JP3998384B2 - 流動層の流動媒体選別装置及びその方法 - Google Patents

流動層の流動媒体選別装置及びその方法 Download PDFInfo

- Publication number

- JP3998384B2 JP3998384B2 JP2000002462A JP2000002462A JP3998384B2 JP 3998384 B2 JP3998384 B2 JP 3998384B2 JP 2000002462 A JP2000002462 A JP 2000002462A JP 2000002462 A JP2000002462 A JP 2000002462A JP 3998384 B2 JP3998384 B2 JP 3998384B2

- Authority

- JP

- Japan

- Prior art keywords

- fluid medium

- fluidized bed

- fluidized

- medium

- sorter

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000000034 method Methods 0.000 title claims description 7

- 239000012530 fluid Substances 0.000 claims description 135

- 239000000463 material Substances 0.000 claims description 50

- 239000002245 particle Substances 0.000 claims description 23

- 239000000428 dust Substances 0.000 claims description 16

- 238000002485 combustion reaction Methods 0.000 claims description 13

- 239000012535 impurity Substances 0.000 claims description 10

- 238000007599 discharging Methods 0.000 claims description 4

- 239000003500 flue dust Substances 0.000 claims 2

- 239000007789 gas Substances 0.000 description 44

- 229910052783 alkali metal Inorganic materials 0.000 description 16

- 150000001340 alkali metals Chemical class 0.000 description 16

- 239000002699 waste material Substances 0.000 description 13

- 239000000126 substance Substances 0.000 description 8

- 238000001816 cooling Methods 0.000 description 6

- 238000002844 melting Methods 0.000 description 6

- 230000008018 melting Effects 0.000 description 6

- 229910052700 potassium Inorganic materials 0.000 description 6

- 239000007788 liquid Substances 0.000 description 5

- 229910052708 sodium Inorganic materials 0.000 description 5

- 239000011734 sodium Substances 0.000 description 5

- 239000011362 coarse particle Substances 0.000 description 4

- 238000005245 sintering Methods 0.000 description 4

- 230000000694 effects Effects 0.000 description 3

- 230000006698 induction Effects 0.000 description 3

- 150000003839 salts Chemical group 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 241000251468 Actinopterygii Species 0.000 description 2

- 241001474374 Blennius Species 0.000 description 2

- ZLMJMSJWJFRBEC-UHFFFAOYSA-N Potassium Chemical compound [K] ZLMJMSJWJFRBEC-UHFFFAOYSA-N 0.000 description 2

- 239000002253 acid Substances 0.000 description 2

- 239000003513 alkali Substances 0.000 description 2

- 238000007664 blowing Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000000605 extraction Methods 0.000 description 2

- 239000010419 fine particle Substances 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 239000011591 potassium Substances 0.000 description 2

- 239000004576 sand Substances 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 235000015170 shellfish Nutrition 0.000 description 2

- 238000007873 sieving Methods 0.000 description 2

- 238000005979 thermal decomposition reaction Methods 0.000 description 2

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 150000001447 alkali salts Chemical class 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 239000000295 fuel oil Substances 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 238000002203 pretreatment Methods 0.000 description 1

- 238000000197 pyrolysis Methods 0.000 description 1

- 238000007790 scraping Methods 0.000 description 1

- 238000012216 screening Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000010802 sludge Substances 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 210000001835 viscera Anatomy 0.000 description 1

- 239000002918 waste heat Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

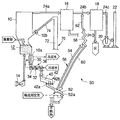

Images

Landscapes

- Fluidized-Bed Combustion And Resonant Combustion (AREA)

- Combined Means For Separation Of Solids (AREA)

- Devices And Processes Conducted In The Presence Of Fluids And Solid Particles (AREA)

- Crucibles And Fluidized-Bed Furnaces (AREA)

- Furnace Details (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000002462A JP3998384B2 (ja) | 2000-01-11 | 2000-01-11 | 流動層の流動媒体選別装置及びその方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000002462A JP3998384B2 (ja) | 2000-01-11 | 2000-01-11 | 流動層の流動媒体選別装置及びその方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2001193912A JP2001193912A (ja) | 2001-07-17 |

| JP2001193912A5 JP2001193912A5 (enExample) | 2004-12-02 |

| JP3998384B2 true JP3998384B2 (ja) | 2007-10-24 |

Family

ID=18531567

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2000002462A Expired - Fee Related JP3998384B2 (ja) | 2000-01-11 | 2000-01-11 | 流動層の流動媒体選別装置及びその方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3998384B2 (enExample) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101077101B1 (ko) * | 2009-02-24 | 2011-10-26 | 한국기계연구원 | 폐기물 재활용 폐회로 내부순환 풍력 선별장치 |

| JP5372713B2 (ja) * | 2009-11-13 | 2013-12-18 | 住友重機械工業株式会社 | 流動層の流動媒体再生装置及びその方法 |

| CN107530738B (zh) * | 2015-04-21 | 2021-01-05 | 荏原环境工程株式会社 | 流化层分级方法及流化层分级装置 |

| CN110805895A (zh) * | 2019-11-02 | 2020-02-18 | 中能锐赫科技(北京)股份有限公司 | 一种循环流化床底渣再循环装置及方法 |

-

2000

- 2000-01-11 JP JP2000002462A patent/JP3998384B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2001193912A (ja) | 2001-07-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4437419A (en) | Incinerator | |

| JP2001348252A (ja) | ステンレス鋼スラグの処理設備 | |

| JPH02107301A (ja) | 蒸気状の重金属化合物を担持ガスから分離する方法およびこの方法を実施するための装置 | |

| JP3998384B2 (ja) | 流動層の流動媒体選別装置及びその方法 | |

| JP4776211B2 (ja) | スラグ中の異物除去方法及び装置 | |

| US20150246361A1 (en) | Method and device for separating fine-grained fractions from the cinders of a waste incineration plant | |

| JP3732429B2 (ja) | 灰溶融炉の前処理設備および前処理方法 | |

| JP6612655B2 (ja) | 流動層炉における流動媒体の処理方法および装置 | |

| JP4167857B2 (ja) | 焼却灰の処理方法 | |

| JP2001021125A (ja) | 廃棄物の乾留熱分解溶融燃焼装置に於ける有価物の回収装置及び有価物の回収方法 | |

| JP4321823B2 (ja) | 流動床ガス化炉の流動媒体分離装置、及び該装置を備えた流動媒体循環機構 | |

| JP3820247B2 (ja) | 重金属回収装置、重金属回収方法および廃棄物処理装置 | |

| JP3975041B2 (ja) | 熱分解残渣処理装置および廃棄物処理システム | |

| JP3774833B2 (ja) | 流動床式焼却炉の焼却灰処理システム | |

| JP2003185104A (ja) | 流動層ボイラ設備 | |

| JP3934894B2 (ja) | 流動層ガス化炉排出物の処理装置および処理方法 | |

| JPH0490816A (ja) | 焼却炉の排ガス処理方法および同装置 | |

| JP4918833B2 (ja) | 廃棄物溶融炉および廃棄物溶融炉の操業方法 | |

| JP7528831B2 (ja) | 可燃物選別回収装置、可燃物選別回収方法、及び可燃物選別回収装置を備えた廃棄物処理設備 | |

| JP2003311215A (ja) | 選別装置及びそれを備えた溶融処理システム | |

| JP2005066423A (ja) | 熱分解残渣分離装置 | |

| JP2002219417A (ja) | 熱分解残渣の流動層分別装置 | |

| JP3516260B2 (ja) | 廃棄物溶融炉 | |

| JP2024063580A (ja) | 振動ふるい装置、ストーカ式焼却炉及びストーカ式焼却炉の灰からの有価金属類の回収方法 | |

| JP2024063578A (ja) | 振動ふるい装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20031215 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20031215 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20060517 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20060530 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060731 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070130 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070329 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20070807 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20070807 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20100817 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |