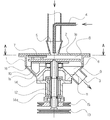

JP3841927B2 - 液体と粉体の連続混練装置および連続混練方法 - Google Patents

液体と粉体の連続混練装置および連続混練方法 Download PDFInfo

- Publication number

- JP3841927B2 JP3841927B2 JP18914297A JP18914297A JP3841927B2 JP 3841927 B2 JP3841927 B2 JP 3841927B2 JP 18914297 A JP18914297 A JP 18914297A JP 18914297 A JP18914297 A JP 18914297A JP 3841927 B2 JP3841927 B2 JP 3841927B2

- Authority

- JP

- Japan

- Prior art keywords

- powder

- liquid

- rotating disk

- continuous kneading

- rotating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000004898 kneading Methods 0.000 title claims description 67

- 239000000843 powder Substances 0.000 title claims description 58

- 239000007788 liquid Substances 0.000 title claims description 55

- 239000000203 mixture Substances 0.000 claims description 25

- 238000002156 mixing Methods 0.000 claims description 10

- 238000007790 scraping Methods 0.000 claims description 3

- 238000007599 discharging Methods 0.000 claims description 2

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 10

- 239000000945 filler Substances 0.000 description 9

- 229920000642 polymer Polymers 0.000 description 6

- 239000004944 Liquid Silicone Rubber Substances 0.000 description 5

- 229920005573 silicon-containing polymer Polymers 0.000 description 5

- 229920002379 silicone rubber Polymers 0.000 description 5

- 230000000052 comparative effect Effects 0.000 description 4

- 229910021485 fumed silica Inorganic materials 0.000 description 4

- 229910052751 metal Inorganic materials 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 238000010008 shearing Methods 0.000 description 3

- 229910002012 Aerosil® Inorganic materials 0.000 description 2

- VTYYLEPIZMXCLO-UHFFFAOYSA-L Calcium carbonate Chemical compound [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 description 2

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 2

- 229920002472 Starch Polymers 0.000 description 2

- 239000000654 additive Substances 0.000 description 2

- 230000000996 additive effect Effects 0.000 description 2

- 239000006229 carbon black Substances 0.000 description 2

- 239000004205 dimethyl polysiloxane Substances 0.000 description 2

- 235000013870 dimethyl polysiloxane Nutrition 0.000 description 2

- 235000013312 flour Nutrition 0.000 description 2

- 230000002209 hydrophobic effect Effects 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 229920000435 poly(dimethylsiloxane) Polymers 0.000 description 2

- 229920001296 polysiloxane Polymers 0.000 description 2

- 239000000377 silicon dioxide Substances 0.000 description 2

- 239000008107 starch Substances 0.000 description 2

- 235000019698 starch Nutrition 0.000 description 2

- 241000251468 Actinopterygii Species 0.000 description 1

- 240000008620 Fagopyrum esculentum Species 0.000 description 1

- 235000009419 Fagopyrum esculentum Nutrition 0.000 description 1

- 239000005909 Kieselgur Substances 0.000 description 1

- MXRIRQGCELJRSN-UHFFFAOYSA-N O.O.O.[Al] Chemical compound O.O.O.[Al] MXRIRQGCELJRSN-UHFFFAOYSA-N 0.000 description 1

- 229920002367 Polyisobutene Polymers 0.000 description 1

- 239000004721 Polyphenylene oxide Substances 0.000 description 1

- 241000209140 Triticum Species 0.000 description 1

- 235000021307 Triticum Nutrition 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 229910000019 calcium carbonate Inorganic materials 0.000 description 1

- 239000003054 catalyst Substances 0.000 description 1

- 239000004568 cement Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 238000013329 compounding Methods 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 238000000748 compression moulding Methods 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 239000003431 cross linking reagent Substances 0.000 description 1

- 239000008157 edible vegetable oil Substances 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 229920001971 elastomer Polymers 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 235000019688 fish Nutrition 0.000 description 1

- 230000020169 heat generation Effects 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000001746 injection moulding Methods 0.000 description 1

- 239000004850 liquid epoxy resins (LERs) Substances 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 239000002480 mineral oil Substances 0.000 description 1

- 235000010446 mineral oil Nutrition 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 229920000620 organic polymer Polymers 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 239000000049 pigment Substances 0.000 description 1

- 229920001083 polybutene Polymers 0.000 description 1

- 229920000570 polyether Polymers 0.000 description 1

- 229920002635 polyurethane Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 239000003566 sealing material Substances 0.000 description 1

- 239000004575 stone Substances 0.000 description 1

- 239000006188 syrup Substances 0.000 description 1

- 235000020357 syrup Nutrition 0.000 description 1

- -1 that is Polymers 0.000 description 1

- 239000002562 thickening agent Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/30—Mixing; Kneading continuous, with mechanical mixing or kneading devices

- B29B7/34—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices

- B29B7/38—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/50—Mixing liquids with solids

- B01F23/53—Mixing liquids with solids using driven stirrers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/05—Stirrers

- B01F27/09—Stirrers characterised by the mounting of the stirrers with respect to the receptacle

- B01F27/091—Stirrers characterised by the mounting of the stirrers with respect to the receptacle with elements co-operating with receptacle wall or bottom, e.g. for scraping the receptacle wall

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/80—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis

- B01F27/808—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis with stirrers driven from the bottom of the receptacle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/80—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis

- B01F27/93—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis with rotary discs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/30—Mixing; Kneading continuous, with mechanical mixing or kneading devices

- B29B7/58—Component parts, details or accessories; Auxiliary operations

- B29B7/60—Component parts, details or accessories; Auxiliary operations for feeding, e.g. end guides for the incoming material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/80—Component parts, details or accessories; Auxiliary operations

- B29B7/88—Adding charges, i.e. additives

- B29B7/90—Fillers or reinforcements, e.g. fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F35/00—Accessories for mixers; Auxiliary operations or auxiliary devices; Parts or details of general application

- B01F35/30—Driving arrangements; Transmissions; Couplings; Brakes

- B01F35/32—Driving arrangements

- B01F35/321—Disposition of the drive

- B01F35/3213—Disposition of the drive at the lower side of the axis, e.g. driving the stirrer from the bottom of a receptacle

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Dispersion Chemistry (AREA)

- Mixers Of The Rotary Stirring Type (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP18914297A JP3841927B2 (ja) | 1997-06-30 | 1997-06-30 | 液体と粉体の連続混練装置および連続混練方法 |

| US09/106,251 US6019498A (en) | 1997-06-30 | 1998-06-29 | Apparatus and process for continuously mixing liquid with powder |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP18914297A JP3841927B2 (ja) | 1997-06-30 | 1997-06-30 | 液体と粉体の連続混練装置および連続混練方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JPH1119495A JPH1119495A (ja) | 1999-01-26 |

| JPH1119495A5 JPH1119495A5 (enExample) | 2005-02-10 |

| JP3841927B2 true JP3841927B2 (ja) | 2006-11-08 |

Family

ID=16236128

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP18914297A Expired - Fee Related JP3841927B2 (ja) | 1997-06-30 | 1997-06-30 | 液体と粉体の連続混練装置および連続混練方法 |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US6019498A (enExample) |

| JP (1) | JP3841927B2 (enExample) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3739533B2 (ja) * | 1996-09-30 | 2006-01-25 | 東レ・ダウコーニング株式会社 | 液状シリコーンゴムベースの連続的製造方法 |

| AT407970B (de) * | 1999-06-02 | 2001-07-25 | Bacher Helmut | Vorrichtung und verfahren zum aufbereiten von, insbesondere thermoplastischem, kunststoffmaterial |

| KR100926916B1 (ko) * | 2000-03-08 | 2009-11-17 | 스미또모 가가꾸 가부시끼가이샤 | 수산화알루미늄 분말의 제조 방법 |

| KR20020011117A (ko) * | 2000-07-31 | 2002-02-07 | 다우 코닝 도레이 실리콘 캄파니 리미티드 | 연속 혼합 장치 |

| JP2002166154A (ja) * | 2000-11-30 | 2002-06-11 | Dow Corning Toray Silicone Co Ltd | 連続混合装置 |

| US7090391B2 (en) | 2002-09-25 | 2006-08-15 | Reika Kogyo Kabushiki Kaisha | Apparatus and method for mixing by agitation in a multichambered mixing apparatus including a pre-agitation mixing chamber |

| US7281839B1 (en) * | 2003-02-28 | 2007-10-16 | Zimmerman Industries, Inc. | Turbine cement/water mixer for concrete production |

| US7331702B2 (en) | 2003-10-31 | 2008-02-19 | Reika Kogyo Kabushiki Kaisha | Agitation mixer |

| JP2006187756A (ja) * | 2004-12-07 | 2006-07-20 | Reika Kogyo Kk | 撹拌混合装置 |

| CN1927437B (zh) * | 2005-09-06 | 2010-09-08 | 株式会社粉研宝泰司 | 粉体/液体连续混合造粒方法及装置 |

| DE102007041857A1 (de) * | 2007-09-03 | 2009-03-05 | Wacker Chemie Ag | Verfahren zur kontinuierlichen Herstellung von vernetzbaren Massen auf der Basis von Organosiliciumverbindungen |

| JP5933298B2 (ja) * | 2011-03-23 | 2016-06-08 | 株式会社粉研パウテックス | 連続混練装置 |

| US10173184B2 (en) * | 2015-03-25 | 2019-01-08 | Schlumberger Technology Corporation | Blender for mixing and pumping solids and fluids and method of use thereof |

| CA3056425A1 (en) * | 2017-03-16 | 2018-09-20 | UGSI Chemical Feed, Inc. | High-capacity polymer system and method of preparing polymeric mixtures |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2639901A (en) * | 1951-11-20 | 1953-05-26 | Nat Gypsum Co | Pin mixer |

| DE1144693B (de) * | 1955-11-02 | 1963-03-07 | Dante Sandro Cusi | Ruehrvorrichtung fuer fluessige Mischungen |

| CH604861A5 (enExample) * | 1974-05-10 | 1978-09-15 | Hiroyuki Iwako | |

| US4175873A (en) * | 1976-09-10 | 1979-11-27 | Funken Co., Ltd. | Process and apparatus for mechanically mixing two immiscible liquids and one or more other substances |

| FR2395774A1 (fr) * | 1977-06-29 | 1979-01-26 | Bonvillain & Ronceray | Malaxeur pour produits divers et en particulier pour sables de fonderie |

| US4192615A (en) * | 1979-02-23 | 1980-03-11 | Fargo Machine & Tool Company | Sand mulling machine plow |

| JPH022610A (ja) * | 1988-06-15 | 1990-01-08 | Fujitsu Ltd | 光電子転写装置および光電子転写方法 |

| JP3591874B2 (ja) * | 1994-06-21 | 2004-11-24 | 東レ・ダウコーニング・シリコーン株式会社 | 液体と粉体の連続混練装置 |

-

1997

- 1997-06-30 JP JP18914297A patent/JP3841927B2/ja not_active Expired - Fee Related

-

1998

- 1998-06-29 US US09/106,251 patent/US6019498A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| US6019498A (en) | 2000-02-01 |

| JPH1119495A (ja) | 1999-01-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3591874B2 (ja) | 液体と粉体の連続混練装置 | |

| JP3841927B2 (ja) | 液体と粉体の連続混練装置および連続混練方法 | |

| CN1269559C (zh) | 动态混合器 | |

| US6431742B2 (en) | Continuous mixing apparatus with upper and lower disk impellers each having scrapers | |

| CN102712105B (zh) | 搅拌/混合装置及半导体封装用树脂组合物的制造方法 | |

| US6435707B1 (en) | Continuous mixing apparatus with upper and lower bladed disk impellers and a notched blade | |

| JPH11116693A (ja) | シリコーンゴムベースの連続的製造方法 | |

| JPH1119495A5 (enExample) | ||

| US5861460A (en) | Method for the continuous production of room-temperature-curable organopolysiloxane compositions | |

| US6218466B1 (en) | Method for the continuous preparation of liquid silicone rubber base | |

| EP0902057A2 (en) | Method for continuous manufacture of a silicone rubber composition | |

| US7097442B2 (en) | Extruder | |

| CN118620280A (zh) | 一种再生橡胶生产用脱硫机 | |

| JP2001009830A (ja) | 連続混練機とその混練方法及び連続混練機のロータ | |

| CN219405341U (zh) | 融化挤料装置 | |

| CN210252078U (zh) | 一种新型快速成型搅拌设备 | |

| JP2004230591A (ja) | ピンタイプ混練連続押出し装置の冷却装置 | |

| JP2889758B2 (ja) | 横型二軸混練機 | |

| CN222724196U (zh) | 一种沥青生产用原料混合装置 | |

| CN207951229U (zh) | 一种多功能分散混合釜 | |

| CN213563684U (zh) | 一种小型pvc混料机 | |

| CN213194164U (zh) | 一种增塑剂生产装置 | |

| CN219600048U (zh) | 钢塑保护环注塑生产用混合料机 | |

| CN209917674U (zh) | 导电浆料预混装置 | |

| JP2006001265A (ja) | 熱可塑性樹脂成形用スクリュー |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20040305 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20040305 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20060714 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20060720 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20060809 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |