JP2009126376A - Washing brush for car wash, and car wash - Google Patents

Washing brush for car wash, and car wash Download PDFInfo

- Publication number

- JP2009126376A JP2009126376A JP2007304014A JP2007304014A JP2009126376A JP 2009126376 A JP2009126376 A JP 2009126376A JP 2007304014 A JP2007304014 A JP 2007304014A JP 2007304014 A JP2007304014 A JP 2007304014A JP 2009126376 A JP2009126376 A JP 2009126376A

- Authority

- JP

- Japan

- Prior art keywords

- brush

- washing

- car wash

- cleaning

- wash machine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Brushes (AREA)

- Vehicle Cleaning, Maintenance, Repair, Refitting, And Outriggers (AREA)

Abstract

Description

本発明は、自動車あるいは車両の外面の被洗浄面に付着した汚れ等を洗浄する為の洗車機に使用する洗車機用洗浄ブラシ、及びその洗車機用洗浄ブラシを搭載した洗車機に関するものである。 The present invention relates to a washing brush for a car wash machine used in a car wash machine for washing dirt or the like adhering to a surface to be washed of an automobile or a vehicle, and a car wash machine equipped with the washing brush for the car wash machine. .

自動車あるいは車両の外面の被洗浄面に付着した汚れ等を洗浄する為の洗車機に使用する洗浄ブラシ、及びその洗浄ブラシを搭載した洗車機に関しては、使用目的に応じて、さまざまな改良がなされ、例えば、回転軸の周囲にブラシエレメントを植設してなる洗車機用回転ブラシにおいて、ブラシエレメントの密度が回転軸に対する半径方向の内方側で密に、外方側で粗になる植設状態を、回転軸の周方向で繰り返してなることを特徴とする洗車機用回転ブラシ(特許文献1)が考案されている。 Various improvements have been made to cleaning brushes used in car wash machines for washing dirt or the like adhering to the surface to be cleaned of automobiles or vehicles, and car wash machines equipped with the wash brushes, depending on the purpose of use. For example, in a rotating brush for a car wash machine in which brush elements are implanted around the rotating shaft, the density of the brush elements is dense on the inner side in the radial direction with respect to the rotating shaft, and is implanted on the outer side. A rotating brush for car wash machines (Patent Document 1) is devised in which the state is repeated in the circumferential direction of the rotating shaft.

また、被洗浄面に付着した汚れ等を洗浄する為の洗浄ブラシにおいて、前記洗浄ブラシは台座、チャンネルブラシ、及び止め金具より形成されてあり、前記チャンネルブラシはブラシ片、芯線、及び帯状体より形成されてあり、前記ブラシ片は、長尺形状のフィルム状樹脂組成物、及び平板状の合成樹脂発泡体より形成されてあり、前記長尺形状のフィルム状樹脂組成物、及び前記平板状の合成樹脂発泡体を重ね合わせると共に、前記芯線、及び前記帯状体に挟み付けて折り込んで前記チャンネルブラシを形成した後、前記チャンネルブラシが、前記台座に巻き付けて前記止め金具にて固定されてあることを特徴とする洗浄ブラシ(特許文献2)がある。 In the cleaning brush for cleaning dirt and the like adhering to the surface to be cleaned, the cleaning brush is formed of a pedestal, a channel brush, and a metal fitting, and the channel brush includes a brush piece, a core wire, and a belt-like body. The brush piece is formed of a long film-shaped resin composition and a flat synthetic resin foam, and the long film-shaped resin composition and the flat plate-shaped resin composition. After the synthetic resin foam is overlaid and sandwiched between the core wire and the belt-like body to form the channel brush, the channel brush is wound around the base and fixed by the fastener. There is a cleaning brush characterized in that (Patent Document 2).

特許文献1の洗車機用回転ブラシは、ブラシエレメントの密度が回転軸に対する半径方向の内方側で密に、外方側で粗になるよう構成されているので、ブラシエレメントに毛腰を付与し、車体の凹部に洗い残しを生ずることなく、洗車性の良い回転ブラシを提供することはできる。しかしながら、ブラシエレメントは全て略同一の剛性の素材からなる為、素材の剛性を高くすれば毛腰はより強くなるが、車体に傷を付着させやすくなる。また、素材の剛性を低くすれば車体への傷は付着し難くなるが、毛腰が弱く、洗車機用回転ブラシの洗浄性能が劣るという課題を有していた。

The rotating brush for a car wash machine of

特許文献2の洗浄ブラシは、長尺形状のフィルム状樹脂組成物に平板状の合成樹脂発泡体が重ね合わされ、フィルム状樹脂組成物が被洗浄面に当接するよう形成されているので、弾力性に優れた合成樹脂発泡体によりフィルム状樹脂組成物に毛腰が付与され、フィルム状樹脂組成物は毛腰を強く設定して被洗浄面に当接することができる為、優れた洗浄性能を発揮することができる。しかしながら、フィルムとは、一般的に厚みが0.5mm未満の樹脂組成物のことであり、厚みが薄いことから耐衝撃性が極めて弱く、フィルム状樹脂組成物は被洗浄面に繰り返し当接を続けると、破れ、折れ、切れ、裂け等が発生する。その為、洗浄ブラシの耐久性が極めて低いという課題を有していた。 The cleaning brush of Patent Document 2 is formed by laminating a flat synthetic resin foam on a long film-shaped resin composition, and the film-shaped resin composition is formed so as to contact the surface to be cleaned. Synthetic resin foam that gives excellent elasticity to the film-like resin composition, and because the film-like resin composition can strongly set the elasticity and abut against the surface to be cleaned, it exhibits excellent cleaning performance can do. However, the film is generally a resin composition having a thickness of less than 0.5 mm, and since the thickness is small, the impact resistance is extremely weak, and the film-like resin composition repeatedly contacts the surface to be cleaned. If it continues, tearing, breaking, cutting, tearing, etc. will occur. Therefore, there has been a problem that the durability of the cleaning brush is extremely low.

また、合成樹脂発泡体は、フィルム状樹脂組成物に比べてコストが高いことから、洗浄ブラシのコストが上昇するという課題も有していた。 In addition, the synthetic resin foam has a problem that the cost of the cleaning brush is increased because the cost is higher than that of the film-shaped resin composition.

本発明は、上記従来の課題を解決するもので、被洗浄面に傷を付着させることなく、洗い残しの発生のない優れた洗浄性能が長期間に亘り発揮される洗車機用洗浄ブラシ、及びその洗車機用洗浄ブラシを搭載した洗車機を安価にて提供することを目的としている。 The present invention solves the above-described conventional problems, and does not cause scratches on the surface to be cleaned, and a cleaning brush for a car wash machine that exhibits excellent cleaning performance over a long period of time without generation of washing residue, and The object is to provide a car washing machine equipped with the washing brush for the car washing machine at a low cost.

前記従来の課題を解決する為に、請求項1の発明の洗車機用洗浄ブラシは、自動車あるいは車両の外面の被洗浄面に付着した汚れ等を洗浄する為の洗車機に使用する洗車機用洗浄ブラシにおいて、前記洗車機用洗浄ブラシはブラシ部及び軸体を有し、前記ブラシ部は前記軸体の外周部に形成されてあると共に、長尺状の合成樹脂繊維からなる洗浄部材及び補強部材を有するブラシ片を芯線及び帯状体に挟み付けたチャンネルブラシにて形成されたブラシ体、及び前記ブラシ体を前記軸体に固定する固定手段を有し、前記ブラシ体は前記軸体の外周部に螺旋状に装着されてあり、前記ブラシ片は前記補強部材が前記洗浄部材より剛性が大であると共に、前記洗浄部材に重ね合わされ、前記洗浄部材が前記被洗浄面に当接するよう形成されてあるもので、ブラシ片は軸体の回転に伴い、洗浄部材より大の剛性を有する補強部材により強い毛腰が付与されながら、補強部材より小の剛性を有する柔軟な洗浄部材が被洗浄面に当接する。その為、洗車機用洗浄ブラシは、被洗浄面に傷を付着させることなく、優れた洗浄性能が発揮される。なお、剛性とは圧縮、ずれ、捩れ等の外力にたいする物体の変形し難い性質を表わす。主に形状、材質、硬度を設定することにより、洗浄部材、及び補強部材の剛性は設定される。洗浄部材、及び補強部材の剛性を示すひとつの指標として硬度が採用される。硬度とは、物質の硬さを表わし、JISK6253加硫ゴム及び熱可塑性ゴムの硬さ試験方法に記載のデュロメータ硬さ試験により測定した硬度である。 In order to solve the above-mentioned conventional problems, the washing brush for a car wash machine according to the first aspect of the present invention is for a car wash machine used for a car wash machine for washing dirt or the like adhering to an automobile or a surface to be washed of a vehicle. In the cleaning brush, the cleaning brush for a car wash machine has a brush portion and a shaft body, and the brush portion is formed on an outer peripheral portion of the shaft body, and includes a cleaning member and a reinforcement made of a long synthetic resin fiber. A brush body formed by a channel brush in which a brush piece having a member is sandwiched between a core wire and a belt-like body, and fixing means for fixing the brush body to the shaft body, the brush body being an outer periphery of the shaft body The brush piece is formed so that the reinforcing member has a rigidity higher than that of the cleaning member and is superimposed on the cleaning member so that the cleaning member contacts the surface to be cleaned. Have Therefore, as the shaft piece rotates, the brush piece is given a strong bristle by a reinforcing member having a rigidity greater than that of the cleaning member, and a flexible cleaning member having a rigidity smaller than that of the reinforcing member comes into contact with the surface to be cleaned. . Therefore, the cleaning brush for car wash machines exhibits excellent cleaning performance without causing scratches on the surface to be cleaned. The rigidity represents the property that an object is difficult to deform against an external force such as compression, displacement, and twist. The rigidity of the cleaning member and the reinforcing member is set mainly by setting the shape, material, and hardness. Hardness is adopted as one index indicating the rigidity of the cleaning member and the reinforcing member. The hardness represents the hardness of a substance and is a hardness measured by a durometer hardness test described in JIS K6253 vulcanized rubber and thermoplastic rubber hardness test method.

また、洗浄部材は耐摩耗性に優れた合成樹脂繊維からなる為、繰り返し被洗浄面に当接を続けても、折れ、切れ等が発生し難く、洗車機用洗浄ブラシは優れた耐久性を有する。 In addition, since the cleaning member is made of synthetic resin fibers with excellent wear resistance, even if it continues to contact the surface to be cleaned repeatedly, it does not easily break or break, and the washing brush for car wash machines has excellent durability. Have.

さらに、補強部材はコストの低い合成樹脂繊維からなる為、安価にて洗車機用洗浄ブラシを提供することができる。 Furthermore, since the reinforcing member is made of a synthetic resin fiber having a low cost, a washing brush for a car wash machine can be provided at a low cost.

請求項2の発明の洗車機用洗浄ブラシは、特に、請求項1の発明の洗車機用洗浄ブラシにおいて、洗浄部材は長手方向の端部に細分割部が形成されてあるもので、細分割部により被洗浄面の細かな凹凸部分に付着している汚れが掻き取られ、除去される。その為、洗車機用洗浄ブラシの洗浄性能が大幅に向上する。

The cleaning brush for a car wash machine according to the invention of claim 2 is particularly the car brush washing brush according to the invention of

請求項3の発明の洗車機用洗浄ブラシは、特に、請求項1から2の発明の洗車機用洗浄ブラシにおいて、洗浄部材は長手方向に少なくとも一本以上の溝部が形成されてあるもので、溝部に洗浄水を一時的に溜めることができる為、洗車中の保水性が高まる。その為、洗車機用洗浄ブラシの洗浄性能が飛躍的に向上する。

The washing brush for a car wash machine of the invention of claim 3 is the washing brush for a car wash machine of the invention of

請求項4の発明の洗車機用洗浄ブラシは、特に、請求項1から3の発明の洗車機用洗浄ブラシにおいて、洗浄部材は断面の幅と高さが略同一寸法にて形成されてあるもので、チャンネルブラシにて形成されてあるブラシ体が、軸体の外周部に螺旋状に巻き付けられて形成されている場合、ブラシ片は軸体の回転に伴い、洗浄部材の側面が被洗浄面に当接する。従って、洗浄部材の幅と高さが略同一寸法にて形成されてあると、洗浄部材の高さが幅より小にて形成されてある場合に比べて、洗浄部材の被洗浄面にたいする接触面積が広がる。その為、洗車機用洗浄ブラシの洗浄性能が一段と向上する。

The cleaning brush for a car wash machine according to the invention of

請求項5の発明の洗車機用洗浄ブラシは、特に、請求項1から4の発明の洗車機用洗浄ブラシにおいて、ブラシ片は複数本の洗浄部材及び/又は複数本の補強部材が略中央部にて接合されて一体化したシート状体にて形成されてあるもので、洗浄部材及び/又は補強部材はシート状に形成されている。その為、ブラシ片を芯線、及び帯状体に挟み付け、チャンネルブラシを形成する際、長尺状の洗浄部材及び/又は補強部材を一本ずつ並べる作業が簡略化され、作業性が向上するので、洗車機用洗浄ブラシの生産コストの低減につながる。また、洗浄部材及び/又は補強部材は、挟み付けられた芯線と帯状体の間から脱落することが防止される。

The cleaning brush for a car wash machine of the invention of claim 5 is the cleaning brush for a car wash machine of the invention of

請求項6の発明の洗車機は、駆動源と、被洗浄面に散布する洗浄剤及び洗浄水を噴出させるノズルと、洗浄後の被洗浄面を乾燥させる乾燥手段を備えると共に、請求項1から5のいずれか1項に記載の洗車機用洗浄ブラシを搭載したもので、ブラシ片が長期間に亘って毛腰を保持しながら被洗浄面に当接し、高い洗浄性能を有する洗車機用洗浄ブラシが搭載されてある為、洗車機は、駆動源により洗車機用洗浄ブラシの回転を低速に設定すると共に、洗浄時間を短時間に設定した場合においても、優れた洗浄性能が発揮される。

The car wash machine of the invention of

請求項1の発明の洗車機用洗浄ブラシは、ブラシ片が軸体の回転に伴い、補強部材により強い毛腰を付与しながら、柔軟な洗浄部材が被洗浄面に当接するので、被洗浄面に傷を付着させることなく、優れた洗浄性能を発揮することができる。また、洗浄部材、及び補強部材は、耐摩耗性に優れ、安価な合成樹脂繊維からなる為、耐久性に優れた洗車機用洗浄ブラシを、コストを抑えて提供することができる。 In the washing brush for a car wash machine according to the first aspect of the present invention, the flexible cleaning member comes into contact with the surface to be cleaned while the brush piece imparts strong bristle to the reinforcing member as the shaft rotates. Excellent cleaning performance can be exhibited without attaching scratches to the surface. In addition, since the cleaning member and the reinforcing member are made of synthetic resin fibers that are excellent in wear resistance and inexpensive, it is possible to provide a cleaning brush for a car wash machine that is excellent in durability at a reduced cost.

請求項2の発明の洗車機用洗浄ブラシは、洗浄部材が有する細分割部により被洗浄面の細かな凹凸部分に付着している汚れが掻き取られ、除去されるので、洗浄性能が大幅に向上する。 In the washing brush for a car wash machine of the invention of claim 2, the dirt adhering to the fine uneven portions of the surface to be cleaned is scraped and removed by the subdivided portion of the cleaning member, so that the cleaning performance is greatly improved. improves.

請求項3の発明の洗車機用洗浄ブラシは、洗浄部材が有する溝部に洗浄水を一時的に溜め、洗浄部材の洗車中の保水性が高まるので、洗浄性能が飛躍的に向上する。 In the washing brush for a car wash machine according to the third aspect of the present invention, the washing water is temporarily stored in the groove portion of the washing member, and the water retention during washing of the washing member is increased, so that the washing performance is drastically improved.

請求項4の発明の洗車機用洗浄ブラシは、一本あたりの洗浄部材の被洗浄面にたいする接触面積が広がるので、洗浄性能が一段と向上する。 In the washing brush for a car wash machine according to the fourth aspect of the present invention, the contact area with respect to the surface to be cleaned of each cleaning member is increased, so that the cleaning performance is further improved.

請求項5の発明の洗車機用洗浄ブラシは、チャンネルブラシを形成する際の作業性が向上するので、生産コストの低減を図ることができる。また、洗浄部材及び/又は補強部材が、挟み付けられた芯線と帯状体の間から脱落することが防止される。 Since the washing brush for a car wash machine of the invention of claim 5 improves the workability when forming the channel brush, the production cost can be reduced. Further, the cleaning member and / or the reinforcing member is prevented from falling off between the sandwiched core wire and the belt-like body.

請求項6の発明の洗車機は、駆動源により洗車機用洗浄ブラシの回転を低速に設定すると共に、洗浄時間を短時間に設定した場合においても、優れた洗浄性能を発揮することができる。

The car wash machine of the invention of

以下、本発明の実施の形態について図面を参照しながら説明する。なお、この実施の形態により本発明が限定されるものではない。 Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, this invention is not limited by this embodiment.

(実施例1)

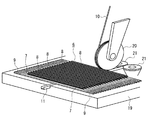

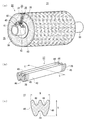

図1(a)は、本発明の第1の実施例における洗車機用洗浄ブラシの正面図、図1(b)は、ブラシ体の断面図、図2(a)は、洗浄部材を前面側から見た斜視図、図2(b)は、図2(a)のA−A断面図、図2(c)は、補強部材を前面側から見た斜視図、図2(d)は、図2(c)のB−B断面図、図3は、本発明の第1の実施例における洗車機用洗浄ブラシを構成する係止具が固定された軸体を前面側から見た斜視図、図4は、チャンネルブラシの製造状態を前面側から見た斜視図である。

Example 1

1A is a front view of a washing brush for a car wash machine according to the first embodiment of the present invention, FIG. 1B is a cross-sectional view of the brush body, and FIG. 2A is a front view of the cleaning member. 2B is a cross-sectional view taken along the line AA of FIG. 2A, FIG. 2C is a perspective view of the reinforcing member as seen from the front side, and FIG. FIG. 2C is a cross-sectional view taken along the line BB of FIG. 2 and FIG. 3 is a perspective view of the shaft body to which the locking member constituting the washing brush for the car wash machine according to the first embodiment of the present invention is fixed viewed from the front side. FIG. 4 is a perspective view of the manufacturing state of the channel brush as seen from the front side.

図1(a)、及び図1(b)において、洗車機用洗浄ブラシ1は、長尺状の洗浄部材7、及び補強部材8からなるブラシ片6を芯線10、及び帯状体11にて挟み付けると共に、折り合わして形成された長尺状のチャンネルブラシ5にて形成されたブラシ体4が、アルミニウム、鉄等の金属材料、あるいは塩化ビニル、ポリアセタール等の合成樹脂材料からなる略円筒形状の軸体3の外周部に螺旋状に巻き付けられ、ブラシ体4の両端部に係止具12を覆い被せ、係止具12の両端部をネジ13にて軸体3に固定して形成されたブラシ部2から構成されている。

1 (a) and 1 (b), a

チャンネルブラシ5を構成する芯線10は、概丸形断面を有する略円柱形状で、アルミニウム、鉄等の金属材料からなる。また、帯状体11は、概コ字状断面を有する長尺状で、アルミニウム、鉄、ステンレス等の金属材料からなる。

The

図1(b)において、ブラシ片6は、長尺状の洗浄部材7と補強部材8が重ね合わされ、芯線10、及び帯状体11にて挟み付けられてチャンネルブラシ5に形成されてあると共に、重ね合わされた洗浄部材7と補強部材8は洗浄部材7が外方となるよう概V字断面を有するように折り合わされている。従って、ブラシ片6は、洗車機用洗浄ブラシ1を構成する軸体3の回転に伴い、洗浄部材7が被洗浄面に当接する。また、洗浄部材7の両端部には細分割部9が形成されてあると共に、洗浄部材7の毛丈は補強部材8の毛丈よりも大となるよう設定されている。さらに、補強部材8は、洗浄部材7よりも剛性が大となるよう設定されている。

In FIG. 1B, the

次に、洗車機用洗浄ブラシ1の製作方法について詳述する。

Next, the manufacturing method of the

最初に、図2(a)の如く、長尺状の合成樹脂繊維からなる洗浄部材7を用意する。図2(a)、及び図2(b)において、洗浄部材7は、概波形断面を有する長尺状であり、両端部には細分割部9が形成されている。洗浄部材7は、概波形断面を有していることから、表面には複数の溝部14が形成されている。洗浄部材7の厚みは0.5〜3mm程度、幅は1〜10mm程度に設定される。厚みが0.5mm未満の場合には、耐久性が劣り、3mmを超える場合には、柔軟性が損なわれる。幅が1mm未満の場合には、毛腰が弱く、10mmを超える場合には、柔軟性が劣ることになる。また、細分割部9に形成された一本あたりのブラシ毛15の幅、及び長さは、洗浄部材7の幅、長さにもよるが、幅は0.05〜0.5mm程度、長さは10〜50mm程度に設定されるのが望ましい。幅が0.05mm未満の場合には、切れやすく耐久性が劣り、0.5mmを超える場合には、被洗浄面の細かな凹凸部分に付着した汚れの掻き取り性能が劣る。長さが10mm未満の場合には、汚れの掻き取り性能が劣り、50mmを超える場合には、毛腰が極めて弱くなる。なお、洗浄部材7の断面形状は、特に限定されるものではなく、概丸形断面でもよく、例えば、十字形断面、M字形断面、N字形断面、卍形断面等の異形断面形状であっても構わない。

First, as shown in FIG. 2A, a cleaning

洗浄部材7は、超低密度ポリエチレン、低密度ポリエチレン、直鎖状低密度ポリエチレン、中密度ポリエチレン、高密度ポリエチレン、ポリプロピレン等のポリオレフィン系の熱可塑性樹脂に、エチレン−αオレフィン共重合体エラストマー、エチレン−αオレフィン架橋共重合体エラストマー、スチレン・エチレン・ブロック共重合体エラストマー等のポリオレフィン系の熱可塑性エラストマーをブレンドしてポリマーアロイされたモノフィラメントである。熱可塑性樹脂に、熱可塑性エラストマーをブレンドしてポリマーアロイするのは、洗浄部材に柔軟性を付与するためである。熱可塑性樹脂と熱可塑性エラストマーの重量配合比率は、熱可塑性樹脂100重量部にたいして、熱可塑性エラストマー1〜10重量部にて設定されるのが望ましい。熱可塑性エラストマーが1重量部未満の場合には、洗浄部材7に柔軟性を付与することが難しく、10重量部を超える場合には洗浄部材7の毛腰が弱くなり、耐久性が劣ることになる。

The cleaning

洗浄部材7の剛性を示すひとつの指標として硬度があり、硬度は、40°以上70°未満に設定されるのが望ましい。硬度が40°未満の場合、柔らかすぎて、被洗浄面に当接した際に摩耗しやすく、耐久性に劣り、70°以上の場合、硬すぎて、被洗浄面に傷を付着させやすくなる。なお、硬度とは、物質の硬さを表わし、JISK6253加硫ゴム及び熱可塑性ゴムの硬さ試験方法に記載のデュロメータ硬さ試験により測定した硬度である。

One index indicating the rigidity of the cleaning

洗浄部材7は、次の手順にて製造される。最初にペレット状、あるいは粉末状の熱可塑性樹脂、及び熱可塑性エラストマーを融点以上の温度にて加熱して溶融する。その際、紫外線吸収剤、架橋剤、顔料等の添加剤を必要に応じて配合しても構わない。次に、押出機の先端に取り付けられた概波形の口金を通して、紡糸する。押し出し後、加熱しながら延伸機にて長手方向に延伸をかけ、延伸後、アニーリングと呼ばれる工程にて冷却固化させることにより、モノフィラメントが形成される。前記の如くの製造方法は、一般的には押出成形と呼ばれている。次に、得られたモノフィラメントを所望の長さに切断し、モノフィラメントの両端部の所定長さを、所定回転速度で回転している分割刃やカッターを有する細分割加工機にて加工することにより、両端部に複数本のブラシ毛15を有する細分割部9が形成された洗浄部材7が製造される。

The cleaning

モノフィラメントの長手方向に延伸をかける上記の如くの方法は、一軸延伸と呼ばれている。一軸延伸は、一方向にのみ延伸応力をかける加工方法であり、延伸方向にたいして平行の方向は、分子配向が起こるので、引張強さが著しく向上するが、延伸方向にたいして直角の方向は、引張強さが向上しない為、延伸方向にたいして平行の方向に、裂けやすくなるという性質を有している。その為、洗浄部材7は、細分割部9を形成することが可能となる。なお、分子配向とは、線状分子が溶融または固体状態において、外力の作用により、一定方向に配列することである。

The above-described method of stretching the monofilament in the longitudinal direction is called uniaxial stretching. Uniaxial stretching is a processing method in which stretching stress is applied only in one direction. In the direction parallel to the stretching direction, molecular orientation occurs, so the tensile strength is remarkably improved, but the direction perpendicular to the stretching direction is tensile strength. Therefore, it has a property that it is easy to tear in a direction parallel to the stretching direction. Therefore, the cleaning

次に、図2(c)の如く、長尺状の合成樹脂繊維からなる補強部材8を用意する。図2(c)、及び図2(d)において、補強部材8は、十字形断面を有する長尺状にて形成されている。補強部材8は、十字形断面を有していることから、4箇所の角部16に洗浄水を一時的に溜めることができるので、洗車中の保水性が高まり、ブラシ片6の洗浄性能の向上につながる。また、補強部材8は、断面の中心に芯部17を有することから、剛性が向上し、洗浄部材7に重ね合わされ、ブラシ片6に形成された場合、洗浄部材7に強い毛腰を付与することができる。補強部材8の幅、及び高さは0.5〜3mm程度に設定される。幅、及び高さが0.5mm未満の場合には、耐久性が劣り、3mmを超える場合には、柔軟性が損なわれる。なお、洗浄部材7の断面形状は、特に限定されるものではなく、概丸形断面でもよく、例えば、M字形断面、N字形断面、卍形断面、概波形断面等の異形断面形状であっても構わない。

Next, as shown in FIG. 2C, a reinforcing

補強部材8は、超低密度ポリエチレン、低密度ポリエチレン、直鎖状低密度ポリエチレン、中密度ポリエチレン、高密度ポリエチレン、ポリプロピレン等のポリオレフィン系の熱可塑性樹脂からなるモノフィラメントである。ポリオレフィン系の熱可塑性樹脂は、吸水率が0%であり、吸水により毛腰が弱くなることがない。また、吸水により洗車機用洗浄ブラシ1の重量が重くなり、洗車機の駆動源にたいする負荷が増すことがなく、長期間に亘り、安定した回転駆動が維持される。また、吸水により、冬季、特に寒冷地におけるブラシ片6の凍結の問題もない。さらに、ポリオレフィン系の熱可塑性樹脂は安価である。

The reinforcing

補強部材8の剛性を示すひとつの指標として硬度があり、硬度は、70°以上90°以下に設定されるのが望ましい。硬度が70°未満の場合、柔らかすぎて、洗浄部材7に強い毛腰を付与することが難しく、90°を超える場合、硬すぎて、ブラシ片6が被洗浄面への当接を繰り返すと、早期に毛折れが発生し、耐久性が劣る。なお、硬度とは、物質の硬さを表わし、JISK6253加硫ゴム及び熱可塑性ゴムの硬さ試験方法に記載のデュロメータ硬さ試験により測定した硬度である。

One index indicating the rigidity of the reinforcing

補強部材8は、次の手順にて製造される。最初にペレット状、あるいは粉末状の熱可塑性樹脂を融点以上の温度にて加熱して溶融する。その際、紫外線吸収剤、架橋剤、顔料等の添加剤を必要に応じて配合しても構わない。次に、押出機の先端に取り付けられた十字形の口金を通して、紡糸する。押し出し後、加熱しながら延伸機にて長手方向に延伸をかけ、延伸後、アニーリングと呼ばれる工程にて冷却固化させることにより、モノフィラメントが形成される。前記の如くの製造方法は、一般的には押出成形と呼ばれている。次に、得られたモノフィラメントを所望の長さに切断し、補強部材8が製造される。補強部材8の毛丈は、洗浄部材7の毛丈以下に設定される。

The reinforcing

次に、図3の如く、略円筒形状の軸体3の外周部の両端部近傍に、複数の爪18を有する係止具12を、ネジ13にて固定する。そして、図4の如く、断面が概コ字状の長尺の帯状体11にたいして、複数本の洗浄部材7、及び補強部材8を重ね合せると共に、重ね合わされた洗浄部材7と補強部材8の略中央部が、帯状体11の上部に重なるよう基台19に設置する。なお、洗浄部材7が帯状体11の上部に位置し、補強部材8は洗浄部材7の上部に位置するよう設置する。次いで、縦ロール20を使用して、芯線10にて重ね合わされた洗浄部材7、及び補強部材8からなるブラシ片6を挟み付けると共に、芯線10を概コ字状の帯状体11の内部に押し込む。次に、帯状体11の両側に設置された横ロール21を使用して、帯状体11を両側から、かしめる。その結果、図1(b)の如く、外方に洗浄部材7、内方に補強部材8を有するよう構成された長尺状のブラシ片6の略中央部が芯線10、及び帯状体11に挟み付けられて折り合わされたチャンネルブラシ5が形成される。

Next, as shown in FIG. 3, a

そして、チャンネルブラシ5からなるブラシ体4の一方の端部に形成されたブラシ片6は切り取られ、前記チャンネルブラシ5の端部は、図3に示した一方の係止具12の両側に形成された爪18の間に挿入され、爪18を内側に折り畳むことにより、固定される。次に、軸体3を回転させながら、一本の長尺状に形成されたチャンネルブラシ5からなるブラシ体4を、軸体3の外周部の周りに捩りを加えて螺旋状に巻き付け、チャンネルブラシ5の他方の端部に形成されたブラシ片6を切り取り、軸体3の外周部に取り付けられた他方の係止具12に形成された爪18にて、ブラシ体4の他方の端部を固定したブラシ部2からなる洗車機用洗浄ブラシ1が、図1(a)の如く製造される。なお、ブラシ体4の端部を、係止具12の両側に形成された爪18の間に挿入する際、ブラシ体4の端部に形成されたブラシ片6を切り取らないで爪18の間に挿入する形態も採用される。

And the

本実施例では、洗浄部材7と補強部材8の断面形状は異なる形状を採用しているが、洗浄部材7と補強部材8の剛性が異なっているのであれば、洗浄部材7と補強部材8の断面形状が略同一であっても構わない。洗浄部材7と補強部材8の断面形状が略同一である場合、溶融紡糸する際に同一形状の口金を利用することができ、複数の異なる口金を用意する必要がないので、生産コストの低減につながる。洗浄部材7、及び補強部材8の断面形状、使用されるポリオレフィン系の材質等の条件については、洗車機用洗浄ブラシ1の使用環境、コスト等の条件により、適宜、決定されるものである。

In this embodiment, the cleaning

上記の如く構成された洗車機用洗浄ブラシ1の動作、作用は下記の通りである。

The operation and action of the

洗車機用洗浄ブラシ1は、ブラシ片6が軸体3の回転に伴い、洗浄部材7より大の剛性を有する補強部材8により強い毛腰が付与されながら、補強部材8より小の剛性を有する柔軟な洗浄部材7が被洗浄面に当接する。その為、洗車機用洗浄ブラシ1は、被洗浄面に傷を付着させることなく、優れた洗浄性能が発揮される。

The

また、洗浄部材7の両端部に細分割部9が形成されてあるので、細分割部9により形成されたブラシ毛15が被洗浄面の細かな凹凸部分に付着している汚れを掻き取り、除去する。その為、洗車機用洗浄ブラシ1の洗浄性能が大幅に向上する。

Further, since the finely divided

また、洗浄部材7は長手方向に複数の溝部14が形成されてあるので、溝部14に洗浄水を一時的に溜めることができる為、洗車中の保水性が高まる。その為、洗車機用洗浄ブラシ1の洗浄性能が飛躍的に向上する。

Further, since the cleaning

また、洗浄部材7、及び補強部材8は耐摩耗性に優れた合成樹脂繊維からなる為、ブラシ片6が繰り返し被洗浄面に当接を続けても、折れ、切れ等が発生し難く、洗車機用洗浄ブラシ1は優れた耐久性を有する。

Further, since the cleaning

さらに、洗浄部材7、及び補強部材8はコストの低いポリオレフィン系の熱可塑性樹脂を有する合成樹脂繊維からなる為、安価にて洗車機用洗浄ブラシ1を提供することができる。

Furthermore, since the cleaning

次に、本発明の洗車機用洗浄ブラシ1の洗浄性能、及び塗装鋼板にたいする傷の付着について試験した。下記に示した要領で測定し、その結果を表1に示した。

Next, the cleaning performance of the cleaning

実施例1として、厚みが0.6mm、幅が7mm、長さが240mmの概波形断面を有する長尺状の洗浄部材7を複数本用意した。洗浄部材7の両端部には、1本あたりの幅が0.05mm、長さが10mmのブラシ毛15からなる細分割部9を形成した。また、幅が1mm、高さが1mm、長さが160mmの十字形断面を有する長尺状の補強部材8を複数本用意した。次に、洗浄部材7と補強部材8のそれぞれの長手方向の略中央部を重ね合わせてブラシ片6を形成すると共に、アルミニウムからなる芯線10と帯状体11にてブラシ片6を挟み付けて、折り合わされたブラシ片6を有するチャンネルブラシ5からなるブラシ体4を形成した。なお、ブラシ片6は、洗浄部材7が外方、補強部材8が内方となるよう形成した。次に、チャンネルブラシ5の一方の端部に形成されたブラシ片6は、チャンネルブラシ5の長手方向50mmに亘って、帯状体11の近傍にて切り取り、直径が114mmで且つ長さが360mmの鉄製の略円筒形状の軸体3の外周部の端部近傍に、ネジ13にて装着された係止具12を用いて固定した。そして、チャンネルブラシ5を軸体3の外周部に螺旋状に巻き付けて配置し、チャンネルブラシ5の他方の端部に形成されたブラシ片6も、チャンネルブラシ5の長手方向50mmに亘って、帯状体11の近傍にて切り取り、係止具12を用いて固定して試験用の洗車機用洗浄ブラシ1を1本製作した。なお、洗浄部材7は、低密度ポリエチレン100重量部にたいし、エチレン−αオレフィン共重合体エラストマーを5重量部配合し、硬度は65°であった。一方、補強部材8は、低密度ポリエチレンからなり、硬度は80°であった。また、帯状体11の幅は5mmで、軸体3の外周部に螺旋状に巻き付けられ、隣り合う帯状体11の間隔は25mmに設定した。

As Example 1, a plurality of

比較例1として、ブラシ片6を洗浄部材7のみで構成すると共に、ブラシ片6の重量を実施例1と略同一にし、洗浄部材7に低密度ポリエチレンからなる概波形断面を有する合成樹脂繊維を用いたこと以外は、上記実施例1の洗車機用洗浄ブラシ1と同一条件の洗車機用洗浄ブラシ1を1本製作した。比較例1の洗浄部材7の硬度は80°であった。

As Comparative Example 1, the

比較例2として、ブラシ片6を洗浄部材7のみで構成すると共に、ブラシ片6の重量を実施例1と略同一にし、洗浄部材7に低密度ポリエチレン100重量部にたいし、エチレン−αオレフィン共重合体エラストマーを5重量部配合した概波形断面を有する合成樹脂繊維を用いたこと以外は、上記実施例1の洗車機用洗浄ブラシ1と同一条件の洗車機用洗浄ブラシ1を1本製作した。比較例2の洗浄部材7の硬度は65°であった。

As Comparative Example 2, the

次に、上記の如く構成された実施例1、比較例1、及び比較例2の洗車機用洗浄ブラシ1を、それぞれ回転試験機に取り付け、240rpmの一定の回転速度で回転させる一方、一面に擬似汚れを塗布した白色ソリッド塗装鋼板を用意し、前記回転速度で回転している軸体3の外周部に取り付けられたブラシ片6の先端が描く仮想円上から30mmだけ軸体3の方向に近接した位置に前記白色ソリッド塗装鋼板を、その汚れ面が軸体3に対向した状態に配設すると共に、6L毎分の散布量にて洗浄水を吹き付けながら1分間に亘って鋼板の汚れ面にブラシ片6を当接させることによって鋼板の擬似汚れを除去した。

Next, the washing brushes 1 for the car wash machine of Example 1, Comparative Example 1 and Comparative Example 2 configured as described above are respectively attached to a rotating test machine and rotated at a constant rotational speed of 240 rpm, while on one side. A white solid-coated steel sheet coated with pseudo-stain is prepared, and the direction of the shaft body 3 is 30 mm from the virtual circle drawn by the tip of the

そして、鋼板の汚れ面におけるブラシ片6によって擬似汚れを除去した部分の明度を、日本電色工業株式会社製の色差計NR−1で測定して、下記基準により、洗浄性能を判断した。

○・・・明度の向上が+5以上

×・・・明度の向上が+5未満

And the brightness of the part which removed the pseudo dirt by the

○ ・ ・ ・ Brightness improvement is +5 or more × ・ ・ ・ Brightness improvement is less than +5

次に、実施例1、比較例1、及び比較例2の試験用の洗車機用洗浄ブラシ1を、それぞれ回転試験機に取り付け、240rpmの一定の回転速度で回転させる一方、黒色メタリック塗装鋼板を用意し、前記回転速度で回転している軸体3の外周部に取り付けられたブラシ片6の先端が描く仮想円上から30mmだけ軸体3の回転軸方向に近接した位置に前記黒色メタリック塗装鋼板を、軸体3に対向した状態に配設すると共に、6L毎分の散布量にて洗浄水を吹き付けながら30秒間に亘ってブラシ片6を当接させた。

Next, the test

そして、ブラシ片6が当接した鋼板の表面の平均粗さを、株式会社ミツトヨ製の面粗度計Surftest301で測定して、下記基準により、被洗浄面にたいする傷の付着を判断した。

○・・・ブランクの平均粗さの値との差が0.01μ以下であった

×・・・ブランクの平均粗さの値との差が0.01μを超えていた

なお、ブランクとはブラシ片6が当接しない鋼板の表面のことである。

And the average roughness of the surface of the steel plate which the

○ ・ ・ ・ The difference from the average roughness value of the blank was 0.01 μm or less. × ・ ・ ・ The difference from the average roughness value of the blank exceeded 0.01 μm. It is the surface of the steel plate which the

上記試験結果より、実施例1の洗車機用洗浄ブラシ1は、ブラシ片6を構成する硬質な補強部材8により毛腰が付与されながら、被洗浄面にたいして、ブラシ片6を構成する軟質な洗浄部材7が当接するので、洗車機用洗浄ブラシ1は優れた洗浄性能を有するものであった。また、洗浄部材7は軟質であることから、被洗浄面に当接しても、被洗浄面の平均粗さはブランク値と差が無く、ブラシ片6による被洗浄面にたいする傷の付着は認められなかった。

From the above test results, the

比較例1の洗車機用洗浄ブラシ1は、被洗浄面にたいして、硬質な洗浄部材7からなるブラシ片6が当接する。その為、ブラシ片6は、毛腰を強く設定して被洗浄面に当接することから、洗車機用洗浄ブラシ1は優れた洗浄性能を有する。しかしながら、硬質な洗浄部材7が直接、被洗浄面に当接するので、被洗浄面の平均粗さはブランク値と0.09μの差があり、ブラシ片6による被洗浄面にたいする傷の付着が認められた。

In the

比較例2の洗車機用洗浄ブラシ1は、被洗浄面にたいして、軟質な洗浄部材7からなるブラシ片6が当接する。その為、ブラシ片6が、被洗浄面に当接しても、被洗浄面の平均粗さはブランク値と差が無く、ブラシ片6による被洗浄面にたいする傷の付着は認められなかった。しかしながら、ブラシ片6は軟質な洗浄部材7のみにより構成されていることから、ブラシ片6の毛腰は極めて弱く、洗車機用洗浄ブラシ1は洗浄性能が劣るものであった。

In the

(実施例2)

図5(a)は、本発明の第2の実施例における洗車機用洗浄ブラシを前面側から見た斜視図、図5(b)は、洗浄部材を前面側から見た斜視図、図5(c)は、図5(b)のC−C断面図である。なお、上記第1の実施例と同一部材については、詳しい説明を省略する。

(Example 2)

FIG. 5A is a perspective view of a washing brush for a car wash machine according to the second embodiment of the present invention as viewed from the front side, and FIG. 5B is a perspective view of the cleaning member as viewed from the front side. (C) is CC sectional drawing of FIG.5 (b). Detailed description of the same members as those in the first embodiment is omitted.

図5(a)において、洗車機用洗浄ブラシ31は、チャンネルブラシ35の長手方向に図5(c)の幅Wが配されるようにした長尺状の洗浄部材37と、補強部材38が重ね合わされたブラシ片36を芯線40、及び帯状体41にて挟み付けると共に、折り合わして形成された長尺状のチャンネルブラシ35からなるブラシ体34が、略円筒形状の軸体33の外周部に螺旋状に巻き付けられ、ブラシ体34の両端部に係止具42を覆い被せ、係止具42の両端部をネジ43にて軸体33に固定して形成されたブラシ部32からなる。

In FIG. 5A, a

洗浄部材37の毛丈は、補強部材38の毛丈より大にて設定されてあり、軸体33の回転に伴い、洗浄部材37が被洗浄面に当接するよう構成されている。また、洗浄部材37の端部には細分割部39が形成されている。

The bristle length of the cleaning

図5(b)、及び図5(c)において、洗浄部材37は、溝部44が形成された概波形断面を有する長尺状の合成樹脂繊維である。両端部には、多数本のブラシ毛45を有する細分割部39が形成されている。また、洗浄部材37の断面は、幅Wと高さHが略同一寸法である。

In FIG. 5B and FIG. 5C, the cleaning

上記の如く構成された洗車機用洗浄ブラシ31の動作、作用は下記の通りである。

The operation and action of the

洗車機用洗浄ブラシ31は、洗浄部材37の幅Wがチャンネルブラシ35の長手方向に配されるようにしたチャンネルブラシ35にて形成されてあるブラシ体34が、軸体33の外周部に螺旋状に巻き付けられているので、ブラシ片36は軸体33の回転に伴い、洗浄部材37の側面部46が被洗浄面に当接する。従って、洗浄部材37の幅Wと高さHが略同一寸法にて形成されてあることから、高さが幅より小にて形成されてある上記実施例1の洗浄部材7に比べて、洗浄部材37の被洗浄面にたいする接触面積が広がる。その為、洗車機用洗浄ブラシ31は、より一層効率よく確実に被洗浄面に付着している汚れを除去することができるので、洗浄性能が一段と向上する。

In the

(実施例3)

図6(a)は、本発明の第3の実施例における洗車機用洗浄ブラシの正面図、図6(b)は、ブラシ体の断面図、図6(c)は、シート状体の平面図である。なお、上記第1、及び第2の実施例と同一部材については、詳しい説明を省略する。

(Example 3)

6A is a front view of a washing brush for a car wash machine according to a third embodiment of the present invention, FIG. 6B is a sectional view of the brush body, and FIG. 6C is a plan view of the sheet-like body. FIG. Detailed description of the same members as those in the first and second embodiments will be omitted.

図6(a)、及び図6(b)において、洗車機用洗浄ブラシ51は、長尺状の複数本の洗浄部材57が接合されたシート状体64と、複数本の補強部材58が重ね合わされたブラシ片56を芯線60、及び帯状体61にて挟み付けると共に、折り合わして形成された長尺状のチャンネルブラシ55からなるブラシ体54が、略円筒形状の軸体53の外周部に螺旋状に巻き付けられ、ブラシ体54の両端部に係止具62を覆い被せ、係止具62の両端部をネジ63にて軸体53に固定して形成されたブラシ部52からなる。

In FIG. 6A and FIG. 6B, the

洗浄部材57の毛丈は、補強部材58の毛丈より大にて設定されてあり、軸体53の回転に伴い、洗浄部材57が被洗浄面に当接するよう構成されている。また、洗浄部材57の端部には細分割部59が形成されている。

The bristle length of the cleaning

シート状体64は、図6(c)の如く、両端部にブラシ毛65を有する細分割部59が形成された洗浄部材57が、複数本並べられると共に、並列された複数本の洗浄部材57の長手方向の略中央部に、接合部材66が被覆され、洗浄部材57と接合部材66は、縫製による接合部67を介して接合されている。その結果、複数本の洗浄部材57は、接合されたシート状体64として形成されている。なお、接合部材66、及び接合部67は、図6(b)の如く、帯状体61の内部に位置するよう形成されている。

As shown in FIG. 6C, the sheet-

接合部材66は、平板状の織布、不織布、編物等の布帛、フィルム状樹脂組成物、合成樹脂発泡体等からなる。また、接合部67の形成方法は、縫製以外にも、ネジ止め、ボタン止め等の物理的接合方法、接着、溶着等の化学的接合方法を用いることができる。

The joining

上記の如く構成された洗車機用洗浄ブラシ51の動作、作用は下記の通りである。

The operation and action of the

洗車機用洗浄ブラシ51は、洗浄部材57がシート状体64として形成されている。その為、ブラシ片56を芯線60、及び帯状体61に挟み付け、チャンネルブラシ55を形成する際、図4に示す基台19の上にシート状体64に形成された洗浄部材57を設置すればよい。すなわち、長尺状の洗浄部材57を一本ずつ基台19の上に並べていく必要がなく、作業性が向上するので、洗車機用洗浄ブラシ51の生産コストの低減につながる。また、洗浄部材57は、シート状体64にて一体化されている為、挟み付けられた芯線60と帯状体61の間から脱落することが防止されるので、洗車機用洗浄ブラシ51の耐久性の向上につながる。

In the

なお、本実施例では、洗浄部材57のみをシート状体64に形成してあるが、複数本の補強部材58のみをシート状体64に形成してもよいし、洗浄部材57、及び補強部材58の両方をシート状体64に形成しても構わない。

In this embodiment, only the cleaning

(実施例4)

図7(a)は、本発明の第4の実施例における洗車機用洗浄ブラシの正面図、図7(b)は、ブラシ体の断面図、図7(c)は、シート状体の平面図である。なお、上記第1、第2、及び第3の実施例と同一部材については、詳しい説明を省略する。

Example 4

7A is a front view of a washing brush for a car wash machine according to a fourth embodiment of the present invention, FIG. 7B is a cross-sectional view of the brush body, and FIG. 7C is a plan view of the sheet-like body. FIG. Detailed description of the same members as those in the first, second, and third embodiments is omitted.

図7(a)、及び図7(b)において、洗車機用洗浄ブラシ71は、長尺状の複数本の洗浄部材77、及び複数本の補強部材78が重ね合わされて接合されたシート状体84からなるブラシ片76を芯線80、及び帯状体81にて挟み付けると共に、折り合わして形成された長尺状のチャンネルブラシ75からなるブラシ体74が、略円筒形状の軸体73の外周部に螺旋状に巻き付けられ、ブラシ体74の両端部に係止具82を覆い被せ、係止具82の両端部をネジ83にて軸体73に固定して形成されたブラシ部72からなる。

7A and 7B, a

洗浄部材77の毛丈は、補強部材78の毛丈より大にて設定されてあり、軸体73の回転に伴い、洗浄部材77が被洗浄面に当接するよう構成されている。また、洗浄部材77の端部には細分割部79が形成されている。

The bristle length of the cleaning

シート状体84は、図7(c)の如く、両端部にブラシ毛85を有する細分割部79が形成された洗浄部材77と、補強部材78が、複数本並べられると共に、重ね合わされ、並列された複数本の洗浄部材77と補強部材78の長手方向の略中央部は、溶着による接合部87を介して接合されている。その結果、ブラシ片76は、複数本の洗浄部材77と補強部材78が接合されたシート状体84として形成されている。なお、接合部87は、図7(b)の如く、帯状体81の内部に位置するよう形成されている。

As shown in FIG. 7C, the sheet-

接合部87の形成方法は、溶着以外にも、縫製、ネジ止め、ボタン止め等の物理的接合方法、接着等の化学的接合方法を用いることができる。

As a method for forming the

上記の如く構成された洗車機用洗浄ブラシ71の動作、作用は下記の通りである。

The operation and action of the car

洗車機用洗浄ブラシ71は、ブラシ片76が洗浄部材77と補強部材78が重ね合わされ、溶着による接合部87を介して接合されたシート状体84として形成されている。その為、ブラシ片76を芯線80、及び帯状体81に挟み付け、チャンネルブラシ75を形成する際、図4に示す基台19の上にシート状体84に形成されたブラシ片76を設置すればよい。すなわち、長尺状の洗浄部材77、及び補強部材78を一本ずつ基台19の上に並べていく必要がなく、作業性が向上するので、洗車機用洗浄ブラシ71の生産コストの低減につながる。また、ブラシ片76は、複数本の洗浄部材77、及び複数本の補強部材78がシート状体84にて一体化されている為、挟み付けられた芯線80と帯状体81の間から脱落することが防止されるので、洗車機用洗浄ブラシ71の耐久性の向上につながる。

The

(実施例5)

図8は、本発明の洗車機用洗浄ブラシが搭載されてある洗車機の正面図である。

(Example 5)

FIG. 8 is a front view of a car wash machine on which the car brush washing brush of the present invention is mounted.

図8において、洗車機90は、本発明の洗車機用洗浄ブラシ91が搭載されてあり、洗車機用洗浄ブラシ91は駆動源92により回転駆動される。複数のノズル93からは、被洗浄面にたいして、洗浄剤、及び洗浄水等が散布され、洗車機用洗浄ブラシ91により、被洗浄面に付着している汚れが除去され、洗浄後は洗車機90の乾燥手段である乾燥機94により被洗浄面が乾燥される。なお、洗車機用洗浄ブラシ91は、上記実施例における洗車機用洗浄ブラシ1、31、51、71のいずれかと同一である。

In FIG. 8, the

上記の如く構成された洗車機90の動作、作用は下記の通りである。

The operation and action of the

洗車機90は、ブラシ片6、36、56、76が長期間に亘って毛腰を保持しながら被洗浄面に当接し、高い洗浄性能を有する洗車機用洗浄ブラシ91が搭載されてある為、駆動源92により洗車機用洗浄ブラシ91の回転を低速に設定すると共に、洗浄時間を短時間に設定した場合においても、高い洗浄性能が発揮される。

Since the

本発明の洗車機用洗浄ブラシは、主に、自動車あるいは車両の外面の被洗浄面に付着した汚れ等を洗浄する為の洗車機に搭載する洗車機用洗浄ブラシとして使用する。 The washing brush for a car wash machine according to the present invention is mainly used as a washing brush for a car wash machine mounted on a car wash machine for washing dirt or the like adhering to an automobile or a surface to be cleaned of a vehicle.

1、31、51、71、91 洗車機用洗浄ブラシ

2、32、52、72 ブラシ部

3、33、53、73 軸体

4、34、54、74 ブラシ体

5、35、55、75 チャンネルブラシ

6、36、56、76 ブラシ片

7、37、57、77 洗浄部材

8、38、58、78 補強部材

9、39、59、79 細分割部

10、40、60、80 芯線

11、41、61、81 帯状体

12、42、62、82 係止具

13、43、63、83 ネジ

14、44 溝部

15、45、65、85 ブラシ毛

16 角部

17 芯部

18 爪

19 基台

20 縦ロール

21 横ロール

46 側面部

64、84 シート状体

66 接合部材

67、87 接合部

90 洗車機

92 駆動源

93 ノズル

94 乾燥機

1, 31, 51, 71, 91 Car wash machine cleaning brushes 2, 32, 52, 72

Claims (6)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007304014A JP2009126376A (en) | 2007-11-26 | 2007-11-26 | Washing brush for car wash, and car wash |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007304014A JP2009126376A (en) | 2007-11-26 | 2007-11-26 | Washing brush for car wash, and car wash |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2009126376A true JP2009126376A (en) | 2009-06-11 |

| JP2009126376A5 JP2009126376A5 (en) | 2011-01-20 |

Family

ID=40817717

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007304014A Pending JP2009126376A (en) | 2007-11-26 | 2007-11-26 | Washing brush for car wash, and car wash |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2009126376A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20150210252A1 (en) * | 2011-11-02 | 2015-07-30 | Michael J. Belanger | Hub for a vehicle component having an arcuate pattern of media elements |

| CN113022500A (en) * | 2021-03-01 | 2021-06-25 | 内蒙古机电职业技术学院 | Intelligent car washing station |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60146427U (en) * | 1984-03-12 | 1985-09-28 | ヤスヰ産業株式会社 | car wash brush |

| JPH0389130U (en) * | 1989-12-28 | 1991-09-11 | ||

| JP2005305072A (en) * | 2004-04-21 | 2005-11-04 | Kowa Co Ltd | Washing brush |

| JP2007244815A (en) * | 2006-03-13 | 2007-09-27 | Kowa Co Ltd | Bristle material of washing brush for car wash, washing brush for car wash and car wash |

-

2007

- 2007-11-26 JP JP2007304014A patent/JP2009126376A/en active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60146427U (en) * | 1984-03-12 | 1985-09-28 | ヤスヰ産業株式会社 | car wash brush |

| JPH0389130U (en) * | 1989-12-28 | 1991-09-11 | ||

| JP2005305072A (en) * | 2004-04-21 | 2005-11-04 | Kowa Co Ltd | Washing brush |

| JP2007244815A (en) * | 2006-03-13 | 2007-09-27 | Kowa Co Ltd | Bristle material of washing brush for car wash, washing brush for car wash and car wash |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20150210252A1 (en) * | 2011-11-02 | 2015-07-30 | Michael J. Belanger | Hub for a vehicle component having an arcuate pattern of media elements |

| US10369973B2 (en) * | 2011-11-02 | 2019-08-06 | Washme Properties, Llc | Hub for a vehicle component having an arcuate pattern of media elements |

| CN113022500A (en) * | 2021-03-01 | 2021-06-25 | 内蒙古机电职业技术学院 | Intelligent car washing station |

| CN113022500B (en) * | 2021-03-01 | 2022-09-23 | 内蒙古机电职业技术学院 | Intelligent car washing station |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2009055960A (en) | Washing brush for car wash and car wash | |

| JP2009126376A (en) | Washing brush for car wash, and car wash | |

| JP4869673B2 (en) | Brush piece of washing brush for car wash machine, washing brush for car wash machine and car wash machine | |

| JP4925714B2 (en) | Car wash machine washing brush and car wash machine | |

| JP3275088B2 (en) | Brush roller for automatic car washer | |

| JP4986716B2 (en) | Car wash machine washing brush and car wash machine | |

| JP5118367B2 (en) | Brush piece of washing brush for car wash machine, washing brush for car wash machine and car wash machine | |

| JP2008264139A (en) | Washing brush for car washer and car washer | |

| JP2008061723A (en) | Washing brush for car wash and car wash | |

| JP2009018597A (en) | Washing brush for car wash, and car wash | |

| JP4570322B2 (en) | Cleaning brush | |

| JP2009067164A (en) | Washing brush for car washing machine and car washing machine | |

| JPH10331028A (en) | Readily slippery fiber and pressing tool of sliding member | |

| JP2009095395A (en) | Road surface cleaning brush and road sweeper | |

| JP2007209735A (en) | Brush member of washing brush for car wash, washing brush for car wash, and car wash | |

| JP2006036176A (en) | Washing brush | |

| JP4716697B2 (en) | Cleaning brush for car wash machine | |

| JP2001506174A (en) | Plastic hair for washing brush of automatic car wash | |

| JP3059331U (en) | Cleaning body for automatic car wash brush and automatic car wash brush using the same | |

| JP2012187307A (en) | Bristle material for brush | |

| JP2007244815A (en) | Bristle material of washing brush for car wash, washing brush for car wash and car wash | |

| JP2007185468A (en) | Brush piece of washing brush for car washing machine, washing brush for car washing machine, and car washing machine | |

| JP4614815B2 (en) | Brush piece of washing brush for car wash machine | |

| JP2008174125A (en) | Brush strip of washing brush for car washing machine, washing brush for car washing machine, and car washing machine | |

| JP5118322B2 (en) | Car wash machine washing brush and car wash machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Effective date: 20101125 Free format text: JAPANESE INTERMEDIATE CODE: A523 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20101125 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20101125 |

|

| A977 | Report on retrieval |

Effective date: 20120412 Free format text: JAPANESE INTERMEDIATE CODE: A971007 |

|

| A131 | Notification of reasons for refusal |

Effective date: 20120426 Free format text: JAPANESE INTERMEDIATE CODE: A131 |

|

| A02 | Decision of refusal |

Effective date: 20120907 Free format text: JAPANESE INTERMEDIATE CODE: A02 |