JP2010043837A - 燃焼器燃料ノズルにおける超低噴射角燃料孔 - Google Patents

燃焼器燃料ノズルにおける超低噴射角燃料孔 Download PDFInfo

- Publication number

- JP2010043837A JP2010043837A JP2009140642A JP2009140642A JP2010043837A JP 2010043837 A JP2010043837 A JP 2010043837A JP 2009140642 A JP2009140642 A JP 2009140642A JP 2009140642 A JP2009140642 A JP 2009140642A JP 2010043837 A JP2010043837 A JP 2010043837A

- Authority

- JP

- Japan

- Prior art keywords

- fuel

- fuel nozzle

- swirler

- mixing passage

- swirler vanes

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R3/00—Continuous combustion chambers using liquid or gaseous fuel

- F23R3/28—Continuous combustion chambers using liquid or gaseous fuel characterised by the fuel supply

- F23R3/286—Continuous combustion chambers using liquid or gaseous fuel characterised by the fuel supply having fuel-air premixing devices

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R3/00—Continuous combustion chambers using liquid or gaseous fuel

- F23R3/02—Continuous combustion chambers using liquid or gaseous fuel characterised by the air-flow or gas-flow configuration

- F23R3/04—Air inlet arrangements

- F23R3/10—Air inlet arrangements for primary air

- F23R3/12—Air inlet arrangements for primary air inducing a vortex

- F23R3/14—Air inlet arrangements for primary air inducing a vortex by using swirl vanes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y80/00—Products made by additive manufacturing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C2900/00—Special features of, or arrangements for combustion apparatus using fluid fuels or solid fuels suspended in air; Combustion processes therefor

- F23C2900/07001—Air swirling vanes incorporating fuel injectors

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Nozzles For Spraying Of Liquid Fuel (AREA)

- Pressure-Spray And Ultrasonic-Wave- Spray Burners (AREA)

Abstract

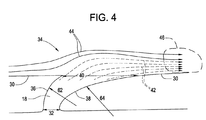

【解決手段】本燃焼器用の燃料ノズル(10)は、それを通して流体が燃焼区域(16)に向かって導かれる混合通路(34)と、該混合通路(34)内に配置された複数のスワーラベーン(18)とを含む。複数のスワーラベーン(18)の各スワーラベーン(18)は、それを通して燃料が該複数のスワーラベーン(18)の外表面(30)にほぼ平行な噴射方向において混合通路(34)に流入し、それによって燃料ノズル(10)の保炎傾向を減少させる1以上の燃料孔(28)を含む。さらに開示するのは、燃焼器用の燃料ノズル(10)を作動させる方法であり、本方法は、複数のスワーラベーン(18)を通過する混合通路(34)内に流体を流すステップと、複数のスワーラベーン(18)の外表面(30)にほぼ平行な噴射方向において混合通路(34)内に燃料を噴射するステップとを含む。

【選択図】 図4

Description

12 スワーラ

14 ノズル入口

16 燃焼区域

18 スワーラベーン

20 中心本体

22 シュラウド

24 プレナム

26 中心本体孔

28 燃料孔

30 外表面

32 調量セクション

34 混合通路

36 リーディング壁

38 トレーリング壁

40 断面積

42 矢印

44 空気流

46 下流区域

48 出口

50 下流端縁部

52 上流端縁部

54 側方端縁部

56 流れ方向

58 フレア角度

60 幅

62 曲率

64 曲率

Claims (10)

- 燃焼器用の燃料ノズル(10)であって、

それを通して流体が燃焼区域(16)に向かって導かれる混合通路(34)と、

前記混合通路(34)内に配置された複数のスワーラベーン(18)と、を含み、

前記複数のスワーラベーン(18)の各スワーラベーン(18)が、それを通して燃料が該複数のスワーラベーン(18)の外表面(30)にほぼ平行な噴射方向において前記混合通路(34)に流入し、それによって該燃料ノズル(10)の保炎傾向を減少させる1以上の燃料孔(28)を

含む燃料ノズル(10)。 - 前記1以上の燃料孔(28)が、前記外表面(30)と接線方向に交差したトレーリング壁(38)を含む、請求項1記載の燃料ノズル(10)。

- 前記トレーリング壁(38)が、前記1以上の燃料孔(28)の対向可能に配置されたリーディング壁(36)よりも大きい曲率半径(62)を有する、請求項2記載の燃料ノズル(10)。

- 前記リーディング壁(36)が、約15〜約55°の範囲内の角度で前記外表面(30)と交差する、請求項3記載の燃料ノズル(10)。

- 前記トレーリング壁(38)の構成が、前記外表面(30)に対する、前記混合通路(34)内への燃料の噴射角度を決定する、請求項2記載の燃料ノズル(10)。

- 前記噴射角度が、前記トレーリング壁(38)が前記外表面(30)と交差する箇所においてほぼ0°である、請求項5記載の燃料ノズル(10)。

- 前記複数のスワーラベーン(18)の各スワーラベーン(18)が、前記1以上の燃料孔(28)を介して前記混合通路(34)に連結された1以上の燃料プレナム(24)を含む、請求項1記載の燃料ノズル(10)。

- 燃焼器用の燃料ノズル(10)を作動させる方法であって、

複数のスワーラベーン(18)を通過する混合通路(34)内に流体を流すステップと、

前記複数のスワーラベーン(18)の外表面(30)にほぼ平行な噴射方向において前記混合通路(34)内に燃料を噴射し、それによって前記燃料ノズル(10)の保炎傾向を減少させるステップと

を含む方法。 - 前記複数のスワーラベーン(18)内に配置された1以上の燃料孔(28)を通して前記混合通路(34)内に燃料を噴射するステップを含む、請求項8記載の方法。

- 前記1以上の燃料孔(28)が、前記外表面(30)と接線方向に交差したトレーリング壁(38)を含む、請求項9記載の方法。

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US12/190,918 US8291705B2 (en) | 2008-08-13 | 2008-08-13 | Ultra low injection angle fuel holes in a combustor fuel nozzle |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010043837A true JP2010043837A (ja) | 2010-02-25 |

| JP2010043837A5 JP2010043837A5 (ja) | 2013-03-07 |

Family

ID=41528288

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009140642A Pending JP2010043837A (ja) | 2008-08-13 | 2009-06-12 | 燃焼器燃料ノズルにおける超低噴射角燃料孔 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US8291705B2 (ja) |

| JP (1) | JP2010043837A (ja) |

| CN (1) | CN101650032A (ja) |

| DE (1) | DE102009025961A1 (ja) |

| FR (1) | FR2935042A1 (ja) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9121609B2 (en) * | 2008-10-14 | 2015-09-01 | General Electric Company | Method and apparatus for introducing diluent flow into a combustor |

| US20130040254A1 (en) * | 2011-08-08 | 2013-02-14 | General Electric Company | System and method for monitoring a combustor |

| US20130192243A1 (en) * | 2012-01-31 | 2013-08-01 | Matthew Patrick Boespflug | Fuel nozzle for a gas turbine engine and method of operating the same |

| US9289826B2 (en) | 2012-09-17 | 2016-03-22 | Honeywell International Inc. | Turbine stator airfoil assemblies and methods for their manufacture |

| US9400104B2 (en) | 2012-09-28 | 2016-07-26 | United Technologies Corporation | Flow modifier for combustor fuel nozzle tip |

| KR102363091B1 (ko) | 2020-07-06 | 2022-02-14 | 두산중공업 주식회사 | 연소기용 노즐, 이를 포함하는 연소기, 및 가스 터빈 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008089298A (ja) * | 2006-10-03 | 2008-04-17 | General Electric Co <Ge> | 天然ガススワール安定化ノズル及び方法に対する液体燃料による機能強化 |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1139004A (en) * | 1966-02-28 | 1969-01-08 | Mini Of Technology | Improvements in or relating to combustion devices |

| US4887425A (en) * | 1988-03-18 | 1989-12-19 | General Electric Company | Fuel spraybar |

| US5351477A (en) * | 1993-12-21 | 1994-10-04 | General Electric Company | Dual fuel mixer for gas turbine combustor |

| EP1096201A1 (de) * | 1999-10-29 | 2001-05-02 | Siemens Aktiengesellschaft | Brenner |

| US6619026B2 (en) * | 2001-08-27 | 2003-09-16 | Siemens Westinghouse Power Corporation | Reheat combustor for gas combustion turbine |

| US6655145B2 (en) * | 2001-12-20 | 2003-12-02 | Solar Turbings Inc | Fuel nozzle for a gas turbine engine |

| US6832481B2 (en) * | 2002-09-26 | 2004-12-21 | Siemens Westinghouse Power Corporation | Turbine engine fuel nozzle |

| US7658076B2 (en) * | 2003-07-04 | 2010-02-09 | Siemens Aktiengesellschaft | Open cooled component for a gas turbine, combustion chamber, and gas turbine |

| US7596950B2 (en) * | 2005-09-16 | 2009-10-06 | General Electric Company | Augmentor radial fuel spray bar with counterswirling heat shield |

| US7703288B2 (en) * | 2005-09-30 | 2010-04-27 | Solar Turbines Inc. | Fuel nozzle having swirler-integrated radial fuel jet |

| US20070163114A1 (en) * | 2006-01-13 | 2007-07-19 | General Electric Company | Methods for fabricating components |

| EP1847684A1 (de) * | 2006-04-21 | 2007-10-24 | Siemens Aktiengesellschaft | Turbinenschaufel |

| EP1847696A1 (de) * | 2006-04-21 | 2007-10-24 | Siemens Aktiengesellschaft | Bauteil für eine gestufte Verbrennung in einer Gasturbine und entsprechende Gasturbine. |

| US20080078182A1 (en) * | 2006-09-29 | 2008-04-03 | Andrei Tristan Evulet | Premixing device, gas turbines comprising the premixing device, and methods of use |

| US20080134685A1 (en) * | 2006-12-07 | 2008-06-12 | Ronald Scott Bunker | Gas turbine guide vanes with tandem airfoils and fuel injection and method of use |

-

2008

- 2008-08-13 US US12/190,918 patent/US8291705B2/en not_active Expired - Fee Related

-

2009

- 2009-06-10 DE DE102009025961A patent/DE102009025961A1/de not_active Withdrawn

- 2009-06-11 FR FR0953896A patent/FR2935042A1/fr not_active Withdrawn

- 2009-06-12 JP JP2009140642A patent/JP2010043837A/ja active Pending

- 2009-06-15 CN CN200910149455A patent/CN101650032A/zh active Pending

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008089298A (ja) * | 2006-10-03 | 2008-04-17 | General Electric Co <Ge> | 天然ガススワール安定化ノズル及び方法に対する液体燃料による機能強化 |

Also Published As

| Publication number | Publication date |

|---|---|

| US8291705B2 (en) | 2012-10-23 |

| US20100037614A1 (en) | 2010-02-18 |

| FR2935042A1 (fr) | 2010-02-19 |

| DE102009025961A1 (de) | 2010-02-18 |

| CN101650032A (zh) | 2010-02-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5773342B2 (ja) | 燃料噴射装置 | |

| US8393157B2 (en) | Swozzle design for gas turbine combustor | |

| JP6335903B2 (ja) | 火炎シート燃焼器ドーム | |

| JP5772245B2 (ja) | 燃料噴射装置 | |

| EP2218966B1 (en) | Fuel injection for gas turbine combustors | |

| US8925323B2 (en) | Fuel/air premixing system for turbine engine | |

| RU2430307C2 (ru) | Устройство впрыскивания смеси воздуха с топливом, камера сгорания и газотурбинный двигатель, снабженные таким устройством | |

| CA2820071C (en) | Axial swirler for a gas turbine burner | |

| JP5850900B2 (ja) | 再熱バーナ配列 | |

| CN102798147B (zh) | 用于燃气涡轮发动机中的流控制的系统和方法 | |

| KR102543858B1 (ko) | 환형 유동로 아키텍쳐를 갖는 시스템 및 방법 | |

| JP5798301B2 (ja) | ガスタービンバーナ | |

| US20120297784A1 (en) | System and method for flow control in gas turbine engine | |

| JP2010159951A (ja) | ガスタービンエンジン内における保炎を強化するための方法及びシステム | |

| JP2011075271A (ja) | ガスタービンノズルのための装置及び方法 | |

| US20180045414A1 (en) | Swirler, burner and combustor for a gas turbine engine | |

| JP2010060275A (ja) | ターボ機械燃焼器用の二次燃料ノズルの旋回角度 | |

| JP2010043837A (ja) | 燃焼器燃料ノズルにおける超低噴射角燃料孔 | |

| JP2004526933A (ja) | 燃料と空気を混合して燃焼させるバーナ装置 | |

| JP2013238386A (ja) | 混合回路を有する燃料噴射器 | |

| WO2011092779A1 (ja) | ガスタービン燃焼器 | |

| KR102405991B1 (ko) | 화염시트 연소기 윤곽형 라이너 | |

| US20150033752A1 (en) | Gas turbine combustion system and method of flame stabilization in such a system | |

| JP6092007B2 (ja) | ガスタービン燃焼器 | |

| JP6417620B2 (ja) | 燃焼器、ガスタービン |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20120607 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130111 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130111 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20130111 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20130131 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130409 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130411 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130709 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130712 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130809 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130814 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130909 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130912 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20131008 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20131203 |