JP4128373B2 - ロータ組立体の振動を減衰する方法及び装置 - Google Patents

ロータ組立体の振動を減衰する方法及び装置 Download PDFInfo

- Publication number

- JP4128373B2 JP4128373B2 JP2002049093A JP2002049093A JP4128373B2 JP 4128373 B2 JP4128373 B2 JP 4128373B2 JP 2002049093 A JP2002049093 A JP 2002049093A JP 2002049093 A JP2002049093 A JP 2002049093A JP 4128373 B2 JP4128373 B2 JP 4128373B2

- Authority

- JP

- Japan

- Prior art keywords

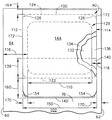

- airfoil

- rotor

- layer

- cavity

- damping material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000000034 method Methods 0.000 title claims 6

- 238000013016 damping Methods 0.000 claims description 47

- 239000000463 material Substances 0.000 claims description 40

- 239000000853 adhesive Substances 0.000 claims description 23

- 230000001070 adhesive effect Effects 0.000 claims description 23

- 230000000452 restraining effect Effects 0.000 claims description 5

- 239000003190 viscoelastic substance Substances 0.000 claims description 5

- 238000007789 sealing Methods 0.000 claims description 4

- 238000003754 machining Methods 0.000 claims 1

- 238000004519 manufacturing process Methods 0.000 claims 1

- 239000000758 substrate Substances 0.000 claims 1

- 239000007789 gas Substances 0.000 description 9

- 230000001629 suppression Effects 0.000 description 6

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 4

- 229910052719 titanium Inorganic materials 0.000 description 4

- 239000010936 titanium Substances 0.000 description 4

- 230000000712 assembly Effects 0.000 description 3

- 238000000429 assembly Methods 0.000 description 3

- 238000002485 combustion reaction Methods 0.000 description 3

- 239000012530 fluid Substances 0.000 description 2

- 230000002238 attenuated effect Effects 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 239000000567 combustion gas Substances 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/14—Form or construction

- F01D5/16—Form or construction for counteracting blade vibration

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S416/00—Fluid reaction surfaces, i.e. impellers

- Y10S416/50—Vibration damping features

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US09/844,207 US6471484B1 (en) | 2001-04-27 | 2001-04-27 | Methods and apparatus for damping rotor assembly vibrations |

| US09/844207 | 2001-04-27 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2002339704A JP2002339704A (ja) | 2002-11-27 |

| JP2002339704A5 JP2002339704A5 (cg-RX-API-DMAC7.html) | 2005-08-11 |

| JP4128373B2 true JP4128373B2 (ja) | 2008-07-30 |

Family

ID=25292115

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2002049093A Expired - Fee Related JP4128373B2 (ja) | 2001-04-27 | 2002-02-26 | ロータ組立体の振動を減衰する方法及び装置 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US6471484B1 (cg-RX-API-DMAC7.html) |

| EP (1) | EP1253290B1 (cg-RX-API-DMAC7.html) |

| JP (1) | JP4128373B2 (cg-RX-API-DMAC7.html) |

| ES (1) | ES2393917T3 (cg-RX-API-DMAC7.html) |

Families Citing this family (33)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7026736B2 (en) * | 2003-12-01 | 2006-04-11 | Vladilen Safonov | Turbine generator vibration damper system |

| GB0406444D0 (en) * | 2004-03-23 | 2004-04-28 | Rolls Royce Plc | An article having a vibration damping coating and a method of applying a vibration damping coating to an article |

| US20080124480A1 (en) * | 2004-09-03 | 2008-05-29 | Mo-How Herman Shen | Free layer blade damper by magneto-mechanical materials |

| US20120135272A1 (en) | 2004-09-03 | 2012-05-31 | Mo-How Herman Shen | Method for applying a low residual stress damping coating |

| US7121800B2 (en) * | 2004-09-13 | 2006-10-17 | United Technologies Corporation | Turbine blade nested seal damper assembly |

| US7278830B2 (en) * | 2005-05-18 | 2007-10-09 | Allison Advanced Development Company, Inc. | Composite filled gas turbine engine blade with gas film damper |

| DE102006002617A1 (de) * | 2006-01-19 | 2007-07-26 | Mtu Aero Engines Gmbh | Verfahren zur Fräsbearbeitung von Bauteilen |

| GB2444485B (en) * | 2006-12-05 | 2009-03-04 | Rolls Royce Plc | A method of applying a constrained layer damping material |

| FR2918107B1 (fr) | 2007-06-26 | 2013-04-12 | Snecma | Dispositif amortisseur adapte aux arbres de turbomachine. |

| FR2918109B1 (fr) | 2007-06-26 | 2013-05-24 | Snecma | Roue mobile pour un turboreacteur et turboreacteur la comportant |

| FR2918108B1 (fr) | 2007-06-26 | 2009-10-02 | Snecma Sa | Dispositif amortisseur pour stator de turbomachine |

| US8011892B2 (en) * | 2007-06-28 | 2011-09-06 | United Technologies Corporation | Turbine blade nested seal and damper assembly |

| GB2450936B (en) * | 2007-07-13 | 2010-01-20 | Rolls Royce Plc | Bladed rotor balancing |

| FR2921099B1 (fr) | 2007-09-13 | 2013-12-06 | Snecma | Dispositif d'amortissement pour aube en materiau composite |

| US8172541B2 (en) * | 2009-02-27 | 2012-05-08 | General Electric Company | Internally-damped airfoil and method therefor |

| FR2943102B1 (fr) * | 2009-03-12 | 2014-05-02 | Snecma | Aube en materiau composite comportant un dispositif d'amortissement. |

| US9151170B2 (en) | 2011-06-28 | 2015-10-06 | United Technologies Corporation | Damper for an integrally bladed rotor |

| FR2978196B1 (fr) * | 2011-07-20 | 2016-12-09 | Snecma | Aubes de turbomachine comprenant une plaque rapportee sur une partie principale |

| US9221120B2 (en) * | 2012-01-04 | 2015-12-29 | United Technologies Corporation | Aluminum fan blade construction with welded cover |

| US10215027B2 (en) | 2012-01-04 | 2019-02-26 | United Technologies Corporation | Aluminum fan blade construction with welded cover |

| US9121288B2 (en) | 2012-05-04 | 2015-09-01 | Siemens Energy, Inc. | Turbine blade with tuned damping structure |

| US9151165B2 (en) | 2012-10-22 | 2015-10-06 | United Technologies Corporation | Reversible blade damper |

| WO2014158254A1 (en) * | 2013-03-14 | 2014-10-02 | United Technologies Corporation | Fan blade damping device |

| US10023951B2 (en) | 2013-10-22 | 2018-07-17 | Mo-How Herman Shen | Damping method including a face-centered cubic ferromagnetic damping material, and components having same |

| US9458534B2 (en) | 2013-10-22 | 2016-10-04 | Mo-How Herman Shen | High strain damping method including a face-centered cubic ferromagnetic damping coating, and components having same |

| US10808718B2 (en) | 2013-10-30 | 2020-10-20 | Raytheon Technologies Corporation | Fan blade composite segments |

| GB201506197D0 (en) | 2015-04-13 | 2015-05-27 | Rolls Royce Plc | Rotor damper |

| GB201506196D0 (en) | 2015-04-13 | 2015-05-27 | Rolls Royce Plc | Rotor damper |

| FR3085300B1 (fr) * | 2018-08-31 | 2022-01-21 | Safran Aircraft Engines | Aube en materiau composite a film anti-erosion renforce et procede de protection associe |

| US10995632B2 (en) * | 2019-03-11 | 2021-05-04 | Raytheon Technologies Corporation | Damped airfoil for a gas turbine engine |

| US11274557B2 (en) * | 2019-11-27 | 2022-03-15 | General Electric Company | Damper assemblies for rotating drum rotors of gas turbine engines |

| US11280219B2 (en) * | 2019-11-27 | 2022-03-22 | General Electric Company | Rotor support structures for rotating drum rotors of gas turbine engines |

| GB201918607D0 (en) * | 2019-12-17 | 2020-01-29 | Rolls Royce Plc | Gimbals and their manufacture |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3796513A (en) * | 1972-06-19 | 1974-03-12 | Westinghouse Electric Corp | High damping blades |

| US5226784A (en) | 1991-02-11 | 1993-07-13 | General Electric Company | Blade damper |

| IL103521A (en) * | 1991-12-26 | 1996-10-31 | Gen Electric | Visco-elastic muffler for motor struts |

| US5302085A (en) | 1992-02-03 | 1994-04-12 | General Electric Company | Turbine blade damper |

| US5498137A (en) * | 1995-02-17 | 1996-03-12 | United Technologies Corporation | Turbine engine rotor blade vibration damping device |

| US5820343A (en) | 1995-07-31 | 1998-10-13 | United Technologies Corporation | Airfoil vibration damping device |

| US5827047A (en) | 1996-06-27 | 1998-10-27 | United Technologies Corporation | Turbine blade damper and seal |

| US5725355A (en) * | 1996-12-10 | 1998-03-10 | General Electric Company | Adhesive bonded fan blade |

| US5820346A (en) | 1996-12-17 | 1998-10-13 | General Electric Company | Blade damper for a turbine engine |

| US5785499A (en) | 1996-12-24 | 1998-07-28 | United Technologies Corporation | Turbine blade damper and seal |

| US6039542A (en) * | 1997-12-24 | 2000-03-21 | General Electric Company | Panel damped hybrid blade |

| JPH11247605A (ja) * | 1997-12-26 | 1999-09-14 | United Technol Corp <Utc> | タ―ボマシ―ンコンポ―ネントの振動緩衝方法及び装置 |

| US6193465B1 (en) | 1998-09-28 | 2001-02-27 | General Electric Company | Trapped insert turbine airfoil |

| JP2000130102A (ja) * | 1998-10-29 | 2000-05-09 | Ishikawajima Harima Heavy Ind Co Ltd | 回転機械翼端構造 |

| US6171058B1 (en) | 1999-04-01 | 2001-01-09 | General Electric Company | Self retaining blade damper |

| US6155789A (en) | 1999-04-06 | 2000-12-05 | General Electric Company | Gas turbine engine airfoil damper and method for production |

-

2001

- 2001-04-27 US US09/844,207 patent/US6471484B1/en not_active Expired - Lifetime

-

2002

- 2002-02-15 ES ES02251040T patent/ES2393917T3/es not_active Expired - Lifetime

- 2002-02-15 EP EP02251040A patent/EP1253290B1/en not_active Expired - Lifetime

- 2002-02-26 JP JP2002049093A patent/JP4128373B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| ES2393917T3 (es) | 2013-01-02 |

| US6471484B1 (en) | 2002-10-29 |

| EP1253290A2 (en) | 2002-10-30 |

| EP1253290A3 (en) | 2006-06-07 |

| JP2002339704A (ja) | 2002-11-27 |

| EP1253290B1 (en) | 2012-09-12 |

| US20020159882A1 (en) | 2002-10-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4128373B2 (ja) | ロータ組立体の振動を減衰する方法及び装置 | |

| CA2358673C (en) | Method and apparatus for reducing rotor assembly circumferential rim stress | |

| CA2313929C (en) | Reduced-stress compressor blisk flowpath | |

| US6524070B1 (en) | Method and apparatus for reducing rotor assembly circumferential rim stress | |

| EP2305954B1 (en) | Internally damped blade | |

| EP1890008B1 (en) | Rotor blade | |

| EP1451446B1 (en) | Turbine blade pocket shroud | |

| JP4837203B2 (ja) | 偏心によりバランスされたブリスク | |

| EP2372094B1 (en) | Section of a gas turbine and method of damping blade vibration | |

| JP2938908B2 (ja) | タービンロータ構成部品の保持構造 | |

| US8662834B2 (en) | Method for reducing tip rub loading | |

| US8657570B2 (en) | Rotor blade with reduced rub loading | |

| JP2002161702A5 (cg-RX-API-DMAC7.html) | ||

| EP1942254A2 (en) | Methods and apparatus for fabricating a fan assembly for use with turbine engines | |

| JPH08326502A5 (cg-RX-API-DMAC7.html) | ||

| EP1734227A1 (en) | V-shaped blade tip shroud and method of fabricating same | |

| CA2766534C (en) | Rotor blade and method for reducing tip rub loading |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050118 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050118 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070814 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20071114 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20080415 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20080514 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110523 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110523 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120523 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130523 Year of fee payment: 5 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |