JP4766889B2 - Air conditioner - Google Patents

Air conditioner Download PDFInfo

- Publication number

- JP4766889B2 JP4766889B2 JP2005074817A JP2005074817A JP4766889B2 JP 4766889 B2 JP4766889 B2 JP 4766889B2 JP 2005074817 A JP2005074817 A JP 2005074817A JP 2005074817 A JP2005074817 A JP 2005074817A JP 4766889 B2 JP4766889 B2 JP 4766889B2

- Authority

- JP

- Japan

- Prior art keywords

- fan

- end edge

- rear guider

- separator

- center

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000005192 partition Methods 0.000 description 7

- 238000007664 blowing Methods 0.000 description 4

- 230000000694 effects Effects 0.000 description 3

- 238000000638 solvent extraction Methods 0.000 description 2

- 230000001133 acceleration Effects 0.000 description 1

- 238000004378 air conditioning Methods 0.000 description 1

- 239000011436 cob Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F13/00—Details common to, or for air-conditioning, air-humidification, ventilation or use of air currents for screening

- F24F13/24—Means for preventing or suppressing noise

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F1/00—Room units for air-conditioning, e.g. separate or self-contained units or units receiving primary air from a central station

- F24F1/0007—Indoor units, e.g. fan coil units

- F24F1/0083—Indoor units, e.g. fan coil units with dehumidification means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D17/00—Radial-flow pumps, e.g. centrifugal pumps; Helico-centrifugal pumps

- F04D17/02—Radial-flow pumps, e.g. centrifugal pumps; Helico-centrifugal pumps having non-centrifugal stages, e.g. centripetal

- F04D17/04—Radial-flow pumps, e.g. centrifugal pumps; Helico-centrifugal pumps having non-centrifugal stages, e.g. centripetal of transverse-flow type

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D25/00—Pumping installations or systems

- F04D25/16—Combinations of two or more pumps ; Producing two or more separate gas flows

- F04D25/166—Combinations of two or more pumps ; Producing two or more separate gas flows using fans

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/58—Cooling; Heating; Diminishing heat transfer

- F04D29/582—Cooling; Heating; Diminishing heat transfer specially adapted for elastic fluid pumps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F1/00—Room units for air-conditioning, e.g. separate or self-contained units or units receiving primary air from a central station

- F24F1/0007—Indoor units, e.g. fan coil units

- F24F1/0018—Indoor units, e.g. fan coil units characterised by fans

- F24F1/0025—Cross-flow or tangential fans

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F1/00—Room units for air-conditioning, e.g. separate or self-contained units or units receiving primary air from a central station

- F24F1/0007—Indoor units, e.g. fan coil units

- F24F1/0018—Indoor units, e.g. fan coil units characterised by fans

- F24F1/0033—Indoor units, e.g. fan coil units characterised by fans having two or more fans

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F1/00—Room units for air-conditioning, e.g. separate or self-contained units or units receiving primary air from a central station

- F24F1/0007—Indoor units, e.g. fan coil units

- F24F1/0043—Indoor units, e.g. fan coil units characterised by mounting arrangements

- F24F1/005—Indoor units, e.g. fan coil units characterised by mounting arrangements mounted on the floor; standing on the floor

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Air-Conditioning Room Units, And Self-Contained Units In General (AREA)

- Air Filters, Heat-Exchange Apparatuses, And Housings Of Air-Conditioning Units (AREA)

Description

この発明は空気調和機、特に、前面上下に吹き出し口を有する空気調和機の室内機に関する。 The present invention relates to an air conditioner, and more particularly, to an indoor unit of an air conditioner having outlets on the upper and lower sides of a front surface.

従来、室内の温度や湿度を快適に維持するため、上下に吹き出し口を具備した空気調和機が開示されている(例えば、特許文献1参照)。

また、上下に吹き出す風の風量が互いに干渉しないように、上ファンと下ファンとの間に仕切板を設置した発明が開示されている(例えば、特許文献2参照)。

さらに、上部ファンと下部ファンとの回転数に差を設けた場合でも、風流れが安定するように、上部ファンと下部ファンとの間の仕切板を移動自在にした発明が開示されている(例えば、特許文献3参照)。

Conventionally, in order to maintain indoor temperature and humidity comfortably, an air conditioner having upper and lower outlets has been disclosed (see, for example, Patent Document 1).

Further, an invention is disclosed in which a partition plate is installed between the upper fan and the lower fan so that the amounts of winds blown up and down do not interfere with each other (see, for example, Patent Document 2).

Furthermore, an invention is disclosed in which the partition plate between the upper fan and the lower fan is movable so that the wind flow is stable even when there is a difference in the rotational speed between the upper fan and the lower fan ( For example, see Patent Document 3).

しかしながら、特許文献1〜3に開示された発明は、上側送風機(上ファン、上部ファン)および下側送風機(下ファン、下部ファン)の能力が発揮されず、また、騒音が出るという問題があった。

すなわち、特許文献1に開示された発明は、上側送風機と下側送風機との間に前面に向かって断面山状に突出するセパレータを有し、吸引する空気を上下に分流させるものであるため、該セパレータの裾野と上側送風機および下側送風機との間(吸込側に同じ)に、所定の範囲にわたる所定の隙間が確保されないため、気流が乱れ風速を増すことができない。

However, the inventions disclosed in

That is, the invention disclosed in

また、特許文献2に開示された発明は、平面状の背面に仕切板を立設しただけのものであるため、仕切板の周囲で吸引する空気に淀や乱れが生じると共に、上ファンおよび下ファンの吸込側に所定の範囲にわたる所定の隙間が確保されないため、気流が乱れ風速を増すことができない。

さらに、特許文献3に開示された発明は、移動自在な仕切板を設置しているため、そのための移動機構を必要とし、部品点数の増大や重量の増加、さらには故障等による保全性の悪化と共に、仕切板の移動範囲を確保するために、上部ファンおよび下部ファンの吸込側に所定の範囲にわたる所定の隙間が確保されないため、気流が乱れ風速を増すことができない。

Further, since the invention disclosed in

Furthermore, since the invention disclosed in

この発明は、上記のような課題を解決するためになされたもので、簡素な構成であって、上方ファンおよび下方ファンのそれぞれに向かってなめらかに分流され、且つ、乱れが少なく風速の増した気流を形成するセパレータを具備する空気調和機を得ることを目的とする。合わせて、上吹き単独(上方ファンのみ運転して、下方ファンを停止する)でも風量が低下せず、低騒音な空気調和機を得ることを目的とする。 The present invention has been made in order to solve the above-described problems, has a simple configuration, smoothly diverts toward the upper fan and the lower fan, and has less turbulence and increased wind speed. It aims at obtaining the air conditioner which comprises the separator which forms airflow. In addition, an object is to obtain a low-noise air conditioner in which the air volume does not decrease even when the top blower is alone (only the upper fan is operated and the lower fan is stopped).

この発明に係る空気調和機は、筐体と、該筐体の前面中央部に設置された吸込口と、該吸込口に対峙して前記筐体の内部に設置された熱交換器と、該筐体の前面上部および前面下部にそれぞれ設置された上方吹出口および下方吹出口と、該上方吹出口および下方吹出口のそれぞれに向けて送風する上方ファンおよび下方ファンと、該上方ファンおよび下方ファンのそれぞれの後面側に設置された断面円弧状の上方リアガイダおよび下方リアガイダと、前記熱交換器に対峙して前記筐体の内部に設置された断面略W字状の波形セパレータと、を有し、

前記波状セパレータは、断面中央部で前面に向かって略円弧状に突出する中央山部と、該中央山部の上方および下方のそれぞれになめらかに連なって、背面に向かって略円弧状に凹陥する上方谷部および下方谷部とを具備し、

前記上方リアガイダの下端縁と前記波状セパレータの上方谷部の上端縁とが接続され、前記下方リアガイダの上端縁と前記波状セパレータの下方谷部の下端縁とが接続され、

前記上方リアガイダの下端縁および前記下方リアガイダの上端縁が、前記上方ファンの中心と前記下方ファンの中心とを結ぶ線上に略位置し、

前記波状セパレータの中央山部の頂点が、前記熱交換器の下端縁と前記上方リアガイダの下端縁とを結んだ面よりも背面側に位置し、且つ、前記上方ファンの中心と前記下方ファンの中心とを結ぶ線よりも前面側に位置することを特徴とする。

An air conditioner according to the present invention includes a housing, a suction port installed at a front center portion of the housing, a heat exchanger installed inside the housing so as to face the suction port, An upper blower outlet and a lower blower outlet installed at the front upper part and the lower front part of the casing, an upper fan and a lower fan for blowing air toward the upper blower outlet and the lower blower, respectively, and the upper fan and lower fan An upper rear guider and a lower rear guider each having an arcuate cross section installed on each rear surface side thereof, and a corrugated separator having a substantially W-shaped cross section installed inside the casing so as to face the heat exchanger. ,

The corrugated separator is smoothly connected to a central mountain portion that protrudes in a substantially arc shape toward the front surface at the center of the cross section and above and below the central mountain portion, and is recessed in a substantially arc shape toward the back surface. An upper trough and a lower trough,

The lower end edge of the upper rear guider and the upper end edge of the upper valley portion of the wavy separator are connected, the upper end edge of the lower rear guider and the lower end edge of the lower valley portion of the wavy separator are connected,

The lower end edge of the upper rear guider and the upper end edge of the lower rear guider are substantially located on a line connecting the center of the upper fan and the center of the lower fan ,

The apex of the central peak of the wavy separator is located on the back side of the surface connecting the lower end edge of the heat exchanger and the lower end edge of the upper rear guider, and the center of the upper fan and the lower fan It is characterized by being located on the front side of the line connecting the center .

この発明の空気調和機は、該上方ファンおよび下方ファンに上方リアガイダおよび下方リアガイダが設置され、断面略W字状の波状セパレータの略円弧状に突出する中央山部が、気流をなめらかに分流し、該分流された気流をリアガイドにまで導くから、大きな整流効果および低騒音化効果、ならびに上方ファンおよび下方ファンの能力向上効果が奏される。 In the air conditioner of the present invention, an upper rear guider and a lower rear guider are installed on the upper fan and the lower fan, and a central mountain portion protruding in a substantially arc shape of a wave-shaped separator having a substantially W-shaped cross section smoothly divides the airflow. Since the diverted airflow is guided to the rear guide, a large rectifying effect and noise reduction effect, and an ability improvement effect of the upper fan and the lower fan are exhibited.

[実施の形態1]

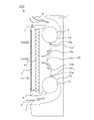

図1は本発明の実施の形態1に係る空気調和機の構成を説明する縦断面図である。

図1において、空気調和機(図示しない)の室内機100は筐体1を有し、筐体1の前面(図中、左側)の上部には上方吹出口3、下部には下方吹出口4があり、前面中央部には吸込口2が設けれて、上方吹出口3および下方吹出口4には、気流の方向を変更する上方風向可変板5および下方風向可変板6が、それぞれ設置されている。

筐体1の内部には、上吹出口3および下吹出口4のそれぞれに向けて送風する上方貫流ファン9および下方貫流ファン10が設置され、上方貫流ファン9および下方貫流ファン10の背面側には、断面略円弧状の上方リアガイダ14および下方リアガイダ15が、それぞれ配置されている。

[Embodiment 1]

FIG. 1 is a longitudinal sectional view illustrating the configuration of an air conditioner according to

In FIG. 1, an

An

そして、吸込口2に対峙して筐体1の内部に、熱交換器13が配置され、熱交換器13の上端縁には上吹出口3との間を仕切るための上吹出ノズル7と、熱交換器13の下端縁には下吹出口4との間を仕切るための下吹出ノズル8と、が配設されている。

さらに、熱交換器13の背面側(図中、右側)には波形セパレータ12が設置されている。波形セパレータ12は断面略W字状であって、断面中央部で前面に向かって略円弧状に突出する中央山部(以下「コブ」と称す)12cと、コブ12cの上方および下方のそれぞれになめらかに連なり、背面に向かって略円弧状に凹陥する上方谷部12bおよび下方谷部12dを具備している。そして、上方リアガイダ14の下端縁14aと波状セパレータ12の上方谷部12bの上端縁12aとが接続され、下方リアガイダ15の上端縁15aと波状セパレータ12の下方谷部12dの下端縁12eとが接続されている。

And the

Further, a

次に動作について説明する。

このように構成された空気調和機の室内機100(上下2フローの室内機)において、室内の空気は上方貫流ファン9および下方貫流ファン10に引かれることより吸込口2から吸い込まれ、熱交換器13で熱交換された後、断面略円弧状のコブ12cで上下に整流されながら分流される。そして、分流された気流はそれぞれ、上方谷部12bおよび下方谷部12dになめらかに案内されて上方貫流ファン9および下方貫流ファン10に吸い込まれ、上方吹出口3および下方吹出口4からそれぞれ上方風向可変版5および下方風向可変版6で決められた角度でもって吹き出される。

Next, the operation will be described.

In the indoor unit 100 (upper and lower two-flow indoor unit) of the air conditioner configured as described above, indoor air is drawn from the

このとき、セパレータ12は断面略円弧状の上方谷部12bとコブ12cと下方谷部12dとがなめらかな曲線で結ばれて略W字状を呈し、上縁部12aおよび下縁部12eが上方リアガイダ14の下縁部14aおよび下方リアガイダ15の上縁部15aにそれぞれ接合されているから、上方リアガイダ14とセパレータ12と下方リアガイダ15とによって、波状(谷数が4)のケーシングが形成されている。したがって、前記分流時に気流の乱れはなく、低騒音な室内機100が形成される。また、気流の乱れがなく、しかも上方リアガイダ14および下方リアガイダ15によって整流や増速が図られるため、風量がアップする。

さらに、上下分流用の仕切板等の移動機構を持たないため、簡素な構造であって、部品点数や重量の増加が防止され、製造コストが安価に維持されながら、信頼性の向上した空気調和機が得られる。

At this time, the

In addition, since it does not have a moving mechanism such as a partition plate for vertical splitting, it has a simple structure, prevents an increase in the number of parts and weight, maintains a low manufacturing cost, and improves air conditioning with improved reliability. A machine is obtained.

[実施の形態2]

以上の実施の形態1では、上下2フロー時の風路構成を示しているが、次に、上吹出し単独の1フロー時の構成について説明する。

図2は本発明の実施の形態2に係る空気調和機の構成を説明する縦断面図である。なお、実施の形態1(図1)と同一又は相当する部分については同一の符号を付し、一部の説明を省略する。

[Embodiment 2]

In the first embodiment described above, the air path configuration at the time of the upper and lower two flows is shown. Next, the configuration at the time of one flow of the upper blowing alone will be described.

FIG. 2 is a longitudinal sectional view illustrating the configuration of an air conditioner according to

図2において、下方風向可変板6は回転することで下方吹出口4を密閉している。また、破線Aは熱交換器13の下端縁13aと上方リアガイダ14の下端縁14aとを結んだ線であり、セパレータ12のコブ12cの頂点は、破線Aよりも背面側に位置することを特徴としている。すなわち、以上のようにセパレータ12を構成しているので、上吹き1フロー時においても熱交換器13の下方から吸い込んだ空気はコブ12cが抵抗とならずなめらかにセパレータ12に沿って流れるため、風量低下が起こらず、且つ低騒音化が可能となる。

In FIG. 2, the lower air

[実施の形態3]

図3は本発明の実施の形態3に係る空気調和機のセパレータの要部縦断面図である。なお、実施の形態1(図1)と同一又は相当する部分については同一の符号を付し、一部の説明を省略する。

図3において、断面略円弧状のコブ12cの頂点は、上方貫流ファン9の中心からの距離h1と下方貫流ファン10の中心からの距離h2が等しくなる位置(h1=h2)に配置されている。

また、コブ12cに連なる上方谷部12bおよび下方谷部12dのカーブは、点線Bのように深過ぎても、また点線Cのように浅過ぎても吸い込んだ風が極端に曲げられて抵抗になるため好ましくなく、なめらかに導かれるカーブを形成することが重要である。またカーブは使用するファンや熱交換器の仕様によっても変動する。

[Embodiment 3]

FIG. 3 is a longitudinal sectional view of a main part of a separator of an air conditioner according to

In FIG. 3, the apex of the

Also, the curves of the

以上のように、上方ファン9および下方ファン10のほぼ中間位置に断面略円弧状状のコブ12cを配置することで、上下の風量比が略等しくなり(1:1に近づき)、熱交換器13を通過する空気の速度が均一化されることで低騒音化になる。さらに、熱交換器13を通過する空気の速度が均一化されることで、熱交換の偏りがなくなり熱交換効率が向上する。

As described above, the upper and lower airflow ratios are substantially equal (approaching 1: 1) by disposing the

1 筐体、2 吸込口、3 上方吹出口、4 下方吹出口、5 上方風向可変板、6 下方風向可変板、7 上方吹出ノズル、8 下方吹出ノズル、9 上方貫流ファン、10 下方貫流ファン、12 セパレータ、12b 上方谷部、12c 中央山部(コブ)、12d 下方谷部、13 熱交換器、14 上方リアガイダ、15 下方リアガイダ。

DESCRIPTION OF

Claims (1)

前記波状セパレータは、断面中央部で前面に向かって略円弧状に突出する中央山部と、該中央山部の上方および下方のそれぞれになめらかに連なって、背面に向かって略円弧状に凹陥する上方谷部および下方谷部とを具備し、

前記上方リアガイダの下端縁と前記波状セパレータの上方谷部の上端縁とが接続され、前記下方リアガイダの上端縁と前記波状セパレータの下方谷部の下端縁とが接続され、

前記上方リアガイダの下端縁および前記下方リアガイダの上端縁が、前記上方ファンの中心と前記下方ファンの中心とを結ぶ線上に略位置し、

前記波状セパレータの中央山部の頂点が、前記熱交換器の下端縁と前記上方リアガイダの下端縁とを結んだ面よりも背面側に位置し、且つ、前記上方ファンの中心と前記下方ファンの中心とを結ぶ線よりも前面側に位置することを特徴とする空気調和機。 A housing, a suction port installed in the center of the front surface of the housing, a heat exchanger installed in the housing facing the suction port, and an upper front portion and a lower front surface of the housing Installed on the rear side of each of the upper fan and the lower fan, the upper fan and the lower fan that blow air toward the upper blower outlet and the lower blower, respectively, and the upper fan and the lower fan. An upper rear guider and a lower rear guider each having an arcuate cross section, and a corrugated separator having a substantially W-shaped cross section installed inside the casing so as to face the heat exchanger;

The corrugated separator is smoothly connected to a central mountain portion that protrudes in a substantially arc shape toward the front surface at the center of the cross section and above and below the central mountain portion, and is recessed in a substantially arc shape toward the back surface. An upper trough and a lower trough,

The lower end edge of the upper rear guider and the upper end edge of the upper valley portion of the wavy separator are connected, the upper end edge of the lower rear guider and the lower end edge of the lower valley portion of the wavy separator are connected,

The lower end edge of the upper rear guider and the upper end edge of the lower rear guider are substantially located on a line connecting the center of the upper fan and the center of the lower fan ,

The apex of the central peak of the wavy separator is located on the back side of the surface connecting the lower end edge of the heat exchanger and the lower end edge of the upper rear guider, and the center of the upper fan and the lower fan An air conditioner characterized by being located on the front side of a line connecting the center .

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005074817A JP4766889B2 (en) | 2005-03-16 | 2005-03-16 | Air conditioner |

| ES06251294T ES2318692T3 (en) | 2005-03-16 | 2006-03-10 | AIR CONDITIONING. |

| EP06251294A EP1703217B1 (en) | 2005-03-16 | 2006-03-10 | Air conditioner |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005074817A JP4766889B2 (en) | 2005-03-16 | 2005-03-16 | Air conditioner |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2006258344A JP2006258344A (en) | 2006-09-28 |

| JP2006258344A5 JP2006258344A5 (en) | 2007-10-18 |

| JP4766889B2 true JP4766889B2 (en) | 2011-09-07 |

Family

ID=36606095

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005074817A Expired - Fee Related JP4766889B2 (en) | 2005-03-16 | 2005-03-16 | Air conditioner |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1703217B1 (en) |

| JP (1) | JP4766889B2 (en) |

| ES (1) | ES2318692T3 (en) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5410047B2 (en) * | 2008-07-25 | 2014-02-05 | 三洋電機株式会社 | Air conditioner |

| CN105841208B (en) * | 2013-07-26 | 2017-12-22 | 广东美的制冷设备有限公司 | Floor air conditioner air channel structure and vertical air conditioner indoor unit |

| CN105240930B (en) * | 2015-09-11 | 2017-12-19 | 珠海格力电器股份有限公司 | Air volume adjusting method of air volume adjusting device |

| CN106091319A (en) * | 2016-06-01 | 2016-11-09 | 珠海格力电器股份有限公司 | Air conditioner |

| CN106287966A (en) * | 2016-08-26 | 2017-01-04 | 沈炜 | Silent air-conditioning |

| CN111089405B (en) * | 2019-12-24 | 2020-11-24 | 珠海格力电器股份有限公司 | Air outlet control method and device for single centrifugal fan, controller and air conditioning unit |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5663914U (en) * | 1979-10-24 | 1981-05-29 | ||

| JPS61153426A (en) * | 1984-12-27 | 1986-07-12 | Matsushita Electric Ind Co Ltd | Air conditioner |

| JP2591041B2 (en) * | 1988-03-16 | 1997-03-19 | 三菱電機株式会社 | Air conditioner |

| JP2810445B2 (en) * | 1989-09-29 | 1998-10-15 | 三洋電機株式会社 | Air conditioner |

| JPH03158630A (en) * | 1989-11-15 | 1991-07-08 | Sanyo Electric Co Ltd | Heat exchanging device |

| JP2689802B2 (en) * | 1992-01-23 | 1997-12-10 | 松下電器産業株式会社 | Air conditioner |

| JPH07233957A (en) * | 1994-02-24 | 1995-09-05 | Toshiba Corp | Air conditioner |

| JPH08178338A (en) * | 1994-12-27 | 1996-07-12 | Toshiba Corp | Indoor device of air conditioner |

| JP3661471B2 (en) * | 1999-02-17 | 2005-06-15 | 松下電器産業株式会社 | Air conditioner |

-

2005

- 2005-03-16 JP JP2005074817A patent/JP4766889B2/en not_active Expired - Fee Related

-

2006

- 2006-03-10 ES ES06251294T patent/ES2318692T3/en active Active

- 2006-03-10 EP EP06251294A patent/EP1703217B1/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| ES2318692T3 (en) | 2009-05-01 |

| JP2006258344A (en) | 2006-09-28 |

| EP1703217B1 (en) | 2009-01-21 |

| EP1703217A1 (en) | 2006-09-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5143173B2 (en) | Turbo fan and air conditioner indoor unit equipped with the same | |

| JP5029577B2 (en) | Air conditioner indoor unit | |

| JP5955402B2 (en) | Turbofan and air conditioner | |

| JP6248486B2 (en) | Air conditioner duct type indoor unit | |

| JP3268279B2 (en) | Air conditioner | |

| JP4766889B2 (en) | Air conditioner | |

| JP6167780B2 (en) | Fan unit and air conditioner | |

| JP6324316B2 (en) | Air conditioner indoor unit | |

| JP2007170331A (en) | Turbofan and indoor unit of air conditioner using it | |

| JP5837235B2 (en) | Air conditioner outdoor unit | |

| JP2000065418A (en) | Air conditioner | |

| CN209541018U (en) | Gas rectifier structure, axial flow blower, air conditioner indoor unit and air-conditioner outdoor unit | |

| JP4371171B2 (en) | Cross flow fan and air conditioner equipped with the same | |

| CN108469073B (en) | Window type air conditioning equipment | |

| JP2008157530A (en) | Indoor unit for air conditioner | |

| JP2007154685A (en) | Turbo fan and air conditioner using the same | |

| JPH0593523A (en) | Air conditioner | |

| US11536290B2 (en) | Fan coil unit and air conditioning system | |

| JP2002357194A (en) | Cross-flow fan | |

| JP7531172B2 (en) | Air conditioner indoor unit | |

| JP3758592B2 (en) | Recessed ceiling air conditioner | |

| WO2014097437A1 (en) | Indoor unit for air conditioning device | |

| CN208671172U (en) | Lead wind pendulum leaf component and air conditioner | |

| WO2013124877A1 (en) | Outdoor unit for air conditioner | |

| JP6094749B2 (en) | Air conditioner |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070830 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070830 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100115 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100126 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100226 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20100413 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110513 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110614 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4766889 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140624 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |