JP4179108B2 - Cooker - Google Patents

Cooker Download PDFInfo

- Publication number

- JP4179108B2 JP4179108B2 JP2003309785A JP2003309785A JP4179108B2 JP 4179108 B2 JP4179108 B2 JP 4179108B2 JP 2003309785 A JP2003309785 A JP 2003309785A JP 2003309785 A JP2003309785 A JP 2003309785A JP 4179108 B2 JP4179108 B2 JP 4179108B2

- Authority

- JP

- Japan

- Prior art keywords

- steam

- heated

- heating

- amount

- heating chamber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Description

本発明は、焼きもの調理などを行う加熱調理器に関するものである。 The present invention relates to a heating cooker that performs grilling and the like.

従来、この種加熱調理器は、加熱室に収納した被加熱物をマイクロ波や放射熱、熱風、蒸気などを用いて加熱するものである。 Conventionally, this type of cooking device heats an object to be heated stored in a heating chamber using microwaves, radiant heat, hot air, steam, or the like.

それぞれ単独で用いる場合もあれば複数の加熱手段を併用する場合もあり、一例としてはオーブンレンジではマイクロ波と放射熱、スチームコンベクションオーブンでは熱風と蒸気といった組み合せで加熱を行う。蒸気を利用する加熱調理器としては、スチームコンベクションの他に飽和蒸気を常圧で100℃以上になるまで加熱した過熱蒸気を利用した過熱蒸気調理器なども開発されている。過熱蒸気の発生方法には各種あり、飽和蒸気の加熱にはIHなどの誘導加熱やヒータなどが用いられる。また、主な過熱蒸気調理器は業務用の大型機器が多いが、一方では蒸気発生部をコンパクトにして機器全体を小型化したものもある(例えば、特許文献1参照)。 Each of them may be used alone or in combination with a plurality of heating means. For example, the microwave oven is heated by a combination of microwave and radiant heat, and the steam convection oven is heated by a combination of hot air and steam. In addition to steam convection, a superheated steam cooker using superheated steam that has been heated to 100 ° C. or higher at normal pressure has been developed as a steam cooker. There are various methods for generating superheated steam, and for heating saturated steam, induction heating such as IH or a heater is used. In addition, the main superheated steam cooker has many large-sized equipment for business use, but on the other hand, there is also one in which the steam generator is made compact to downsize the entire equipment (for example, see Patent Document 1).

図4は前記公報に記載された従来の加熱調理装置を示すものである。加熱調理装置1は、オーブン庫1a、給水器2、送風モータ(図示していない)および制御部(図示していない)とから概略構成され、オーブン庫1a内部には、加熱用ヒータ3、ファン4、蒸発皿5が設けられている。蒸発皿5には、給水器2から水が供給される。加熱用ヒータ3は、オーブン庫1aの空気を加熱するとともに蒸発皿5の水を加熱しその水を蒸発させる。過熱蒸気温度と調理時間は操作パネル6より設定する。加熱用ヒータ3に通電してから予熱設定時間が経過すると、送風モータに通電しファン4を回転させる。壁温センサー7により庫壁の温度が設定値以上と検知すると、送風モータの通電を止め、ファン4を停止させるととともに、給水器2から所定の水を蒸発皿5に給水し、その後給水を停止するとともに、送風モータに通電してファン4を回転させる。過熱蒸気は軽いためオーブン庫1aの上方に溜まりやすく、空気はオーブン庫1aの下方に追いやられ排気口8から排出され、オーブン庫1aの空気が置換される。操作パネル6で設定した調理時間の間、過熱蒸気により食品は加熱調理される。設定時間が経過すると加熱用ヒータ3および送風モータの通電を止め、加熱終了する。

しかしながら、前記従来の構成では、調理時間や過熱蒸気の温度設定を行うには経験が必要であり、誰もが簡便に利用できるわけではない。また、庫内加熱と蒸気発生に同じヒータを利用しているため、庫内の空気加熱効率や蒸気発生効率が低いなどの課題を有している。 However, in the conventional configuration, experience is required to set the cooking time and the temperature of the superheated steam, and not everyone can use it easily. In addition, since the same heater is used for heating inside the chamber and generating steam, there are problems such as low air heating efficiency and low steam generation efficiency inside the chamber.

本発明は、前記従来の課題を解決するもので、被加熱物の加熱進行度を推定して被加熱物に適した加熱調理を蒸気を利用して行う加熱調理器を提供することを目的とする。 This invention solves the said conventional subject, and it aims at providing the heating cooker which estimates the heating progress of a to-be-heated object, and performs the cooking suitable for a to-be-heated object using a steam | vapor. To do.

前記従来の課題を解決するために、本発明の加熱調理器は、被加熱物を収納する加熱室と、前記加熱室内に供給する蒸気を発生する蒸気発生手段と、前記蒸気を前記加熱室内に吹出す蒸気吹出口と、前記加熱室内の空気や蒸気を排出するための排出口と、前記排出口から排出される蒸気量を検知する蒸気量検知手段と、前記被加熱物の種類と量に対する、投入蒸気量、蒸気温度、排出蒸気量の経時変化および加熱終了までに要する時間に関する情報を記憶する記憶手段と、前記蒸気発生手段を制御する制御手段とを備え、前記制御手段は前記蒸気量検知手段の検知信号の時間的な変化に基づき、排出される蒸気量が増加する時を被加熱物の凝縮工程の終了タイミングと推定し、前記凝縮工程終了までに要した時間を前記記憶手段の記憶データと比較して被加熱物の量を推定し、前記凝縮工程に要した時間と前記被加熱物の前記推定した量に基づいて加熱終了までの時間を推定し、凝縮工程終了タイミング以降の前記蒸気発生手段の動作を制御することで、被加熱物に適した加熱制御を行なうことができる。 In order to solve the above-mentioned conventional problems, a heating cooker according to the present invention includes a heating chamber for storing an object to be heated, steam generating means for generating steam to be supplied into the heating chamber, and the steam in the heating chamber. A steam outlet for blowing out, an outlet for discharging air and steam in the heating chamber, a steam amount detecting means for detecting the amount of steam discharged from the outlet, and the type and amount of the object to be heated , Storage means for storing information on time-dependent changes in input steam amount, steam temperature, exhaust steam amount and time required for heating, and control means for controlling the steam generation means, the control means comprising the steam amount Based on the temporal change of the detection signal of the detection means, the time when the amount of discharged steam increases is estimated as the end timing of the condensation process of the object to be heated, and the time required until the end of the condensation process is estimated. Stored data The amount of the object to be heated is estimated in comparison, the time required for the condensation process and the time until the end of heating are estimated based on the estimated amount of the object to be heated, and the steam generation after the condensation process end timing by controlling the operation of the means, it is possible to perform heating control suitable for the object to be heated.

以上のように、本発明の加熱調理器によれば加熱室から排出される蒸気量を検知することで被加熱物の加熱進行度を推定し、蒸気を利用した加熱調理を簡便で効率良く行うことができる。 As described above, according to the cooking device of the present invention, the heating progress of the object to be heated is estimated by detecting the amount of steam discharged from the heating chamber, and cooking using steam is performed simply and efficiently. be able to.

この高温蒸気は、水が気体となっているため約540カロリーの気化熱を持っており、これが調理物にあたり調理物を加熱するので、多くの高温蒸気分子を調理物にあて凝縮熱を与えることで加熱調理を促進し、効率良くスピーディーに被加熱物を加熱調理できると共に、庫内に充満した高温蒸気で加熱するため、ヒータなどの加熱に比べムラ無く均一な加熱を実現することができる。 This high-temperature steam has a heat of vaporization of about 540 calories because water is in the form of gas, and this heats the food by hitting the food, so it gives condensation heat by applying many high-temperature steam molecules to the food. In addition to promoting cooking by heating, the object to be heated can be cooked efficiently and speedily, and heated with high-temperature steam filled in the cabinet, so that uniform heating can be achieved without unevenness compared to heating with a heater or the like.

第1の発明は、被加熱物を収納する加熱室と、前記加熱室内に供給する蒸気を発生する蒸気発生手段と、前記蒸気を前記加熱室内に吹出す蒸気吹出口と、前記加熱室内の空気や蒸気を排出するための排出口と、前記排出口から排出される蒸気量を検知する蒸気量検知手段と、前記被加熱物の種類と量に対する、投入蒸気量、蒸気温度、排出蒸気量の経時変化および加熱終了までに要する時間に関する情報を記憶する記憶手段と、前記蒸気発生手段を制御する制御手段とを備え、前記制御手段は前記蒸気量検知手段の検知信号の時間的な変化に基づき、排出される蒸気量が増加する時を被加熱物の凝縮工程の終了タイミングと推定し、前記凝縮工程終了までに要した時間を前記記憶手段の記憶データと比較して被加熱物の量を推定し、前記凝縮工程に要した時間と前記被加熱物の前記推定した量に基づいて加熱終了までの時間を推定し、凝縮工程終了タイミング以降の前記蒸気発生手段の動作を制御することで、被加熱物の過加熱や加熱不足を防止するとともに被加熱物に適した加熱制御を行なうことができる。 1st invention is the heating chamber which accommodates to-be-heated material, the steam generation means which generate | occur | produces the vapor | steam supplied in the said heating chamber, the steam blower outlet which blows off the said steam in the said heating chamber, The air in the said heating chamber And an outlet for discharging steam, a steam amount detecting means for detecting the amount of steam discharged from the outlet, and the amount of input steam, steam temperature, and amount of discharged steam with respect to the type and amount of the object to be heated. A storage means for storing information on a change over time and a time required for completion of heating; and a control means for controlling the steam generation means. The control means is based on a temporal change in a detection signal of the steam amount detection means. The amount of steam to be heated is estimated as the end timing of the condensation process of the object to be heated, and the time required to complete the condensation process is compared with the data stored in the storage means to determine the amount of the object to be heated. Estimate and condense Based on the required time and the estimated amount of the object to be heated, the time until the end of heating is estimated, and the operation of the steam generating means after the condensation process end timing is controlled, so Heating and heating shortage can be prevented and heating control suitable for the object to be heated can be performed.

以下本発明の実施例について、図面を参照しながら説明する。 Embodiments of the present invention will be described below with reference to the drawings.

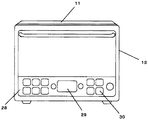

図1は本発明の実施例1における加熱調理器の正面断面図、図2は加熱調理器の外観を示す概略図、図3は本発明の要部の制御ブロック図である。図1〜3において、11は本発明の加熱調理器の本体、12は被加熱物を収納する加熱室である。加熱室12には扉13が配設されている。14は加熱室12内に気流を発生させるための気流発生手段であり、14から加熱室内の空気を吸い込み、14a〜14dから吹出している。15は加熱室12へ投入する蒸気を発生するための蒸気発生手段であり、貯水手段16と、貯水手段16にとりつけられた水加熱手段17と、水加熱手段17で蒸発させた蒸気が通る第一の蒸気管18とから構成される。19は蒸気発生手段15からの蒸気を加熱する過熱蒸気発生手段であり、蒸気発生手段15から発生した蒸気は、第二の蒸気管20を通過する際に蒸気加熱手段19により加熱されて過熱蒸気となる。

FIG. 1 is a front sectional view of a heating cooker in Embodiment 1 of the present invention, FIG. 2 is a schematic view showing the appearance of the heating cooker, and FIG. 3 is a control block diagram of the main part of the present invention. In FIGS. 1-3, 11 is a main body of the heating cooker of this invention, 12 is a heating chamber which accommodates to-be-heated material. A

第二の蒸気管20は蒸気吹出口21と連通しており、蒸気発生手段15で発生した蒸気は、第一の蒸気管18、第二の蒸気管20、蒸気吹出口21を介して加熱室12へ吹出される。蒸気吹出口21には、吹出される蒸気温度を検知するための蒸気温度検知手段22が設けられている。

The

23は加熱室12の空気や蒸気を外部へ排出するための排出口である。排出口23には、排出される気流中の蒸気量を検知する蒸気量検知手段24が設けられる。排出口23には排出口開閉手段25が併設されている。排出口23は、蒸気吹出口21とは離して配設される。排出口23を蒸気吹出口21に近接させて配設すると、加熱室12に蒸気が充満する前に排出口23から蒸気が排出されてしまうことがあるため、本実施例では蒸気吹出口21は排出口23の配設壁面に対向する壁面の下方に配設している。26は加熱室12内の温度を検知する加熱室温度検知手段である。27は吹出し方向可変手段で、蒸気吹出口21に設けられ、加熱室12に吹出す蒸気の方向を可変する。28は扉13に配設された加熱調理器の操作部であり、表示部29や操作キー30が配設されている。ただし、操作部28については、必ずしも扉13に配設せずともよい。31は制御手段であり、蒸気温度検知手段22、蒸気量検知手段24、加熱室温度検知手段26、操作部28の信号に基づき、気流発生手段14、蒸気発生手段15、過熱蒸気発生手段19を制御する。32は記憶手段で、調理条件や操作部28からの入力情報などを一時あるいは恒久的に記憶する。

次に、上記構成からなる加熱調理器について、その動作を説明する。 Next, the operation of the cooking device having the above configuration will be described.

使用者は、加熱室12に被加熱物を収納載置して閉扉する。手動調理によって被加熱物を加熱調理する際には、使用者は加熱条件を入力し、操作部28から加熱開始信号を制御

手段31へ送信する。加熱条件や被加熱物の載置位置などの情報が入力されると、制御手段31は入力された加熱調理工程や加熱条件を記憶手段32に記憶する。一方、自動調理によって被加熱物を加熱調理する際には、被加熱物の載置位置や希望する出来上がり状態を入力する。操作部28から加熱開始信号を制御手段31へ送信すると加熱調理が開始される。手動調理、自動調理ともに、加熱開始信号に先立って「加熱取消し」が選択された場合は、制御手段31は記憶手段32を初期設定に戻す。

The user places the object to be heated in the

加熱調理が開始されると、制御手段31は水加熱手段17に通電し蒸気を発生させる。所定時間後に過熱蒸気発生手段19にも通電し、発生した蒸気を100℃より高温に加熱する。蒸気吹出口21から加熱室12へ吹出される蒸気の温度は蒸気温度検知手段で検知する。また、制御手段31は加熱室温度検知手段26より加熱室内の蒸気の充満度を推定する。制御手段31が加熱室温度検知手段26の信号により加熱室12が過熱蒸気でほぼ充満されたと判断すると、制御手段31は加熱調理工程に移行し、気流発生手段14と排出口開閉手段25を制御し、調理時間の計測を開始する。なお、排出口開閉手段25の制御は、操作部28から開閉動作の制御をすることもできる。

When cooking is started, the

制御手段31は、蒸気温度検知手段22の信号により、蒸気が設定温度かどうかを判断して蒸気発生手段15、過熱蒸気発生手段19の入力を可変制御する。吹出し方向可変手段27は、蒸気の吹出し方向を上下・左右に可変することができる配置構成となっており、制御手段31は蒸気が被加熱物に向かって吹出されるように吹出し方向可変手段27の方向を調節する。 The control means 31 determines whether the steam is at a set temperature based on a signal from the steam temperature detection means 22 and variably controls the inputs of the steam generation means 15 and the superheated steam generation means 19. The blow direction changing means 27 has an arrangement configuration in which the steam blow direction can be changed up and down, left and right, and the control means 31 is arranged so that the steam is blown toward the object to be heated. Adjust the direction.

加熱調理工程に移行すると、加熱室12に収納載置された被加熱物は投入蒸気により加熱される。蒸気は自らの温度よりも被加熱物が低温である場合、被加熱物表面で結露・凝縮し、その際に凝縮熱を被加熱物に与える特性を有している。凝縮熱は高温空気からの伝導熱よりも大きいため、被加熱物の昇温は高温空気からの伝導熱を利用した場合より速くなる。蒸気は被加熱物の表面温度が100℃になるまで凝縮し、表面温度が100℃を超えると凝縮は終了する。また、過熱蒸気は被加熱物を乾燥させる特性を有しているため、過熱蒸気を吹き付けられた被加熱物は凝縮終了後、乾燥・焼成される。

If it transfers to a heat cooking process, the to-be-heated material accommodated and mounted in the

焼きもの調理では、蒸気の凝縮工程を過ぎて乾燥・焼成工程に移行すると被加熱物から水分が蒸発する。乾燥や表面の焦げ生成を促進するためには、被加熱物の表面付近の高湿度の空気層と低湿度の空気層を交換し、表面から蒸発した水分を被加熱物付近から移動させることで、被加熱物の焼成を速める。 In grilled food cooking, when the steam condensing process is passed to the drying / firing process, moisture evaporates from the object to be heated. In order to promote drying and the generation of scorching on the surface, the high-humidity air layer near the surface of the object to be heated and the low-humidity air layer are exchanged, and the moisture evaporated from the surface is moved from the vicinity of the object to be heated. Accelerates the firing of the object to be heated.

次に、加熱調理工程の細部について説明する。まず被加熱物の加熱進行度の推定方法について説明する。 Next, details of the cooking process will be described. First, a method for estimating the heating progress of the article to be heated will be described.

制御手段31は、蒸気量検知手段24の蒸気量の信号を受信し、被加熱物の加熱進行度を推定する。加熱開始の信号により過熱蒸気が加熱室12に投入されると、加熱工程初期では被加熱物の表面温度が低いため表面で凝縮する蒸気量が多く、排出口23から排出される蒸気量は少ない。一方、加熱工程後期では被加熱物の表面温度は上昇しているため表面で凝縮する蒸気量は少なく、排出口23から排出される蒸気量は多くなる。

The control means 31 receives the steam amount signal from the steam amount detection means 24 and estimates the heating progress of the object to be heated. When superheated steam is introduced into the

また、被加熱物量が多い場合は、排出蒸気量が増加するまでに要する時間は長く、被加熱物量が少ない場合は時間は短くなる。 In addition, when the amount of heated object is large, the time required until the amount of discharged steam increases is long, and when the amount of heated object is small, the time is shortened.

一方、過熱蒸気の蒸気温度が高い場合は凝縮工程は短時間であり、蒸気温度が低い場合は凝縮工程は長くなる傾向がある。 On the other hand, when the steam temperature of superheated steam is high, the condensation process is short, and when the steam temperature is low, the condensation process tends to be long.

制御手段31は、蒸気量検知手段24の検知信号に基づいてこの排出される蒸気量の時間的な変化を検出し、被加熱物の凝縮工程の終了タイミングを推定する。 The control means 31 detects the temporal change of the discharged steam amount based on the detection signal of the steam amount detection means 24, and estimates the end timing of the condensation process of the object to be heated.

この際、蒸気温度検出手段22の検知信号を併用することで、過熱蒸気の供給にも対応させることができる。 At this time, by using the detection signal of the steam temperature detecting means 22 together, it is possible to cope with the supply of superheated steam.

すなわち、蒸気量検知手段24の信号により制御手段31が排出口24から排出される蒸気量が加熱工程初期よりも多くなったと判断すると、被加熱物の表面温度は100℃に達したと判定し、凝縮工程が終了したという加熱進行度を推測する。

That is, when the control means 31 determines that the amount of steam discharged from the

次に被加熱物の量の推定について説明する。 Next, estimation of the amount of the object to be heated will be described.

記憶手段32は、被加熱物の種類と量に対する、投入蒸気量、蒸気温度、排出蒸気量の経時変化および加熱終了までに要する時間に関する情報を記憶している。制御手段31は、蒸気温度検知手段22と蒸気量検知手段24の検知信号に基づいて、被加熱物の凝縮工程の終了タイミング、すなわち被加熱物の表面温度が100℃に達するまでに要した時間とその時刻とを記憶手段32の記憶データと比較し、被加熱物の量を演算する。

The storage means 32 stores information on the change over time of the input steam amount, the steam temperature, the exhaust steam amount and the time required for the end of heating with respect to the type and amount of the object to be heated. Based on the detection signals of the steam

また、被加熱物の加熱終了時間の推定について説明する。 The estimation of the heating end time of the object to be heated will be described.

この推定は、上記した被加熱物の量の推定と100℃に達するまでに要した時間と入力された加熱条件情報とに基づいて行う。すなわち、被加熱物の表面温度が100℃に達したと判断した時点から加熱終了時点までの加熱時間を推定する。制御手段31は、この情報に基づき、被加熱物の表面温度が100℃に達したと判断した時点から推定した所定時間が経過すると、加熱調理工程が終了したと判断し加熱終了報知を行う。また、蒸気発生手段15、過熱蒸気発生手段19などの動作を停止する。 This estimation is performed based on the above-described estimation of the amount of the object to be heated, the time required to reach 100 ° C., and the input heating condition information. That is, the heating time from when it is determined that the surface temperature of the object to be heated has reached 100 ° C. until the end of heating is estimated. Based on this information, when the predetermined time estimated from the time when it is determined that the surface temperature of the object to be heated has reached 100 ° C., the control means 31 determines that the heating cooking process has ended and notifies the end of heating. Further, the operation of the steam generating means 15 and the superheated steam generating means 19 is stopped.

これら一連の加熱進行度の推定とそれに基づく加熱調理制御を実行することで、被加熱物に適した加熱調理を行うとともに被加熱物の過加熱や加熱不足を防止することができる。 By performing the estimation of the series of heating progresses and the heating cooking control based on the estimation, it is possible to perform heating cooking suitable for the object to be heated and prevent overheating and insufficient heating of the object to be heated.

なお、加熱終了報知は、表示部29に表示する方法でもよいし、ブザー等で報知する方法でもかまわない。

The heating end notification may be displayed on the

本実施例において、貯水手段16と水加熱手段17は一体構成としたが、貯水手段16から水加熱手段17へ送水する送水手段を配設してもかまわない。 In this embodiment, the water storage means 16 and the water heating means 17 are integrated, but a water supply means for supplying water from the water storage means 16 to the water heating means 17 may be provided.

本実施例では、蒸気吹出口21と排出口23は加熱室12の側壁面に配設したが、この位置に限るものではない。

In the present embodiment, the

また、本実施例では図示していないが、加熱室12の周囲に断熱効果のある材料を併用することができる。

Although not shown in the present embodiment, a material having a heat insulating effect can be used around the

また、使用者の火傷などによる負傷を防止するために、蒸気投入時は使用者が扉13の開閉ができないよう開扉状態を検知する扉検知手段を設け、扉13が開いている間は蒸気発生手段15および過熱蒸気発生手段19の動作を停止するようにしても構わない。

In addition, in order to prevent injuries due to burns and the like of the user, door detection means for detecting the open state is provided so that the user cannot open and close the

12 加熱室

15 蒸気発生手段

19 過熱蒸気発生手段

21 蒸気吹出口

22 蒸気温度検知手段

23 排出口

24 蒸気量検知手段

31 制御手段

DESCRIPTION OF

Claims (1)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003309785A JP4179108B2 (en) | 2003-09-02 | 2003-09-02 | Cooker |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003309785A JP4179108B2 (en) | 2003-09-02 | 2003-09-02 | Cooker |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2005077020A JP2005077020A (en) | 2005-03-24 |

| JP2005077020A5 JP2005077020A5 (en) | 2006-10-12 |

| JP4179108B2 true JP4179108B2 (en) | 2008-11-12 |

Family

ID=34411841

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003309785A Expired - Fee Related JP4179108B2 (en) | 2003-09-02 | 2003-09-02 | Cooker |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4179108B2 (en) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4599232B2 (en) * | 2005-06-02 | 2010-12-15 | 株式会社東芝 | Cooker |

| JP4589819B2 (en) | 2005-06-20 | 2010-12-01 | 株式会社東芝 | Cooking equipment |

| JP4817884B2 (en) * | 2006-02-28 | 2011-11-16 | 株式会社東芝 | Cooker |

| US11067289B2 (en) | 2016-08-10 | 2021-07-20 | Sharp Kabushiki Kaisha | Cooker |

| JP6828041B2 (en) | 2016-08-29 | 2021-02-10 | シャープ株式会社 | Cooker |

| US10845058B2 (en) | 2016-08-29 | 2020-11-24 | Sharp Kabushiki Kaisha | Heating cooker |

-

2003

- 2003-09-02 JP JP2003309785A patent/JP4179108B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2005077020A (en) | 2005-03-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3781759B2 (en) | Steam cooker | |

| JP6421339B2 (en) | Heating device | |

| JP2008185293A (en) | Heating cooking device | |

| JP4179108B2 (en) | Cooker | |

| JP2007010164A (en) | Heating cooker | |

| JP2005077020A5 (en) | ||

| JP2005077019A (en) | Heating cooker | |

| JP2002048344A (en) | Heating cooking apparatus | |

| JP4022880B2 (en) | Cooker | |

| JP3973479B2 (en) | Cooker | |

| DK2445311T3 (en) | Combination preparation device | |

| JP2003050015A (en) | Heating cooking apparatus | |

| JP4239681B2 (en) | Cooker | |

| JP5959369B2 (en) | Cooker | |

| JP4432524B2 (en) | Heating device | |

| JP2004205130A (en) | Heating cooker | |

| JP4194642B2 (en) | Cooker | |

| JP2005233466A5 (en) | ||

| JP2007064583A (en) | Heating cooker | |

| JP2004347149A (en) | Heating cooker | |

| JP2006071157A (en) | Heating cooker | |

| JP2006057912A (en) | Heating cooker | |

| JP4403092B2 (en) | Cooker | |

| JP4470536B2 (en) | Cooking equipment | |

| JP2005233493A (en) | High frequency heating cooker |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060825 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060825 |

|

| RD01 | Notification of change of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7421 Effective date: 20060913 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20071226 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080108 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080310 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20080805 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20080818 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110905 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110905 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120905 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130905 Year of fee payment: 5 |

|

| LAPS | Cancellation because of no payment of annual fees |