JP4653758B2 - 溶融金属のための加熱樋 - Google Patents

溶融金属のための加熱樋 Download PDFInfo

- Publication number

- JP4653758B2 JP4653758B2 JP2006543326A JP2006543326A JP4653758B2 JP 4653758 B2 JP4653758 B2 JP 4653758B2 JP 2006543326 A JP2006543326 A JP 2006543326A JP 2006543326 A JP2006543326 A JP 2006543326A JP 4653758 B2 JP4653758 B2 JP 4653758B2

- Authority

- JP

- Japan

- Prior art keywords

- heating element

- heat

- metal

- molten metal

- bag

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D41/00—Casting melt-holding vessels, e.g. ladles, tundishes, cups or the like

- B22D41/005—Casting melt-holding vessels, e.g. ladles, tundishes, cups or the like with heating or cooling means

- B22D41/01—Heating means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D35/00—Equipment for conveying molten metal into beds or moulds

- B22D35/04—Equipment for conveying molten metal into beds or moulds into moulds, e.g. base plates, runners

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D35/00—Equipment for conveying molten metal into beds or moulds

- B22D35/06—Heating or cooling equipment

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Furnace Details (AREA)

- Vertical, Hearth, Or Arc Furnaces (AREA)

- Casting Support Devices, Ladles, And Melt Control Thereby (AREA)

- Furnace Charging Or Discharging (AREA)

- Continuous Casting (AREA)

- Furnace Housings, Linings, Walls, And Ceilings (AREA)

- Refinement Of Pig-Iron, Manufacture Of Cast Iron, And Steel Manufacture Other Than In Revolving Furnaces (AREA)

- Coating With Molten Metal (AREA)

Description

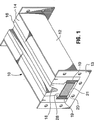

12 外胴部、

13 エンドプレート、

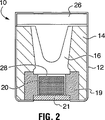

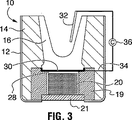

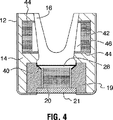

14 断熱層、

16 樋本体、

18 溶融金属、

19 支柱、

20 発熱体、

21 閉鎖板、

26 断熱蓋、

28 空隙、

30 素焼板、

32 探針、

34 電気的接続部、

36 伝導率検出器、

40 先細り形、

42 (側面)加熱器、

44 支持材、

46 放熱間隙。

Claims (18)

- 溶融金属を輸送するための樋であって、

(a)下部壁と2つの側壁とにより形成された外胴部と、

(b)外胴部を満たす断熱層と、

(c)断熱層に埋め込まれた、溶融金属を輸送するための伝導性及び耐熱性のある樋本体と、

(d)発熱体と樋本体との間に空隙を設けるため、樋本体に近接させつつ間隙を置いて、断熱層の中に位置付けられた発熱体とを備えたことを特徴とする樋。 - 発熱体と樋本体との間の空隙は少なくとも0.5cmであることを特徴とする請求項1記載の樋。

- 発熱体と樋本体との間の空隙は1.0cmより小さいことを特徴とする請求項1記載の樋。

- 発熱体は樋の下部端近傍に位置付けられていることを特徴とする請求項1記載の樋。

- 発熱体は樋の側壁近傍に位置付けられていることを特徴とする請求項4記載の樋。

- 樋本体は炭化珪素又は黒鉛で作られていることを特徴とする請求項1記載の樋。

- 発熱体近傍に、樋本体の外部表面に取り付けられた金属浸入防壁手段をさらに備えたことを特徴とする請求項1記載の樋。

- 金属浸入防壁手段は合金又は非金属で作られていることを特徴とする請求項7記載の樋。

- 合金は鉄・ニッケル・クロム合金であることを特徴とする請求項8記載の樋。

- 非金属は黒鉛であることを特徴とする請求項8記載の樋。

- 発熱体と溶融金属近傍の樋本体の中とに取り付けられた熱電対と、

発熱体から出力される熱を制御するためのP.I.D.閉ループ制御プログラムとをさらに備えたことを特徴とする請求項1記載の樋。 - 金属浸入防壁との1つの連結部と、樋の中の溶融金属の中に挿入するのに適したもう1つの連結部とに接続された伝導率検出器をさらに備え、

上記伝導率検出器は、測定された伝導率が樋内面への金属浸入の結果として増加したとき信号を出すための手段を備えたことを特徴とする請求項7記載の樋。 - 樋の中で輸送されている溶融金属を加熱するための方法であって、

上記樋は、

下部壁と一対の側壁とにより形成された外胴部と、

外胴部を満たす断熱層と

断熱層に埋め込まれた、溶融金属を輸送するための伝導性及び耐熱性のある樋本体と、

発熱体と樋との間に空隙を設けるため、樋本体に近接させつつ間隙を置いて、断熱層の中に位置付けられた発熱体とを備え、

空隙を横切る放射熱伝達により加熱器から樋本体へ熱を移動させ、それによって樋本体及びその中で輸送されている溶融金属を一様に加熱することを特徴とする方法。 - 空隙幅は、0.5cmから1.0cmまでであることを特徴とする請求項13記載の方法。

- 発熱体を樋の下部端近傍に位置付けることを特徴とする請求項13記載の方法。

- 発熱体を樋の側壁近傍に位置付けることを特徴とする請求項13記載の方法。

- 発熱体から出力される熱を制御するため、発熱体と溶融金属近傍の樋本体の温度を測定し利用することを特徴とする請求項13記載の方法。

- 金属浸入防壁手段を発熱体近傍の樋本体の外側表面上に設け、

浸入防壁と樋の中の溶融金属との間で伝導率を測定し、伝導率の増加により樋内面への金属浸入を知らせることを特徴とする請求項13記載の方法。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/735,075 US6973955B2 (en) | 2003-12-11 | 2003-12-11 | Heated trough for molten metal |

| PCT/CA2004/002085 WO2005056219A1 (en) | 2003-12-11 | 2004-12-07 | Heated trough for molten metal |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2007513770A JP2007513770A (ja) | 2007-05-31 |

| JP4653758B2 true JP4653758B2 (ja) | 2011-03-16 |

Family

ID=34653527

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006543326A Expired - Lifetime JP4653758B2 (ja) | 2003-12-11 | 2004-12-07 | 溶融金属のための加熱樋 |

Country Status (14)

| Country | Link |

|---|---|

| US (1) | US6973955B2 (ja) |

| EP (1) | EP1691945B1 (ja) |

| JP (1) | JP4653758B2 (ja) |

| KR (1) | KR101130362B1 (ja) |

| CN (1) | CN1894061B (ja) |

| AT (1) | ATE385868T1 (ja) |

| BR (1) | BRPI0417475B1 (ja) |

| CA (1) | CA2546085C (ja) |

| DE (1) | DE602004011816T2 (ja) |

| ES (1) | ES2298844T3 (ja) |

| NO (1) | NO20063130L (ja) |

| PT (1) | PT1691945E (ja) |

| RU (1) | RU2358831C2 (ja) |

| WO (1) | WO2005056219A1 (ja) |

Families Citing this family (34)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2107956A1 (en) * | 2006-12-19 | 2009-10-14 | Novelis Inc. | Method of and apparatus for conveying molten metals while providing heat thereto |

| US20110017785A1 (en) * | 2008-01-21 | 2011-01-27 | Edward Dean Carman | Launder assembly and launder section |

| US9095896B2 (en) * | 2008-11-03 | 2015-08-04 | Pyrotek, Inc. | Heated molten metal handling device |

| RU2542038C2 (ru) * | 2009-12-10 | 2015-02-20 | Новелис Инк. | Способ формирования герметичных огнеупорных стыков в емкости для металла, и емкость, имеющая такие стыки |

| US8883070B2 (en) * | 2009-12-10 | 2014-11-11 | Novelis Inc. | Molten metal containment structure having flow through ventilation |

| ES2537981T3 (es) | 2009-12-10 | 2015-06-16 | Novelis, Inc. | Recipiente que contiene metal fundido y procedimientos de fabricación del mismo |

| US8945465B2 (en) * | 2009-12-10 | 2015-02-03 | Novelis Inc. | Compressive rod assembly for molten metal containment structure |

| EP2998047B1 (en) * | 2010-04-19 | 2017-06-07 | Novelis, Inc. | Thermal optimization in vessels used for containing molten metals |

| CN102719808A (zh) * | 2011-03-30 | 2012-10-10 | 北京北方微电子基地设备工艺研究中心有限责任公司 | 托盘及具有其的基片加工设备 |

| CN102497680B (zh) * | 2011-11-28 | 2013-06-19 | 武汉船用机械有限责任公司 | 一种衬套的加热装置 |

| CN103286286B (zh) * | 2012-02-22 | 2016-08-03 | 株式会社神户制钢所 | 对镁或镁合金构成的铸造物进行连续铸造的连续铸造装置及连续铸造方法 |

| EP2861340B1 (en) * | 2012-06-14 | 2017-12-06 | Pyrotek, Inc. | Receptacle for handling molten metal |

| CN102997684A (zh) * | 2012-11-09 | 2013-03-27 | 江苏熙友磁电科技有限公司 | 保温炉入口浇嘴 |

| CN102974813A (zh) * | 2012-12-26 | 2013-03-20 | 烟台孚信达双金属股份有限公司 | 用于铜包铝水平连铸的铝液保温净化输送包 |

| GB2515475B (en) * | 2013-06-21 | 2016-08-31 | Emp Tech Ltd | Metallurgical apparatus |

| CN103438718A (zh) * | 2013-07-24 | 2013-12-11 | 无锡圣恩铜业有限公司 | 保温炉入口浇嘴 |

| GB201314376D0 (en) * | 2013-08-12 | 2013-09-25 | Pyrotek Engineering Materials | Cross Feeder |

| US20150108325A1 (en) * | 2013-10-23 | 2015-04-23 | Keith Ryan | Method and apparatus for electrically-heated refractory moulds and mandrels |

| CN103639376A (zh) * | 2013-12-24 | 2014-03-19 | 金隆铜业有限公司 | 一种铜冶炼保温溜槽装置 |

| US9781776B2 (en) | 2015-06-15 | 2017-10-03 | Pyrotek, Incorporated | Molten metal handling device heating system |

| CN106466710A (zh) * | 2015-08-21 | 2017-03-01 | 宁波创润新材料有限公司 | 流槽预热罩和流槽预热方法 |

| GB2543518A (en) * | 2015-10-20 | 2017-04-26 | Pyrotek Eng Mat Ltd | Metal transfer device |

| JP2017177130A (ja) * | 2016-03-29 | 2017-10-05 | 助川電気工業株式会社 | 高温流体用樋 |

| US10408540B2 (en) * | 2016-12-21 | 2019-09-10 | Fives North American Combustion, Inc. | Launder assembly |

| WO2019060970A1 (pt) * | 2017-09-28 | 2019-04-04 | Alum Industria E Comercio De Insumos Para Fundicao Ltda Epp | Sistema de aquecimento interno para calhas refratárias |

| BR112020006164B1 (pt) * | 2017-09-29 | 2022-08-30 | Alum Indústria E Comércio De Insumos Para Fundição Ltda Epp | Sistema de drenagem para calhas refratárias |

| RU2691827C1 (ru) * | 2018-01-16 | 2019-06-18 | Общество с ограниченной ответственностью "Резонанс" | Желоб с радиационным нагревом для транспортировки расплавленных металлов |

| RU192356U1 (ru) * | 2018-12-03 | 2019-09-13 | Общество с ограниченной ответственностью "Научно-производственный центр магнитной гидродинамики" | Транспортный желоб литейного комплекса разливки жидкого металла |

| CN112944919A (zh) * | 2019-11-26 | 2021-06-11 | 科德尔科股份公司 | 用于转移熔炼炉中白金属的热通道 |

| CN111283150A (zh) * | 2020-04-01 | 2020-06-16 | 太原钢铁(集团)有限公司 | 一种非晶合金浇注用滤渣式流钢槽 |

| CN112059160A (zh) * | 2020-09-25 | 2020-12-11 | 无锡元基精密机械有限公司 | 一种中空型铸造流体流通保温系统 |

| US20220111434A1 (en) * | 2020-10-08 | 2022-04-14 | Wagstaff, Inc. | Material, apparatus, and method for refractory castings |

| US20240357712A1 (en) * | 2023-04-21 | 2024-10-24 | Wagstaff, Inc. | Material, apparatus, and method for electrically shielding heated components |

| CN117000980A (zh) * | 2023-06-26 | 2023-11-07 | 太原重工股份有限公司 | 槽形专用铸件浇注外设浇道工装 |

Family Cites Families (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3551578A (en) * | 1966-10-28 | 1970-12-29 | Asea Ab | Channel type furnace for vacuum |

| US3494410A (en) | 1966-12-12 | 1970-02-10 | Kaiser Aluminium Chem Corp | Casting molten metal |

| JPS49325Y1 (ja) * | 1970-11-09 | 1974-01-08 | ||

| JPS5065914U (ja) * | 1973-10-23 | 1975-06-13 | ||

| JPS5098408A (ja) * | 1973-12-29 | 1975-08-05 | ||

| JPS52129603A (en) * | 1976-04-23 | 1977-10-31 | Taiko Refractories | Channel for molten metals and method for construction thereof |

| JPS53127344U (ja) * | 1977-03-18 | 1978-10-09 | ||

| US4345743A (en) * | 1980-10-10 | 1982-08-24 | Alcan Research And Development Limited | Means and method for containing flowing or standing molten metal |

| JPS59114786U (ja) * | 1983-01-20 | 1984-08-02 | 助川電気工業株式会社 | 溶融金属移送用ダクト |

| KR840007900A (ko) * | 1983-03-04 | 1984-12-11 | 무라마쯔 후미오 | 언더 히이터(under-heater)형로(爐) |

| US4531717A (en) | 1984-03-22 | 1985-07-30 | Kaiser Aluminum & Chemical Corporation | Preheated trough for molten metal transfer |

| US4635706A (en) | 1985-06-06 | 1987-01-13 | The Dow Chemical Company | Molten metal handling system |

| CN85205652U (zh) * | 1985-12-27 | 1986-11-05 | 哈尔滨市第一耐火材料厂 | 轻质保温流槽 |

| SE462395B (sv) * | 1988-11-18 | 1990-06-18 | Avesta Ab | Austenitisk jaern-nickel-krom-baslegering med goda hoegtemperaturegenskaper samt anvaendning av denna |

| NL8803103A (nl) * | 1988-12-19 | 1990-07-16 | Hoogovens Groep Bv | Ijzergoot. |

| US4993607A (en) | 1989-07-10 | 1991-02-19 | General Electric Company | Transfer tube with in situ heater |

| US5316071A (en) | 1993-05-13 | 1994-05-31 | Wagstaff Inc. | Molten metal distribution launder |

| FR2705259B1 (fr) * | 1993-05-19 | 1995-07-07 | Pont A Mousson | Dispositif d'alimentation en métal en fusion, notamment en fonte, d'une machine de coulée, et installation de coulée intégrant ce dispositif d'alimentation. |

| US5913353A (en) | 1994-09-26 | 1999-06-22 | Ford Global Technologies, Inc. | Process for casting light metals |

| AT404328B (de) * | 1995-03-24 | 1998-10-27 | Rauch Fertigungstech Gmbh | Verfahren und vorrichtung zum beschicken von giessmaschinen |

| RU2119556C1 (ru) * | 1996-05-30 | 1998-09-27 | Акционерное общество "АВИСМА титано-магниевый комбинат" | Устройство для транспортировки расплавов |

| NL1003885C2 (nl) * | 1996-08-27 | 1998-03-03 | Hoogovens Tech Services | Goot voor een hete smelt en gootsysteem. |

| DK0867412T3 (da) * | 1997-03-27 | 2001-06-18 | Cit Alcatel | Termisk isolation til en ovn til trækning af optiske fibre |

| JP2000017313A (ja) * | 1998-07-03 | 2000-01-18 | Kawasaki Steel Corp | 溶融金属用樋 |

| JP4534048B2 (ja) * | 1998-10-28 | 2010-09-01 | 有明セラコ株式会社 | 金属溶湯用樋 |

| US6444165B1 (en) * | 1999-01-12 | 2002-09-03 | C. Edward Eckert | Heated trough for molten aluminum |

| WO2003066913A1 (en) | 2001-12-28 | 2003-08-14 | Eckert Edward C | Heatable trough for molten aluminium flow |

| DE10352453A1 (de) | 2003-11-07 | 2005-06-02 | Volkswagen Ag | Verfahren zur Herstellung von Metall-Matrix-Verbundwerkstoffen |

-

2003

- 2003-12-11 US US10/735,075 patent/US6973955B2/en not_active Expired - Lifetime

-

2004

- 2004-12-07 AT AT04802262T patent/ATE385868T1/de active

- 2004-12-07 PT PT04802262T patent/PT1691945E/pt unknown

- 2004-12-07 BR BRPI0417475-5A patent/BRPI0417475B1/pt not_active IP Right Cessation

- 2004-12-07 KR KR1020067013846A patent/KR101130362B1/ko not_active Expired - Lifetime

- 2004-12-07 JP JP2006543326A patent/JP4653758B2/ja not_active Expired - Lifetime

- 2004-12-07 CA CA002546085A patent/CA2546085C/en not_active Expired - Lifetime

- 2004-12-07 EP EP04802262A patent/EP1691945B1/en not_active Expired - Lifetime

- 2004-12-07 DE DE602004011816T patent/DE602004011816T2/de not_active Expired - Lifetime

- 2004-12-07 WO PCT/CA2004/002085 patent/WO2005056219A1/en not_active Ceased

- 2004-12-07 CN CN2004800370499A patent/CN1894061B/zh not_active Expired - Lifetime

- 2004-12-07 RU RU2006122205/02A patent/RU2358831C2/ru active

- 2004-12-07 ES ES04802262T patent/ES2298844T3/es not_active Expired - Lifetime

-

2006

- 2006-07-05 NO NO20063130A patent/NO20063130L/no not_active Application Discontinuation

Also Published As

| Publication number | Publication date |

|---|---|

| CA2546085C (en) | 2009-10-13 |

| US6973955B2 (en) | 2005-12-13 |

| US20050126738A1 (en) | 2005-06-16 |

| RU2006122205A (ru) | 2008-01-20 |

| RU2358831C2 (ru) | 2009-06-20 |

| JP2007513770A (ja) | 2007-05-31 |

| CN1894061A (zh) | 2007-01-10 |

| DE602004011816T2 (de) | 2009-01-29 |

| WO2005056219A1 (en) | 2005-06-23 |

| CN1894061B (zh) | 2011-12-21 |

| KR101130362B1 (ko) | 2012-03-28 |

| EP1691945A1 (en) | 2006-08-23 |

| ES2298844T3 (es) | 2008-05-16 |

| EP1691945A4 (en) | 2007-04-18 |

| BRPI0417475B1 (pt) | 2012-06-26 |

| KR20060127034A (ko) | 2006-12-11 |

| CA2546085A1 (en) | 2005-06-23 |

| ATE385868T1 (de) | 2008-03-15 |

| NO20063130L (no) | 2006-07-05 |

| DE602004011816D1 (de) | 2008-03-27 |

| EP1691945B1 (en) | 2008-02-13 |

| BRPI0417475A (pt) | 2007-05-08 |

| PT1691945E (pt) | 2008-04-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4653758B2 (ja) | 溶融金属のための加熱樋 | |

| JP5778249B2 (ja) | 溶融金属を収容するために用いる容器での溶融金属の漏出の制限および熱的最適化 | |

| KR101240029B1 (ko) | 용융 구리 주조용 라운더 | |

| JP2008526512A5 (ja) | ||

| WO1995022732A1 (en) | Internal refractory cooler | |

| EP0090761A1 (fr) | Rigole de coulée pour métaux liquides | |

| JP2009061457A (ja) | 溶湯搬送用取鍋 | |

| JP7244445B2 (ja) | 非鉄金属用溶解炉及び非鉄金属用保持炉 | |

| TW561081B (en) | Method to adjust the temperature of a moulding trough and the moulding trough to implement this method | |

| JP6054162B2 (ja) | 取鍋予熱装置 | |

| RU2791751C1 (ru) | Транспортный желоб жидкого металла c электрическим нагревом | |

| AU682578B2 (en) | Internal refractory cooler | |

| RU2330391C2 (ru) | Электрод и способ установки электрода в дуговой электропечи | |

| JP2017177130A (ja) | 高温流体用樋 | |

| CA2183520C (en) | Internal refractory cooler | |

| Uchida et al. | HEAT TRANSFER ANALYSIS OF VARIOUS LADLE REFRACTORY LININGS | |

| Roach et al. | Induction melter apparatus |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070808 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090915 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090924 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091224 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20101124 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20101217 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4653758 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131224 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| EXPY | Cancellation because of completion of term |