JP2015206380A - ライザー管 - Google Patents

ライザー管 Download PDFInfo

- Publication number

- JP2015206380A JP2015206380A JP2014085629A JP2014085629A JP2015206380A JP 2015206380 A JP2015206380 A JP 2015206380A JP 2014085629 A JP2014085629 A JP 2014085629A JP 2014085629 A JP2014085629 A JP 2014085629A JP 2015206380 A JP2015206380 A JP 2015206380A

- Authority

- JP

- Japan

- Prior art keywords

- carbon fiber

- synthetic resin

- riser pipe

- resin layer

- fiber reinforced

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 229920000049 Carbon (fiber) Polymers 0.000 claims abstract description 81

- 239000004917 carbon fiber Substances 0.000 claims abstract description 81

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 claims abstract description 69

- 229920003002 synthetic resin Polymers 0.000 claims abstract description 62

- 239000000057 synthetic resin Substances 0.000 claims abstract description 62

- 239000011302 mesophase pitch Substances 0.000 claims abstract description 19

- 230000002093 peripheral effect Effects 0.000 claims abstract description 9

- 239000002184 metal Substances 0.000 claims abstract description 5

- 229910052751 metal Inorganic materials 0.000 claims abstract description 5

- 238000005452 bending Methods 0.000 claims description 15

- 239000010936 titanium Substances 0.000 claims description 5

- 229910001069 Ti alloy Inorganic materials 0.000 claims description 4

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 claims description 4

- 229910052719 titanium Inorganic materials 0.000 claims description 4

- 238000009412 basement excavation Methods 0.000 abstract description 3

- 239000010410 layer Substances 0.000 description 47

- 238000012360 testing method Methods 0.000 description 22

- 239000000835 fiber Substances 0.000 description 19

- 238000004804 winding Methods 0.000 description 12

- 238000005553 drilling Methods 0.000 description 11

- 230000005484 gravity Effects 0.000 description 10

- 238000009730 filament winding Methods 0.000 description 9

- 238000000034 method Methods 0.000 description 9

- 229920005989 resin Polymers 0.000 description 9

- 239000011347 resin Substances 0.000 description 9

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 8

- 229910000831 Steel Inorganic materials 0.000 description 7

- 239000010959 steel Substances 0.000 description 7

- 238000003475 lamination Methods 0.000 description 6

- 238000005259 measurement Methods 0.000 description 6

- 230000000052 comparative effect Effects 0.000 description 5

- 239000003822 epoxy resin Substances 0.000 description 5

- 239000000463 material Substances 0.000 description 5

- 229920000647 polyepoxide Polymers 0.000 description 5

- 239000007769 metal material Substances 0.000 description 3

- 230000000704 physical effect Effects 0.000 description 3

- ZEASXVYVFFXULL-UHFFFAOYSA-N amezinium metilsulfate Chemical compound COS([O-])(=O)=O.COC1=CC(N)=CN=[N+]1C1=CC=CC=C1 ZEASXVYVFFXULL-UHFFFAOYSA-N 0.000 description 2

- 239000002131 composite material Substances 0.000 description 2

- 238000007667 floating Methods 0.000 description 2

- 238000013007 heat curing Methods 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- 239000010935 stainless steel Substances 0.000 description 2

- 238000009864 tensile test Methods 0.000 description 2

- 229920001187 thermosetting polymer Polymers 0.000 description 2

- 239000011800 void material Substances 0.000 description 2

- 239000004925 Acrylic resin Substances 0.000 description 1

- 229920000178 Acrylic resin Polymers 0.000 description 1

- 238000007088 Archimedes method Methods 0.000 description 1

- 229910000975 Carbon steel Inorganic materials 0.000 description 1

- 239000004696 Poly ether ether ketone Substances 0.000 description 1

- 239000004697 Polyetherimide Substances 0.000 description 1

- 229920000491 Polyphenylsulfone Polymers 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 239000010962 carbon steel Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 238000013016 damping Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000011549 displacement method Methods 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 238000009415 formwork Methods 0.000 description 1

- 239000003365 glass fiber Substances 0.000 description 1

- LNEPOXFFQSENCJ-UHFFFAOYSA-N haloperidol Chemical compound C1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1 LNEPOXFFQSENCJ-UHFFFAOYSA-N 0.000 description 1

- 230000009931 harmful effect Effects 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000011229 interlayer Substances 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000000691 measurement method Methods 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 239000005011 phenolic resin Substances 0.000 description 1

- 238000013001 point bending Methods 0.000 description 1

- 229920003192 poly(bis maleimide) Polymers 0.000 description 1

- 229920003229 poly(methyl methacrylate) Polymers 0.000 description 1

- 229920006122 polyamide resin Polymers 0.000 description 1

- 229920005668 polycarbonate resin Polymers 0.000 description 1

- 239000004431 polycarbonate resin Substances 0.000 description 1

- 229920002530 polyetherether ketone Polymers 0.000 description 1

- 229920001601 polyetherimide Polymers 0.000 description 1

- 239000004926 polymethyl methacrylate Substances 0.000 description 1

- 239000011241 protective layer Substances 0.000 description 1

- 238000010298 pulverizing process Methods 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 239000012783 reinforcing fiber Substances 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 239000011342 resin composition Substances 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 229910001256 stainless steel alloy Inorganic materials 0.000 description 1

- 229920002803 thermoplastic polyurethane Polymers 0.000 description 1

- 229920005992 thermoplastic resin Polymers 0.000 description 1

- 239000013585 weight reducing agent Substances 0.000 description 1

Images

Landscapes

- Earth Drilling (AREA)

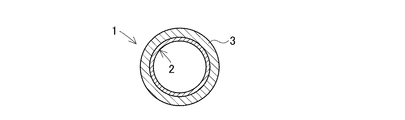

- Rigid Pipes And Flexible Pipes (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014085629A JP2015206380A (ja) | 2014-04-17 | 2014-04-17 | ライザー管 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014085629A JP2015206380A (ja) | 2014-04-17 | 2014-04-17 | ライザー管 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2015206380A true JP2015206380A (ja) | 2015-11-19 |

| JP2015206380A5 JP2015206380A5 (enExample) | 2017-03-16 |

Family

ID=54603344

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014085629A Pending JP2015206380A (ja) | 2014-04-17 | 2014-04-17 | ライザー管 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2015206380A (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20170138208A (ko) * | 2016-06-07 | 2017-12-15 | 한국항공우주연구원 | 복합재 배관 및 그 제조 방법 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4634314A (en) * | 1984-06-26 | 1987-01-06 | Vetco Offshore Inc. | Composite marine riser system |

| JPH05293919A (ja) * | 1992-02-19 | 1993-11-09 | Nippon Steel Corp | 炭素繊維強化樹脂複合材料とその製造方法 |

| JPH06143275A (ja) * | 1992-11-09 | 1994-05-24 | Nippon Steel Chem Co Ltd | ピッチ系炭素繊維プリプレグ |

| JPH09310998A (ja) * | 1996-05-23 | 1997-12-02 | Toshiba Corp | 海水流通用機器類およびその保守補修方法 |

-

2014

- 2014-04-17 JP JP2014085629A patent/JP2015206380A/ja active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4634314A (en) * | 1984-06-26 | 1987-01-06 | Vetco Offshore Inc. | Composite marine riser system |

| JPH05293919A (ja) * | 1992-02-19 | 1993-11-09 | Nippon Steel Corp | 炭素繊維強化樹脂複合材料とその製造方法 |

| JPH06143275A (ja) * | 1992-11-09 | 1994-05-24 | Nippon Steel Chem Co Ltd | ピッチ系炭素繊維プリプレグ |

| JPH09310998A (ja) * | 1996-05-23 | 1997-12-02 | Toshiba Corp | 海水流通用機器類およびその保守補修方法 |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20170138208A (ko) * | 2016-06-07 | 2017-12-15 | 한국항공우주연구원 | 복합재 배관 및 그 제조 방법 |

| KR101880581B1 (ko) * | 2016-06-07 | 2018-07-20 | 한국항공우주연구원 | 복합재 배관 및 그 제조 방법 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DK2888474T3 (en) | The wind turbine tower | |

| US10197198B2 (en) | Flexible pipe | |

| US20090272855A1 (en) | Device | |

| BR112019020051A2 (pt) | tubo flexível com camadas de blindagens metálicas e com camadas de blindagens compósitas | |

| US9033614B2 (en) | Pipe components and methods of manufacture | |

| US6581644B1 (en) | Composite pipe structure having improved containment and axial strength | |

| US11345111B2 (en) | Composite | |

| JP2015206380A (ja) | ライザー管 | |

| AU743991B2 (en) | Composite pipe structures having improved containment and axial strength | |

| US20140345741A1 (en) | Flexible pipe body and method of manufacture | |

| RU2441798C1 (ru) | Корпус для внешнего давления из композиционных материалов | |

| WO1998045634A1 (en) | Composite pipe structures having high containment and axial strength | |

| CN105240617A (zh) | 一种基于frp的海底管道缠绕式止屈器 | |

| CN204704477U (zh) | 基于碳纤维的缠绕式海底管道止屈器 | |

| Kanagaraj et al. | FRP materials for rehabilitation of buried pipes | |

| Aydın | Development of fiber reinforced cylindrical composite structures by filament winding technique | |

| CN218063744U (zh) | 一种超深水油气开采用柔性管 | |

| Nishino et al. | Effective lamination and evaluation of reinforcing fibers: Research dealing with strength behavior characteristics is in the area of theoretical effective strength of 80% or more (E) | |

| RU2717728C1 (ru) | Труба стеклокомпозитная для напорных и безнапорных трубопроводов, прокладываемых методом микротоннелирования | |

| AU2017243882B2 (en) | A flow modification device having helical strakes and a system and method for modifying flow | |

| Sakonder et al. | Selective Patterns for Circular Dimples Distribution As a Means to Enhance Structural Mechanical Response of Tubular Components | |

| RU2463510C2 (ru) | Секция райзера из полимерных композиционных материалов | |

| Gautam | Hybrid Composite Wires for Tensile Armour in Flexible Risers | |

| JP2011126141A (ja) | 耐食層を有する管状繊維強化複合材料 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170203 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20170203 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20171107 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20171114 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20180109 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20180724 |