JP4583711B2 - 準cwダイオードポンプ式固体uvレーザシステム及びそれを使用する方法 - Google Patents

準cwダイオードポンプ式固体uvレーザシステム及びそれを使用する方法 Download PDFInfo

- Publication number

- JP4583711B2 JP4583711B2 JP2002572515A JP2002572515A JP4583711B2 JP 4583711 B2 JP4583711 B2 JP 4583711B2 JP 2002572515 A JP2002572515 A JP 2002572515A JP 2002572515 A JP2002572515 A JP 2002572515A JP 4583711 B2 JP4583711 B2 JP 4583711B2

- Authority

- JP

- Japan

- Prior art keywords

- laser

- time interval

- current level

- current

- output

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000000034 method Methods 0.000 title claims description 23

- 238000005086 pumping Methods 0.000 claims description 103

- 238000003672 processing method Methods 0.000 claims description 24

- 239000007787 solid Substances 0.000 claims description 22

- 230000015572 biosynthetic process Effects 0.000 claims description 18

- 239000000463 material Substances 0.000 claims description 11

- 229910052751 metal Inorganic materials 0.000 claims description 10

- 238000012545 processing Methods 0.000 claims description 10

- 239000002184 metal Substances 0.000 claims description 9

- 230000008569 process Effects 0.000 claims description 7

- 230000008859 change Effects 0.000 claims description 5

- 238000005553 drilling Methods 0.000 claims description 4

- 230000003287 optical effect Effects 0.000 claims description 3

- 239000010410 layer Substances 0.000 claims 11

- 239000013077 target material Substances 0.000 claims 4

- 230000007423 decrease Effects 0.000 claims 2

- 230000001678 irradiating effect Effects 0.000 claims 2

- 229910009372 YVO4 Inorganic materials 0.000 claims 1

- 238000004070 electrodeposition Methods 0.000 claims 1

- 238000003754 machining Methods 0.000 claims 1

- 239000002356 single layer Substances 0.000 claims 1

- 238000006243 chemical reaction Methods 0.000 description 5

- 238000013461 design Methods 0.000 description 4

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 3

- -1 Purachiumu Chemical compound 0.000 description 3

- 230000009471 action Effects 0.000 description 3

- 229910052802 copper Inorganic materials 0.000 description 3

- 239000010949 copper Substances 0.000 description 3

- 238000012937 correction Methods 0.000 description 3

- 239000003989 dielectric material Substances 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 230000003014 reinforcing effect Effects 0.000 description 3

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 2

- 230000002411 adverse Effects 0.000 description 2

- UMIVXZPTRXBADB-UHFFFAOYSA-N benzocyclobutene Chemical compound C1=CC=C2CCC2=C1 UMIVXZPTRXBADB-UHFFFAOYSA-N 0.000 description 2

- 230000006378 damage Effects 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 2

- 239000004810 polytetrafluoroethylene Substances 0.000 description 2

- 230000003685 thermal hair damage Effects 0.000 description 2

- 238000013519 translation Methods 0.000 description 2

- JYEUMXHLPRZUAT-UHFFFAOYSA-N 1,2,3-triazine Chemical compound C1=CN=NN=C1 JYEUMXHLPRZUAT-UHFFFAOYSA-N 0.000 description 1

- XQUPVDVFXZDTLT-UHFFFAOYSA-N 1-[4-[[4-(2,5-dioxopyrrol-1-yl)phenyl]methyl]phenyl]pyrrole-2,5-dione Chemical compound O=C1C=CC(=O)N1C(C=C1)=CC=C1CC1=CC=C(N2C(C=CC2=O)=O)C=C1 XQUPVDVFXZDTLT-UHFFFAOYSA-N 0.000 description 1

- 241000270730 Alligator mississippiensis Species 0.000 description 1

- FOXXZZGDIAQPQI-XKNYDFJKSA-N Asp-Pro-Ser-Ser Chemical compound OC(=O)C[C@H](N)C(=O)N1CCC[C@H]1C(=O)N[C@@H](CO)C(=O)N[C@@H](CO)C(O)=O FOXXZZGDIAQPQI-XKNYDFJKSA-N 0.000 description 1

- 239000004593 Epoxy Substances 0.000 description 1

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 1

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- 238000002679 ablation Methods 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 239000004760 aramid Substances 0.000 description 1

- 229920006231 aramid fiber Polymers 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 239000003990 capacitor Substances 0.000 description 1

- 239000011111 cardboard Substances 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 239000004643 cyanate ester Substances 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

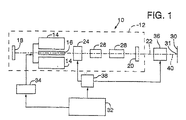

- 238000010586 diagram Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 239000003365 glass fiber Substances 0.000 description 1

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 1

- 229910052737 gold Inorganic materials 0.000 description 1

- 239000010931 gold Substances 0.000 description 1

- 230000031700 light absorption Effects 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 229910052750 molybdenum Inorganic materials 0.000 description 1

- 239000011733 molybdenum Substances 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 150000004767 nitrides Chemical class 0.000 description 1

- 229910052763 palladium Inorganic materials 0.000 description 1

- 230000000737 periodic effect Effects 0.000 description 1

- 229920003192 poly(bis maleimide) Polymers 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 239000012779 reinforcing material Substances 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 230000001360 synchronised effect Effects 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- 239000010936 titanium Substances 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 1

- 239000010937 tungsten Substances 0.000 description 1

- 229910052721 tungsten Inorganic materials 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/36—Removing material

- B23K26/38—Removing material by boring or cutting

- B23K26/382—Removing material by boring or cutting by boring

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/0011—Working of insulating substrates or insulating layers

- H05K3/0017—Etching of the substrate by chemical or physical means

- H05K3/0026—Etching of the substrate by chemical or physical means by laser ablation

- H05K3/0032—Etching of the substrate by chemical or physical means by laser ablation of organic insulating material

- H05K3/0038—Etching of the substrate by chemical or physical means by laser ablation of organic insulating material combined with laser drilling through a metal layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/50—Inorganic material, e.g. metals, not provided for in B23K2103/02 – B23K2103/26

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/0011—Working of insulating substrates or insulating layers

- H05K3/0017—Etching of the substrate by chemical or physical means

- H05K3/0026—Etching of the substrate by chemical or physical means by laser ablation

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Plasma & Fusion (AREA)

- Mechanical Engineering (AREA)

- Lasers (AREA)

- Manufacturing & Machinery (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Laser Beam Processing (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US27524601P | 2001-03-12 | 2001-03-12 | |

| PCT/US2002/007486 WO2002073322A1 (en) | 2001-03-12 | 2002-03-12 | Quasi-cw diode-pumped, solid-state uv laser system and method employing same |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2004528984A JP2004528984A (ja) | 2004-09-24 |

| JP2004528984A5 JP2004528984A5 (de) | 2005-12-22 |

| JP4583711B2 true JP4583711B2 (ja) | 2010-11-17 |

Family

ID=23051465

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2002572515A Expired - Fee Related JP4583711B2 (ja) | 2001-03-12 | 2002-03-12 | 準cwダイオードポンプ式固体uvレーザシステム及びそれを使用する方法 |

Country Status (8)

| Country | Link |

|---|---|

| JP (1) | JP4583711B2 (de) |

| KR (1) | KR100853254B1 (de) |

| CN (1) | CN100351719C (de) |

| CA (1) | CA2440694A1 (de) |

| DE (1) | DE10296512T5 (de) |

| GB (1) | GB2390994B (de) |

| TW (1) | TW523435B (de) |

| WO (1) | WO2002073322A1 (de) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100985018B1 (ko) * | 2010-04-06 | 2010-10-04 | 주식회사 엘앤피아너스 | 기판 가공 장치 |

| JP6309977B2 (ja) * | 2013-02-27 | 2018-04-11 | ノバルティス アーゲー | レーザー装置および標的材料をレーザー処理するための方法 |

| CN105142853B (zh) * | 2013-02-28 | 2017-07-04 | Ipg光子公司 | 用于加工蓝宝石的激光系统和方法 |

| CN111478173B (zh) * | 2020-05-19 | 2021-03-05 | 中国科学院福建物质结构研究所 | 一种1.5微米被动调q激光器 |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2547519B1 (fr) * | 1983-06-15 | 1987-07-03 | Snecma | Procede et dispositif de percage par laser |

| US5477043A (en) | 1989-10-30 | 1995-12-19 | Symbol Technologies, Inc. | Scanning arrangement for the implementation of scanning patterns over indicia by driving the scanning elements in different component directions |

| EP0460338B1 (de) * | 1990-06-05 | 1994-07-27 | R. Audemars Sa | Verfahren und Vorrichtung zum Schneiden von Material |

| JPH0529693A (ja) * | 1990-09-19 | 1993-02-05 | Hitachi Ltd | マルチパルスレーザ発生装置、及びその方法、並びにそのマルチパルスレーザを用いた加工方法 |

| US5293025A (en) * | 1991-08-01 | 1994-03-08 | E. I. Du Pont De Nemours And Company | Method for forming vias in multilayer circuits |

| JP3315556B2 (ja) * | 1994-04-27 | 2002-08-19 | 三菱電機株式会社 | レーザ加工装置 |

| US5593606A (en) * | 1994-07-18 | 1997-01-14 | Electro Scientific Industries, Inc. | Ultraviolet laser system and method for forming vias in multi-layered targets |

| US5841099A (en) * | 1994-07-18 | 1998-11-24 | Electro Scientific Industries, Inc. | Method employing UV laser pulses of varied energy density to form depthwise self-limiting blind vias in multilayered targets |

| US5751585A (en) * | 1995-03-20 | 1998-05-12 | Electro Scientific Industries, Inc. | High speed, high accuracy multi-stage tool positioning system |

| JPH09163984A (ja) * | 1995-10-12 | 1997-06-24 | Sony Corp | 遺伝子組替え用レーザ装置およびこれを用いた遺伝子組替え方法 |

| US5822211A (en) | 1996-11-13 | 1998-10-13 | International Business Machines Corporation | Laser texturing apparatus with dual laser paths having an independently adjusted parameter |

| US5943351A (en) * | 1997-05-16 | 1999-08-24 | Excel/Quantronix, Inc. | Intra-cavity and inter-cavity harmonics generation in high-power lasers |

| US6160568A (en) * | 1997-05-27 | 2000-12-12 | Sdl, Inc. | Laser marking system and method of energy control |

| US6188704B1 (en) * | 1998-01-26 | 2001-02-13 | Rocky Mountain Instrument Co. | Diode-pumped laser drive |

| JPH11267867A (ja) * | 1998-03-23 | 1999-10-05 | Seiko Epson Corp | レーザ加工方法及び装置 |

| US6197133B1 (en) * | 1999-02-16 | 2001-03-06 | General Electric Company | Short-pulse high-peak laser shock peening |

| JP2000301372A (ja) * | 1999-04-23 | 2000-10-31 | Seiko Epson Corp | 透明材料のレーザ加工方法 |

| US6252195B1 (en) * | 1999-04-26 | 2001-06-26 | Ethicon, Inc. | Method of forming blind holes in surgical needles using a diode pumped Nd-YAG laser |

-

2002

- 2002-03-12 GB GB0323441A patent/GB2390994B/en not_active Expired - Fee Related

- 2002-03-12 CA CA002440694A patent/CA2440694A1/en not_active Abandoned

- 2002-03-12 DE DE10296512T patent/DE10296512T5/de not_active Ceased

- 2002-03-12 JP JP2002572515A patent/JP4583711B2/ja not_active Expired - Fee Related

- 2002-03-12 CN CNB028064038A patent/CN100351719C/zh not_active Expired - Fee Related

- 2002-03-12 TW TW091104537A patent/TW523435B/zh not_active IP Right Cessation

- 2002-03-12 KR KR1020037011920A patent/KR100853254B1/ko not_active IP Right Cessation

- 2002-03-12 WO PCT/US2002/007486 patent/WO2002073322A1/en active Application Filing

Also Published As

| Publication number | Publication date |

|---|---|

| CA2440694A1 (en) | 2002-09-19 |

| WO2002073322A1 (en) | 2002-09-19 |

| KR100853254B1 (ko) | 2008-08-21 |

| JP2004528984A (ja) | 2004-09-24 |

| CN1714318A (zh) | 2005-12-28 |

| TW523435B (en) | 2003-03-11 |

| CN100351719C (zh) | 2007-11-28 |

| WO2002073322B1 (en) | 2003-02-20 |

| GB0323441D0 (en) | 2003-11-05 |

| GB2390994A (en) | 2004-01-28 |

| DE10296512T5 (de) | 2004-04-29 |

| KR20030087017A (ko) | 2003-11-12 |

| GB2390994B (en) | 2004-10-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TWI386270B (zh) | 提供有關於被微加工於工件中的特徵形狀的資訊之方法 | |

| US8816246B2 (en) | Method and apparatus for drilling using a series of laser pulses | |

| EP0900132B1 (de) | Verfahren zur verwendung von uv-laserimpulsen variierter engergiedichte zum formen von blindlöchern in mehrschichtigen zielen | |

| US6806440B2 (en) | Quasi-CW diode pumped, solid-state UV laser system and method employing same | |

| TWI403379B (zh) | 以短脈衝,固態紫外線雷射做微加工 | |

| TW528636B (en) | Micromachining with high-energy, intra-cavity Q-switched CO2 laser pulses | |

| US20050087522A1 (en) | Laser processing of a locally heated target material | |

| EP0771243A1 (de) | Verfahren und vorrichtung zum bohren von mehrlagigen zielen mit einem ultravioletten laser | |

| US20030168435A1 (en) | Method and apparatus for laser processing | |

| US6781090B2 (en) | Quasi-CW diode-pumped, solid-state harmonic laser system and method employing same | |

| JP4583711B2 (ja) | 準cwダイオードポンプ式固体uvレーザシステム及びそれを使用する方法 | |

| JP2004528984A5 (de) | ||

| Porneala et al. | Selective removal of conformal coatings by pulsed ultraviolet lasers | |

| CA2246329A1 (en) | Method employing uv laser pulses of varied energy density to form blind vias in multilayered targets | |

| Berényi | Laser processing of solder resist layers on laminated substrates |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050105 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050105 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080122 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20080422 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20080430 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20080520 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20080527 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080618 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20080618 |

|

| RD13 | Notification of appointment of power of sub attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7433 Effective date: 20090127 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090203 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20090127 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20090428 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20090511 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090602 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100112 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100409 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100810 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100901 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130910 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |