JP2014513766A - タービンエンジン燃焼器の点検システム - Google Patents

タービンエンジン燃焼器の点検システム Download PDFInfo

- Publication number

- JP2014513766A JP2014513766A JP2014509300A JP2014509300A JP2014513766A JP 2014513766 A JP2014513766 A JP 2014513766A JP 2014509300 A JP2014509300 A JP 2014509300A JP 2014509300 A JP2014509300 A JP 2014509300A JP 2014513766 A JP2014513766 A JP 2014513766A

- Authority

- JP

- Japan

- Prior art keywords

- camera

- inspection system

- support shaft

- camera support

- extendable

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000007689 inspection Methods 0.000 title claims abstract description 93

- 238000013523 data management Methods 0.000 claims description 21

- 230000007704 transition Effects 0.000 claims description 8

- 238000004458 analytical method Methods 0.000 claims description 3

- 238000013024 troubleshooting Methods 0.000 abstract description 3

- 238000012423 maintenance Methods 0.000 abstract description 2

- 230000003449 preventive effect Effects 0.000 abstract description 2

- 239000007789 gas Substances 0.000 description 10

- 230000008901 benefit Effects 0.000 description 6

- 239000000446 fuel Substances 0.000 description 4

- 238000005286 illumination Methods 0.000 description 3

- 230000009467 reduction Effects 0.000 description 3

- 239000012720 thermal barrier coating Substances 0.000 description 3

- 238000011960 computer-aided design Methods 0.000 description 2

- 230000007797 corrosion Effects 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- 230000007547 defect Effects 0.000 description 2

- 229910052736 halogen Inorganic materials 0.000 description 2

- 150000002367 halogens Chemical class 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 239000010453 quartz Substances 0.000 description 2

- 238000012552 review Methods 0.000 description 2

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- 230000006978 adaptation Effects 0.000 description 1

- 239000000567 combustion gas Substances 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 238000007405 data analysis Methods 0.000 description 1

- 238000013480 data collection Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 230000037406 food intake Effects 0.000 description 1

- 231100001261 hazardous Toxicity 0.000 description 1

- 238000011065 in-situ storage Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

- 238000011179 visual inspection Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23M—CASINGS, LININGS, WALLS OR DOORS SPECIALLY ADAPTED FOR COMBUSTION CHAMBERS, e.g. FIREBRIDGES; DEVICES FOR DEFLECTING AIR, FLAMES OR COMBUSTION PRODUCTS IN COMBUSTION CHAMBERS; SAFETY ARRANGEMENTS SPECIALLY ADAPTED FOR COMBUSTION APPARATUS; DETAILS OF COMBUSTION CHAMBERS, NOT OTHERWISE PROVIDED FOR

- F23M11/00—Safety arrangements

- F23M11/04—Means for supervising combustion, e.g. windows

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D21/00—Shutting-down of machines or engines, e.g. in emergency; Regulating, controlling, or safety means not otherwise provided for

- F01D21/003—Arrangements for testing or measuring

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D9/00—Stators

- F01D9/02—Nozzles; Nozzle boxes; Stator blades; Guide conduits, e.g. individual nozzles

- F01D9/023—Transition ducts between combustor cans and first stage of the turbine in gas-turbine engines; their cooling or sealings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C7/00—Features, components parts, details or accessories, not provided for in, or of interest apart form groups F02C1/00 - F02C6/00; Air intakes for jet-propulsion plants

- F02C7/20—Mounting or supporting of plant; Accommodating heat expansion or creep

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23M—CASINGS, LININGS, WALLS OR DOORS SPECIALLY ADAPTED FOR COMBUSTION CHAMBERS, e.g. FIREBRIDGES; DEVICES FOR DEFLECTING AIR, FLAMES OR COMBUSTION PRODUCTS IN COMBUSTION CHAMBERS; SAFETY ARRANGEMENTS SPECIALLY ADAPTED FOR COMBUSTION APPARATUS; DETAILS OF COMBUSTION CHAMBERS, NOT OTHERWISE PROVIDED FOR

- F23M7/00—Doors

-

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N7/00—Television systems

- H04N7/18—Closed-circuit television [CCTV] systems, i.e. systems in which the video signal is not broadcast

- H04N7/183—Closed-circuit television [CCTV] systems, i.e. systems in which the video signal is not broadcast for receiving images from a single remote source

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R2900/00—Special features of, or arrangements for continuous combustion chambers; Combustion processes therefor

- F23R2900/00019—Repairing or maintaining combustion chamber liners or subparts

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Multimedia (AREA)

- Signal Processing (AREA)

- Investigating Materials By The Use Of Optical Means Adapted For Particular Applications (AREA)

- Testing Of Devices, Machine Parts, Or Other Structures Thereof (AREA)

- Instruments For Viewing The Inside Of Hollow Bodies (AREA)

- Testing Of Engines (AREA)

Abstract

【選択図】図1

Description

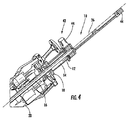

12 点検システムハウジング

14 内部チャンバー

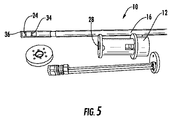

16 延伸可能なカメラ支持シャフト

18 パイロットノズル接続口

20 燃焼器(燃焼器内筒)

22 ガスタービンエンジン

24 カメラ

26 長手軸

28 末端開口部

32 レンズ

34 カメラ収容空洞

38 長手軸に直交する軸

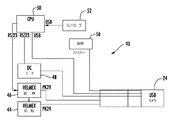

40 データ管理システム

44、46、48 モータ

50 CPU(中央処理ユニット)

52 コントローラ

56 照明

Claims (14)

- タービンエンジン(22)の点検システム(10)であって、

少なくとも1つの内部チャンバー(14)を含む少なくとも1つの点検システムハウジング(12)と、

前記少なくとも1つの内部チャンバー(14)内に設置され、前記少なくとも1つの点検システムハウジング(12)の末端開口部(28)から遠方へ延びる少なくとも1つの延伸可能なカメラ支持シャフト(16)と、

前記少なくとも1つの点検システムハウジング(12)の外側で前記末端開口部(28)から遠い方の位置で、前記少なくとも1つの延伸可能なカメラ支持シャフト(16)により支持された少なくとも1つのカメラレンズ(32)と、

前記少なくとも1つのカメラレンズ(32)と連動する少なくとも1つのカメラ(24)により取り込まれた少なくとも1つの画像を伴った詳細な画像情報を座標化すべく構成されたデータ管理システム(40)とを有し、

前記少なくとも1つの点検システムハウジング(12)は、前記タービンエンジン(22)の燃焼器(20)内のパイロットノズル接続口(18)に取付け可能であり、

前記少なくとも1つの延伸可能なカメラ支持シャフト(16)は、この少なくとも1つの延伸可能なカメラ支持シャフト(16)の長手軸(26)の周りに回転可能であり、

前記少なくとも1つの延伸可能なカメラ支持シャフト(16)は、この少なくとも1つの延伸可能なカメラ支持シャフト(16)が前記長手軸(26)に沿って長手方向に移動できるように延伸可能であり、

前記少なくとも1つのカメラレンズ(32)は、前記少なくとも1つの延伸可能なカメラ支持シャフト(16)の長手軸(26)に対してほぼ直交する軸(38)の周りに回転可能である

ことを特徴とするタービンエンジン(22)の点検システム(10)。 - 前記少なくとも1つのカメラ(24)が前記少なくとも1つの延伸可能なカメラ支持シャフト(16)に取付られ、前記少なくとも1つのカメラレンズ(32)が前記少なくとも1つのカメラ(24)に取付けられていることを特徴とする請求項1に記載の点検システム(10)。

- 前記少なくとも1つのカメラ(24)が前記少なくとも1つの延伸可能なカメラ支持シャフト(16)の遠方末端(36)に配設されていることを特徴とする請求項1に記載の点検システム(10)。

- 前記少なくとも1つの延伸可能なカメラ支持シャフト(16)が1本のチューブであることを特徴とする請求項1に記載の点検システム(10)。

- 前記少なくとも1つの延伸可能なカメラ支持シャフト(16)が1つのカメラ収容空洞(34)を含み、前記少なくとも1つのカメラ(24)が少なくとも部分的にこのカメラ収容空洞(34)内に設置されていることを特徴とする請求項4に記載の点検システム(10)。

- 前記少なくとも1つのモータ(44)が回転における変化のために、前記少なくとも1つの延伸可能なカメラ支持シャフト(16)を回転するように構成された前記少なくとも1つの延伸可能なカメラ支持シャフト(16)と連動することをさらに特徴とする請求項1に記載の点検システム(10)。

- 前記少なくとも1つのモータ(46)が、横方向における変化のために、前記少なくとも1つの延伸可能なカメラ支持シャフト(16)をその長手軸(26)に沿って動かするように構成された前記少なくとも1つの延伸可能なカメラ支持シャフト(16)と連動することをさらに特徴とする請求項1に記載の点検システム(10)。

- 前記少なくとも1つのモータ(48)が前記少なくとも1つのカメラレンズ(32)の傾斜を変えるために、前記少なくとも1つの延伸可能なカメラ支持シャフト(16)の長手軸(26)とほぼ直交する軸(38)の周りにこのレンズを回転するために前記少なくとも1つのカメラレンズ(32)と連動することをさらに特徴とする請求項1に記載の点検システム(10)。

- 前記データ管理システム(40)がメタデータとしての複数の画像と複数の位置座標との相関をとることを特徴とする請求項1に記載の点検システム(10)。

- 前記データ管理システム(40)が複数の位置座標を伴った複数の画像を記憶することを特徴とする請求項1に記載の点検システム(10)。

- 前記データ管理システム(40)が、タービンエンジン(22)内部の特定コンポーネントの期間延長を演算するために、複数のアルゴリズムと共に、分析用の複数の位置座標を伴った複数の画像を提供することを特徴とする請求項1に記載の点検システム(10)。

- 前記少なくとも1つのカメラレンズ(32)が自動フォーカスレンズと手動フォーカスレンズとの組合せであることを特徴とする請求項1に記載の点検システム(10)。

- 前記少なくとも1つのカメラ(24)が電荷結合デバイス(CCD)カメラであることを特徴とする請求項1に記載の点検システム(10)。

- 前記少なくとも1つの延伸可能なカメラ支持シャフト(16)が、パイロットノズル接続口(18)において前記少なくとも1つの点検システムハウジング(12)から前記燃焼器(20)を通って、この燃焼器(20)の遠い方の移行部の遠方末端(36)に至るまで延長するように寸法決めされており、前記少なくとも1つの延伸可能なカメラ支持シャフト(16)は入れ子式に伸縮自在であることを特徴とする請求項1に記載の点検システム(10)。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/101,338 | 2011-05-05 | ||

| US13/101,338 US8786848B2 (en) | 2011-05-05 | 2011-05-05 | Inspection system for a combustor of a turbine engine |

| PCT/US2012/033893 WO2012151046A2 (en) | 2011-05-05 | 2012-04-17 | Inspection system for a combustor of a turbine engine |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2014513766A true JP2014513766A (ja) | 2014-06-05 |

| JP2014513766A5 JP2014513766A5 (ja) | 2015-04-23 |

Family

ID=46001849

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014509300A Pending JP2014513766A (ja) | 2011-05-05 | 2012-04-17 | タービンエンジン燃焼器の点検システム |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8786848B2 (ja) |

| EP (1) | EP2705304B1 (ja) |

| JP (1) | JP2014513766A (ja) |

| KR (1) | KR101944962B1 (ja) |

| CN (1) | CN103649641B (ja) |

| CA (1) | CA2834739A1 (ja) |

| WO (1) | WO2012151046A2 (ja) |

Families Citing this family (36)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102011114541A1 (de) * | 2011-09-30 | 2013-04-04 | Lufthansa Technik Ag | Endoskopiesystem und korrespondierendesVerfahren zur Untersuchung von Gasturbinen |

| US8922640B2 (en) | 2012-01-31 | 2014-12-30 | Siemens Energy, Inc. | System and method for automated optical inspection of industrial gas turbines and other power generation machinery with articulated multi-axis inspection scope |

| US10274718B2 (en) * | 2012-01-31 | 2019-04-30 | Siemens Energy, Inc. | Single-axis inspection scope with anti-rotation extension and method for internal inspection of power generation machinery |

| US10281712B2 (en) | 2012-01-31 | 2019-05-07 | Siemens Energy, Inc. | Single-axis inspection scope with bendable knuckle and method for internal inspection of power generation machinery |

| US9154743B2 (en) * | 2012-01-31 | 2015-10-06 | Siemens Energy, Inc. | System and method for optical inspection of off-line industrial gas turbines and other power generation machinery while in turning gear mode |

| US8713999B2 (en) * | 2012-01-31 | 2014-05-06 | Siemens Energy, Inc. | System and method for automated optical inspection of industrial gas turbines and other power generation machinery with multi-axis inspection scope |

| US9709463B2 (en) | 2012-01-31 | 2017-07-18 | Siemens Energy, Inc. | Method and system for surface profile inspection of off-line industrial gas turbines and other power generation machinery |

| US9057710B2 (en) | 2012-01-31 | 2015-06-16 | Siemens Energy, Inc. | System and method for automated optical inspection of industrial gas turbines and other power generation machinery |

| US9116071B2 (en) * | 2012-01-31 | 2015-08-25 | Siemens Energy, Inc. | System and method for visual inspection and 3D white light scanning of off-line industrial gas turbines and other power generation machinery |

| US9948835B2 (en) | 2012-01-31 | 2018-04-17 | Siemens Energy, Inc. | Single-axis inspection scope with spherical camera and method for internal inspection of power generation machinery |

| US9778141B2 (en) | 2012-01-31 | 2017-10-03 | Siemens Energy, Inc. | Video inspection system with deformable, self-supporting deployment tether |

| JP5946733B2 (ja) * | 2012-09-24 | 2016-07-06 | 三菱日立パワーシステムズ株式会社 | 燃焼器の隙間計測装置及び隙間計測方法 |

| US9228941B2 (en) * | 2012-11-07 | 2016-01-05 | Solar Turbines Incorporated | Combustor imaging inspection system |

| US9182285B2 (en) * | 2013-08-15 | 2015-11-10 | Siemens Energy, Inc. | Methods regarding optical probe having an inner tube with separable tube sections to house optical elements |

| US9195044B2 (en) | 2013-08-15 | 2015-11-24 | Siemens Energy, Inc | Optical probe having an inner tube with separable tube sections to house optical elements |

| US9518895B2 (en) | 2013-08-15 | 2016-12-13 | Siemens Energy, Inc. | Optical probe with improved affixing structure for supporting a light-redirecting element |

| US9599537B2 (en) | 2013-08-21 | 2017-03-21 | Siemens Energy, Inc. | Internal inspection of machinery by stitched surface imaging |

| US9470147B2 (en) | 2013-11-12 | 2016-10-18 | Siemens Energy, Inc. | Apparatus and method for determining a temperature distribution of a hot-temperature flow in a turbine engine |

| US9670795B2 (en) | 2014-02-26 | 2017-06-06 | Siemens Energy, Inc. | Method for inspecting a turbine engine rotor with a rotor disc cavity inspection apparatus |

| US9681107B2 (en) * | 2014-05-22 | 2017-06-13 | Siemens Energy, Inc. | Flexible tether position tracking camera inspection system for visual inspection of off line industrial gas turbines and other power generation machinery |

| US9618424B2 (en) * | 2014-07-18 | 2017-04-11 | Siemens Energy, Inc. | Gas turbine inspection apparatus and method and system for inspecting a gas turbine |

| US9459153B2 (en) * | 2014-09-17 | 2016-10-04 | General Electric Company | Automated analytics systems and methods |

| US10041371B1 (en) | 2015-02-06 | 2018-08-07 | Siemens Energy, Inc. | In-situ measurement of blade tip-to-shroud gap in turbine engine |

| DE102016113406B4 (de) * | 2015-07-20 | 2022-02-10 | Siemens Energy, Inc. | Einachsiges Inspektionsendoskop mit sphärischer Kamera und Verfahren für die interne Inspektion von Stromerzeugungsmaschinen |

| US10119863B2 (en) * | 2016-11-07 | 2018-11-06 | Siemens Energy, Inc. | Flash thermography photobox |

| US11111813B2 (en) * | 2016-12-06 | 2021-09-07 | General Electric Company | Gas turbine engine maintenance method |

| US10533901B2 (en) * | 2017-06-06 | 2020-01-14 | General Electric Company | Imaging system for inspecting components of turbomachines and method of assembly thereof |

| SE541623C2 (en) * | 2017-10-11 | 2019-11-12 | Chris Marine Ab | Liner imaging device and a method for establishing an image of an inner wall of a liner |

| US12194620B2 (en) | 2018-10-15 | 2025-01-14 | Oliver Crisipin Robotics Limited | Selectively flexible extension tool |

| US11702955B2 (en) | 2019-01-14 | 2023-07-18 | General Electric Company | Component repair system and method |

| CN209105309U (zh) * | 2019-01-22 | 2019-07-12 | 京东方科技集团股份有限公司 | 摄像装置及终端设备 |

| US11260477B2 (en) * | 2019-05-02 | 2022-03-01 | MTU Aero Engines AG | Repair tool for turbomachinery and related method |

| DE102019219273A1 (de) * | 2019-12-10 | 2021-06-10 | MTU Aero Engines AG | Verfahren zum vermessen eines bauteils einer strömungsmaschine |

| US12091981B2 (en) | 2020-06-11 | 2024-09-17 | General Electric Company | Insertion tool and method |

| DE102020135067A1 (de) | 2020-12-29 | 2022-06-30 | Chemin Gmbh | Sondenkopf und Verwendung eines Sondenkopfs |

| CN113514469B (zh) * | 2021-05-28 | 2024-06-04 | 华能苏州热电有限责任公司 | 一种环形燃烧室燃机透平叶片孔窥检查辅助工装及方法 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050073673A1 (en) * | 2003-10-01 | 2005-04-07 | General Electric Company | Imaging system for robotically inspecting gas turbine combustion components |

| JP2009510302A (ja) * | 2005-09-26 | 2009-03-12 | シーメンス アクチエンゲゼルシヤフト | 露出した開口部を備えるコーティングされるべきガスタービン構成部品を製造する方法、この方法を実施する装置、およびフィルム冷却開口部を備えるコーティング可能なタービン羽根 |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6009189A (en) * | 1996-08-16 | 1999-12-28 | Schaack; David F. | Apparatus and method for making accurate three-dimensional size measurements of inaccessible objects |

| GB2333595B (en) * | 1996-08-16 | 2001-03-21 | David Francis Schaack | Apparatus and method for making accurate three-dimensional size measurements of inaccessible objects |

| GB9816421D0 (en) * | 1998-07-28 | 1998-09-23 | Keymed Medicals & Ind Equip | Apparatus for delivering laser energy to a remote location |

| US7690840B2 (en) | 1999-12-22 | 2010-04-06 | Siemens Energy, Inc. | Method and apparatus for measuring on-line failure of turbine thermal barrier coatings |

| US6414458B1 (en) * | 2000-12-19 | 2002-07-02 | General Electric Company | Apparatus for robotically inspecting gas turbine combustion components |

| US6532840B2 (en) * | 2000-12-19 | 2003-03-18 | General Electric Company | Methods for robotically inspecting gas turbine combustion components |

| US6380512B1 (en) * | 2001-10-09 | 2002-04-30 | Chromalloy Gas Turbine Corporation | Method for removing coating material from a cooling hole of a gas turbine engine component |

| EP1532433A2 (en) | 2002-08-28 | 2005-05-25 | Wayne State University | System for infrared imaging by inducing acoustic chaos |

| US7121098B2 (en) | 2003-04-30 | 2006-10-17 | Siemens Power Generation, Inc. | High-temperature inspection device and cooling apparatus therefor |

| US6992315B2 (en) | 2004-03-10 | 2006-01-31 | Siemens Westinghouse Power Corporation | In situ combustion turbine engine airfoil inspection |

| US7294817B2 (en) | 2004-05-06 | 2007-11-13 | Siemens Power Generation, Inc. | System and methods for determining nonuniformity correction parameters in detector-array imaging |

| EP1756399B1 (en) * | 2004-06-14 | 2010-03-31 | Gas Turbine Efficiency AB | System and devices for collecting and treating waste water from engine washing |

| US7489811B2 (en) | 2004-10-08 | 2009-02-10 | Siemens Energy, Inc. | Method of visually inspecting turbine blades and optical inspection system therefor |

| US7231817B2 (en) | 2005-01-18 | 2007-06-19 | Siemens Power Generation, Inc. | Inspection system for a turbine blade region of a turbine engine |

| US7689003B2 (en) | 2006-03-20 | 2010-03-30 | Siemens Energy, Inc. | Combined 2D and 3D nondestructive examination |

| US7887234B2 (en) | 2006-10-20 | 2011-02-15 | Siemens Corporation | Maximum blade surface temperature estimation for advanced stationary gas turbines in near-infrared (with reflection) |

| US7961401B1 (en) * | 2009-12-23 | 2011-06-14 | Ge Inspection Technologies, Lp | System for providing two position zoom-focus |

-

2011

- 2011-05-05 US US13/101,338 patent/US8786848B2/en active Active

-

2012

- 2012-04-17 JP JP2014509300A patent/JP2014513766A/ja active Pending

- 2012-04-17 KR KR1020137032218A patent/KR101944962B1/ko active Active

- 2012-04-17 EP EP12716986.0A patent/EP2705304B1/en active Active

- 2012-04-17 CN CN201280032966.2A patent/CN103649641B/zh active Active

- 2012-04-17 WO PCT/US2012/033893 patent/WO2012151046A2/en active Application Filing

- 2012-04-17 CA CA2834739A patent/CA2834739A1/en not_active Abandoned

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050073673A1 (en) * | 2003-10-01 | 2005-04-07 | General Electric Company | Imaging system for robotically inspecting gas turbine combustion components |

| JP2009510302A (ja) * | 2005-09-26 | 2009-03-12 | シーメンス アクチエンゲゼルシヤフト | 露出した開口部を備えるコーティングされるべきガスタービン構成部品を製造する方法、この方法を実施する装置、およびフィルム冷却開口部を備えるコーティング可能なタービン羽根 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN103649641A (zh) | 2014-03-19 |

| WO2012151046A2 (en) | 2012-11-08 |

| KR20140027390A (ko) | 2014-03-06 |

| EP2705304B1 (en) | 2020-09-16 |

| WO2012151046A3 (en) | 2013-11-28 |

| US8786848B2 (en) | 2014-07-22 |

| CA2834739A1 (en) | 2012-11-08 |

| KR101944962B1 (ko) | 2019-02-01 |

| EP2705304A2 (en) | 2014-03-12 |

| CN103649641B (zh) | 2016-06-08 |

| US20120281084A1 (en) | 2012-11-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2014513766A (ja) | タービンエンジン燃焼器の点検システム | |

| CN104718446B (zh) | 离线工业燃气轮机及其它发电机械的目视检查与三维白光扫描系统和方法 | |

| US9228941B2 (en) | Combustor imaging inspection system | |

| US9709463B2 (en) | Method and system for surface profile inspection of off-line industrial gas turbines and other power generation machinery | |

| US7489811B2 (en) | Method of visually inspecting turbine blades and optical inspection system therefor | |

| US7619728B2 (en) | Methods and systems for in-situ machinery inspection | |

| US9294737B2 (en) | Flexible linkage camera system and method for visual inspection of off line industrial gas turbines and other power generation machinery | |

| CN104797918B (zh) | 燃气轮机燃烧室段内的在线光学监测系统与方法 | |

| US20130335530A1 (en) | System and method for visual inspection and 3d white light scanning of off-line industrial gas turbines and other power generation machinery | |

| US20130335549A1 (en) | System and method for optical inspection of off-line industrial gas turbines and other power generation machinery while in turning gear mode | |

| US20050073673A1 (en) | Imaging system for robotically inspecting gas turbine combustion components | |

| US20170031492A1 (en) | Control of non-destructive testing devices | |

| US20130197855A1 (en) | Method and apparatus to determine temperature of a gas turbine engine | |

| JP4978375B2 (ja) | 排気管内可視化装置 | |

| JP5138148B2 (ja) | 流れ開口面積を測定するための方法及び装置 | |

| US10126175B2 (en) | Long wave infrared sensing for turbomachine | |

| JP2003274228A (ja) | 管内観察装置 | |

| JP3776677B2 (ja) | 煙突内部の点検装置 | |

| CN219104765U (zh) | 一种车内管路检测探头 | |

| US20250054229A1 (en) | 3d imaging for engine assembly inspection | |

| RU105736U1 (ru) | Адаптивное устройство измерения радиального зазора между торцами лопаток вращающегося ротора и корпусом турбины газотурбинного двигателя | |

| WO2019133112A2 (en) | A positioning device and an associated method thereof | |

| JP2009044455A (ja) | 画像監視システム | |

| JPH1115525A (ja) | 設備診断用装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150303 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20150303 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20160224 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160301 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20161004 |