JP2015183309A - Woven base cloth for air-bag - Google Patents

Woven base cloth for air-bag Download PDFInfo

- Publication number

- JP2015183309A JP2015183309A JP2014060328A JP2014060328A JP2015183309A JP 2015183309 A JP2015183309 A JP 2015183309A JP 2014060328 A JP2014060328 A JP 2014060328A JP 2014060328 A JP2014060328 A JP 2014060328A JP 2015183309 A JP2015183309 A JP 2015183309A

- Authority

- JP

- Japan

- Prior art keywords

- base fabric

- yarn

- fabric

- warp

- dtex

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Abstract

Description

本発明は、エアバッグ用織物基布に関する。より詳しくは、本発明は、気密性が高く柔軟であり、収納性に優れ、かつ、生産性の高いエアバッグ用織物基布に関する。 The present invention relates to a fabric base fabric for an airbag. More specifically, the present invention relates to a fabric base fabric for an air bag having high airtightness and flexibility, excellent storage properties, and high productivity.

エアバッグは、事故時の衝突の衝撃や、車内装備品と人体の接触を軽減するものである。そのために、エアバッグには気密性が求められている。詳しくは膨張部と非膨張部の境界部分の気密性がバッグ全体の気密性に影響を与えるが、特に、インフレータ作動時の高温ガスが存在する環境下での前述した部分の気密性は特に重要である。他方、昨今の傾向として車両の居住空間拡大等によってエアバッグの収容スペースが限られてきている為に、収納性も重要な項目として挙げられるようになった。

これを解決すべく、以下の特許文献1には、低繊度糸を適用し、構成糸の引き抜き強力、引張強力での300N時の伸び、剛軟度、目付を特定の領域に設計することで軽量化、収納性、気密性を達成する技術が開示されている。この技術は収納性と気密性を実現することができるものの、これを達成する為に低繊度糸の高密度製織を余儀なくされているため、生産性が低く、コストが高くなりやすいという欠点を有する。また、以下の特許文献2には、扁平単糸で構成される糸条を用い、特定の糸幅に製織することで高気密かつ安価な製品を提供することが開示されている。これには扁平糸が必須であり、扁平糸は、丸断面と比較して強力が低下しやすく、昨今のエアバッグはインフレータの高出力化もあり、必ずしも十分な強力を有しているとは言えない。

このように、十分な機械強度を有し、気密性が高く、収納性の優れた基布を効率よく生産できる技術は未だ開示されていない。

The airbag reduces the impact of a collision at the time of an accident and the contact between in-vehicle equipment and the human body. Therefore, the air bag is required to be airtight. Specifically, the airtightness of the boundary between the inflatable part and the non-inflatable part affects the airtightness of the entire bag, but the airtightness of the aforementioned part is particularly important in an environment where high temperature gas is present during operation of the inflator. It is. On the other hand, since the storage space for airbags has been limited due to the expansion of the living space of vehicles as a recent trend, the storage property has also been cited as an important item.

In order to solve this, the following

As described above, a technology that can efficiently produce a base fabric having sufficient mechanical strength, high airtightness, and excellent storage properties has not yet been disclosed.

かかる技術の現状の下、本発明が解決しようとする課題は、袋体としたときの膨張部と非膨張部の境界部分の目開きが抑制され、かつ、収納性に優れた安価な織物基布を提供することである。 Under the current state of the art, the problem to be solved by the present invention is that an inexpensive fabric base that is suppressed from opening at the boundary between the inflatable portion and the non-inflatable portion when used as a bag and has excellent storage properties. Is to provide a cloth.

本発明者は、繊維表面に特定の物質を特定量存在させることで製織時の糸条にかかる応力を利用し、糸条の扁平化を促進させた。更に、丸断面の単糸によって、織張力による糸条同士の滑りがスムーズに行われ、先述した表面物質の効果と相まって扁平化をより促進させることで、基布としたときの気密性が向上し、織り込み密度を低下させても気密性が維持できることを見出し発明に至ったものである。 The present inventor has made a specific amount of a specific substance present on the fiber surface to utilize the stress applied to the yarn during weaving to promote flattening of the yarn. In addition, the single yarn with a round cross section allows the yarns to slide smoothly due to the weaving tension, and in combination with the effect of the surface material described above, further flattening promotes the airtightness of the base fabric. The inventors have found that the airtightness can be maintained even when the weaving density is lowered, and have reached the invention.

すなわち、本発明は以下のとおりのものである。

[1]単糸が1.5以上7dtex未満の丸断面である熱可塑性樹脂の経糸及び緯糸の糸条で平織された織物基布であって、以下の条件:

(1)下記式1:

Z=(Ww×Dw+Wf×Df)−50.8

{式中、Ww=経糸最大幅(μm)、Dw=経糸密度(本/inch)、Wf=緯糸最大幅(μm)、Df=緯糸密度(本/inch)}で表されるZ値が0〜7である;

(2)下記式2:

Q=q/S

{式中、q=ASTM_D6476で測定された30〜70kPa間のADAP(mm/s)、S=基布目付(g/m2)}で表されるQ値が0.5〜2.5である;

(3)下記式3:

CF=((Tw/ρ)0.5×Dw)+(Tf/ρ)0.5×Df)

{式中、Tw=経糸繊度(Dtex)、Tf=緯糸繊度(Dtex)、ρ=繊維密度(g/cm3)}で表されるカバーファクター(CF)が1850〜2200である;及び

(4)ポリオレフィン樹脂、シリコン樹脂、及びエステル類からなる群から選択されたいずれか1種又は2種以上の混合物が、該織物基布の繊維表面に該繊維重量に対し100〜3000ppmで存在している;

を満たす基布。

That is, the present invention is as follows.

[1] A fabric base fabric plain woven with warp and weft yarns of thermoplastic resin having a round cross section with a single yarn of 1.5 or more and less than 7 dtex, under the following conditions:

(1) The following formula 1:

Z = (Ww × Dw + Wf × Df) −50.8

{Where Z value represented by Ww = maximum warp width (μm), Dw = warp density (main / inch), Wf = maximum weft width (μm), Df = weft density (main / inch)} is 0 ~ 7;

(2) Formula 2 below:

Q = q / S

{In the formula, q = 30 to 70 kPa of ADAP (mm / s) measured by ASTM_D6476, S = basis weight (g / m 2 )} Q value is 0.5 to 2.5 is there;

(3) Formula 3 below:

CF = ((Tw / ρ) 0.5 × Dw) + (Tf / ρ) 0.5 × Df)

{Wherein the cover factor (CF) represented by Tw = warp fineness (Dtex), Tf = weft fineness (Dtex), ρ = fiber density (g / cm 3 )} is 1850-2200; and (4 ) Any one or a mixture of two or more selected from the group consisting of polyolefin resins, silicone resins, and esters is present on the fiber surface of the fabric base fabric at 100 to 3000 ppm based on the fiber weight. ;

Satisfy the fabric.

[2]前記経糸及び緯糸の糸条の繊度が共に300以上800dtex未満である、前記[1]に記載の基布。 [2] The base fabric according to [1], wherein both the warp and weft yarns have a fineness of 300 or more and less than 800 dtex.

[3]前記基布を構成する経糸及び緯糸の引き抜き抵抗値が共に20〜150N/cm/cmである、前記[1]又は[2]に記載の基布。 [3] The base fabric according to the above [1] or [2], wherein the drawing resistance values of the warp and the weft constituting the base fabric are both 20 to 150 N / cm / cm.

[4]前記基布を構成する経糸及び緯糸の幅を厚みで除した値が共に2.5〜5である、前記[1]〜[3]のいずれかに記載の基布。 [4] The base fabric according to any one of [1] to [3], wherein a value obtained by dividing the width of the warp and the weft constituting the base fabric by the thickness is 2.5 to 5.

[5]反物両端の絡み糸と地糸の間に、地糸以外の、繊度が20以上70dtex未満の糸が左右合計4本以上織り込まれている、前記[1]〜[4]のいずれかに記載の基布。 [5] Any of [1] to [4] above, wherein a total of four or more yarns with a fineness of 20 or more and less than 70 dtex other than the ground yarn are woven between the tangled yarn and the ground yarn at both ends of the fabric. The base fabric described in 1.

[6]ロール中央部の直径Dとロール端部の直径dの比d/Dが1.07未満である、前記[1]〜[5]のいずれかに記載の織物基布の織物ロール。 [6] The fabric roll of the fabric base fabric according to any one of [1] to [5], wherein a ratio d / D between the diameter D of the roll center and the diameter d of the roll end is less than 1.07.

[7]前記[1]〜[5]のいずれかに記載の基布又は前記[6]に記載の織物ロールを用いて製造されたノンコートエアバッグ。 [7] A non-coated airbag manufactured using the base fabric according to any one of [1] to [5] or the fabric roll according to [6].

本発明に係る織物基布は、柔軟かつ気密性に優れた基布であり、生産効率の高い基布である。 The fabric base fabric according to the present invention is a base fabric excellent in flexibility and airtightness, and has a high production efficiency.

以下、本発明の実施形態を詳細に説明する。

本発明に係る織物基布は、柔軟で収納性に優れ、かつ、丸断面単糸と経緯糸の表面処理による摩擦力調整及び高張力製織とあいまって糸条の扁平を促進し、通気性を実用なレベルまで抑制することができるものである。

本発明に係る織物を構成する繊維は、単糸繊度1.5〜7dtexの丸断面であり、好ましくは単糸繊度2〜4dtexである。単糸繊度1.5dtex未満であれば、単糸強力が弱くなり、製織時の筬や綜絖での摩擦において毛羽や糸切れ等の工程トラブルが増加する。また、単糸繊度が7dtexを超える場合は糸束が広がって十分な気密を維持できなくなる。また、本発明に使用する繊維の単糸断面は丸断面である。扁平断面であると製織時に単糸が再配置しても単糸の向きにより大きく気密性に変化を与えるため、気密性の向上が不足する場合がある。

Hereinafter, embodiments of the present invention will be described in detail.

The fabric base fabric according to the present invention is flexible and excellent in storage property, and, in combination with frictional force adjustment by surface treatment of round cross-section single yarn and warp and weft, promotes flattening of the yarn and promotes air permeability. It can be suppressed to a practical level.

The fibers constituting the woven fabric according to the present invention have a round cross section with a single yarn fineness of 1.5 to 7 dtex, and preferably a single yarn fineness of 2 to 4 dtex. If the single yarn fineness is less than 1.5 dtex, the single yarn strength becomes weak, and process troubles such as fluff and yarn breakage increase due to friction with the wrinkles and wrinkles during weaving. On the other hand, when the single yarn fineness exceeds 7 dtex, the yarn bundle spreads and sufficient airtightness cannot be maintained. Moreover, the single yarn cross section of the fiber used for this invention is a round cross section. If the cross section is flat, even if the single yarn is rearranged at the time of weaving, the air tightness is greatly changed depending on the direction of the single yarn.

本発明に係る織物基布においては、下記式1:

Z=(Ww×Dw+Wf×Df)−50.8

{式中、Ww=経糸最大幅(μm)、Dw=経糸密度(本/inch)、Wf=緯糸最大幅(μm)、Df=緯糸密度(本/inch)}で表されるZ値が0〜7であり、好ましくは2〜5であり、より好ましくは2〜3である。0未満であると基布の気密性が十分とは言えず、バッグとしたときの膨張部と非膨張部分の目開きが拡大しやすくなり気密性が急激に悪化する場合があり、また、7を超えると必要以上の糸条の広がりとなる為、過大な経緯間の摩擦が発生し、基布の引裂き強力の低下よりバッグとしたときの縫目部からの破壊が発生する場合がある。

In the textile base fabric according to the present invention, the following formula 1:

Z = (Ww × Dw + Wf × Df) −50.8

{Where Z value represented by Ww = maximum warp width (μm), Dw = warp density (main / inch), Wf = maximum weft width (μm), Df = weft density (main / inch)} is 0 It is -7, Preferably it is 2-5, More preferably, it is 2-3. If it is less than 0, it cannot be said that the airtightness of the base fabric is sufficient, and the opening of the inflatable part and the non-inflatable part when used as a bag is likely to expand, and the airtightness may deteriorate rapidly. Exceeding the width of the yarn causes an unnecessarily widening of the yarn, resulting in excessive friction between the wefts, which may cause breakage from the seam portion of the bag due to a decrease in the tear strength of the base fabric.

また、本発明に係る織物基布においては、下記式2:

Q=q/S

{式中、q=ASTM_D6476で測定された30〜70kPa間のADAP(mm/s)、S=基布目付(g/m2)}で表されるQ値が0.5〜2.5であり、好ましくは1〜2である。0.5未満であれば、基布は硬くなりやすく、収納性が悪化する場合があり、また、2.5を超えると気密性が損なわれる場合がある。

Moreover, in the textile base fabric which concerns on this invention, following formula 2:

Q = q / S

{In the formula, q = 30 to 70 kPa of ADAP (mm / s) measured by ASTM_D6476, S = basis weight (g / m 2 )} Q value is 0.5 to 2.5 Yes, preferably 1-2. If it is less than 0.5, the base fabric tends to be hard and the storage property may be deteriorated, and if it exceeds 2.5, the airtightness may be impaired.

また、本発明に係る織物基布においては、下記式3:

CF=((Tw/ρ)0.5×Dw)+(Tf/ρ)0.5×Df)

{式中、Tw=経糸繊度(Dtex)、Tf=緯糸繊度(Dtex)、ρ=繊維密度(g/cm3)}で表されるカバーファクター(CF)が1850〜2200であり、好ましくは1900〜2100であり、さらに好ましくは1950〜2050である。1850未満であれば気密性が損なわれる場合があり、また、2200を超える場合は基布の剛軟度が高くなり、目的の柔軟な基布が得られなくなる。

Moreover, in the textile base fabric which concerns on this invention, following formula 3:

CF = ((Tw / ρ) 0.5 × Dw) + (Tf / ρ) 0.5 × Df)

The cover factor (CF) represented by {wherein Tw = warp fineness (Dtex), Tf = weft fineness (Dtex), ρ = fiber density (g / cm 3 )} is 1850-2200, preferably 1900. ~ 2100, more preferably 1950 ~ 2050. If it is less than 1850, airtightness may be impaired, and if it exceeds 2200, the bending resistance of the base fabric becomes high, and the desired flexible base fabric cannot be obtained.

また、本発明に係る織物基布においては、基布特性を発現させるために、ポリオレフィン樹脂、シリコン樹脂、及びエステル類からなる群から選択されたいずれか1種又は2種以上の混合物が、該織物基布の繊維表面に該繊維重量に対し100〜3000ppmで存在している必要があり、好ましくは500〜2000ppmである。100ppm未満であれば目的の経緯糸間の摩擦力が高くなって製織時の糸束の十分な扁平化ができない為にZ値が小さくなる場合がある。3000ppmを超える場合は摩擦力低下が過剰となってバッグとしたときに膨張部と非膨張部分の境目の目開きが起きやすくなり、縫製部分の気密性が損なわれたり、燃焼性を規格内に維持できなくなる可能性がある。ここで表面とは、繊維を構成している単糸の表面を指す。 Moreover, in the textile base fabric according to the present invention, in order to express the base fabric characteristics, any one or a mixture of two or more selected from the group consisting of polyolefin resins, silicone resins, and esters, It is necessary to be present on the fiber surface of the woven base fabric at 100 to 3000 ppm, preferably 500 to 2000 ppm based on the fiber weight. If it is less than 100 ppm, the frictional force between the desired warp and weft yarns becomes high and the yarn bundle cannot be sufficiently flattened during weaving, so the Z value may be small. If it exceeds 3000 ppm, the frictional force will drop excessively, and when the bag is used, the boundary between the inflatable part and the non-inflatable part will easily open, and the airtightness of the sewn part will be impaired, and the flammability will be within the standard. It may become impossible to maintain. Here, the surface refers to the surface of a single yarn constituting the fiber.

繊維を構成している単糸の表面に前述した処理剤付着させる方法としては、紡糸段階若しくは経糸整経時に給油ロールを設けて付与するか、熱セット工程の前で浸漬付与する。また、付与する工程は前述した工程のどれか一つ又はいくつかの工程に分けて付与することができる。付着する物質は、ポリオレフィン類としては、例えば、ポリエチレン、ポリプロピレン樹脂、脂肪酸エステル類としては、2塩基酸と1価アルコールや多価アルコールと1塩基酸のエステル、又は多価アルコールと2塩基酸のエステル、シリコン樹脂類としては、ジメチルシリコン又はその変性体を使用することができる。付与する形態としては、炭化水素等の有機溶液、水溶液、エマルジョンの形態があるが、工程安全性より、水を使用する方が好ましく、エマルションが最も好ましい。熱可塑性繊維としては、ポリアミド類及びポリエステル類からなる群から選択されるものがコストや物性等でバランスが取れていて好適である。特に、ナイロン66やポリエチレンテレフタレート繊維が好適に使用でき、耐熱性、摩擦特性、強伸度を考慮すると、ナイロン66が最も好適である。当該繊維は溶融紡糸によりマルチフィラメントを得て、冷却後、油剤を付与し、熱ロールにて延伸し、圧力空気により交絡を付与して得られる。 As a method of attaching the above-mentioned treatment agent to the surface of the single yarn constituting the fiber, it is provided by providing an oil supply roll at the spinning stage or warp aging, or by immersion before the heat setting step. Moreover, the process to provide can be divided and provided in any one or several processes mentioned above. Substances to be adhered include, for example, polyethylene, polypropylene resin, and fatty acid esters as polyolefins, such as dibasic acid and monohydric alcohol, polyhydric alcohol and monobasic ester, or polyhydric alcohol and dibasic acid. Dimethyl silicon or a modified product thereof can be used as the ester or silicon resin. Examples of forms to be applied include organic solutions such as hydrocarbons, aqueous solutions, and emulsions. However, it is preferable to use water from the viewpoint of process safety, and emulsions are most preferable. As the thermoplastic fiber, those selected from the group consisting of polyamides and polyesters are suitable because they are balanced in terms of cost, physical properties, and the like. In particular, nylon 66 and polyethylene terephthalate fiber can be preferably used, and nylon 66 is most preferable in consideration of heat resistance, friction characteristics, and high elongation. The fiber is obtained by obtaining multifilaments by melt spinning, applying an oil agent after cooling, drawing with a hot roll, and providing entanglement with pressurized air.

本発明の織物基布を構成する繊維束の断面の幅を高さで除した値が2.5〜5.0であると柔軟性と気密性がより好適に発現する。2.5以上であると基布に力が加わった場合、構成する繊維が程度に移動し、引裂き強力が有利に働く。また、5.0以下であれば経緯糸の拘束力が向上し、気密性が有利になる。 When the value obtained by dividing the width of the cross section of the fiber bundle constituting the woven fabric of the present invention by the height is 2.5 to 5.0, flexibility and airtightness are more suitably expressed. When the force is applied to the base fabric when it is 2.5 or more, the constituent fibers move to the extent, and the tearing strength works advantageously. Moreover, if it is 5.0 or less, the binding force of the warp will be improved, and airtightness will be advantageous.

本発明の基布を構成する経糸及び緯糸の糸条の繊度は共に300〜800dtexであるとより好適である。300dtex以上では柔軟性向上により収納性がより向上する。また、800dtex以下であれば密度は少なくて済むために、より生産性に有利になる。より好ましくは、400〜700dtexである。 The fineness of the warp and weft yarns constituting the base fabric of the present invention is more preferably 300 to 800 dtex. At 300 dtex or more, the storage property is further improved due to the improved flexibility. Further, if it is 800 dtex or less, the density can be reduced, which is more advantageous for productivity. More preferably, it is 400-700 dtex.

本発明の織物基布を構成する糸の引き抜き抵抗値は、20〜150N/cm/cmであると気密性をより良く維持することができる。20N/cm/cm以上であると糸条の自由度が高いことより、柔軟な基布となり柔軟性かつ、引裂き強力が有利に働く。他方、150N/cm/cm以下であれば経緯糸間の摩擦が大きくなり、縫製部分の気密性維持に有利である。この範囲の引き抜き抵抗は、0.22cN/dtex以上の経糸張力で製織することが好ましいが、あまり張力を上げ過ぎると綜絖や筬によって毛羽が発生する場合があり、筬の1羽当たりの入れ数やテンプル、綜絖の材質、形状等の工夫が必要である。本発明の織物基布の両端には耳緩み防止のために、織物の地糸とは同種及び/又は別種の糸を適用する。例えば、絡み糸と力糸である。 When the drawing resistance value of the yarn constituting the woven fabric of the present invention is 20 to 150 N / cm / cm, the airtightness can be better maintained. When it is 20 N / cm / cm or more, the degree of freedom of the yarn is high, so that it becomes a flexible base fabric, and the flexibility and the tearing strength work advantageously. On the other hand, if it is 150 N / cm / cm or less, the friction between the warp and weft is increased, which is advantageous for maintaining the airtightness of the sewing portion. The weaving resistance within this range is preferably weaving with a warp tension of 0.22 cN / dtex or more, but if the tension is increased too much, fluff may be generated due to wrinkles and wrinkles. It is necessary to devise materials such as the material and shape of the temples and temples. In order to prevent the loosening of the ears, the same type and / or different types of yarn from the fabric base yarn are applied to both ends of the fabric base fabric of the present invention. For example, entangled yarn and force yarn.

前記したように、本発明の基布を構成する糸条の幅を厚みで除した値は2.5〜5が好ましい。2.5以上であれば厚みの効果で耐熱性に有利となる。5以下では扁平化が進み、柔軟性、気密性に有利である。上記値の範囲とするには、0.25cN/dtex以上の経糸張力で製織することが好ましいが、あまり張力を上げ過ぎると綜絖や筬によって毛羽が発生する場合があり、バランスさせることが必要であるが、単糸数を多くすると製織張力も低くできる場合がある。 As described above, the value obtained by dividing the width of the yarn constituting the base fabric of the present invention by the thickness is preferably 2.5 to 5. If it is 2.5 or more, the effect of thickness is advantageous for heat resistance. If it is 5 or less, flattening progresses, which is advantageous for flexibility and airtightness. In order to make the above range, weaving is preferably performed with a warp tension of 0.25 cN / dtex or more, but if the tension is increased too much, fluff may be generated by wrinkles and wrinkles, and it is necessary to balance. There are cases where weaving tension can be lowered by increasing the number of single yarns.

本発明の織物基布を作製するに際しては、絡み糸と増し糸を用いる方が品質向上に好適である。絡み糸は、一番反物の端に配置して、耳部のほつれや緩みを防止する。絡み糸は、通常2本1組で両耳部分にレノ装置にて織物に織り込む。15〜100dtexのモノフィラメントを適用した場合、耳部の締まりが良く、耳部のたるみや、これに起因するフレアおよび経糸密度のばらつきを有効に軽減できる。絡み糸は15dtex以上であると耳部の締まりが特によく、100dtex以下では適度に太い糸である為にハンドリングが容易である。 When producing the fabric base fabric of the present invention, it is preferable to use entangled yarn and additional yarn for quality improvement. The entanglement thread is placed at the end of the most fabric to prevent the ears from fraying or loosening. The entangled yarn is usually woven into a woven fabric with a Leno device at both ears in pairs. When a monofilament of 15 to 100 dtex is applied, the ears are tightly tightened, and the sagging of the ears and the resulting flare and warp density variations can be effectively reduced. When the entangled yarn is 15 dtex or more, the ear portion is particularly tight, and when it is 100 dtex or less, the yarn is reasonably thick, so that handling is easy.

更に増し糸と称する糸を反物地糸と両反端絡み糸の間に片側当たり2本以上存在させると反物の緩み防止により有効となる。これは別の給糸台より供給する。反物両端の絡み糸と地糸の間に、繊度が20以上100dtex未満の増し糸が左右合計4本以上織り込まれていることが好ましい。増し糸には、モノフィラメント、捲縮加工糸、スパン糸、地糸と同種の糸を単独で又は組み合わせて使用できる。これらは、耳部のしわや緩み、製品ロールの耳高さを見ながら張力や適用する糸種を適宜選択する。また、増し糸部は平織組織が一般的に採用されるが、耳部の状態により変更でき、特に限定されない。 Furthermore, if two or more yarns, called additional yarns, are present between one side of the fabric and the opposite end entangled yarn, it is effective for preventing the fabric from loosening. This is supplied from another yarn feeder. It is preferable that a total of four or more additional yarns having a fineness of 20 to less than 100 dtex are woven between the entangled yarn and the ground yarn at both ends of the fabric. As the reinforcing yarn, monofilament, crimped yarn, spun yarn, and yarn of the same type as the ground yarn can be used alone or in combination. For these, the tension and the thread type to be applied are appropriately selected while observing the wrinkles and looseness of the ears and the ear height of the product roll. Further, a plain weave structure is generally adopted as the reinforcing yarn part, but it can be changed depending on the state of the ear part and is not particularly limited.

本発明の織物基布を製織する場合に使用する織機の緯入れ機構は、レピア、ウォータジェット、エアージェット、シャットル、プロジェクタイル等一般的な装置を選択できる。 As the weft insertion mechanism of the loom used when weaving the fabric base fabric of the present invention, a general device such as rapier, water jet, air jet, shuttle, or projectile can be selected.

本発明の織物基布を得るためのセット加工において、熱セットを行う場合もある。その時のセット方法は特に限定されず、公知の方法が選択できる。例えば、熱水槽に通した後に乾燥し、テンター等の熱固定炉にて熱固定する方法や、テンターを省略した方法も選択できる。熱固定時には経方向では供給ロールと炉内固定具の進行速度差により張力をかける方法が一般的にとられる。また、緯方向では、例えばピン、クリップ固定や、炉内ロールと織物との摩擦のみで緯方向の収縮を抑制する方法が採用できる。加熱においても電気やガス燃焼加熱空気を循環させる方法や赤外線ヒーターでの輻射を利用してもよい。この時のセット温度は100〜200℃の範囲が好適である。また、熱セット時にテンターを用いる場合は、下記式4:

テンターオーバーフィード率=(Vw−Vs)/Vs×100

{式中、Vs=反物精錬後の加熱セット機への供給速度(m/min)、Vw=反物精錬後の加熱セット機内速度(m/min)}で表されるテンターオーバーフィード率を−10〜2%に調整し、さらに、下記式5:

テンター横幅変化率=(Dw−Ds)/Ds*100

{式中、Ds=反物精錬後の加熱セット機への供給反物幅(mm)、Dw=反物精錬後の加熱セット機内の反物幅(mm)}で表されるテンター横幅変化率を−10〜2%程度の範囲で調整することで、密度分布の小さい品質の良い基布が得られる。

In the set processing for obtaining the fabric base fabric of the present invention, heat setting may be performed. The setting method at that time is not particularly limited, and a known method can be selected. For example, a method of drying after passing through a hot water tank and heat setting in a heat setting furnace such as a tenter, or a method of omitting the tenter can be selected. Generally, a method of applying tension by a difference in traveling speed between the supply roll and the in-furnace fixture in the warp direction during heat setting is generally used. Further, in the weft direction, for example, a method of suppressing shrinkage in the weft direction only by pin and clip fixation or friction between the in-furnace roll and the fabric can be employed. In heating, electricity or gas combustion heating air may be circulated or radiation from an infrared heater may be used. The set temperature at this time is preferably in the range of 100 to 200 ° C. Moreover, when using a tenter at the time of heat setting, the following formula 4:

Tenter overfeed rate = (Vw−Vs) / Vs × 100

A tenter overfeed rate represented by {in the formula, Vs = feed rate to the heating set machine after refining of the workpiece (m / min), Vw = speed in the heating set machine after refining of the object (m / min)} is −10 Adjust to ˜2%, and the following formula 5:

Tenter width change rate = (Dw−Ds) / Ds * 100

The tenter width change rate represented by {in the formula, Ds = feed workpiece width to the heating set machine after fabric refining (mm), Dw = fabric width in the heating set machine after fabric refining}. By adjusting in the range of about 2%, a good quality base fabric with a small density distribution can be obtained.

また、テンター等の加熱セット機を用いず、精錬後そのまま乾燥のみを実施してもよい。この場合には、下記式6:

精錬オーバーフィード率=(Sw−Ss)/Ss*100

{式中、Ss=反物の精錬機への供給速度(m/min)、Sw=反物の巻き取り速度(m/min)}で表される精錬オーバーフィード率を−15〜0%程度とすることが好ましい。

Moreover, you may implement only drying as it is after refining, without using heating setting machines, such as a tenter. In this case, the following formula 6:

Refining overfeed rate = (Sw−Ss) / Ss * 100

{In the formula, Ss = feeding speed of fabric to refining machine (m / min), Sw = winding speed of fabric (m / min)}, and a refining overfeed rate of about −15 to 0%. It is preferable.

本発明に係る織物基布が巻かれてロールとなった場合、当該ロール中央部と端部の直径比は7%である、すなわち、ロール中央部の直径Dとロール端部の直径dの比d/Dが1.07未満であることが好ましい。7%未満とすることで、製品の耳部のしわがより少ない品質の良い反物が得られ、ロール運搬時に反物耳部が床面や包装材と擦れるなどの損傷リスクがより低い製品を作製することができる。 When the fabric base fabric according to the present invention is wound into a roll, the diameter ratio between the roll center and the end is 7%, that is, the ratio of the diameter D of the roll center to the diameter d of the roll end. It is preferable that d / D is less than 1.07. By making the content less than 7%, a good quality product with less wrinkles on the product's ears can be obtained, and a product with a lower risk of damage such as rubbing of the product's product ears with the floor or packaging material during roll transportation is produced. be able to.

本発明に係る織物基布は、特に、エアバッグ用基布として好適に用いることができる。バッグは縫製又は袋織により形成可能であり、運転席、助手席、サイドカーテン、ニーバッグ、歩行者保護用バッグとして用いることができる。 The fabric base fabric according to the present invention can be particularly suitably used as an airbag base fabric. The bag can be formed by sewing or bag weaving, and can be used as a driver seat, a passenger seat, a side curtain, a knee bag, and a pedestrian protection bag.

以下、実施例、比較例によって本発明を具体的に説明するが、本発明はこれらの実施例のみに限定されるものではない。

先ず、実施例等において用いた各種測定方法及び評価方法を説明する。

(1)繊維の繊度、強度、及び伸度は、JIS L1013に従って測定した。

(2)繊維の密度は密度勾配管により測定した。

(3)基布重量:10cm正方を3点切り出し、電子天秤にて小数点3ケタまで測定し、その平均より1m2当たりの重量として求めた。

(4)基布密度;TEXTEST社製FX3255を用い経、緯それぞれ5点測定し、その平均を密度とした。

(5)基布の強力及び伸度はJIS L1096のストリップ法に従って測定した。

EXAMPLES Hereinafter, although an Example and a comparative example demonstrate this invention concretely, this invention is not limited only to these Examples.

First, various measurement methods and evaluation methods used in Examples and the like will be described.

(1) The fineness, strength, and elongation of the fiber were measured according to JIS L1013.

(2) The density of the fiber was measured with a density gradient tube.

(3) Base fabric weight: 3 points of 10 cm square were cut out, measured to 3 decimal places with an electronic balance, and determined as the weight per 1 m 2 from the average.

(4) Density of base fabric; using a TEXTEST FX3255, the warp and the weft were measured at 5 points, and the average was taken as the density.

(5) The strength and elongation of the base fabric were measured according to the strip method of JIS L1096.

(6)基布の引裂き強力はJIS L1096のシングルタング法にて測定した。

(7)製織停台:2日間製織を実施し、1日当たりの停台を見た。但し、緯糸交換よる停台は除外した。

(8)布残留シリコン樹脂付着量は、基布をノルマルヘキサンにてソックスレー抽出後、抽出液を乾燥させ、残留分を蛍光X線分析にてシリコン原子含有量より算出した。

(9)基布残留オレフィン樹脂付着量は、基布をノルマルヘキサンにてソックスレー抽出後、抽出液を乾燥させ、残留分をGPCにて分離し、含有量を算出した。

(10)基布残留エステル類は、単独付着の場合、基布をノルマルヘキサンにてソックスレー抽出後、抽出液を乾燥させ、その重量より算出した。シリコン及び/又はオレフィン樹脂と混合した場合は、全量をソックスレー抽出にて測定後、各々の量を差し引いて求めた。

(6) The tear strength of the base fabric was measured by the single tongue method of JIS L1096.

(7) Weaving stop: Weaving was carried out for 2 days and the stop per day was observed. However, the stop by changing the weft was excluded.

(8) The amount of cloth-residual silicon resin adhered was calculated from the silicon atom content by fluorescent X-ray analysis after drying the extract after Soxhlet extraction of the base fabric with normal hexane.

(9) The amount of base fabric residual olefin resin adhered was calculated after the base fabric was Soxhlet extracted with normal hexane, the extract was dried, the residue was separated by GPC, and the content was calculated.

(10) The base fabric residual esters were calculated from the weight of the base fabric after the base fabric was Soxhlet extracted with normal hexane after drying, and the extract was dried. When mixed with silicon and / or olefin resin, the total amount was determined by Soxhlet extraction and then subtracted from each amount.

(11)基布を構成する繊維の幅と厚みはリガク製高分解能X線顕微鏡nano3DXを用い、X線ターゲットにCu、管電圧40kV/30mAでX線を発生し、サンプルを撮影し、寸法を求めた。

(12)引き抜き抵抗値は、図1に示す引き抜き抵抗測定試料(サンプル)を作製し、A&D社製テンシロンにおいて10mm/minの速度にて幅方向に3か所測定し、下記式7:

P=F(Dx/2.54)/(15×2.54/Dy)

{式中、P=引き抜き抵抗力(N/cm/cm)、F=引き抜き測定値(N)、Dx=測定方向の織密度(本/inch)、Dy=測定方向と直交する方向の織密度(本/inch)}により算出した。

(13)織密度:TEXTEST社製FX3255を用いた。

(14)基布通気量;TEXTEST社製FX3350にて400ccタンクを用い、初期圧170kPaにて測定し、30kPaから70kPaの平均の動的通気量を測定した。

(15)縫目通気量:織物より縦38cm×横15cmの布2枚を切り出し、1350dtexの撚糸からなる縫い糸にて50針/dmの本縫で縫合し、糸両端を結ぶ。これを織物の経方向同士の合わせ及び緯方向同士の合わせの縫合で経、緯用の試料を作製した。その後、A&D社製テンシロンにおいてチャック幅60mmにはさみ、100mm/分の速度にて1500Nの荷重をかけた後に、一旦張力を開放し、3時間放置した。この試料をTEXTEST社製FX3350にて400ccタンクを用い、初期圧300kPaにて測定し、30kPaから70kPaの平均の動的通気量を測定した。

(11) The width and thickness of the fibers constituting the base fabric were measured using a Rigaku high-resolution X-ray microscope nano3DX, X-rays were generated on the X-ray target with Cu and a tube voltage of 40 kV / 30 mA, the sample was photographed, and the dimensions were measured. Asked.

(12) The pulling resistance value was measured by measuring the pulling resistance measurement sample (sample) shown in FIG. 1 at three locations in the width direction at a speed of 10 mm / min in Tensilon manufactured by A & D.

P = F (Dx / 2.54) / (15 × 2.54 / Dy)

{In the formula, P = pull resistance (N / cm / cm), F = measurement value (N), Dx = weave density in the measurement direction (main / inch), Dy = weave density in the direction perpendicular to the measurement direction (Book / inch)}.

(13) Weave density: FX3255 manufactured by TEXTEST was used.

(14) Base fabric aeration rate: Measured at an initial pressure of 170 kPa using a 400 cc tank with FX3350 manufactured by TEXTEST, and an average dynamic aeration rate of 30 kPa to 70 kPa was measured.

(15) Stitch aeration: Cut out two pieces of fabric with a length of 38 cm and a width of 15 cm from the woven fabric and sew them with 50 stitches / dm main stitch with a sewing thread made of 1350 dtex twisted yarn, and tie both ends of the yarn. A sample for weft and weft was prepared by stitching together the warp directions of the woven fabric and stitching the weft directions. Thereafter, the A & D Tensilon was sandwiched between 60 mm and a load of 1500 N was applied at a speed of 100 mm / min, after which the tension was once released and left for 3 hours. This sample was measured at an initial pressure of 300 kPa using a 400 cc tank by FX3350 manufactured by TEXTEST, and an average dynamic air flow rate from 30 kPa to 70 kPa was measured.

(16)ロール形状指数(d/D):ロール中央部の直径Dとロール端部の直径を測定し、算出した。

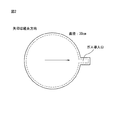

(17)バッグ展開評価:織物より幅8cm×長さ10cmガス導入口を有した直径30cmのバッグを1350dtexの撚糸からなる縫い糸にて65針/dmの本縫で縫合し作製した。これを表裏反転させバッグとして、図2に示すバッグを作製した。これをマイクロシス社製CGSシステムを用い、圧力5MPa、オリフィス0.6インチ、タンク容量250ccの条件でヘリウムガスを瞬時に供給したときの展開後の該バッグの様子を観察した。縫目部の一番開いている部分を目視にて測定し、3mm以下を小、3〜6mmを中、6mm以上を大として評価した。

(16) Roll shape index (d / D): The diameter D of the roll center and the diameter of the roll end were measured and calculated.

(17) Bag development evaluation: A bag having a diameter of 8 cm and a length of 10 cm from the woven fabric and having a diameter of 30 cm was sewn with a sewing thread composed of 1350 dtex twisted thread with 65 stitches / dm main stitch. The bag shown in FIG. 2 was produced by inverting this front and back. Using the CGS system manufactured by Microsys, the state of the bag after deployment was observed when helium gas was instantaneously supplied under the conditions of a pressure of 5 MPa, an orifice of 0.6 inches, and a tank capacity of 250 cc. The most open portion of the seam portion was visually measured and evaluated as 3 mm or less as small, 3 to 6 mm as medium, and 6 mm or more as large.

[実施例1]

ポリアミド6・6樹脂を300℃で溶融紡糸し、冷却しながら紡糸油剤を繊維に対し0.8%付与し、その後200℃の熱延伸ロールにて4.9倍に延伸し、圧縮空気にて交絡を付与後、繊度470dtex、フィラメント数136本の原糸を得た。原糸の強度は8.56cN/dtex、破断伸び率は21%であった。この原糸を用い、糊付けすることなく豊田自動織機社製LWT710の織幅2.3mにて、経糸密度45.2本/inch、緯糸設定密度44本/inch、織物幅230cm、経糸張力0.32cN/dtex、織機回転数600rpmで平織製織を行った。緯入れ装置は自由飛送のみで挿入するタイプを用いた。両耳部分は絡み糸として22dtexナイロン66モノフィラメント片側2本ずつ使用した。増し糸は22dtexナイロン66モノフィラメントを絡み糸と地糸の間に片側2本ずつ使用して、平織とした。その後、80℃の湯浴に精錬時オーバーフィード率は−10%の設定で400Nの張力下で60秒間処理した後、固形分1500ppmのシリコン樹脂エマルションに浸漬し、その後ピンテンターにてテンターオーバーフィード−4%、テンター横幅設定率−2%、熱セット温度180℃で、目的のノンコート基布を得た。この基布について織密度、製織時の停台数、構成糸の厚みと幅、基布の引張強伸度、引き抜き抵抗、剛軟度、縫目開き後通気量、ロール形状、バッグ展開試験を実施し、以下の表1に示す結果を得た。

[Example 1]

Polyamide 6 · 6 resin is melt-spun at 300 ° C, the spinning oil is applied to the fiber 0.8% while cooling, and then stretched 4.9 times with a 200 ° C hot-drawing roll, and compressed air After imparting entanglement, a raw yarn having a fineness of 470 dtex and 136 filaments was obtained. The strength of the raw yarn was 8.56 cN / dtex and the elongation at break was 21%. Using this raw yarn, without any gluing, a weft width of 2.3 m of LWT710 manufactured by Toyota Industries Corporation, a warp density of 45.2 / inch, a set weft density of 44 / inch, a fabric width of 230 cm, a warp tension of 0. Plain weaving was performed at 32 cN / dtex and a loom rotation speed of 600 rpm. The weft insertion device used was a type that was inserted only by free flight. The two ears were used as two entangled yarns, one each of 22 dtex nylon 66 monofilament. The reinforcing yarn was made into a plain weave by using 22 dtex nylon 66 monofilament, two on each side between the entangled yarn and the ground yarn. After that, after refining in an 80 ° C. hot water bath at a refining overfeed rate of −10% under 400 N tension for 60 seconds, it was immersed in a silicone resin emulsion with a solid content of 1500 ppm, and then a tenter overfeed with a pin tenter. The desired non-coated base fabric was obtained at 4%, a tenter width setting ratio of -2%, and a heat setting temperature of 180 ° C. For this base fabric, weaving density, number of stops during weaving, thickness and width of constituent yarn, tensile strength and elongation of base fabric, pulling resistance, bending resistance, air permeability after seam opening, roll shape, bag deployment test The results shown in Table 1 below were obtained.

[実施例2]

実施例1と同じ糸条を用い、整経時に実施例1と同じシリコン樹脂エマルションを固形分濃度3.0%に調整した物をタッチロールにて付与した。タッチロールと経糸の接触長は30mmとして糸速100m/min、ロール回転数15rpmとして経糸を準備し、実施例1と同じ製織条件で生機を得た。この後、80℃の湯浴に400Nの張力下で60秒間処理し、その時の精錬オーバーフィード率−10%で処理し、乾燥ドラムにて110℃で60秒間乾燥し、目的の基布を得た。この基布について実施例1と同様の評価を行い、以下の表1に示す結果を得た。

[Example 2]

The same yarn as in Example 1 was used, and the same silicon resin emulsion as in Example 1 was adjusted to a solid content concentration of 3.0% with a touch roll during aging. The contact length between the touch roll and the warp was 30 mm, the yarn speed was 100 m / min, the warp speed was 15 rpm, and a warp was prepared under the same weaving conditions as in Example 1. Thereafter, it is treated in a hot water bath at 80 ° C. under a tension of 400 N for 60 seconds, treated at a refining overfeed rate of −10% at that time, and dried at 110 ° C. for 60 seconds in a drying drum to obtain a desired base fabric. It was. Evaluation similar to Example 1 was performed about this base fabric, and the result shown in the following Table 1 was obtained.

[実施例3]

ポリアミド6・6樹脂を300℃で溶融紡糸し、冷却しながら紡糸油剤を繊維に対し0.8%付与し、その後200℃の熱延伸ロールにて4.7倍に延伸し、圧縮空気にて交絡を付与後、繊度470dtex、フィラメント数216本の原糸を得た。原糸の強度は8.6cN/dtex、破断伸び率は20%であった。この原糸を用いて経糸張力を0.36cN/dtexとした以外は実施例2と同様の製織を実施した。次いで、精錬槽に通すことなく精錬オーバーフィード率−6%で処理し、乾燥ドラムにて110℃で60秒間乾燥し、目的の基布を得た。この基布について実施例1と同様な評価を実施し、以下の表1に示す結果を得た。

[Example 3]

Polyamide 6 · 6 resin is melt-spun at 300 ° C, and the spinning oil is applied to the fiber 0.8% while cooling, then stretched 4.7 times with a 200 ° C hot-drawing roll, and compressed air After imparting entanglement, a raw yarn having a fineness of 470 dtex and a filament number of 216 was obtained. The strength of the raw yarn was 8.6 cN / dtex and the elongation at break was 20%. Weaving was performed in the same manner as in Example 2 except that the warp tension was changed to 0.36 cN / dtex using this raw yarn. Subsequently, it processed with the refining overfeed rate of -6% without letting it pass through a refining tank, and it dried at 110 degreeC for 60 second with the drying drum, and obtained the target base fabric. Evaluation similar to Example 1 was implemented about this base fabric, and the result shown in the following Table 1 was obtained.

[実施例4]

実施例2と同じ経糸ビームを用い、製織時に経糸張力を0.22cN/dtexとした以外は同じ製織条件とした。後加工は実施例3と同様にして目的の基布を得た。この基布について実施例1と同様に評価した結果を以下の表1に示す。

[Example 4]

The same weaving conditions as in Example 2 were used except that the warp tension was 0.22 cN / dtex during weaving. Post-processing was performed in the same manner as in Example 3 to obtain the desired base fabric. The results of evaluating this base fabric in the same manner as in Example 1 are shown in Table 1 below.

[実施例5]

実施例1と同じ製織後、同じシリコン樹脂エマルションを固形分5000ppmに調整して浸漬し、熱水槽を通すことなく乾燥ドラムにて110℃、60secで乾燥し目的の基布を得た。この基布について実施例1と同様に評価した結果を以下の表1に示す。

[Example 5]

After weaving the same as in Example 1, the same silicone resin emulsion was adjusted to a solid content of 5000 ppm and immersed, and dried in a drying drum at 110 ° C. for 60 seconds without passing through a hot water bath to obtain the desired base fabric. The results of evaluating this base fabric in the same manner as in Example 1 are shown in Table 1 below.

[実施例6]

実施例1と同じ糸条を用い、整経は、ポリプロピレン樹脂を付与した以外は実施例2と同じとした。この経糸ビームを用いて実施例2と同様な製織を実施し、後加工は実施例3と同じとして目的の基布を得た。この基布について実施例1と同様な評価を実施し、以下の表1に示す結果を得た。

[Example 6]

The same yarn as in Example 1 was used, and warping was the same as in Example 2 except that a polypropylene resin was applied. Using this warp beam, weaving was performed in the same manner as in Example 2, and post-processing was performed in the same manner as in Example 3 to obtain the desired base fabric. Evaluation similar to Example 1 was implemented about this base fabric, and the result shown in the following Table 1 was obtained.

[実施例7]

繊維をポリエチレンテレフタレートに変更し、他は実施例6と同様な製織条件、加工条件として目的の基布を得た。この基布について実施例1と同様な評価を実施し、以下の表1に示す結果を得た。

[Example 7]

The fiber was changed to polyethylene terephthalate, and the other base fabric was obtained under the same weaving conditions and processing conditions as in Example 6. Evaluation similar to Example 1 was implemented about this base fabric, and the result shown in the following Table 1 was obtained.

[実施例8]

実施例1と同様な糸条を使用し、経糸整経時に樹脂等を付与することなく経糸ビームを作製し、実施例1と同様な条件で製織した。これを実施例3と同様な後加工を実施して目的の基布を得た。この基布を実施例1と同様な評価を実施し、以下の表1に示す結果を得た。

[Example 8]

A yarn similar to that used in Example 1 was used, and a warp beam was produced without applying a resin or the like during warp aging. The yarn was woven under the same conditions as in Example 1. This was post-processed in the same manner as in Example 3 to obtain the desired base fabric. Evaluation similar to Example 1 was implemented for this base fabric, and the results shown in Table 1 below were obtained.

[実施例9]

実施例1と同様な糸条を使用し、経糸整経時に樹脂等を付与することなく経糸ビームを作製し、実施例1と同様な条件で製織した。これを実施例2と同様な条件にて後加工を行い、目的の基布を得た。この基布を実施例1と同様な評価を実施し、以下の表1に示す結果を得た。

[Example 9]

A yarn similar to that used in Example 1 was used, and a warp beam was produced without applying a resin or the like during warp aging. The yarn was woven under the same conditions as in Example 1. This was post-processed under the same conditions as in Example 2 to obtain the desired base fabric. Evaluation similar to Example 1 was implemented for this base fabric, and the results shown in Table 1 below were obtained.

[実施例10]

ポリアミド6・6樹脂を300℃において溶融紡糸し、冷却しながら紡糸油剤を繊維に対し0.8%付与し、その後200℃の熱延伸ロールにて4.9倍に延伸し、圧縮空気にて交絡を付与後、繊度235dtex、フィラメント数36本の原糸を得た。原糸の強度は8.90cN/dtex、破断伸び率は21%であった。この糸条を経密度65本/inchとした以外は実施例2と同じ条件で整経ビームを得た。これを緯密度66本/inchとした以外は実施例1と同様な条件で製織した。後加工は実施例3の条件と同じとして目的の基布を得た。この基布ついて実施例1と同様な評価を実施し、以下の表1に示す結果を得た。

[Example 10]

Polyamide 6 · 6 resin is melt-spun at 300 ° C, and the spinning oil is applied to the fiber 0.8% while cooling, and then stretched 4.9 times with a 200 ° C hot-stretching roll, and compressed air After imparting entanglement, a yarn having a fineness of 235 dtex and a filament count of 36 was obtained. The strength of the raw yarn was 8.90 cN / dtex and the elongation at break was 21%. A warp beam was obtained under the same conditions as in Example 2 except that the yarn had a warp density of 65 yarns / inch. Weaving was performed under the same conditions as in Example 1 except that the weft density was 66 / inch. Post-processing was performed under the same conditions as in Example 3 to obtain the desired base fabric. Evaluation similar to Example 1 was implemented about this base fabric, and the result shown in the following Table 1 was obtained.

[実施例11]

増し糸を110dtexポリアミド糸に変更した以外は実施例2と同じ経糸ビーム、製織条件とした。後加工条件は実施例3と同様にして目的の織物を得た。この基布について実施例1と同様な評価を実施し、以下の表1に示す結果を得た。

[Example 11]

The warp beam and weaving conditions were the same as in Example 2 except that the additional yarn was changed to 110 dtex polyamide yarn. Post-processing conditions were the same as in Example 3 to obtain the desired woven fabric. Evaluation similar to Example 1 was implemented about this base fabric, and the result shown in the following Table 1 was obtained.

前記発明[1]の範囲内の物は柔軟性と気密性の両立が出来ており、バッグ展開後も目開きが抑制された基布が得られた。 The thing in the range of the said invention [1] was able to have coexistence of a softness | flexibility and airtightness, and the base fabric by which the opening was suppressed after the bag expansion | deployment was obtained.

[比較例1]

ポリアミド6・6樹脂を300℃において溶融紡糸し、冷却しながら紡糸油剤を繊維に対し0.8%付与し、その後200℃の熱延伸ロールにて4.85倍に延伸し、圧縮空気にて交絡を付与後、繊度470dtxex、フィラメント数36本の原糸を得た。原糸の強度は8.56cN/dtex、破断伸び率は20%であった。この糸条を実施例2と同様な整経、製織を行い、後加工は実施例3と同様としたて目的の基布を得た。この基布について実施例1と同様な評価を実施し、以下の表2に示す結果を得た。比較例1では、単糸繊度の大きい糸条を用いたことによってZ値が小さくなり、気密性が維持できない結果となった。またバッグ展開にてバーストが発生した。

[Comparative Example 1]

Polyamide 6.6 resin is melt-spun at 300 ° C., and a spinning oil is applied to the fiber at a rate of 0.8% while cooling, and then stretched 4.85 times with a 200 ° C. hot stretch roll, and compressed air. After imparting entanglement, a yarn having a fineness of 470 dtxex and a filament count of 36 was obtained. The strength of the raw yarn was 8.56 cN / dtex, and the elongation at break was 20%. This yarn was subjected to warping and weaving in the same manner as in Example 2, and post-processing was performed in the same manner as in Example 3 to obtain the desired base fabric. Evaluation similar to Example 1 was implemented about this base fabric, and the result shown in the following Table 2 was obtained. In Comparative Example 1, the Z value was decreased by using a yarn having a large single yarn fineness, and the airtightness could not be maintained. In addition, bursts occurred during bag deployment.

[比較例2]

ポリアミド6・6樹脂を300℃において溶融紡糸し、冷却しながら紡糸油剤を繊維に対し0.8%付与し、その後200℃の熱延伸ロールにて4.75倍に延伸し、圧縮空気にて交絡を付与後、繊度155dtxex、フィラメント数136本の原糸を得た。原糸の強度は8.1cN/dtex、破断伸び率は25%であった。この糸条を3本合糸して465dtexとした。これを比較例1と同様に整経し、同様な条件で製織を実施した。その後、実施例2と同じ後加工を実施し目的の基布を得た。この基布について実施例1と同様な評価を実施し、以下の表2に示す結果を得た。この基布は、単糸繊度が小さい為に抵触時の停台、また得られた基布はZ値が大きく、繊維の自由度が無い為に引裂が低い基布となった。この展開試験はバーストが発生した。

[Comparative Example 2]

Polyamide 6.6 resin is melt-spun at 300 ° C, and a spinning oil is applied to the fiber 0.8% while cooling, and then stretched 4.75 times with a 200 ° C hot-drawing roll, and compressed air. After imparting entanglement, a raw yarn having a fineness of 155 dtxex and 136 filaments was obtained. The strength of the raw yarn was 8.1 cN / dtex, and the elongation at break was 25%. Three yarns were combined to make 465 dtex. This was warped in the same manner as in Comparative Example 1, and weaving was performed under the same conditions. Then, the same post-processing as Example 2 was implemented and the target base fabric was obtained. Evaluation similar to Example 1 was implemented about this base fabric, and the result shown in the following Table 2 was obtained. This base fabric was a base fabric at the time of conflict because the single yarn fineness was small, and the obtained base fabric had a large Z value, and because there was no degree of freedom of fibers, it became a base fabric with low tearing. This development test caused a burst.

[比較例3]

実施例1と同様な整経ビームを用い、同様な製織を実施した。後加工では水洗槽の前にバスを設け、固形分1%に希釈した実施例1と同様なシリコン樹脂エマルションに基布を浸漬し、精錬することなく110℃の乾燥ドラムにて60sec乾燥させ目的の基布を得た。この基布について比較例1と同様な評価を実施し、以下の表2に示す結果を得た。この基布は過剰な加工剤の存在によって目開き後通気量が高い基布となり、展開試験ではバーストが発生した。

[Comparative Example 3]

The same weaving was carried out using the same warping beam as in Example 1. In post-processing, a bath is provided in front of the washing tank, the base fabric is immersed in the same silicone resin emulsion as in Example 1 diluted to 1% solid content, and dried for 60 seconds in a 110 ° C. drying drum without refining. A base fabric was obtained. This base fabric was evaluated in the same manner as in Comparative Example 1, and the results shown in Table 2 below were obtained. This base fabric became a base fabric having a high air permeability after opening due to the presence of an excessive processing agent, and a burst occurred in the development test.

[比較例4]

実施例1と同じ糸条を用い、整経時に樹脂エマルションの代わりに直鎖アルキル硫酸塩を1%含む水溶液を塗布し経糸を巻き取った。この糸条を実施例2と同じ製織と後加工を実施し、目的の基布を得た。得られた基布に残留していたものはエステル類20ppmであった。この基布について実施例1と同様な評価を実施し、以下の表2に示す結果を得た。比較例4では、製織停台が多く、得られた基布も引裂き強力が低くなり、バッグ展開試験にてバーストが発生した。

[Comparative Example 4]

Using the same yarn as in Example 1, an aqueous solution containing 1% linear alkyl sulfate was applied instead of the resin emulsion during aging, and the warp was wound up. The yarn was subjected to the same weaving and post-processing as in Example 2 to obtain the desired base fabric. What remained in the obtained base fabric was 20 ppm of esters. Evaluation similar to Example 1 was implemented about this base fabric, and the result shown in the following Table 2 was obtained. In Comparative Example 4, there were many weaving stops, and the obtained base fabric also had low tear strength, and bursts occurred in the bag deployment test.

[比較例5]

実施例2と同じ糸条を用い、経密度を52本/inchとした以外は、同様な整経を行った。この経糸を用いて緯糸密度設計を53本/inch、両耳部分は絡み糸として22dtexナイロン66モノフィラメント片側2本ずつ使用した。増し糸は22dtexナイロン66モノフィラメントを絡み糸と地糸の間に片側4本ずつ使用して、平織とした。その後、実施例3と同様な後加工を実施し、目的の基布を得た。この基布を実施例1と同様な評価を行い、以下の表2に示す結果を得た。この条件は織密度が過剰に高すぎる為に、基布の剛軟度が非常に高い物となった。

[Comparative Example 5]

The same warping was performed except that the same yarn as in Example 2 was used and the warp density was 52 / inch. Using this warp, the weft density design was 53 / inch, and both ears were used as two entangled yarns on each side of 22 dtex nylon 66 monofilament. The reinforce yarn was made into a plain weave by using 22 dtex nylon 66 monofilament and four pieces on each side between the entangled yarn and the ground yarn. Then, the post-processing similar to Example 3 was implemented, and the target base fabric was obtained. This base fabric was evaluated in the same manner as in Example 1, and the results shown in Table 2 below were obtained. Under these conditions, the weave density was too high, and the bending resistance of the base fabric was very high.

[比較例6]

実施例2と同じ糸条を用い、経密度を38本/inchとした以外は、同様な整経を行った。この経糸を用いて緯糸密度を39本/inchとしてそれ以外は実施例2と同じ条件で製織し、実施例3と同じ条件で加工を行い、目的の基布を得た。この基布について実施例1と同様な評価を行い、以下の表2に示す結果を得た。この条件は織密度が低すぎる為に、気密性が損なわれ、作製したバッグのバーストが認められた。

[Comparative Example 6]

The same warp was performed except that the same yarn as in Example 2 was used and the warp density was 38 / inch. Using this warp, the weft density was set to 39 / inch, and weaving was performed under the same conditions as in Example 2 and processed under the same conditions as in Example 3 to obtain the desired base fabric. Evaluation similar to Example 1 was performed about this base fabric, and the result shown in the following Table 2 was obtained. Under these conditions, since the weave density was too low, the airtightness was impaired, and a burst of the produced bag was observed.

比較例1〜6から明らかなように、前記発明[1]の範囲外の物は、縫目に負荷がかかった場合に縫目部分の気密性の維持が出来なくなったり、引裂き強力が低下し、作製したバッグにバーストが発生する不具合や、基布が硬くなって課題が達成できないことが認められた。 As is clear from Comparative Examples 1 to 6, the thing outside the range of the invention [1] cannot maintain the airtightness of the seam portion when a load is applied to the seam, or the tear strength is reduced. It was confirmed that the problem was not able to be achieved because of the inconvenience of bursting in the produced bag and the base fabric becoming hard.

本発明に係る織物基布は、気密性が高く柔軟で、収納性に優れかつ、生産性の高いエアバッグ用基布として好適に利用可能である。 The fabric base fabric according to the present invention can be suitably used as an airbag base fabric having high airtightness and flexibility, excellent storage properties, and high productivity.

Claims (7)

(1)下記式1:

Z=(Ww×Dw+Wf×Df)−50.8

{式中、Ww=経糸最大幅(μm)、Dw=経糸密度(本/inch)、Wf=緯糸最大幅(μm)、Df=緯糸密度(本/inch)}で表されるZ値が0〜7である;

(2)下記式2:

Q=q/S

{式中、q=ASTM_D6476で測定された30〜70kPa間のADAP(mm/s)、S=基布目付(g/m2)}で表されるQ値が0.5〜2.5である;

(3)下記式3:

CF=((Tw/ρ)0.5×Dw)+(Tf/ρ)0.5×Df)

{式中、Tw=経糸繊度(Dtex)、Tf=緯糸繊度(Dtex)、ρ=繊維密度(g/cm3)}で表されるカバーファクター(CF)が1850〜2200である;及び

(4)ポリオレフィン樹脂、シリコン樹脂、及びエステル類からなる群から選択されたいずれか1種又は2種以上の混合物が、該織物基布の繊維表面に該繊維重量に対し100〜3000ppmで存在している;

を満たす前記基布。 A fabric base fabric plain woven with warp and weft yarns of a thermoplastic resin having a round cross section with a single yarn of 1.5 or more and less than 7 dtex, under the following conditions:

(1) The following formula 1:

Z = (Ww × Dw + Wf × Df) −50.8

{Where Z value represented by Ww = maximum warp width (μm), Dw = warp density (main / inch), Wf = maximum weft width (μm), Df = weft density (main / inch)} is 0 ~ 7;

(2) Formula 2 below:

Q = q / S

{In the formula, q = 30 to 70 kPa of ADAP (mm / s) measured by ASTM_D6476, S = basis weight (g / m 2 )} Q value is 0.5 to 2.5 is there;

(3) Formula 3 below:

CF = ((Tw / ρ) 0.5 × Dw) + (Tf / ρ) 0.5 × Df)

{Wherein the cover factor (CF) represented by Tw = warp fineness (Dtex), Tf = weft fineness (Dtex), ρ = fiber density (g / cm 3 )} is 1850-2200; and (4 ) Any one or a mixture of two or more selected from the group consisting of polyolefin resins, silicone resins, and esters is present on the fiber surface of the fabric base fabric at 100 to 3000 ppm based on the fiber weight. ;

Satisfying the base fabric.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014060328A JP2015183309A (en) | 2014-03-24 | 2014-03-24 | Woven base cloth for air-bag |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014060328A JP2015183309A (en) | 2014-03-24 | 2014-03-24 | Woven base cloth for air-bag |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2018209966A Division JP6694490B2 (en) | 2018-11-07 | 2018-11-07 | Fabric base fabric for airbags |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2015183309A true JP2015183309A (en) | 2015-10-22 |

| JP2015183309A5 JP2015183309A5 (en) | 2017-03-30 |

Family

ID=54350192

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014060328A Withdrawn JP2015183309A (en) | 2014-03-24 | 2014-03-24 | Woven base cloth for air-bag |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2015183309A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020002969A (en) * | 2018-06-26 | 2020-01-09 | コスモ工機株式会社 | Stop fluid plug |

| WO2021193966A1 (en) | 2020-03-26 | 2021-09-30 | 旭化成株式会社 | Base cloth for material and manufacturing method therefor |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH09302550A (en) * | 1996-05-15 | 1997-11-25 | Toray Ind Inc | Base fabric for air bag and air bag |

| JP2002363835A (en) * | 2001-06-06 | 2002-12-18 | Toray Ind Inc | Woven fabric for air bag, method for producing the same and air bag |

| JP2009256860A (en) * | 2008-03-21 | 2009-11-05 | Toray Ind Inc | Woven fabric for air bag and method for producing woven fabric for air bag |

| JP2010174390A (en) * | 2009-01-28 | 2010-08-12 | Toray Ind Inc | Woven fabric for airbag, and method for producing the same |

| WO2011162073A1 (en) * | 2010-06-24 | 2011-12-29 | 松本油脂製薬株式会社 | Synthetic fiber treatment agent for airbag, synthetic fiber filament for airbag, and base fabric for airbag |

| WO2013133382A1 (en) * | 2012-03-09 | 2013-09-12 | 旭化成せんい株式会社 | Base fabric for airbag |

| WO2013168728A1 (en) * | 2012-05-11 | 2013-11-14 | 東洋紡株式会社 | Airbag base fabric that is unlikely to bottom at impact |

| WO2014003392A1 (en) * | 2012-06-29 | 2014-01-03 | 코오롱인더스트리 주식회사 | Fabric for airbag and method for manufacturing same |

-

2014

- 2014-03-24 JP JP2014060328A patent/JP2015183309A/en not_active Withdrawn

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH09302550A (en) * | 1996-05-15 | 1997-11-25 | Toray Ind Inc | Base fabric for air bag and air bag |

| JP2002363835A (en) * | 2001-06-06 | 2002-12-18 | Toray Ind Inc | Woven fabric for air bag, method for producing the same and air bag |

| JP2009256860A (en) * | 2008-03-21 | 2009-11-05 | Toray Ind Inc | Woven fabric for air bag and method for producing woven fabric for air bag |

| JP2010174390A (en) * | 2009-01-28 | 2010-08-12 | Toray Ind Inc | Woven fabric for airbag, and method for producing the same |

| WO2011162073A1 (en) * | 2010-06-24 | 2011-12-29 | 松本油脂製薬株式会社 | Synthetic fiber treatment agent for airbag, synthetic fiber filament for airbag, and base fabric for airbag |

| WO2013133382A1 (en) * | 2012-03-09 | 2013-09-12 | 旭化成せんい株式会社 | Base fabric for airbag |

| WO2013168728A1 (en) * | 2012-05-11 | 2013-11-14 | 東洋紡株式会社 | Airbag base fabric that is unlikely to bottom at impact |

| WO2014003392A1 (en) * | 2012-06-29 | 2014-01-03 | 코오롱인더스트리 주식회사 | Fabric for airbag and method for manufacturing same |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020002969A (en) * | 2018-06-26 | 2020-01-09 | コスモ工機株式会社 | Stop fluid plug |

| JP7118506B2 (en) | 2018-06-26 | 2022-08-16 | コスモ工機株式会社 | stop current plug |

| WO2021193966A1 (en) | 2020-03-26 | 2021-09-30 | 旭化成株式会社 | Base cloth for material and manufacturing method therefor |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5679076B2 (en) | Woven fabric and its manufacturing method | |

| JP5100895B2 (en) | Airbag base fabric | |

| KR102358963B1 (en) | Polyester airbag for airbag, polyester airbag and method for manufacturing polyester airbag for airbag | |

| JP6760067B2 (en) | Manufacturing method of airbag base cloth, airbag and airbag base cloth | |

| JP6013710B2 (en) | Airbag fabrics and airbags | |

| JP6011721B2 (en) | Airbag base fabric and manufacturing method thereof | |

| BR112019022728A2 (en) | FABRIC FABRIC WITH LOW PERMEABILITY AND HIGH RESISTANCE AND METHODS FOR THE PRODUCTION OF THE SAME | |

| CN104060366A (en) | High-density fabric | |

| JP2009035834A (en) | Method for producing base fabric for airbag | |

| JPWO2014123090A1 (en) | Airbag fabrics and fabric rolls | |

| JP2015183309A (en) | Woven base cloth for air-bag | |

| US10385482B2 (en) | Woven fabric | |

| JP7188393B2 (en) | Airbag base fabric and airbag including the same | |

| JP6694490B2 (en) | Fabric base fabric for airbags | |

| JP2015110857A (en) | Air bag base fabric | |

| JP2007023411A (en) | Woven fabric for air bag, air bag and method for producing woven fabric for air bag | |

| JP3745627B2 (en) | High density fabric | |

| CN104294443A (en) | Airbag fabric and production method thereof | |

| JP3544179B2 (en) | Weaving method of high density fabric | |

| CN115349037A (en) | Base cloth for materials and method for producing the same | |

| WO2020179456A1 (en) | Base fabric for airbag, and manufacturing method of base fabric for airbag | |

| CN111155219A (en) | Fabric for airbag, method for producing same, and airbag | |

| JP5789068B2 (en) | Airbag fabric | |

| CN104743386B (en) | Wide cut high-density fabric is rolled up | |

| JP7068633B2 (en) | Non-coated woven fabric for airbags and airbags using it |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A712 Effective date: 20160404 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170223 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20170223 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20180129 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20180206 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180406 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20180807 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20181107 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20181114 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20181207 |

|

| A761 | Written withdrawal of application |

Free format text: JAPANESE INTERMEDIATE CODE: A761 Effective date: 20181217 |