JP3882741B2 - 金属箔の圧延制御装置 - Google Patents

金属箔の圧延制御装置 Download PDFInfo

- Publication number

- JP3882741B2 JP3882741B2 JP2002323404A JP2002323404A JP3882741B2 JP 3882741 B2 JP3882741 B2 JP 3882741B2 JP 2002323404 A JP2002323404 A JP 2002323404A JP 2002323404 A JP2002323404 A JP 2002323404A JP 3882741 B2 JP3882741 B2 JP 3882741B2

- Authority

- JP

- Japan

- Prior art keywords

- metal foil

- rolling

- roll

- plate thickness

- active material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000011888 foil Substances 0.000 title claims description 103

- 229910052751 metal Inorganic materials 0.000 title claims description 93

- 239000002184 metal Substances 0.000 title claims description 93

- 238000005096 rolling process Methods 0.000 title claims description 87

- 239000011149 active material Substances 0.000 claims description 31

- 238000005259 measurement Methods 0.000 claims description 8

- 238000001514 detection method Methods 0.000 claims description 6

- 238000010586 diagram Methods 0.000 description 4

- 238000000748 compression moulding Methods 0.000 description 2

- 239000011162 core material Substances 0.000 description 2

- 239000007772 electrode material Substances 0.000 description 2

- 239000010720 hydraulic oil Substances 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 239000003921 oil Substances 0.000 description 2

- 238000004804 winding Methods 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 239000011889 copper foil Substances 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000005489 elastic deformation Effects 0.000 description 1

- 229910052744 lithium Inorganic materials 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Landscapes

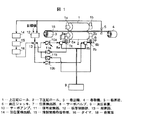

- Control Of Metal Rolling (AREA)

- Battery Electrode And Active Subsutance (AREA)

- Metal Rolling (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002323404A JP3882741B2 (ja) | 2002-11-07 | 2002-11-07 | 金属箔の圧延制御装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002323404A JP3882741B2 (ja) | 2002-11-07 | 2002-11-07 | 金属箔の圧延制御装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2004154828A JP2004154828A (ja) | 2004-06-03 |

| JP2004154828A5 JP2004154828A5 (enExample) | 2005-09-29 |

| JP3882741B2 true JP3882741B2 (ja) | 2007-02-21 |

Family

ID=32803274

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2002323404A Expired - Lifetime JP3882741B2 (ja) | 2002-11-07 | 2002-11-07 | 金属箔の圧延制御装置 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3882741B2 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101490234B1 (ko) * | 2013-08-21 | 2015-02-05 | 씨아이에스(주) | 유압서보 제어를 통한 변위 및 압력제어를 구현한 고속 롤 프레스 |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4565953B2 (ja) * | 2004-09-30 | 2010-10-20 | 大日本印刷株式会社 | 電極板の製造方法及び製造装置 |

| WO2006080045A1 (ja) | 2005-01-25 | 2006-08-03 | Ishikawajima-Harima Heavy Industries Co., Ltd. | 電池電極板成形設備 |

| JP5176347B2 (ja) * | 2007-03-08 | 2013-04-03 | トヨタ自動車株式会社 | 電極板のプレス方法、及び、電極板のプレス装置 |

| JP5737617B2 (ja) * | 2011-04-01 | 2015-06-17 | 株式会社Ihi | 電極帯板の連続圧縮装置と方法 |

| JP6209900B2 (ja) * | 2013-08-22 | 2017-10-11 | 日産自動車株式会社 | シート状電極の製造方法及び圧延装置の制御方法 |

| CN106064179A (zh) * | 2016-06-29 | 2016-11-02 | 山东钢铁股份有限公司 | 一种预防ucm轧机成品道次启车断带的方法 |

| JP2018184236A (ja) * | 2017-04-24 | 2018-11-22 | 日産自動車株式会社 | 帯状電極材の巻き取り方法および巻き取り装置 |

| CN116586434B (zh) * | 2023-07-19 | 2023-09-08 | 邢台纳科诺尔精轧科技股份有限公司 | 电池极片轧机辊缝调节装置及方法 |

-

2002

- 2002-11-07 JP JP2002323404A patent/JP3882741B2/ja not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101490234B1 (ko) * | 2013-08-21 | 2015-02-05 | 씨아이에스(주) | 유압서보 제어를 통한 변위 및 압력제어를 구현한 고속 롤 프레스 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2004154828A (ja) | 2004-06-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3882741B2 (ja) | 金属箔の圧延制御装置 | |

| JP5328876B2 (ja) | ロールプレス設備 | |

| JP4781361B2 (ja) | 金属ストリップの矯正方法 | |

| JP5411371B1 (ja) | ロールプレス設備及び厚み計測システム | |

| JP7557790B2 (ja) | ロールプレス装置、及び制御装置 | |

| CN110880580B (zh) | 辊压装置 | |

| JP2004520939A5 (enExample) | ||

| CN106180189B (zh) | 一种多辊压延装置 | |

| JP5280593B1 (ja) | ロールプレス設備およびそれに用いる厚み計 | |

| JPH10305352A (ja) | 双ロール式連続鋳造機の制御方法 | |

| CN115020648B (zh) | 极片复合装置和极片复合方法 | |

| JP7627846B2 (ja) | ロールプレス装置、及び制御装置 | |

| JP2004154828A5 (enExample) | ||

| KR100833006B1 (ko) | 쌍롤형 박판주조 제어 장치 및 방법 | |

| KR20100065667A (ko) | 쌍롤식 박판주조장치의 핀치롤 위치 및 압하력 제어를 통한박판 사행제어방법 | |

| KR20150007035A (ko) | 쌍롤식 박판 주조 공정에서의 에지댐 마모 제어 장치 및 방법 | |

| JP3340359B2 (ja) | ツインロール型薄板連続鋳造機におけるロール間隔の制御方法およびロール間隔の制御装置 | |

| JPH06106305A (ja) | ツインモールドロール型薄板連続鋳造設備の鋳片厚さ制御装置 | |

| US10888920B2 (en) | Monitoring and control system for continuous casting machine | |

| JP4256832B2 (ja) | 金属板材の圧延方法および圧延装置 | |

| JPH0515922A (ja) | 圧延機の油圧圧下制御方法及び油圧圧下装置 | |

| JP2993376B2 (ja) | 蛇行防止機能を有する熱間連続仕上圧延機 | |

| KR100986849B1 (ko) | 워크롤의 한계 각 가속도 측정방법 및 워크롤을 이용한 압연소재의 압연방법 | |

| KR20100078816A (ko) | 두께 제어 압연 방법 | |

| JP2811665B2 (ja) | 鋳片圧下方法及び鋳片圧下装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050426 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050426 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20061006 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20061024 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20061106 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 3882741 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101124 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101124 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111124 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111124 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121124 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121124 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131124 Year of fee payment: 7 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| EXPY | Cancellation because of completion of term |