内側に前記レンズと前記ねじりばねが位置していることを特徴とする。

To achieve the above object, the present invention provides a lens frame that supports a lens, a wall portion having an opening, and the lens frame is moved in the optical axis direction of the lens with the lens facing the opening. A lens device comprising: a support mechanism for supporting the lens frame; and an adjustment mechanism for displacing the lens frame in a plane orthogonal to the optical axis. The adjustment mechanism includes two adjustment members and one adjustment member. The two adjustment members extend so that their extension lines intersect at a position away from the center of the lens, and the two adjustment members are the lens frame. The adjustment urging member is provided so as to be displaceable in the axial direction by contacting two different positions of the lens frame, and the adjustment biasing member is configured so that the two different positions of the lens frame are in contact with the two adjustment members. It urges the frame, urging for the adjustment The material is composed of a torsion spring provided between the wall portion and the lens frame, and the extension line of the axial center of the two adjusting members extends so as to intersect at a location outside the lens in the radial direction. In addition, the lens and the torsion spring are located inside a region surrounded by the extension lines when viewed from the optical axis direction .

The present invention also provides a lens frame that supports the lens, a wall portion having an opening, and a support mechanism that supports the lens frame so as not to move in the optical axis direction of the lens with the lens facing the opening. An image pickup apparatus including an adjustment mechanism for displacing the lens frame in a plane orthogonal to the optical axis, and an image pickup device disposed behind the lens, wherein the adjustment mechanism includes two adjustment members; And the two adjustment members extend so that their extension lines intersect at a position away from the center of the lens, and the two adjustment members The member is provided so as to be in contact with two different positions of the lens frame and displaceable in the axial direction thereof, and the adjustment biasing member has two different positions of the lens frame that contact the two adjustment members. said lens frame and biased in a direction in contact The adjustment biasing member is constituted by a torsion spring provided between the wall portion and the lens frame, and the extension line of the axis of the two adjustment members intersects at a location outside the lens in the radial direction. And the lens and the torsion spring are located inside a region surrounded by the extension lines when viewed from the optical axis direction .

そのため、本発明によれば、レンズ枠の周囲で2つの調整部材の間に大きなスペースを確保することが可能となり、これらスペースに調整機構と隣接する他の機構、例えば、絞り機構やフォーカス機構などを位置させて配置でき、したがって、撮像装置の光軸方向における小型化を図る上で有利となる。 Therefore, according to the present invention, it is possible to secure a large space between the two adjustment members around the lens frame, and other mechanisms adjacent to the adjustment mechanism in these spaces, such as a diaphragm mechanism and a focus mechanism. Therefore, it is advantageous in reducing the size of the imaging device in the optical axis direction.

次に本発明の実施の形態について図面を参照して説明する。

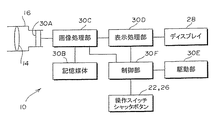

図1は本実施の形態の撮像装置の斜視図、図2は本実施の形態の撮像装置の構成を示すブロック図である。

図1に示すように、本実施例の撮像装置10はデジタルスチルカメラであり、外装を構成するケース12を有している。

ケース12の前面右側部寄りの箇所には撮影光学系14を収容保持する鏡筒16が設けられ、ケース12の前面上部寄りの箇所には閃光を発光するフラッシュ部18、光学式ファインダの対物レンズ20などが設けられている。なお、本明細書において前方とは被写体側をいい、後方とは結像側をいうものとする。

ケース12の上端面にはシャッタボタン22が設けられ、ケース12の後面には、前記光学式ファインダの接眼窓24、電源のオンオフ、撮影モード、再生モードの切替など種々の操作を行なうための複数の操作スイッチ26、撮像した映像を表示するディスプレイ28(図2)などが設けられている。

Next, embodiments of the present invention will be described with reference to the drawings.

FIG. 1 is a perspective view of an imaging apparatus according to the present embodiment, and FIG. 2 is a block diagram illustrating a configuration of the imaging apparatus according to the present embodiment.

As shown in FIG. 1, the

A

A

図2に示すように、撮像装置10は、撮影光学系14によって結像された被写体像を撮像するCCDやCMOSセンサなどで構成された撮像素子30A、該撮像素子30Aから出力された撮像信号に基づいて画像データを生成し、メモリカードなどの記憶媒体30Bに記録する画像処理部30C、前記画像データをディスプレイ28に表示させる表示処理部30D、後述する第2、第4レンズ群14B、14D(図3参照)を光軸方向に動かす駆動部30E、操作スイッチ26やシャッタボタン22の操作に応じて画像処理部30C、表示処理部30D、駆動部30Eを制御するCPUなどを含む制御部30Fなどを備えている。

As shown in FIG. 2, the

次に、鏡筒16の概略構成について説明する。

図3は鏡筒16の断面図である。

図3に示すように、鏡筒16は光学的には4群インナーフォーカスとして構成されている。

鏡筒16はその内部に第1筒部32と第2筒部34とを有している。

第1筒部32は、断面が矩形状に形成され、第1筒部32は、後壁3202と後壁3202の周縁から前方に起立された周壁3204とを備えている。

第2筒部34は、第1筒部32の前端に取着され、第2筒部34には第1レンズ群14Aが収容されている。

第1筒部32の内側で第1レンズ群14Aの後方には、第2レンズ群14B、第3レンズ群14C、第4レンズ群14Dがこの順番で前方から後方に向かって配置されている。

後壁3202には開口部3206が設けられ、この開口部3206に臨ませて撮像素子30Aが取着されている。

Next, a schematic configuration of the

FIG. 3 is a cross-sectional view of the

As shown in FIG. 3, the

The

The

The second

A second lens group 14B, a third lens group 14C, and a fourth lens group 14D are arranged in this order from the front side to the rear side behind the

The

第1レンズ群14A、第3レンズ群14Cは第1筒部32および第2筒部34に固定された固定レンズ群として構成され、第2レンズ群14B、第4レンズ群14Dは光軸方向に移動可能に設けられた可動レンズ群として構成されている。

また、第1筒部32の光軸方向の中間に壁部3208が形成され、該壁部3208の中央に前記光軸を中心とする開口部3210が設けられている。

開口部3210の後方寄り箇所には、後レンズ36がその中心と前記光軸とが一致するように位置決めされた状態で取着されている。

開口部3210の前方、すなわち後レンズ36の前方には、前レンズ38(特許請求の範囲のレンズに相当)が配置され、これら前レンズ38と後レンズ36とによって第3レンズ群14Cが構成されている。

そして、第2、第4レンズ群14B、14Dが駆動部30Eの駆動力によって所定のカムカーブに沿ってこれら第1乃至第4レンズ群14A、14B、14C、14Dの光軸方向に動かされることによって広角および望遠の間でズーミングを行うように構成されている。

また、前レンズ38の前方には、第1乃至第4レンズ群14A、14B、14C、14Dによって撮像素子30Aに導かれる光束の光量を調整するための絞り機構40が配設されている。

このような絞り機構40としては、例えば、撮影光学系14の光軸を挟むように一対の絞り羽根を設けるとともに、それら絞り羽根を前記光軸と直交する方向で離間、接近する方向に移動させることにより、一対の絞り羽根の縁部の間に形成される開口径を変化させるものなど、従来公知のさまざまな構成のものが使用可能である。

このような絞り機構40は、アクチュエータや該アクチュエータからの力を絞り羽根に伝達する伝達機構などを含んで構成されている。

The

A

A

A front lens 38 (corresponding to a lens in claims) is disposed in front of the opening 3210, that is, in front of the

Then, the second and fourth lens groups 14B and 14D are moved in the optical axis direction of the first to

In front of the

As such an

Such a

次に、レンズ装置の構成について詳細に説明する。

図4は本実施の形態に係る前レンズ38の取付構造を示す分解斜視図、図5は図4を前方から見た正面図、図6は図5から板ばね48を取り除いた正面図である。

レンズ装置は、レンズ枠42と、壁部3208と、支持機構44と、調整機構46とを含んで構成されている。

図5、図6に示すように、レンズ枠42と、支持機構44と、調整機構46とは鏡筒16の内側に収容され、壁部3208は鏡筒16に一体に形成されている。

Next, the configuration of the lens device will be described in detail.

4 is an exploded perspective view showing the mounting structure of the

The lens device includes a

As shown in FIGS. 5 and 6, the

図4に示すように、レンズ枠42は、前レンズ38の外周部を支持している。

図3に示すように、壁部3208の開口部3210は前レンズ38に対応した大きさで形成されている。

As shown in FIG. 4, the

As shown in FIG. 3, the

図3に示すように、支持機構44は、前レンズ38を開口部3210に臨ませてレンズ枠42を前レンズ38の光軸方向に移動不能に支持するものである。

支持機構44は、レンズ枠42に弾接しレンズ枠42を壁部3208に当接させる枠状の板ばね48を含んで構成されている。

As shown in FIG. 3, the support mechanism 44 supports the

The support mechanism 44 includes a frame-shaped

図4、図5に示すように、板ばね48には、環状片4801と開口部4802とばね片4804とが設けられている。

環状片4801の中央に開口部4802が設けられ、開口部4802は、前レンズ38に対応する大きさで形成されている。

ばね片4804は、環状片4801に形成されレンズ枠42の前面に当接することで、図3に示すように、レンズ枠42の後面を壁部3208に当接する方向へ付勢するように構成されている。

本例では、ばね片4804は環状片4801の周方向に120度の間隔をおいて3つ設けられ、それぞれ環状片4801の内周箇所において開口部4802の外周縁に沿って円弧状に延在形成され、各ばね片4804は、先端に至るにつれて開口部4802に対して光軸方向に沿って離れ前レンズ38側に変位して形成されている。

また、図4に示すように、環状片4801の下部中央には、開口部4802の半径方向外方に突出する係合爪4810が形成され、該係合爪4810を挟む2箇所には当接片4812がそれぞれ形成されている。

環状片4801の上部には2つのばね片4814が形成されている。

また、係合爪4810の基部と一方のばね片4814の基部には、それぞれ位置決め孔4816が形成されている。

As shown in FIGS. 4 and 5, the

An

The

In this example, three

As shown in FIG. 4, an engaging

Two

In addition,

図3に示すように、第1筒部32の周壁3204のうち、下部には板ばね48の係合爪4810が係合される係合孔3210が形成され、上部には板ばね48の2つのばね片4814が係合される2つの係合孔3212が形成され、図5に示すように、壁部3208には2つの位置決め孔4816に挿通される2つの位置決めボス3214が形成されている。

したがって、図3に示すように、板ばね48は、係合爪4810が係合孔3210に係合されるとともに2つのばね片4814が2つの係合孔3212に係合された状態で、各ばね片4814の弾性により当接片4812が壁部3208の下部に当接し、さらに、2つの位置決め孔4816に2つの位置決めボス3214が挿通されることにより、壁部3208に対して位置決めされた状態で保持されることになる。

As shown in FIG. 3, an

Therefore, as shown in FIG. 3, the

調整機構46は、レンズ枠42を光軸と直交する面内で変位させるものである。

図4に示すように、調整機構46は、2つの調整部材50と、1つの調整用付勢部材52とで構成されている。

図6に示すように、2つの調整部材50はそれらの軸心の延長線50Aが前レンズ38の中心から離れた箇所で交差するように延在し、かつ、2つの調整部材50はレンズ枠42の互いに異なる2箇所に当接してそれらの軸心方向に変位可能に設けられている。

本実施の形態では、2つの調整部材50の軸心の延長線50Aは、前レンズ38の半径方向の外側の箇所で直角に交差するように延在し、かつ、前記光軸方向から見てそれら延長線50Aで囲まれた領域の内側に前レンズ38が位置している。

また、本実施の形態では、2つの調整部材50が当接するレンズ枠42の互いに異なる2箇所は、前レンズ38の光軸を通り前記光軸と直交する面内を延在する想像線L1上に位置し、あるいは、想像線L1の近傍に位置している。

また、本実施の形態では、2つの調整部材50が当接するレンズ枠42の互いに異なる2箇所は、前レンズ38の外周部の近傍に位置している。

言い換えると、2つの調整部材50は、レンズ枠42の周囲でそれら調整部材50の間に大きなスペースが確保されるように設けられている。

また、本実施の形態では、2つの調整部材50はそれぞれ雄ねじ部5002を有し、2つの調整部材50はそれぞれ雄ねじ部5002を壁部3208の雌ねじ3208Aに螺合して配置されている。

各雌ねじ3208Aは、断面が矩形の周壁3204の上壁3204Aと側壁3204Bの各内面に設けられたボス部に形成され、したがって、2つの調整部材50の頭部は、それぞれ周壁3204の上壁3204A上と側壁3204B上に位置し、本実施の形態では、2つの調整部材50は、上壁3204Aと側壁3204Bに対してそれぞれ直交する方向に延在している。

The

As shown in FIG. 4, the

As shown in FIG. 6, the two

In the present embodiment, the

Further, in the present embodiment, two different positions of the

In the present embodiment, two different positions of the

In other words, the two

In the present embodiment, the two

Each

調整用付勢部材52は、レンズ枠42の互いに異なる2箇所が2つの調整部材50に当接する方向にレンズ枠42を付勢している。

調整用付勢部材52は、壁部3208とレンズ枠42とにわたって設けられたねじりばね5202で構成されている。

ねじりばね5202は、前レンズ38と同様に、前記光軸方向から見て2つの調整部材50の軸心の延長線50Aで囲まれた領域の内側に位置している。

調整用付勢部材52としてねじりばね5202を用いることで、調整用付勢部材52の小型化を図っている。

The adjustment biasing member 52 biases the

The adjustment biasing member 52 includes a torsion spring 5202 provided across the

Similar to the

By using the torsion spring 5202 as the adjustment urging member 52, the adjustment urging member 52 is downsized.

次に、前レンズ38の位置調整について説明する。

前レンズ38は、ばね片2406がレンズ枠42の前面を付勢することによりレンズ枠42の後面が壁部3208に当接された状態となっており、この状態で光軸と直交する方向に移動できるようになっている。

ここで、2つの調整部材50のうちの一方の調整部材50のみを回転させてその調整部材50の軸心方向に動かすと、調整用付勢部材52の付勢力により2つの調整部材50の先端に当て付けられたレンズ枠42は、回転されない他方の調整部材50の先端に当接した箇所を支点として一方の調整部材50の移動に追従して前記光軸と直交する面内に沿って揺動され、したがって、前レンズ38はレンズ枠42と一体に前記光軸と直交する面内に沿って変位される。

また、上記とは逆に、2つの調整部材50のうちの他方の調整部材50のみを回転させてその調整部材50の軸心方向に動かすと、調整用付勢部材52の付勢力により2つの調整部材50の先端に当て付けられたレンズ枠42は、回転されない一方の調整部材50の先端に当接した箇所を支点として他方の調整部材50の移動に追従して前記光軸と直交する面内に沿って揺動され、したがって、前レンズ38はレンズ枠42と一体に前記光軸と直交する面内に沿って変位される。

このように2つの調整部材50を回転することにより前レンズ38の位置を光軸と直交する方向に変位させることができる。

前レンズ38の光軸と直交する方向の位置調整は、第2、第4レンズ群12、16を広角側と望遠側とにそれぞれ移動させた状態で、第1乃至第4レンズ群14A、14B、14C、14D全体としてのMTF(空間周波数)、言い換えれば解像度の変動をそれぞれ測定しつつ、その変動が広角側と望遠側とでバランスのとれたものとなるように行なう。

Next, the position adjustment of the

In the

Here, when only one of the two

On the contrary, when only the

Thus, by rotating the two adjusting

The position adjustment in the direction orthogonal to the optical axis of the

次に、2つの調整部材50を回転することにより前レンズ38の位置を光軸と直交する方向に変位させることができることについて、図7の実験結果を参照してさらに説明する。

図7は2つの調整部材50の変位量(シフト量)と前レンズ38の光軸の変位量との関係を示す図である。

すなわち、図6において光軸と直交する面内において光軸と交差しかつ互いに直交するX軸、Y軸を設定する。本実施の形態では、X軸が一方の調整部材50の軸心方向と平行し、Y軸が他方の調整部材50の軸心方向と平行している。

図7において符号Aで示した部分は、Y軸側の調整部材50をレンズ枠42から離間する方向における基準位置に位置させた状態(Y軸側の調整部材50の回転角度が0度)で固定しておき、X軸側の調整部材50を最もレンズ枠42から離間する方向における基準位置に位置させた状態(X軸側の調整部材50の回転角度が0度)からレンズ枠42に近接する方向における最大位置に位置させた状態(X軸側の調整部材50の回転角度が360度)まで変位させた場合の前レンズ38の光軸の変位をX軸、Y軸の座標で示したデータである。

Next, the fact that the position of the

FIG. 7 is a diagram showing the relationship between the displacement amounts (shift amounts) of the two

That is, in FIG. 6, an X axis and a Y axis that intersect with the optical axis and are orthogonal to each other are set in a plane orthogonal to the optical axis. In the present embodiment, the X axis is parallel to the axial direction of one

In FIG. 7, the portion indicated by the symbol A is in a state where the Y-axis

以下これと同様に説明すると、図7において符号Bで示した部分は、X軸側の調整部材50をレンズ枠42に近接する方向における最大位置に位置させた状態(X軸側の調整部材50の回転角度が360度)で固定しておき、Y軸側の調整部材50を最もレンズ枠42から離間する方向における基準位置に位置させた状態(Y軸側の調整部材50の回転角度が0度)からレンズ枠42に近接する方向における最大位置に位置させた状態(Y軸側の調整部材50の回転角度が360度)まで変位させた場合の前レンズ38の光軸の変位をX軸、Y軸の座標で示したデータである。

Hereinafter, in the same manner as described above, the portion indicated by reference numeral B in FIG. 7 is a state where the X-axis

図7において符号Cで示した部分は、X軸側の調整部材50をレンズ枠42から離間する方向における基準位置に位置させた状態(X軸側の調整部材50の回転角度が0度)で固定しておき、Y軸側の調整部材50を最もレンズ枠42から離間する方向における基準位置に位置させた状態(Y軸側の調整部材50の回転角度が0度)からレンズ枠42に近接する方向における最大位置に位置させた状態(Y軸側の調整部材50の回転角度が360度)まで変位させた場合の前レンズ38の光軸の変位をX軸、Y軸の座標で示したデータである。

In FIG. 7, the portion indicated by reference character C is in a state where the X-axis

図7において符号Dで示した部分は、Y軸側の調整部材50をレンズ枠42に近接する方向における最大位置に位置させた状態(Y軸側の調整部材50の回転角度が360度)で固定しておき、X軸側の調整部材50を最もレンズ枠42から離間する方向における基準位置に位置させた状態(X軸側の調整部材50の回転角度が0度)からレンズ枠42に近接する方向における最大位置に位置させた状態(X軸側の調整部材50の回転角度が360度)まで変位させた場合の前レンズ38の光軸の変位をX軸、Y軸の座標で示したデータである。

すなわち、2つの調整部材50を回転することによって、符号A、B、C、Dで示される線で囲まれたひし形の範囲内において前レンズ38の位置を光軸と直交する面内で任意に変位させることができる。

言い換えると、調整機構46による前レンズ38の光軸の調整範囲は、符号A、B、C、Dで示される線で囲まれたひし形の範囲となる。言い換えると、このひし形の範囲に調整範囲が入るように、前レンズ38を含む撮影光学系14を設計すればよい。

7 is a state where the Y-axis

That is, by rotating the two adjusting

In other words, the adjustment range of the optical axis of the

したがって、本実施の形態によれば、前レンズ38の位置調整を行うことが可能となる。

本実施の形態では、2つの調整部材50はそれらの軸心の延長線50Aが前レンズ38の中心から離れた箇所で交差するように延在しているので、レンズ枠42の周囲で2つの調整部材50の間に大きなスペースを確保することが可能となり、これらスペースに調整機構46と隣接する他の機構、例えば、絞り機構40やフォーカス機構などを位置させて配置でき、したがって、レンズ装置および撮像装置10の光軸方向における小型化を図る上で有利となる。

また、2つの調整部材50はそれらの軸心の延長線50Aが前レンズ38の中心から離れた箇所で交差するように延在しているので、各調整部材50の変位に対してレンズ枠42の変位は小さく、したがって、前レンズ38の位置調整を精密に行うことが可能となり、撮像素子30Aの高画素数化に伴って撮影光学系14の光学的性能を向上させる上で有利となる。

Therefore, according to the present embodiment, the position of the

In the present embodiment, the two

Further, the two

10……撮像装置、30A……撮像素子、3208……壁部、3210……開口部、38……前レンズ、42……レンズ枠、44……支持機構、46……調整機構、50……調整部材、52……調整用付勢部材。

DESCRIPTION OF

Claims (8)

開口部を有する壁部と、

前記レンズを前記開口部に臨ませて前記レンズ枠を前記レンズの光軸方向に移動不能に支持する支持機構と、

前記レンズ枠を前記光軸と直交する面内で変位させる調整機構とを備えたレンズ装置であって、

前記調整機構は、2つの調整部材と、1つの調整用付勢部材とで構成され、

前記2つの調整部材はそれらの軸心の延長線が前記レンズの中心から離れた箇所で交差するように延在し、かつ、前記2つの調整部材は前記レンズ枠の互いに異なる2箇所に当接してそれらの軸心方向に変位可能に設けられ、

前記調整用付勢部材は、前記レンズ枠の互いに異なる2箇所が前記2つの調整部材に当接する方向に前記レンズ枠を付勢し、

前記調整用付勢部材は、前記壁部と前記レンズ枠とにわたって設けられたねじりばねで構成され、

前記2つの調整部材の軸心の延長線は、前記レンズの半径方向の外側の箇所で交差するように延在し、かつ、前記光軸方向から見てそれら延長線で囲まれた領域の内側に前記レンズと前記ねじりばねが位置している、

ことを特徴とするレンズ装置。 A lens frame that supports the lens;

A wall having an opening;

A support mechanism for supporting the lens frame so as not to move in the optical axis direction of the lens with the lens facing the opening;

An adjustment mechanism that displaces the lens frame in a plane orthogonal to the optical axis,

The adjustment mechanism includes two adjustment members and one adjustment biasing member,

The two adjustment members extend so that their extension lines intersect at a position away from the center of the lens, and the two adjustment members abut against two different positions of the lens frame. Provided to be displaceable in the axial direction thereof,

The adjustment biasing member biases the lens frame in a direction in which two different positions of the lens frame are in contact with the two adjustment members,

The adjustment biasing member includes a torsion spring provided across the wall portion and the lens frame,

The extension line of the axial center of the two adjusting members extends so as to intersect at a location outside the lens in the radial direction, and is inside the region surrounded by the extension line when viewed from the optical axis direction. The lens and the torsion spring are located in

A lens device.

ことを特徴とする請求項1記載のレンズ装置。 The extension line of the axis of the two adjusting members extends so as to intersect at a right angle at a location outside the lens in the radial direction.

The lens apparatus according to claim 1.

ことを特徴とする請求項1記載のレンズ装置。 Two different positions where the two adjusting members abut on the lens frame are located on an imaginary line extending through a plane orthogonal to the optical axis through the optical axis of the lens, or in the vicinity of the imaginary line Located in the

The lens apparatus according to claim 1.

ことを特徴とする請求項1記載のレンズ装置。 Two different positions where the two adjusting members abut against the lens frame are located in the vicinity of the outer periphery of the lens.

The lens apparatus according to claim 1.

前記2つの調整部材はそれぞれ前記雄ねじ部を前記壁部の雌ねじに螺合して配置されている、

ことを特徴とする請求項1記載のレンズ装置。 Each of the two adjustment members has a male thread portion,

Each of the two adjusting members is disposed by screwing the male screw portion with the female screw of the wall portion,

The lens apparatus according to claim 1.

ことを特徴とする請求項1記載のレンズ装置。 The support mechanism includes a frame-shaped leaf spring that elastically contacts the lens frame and causes the lens frame to abut against the wall portion.

The lens apparatus according to claim 1.

前記撮像装置は、前記レンズ枠、前記支持機構、前記調整機構を収容する鏡筒を備え、

前記壁部は前記鏡筒に一体に設けられている、

ことを特徴とする請求項1記載のレンズ装置。 The support mechanism includes a frame-shaped leaf spring that elastically contacts the lens frame and causes the lens frame to contact the wall portion;

The imaging apparatus includes a lens barrel that houses the lens frame, the support mechanism, and the adjustment mechanism.

The wall is provided integrally with the lens barrel,

The lens apparatus according to claim 1.

開口部を有する壁部と、

前記レンズを前記開口部に臨ませて前記レンズ枠を前記レンズの光軸方向に移動不能に支持する支持機構と、

前記レンズ枠を前記光軸と直交する面内で変位させる調整機構と、

前記レンズの後方に配置された撮像素子とを備えた撮像装置であって、

前記調整機構は、2つの調整部材と、1つの調整用付勢部材とで構成され、

前記2つの調整部材はそれらの軸心の延長線が前記レンズの中心から離れた箇所で交差するように延在し、かつ、前記2つの調整部材は前記レンズ枠の互いに異なる2箇所に当接してそれらの軸心方向に変位可能に設けられ、

前記調整用付勢部材は、前記レンズ枠の互いに異なる2箇所が前記2つの調整部材に当接する方向に前記レンズ枠を付勢し、

前記調整用付勢部材は、前記壁部と前記レンズ枠とにわたって設けられたねじりばねで構成され、

前記2つの調整部材の軸心の延長線は、前記レンズの半径方向の外側の箇所で交差するように延在し、かつ、前記光軸方向から見てそれら延長線で囲まれた領域の内側に前記レンズと前記ねじりばねが位置している、

ことを特徴とする撮像装置。 A lens frame that supports the lens;

A wall having an opening;

A support mechanism for supporting the lens frame so as not to move in the optical axis direction of the lens with the lens facing the opening;

An adjustment mechanism for displacing the lens frame in a plane orthogonal to the optical axis;

An imaging device including an imaging element disposed behind the lens,

The adjustment mechanism includes two adjustment members and one adjustment biasing member,

The two adjustment members extend so that their extension lines intersect at a position away from the center of the lens, and the two adjustment members abut against two different positions of the lens frame. Provided to be displaceable in the axial direction thereof,

The adjustment biasing member biases the lens frame in a direction in which two different positions of the lens frame are in contact with the two adjustment members,

The adjustment biasing member includes a torsion spring provided across the wall portion and the lens frame,

The extension line of the axial center of the two adjusting members extends so as to intersect at a location outside the lens in the radial direction, and is inside the region surrounded by the extension line when viewed from the optical axis direction. The lens and the torsion spring are located in

An imaging apparatus characterized by that.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007008865A JP4858776B2 (en) | 2007-01-18 | 2007-01-18 | LENS DEVICE AND IMAGING DEVICE |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007008865A JP4858776B2 (en) | 2007-01-18 | 2007-01-18 | LENS DEVICE AND IMAGING DEVICE |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2008176013A JP2008176013A (en) | 2008-07-31 |

| JP2008176013A5 JP2008176013A5 (en) | 2010-03-04 |

| JP4858776B2 true JP4858776B2 (en) | 2012-01-18 |

Family

ID=39703084

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007008865A Expired - Fee Related JP4858776B2 (en) | 2007-01-18 | 2007-01-18 | LENS DEVICE AND IMAGING DEVICE |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4858776B2 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012058631A (en) | 2010-09-13 | 2012-03-22 | Ricoh Co Ltd | Lens barrel |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3903948B2 (en) * | 2002-09-25 | 2007-04-11 | ソニー株式会社 | Lens alignment mechanism, lens device, and imaging device |

| JP2005055757A (en) * | 2003-08-06 | 2005-03-03 | Sony Corp | Image pickup device and lens system |

| JP2006172666A (en) * | 2004-12-20 | 2006-06-29 | Pulstec Industrial Co Ltd | Optical pickup device, and method for attaching lens holder in optical disk device |

| JP4633484B2 (en) * | 2005-01-19 | 2011-02-16 | オリンパス株式会社 | Optical element support mechanism |

-

2007

- 2007-01-18 JP JP2007008865A patent/JP4858776B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2008176013A (en) | 2008-07-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9007469B2 (en) | Lens barrel and image pickup device | |

| JP6415102B2 (en) | Lens barrel and optical apparatus having the same | |

| JP4218964B2 (en) | LENS DEVICE AND IMAGING DEVICE | |

| JP6271904B2 (en) | Lens barrel and imaging device | |

| JP5868074B2 (en) | Lens barrel and imaging device | |

| JP5566164B2 (en) | Lens barrel and imaging device | |

| CN110389421B (en) | Lens barrel | |

| JP4858776B2 (en) | LENS DEVICE AND IMAGING DEVICE | |

| JP2005055757A (en) | Image pickup device and lens system | |

| JP2011215278A (en) | Lens barrel and image pickup apparatus | |

| JP5585199B2 (en) | Lens barrel and imaging device | |

| JP4683127B2 (en) | Lens barrel and imaging device provided with the same | |

| JP6448186B2 (en) | Lens barrel and optical apparatus equipped with the same | |

| JP6136089B2 (en) | Lens barrel and imaging device | |

| JP2009181102A (en) | Lens barrel and imaging device | |

| JP2005055761A (en) | Imaging device and lens device and method for manufacturing the same | |

| JP2016031443A (en) | Lens barrel and optical device having the same | |

| JP7646347B2 (en) | Lens barrel and imaging device | |

| JP2012078806A (en) | Lens barrel and imaging device | |

| JP2015118131A (en) | Imaging apparatus | |

| JP7580928B2 (en) | Lens device and imaging device | |

| JP5168024B2 (en) | Lens barrel and imaging device | |

| JP4612910B2 (en) | LENS DEVICE AND IMAGING DEVICE | |

| JP4433270B2 (en) | Imaging device and lens device | |

| JP4636913B2 (en) | Lens barrel and optical equipment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20090814 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20091015 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100114 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100114 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110520 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110609 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110728 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20111006 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20111019 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20141111 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |