JP4023997B2 - Thin film magnetic field sensor - Google Patents

Thin film magnetic field sensor Download PDFInfo

- Publication number

- JP4023997B2 JP4023997B2 JP2000367822A JP2000367822A JP4023997B2 JP 4023997 B2 JP4023997 B2 JP 4023997B2 JP 2000367822 A JP2000367822 A JP 2000367822A JP 2000367822 A JP2000367822 A JP 2000367822A JP 4023997 B2 JP4023997 B2 JP 4023997B2

- Authority

- JP

- Japan

- Prior art keywords

- thin film

- gap

- terminal

- soft magnetic

- magnetic field

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 230000005291 magnetic effect Effects 0.000 title claims description 221

- 239000010409 thin film Substances 0.000 title claims description 198

- 239000010408 film Substances 0.000 claims description 55

- 239000004020 conductor Substances 0.000 claims description 31

- 230000005415 magnetization Effects 0.000 claims description 16

- 239000000463 material Substances 0.000 description 25

- 230000035945 sensitivity Effects 0.000 description 14

- 230000004907 flux Effects 0.000 description 11

- 238000001514 detection method Methods 0.000 description 6

- 230000002093 peripheral effect Effects 0.000 description 4

- 239000000696 magnetic material Substances 0.000 description 3

- 239000012141 concentrate Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 229910000889 permalloy Inorganic materials 0.000 description 2

- 239000000758 substrate Substances 0.000 description 2

- 239000011800 void material Substances 0.000 description 2

- YLZOPXRUQYQQID-UHFFFAOYSA-N 3-(2,4,6,7-tetrahydrotriazolo[4,5-c]pyridin-5-yl)-1-[4-[2-[[3-(trifluoromethoxy)phenyl]methylamino]pyrimidin-5-yl]piperazin-1-yl]propan-1-one Chemical compound N1N=NC=2CN(CCC=21)CCC(=O)N1CCN(CC1)C=1C=NC(=NC=1)NCC1=CC(=CC=C1)OC(F)(F)F YLZOPXRUQYQQID-UHFFFAOYSA-N 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 239000012212 insulator Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000013589 supplement Substances 0.000 description 1

- 230000002123 temporal effect Effects 0.000 description 1

Images

Landscapes

- Hall/Mr Elements (AREA)

- Measuring Magnetic Variables (AREA)

- Magnetic Heads (AREA)

Description

【0001】

【産業上の利用分野】

本発明は、空間中の磁界を測定する薄膜磁界センサに関し、巨大磁気抵抗薄膜、例えばナノグラニュラー巨大磁気抵抗効果薄膜を用いて、磁界を精密に測定するための薄膜磁界センサに関するものである。

【0002】

【従来の技術】

図1は、特開平11−87804号公報および特開平11−274599に記載された磁界センサを示す。図中、巨大磁気抵抗薄膜と書かれた部分は、10kOeの磁界の印加に対して、約10%の電気抵抗変化を示す金属−絶縁体ナノグラニュラー巨大磁気抵抗薄膜である。この例のように、巨大磁気抵抗薄膜の場合には、一般の磁気抵抗効果材料に比して電気抵抗値の変化幅は大であるが、前記の通り電気抵抗変化を起こさせるための印加磁界は大きく、巨大磁気抵抗薄膜のみを単独で用いる場合には、一般に磁界センサとして利用されるような小さな磁界での電気抵抗値変化は期待できない。図1の構成は、それを補うものである。すなわち、軟磁性薄膜は周辺の磁束を集める役割を担っており、適切な軟磁性薄膜の寸法を選定することにより、原理的には、軟磁性薄膜周辺の磁界の大小に拘わらず、巨大磁気抵抗薄膜部分に対して軟磁性薄膜の飽和磁束密度以内で、いかようにも大きな磁束密度を印加することが可能である。また、図1の構成を電気抵抗の観点から見ると、軟磁性薄膜間の電気抵抗値は、軟磁性薄膜部分と巨大磁気抵抗薄膜部分の電気抵抗値の和になっているが、巨大磁気抵抗薄膜の電気比抵抗の値は、軟磁性薄膜のそれに比して100倍以上大きいため、実質的に軟磁性薄膜間の電気抵抗値は巨大磁気抵抗薄膜部分の値と等しい。つまり、軟磁性薄膜間の電気抵抗値には、巨大磁気抵抗薄膜の電気抵抗値変化が直接現れる。図2は、このような図1の構成の電気抵抗変化の例を示すものであり、数Oeの小さな磁界において約6%の電気抵抗値変化を実現している。

【0003】

【発明が解決しようとする課題】

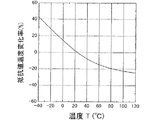

しかし、本発明が目的とする、巨大磁気抵抗薄膜の電気抵抗測定値をもとにして、印加された磁界の絶対値を計測する磁界センサを実現する場合には、図1の構成では、大きな問題があることが判明した。それは、巨大磁気抵抗薄膜の温度による電気抵抗値変化の問題である。前記の通り、図1の構成の場合には検出したい磁界の大小に対しては選択の余地がある。しかし、いかに感度を高めたとしても、それは感動する磁界に対する選択であり、巨大磁気抵抗薄膜の持つ電気抵抗変化以上の変化幅を得ることは、原理的にできない。現実に図1の構成の場合の電気抵抗変化幅は、他の要因を含めて更に圧縮されてほぼ6%程度となっている。この6%の電気抵抗値変化に対して、巨大磁気抵抗薄膜の温度による変化があれば、その電気抵抗値変化分だけは印加された磁界を推定する場合の不確定要素となる。図3は温度特性の実例を示している。この図から明らかな通り、巨大磁気抵抗薄膜の温度による電気抵抗値変化は、磁界印加による抵抗変化よりむしろ大であり、図1の構成のままでは、磁界の絶対値を計測する磁界センサとしては利用が難しい。

【課題を解決するための手段】

【0004】

本発明の特徴とするところは、下記の点にある。第1発明は、所定の空隙長を持つ空隙によって2分割され、所定の膜厚および空隙に接する所定の幅を持つ軟磁性薄膜1、その空隙を埋めるように形成された巨大磁気抵抗薄膜2、2分割された軟磁性薄膜1の各々に電気的に接続された端子3および端子4、前記空隙長と実質的に等しい空隙長を持つ空隙によって2分割され、前記膜厚と実質的に等しい膜厚、および前記空隙に接する幅と実質的に等しい幅を持つ導体膜6、その空隙を埋めるように形成された巨大磁気抵抗薄膜7、および2分割された導体膜6の各々に電気的に接続された端子8および端子9からなり、端子3および端子4と端子8および端子9は、各々ブリッジ回路の2つのアームを形成することを特徴とする薄膜磁界センサを提供する。

【0005】

第2発明は、所定の空隙長を持つ空隙によって2分割され、所定の膜厚および空隙に接する所定の幅を持つ軟磁性薄膜1、その空隙を埋めるように形成された巨大磁気抵抗薄膜2、2分割された軟磁性薄膜1の各々に電気的に接続された端子3および端子4、前記空隙長と実質的に等しい空隙長を持つ空隙によって2分割され、前記膜厚と実質的に等しい膜厚および前記空隙に接する幅と実質的に等しい幅を持つ導体膜6、その空隙を埋めるように形成された巨大磁気抵抗薄膜7、2分割された導体膜6の各々に電気的に接続された端子8および端子9、前記空隙長と実質的に等しい空隙長を持つ空隙によって2分割され、前記膜厚と実質的に等しい膜厚および前記空隙に接する幅と実質的に等しい幅を持つ軟磁性薄膜21、その空隙を埋めるように形成された巨大磁気抵抗薄膜22、2分割された軟磁性薄膜21の各々に電気的に接続された端子23および端子24、前記空隙長と実質的に等しい空隙長を持つ空隙によって2分割され、前記膜厚と実質的に等しい膜厚および前記空隙に接する幅と実質的に等しい幅を持つ導体膜26、その空隙を埋めるように形成された巨大磁気抵抗薄膜27、および2分割された導体膜26の各々に電気的に接続された端子28および端子29からなり、端子3および端子4、端子8および端子9、端子23および端子24、端子28および端子29は、各々ブリッジ回路の4つのアームを形成することを特徴とする薄膜磁界センサを提供する。

【0006】

第3発明は、所定の空隙長を持つ空隙によって2分割され、所定の膜厚および空隙に接する所定の幅を持つ軟磁性薄膜1、その空隙を埋めるように形成された巨大磁気抵抗薄膜2、2分割された軟磁性薄膜1の各々に電気的に接続された端子3および端子4、前記空隙長と実質的に等しい空隙長を持つ空隙によって2分割され、前記膜厚と実質的に等しい膜厚、および前記空隙に接する幅と実質的に等しい幅を持つ軟磁性薄膜31、その空隙を埋めるように形成された巨大磁気抵抗薄膜32、および2分割された軟磁性薄膜31の各々に電気的に接続された端子33および端子34からなり、端子3および端子4、端子33および端子34は、各々ブリッジ回路の2つのアームを形成し、且つまた軟磁性薄膜31の平面上の面積は、軟磁性薄膜1の平面上の面積に比して1/10以下であることを特徴とする薄膜磁界センサを提供する。

【0007】

第4発明は、空隙に接する線と並行な線に沿って測った軟磁性薄膜1の幅寸法の少なくとも一部は、その軟磁性薄膜1が空隙に接する線の幅よりも大であることを特徴とする第1発明ないし第3発明のいずれかに記載の薄膜磁界センサを提供する。

【0008】

第5本発明は、軟磁性薄膜1の磁気特性は一軸異方性であって、その磁化容易軸方向は、実質的に、空隙に接する線と並行な方向であることを特徴とする第1発明ないし第3発明のいずれかに記載の薄膜磁界センサを提供する。

【0009】

【作用】

本発明の作用は下記の通りである。

第一発明の構成は、巨大磁気抵抗薄膜の持つ電気抵抗値変化の中で、温度、湿度および経時的な原因による変化を除外し、磁界による変化のみを抽出することによって、精度の高い磁界センサを実現するものである。すなわち、巨大磁気抵抗薄膜および構造を同一とする2系統の素子によるブリッジ回路を形成し、その中の一方の素子は巨大磁気抵抗薄膜の両側に軟磁性薄膜を配置することによって磁界に対する感度を高め、他方の素子は巨大磁気抵抗薄膜をそのまま用いることにより磁界に対する感度を実質的に零としている。ブリッジ回路の出力電圧はこれら素子の電気抵抗値の差に比例するものであるから、結果的に、巨大磁気抵抗薄膜の持つ温度変化を始めその他の湿度、経時変化等の変動要因は出力電圧より除外され、磁界による電気抵抗値変化のみが出力に現れる。そのため磁界の絶対値の検出が精度良く実現可能になり、また同時に極めて小さな磁界の検出も可能になる。

【0010】

第2発明の構成は、さらに精度が高く、且つ磁界感度の高い薄膜磁界センサを実現するものである。すなわち、巨大磁気抵抗薄膜の両側に軟磁性薄膜を配置した素子と、巨大磁気抵抗薄膜の両側に導体膜を配置した素子を、各々2個用いてブリッジ回路を構成することによって、ブリッジ出力電圧は、第1発明の構成よりも更に2倍大きくすることが可能となり、より精度が高く、且つより磁界感度の高い薄膜磁界センサが実現可能となる。

【0011】

第3発明の構成は、利用する材料の観点から、薄膜磁界センサの精度を更に高めるものである。すなわち、ブリッジを構成する素子中の巨大磁気抵抗薄膜部分の材質・構造が全く同じでも、巨大磁気抵抗薄膜を挟んでいる材料が異なる場合には、接触電位差、あるいは熱起電力等により微小な電気抵抗値の違いが出る場合がある。第3発明の構成によれば、これ等の問題を含めて、2つの構造の磁界印加による抵抗変化以外の要因による巨大磁気抵抗薄膜の電気抵抗値変化を、厳密な意味で相殺することができ、これにより更に精度の高い薄膜磁界センサが実現できる。

【0012】

第4発明の構成は、構造の面から、より小型で高精度の薄膜磁界センサを実現するものである。磁界センサとしての感度を高く、しかも、形状的に小型化するためには、巨大磁気抵抗薄膜の両側に軟磁性薄膜を配置した構造において、軟磁性薄膜の有効面積を一定とした上で、軟磁性薄膜部分の小型化を計る必要がある。第4発明の構成により、感度が高く、また形状的により小型の磁界センサの実現が可能になる。

【0013】

第5発明の構成は、残留磁化の面から薄膜磁界センサの精度を、さらに高めるものである。つまり、印加された磁界の計測を完了し、外部磁界が取り去られた後で、軟磁性薄膜中に磁化が残留する場合には、この残留磁化は、巨大磁気抵抗薄膜に対して外部磁界印加と同様の作用を及ぼすことになり、磁界の検出精度の低下を来たす。このため、第5発明の構成では、軟磁性薄膜を巨大磁気抵抗薄膜の検出磁界と直交する方向に磁化させることにより、軟磁性薄膜中の残留磁化を減らして、より高精度に磁界を計測することができる。

【0014】

【実施例】

以下、図面に基づき、本発明の種々の実施形態につき説明する。尚、各図において同一の要素は同じ番号を付してあり、説明の重複を避けている。

【0015】

[実施例1]

図4は、本発明の第1の実施例を示す。この図および以降の図では、理解を助けるため、巨大磁気抵抗薄膜の部分を点々の印、軟磁性薄膜の部分を斜め線、導体薄膜部分を白ぬき、として区別している。5は、軟磁性薄膜1、巨大磁気抵抗薄膜2および電気端子3、4を含めた素子を表しており、公知技術である図1の構成と同一である。素子5の作用についての記述は本文中の段落0002に述べたので、ここでは重複を避けて本発明の具体内容の記述のみを行う。1は軟磁性薄膜で、15kG以上の高い飽和磁束密度と、0.5Oe以下の低い保磁力を持つパーマロイである。その他の材料を含めて、軟磁性薄膜1の具体的な材料名およびその代表特性は表1に示す。

【0016】

【表1】

【0017】

軟磁性薄膜1の厚さはt=1μmである。軟磁性薄膜1には、空隙長gで示した空隙が形成されている。空隙長gの寸法はg=1μmである。空隙に接する軟磁性薄膜1の幅wの寸法はw=100μmである。その軟磁性薄膜1の空隙を埋めるように巨大磁気抵抗薄膜2が形成されている。巨大磁気抵抗薄膜2の材質は、Co39Y14O47である。この材料を含め、巨大磁気抵抗薄膜2として可能な材料名およびその代表特性は表2に示す。

【0018】

【表2】

【0019】

ここでの軟磁性薄膜1の厚さt、空隙長gおよび空隙に接する軟磁性薄膜1の幅wの寸法については、磁気的な条件と電気的な条件の両面からの要求される特性を満たすように選択する必要があるが、本発明の特徴は広い範囲に亙って目的とする性能を得る事にある。すなわち、寸法の選択範囲は大変広い。磁気的な条件としては、空隙長gが広すぎる場合、例えば軟磁性薄膜の厚さtの数倍以上の場合には、軟磁性薄膜1が周辺の磁束を集めて空隙部分に磁束を十分に集中させる事が出来ない。一方、軟磁性薄膜の厚さtについては、機能上はいかに厚くても本発明の機能を発揮するが、軟磁性薄膜を形成する装置の持つ単位時間当たりの堆積能力、あるいは軟磁性薄膜が基板に形成された場合の応力により、軟磁性薄膜が基板から剥離するなど、現実的な制約条件で厚さの限界は決まってくる。逆に軟磁性薄膜の厚さtが10nm以下の場合には、軟磁性薄膜の磁気特性が劣化するので、実質的に10nmが厚さの下限である。電気的な条件としては、軟磁性薄膜1の幅wは、磁気センサの小型化および電気抵抗の絶対値として周辺回路が扱いやすい値、例えば数10kΩから数100MΩの範囲となることを勘案して設定する必要がある。電気抵抗の絶対値は、巨大磁気抵抗薄膜の電気比抵抗および空隙長gに比例し、軟磁性薄膜の幅wおよび軟磁性薄膜の厚さtに反比例するので、比較的設計での自由度は大であり、具体的な軟磁性薄膜の幅gは、最大数mmから最小数μmの広い範囲での実現の可能性がある。

【0020】

空隙を挟んで2分割された両側の軟磁性薄膜1には、各々Cuによる電気端子3および4が接続されている。この電気端子部分の材質は、磁気的には大きな影響を持たないので、電気的な導通性を中心として決定して良く、軟磁性薄膜の材質を共通に利用することも可能であり、また実際に外部との接続に供せられる部分にのみ、表面にCu膜を形成すること等も可能である。5は軟磁性薄膜1、巨大磁気抵抗薄膜2、ならびに電気端子3および4を含めた素子を表している。電気端子3と4の間の電気抵抗値をRaと表す。図5は、軟磁性薄膜1の長さ寸法Lをパラメータとして、素子5の印加磁界と電気抵抗値変化の関係の一例を示したものであり、長さ寸法Lを大きくすることにより、より小さな磁界において感動させることが可能であることが分かる。図6は素子5の温度による抵抗値変化を示したものである。図5の印加磁界と電気抵抗値との関係は、印加磁界の絶対値を取れば、ある大きさの磁界まではほぼリニアな変化になっている。また、図6の温度と電気抵抗値の変化について、室温付近でリニアな関係とみなす。そこで、印加磁界零で、且つ温度22℃の場合の抵抗値をR0とし、印加磁界の絶対値をH、温度をTとすれば、抵抗値Raは式1のように表現できる。

【0021】

Ra=R0(1+rMH+rT(T−25)) (1)

ここに、rMは電気抵抗値の印加磁界による変化の微係数、rTは電気抵抗値の温度係数である。表3は、軟磁性薄膜の各長さ寸法LについてrMの値および式1が成立する磁界Hの範囲、およびrTの値を示している。

【0022】

【表3】

【0023】

6は、軟磁性薄膜1と実質的に同じ厚さt´を持った導体膜である。導体膜6の材料はCuである。Cu材料は、極く弱い反磁性を示すがほとんど磁気的には透明とみなされる。導体膜6には軟磁性薄膜1の空隙長gと実質的に等しい寸法の空隙長g′が形成されている。空隙に接する導体膜6の幅w´は、実質的に空隙に接する軟磁性薄膜1の幅wと同一である。素子5のLに対応する長さ寸法は任意である。その導体膜6の空隙を埋めるように、巨大磁気抵抗薄膜7が形成されている。巨大磁気抵抗薄膜7の材質は、巨大磁気抵抗薄膜2と同一である。空隙を挟んで2分割された両側の導体膜6には、各々電気端子8および9が接続されている。10は、導体膜6、巨大磁気抵抗薄膜7、および電気端子8、9を含めた素子を表している。電気端子8、9間の電気抵抗をRbと表す。

【0024】

素子10については、導体膜6が磁気的な作用を持たないため、巨大磁気抵抗薄膜7に印加される磁束密度は、巨大磁気抵抗薄膜7の置かれる環境の磁束密度そのものである。図7は、印加磁界によるRbの変化を示すもので、実質的に印加磁界による電気抵抗値変化は零とみなされる。一方、温度に対する変化としては、図6に示す温度係数と同じ温度係数を示す。従って、式1に対応して素子10の場合の電気抵抗値Rbの式を示すと、式2のようになる。

Rb=R 0 (1+r T (T−25)) (2)

【0025】

11は電気抵抗値Rcを持つ第1の抵抗器であり、第1の抵抗器11には電気端子12および13が接続されている。14は電気抵抗値Rdを持つ第2の抵抗器である。第2の抵抗器14には、電気端子15および16が接続されている。第1の抵抗器と第2の抵抗器については、それ等の間で抵抗値およびその温度係数は、精密に一致したものを利用する。式1、2と同様にして、電気抵抗の温度係数をrT′とすれば、式3および4を得る。

Rc=R 0 (1+r T ´(T−25)) (3)

Rd=R 0 (1+r T ´(T−25)) (4)

【0026】

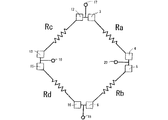

端子4、8および20間、端子3、12および17間、端子9、16および18間、端子13、15および19間は電気的に相互接続されている。図8は、図4の構成を電気的等価回路として表したものであり、全体として一つのブリッジ回路を形成している。素子5および素子10は、ブリッジ回路の2つのアームを形成している。端子17と18間には駆動電圧が印加され、端子19、20間にはブリッジの出力電圧が現れる。図8の回路において、端子17、18間に電圧V0を印加した場合に、端子19、20間に現れる電圧V2は、式5で表される。

V 2 =(RaRd−RbRc)V 0 /((Ra+Rb)・(Rc+Rd)) (5)

【0027】

式5のRa、Rb、Rc、Rdに各々式1、2、3、4を代入し、2次の微小量を省略すれば、V2の温度に関係する項はすべて相殺され、式6を得る。

V 2 =r T HV 0 /4 (6)

【0028】

ここに、V0、rT、R0はあらかじめ決定できる定数であり、V2の測定値を得れば、目的とする磁界は式7のように決定できる。

H=4V 2 /(V 0 r T ) (7)

【0029】

ブリッジ回路出力V2として、V0に対してどの程度のレベルまで安定に検出可能かは、ブリッジ回路出力電圧の増幅器の安定性等で決定されるが、一般にV2/V0=1x10−5は容易に実現可能である。従って、式7において、V2/V0=1x10−5および表3のrTの値を代入すれば、本発明によって可能な磁界の分解能を得る。結果は表4の通りである。

【0030】

【表4】

【0031】

表4の分解能は、従来技術のFluxGateセンサの分解能に匹敵する。このFluxGateセンサは、磁性材料の飽和特性を利用するもので、センサ構造としてもまた周辺回路の構成としてもかなり複雑でまた大型のものである。本発明の構成は、これらの磁界センサに比して極めて簡単、且つ小型軽量であり、本発明の効用は極めて高い。

【0032】

[実施例2−1]

図9は、本発明の第2の実施例の一つを示す。図中、各々、素子25は、図4で述べた素子5と、素子30は素子10と同等の素子である。全体の回路としては、素子25が第1の抵抗器を、素子30が第2の抵抗器をそれぞれ置き換えた形になっている。図9を等価回路として表せば、全体として図8に示した回路と同じ回路となるが、図9の場合は、Rd=RaおよびRc=Rbが成立している。式6と同じく式5に、式1、2を代入すれば、式8を得る。

V 2 =r T HV 0 /2 (8)

【0033】

ここに式8の値は式6の2倍になっている。従って、図9の構成によれば、図4の構成に比してより正確な磁界の大きさの推定が可能であり、また検出可能な磁界の分解能も更に2倍まで高めることができる。

【0034】

[実施例2−2]

図10は、本発明の第2の実施例の他の一つを示す。図10では、素子5および素子25を並行して配置し、それ等の間に素子10および素子30を配置することにより、全体として占有面積の有効利用を計っている。また、端子4と端子8、端子24と端子28、および端子3と端子9、端子23と端子29は各々共通になっており、これ等の端子間の接続を省略して構造の簡単化を計っている。外部回路への接続端子である17、18、19、20については、端子3と9、端子23と29および端子4と8、端子24および28に直接接続はされていないが、素子5および素子25を通して電気的に接続されており、電気機能的には図6と同様の機能を持っている。図10の場合には、巨大磁気抵抗薄膜の置かれている角度が、素子5と素子10および素子25と素子30とで直交している。素子10および素子30については、図7に示した通り、磁界に対する感度はほとんど零であるが、図10のように配置することにより、素子5の長手方向に加えられた磁界に対して更に厳密に素子10および素子30の電気抵抗変化を零とすることができる。

【0035】

[実施例3]

図11は、本発明の第3の実施例を示す。この実施例の第1実施例との違いは、図4で示した6の導体膜として1の軟磁性薄膜と共通の材料を使用している事である。図4では、素子5および素子10の持つ電気抵抗変化の中で、磁界による変化以外のものをできるだけ等しくし、ブリッジ回路において相殺させることが必要である。このためには、先ず、巨大磁気抵抗薄膜そのものの材質、構造を共通化することであるが、巨大磁気抵抗薄膜そのものが全く同じであっても、それに接触する材料によっては微細な電気抵抗値の違いが出る可能性がある。その原因となるのは、接触電位差、あるいは熱起電力等である。図11に示す実施例3では、巨大磁気抵抗薄膜に接触させる材質を、素子5と素子35で共通の軟磁性薄膜とすることにより、この問題を回避している。しかし、素子35の軟磁性薄膜31の寸法を大きくすると、必然的に巨大磁気抵抗薄膜32に加わる磁束密度も大きくなり、素子5と素子32の抵抗値の差としての磁界センサの感度を低下させてしまう。実施例3では、素子35の軟磁性薄膜31の面積を、素子5の軟磁性薄膜1の面積の1/10以下とすることで、この問題を回避している。この構成によれば、素子35の導体部分が非磁性体である場合のブリッジ出力電圧に対し、少なくとも90%以上の出力電圧を確保でき、しかも磁界印加以外の要因による抵抗の変化を、素子5と素子35で厳密に相殺することができ、高精度の薄膜磁界センサの実現が可能になる。

【0036】

[実施例4]

図12は、本発明の第4の実施例を示す。実施例1において、素子5については、軟磁性薄膜のL寸法を大きくすることにより、感動する磁界の感度を高められることを述べた。軟磁性薄膜1の持つ機能は、周辺の磁束を集めて巨大磁気抵抗薄膜部分に集中させることであるが、周辺の磁束を集める機能は、ほぼ軟磁性薄膜の面積に比例する。従って、図4に示す構成の場合には、小さな磁界での感度を持たせるためには、どうしてもL寸法を大きくする必要があり、磁界センサの全体の寸法が大きくなってしまうことは避けられない。図12の構成によれば、軟磁性薄膜が巨大磁気抵抗薄膜と接する幅wに比して大きなwxの幅の部分を設けることにより、軟磁性薄膜の占有面積の有効利用を計り、全体として小型でしかも磁界感度の高い磁気センサが実現できる。

【0037】

[実施例5]

図13は本発明の第5の実施例である。軟磁性薄膜では、外部磁界が加わっても、外部磁界を除いた後は磁化が残留し難いが、保磁力Hcの範囲で、磁化が残留してしまう可能性がある。この残留磁化は、検出する磁界の直接誤差となるものであるから、可及的に残留磁化のない材料が望ましい。表1に示した通りCo77Fe5Si9B 9 材料は、パーマロイに比しても1/6程度の低いHcを有し、この値は磁化困難軸方向に励磁した場合に得られる。一般的に、一軸異方性を有する磁性材料の困難軸方向の磁化過程は磁化回転によるため、ヒステリシスは発生せず、Hcはほぼ零となる。したがって、困難軸方向では残留磁化は発生しない。本発明の第5の構成によれば、一軸異方性を有する材料の困難軸方向を磁界検出方向とするため、外部から印加された磁界が取り去られた後も軟磁性薄膜中に残留磁化が少なく、従って、正確な磁界の計測が可能になる。

【0038】

【発明の効果】

以上の説明の通り、本発明によれば次のような効果が得られる。

【0039】

巨大磁気抵抗薄膜の有する電気抵抗値の温度変化等、磁界印加による電気抵抗値変化以外は、すべてブリッジ回路の中で相殺されてブリッジ出力としては出ないため、従来技術では問題であった巨大磁気抵抗薄膜の温度等による電気抵抗値変化が除外されて、純粋に磁界の印加による変化分が検出可能である。

【0040】

ブリッジ回路の持つ微小な電気抵抗値変化の検出機能が利用出来るため、極めて小さな変化に対応する、高い分解能での磁界検出が可能である。

【0041】

2つの巨大磁気抵抗薄膜の両側に配置された材料の違いによって生じる微小な抵抗値の違いを避けるため、2つの巨大磁気抵抗薄膜の両側に配置する材料を同一とすることにより、磁界以外の要因による電気抵抗値変化は、更に厳密に相殺される。

【0042】

巨大磁気抵抗薄膜の両側に配置する軟磁性薄膜の長さを減らし、その代わりに幅を広く取ることにより、磁界センサの感度を低下させることなく、磁界センサ全体としての小型化が可能である。

【0043】

巨大磁気抵抗薄膜の両側に配置する軟磁性薄膜として、残留磁化が少ない一軸異方性を持った材料を適用することにより、検出すべき磁界を除いた後の残留磁化による磁界検出精度の低下を防止することができる。

【0044】

本発明の薄膜磁界センサは、構造が単純で小型化が可能であり、また優れた磁界感度を有するので、次世代の高性能磁界センサーとして、その工業的意義は極めて大きい。

【図面の簡単な説明】

【図1】従来技術による薄膜磁界センサ

【図2】同上の磁界印加による抵抗値の変化

【図3】同上の抵抗値の温度特性

【図4】本発明の第1の実施例

【図5】本発明の第1の実施例の素子5の磁界と抵抗変化との関係

【図6】本発明の第1の実施例の素子5および素子10の抵抗値温度特性

【図7】本発明の第1の実施例の素子10の磁界と抵抗変化との関係

【図8】同上の電気的等価回路

【図9】本発明の第2の実施例の1

【図10】本発明の第2の実施例の2

【図11】本発明の第3の実施例

【図12】本発明の第4の実施例

【図13】本発明の第5の実施例

【符号の説明】

1:第1の軟磁性薄膜

2:第1の巨大磁気抵抗薄膜

3:第1の軟磁性薄膜に接続される電気端子の1つ

4:第1の軟磁性薄膜に接続される他の電気端子

5:上記1〜4を含めた素子

6:第1の導体膜

7:第2の巨大磁気抵抗薄膜

8:第1の導体膜に接続される電気端子の1つ

9:第1の導体膜に接続される他の電気端子

10:上記6〜9を含めた素子

11:第1の抵抗器

12:第1の抵抗器に接続される電気端子の1つ

13:第1の抵抗器に接続される他の電気端子

14:第2の抵抗器

15:第2の抵抗器に接続される電気端子の1つ

16:第2の抵抗器に接続される他の電気端子

17:駆動電圧を与えられる電気端子の1つ

18:駆動電圧を与えられる他の電気端子

19:ブリッジ出力の電気端子の1つ

20:ブリッジ出力の他の電気端子

21:第2の軟磁性薄膜

22:第3の巨大磁気抵抗薄膜

23:第2の軟磁性薄膜に接続される電気端子の1つ

24:第2の軟磁性薄膜に接続される他の電気端子

25:上記21〜24を含めた素子

26:第2の導体膜

27:第4の巨大磁気抵抗薄膜

28:第2の導体膜に接続される電気端子の1つ

29:第2の導体膜に接続される他の電気端子

30:上記26〜29を含めた素子

31:第3の軟磁性薄膜

32:第5の巨大磁気抵抗膜

33:第3の軟磁性薄膜に接続される電気端子の1つ

34:第3の軟磁性薄膜に接続される他の電気端子

35:上記31〜34を含めた素子[0001]

[Industrial application fields]

The present invention relates to a thin film magnetic field sensor for measuring a magnetic field in space, and relates to a thin film magnetic field sensor for accurately measuring a magnetic field using a giant magnetoresistive thin film, for example, a nanogranular giant magnetoresistive thin film.

[0002]

[Prior art]

FIG. 1 shows a magnetic field sensor described in JP-A-11-87804 and JP-A-11-274599. In the figure, a portion written as a giant magnetoresistive thin film is a metal-insulator nanogranular giant magnetoresistive thin film that exhibits an electric resistance change of about 10% when a magnetic field of 10 kOe is applied. As in this example, in the case of a giant magnetoresistive thin film, the variation range of the electrical resistance value is larger than that of a general magnetoresistive material, but the applied magnetic field for causing the electrical resistance change as described above. When only a giant magnetoresistive thin film is used alone, a change in electrical resistance value with a small magnetic field that is generally used as a magnetic field sensor cannot be expected. The configuration of FIG. 1 supplements this. In other words, the soft magnetic thin film plays the role of collecting the magnetic flux around it, and by selecting the appropriate soft magnetic thin film dimensions, in principle, regardless of the magnitude of the magnetic field around the soft magnetic thin film, It is possible to apply a very high magnetic flux density to the thin film portion within the saturation magnetic flux density of the soft magnetic thin film. Further, from the viewpoint of electrical resistance, the electrical resistance value between the soft magnetic thin films is the sum of the electrical resistance values of the soft magnetic thin film portion and the giant magnetoresistive thin film portion. Since the value of the electrical resistivity of the thin film is 100 times larger than that of the soft magnetic thin film, the electrical resistance value between the soft magnetic thin films is substantially equal to the value of the giant magnetoresistive thin film portion. That is, the electrical resistance value of the giant magnetoresistive thin film directly appears in the electrical resistance value between the soft magnetic thin films. FIG. 2 shows an example of such an electrical resistance change in the configuration of FIG. 1, and an electrical resistance value change of about 6% is realized in a small magnetic field of several Oe.

[0003]

[Problems to be solved by the invention]

However, when the magnetic field sensor for measuring the absolute value of the applied magnetic field based on the measured electric resistance value of the giant magnetoresistive thin film, which is the object of the present invention, is realized, the configuration of FIG. It turns out that there is a problem. That is a problem of change in electrical resistance value due to the temperature of the giant magnetoresistive thin film. As described above, in the case of the configuration of FIG. 1, there is room for selection for the magnitude of the magnetic field to be detected. However, no matter how much the sensitivity is increased, it is a choice for the moving magnetic field, and it is not possible in principle to obtain a change width larger than the electric resistance change of the giant magnetoresistive thin film. Actually, the electrical resistance change width in the case of the configuration of FIG. 1 is about 6% after further compression including other factors. If there is a change due to the temperature of the giant magnetoresistive thin film with respect to this 6% change in electric resistance value, only the change in the electric resistance value becomes an uncertain factor in estimating the applied magnetic field. FIG. 3 shows an example of temperature characteristics. As is clear from this figure, it depends on the temperature of the giant magnetoresistive thin film.ElectricalThe change in resistance value is larger than the change in resistance due to application of a magnetic field, and the configuration shown in FIG. 1 is difficult to use as a magnetic field sensor for measuring the absolute value of a magnetic field.

[Means for Solving the Problems]

[0004]

The features of the present invention are as follows. The first invention includes a soft magnetic

[0005]

The second invention comprises a soft magnetic

[0006]

The third invention comprises a soft magnetic

[0007]

According to a fourth aspect of the present invention, at least a part of the width dimension of the soft magnetic

[0008]

According to a fifth aspect of the present invention, the magnetic properties of the soft magnetic

[0009]

[Action]

The operation of the present invention is as follows.

The configuration of the first invention is a magnetic field sensor with high accuracy by excluding changes due to temperature, humidity and temporal causes from the change in electrical resistance value of the giant magnetoresistive thin film, and extracting only the change due to the magnetic field. Is realized. In other words, a giant magnetoresistive thin film and a bridge consisting of two elements with the same structurecircuitOne of the elements increases the sensitivity to the magnetic field by placing the soft magnetic thin film on both sides of the giant magnetoresistive thin film, and the other element substantially increases the sensitivity to the magnetic field by using the giant magnetoresistive thin film as it is. Is zero. bridgecircuitOutput voltage is proportional to the difference between the electrical resistance values of these elements. As a result, fluctuation factors such as temperature change and other changes in humidity, time, etc. of the giant magnetoresistive thin film are excluded from the output voltage. Only the change in electrical resistance value due to the magnetic field appears in the output. As a result, the absolute value of the magnetic field can be detected with high accuracy, and at the same time, an extremely small magnetic field can be detected.

[0010]

The configuration of the second invention realizes a thin film magnetic field sensor with higher accuracy and higher magnetic field sensitivity. That is, by constructing a bridge circuit using two elements each having a soft magnetic thin film disposed on both sides of a giant magnetoresistive thin film and two elements having conductor films disposed on both sides of the giant magnetoresistive thin film, the bridge output voltage is Further, it is possible to further increase the size by twice as compared with the configuration of the first invention, and it is possible to realize a thin film magnetic field sensor with higher accuracy and higher magnetic field sensitivity.

[0011]

The configuration of the third invention further enhances the accuracy of the thin film magnetic field sensor from the viewpoint of the material to be used. In other words, even if the material and structure of the giant magnetoresistive thin film portion in the elements constituting the bridge are exactly the same, but the material sandwiching the giant magnetoresistive thin film is different, a minute electrical resistance is generated due to the contact potential difference or thermoelectromotive force. There may be a difference in resistance value. According to the configuration of the third invention, including these problems, the change in the electric resistance value of the giant magnetoresistive thin film due to factors other than the resistance change due to the application of the magnetic field of the two structures can be canceled in a strict sense. Thus, a highly accurate thin film magnetic field sensor can be realized.

[0012]

The configuration of the fourth invention realizes a smaller and more accurate thin film magnetic field sensor from the viewpoint of structure. In order to increase the sensitivity as a magnetic field sensor and to reduce the size of the magnetic sensor, the soft magnetic thin film is arranged on both sides of the giant magnetoresistive thin film, and the soft magnetic thin film has a constant effective area and is soft. It is necessary to reduce the size of the magnetic thin film portion. According to the configuration of the fourth aspect of the invention, it is possible to realize a magnetic field sensor having high sensitivity and smaller in shape.

[0013]

The configuration of the fifth invention further increases the accuracy of the thin film magnetic field sensor from the aspect of residual magnetization. In other words, if the magnetization remains in the soft magnetic thin film after the measurement of the applied magnetic field is completed and the external magnetic field is removed, this residual magnetization is applied to the giant magnetoresistive thin film. As a result, the detection accuracy of the magnetic field is lowered. Therefore, in the configuration of the fifth aspect of the invention, the soft magnetic thin film is magnetized in the direction orthogonal to the detection magnetic field of the giant magnetoresistive thin film, thereby reducing the residual magnetization in the soft magnetic thin film and measuring the magnetic field with higher accuracy. be able to.

[0014]

【Example】

Hereinafter, various embodiments of the present invention will be described with reference to the drawings. In each figure, the same elements are denoted by the same reference numerals to avoid duplication of explanation.

[0015]

[Example 1]

FIG. 4 shows a first embodiment of the present invention. In this figure and the subsequent figures, for the sake of understanding, the giant magnetoresistive thin film portion is distinguished by dotted marks, the soft magnetic thin film portion is slanted, and the conductor thin film portion is whitened.

[0016]

[Table 1]

[0017]

The thickness of the soft magnetic

[0018]

[Table 2]

[0019]

Here, the thickness t of the soft magnetic

[0020]

[0021]

Ra = R0(1 + rMH + rT(T-25)) (1)

Where rMIs the differential coefficient of the change in electric resistance value due to the applied magnetic field,TIs the temperature coefficient of the electrical resistance value. Table 3 shows r for each length dimension L of the soft magnetic thin film.MAnd the range of the magnetic field H in which

[0022]

[Table 3]

[0023]

[0024]

For the

Rb = R 0 (1 + r T (T-25)) (2)

[0025]

11ElectricalThis is a first resistor having a resistance value Rc, and

Rc = R 0 (1 + r T '(T-25)) (3)

Rd = R 0 (1 + r T '(T-25)) (4)

[0026]

The

V 2 = (RaRd-RbRc) V 0 /((Ra+Rb).(Rc+Rd)) (5)

[0027]

By substituting

V 2 = R T HV 0 / 4 (6)

[0028]

Where V0, RT, R0Is a constant that can be determined in advance, V2If the measured value is obtained, the target magnetic field can be determined as shown in Equation 7.

H = 4V 2 / (V 0 r T (7)

[0029]

Bridge circuit output V2As V0The level at which stable detection is possible is determined by the stability of the amplifier of the bridge circuit output voltage, etc.2/ V0= 1x10-5Is easily realizable. Therefore, in Equation 7, V2/ V0= 1x10-5And r in Table 3TBy substituting the value of, the magnetic field resolution possible with the present invention is obtained. The results are shown in Table 4.

[0030]

[Table 4]

[0031]

The resolution in Table 4 is comparable to that of a prior art FlexGate sensor. This FluxGate sensor uses the saturation characteristic of a magnetic material, and is quite complicated and large in size as a sensor structure and a peripheral circuit configuration. The configuration of the present invention is extremely simple and small and light compared to these magnetic field sensors, and the utility of the present invention is extremely high.

[0032]

[Example 2-1]

FIG. 9 shows one of the second embodiments of the present invention. In the figure, each of the

V 2 = R T HV 0 / 2 (8)

[0033]

Here, the value of

[0034]

[Example 2-2]

FIG. 10 shows another one of the second embodiment of the present invention. In FIG. 10, the

[0035]

[Example 3]

FIG. 11 shows a third embodiment of the present invention. The difference between this embodiment and the first embodiment is that the same material as that of the soft magnetic

[0036]

[Example 4]

FIG. 12 shows a fourth embodiment of the present invention. In Example 1, it was described that the sensitivity of the moving magnetic field can be increased by increasing the L dimension of the soft magnetic thin film for the

[0037]

[Example 5]

FIG. 13 shows a fifth embodiment of the present invention. In a soft magnetic thin film, even if an external magnetic field is applied, magnetization hardly remains after the external magnetic field is removed, but magnetization may remain within the coercive force Hc range. Since this residual magnetization is a direct error of the magnetic field to be detected, a material having as little residual magnetization as possible is desirable. As shown in Table 1, Co77Fe5Si9B 9 The material has a low Hc of about 1/6 compared with permalloy, and this value is obtained when excited in the hard axis direction. In general, since the magnetization process in the hard axis direction of a magnetic material having uniaxial anisotropy is due to magnetization rotation, no hysteresis occurs and Hc becomes almost zero. Therefore, no residual magnetization occurs in the hard axis direction. According to the fifth configuration of the present invention, since the hard axis direction of the material having uniaxial anisotropy is set as the magnetic field detection direction, the residual magnetization in the soft magnetic thin film is removed even after the externally applied magnetic field is removed. Therefore, accurate magnetic field measurement is possible.

[0038]

【The invention's effect】

As described above, according to the present invention, the following effects can be obtained.

[0039]

Except for changes in electrical resistance due to application of a magnetic field, such as changes in temperature of the electrical resistance of a giant magnetoresistive thin film, they are canceled out in the bridge circuit and do not appear as bridge output. The change in the electric resistance value due to the temperature of the resistive thin film is excluded, and the change due to the application of the magnetic field can be detected purely.

[0040]

Since the detection function of a minute change in electrical resistance value of the bridge circuit can be used, it is possible to detect a magnetic field with high resolution corresponding to an extremely small change.

[0041]

In order to avoid the small difference in resistance value caused by the difference in the materials placed on both sides of the two giant magnetoresistive thin films, the same material is placed on both sides of the two giant magnetoresistive thin films, thereby causing factors other than the magnetic field. The change in the electric resistance value due to is canceled more strictly.

[0042]

By reducing the length of the soft magnetic thin film disposed on both sides of the giant magnetoresistive thin film and taking a wider width instead, it is possible to reduce the size of the magnetic field sensor as a whole without reducing the sensitivity of the magnetic field sensor.

[0043]

The soft magnetic thin film placed on both sides of the giant magnetoresistive thin film can reduce the magnetic field detection accuracy due to the residual magnetization after removing the magnetic field to be detected by applying a material with little residual magnetization and uniaxial anisotropy. Can be prevented.

[0044]

The thin film magnetic field sensor of the present invention has a simple structure, can be miniaturized, and has excellent magnetic field sensitivity. Therefore, the industrial significance of the thin film magnetic field sensor is extremely large as a next-generation high-performance magnetic field sensor.

[Brief description of the drawings]

FIG. 1 shows a conventional thin film magnetic field sensor.

[Fig. 2] Change in resistance due to application of magnetic field

[Fig. 3] Temperature characteristics of resistance values as above

FIG. 4 shows a first embodiment of the present invention.

FIG. 5 shows the relationship between the magnetic field and resistance change of the

FIG. 6 shows resistance-temperature characteristics of the

FIG. 7 shows the relationship between the magnetic field and resistance change of the

FIG. 8 is an electrical equivalent circuit of the above.

FIG. 9 shows a second embodiment of the present invention.

FIG. 10 shows the second embodiment of the present invention.

FIG. 11 shows a third embodiment of the present invention.

FIG. 12 shows a fourth embodiment of the present invention.

FIG. 13 shows a fifth embodiment of the present invention.

[Explanation of symbols]

1: First soft magnetic thin film

2: First giant magnetoresistive thin film

3: One of the electrical terminals connected to the first soft magnetic thin film

4: Other electrical terminals connected to the first soft magnetic thin film

5: Element including 1 to 4 above

6: First conductor film

7: Second giant magnetoresistive thin film

8: One of the electrical terminals connected to the first conductor film

9: Other electrical terminal connected to the first conductor film

10: Element including the above 6 to 9

11: First resistor

12: One of the electrical terminals connected to the first resistor

13: Other electrical terminal connected to the first resistor

14: Second resistor

15: One of the electrical terminals connected to the second resistor

16: Other electrical terminal connected to the second resistor

17: One of the electrical terminals to which the drive voltage is applied

18: Other electrical terminal to which drive voltage is applied

19: One of the electrical terminals for bridge output

20: Other electrical terminal for bridge output

21: Second soft magnetic thin film

22: Third giant magnetoresistive thin film

23: One of the electrical terminals connected to the second soft magnetic thin film

24: Other electrical terminal connected to the second soft magnetic thin film

25: Device including 21 to 24 above

26: Second conductor film

27: Fourth giant magnetoresistive thin film

28: One of the electrical terminals connected to the second conductor film

29: Other electrical terminal connected to the second conductor film

30: Device including the above 26-29

31: Third soft magnetic thin film

32: Fifth giant magnetoresistive film

33: One of the electrical terminals connected to the third soft magnetic thin film

34: Other electrical terminal connected to the third soft magnetic thin film

35: Element including the above 31 to 34

Claims (5)

Priority Applications (9)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000367822A JP4023997B2 (en) | 2000-10-26 | 2000-10-26 | Thin film magnetic field sensor |

| TW090126413A TW550394B (en) | 2000-10-26 | 2001-10-25 | Thin-film magnetic field sensor |

| KR1020027008326A KR100687513B1 (en) | 2000-10-26 | 2001-10-25 | Thin-film magnetic field sensor |

| DE60139017T DE60139017D1 (en) | 2000-10-26 | 2001-10-25 | THIN FILM MAGNETIC SENSOR |

| AT01978911T ATE434192T1 (en) | 2000-10-26 | 2001-10-25 | THIN FILM MAGNETIC FIELD SENSOR |

| PCT/JP2001/009385 WO2002037131A1 (en) | 2000-10-26 | 2001-10-25 | Thin-film magnetic field sensor |

| EP01978911A EP1329735B1 (en) | 2000-10-26 | 2001-10-25 | Thin-film magnetic field sensor |

| CNB018032648A CN100403048C (en) | 2000-10-26 | 2001-10-25 | Thin-film magnetic field sensor |

| US10/225,794 US6642714B2 (en) | 2000-10-26 | 2002-08-22 | Thin-film magnetic field sensor |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000367822A JP4023997B2 (en) | 2000-10-26 | 2000-10-26 | Thin film magnetic field sensor |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2002131407A JP2002131407A (en) | 2002-05-09 |

| JP2002131407A5 JP2002131407A5 (en) | 2005-03-17 |

| JP4023997B2 true JP4023997B2 (en) | 2007-12-19 |

Family

ID=18838177

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2000367822A Expired - Fee Related JP4023997B2 (en) | 2000-10-26 | 2000-10-26 | Thin film magnetic field sensor |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4023997B2 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104508501A (en) * | 2012-05-11 | 2015-04-08 | 公立大学法人大阪市立大学 | Power factor measurement device |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4334914B2 (en) * | 2003-05-28 | 2009-09-30 | 財団法人電気磁気材料研究所 | Thin film magnetic sensor |

| JP4323220B2 (en) * | 2003-05-28 | 2009-09-02 | 財団法人電気磁気材料研究所 | Thin film magnetic sensor and manufacturing method thereof |

| JP2008209224A (en) * | 2007-02-26 | 2008-09-11 | Daido Steel Co Ltd | Magnetic sensor |

| CN103558467B (en) * | 2013-10-29 | 2015-08-26 | 中国南方电网有限责任公司超高压输电公司 | A kind of computing method of capacitive apparatus parameter |

| CN104808158A (en) * | 2015-05-07 | 2015-07-29 | 李川 | Ferroxcube detector |

| CN107037381A (en) * | 2015-12-29 | 2017-08-11 | 爱盛科技股份有限公司 | Magnetic field sensing device and sensing method thereof |

| JP2018151332A (en) * | 2017-03-14 | 2018-09-27 | 大同特殊鋼株式会社 | Thin-film magnetic sensor |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3466470B2 (en) * | 1998-03-18 | 2003-11-10 | 財団法人電気磁気材料研究所 | Thin film magnetoresistive element |

| JP2000180207A (en) * | 1998-12-16 | 2000-06-30 | Yazaki Corp | Magnetism sensor |

-

2000

- 2000-10-26 JP JP2000367822A patent/JP4023997B2/en not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104508501A (en) * | 2012-05-11 | 2015-04-08 | 公立大学法人大阪市立大学 | Power factor measurement device |

| US10120001B2 (en) | 2012-05-11 | 2018-11-06 | Osaka City University | Power factor measurement device |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2002131407A (en) | 2002-05-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR100687513B1 (en) | Thin-film magnetic field sensor | |

| JP4131869B2 (en) | Current sensor | |

| US7501928B2 (en) | Current sensor | |

| US6640652B2 (en) | Rotation angle sensor capable of accurately detecting rotation angle | |

| JP4105147B2 (en) | Current sensor | |

| JP5151551B2 (en) | Thin film magnetic sensor | |

| US6069476A (en) | Magnetic field sensor having a magnetoresistance bridge with a pair of magnetoresistive elements featuring a plateau effect in their resistance-magnetic field response | |

| EP1151482A1 (en) | Spin dependent tunneling sensor | |

| US11002806B2 (en) | Magnetic field detection device | |

| CN109752676A (en) | A kind of improvement Wheatstone bridge formula thin-film magnetoresistive sensor | |

| JP4023997B2 (en) | Thin film magnetic field sensor | |

| KR20010078004A (en) | Magnetic sensor and magnetic storage using same | |

| JP2002131407A5 (en) | ||

| JP6216598B2 (en) | Unit element pair and thin film magnetic sensor | |

| KR101541992B1 (en) | Spontaneous hall effect magnetic sensor and magnetic sensing device having the same | |

| JP4334914B2 (en) | Thin film magnetic sensor | |

| JP3035838B2 (en) | Magnetoresistance composite element | |

| JP2003078187A5 (en) | ||

| CN113433493A (en) | Magnetic resistance element for measuring magnetic field intensity and measuring system thereof | |

| JP3969002B2 (en) | Magnetic sensor | |

| JP3449160B2 (en) | Magnetoresistive element and rotation sensor using the same | |

| JP4204775B2 (en) | Thin film magnetic field sensor | |

| RU2391747C1 (en) | High-frequency magnetosensitive nanoelement | |

| US20040174165A1 (en) | Leakage flux detector | |

| JP3161667B2 (en) | Magnetic field detection sensor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20040415 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20040415 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20040415 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20040415 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20070918 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20071002 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 4023997 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101012 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111012 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111012 Year of fee payment: 4 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111012 Year of fee payment: 4 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111012 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121012 Year of fee payment: 5 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121012 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131012 Year of fee payment: 6 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |